Coffee maker and brewing unit thereof

A coffee machine and coffee technology, applied in beverage preparation devices, home appliances, applications, etc., can solve problems such as coffee liquid leakage, safety hazards, and unusable brewing units, and achieve good sealing, simple operation, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

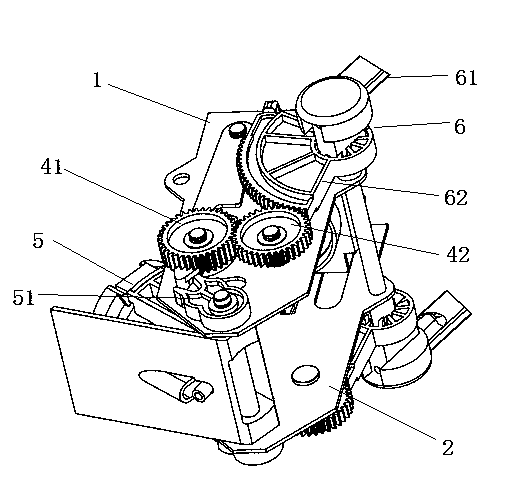

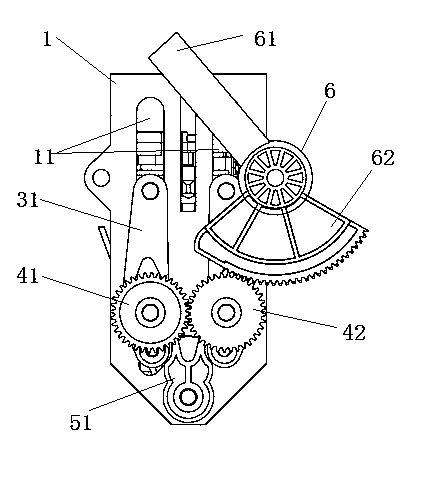

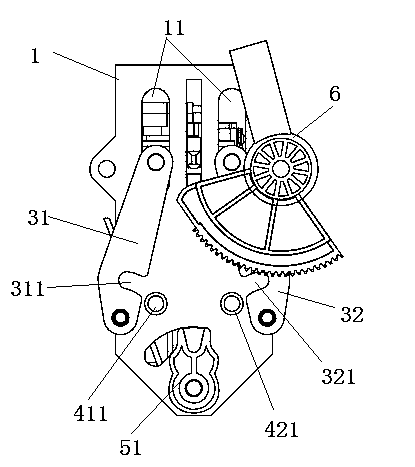

[0034] like Figure 1 to Figure 6 The brewing unit of the coffee machine shown includes a first side wall 1 and a second side wall 2, and the two side walls are opposite to each other to enclose a space for placing a brewing head 7 and a coffee pocket 5, wherein the brewing head 7 is a space for placing a brewing head 7 and a coffee pocket 5. The movable part is placed in the upper part of the space, the coffee pocket 5 is placed under the brewing head 7, and is fixed between the two side walls by the rotating shaft. The brewing head 7 and the coffee pocket 5 together form a brewing cavity. The brewing unit also includes A driving device used to drive the brewing head 7 to move up and down while driving the coffee pocket 5 to rotate.

[0035] The driving device can either be arranged on the first side wall 1 or the second side wall 2 , or can be arranged on the first side wall 1 and the second side wall 2 at the same time. In this embodiment, the driving device is provided on...

Embodiment 2

[0044] like Figure 7 to Figure 11 As shown, this embodiment adds a discharge mechanism on the basis of Embodiment 1. The discharge mechanism is mainly aimed at coffee machines using coffee capsules. The other structures of this embodiment are the same as Embodiment 1 and will not be repeated here. describe.

[0045] like Figure 10 As shown, the coffee capsule 50 used in this embodiment is a jelly-like structure, including a capsule body 52 and a cover body 53 sealed on the opening of the capsule body 52. The opening of the capsule body 52 is provided with a radially outward flange, Namely collar 54.

[0046] The unloading mechanism described in this embodiment includes unloading arms 71 located on both sides of the brewing head 7 and a resetting mechanism for the unloading arms. Above, one end of the unloading arm 71 extends under the brewing head 7, and the other end extends out of the brewing unit. When the brewing chamber is in a closed state, the unloading arm 71 ca...

Embodiment 3

[0051] like Figures 12 to 14 As shown, this embodiment adds an unloading mechanism on the basis of the first embodiment, and the unloading mechanism is mainly aimed at coffee machines using coffee cakes.

[0052] In this embodiment, three uprights 77 extend downwards from the lower end of the brewing head 7, and each upright 77 is provided with a stopper 76. Correspondingly, the coffee pocket 5 is provided with three grooves corresponding to the uprights 77. When the brewing chamber is in a sealed state, the column 77 is just inserted into the groove of the coffee pocket. Of course, the number of columns 77 and grooves is not limited to 3, and more than 2 columns 77 can meet the requirements of the present invention.

[0053] The unloading mechanism shown in this embodiment includes: a pair of ejectors 75, a part of each ejector 75 can extend into the brewing chamber; an unloading arm 71, one end of the unloading arm 71 touches the ejector rod 75, the other end stretches ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com