Multifunctional food processor capable of regulating feeding and feeding apparatus

A multi-functional food and feeding device technology, which is applied to home appliances, applications, kitchen utensils, etc., can solve the problems of excessive material, cracking and damage of extrusion cylinders, etc., and achieve the effects of avoiding jamming, reducing costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

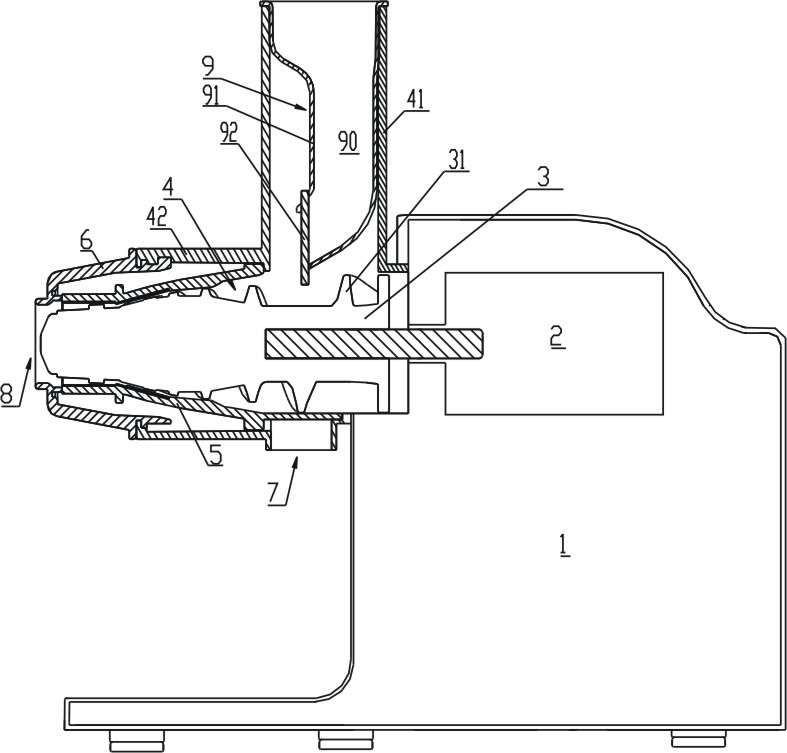

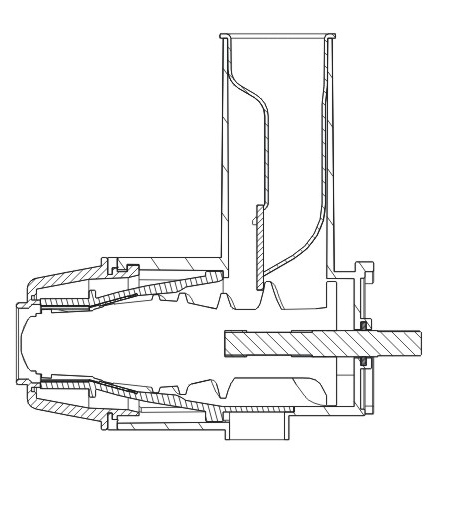

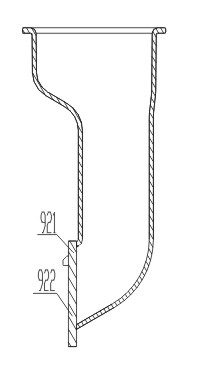

[0037] First, briefly explain the principle of the present invention. In the present invention, a feed baffle is added in order to realize the feed control of the multifunctional food processing machine and the like to prevent jamming. The feed baffle is actively or passively opened or closed to control the falling of materials. More importantly, a preferred solution of the present invention uses the movement of the screw itself to open or close the feeding baffle, and by setting the resetting measures of the feeding baffle, the feeding baffle can be reset automatically. Controlled intermittent feeding to avoid adding large quantities of materials at once.

[0038] As an embodiment of the multifunctional food processing machine with adjustable feed in the present invention, it includes a base, a motor, a feed channel, a discharge channel, and a crushing part. The crushing part includes a crushing cavity and a propelling screw built into the crushing cavity, The discharge channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com