Bidirectional tractor

A two-way traction and rack technology, applied in the direction of the clockwork mechanism, hoisting device, etc., can solve the problems of low efficiency and large workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

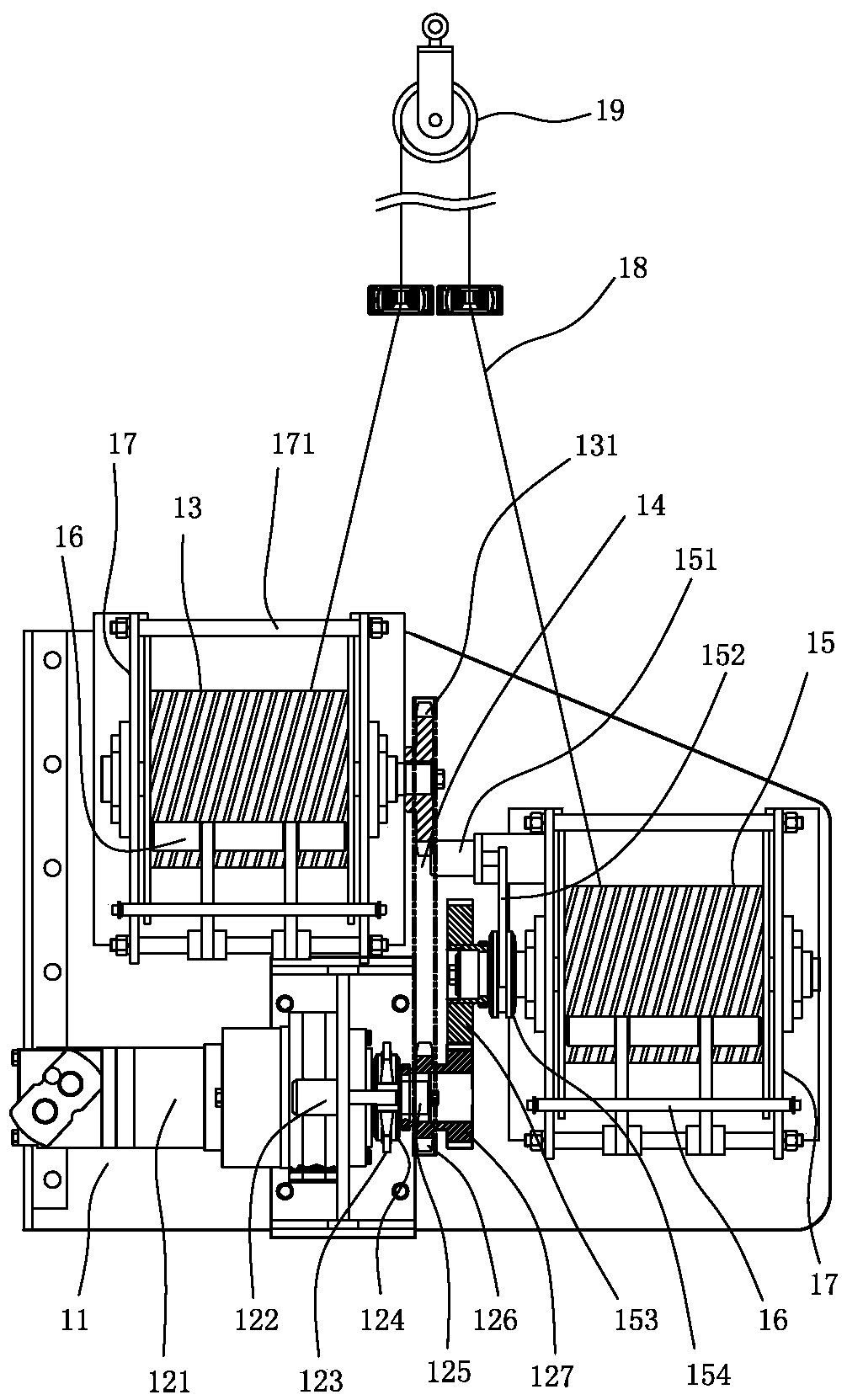

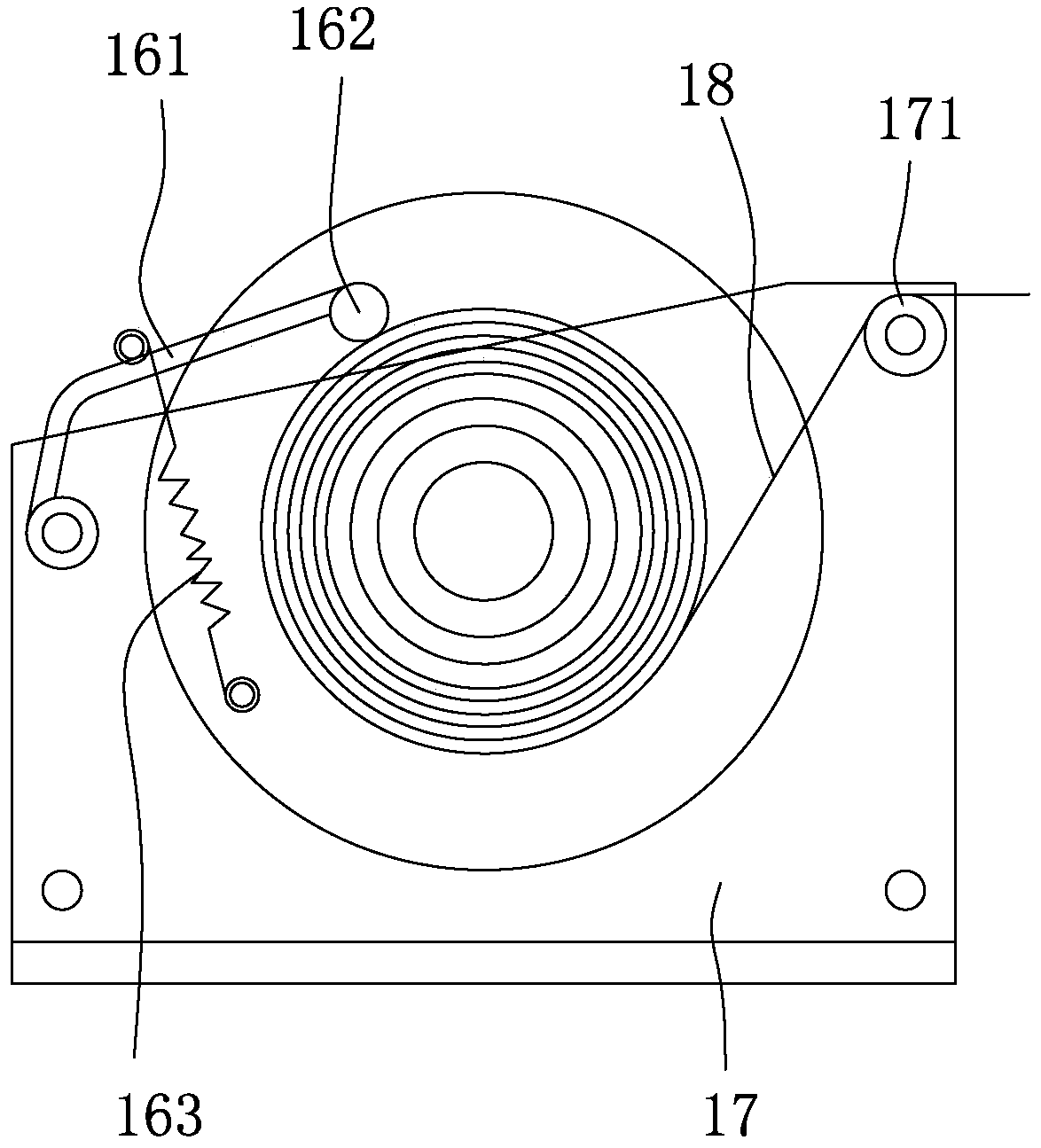

[0013] Such as Figure 1-Figure 2 As shown, the two-way tractor of the present invention includes a frame 11 on which an input shaft 125 , a first reel 13 , a second reel 15 , a wire rope 18 and a pulley 19 are arranged. The input shaft 125 is provided with a first engaging sleeve 124 and a first gear 127 which can rotate synchronously after being engaged with each other. The first engaging sleeve 124 is a synchronizer provided with an inner ring gear. The outer ring gear engaged by the inner ring gear of the sleeve 124, the first sleeve 124 is splined connected with the input shaft 125, the first sleeve 124 is slidably arranged on the input shaft 125; the first gear 127 is idly sleeved on the input shaft 125, It can rotate relative to the input shaft 125 . Sliding the first coupling sleeve 124 can clutch the input shaft 125 and the first gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com