Spare tire fixing device

A fixing device and set technology, applied in the directions of spare tire arrangement, transportation and packaging, vehicle parts, etc., can solve the problems of unstable transmission process, easy chain jam, laborious operation, etc., and achieve easy operation, stable transmission, and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

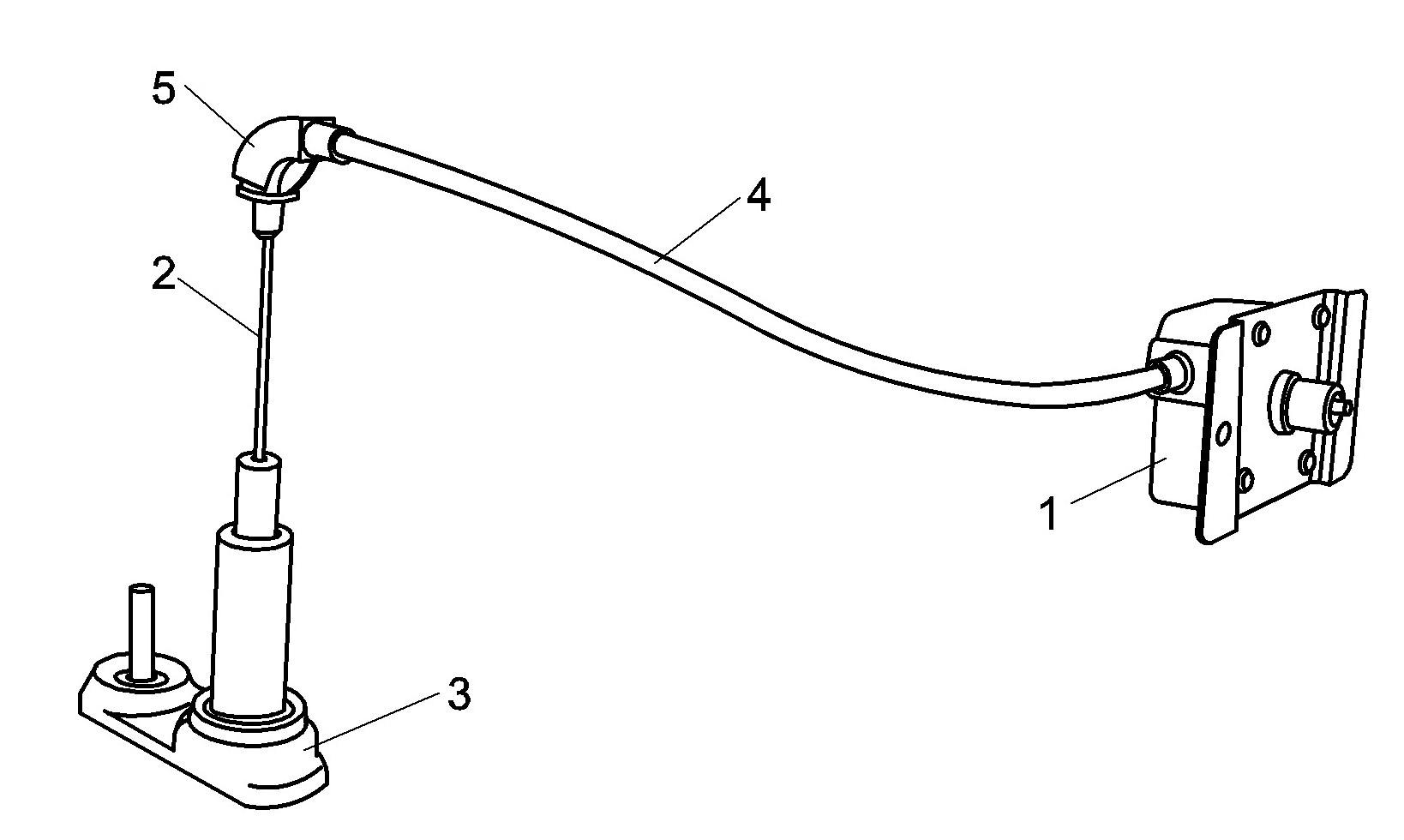

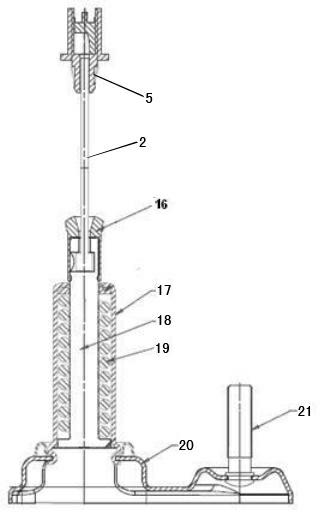

[0026] Embodiment one: see figure 1 — Figure 9 , a spare tire fixing device, including a winch mechanism 1, a wire rope 2 and a spare tire support mechanism 3, considering the distance between the winch mechanism and the spare tire support mechanism and the protection of the wire rope, a wire rope is also installed on the winch mechanism Sleeve 4, one end of this wire rope sleeve is fixed on one side of winch mechanism housing, and its other end 5 is fixed on the car body.

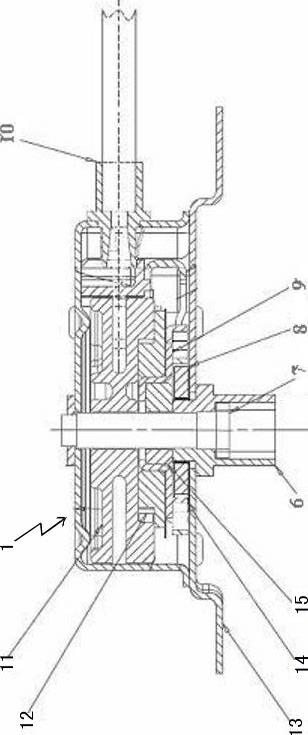

[0027] The winch mechanism 1 includes a housing 13, and a pin shaft 7 is installed through the housing, and a female joint 6 is set on the lower end of the pin shaft. The head matches the prismatic structure, and the female joint is located in the upper end of the housing, and a pressure plate 8 is fixedly set on the outer side; at the same time, an eccentric wheel 15 is movably set on the pin shaft on the upper side of the pressure plate, and a rotating set is set on the outer side of the eccentric whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com