A fully automatic control method for a rolling-type flat-disk-cone-roller crusher

A rolling type and crusher technology, which is applied in the field of crusher control, can solve the problems of shortening the service life of the equipment, wear of the tapered roller and the hollow shaft sleeve, insufficient coal crushing, and excessive particle size, so as to avoid material crushing Severe, reasonable equipment speed, avoiding the effect of material jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

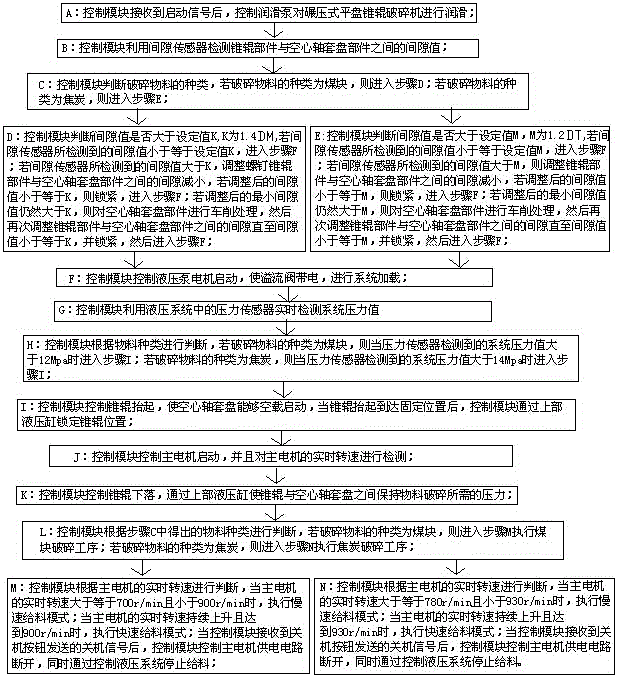

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0036] Such as figure 2 As shown, the automatic control method of the rolling type flat disk cone roller crusher according to the present invention is characterized in that it includes the following steps:

[0037] A: After the control module receives the start signal sent by the start button, it controls the start of the lubrication pump to lubricate the rolling type flat disc cone roller crusher, and then enters step B;

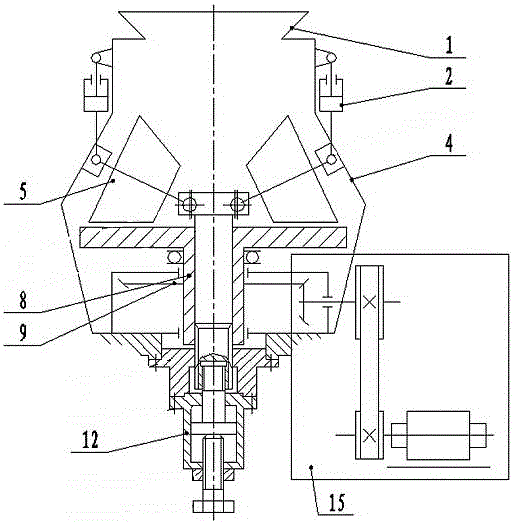

[0038] B: Use the gap sensor to detect the gap value between the tapered roller part 5 and the hollow shaft sleeve part 8, and send the detected gap value to the control module, and then enter step C;

[0039] The gap sensor can be installed on the housing 4, and the gap value can be detected according to the production process requirements before starting up; the gap value between the tapered roller part 5 and the hollow shaft sleeve part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com