Gripping mechanism for replacing spatial on-orbit modules

A space, active mechanism technology, applied in the aerospace field, can solve the problems of low positioning accuracy, single function, complex structure, etc., and achieve the effects of precise position control, accurate capture and positioning, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

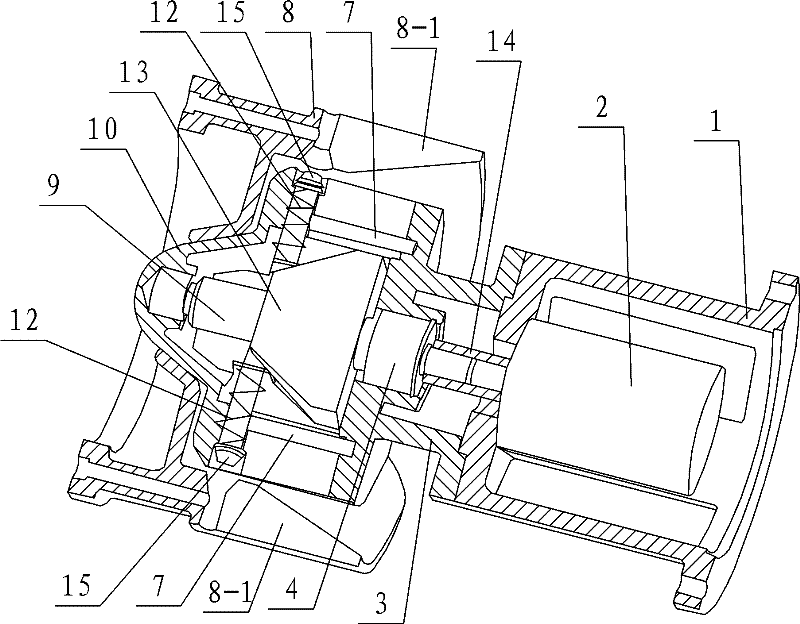

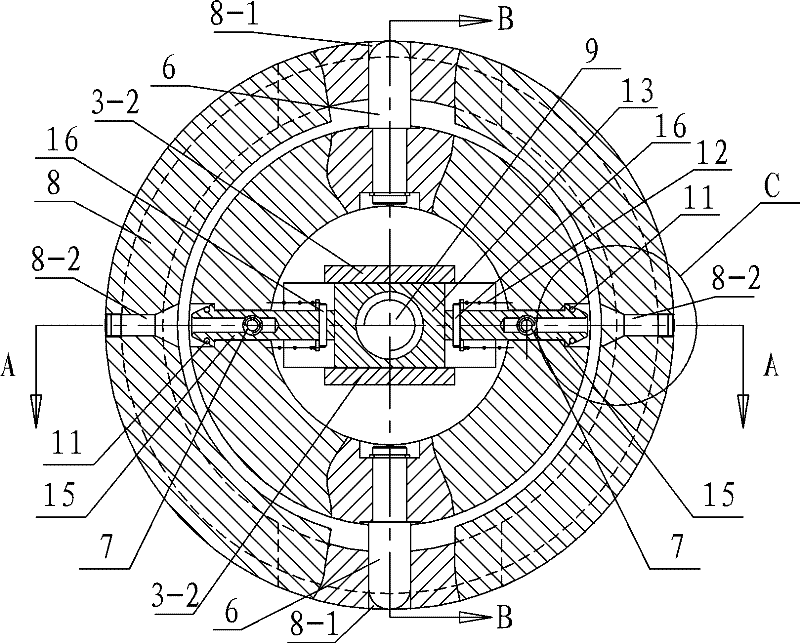

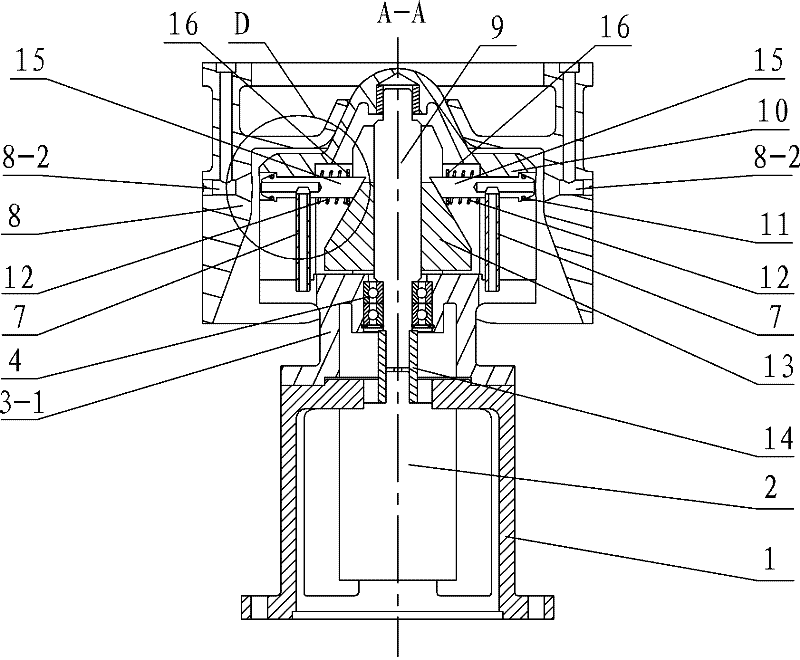

[0008] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, the grasping mechanism for space on-orbit module replacement in this embodiment includes an active mechanism and a passive frame 8, and the active mechanism includes an active frame 1, a stepping motor 2, a transition guide member 3, a positioning Pin 5, screw rod 9, tapered positioning body 10, wedge-shaped slider 13, coupling 14, two rows of bearings 4, two positioning columns 6, two delivery pipes 7, two springs 12, two pipe columns 15 and Two baffles 16; the transition guide member 3 includes a transition plate 3-1 and two guide bodies 3-2, and two guide bodies 3-2 are symmetrically arranged on the upper end surface of the transition plate 3-1; the stepper motor 2 Installed in the active frame body 1, the output end of the stepping motor 2 passes through the active frame body 1, the upper end surface of the active frame body 1 is fixedly connected to the transition plate 3-1 of...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 , image 3 , Figure 5 and Figure 6 To illustrate this embodiment, the outer end of each pipe column 15 in this embodiment is conical, and the radial matching hole 8-2 is a tapered hole. Such setting is convenient for use together. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 2 , image 3 , Figure 5 and Figure 6 To illustrate this embodiment, the grasping mechanism for space on-orbit module replacement in this embodiment further includes two sealing rings 11 , and one sealing ring 11 is sleeved on the outer end of each pipe string 15 . With such arrangement, the sealing between the pipe string and the radial matching hole is realized. Other compositions and connections are the same as those in the second embodiment.

[0012]Working process: During the connection process between the active connection mechanism and the passive frame body, the two positioning columns 6 radially arranged on the conical positioning body 10 cooperate with the first gap 8-1 on the passive frame body 8, and at the same time the passive frame body 8 The conical hole in the center cooperates with the top of the conical positioning body 10, and both play a positioning role together. Now, start the stepper m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com