Pneumatic floor brush and vacuum cleaner thereof

A technology of pneumatic ground brushes and suction nozzles, which is applied to vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems such as the turbine can not be enlarged, the load capacity is poor, and achieve the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

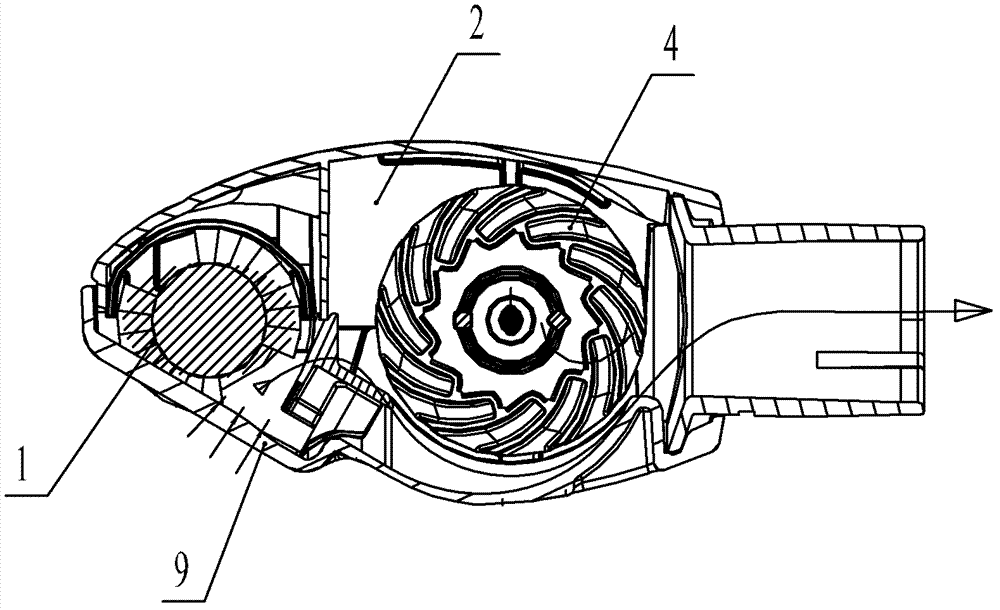

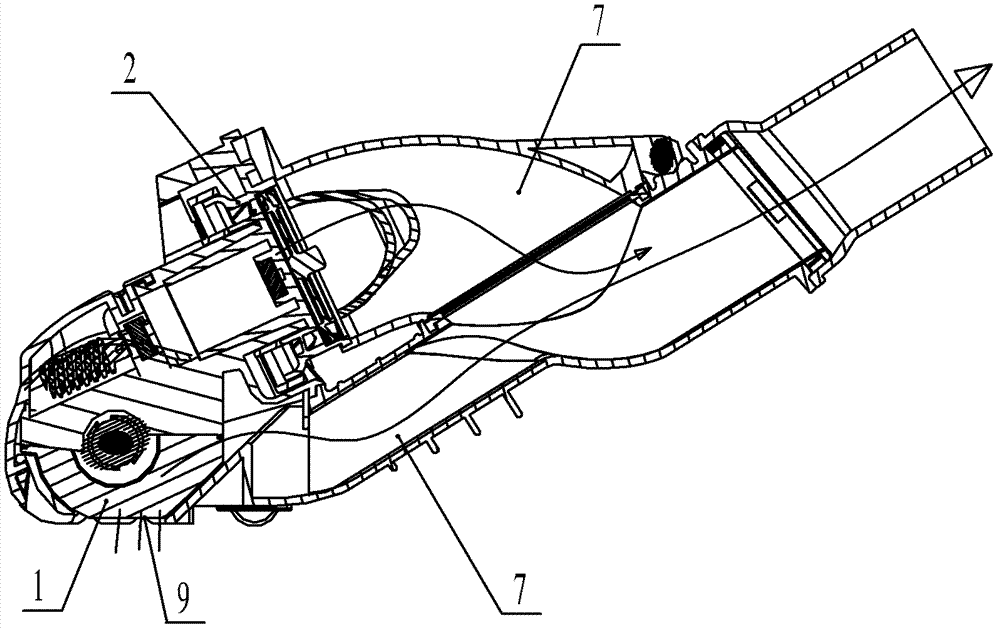

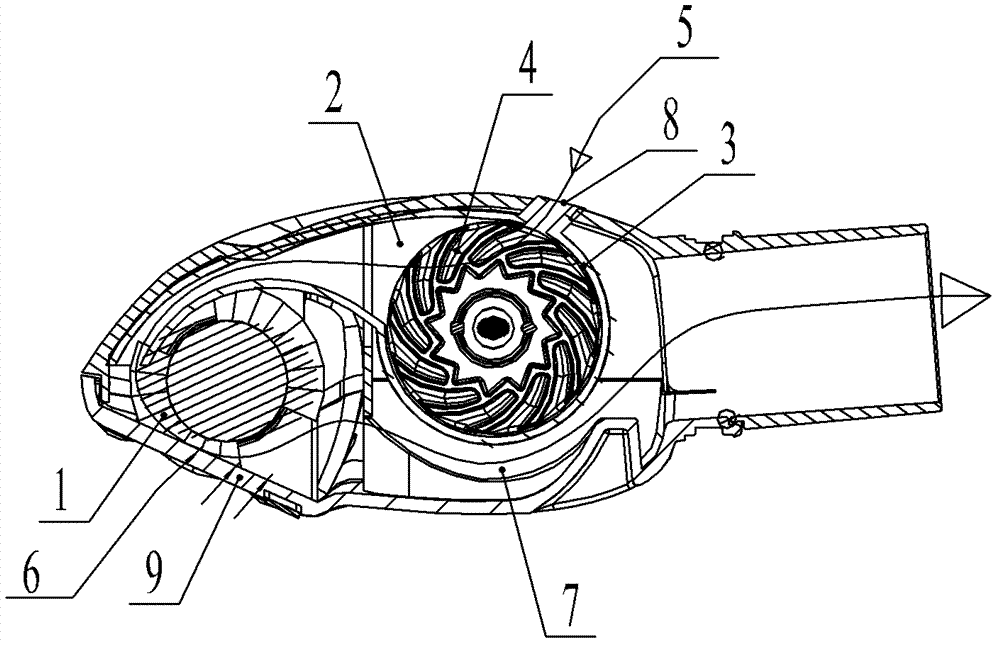

[0020] Such as image 3 As shown, in the working state of the pneumatic ground brush of the present invention, the dust-laden airflow 6 enters the brush chamber 1 from the dust suction port 9 and then enters the air duct 7; a drainage passage is set between the brush chamber and the turbine chamber, and the clean airflow 5 is Enter the turbine chamber 2 from the suction port 8, the clean air flow 5 flowing through the turbine chamber 2 enters the brush chamber 1 through the drainage channel, and finally enters the air duct 7, so that when the clean air flow 5 passing through the turbine chamber 2 enters the brush chamber 1 The dust in the dust-laden airflow 6 can be taken away, so that the clean airflow 5 passing through the turbine chamber 2 can be fully utilized. The turbine can be a radial fan, an axial fan or a mixed flow fan. The rotation of the turbine does not need to be driven by the dust-laden airflow 6, but is mainly driven by the clean airflow 5 before entering the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com