Three-claw inner support clamp assembly

A technology for inner support fixtures and components, used in clamping, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of inability to carry heavy loads, poor self-locking ability of ball screws, and achieve the effect of ensuring the pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

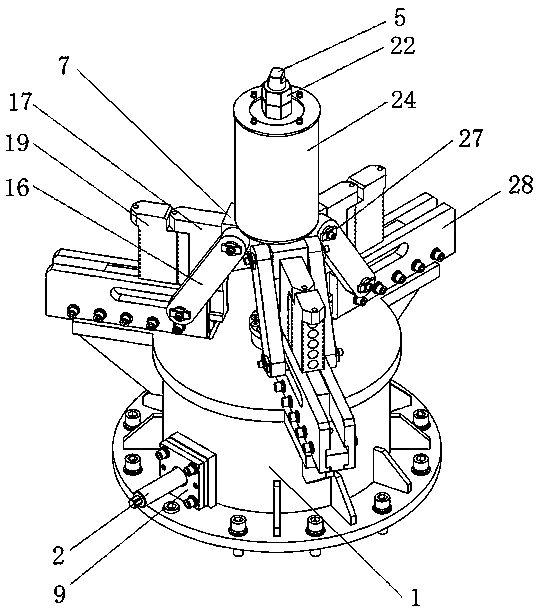

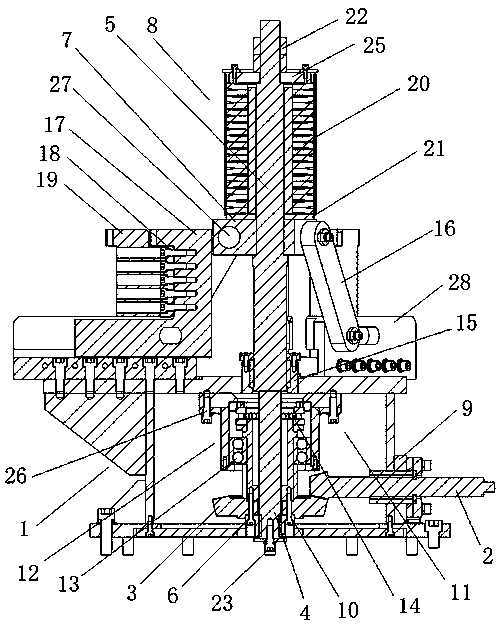

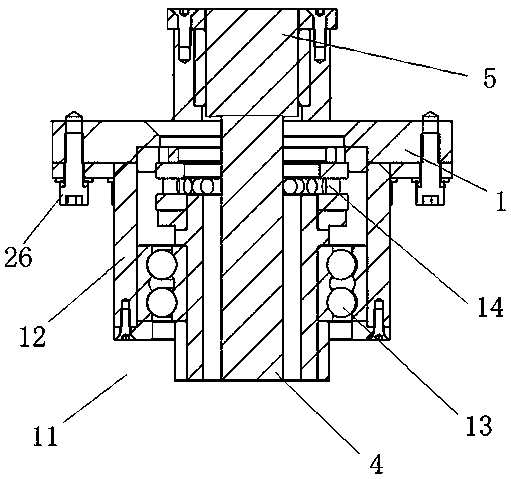

[0023] For further illustrating the present invention, below in conjunction with appendix Figure 1-2 To explain:

[0024] A three-jaw internal support fixture assembly includes a support frame 1, a small bevel gear shaft 2, a large bevel gear 3, a first screw 4, a second screw 5, a screw nut 6, a connecting block 7, and a disc spring 8. One side of the support frame 1 is provided with a fixed seat 9 with an opening in the middle. Through the fixed seat 9, the support frame 1 is rotatably connected to the small bevel gear shaft 2, and the small bevel gear shaft 2 is engaged with the large bevel gear 3 located in the center of the support frame 1. Transmission, the large bevel gear 3 is connected with the lead screw nut 6 through the first screw 10.

[0025] The bottom of the first lead screw 4 passes through the lead screw nut 6 and is threadedly connected with the lead screw nut 6 , and the lead screw nut 6 is rotatably installed at the center of the base of the support fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com