Rotating shaft clamping mechanism

A technology of rotating shafts and moving contacts, which is applied in the direction of contacts, electrical components, electric switches, etc., can solve the problems of high manufacturing and installation precision, poor operation reliability, and difficult manufacturing, and achieve high precision, easy reset, and easy processing The effect of easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

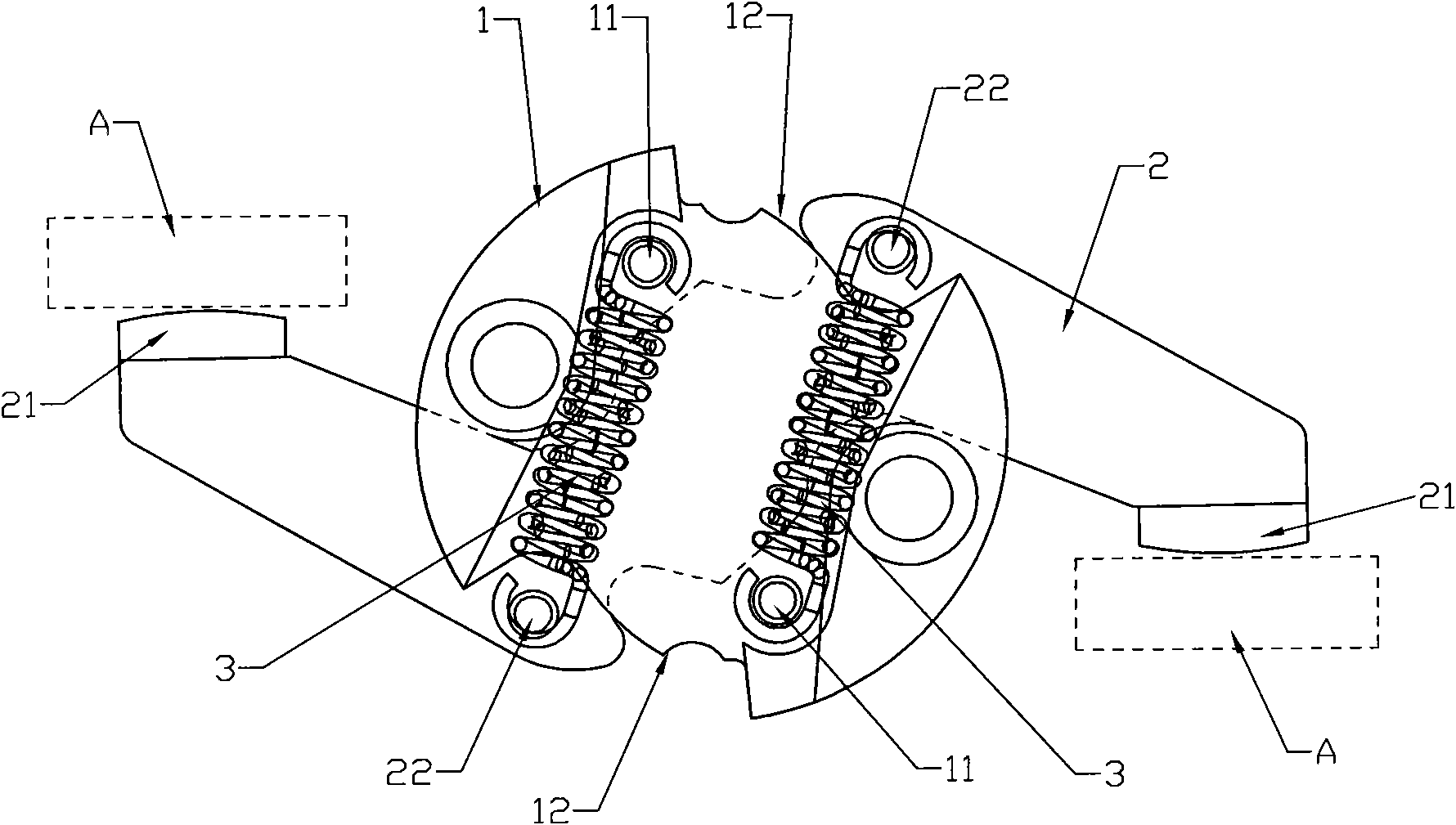

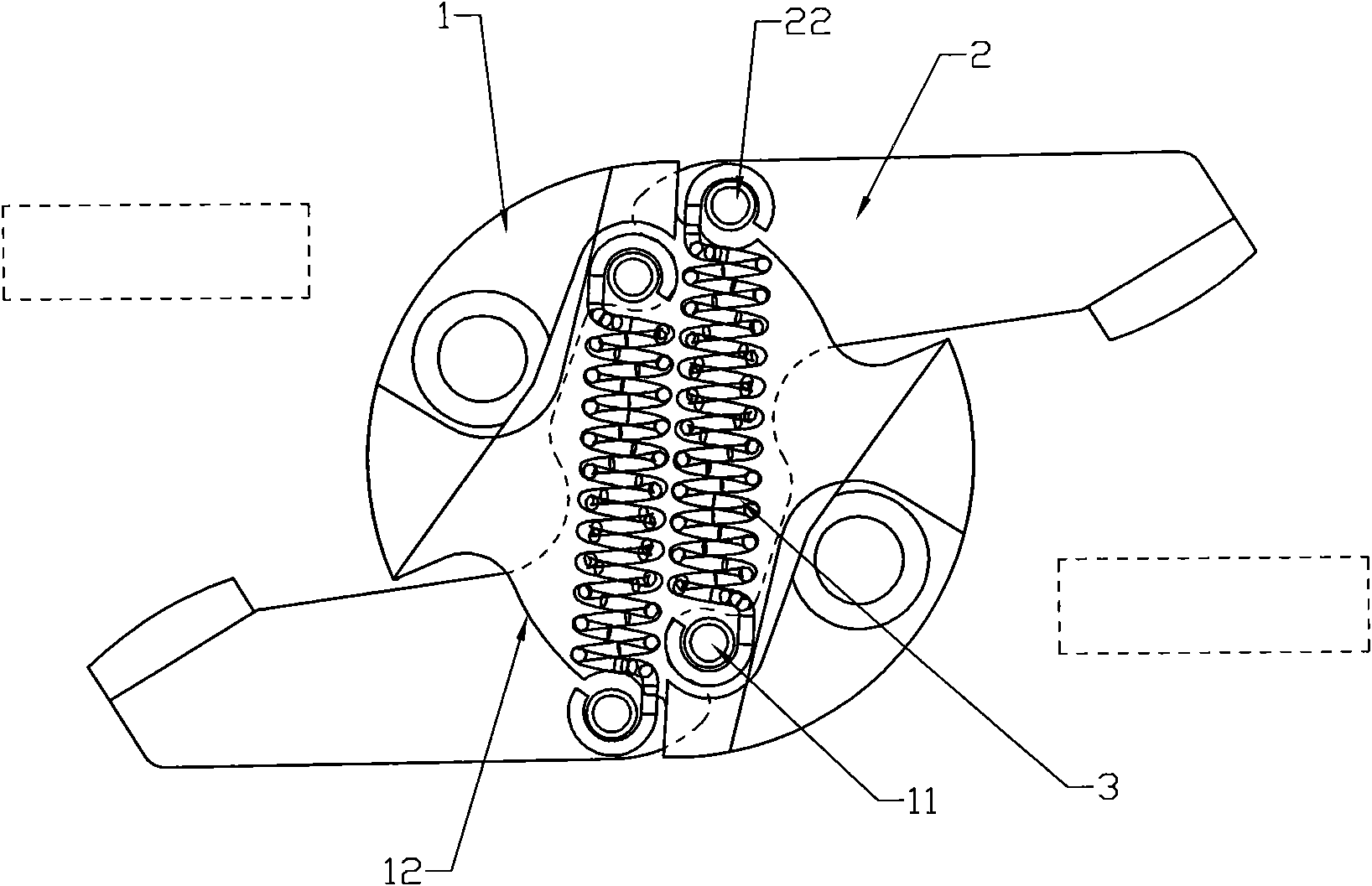

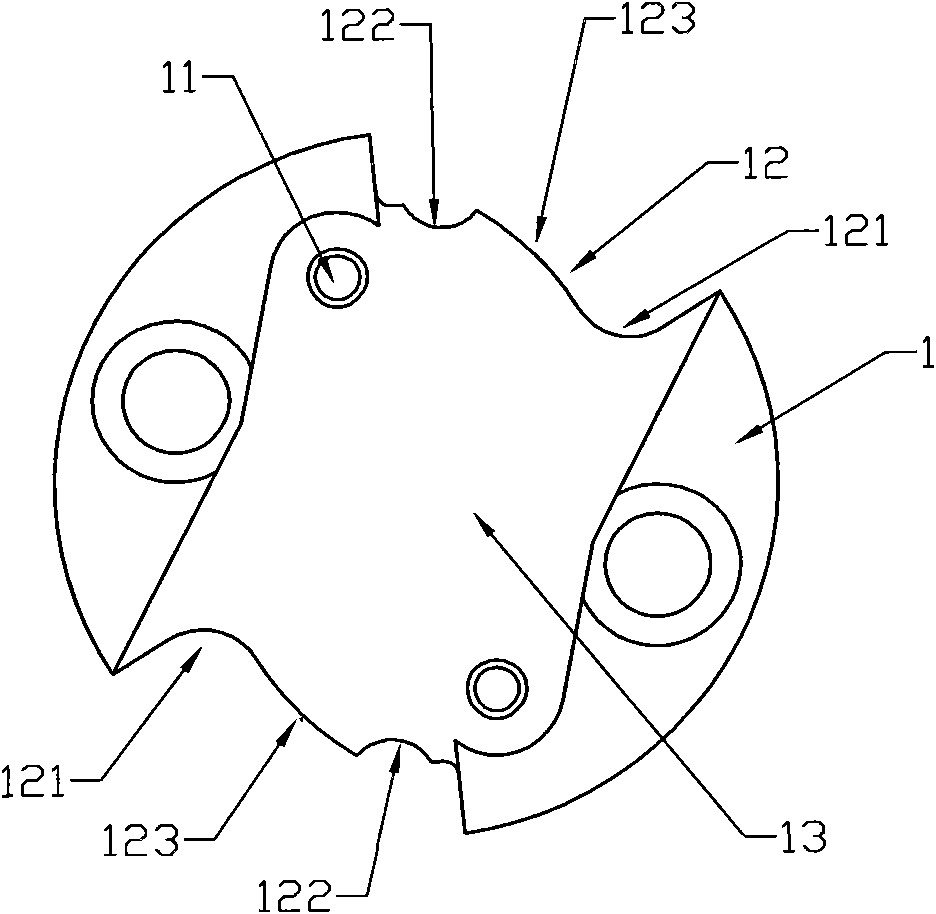

[0015] As shown in the figure, the rotating shaft clamping mechanism includes a rotating shaft body 1 and a movable contact 2 that runs through the inner cavity of the rotating shaft body and can rotate around the center of the rotating shaft body. , the movable contact 21 corresponding to the A contact of the lower two static contacts; the front and rear of the symmetrical center of the movable contact are each fixed with a bayonet 22 protruding to both sides, and each bayonet two ends are arranged by a pair of The extension spring 3 traction of the rotating shaft body outside, the fixed end of extension spring 3 is connected on the fixed pin 11 of rotating shaft body 1 outside both sides; It consists of two concave sections and an arched section in the middle, and the bayonet pin 11 always presses against the cam surface 12 under the force of the extension spring 3 . Both sides of the shaft body 1 are provided with grooves 13, and the extension spring 3 is located in the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com