Patents

Literature

455results about How to "High operational reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

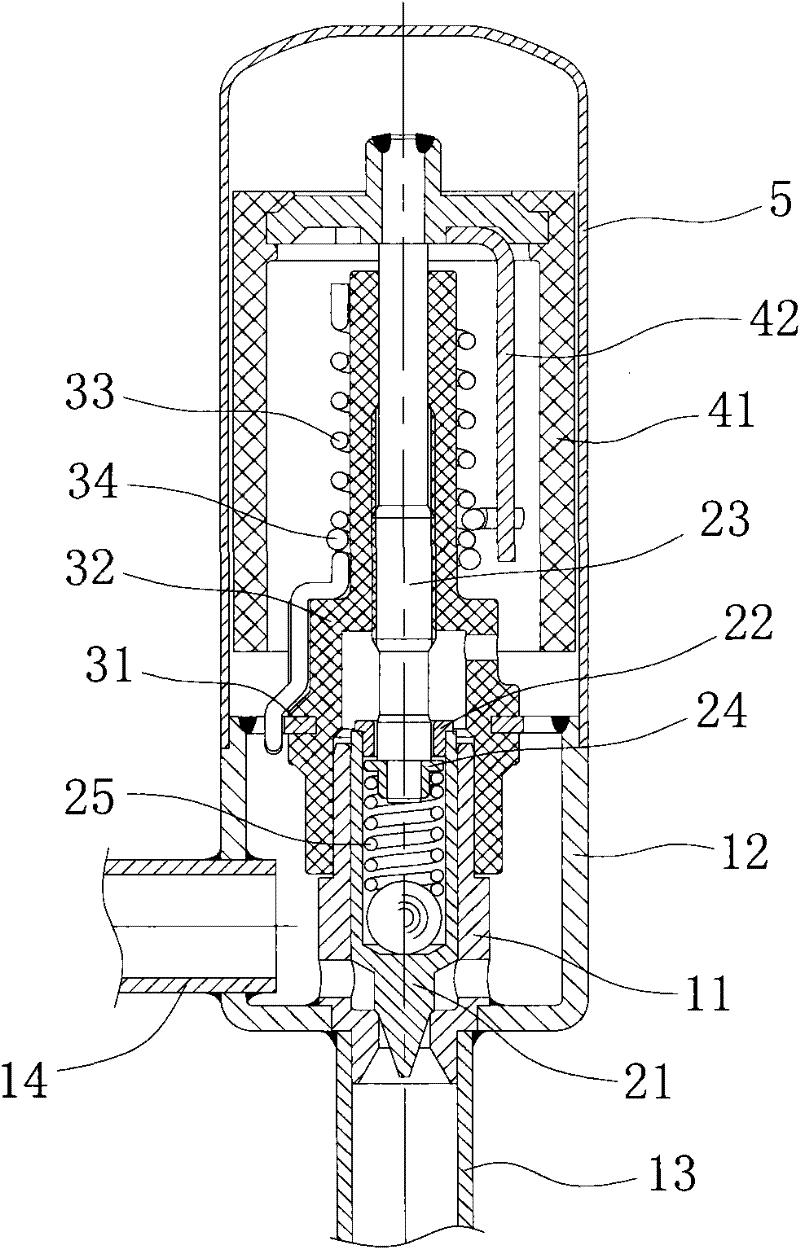

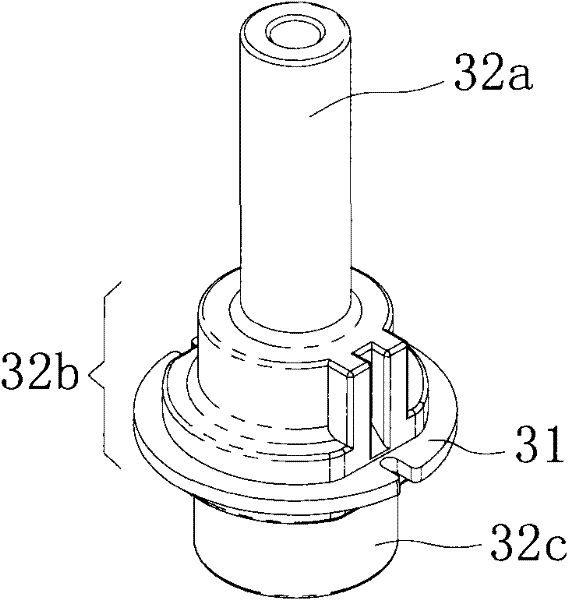

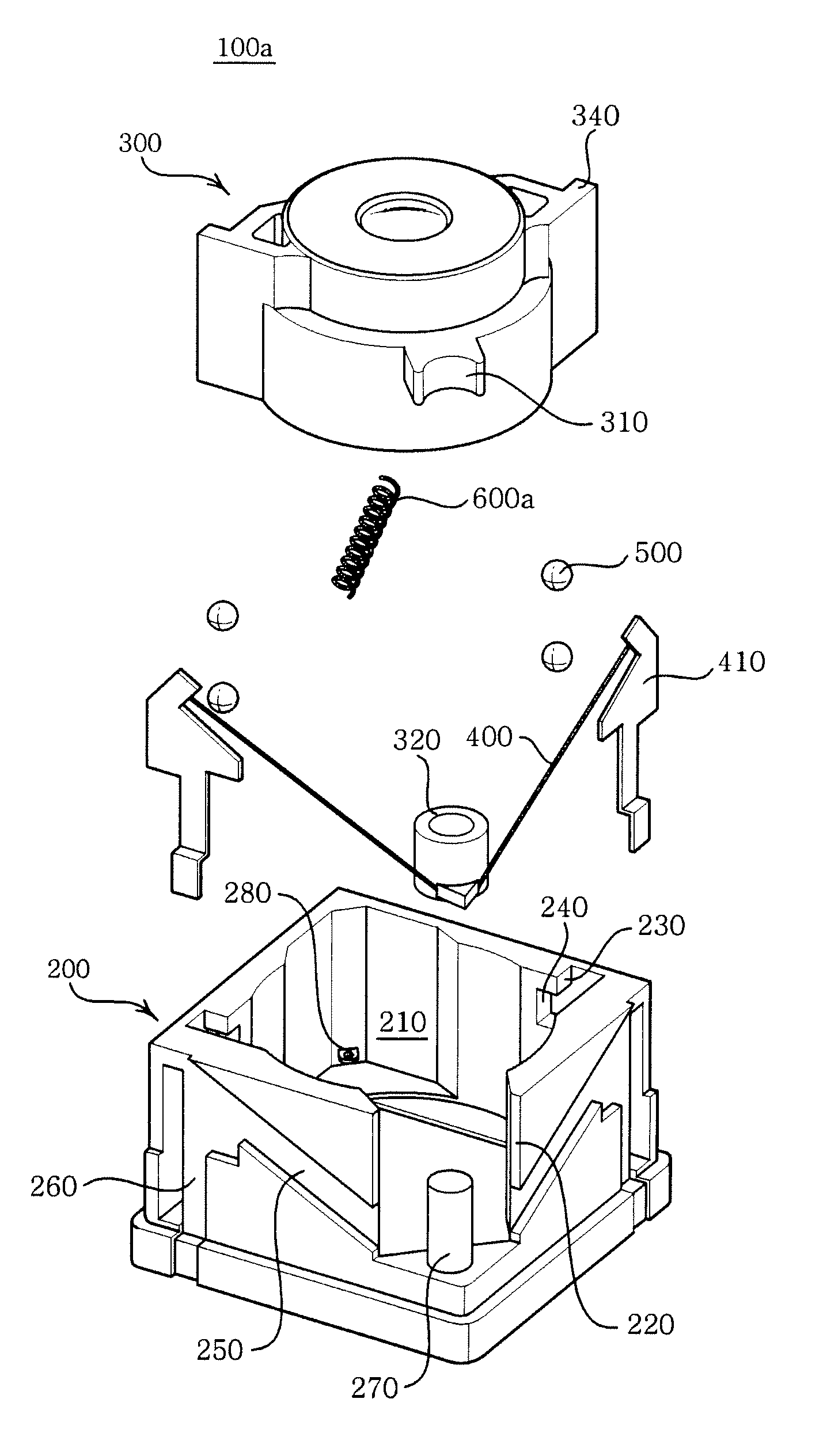

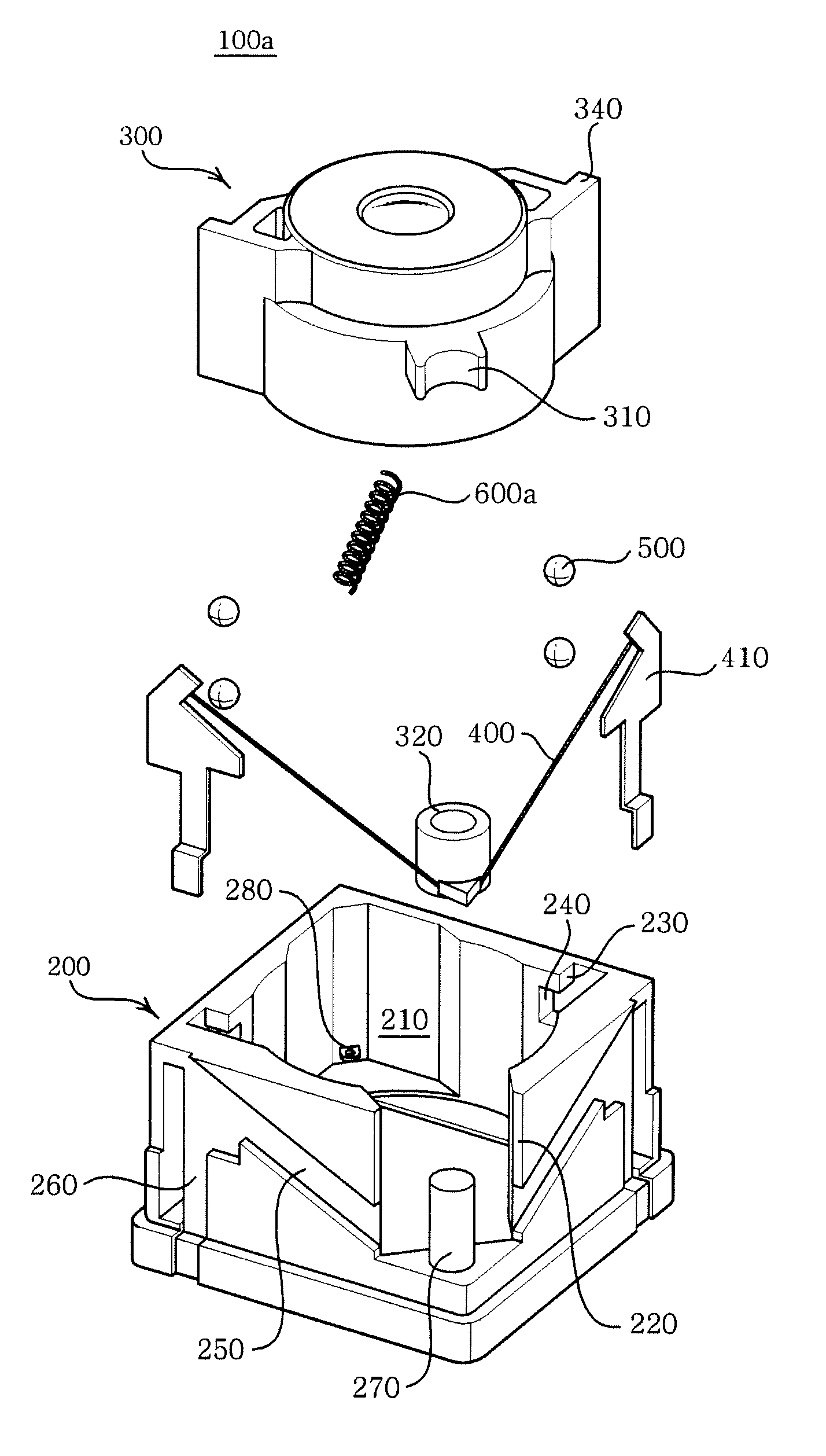

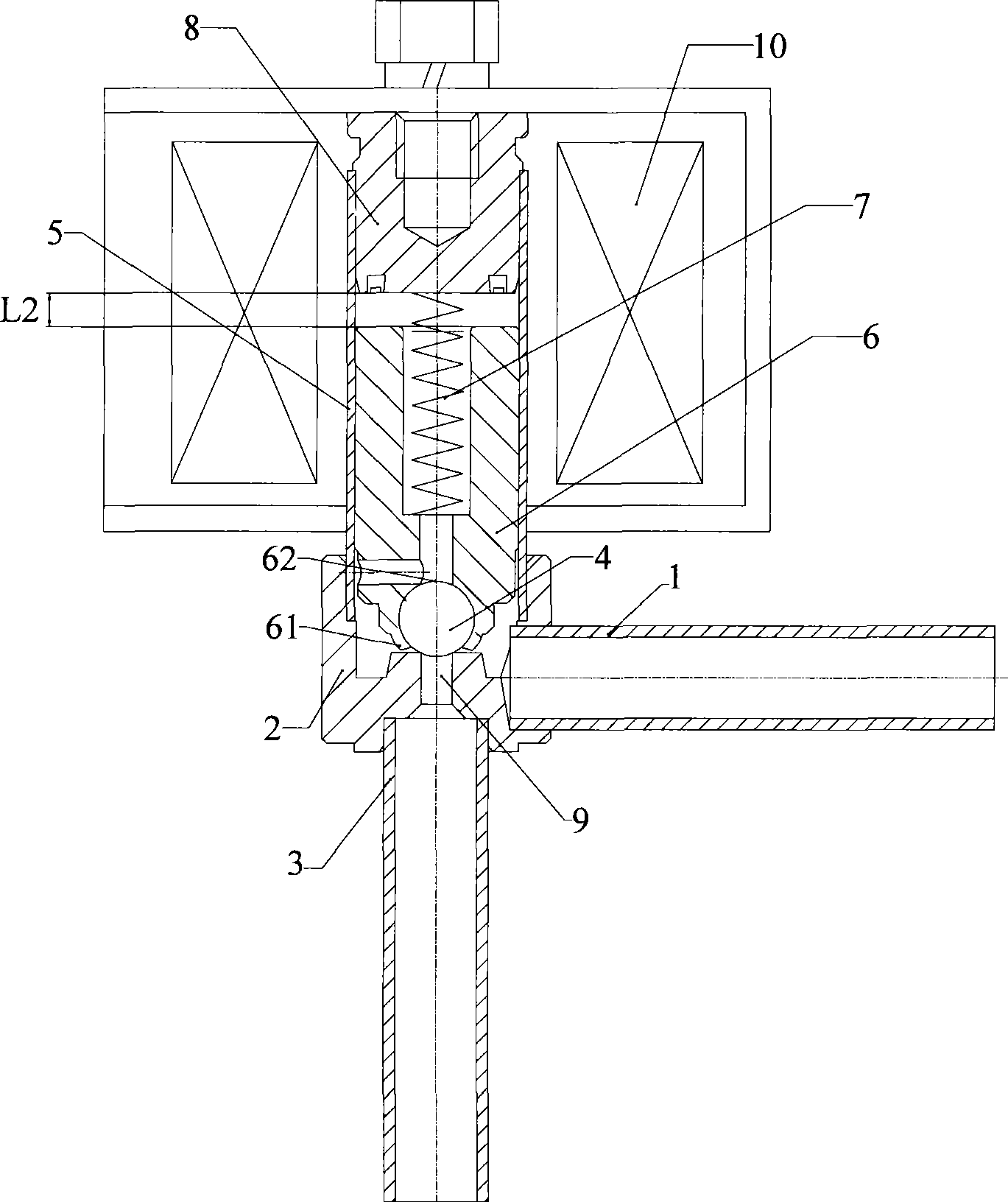

Electric valve

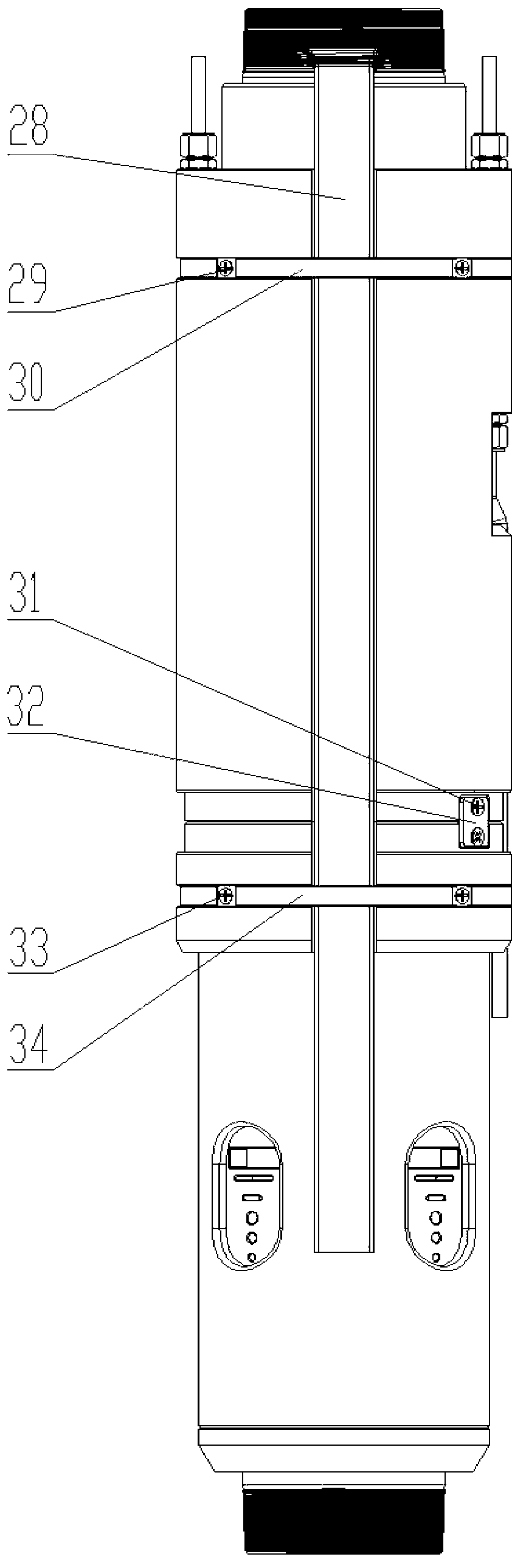

InactiveCN102454818AHigh operational reliabilityAvoid eccentric wearOperating means/releasing devices for valvesLift valveControl valvesFriction force

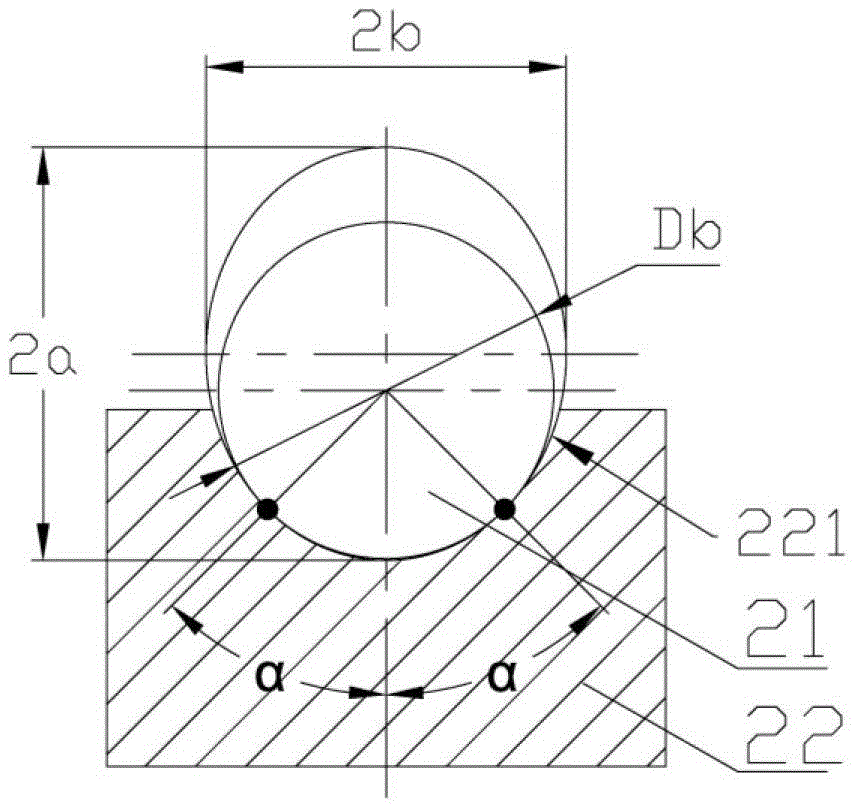

The invention relates to the technical field of control valves, in particular to an electric valve for regulating fluid flow. The electric valve comprises a valve seat component, a nut component and a valve needle lead screw component, wherein the valve seat component comprises a valve seat and a valve core seat; the nut component comprises a nut for mounting the valve needle lead screw component; and the lower end of the nut is sleeved with the upper end of the valve core seat. By the electric valve, the lower end of the nut which is used for mounting the valve needle lead screw component is connected with the upper end of the valve core seat in a sleeved mode, so that the coaxiality of the nut and a valve port of the valve core seat is extremely easy to guarantee, the coaxiality of a valve needle and the valve core seat is higher, and the problem that the valve port is loosely sealed or is subjected to eccentric wear can be solved. Meanwhile, because the coaxiality of the valve needle and the valve port is improved, the friction force can be obviously reduced when a rotor of a rotor component rotates, and the action reliability of the electric valve can be improved.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

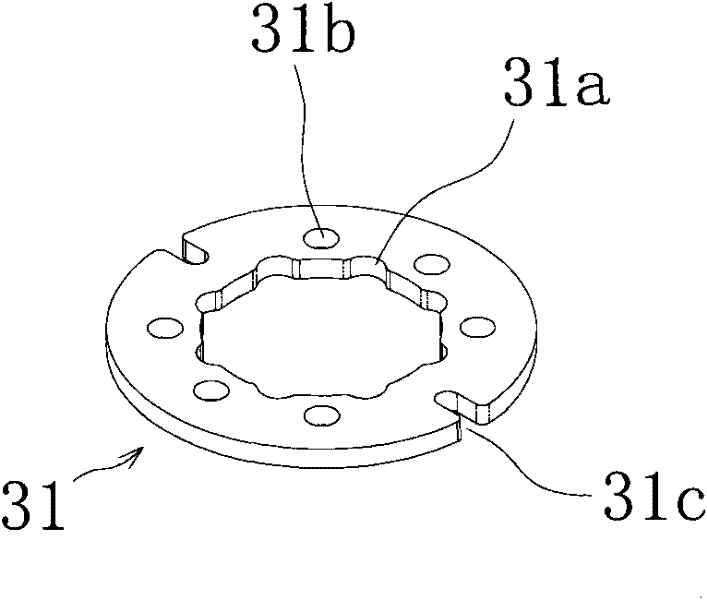

Method for efficiently extracting lithium from salt lake brine

ActiveCN103710549AAvoid interferenceHigh separation factorProcess efficiency improvementSeparation factorIonic liquid

The invention relates to a method for efficiently extracting lithium from salt lake brine. The method comprises the following steps: (1) forming an extraction organic phase by an extraction agent, a co-extraction agent and a diluent, and then mixing the extraction organic phase with salt lake brine according to the volume ratio of (3-4):2 for three-stage extraction with single extraction time being 2-10 minutes to obtain an organic phase; and (2) mixing the organic phase obtained in step (1) with a reverse extraction acid solution (0-1 mol / L) for three-stage reverse extraction with single reverse extraction time being 2-10 minutes, and collecting an aqueous phase which is an aqueous solution containing lithium ions. The co-extraction agent of an extraction system of the method is hydrophobic ionic liquid, compared with conventional synergist ferric trichloride, the interference caused by iron ions is avoided, the reverse extraction acidity is greatly reduced, more importantly the lithium-magnesium separation factor is significantly improved, and the elution step of magnesium ions is reduced; in addition, the method provided by the invention is easy in process, easy to control, high in operation reliability, and good in recyclability of the organic phase, and greatly reduces the production cost for extracting the lithium from the salt lake brine.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

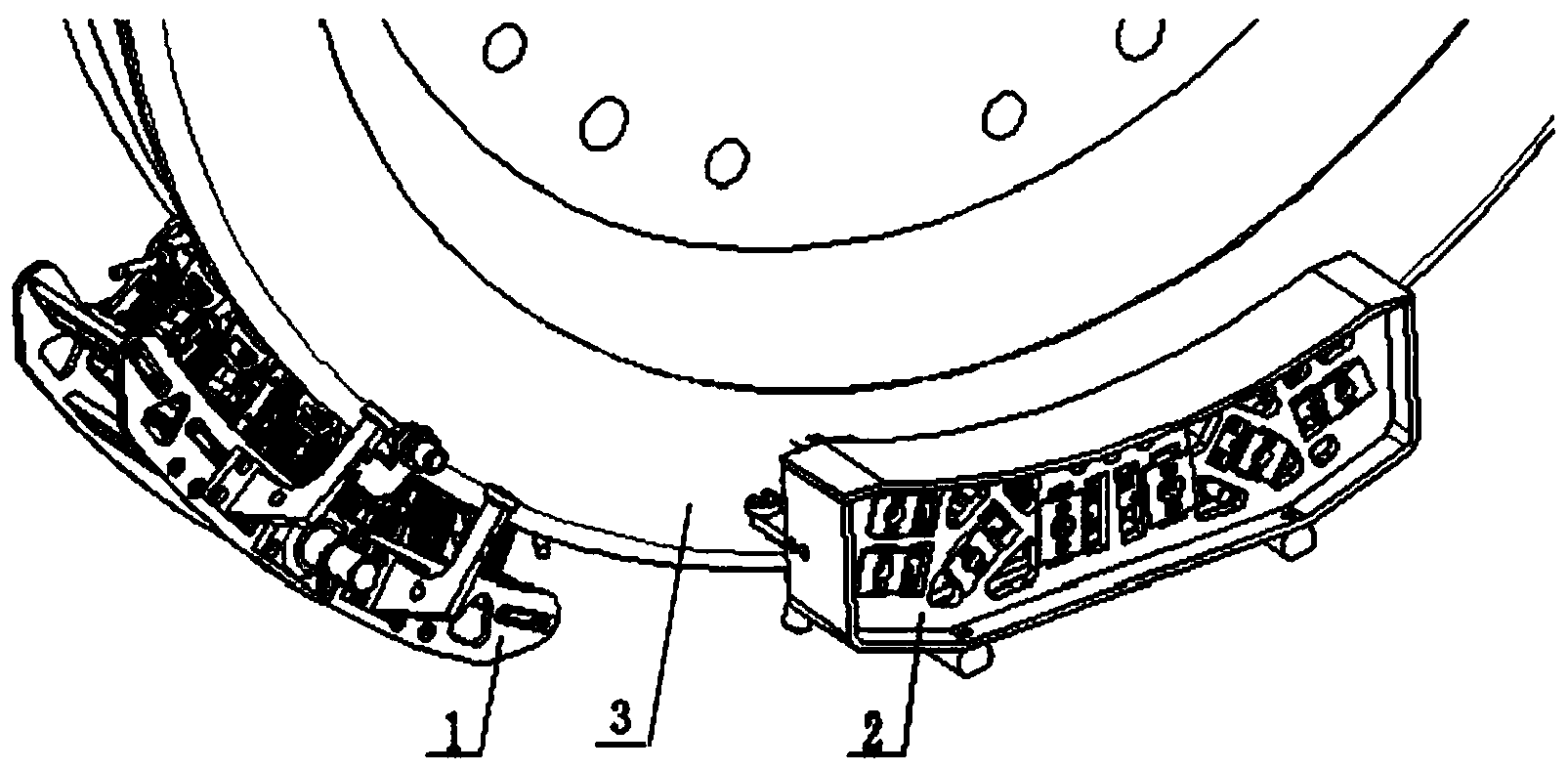

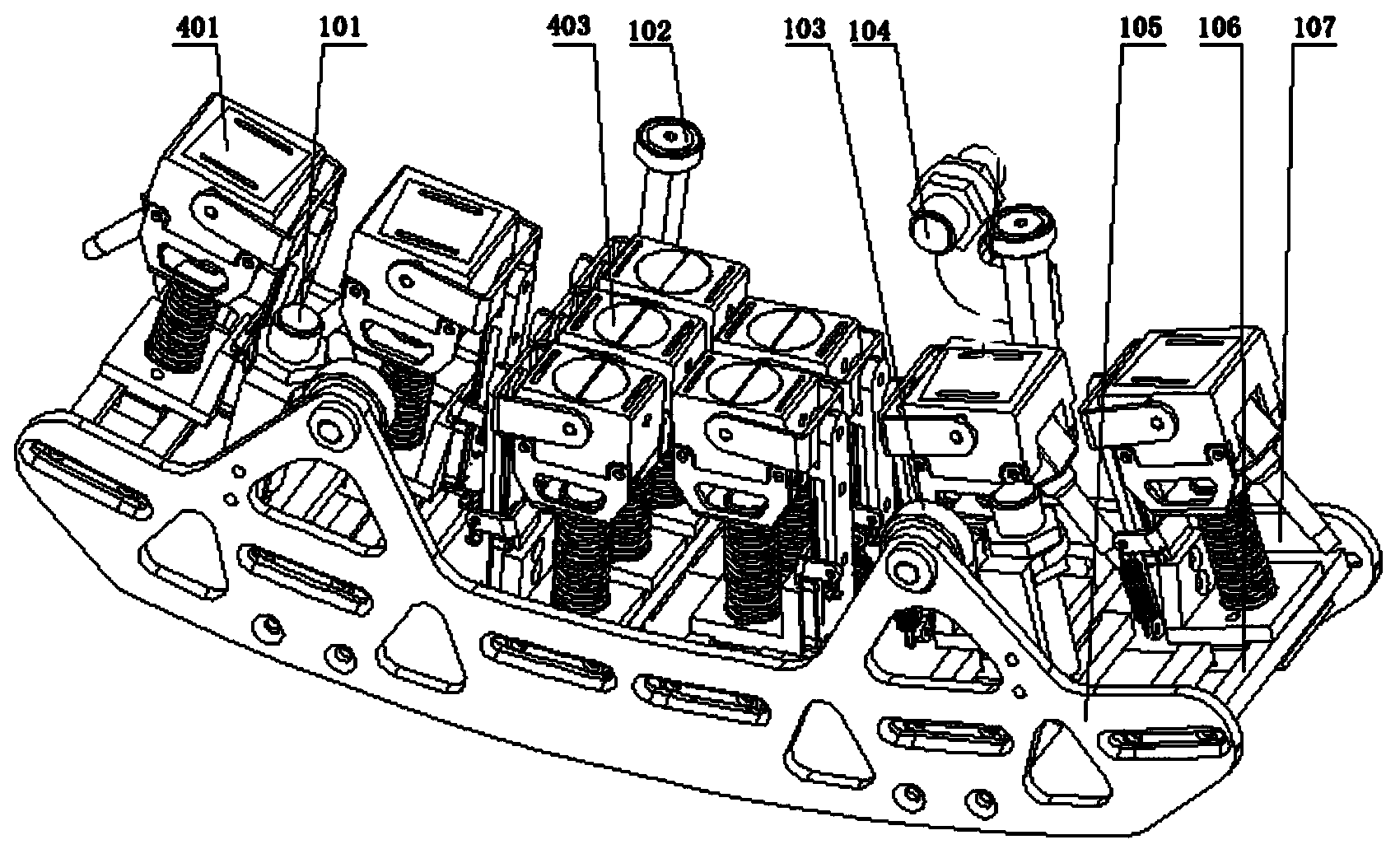

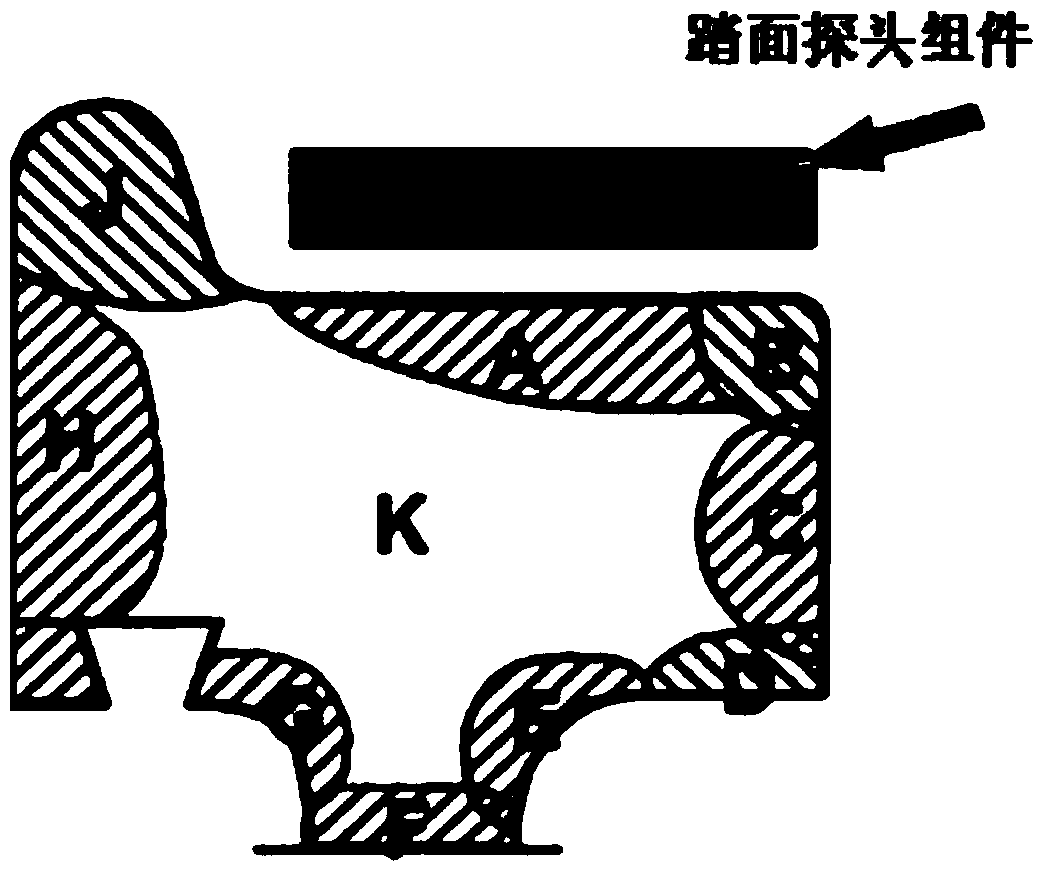

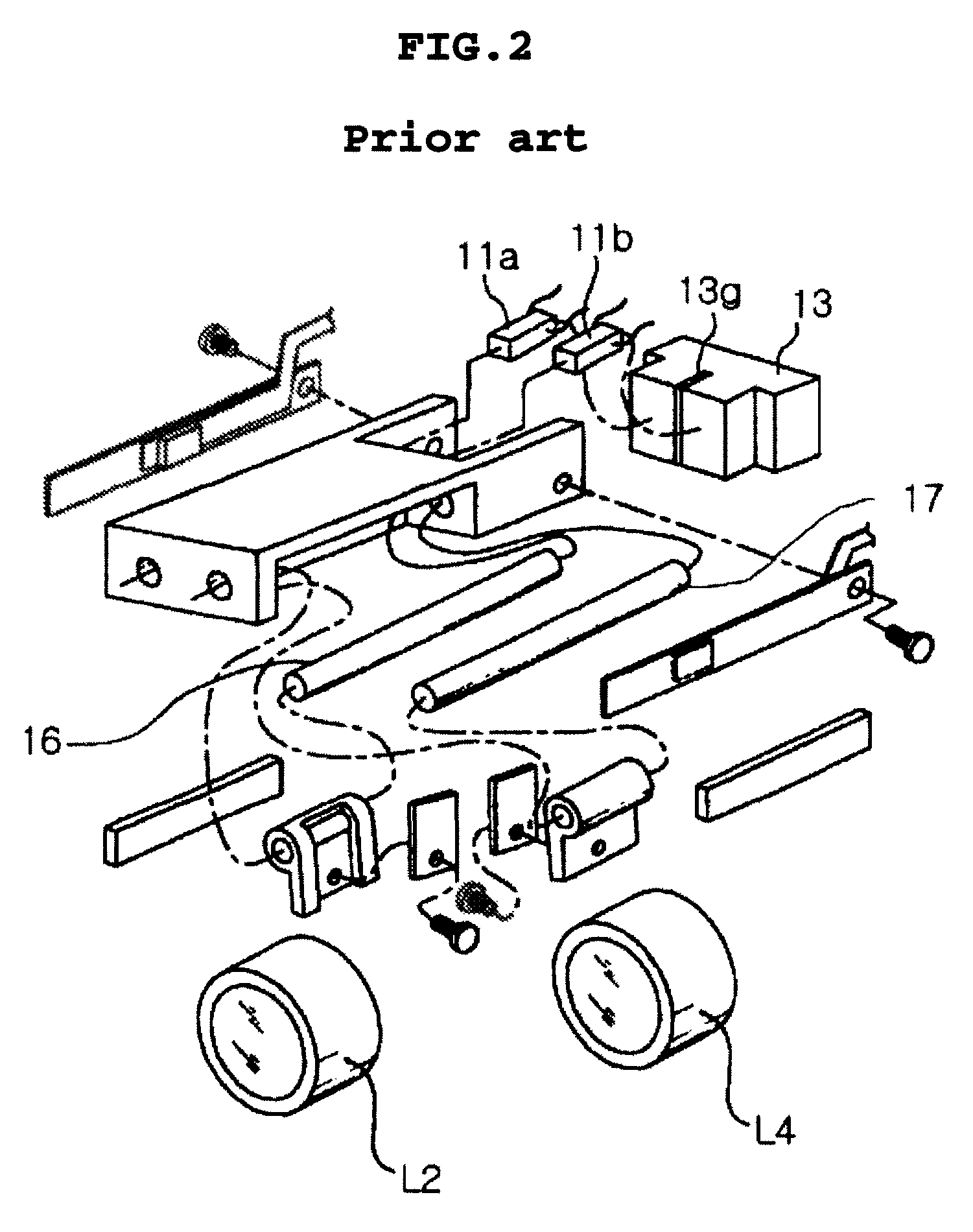

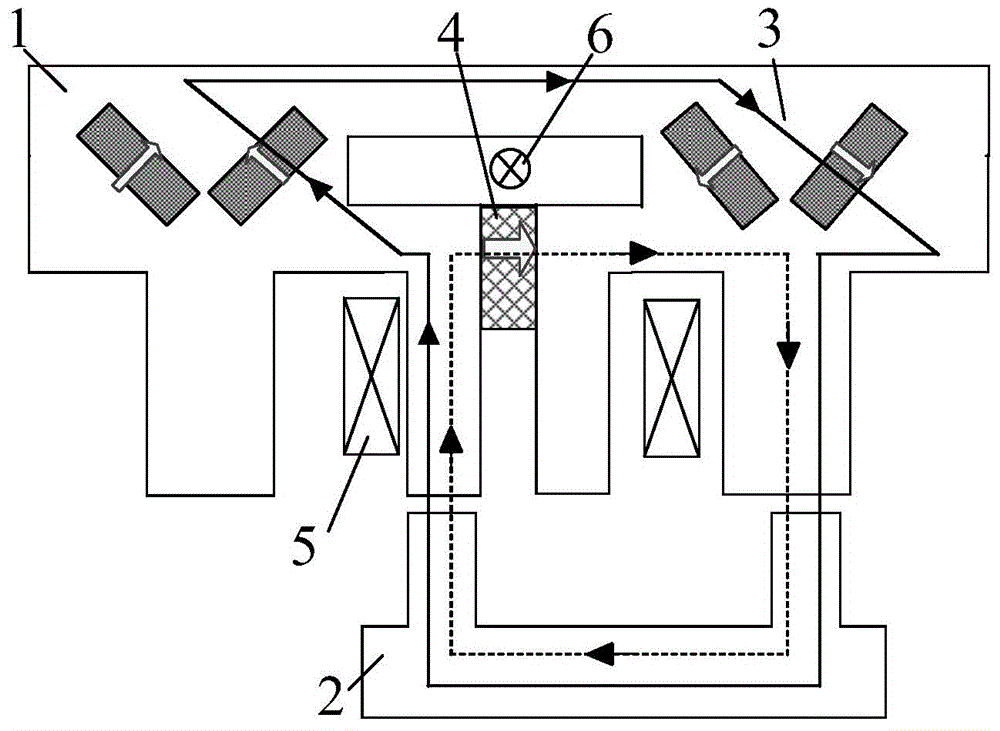

Track vehicle rim and tread flaw detection probe assembly system

ActiveCN103472138AEasy to useProtect the safety of useMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringManipulator

The invention discloses a track vehicle rim and tread flaw detection probe assembly system. The track vehicle rim and tread flaw detection probe assembly system comprises a tread flaw detection probe assembly and a rim flaw detection probe assembly. The tread flaw detection probe assembly leans on the tread of a wheel through a mechanical arm; the rim flaw detection probe assembly leans on the rim surface of the wheel through the mechanical arm; the tread flaw detection probe assembly can automatically detect wheel tread and rim defects from the tread in an online mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate; the rim flaw detection probe assembly can automatically detect wheel rim surface and tread detects from the inner lateral side of the rim in on online-mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate.

Owner:BEIJING SHEENLINE GRP CO LTD

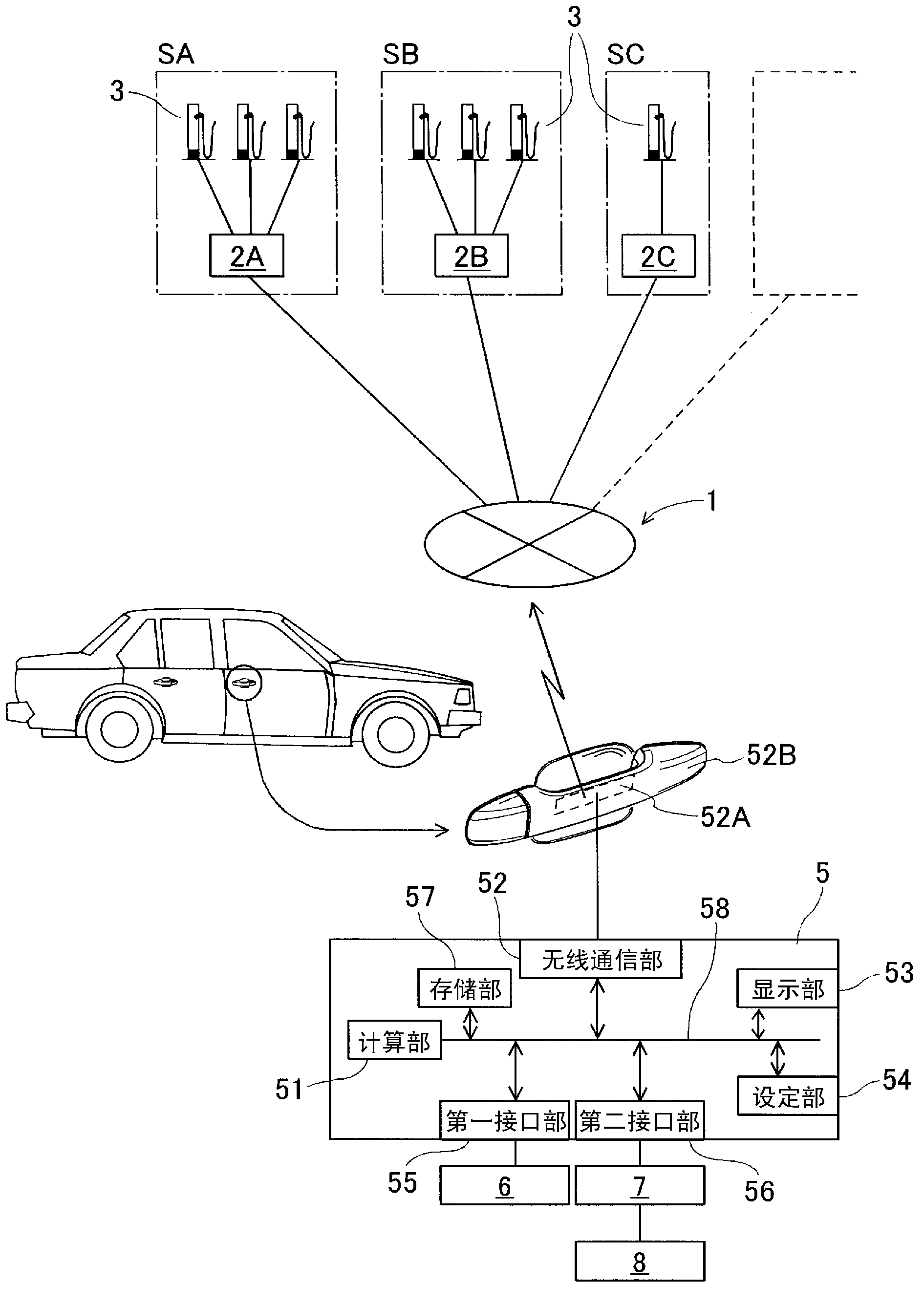

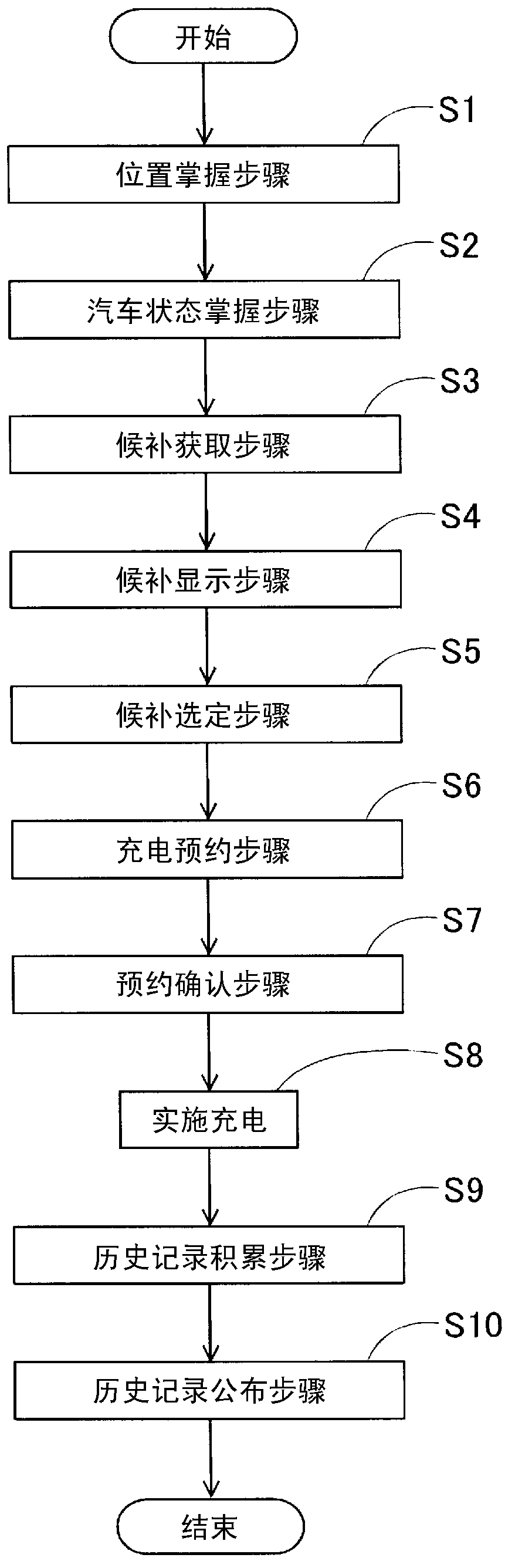

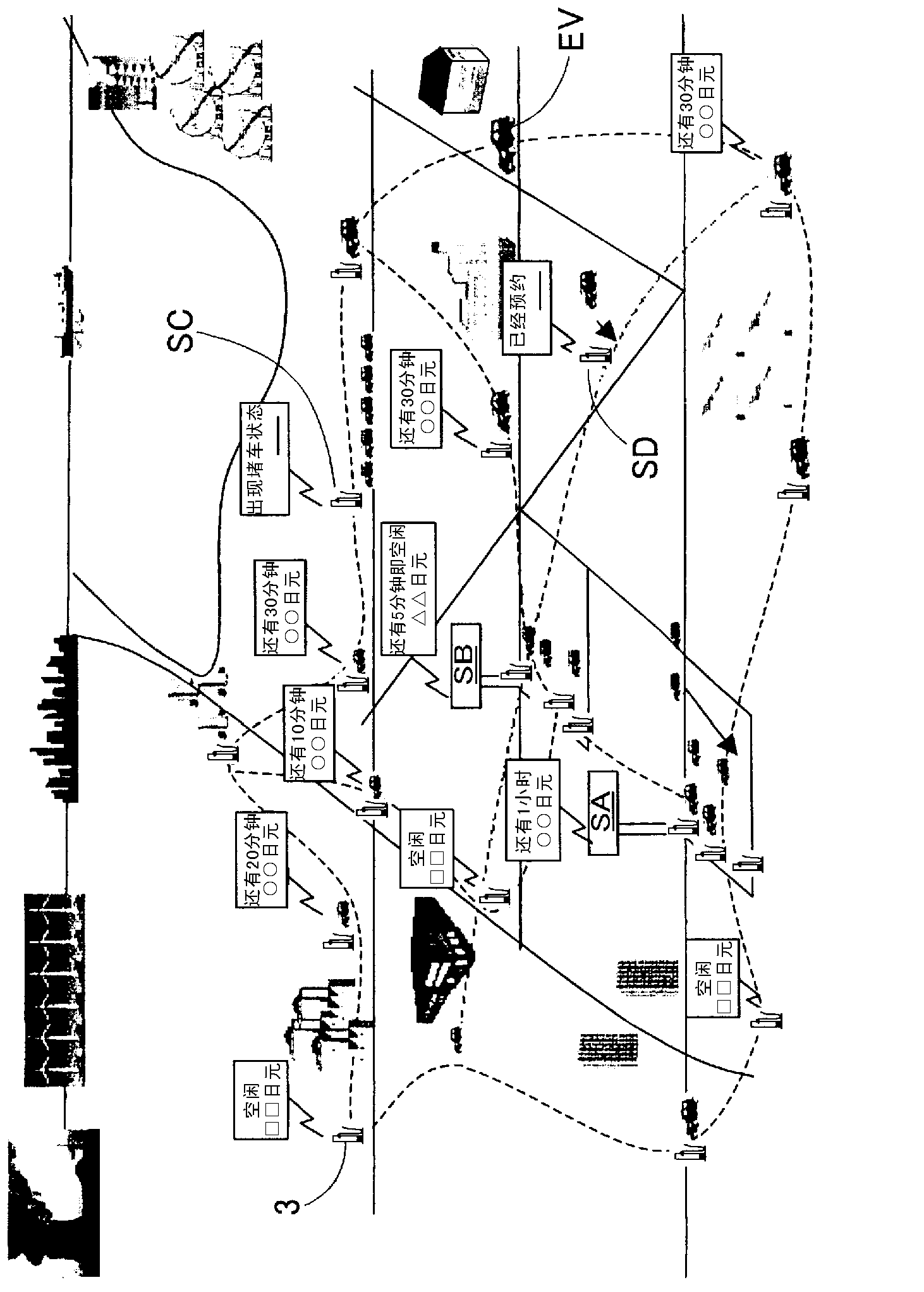

Electric automobile charge scheduling method and charge scheduling device

InactiveCN103262112AImprove convenienceImprove adaptabilityCharging stationsReservationsInformation deviceEngineering

This electric automobile charge scheduling method uses a plurality of connected station management devices which manage charging equipment arranged in a charging station and an vehicle-mounted information device, and comprises the steps of: ascertaining the present location of an electric automobile, using a station management network which connects a plurality of station management devices which manage charging stations' charging infrastructure and a vehicle-mounted information device; acquiring information including the locations of candidate charging stations which are candidates for carrying out a charge on the basis of the present location and information including waiting time of the candidate charging infrastructure and the price of the charge; displaying the candidate charging stations; selecting and setting the candidate charging station with which carrying out the charge is desired; and scheduling the candidate charging station on the basis of the setting. It is thus possible to increase usability, allowing charge scheduling which takes a user's decisions and preferences into account, as well as eliminate actual risks of batteries having insufficient remaining capacity and the emotional concerns therewith, and improve system response time and operational reliability by distributing processing load on the system side and the vehicle side.

Owner:AISIN SEIKI KK

Lens actuating module

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

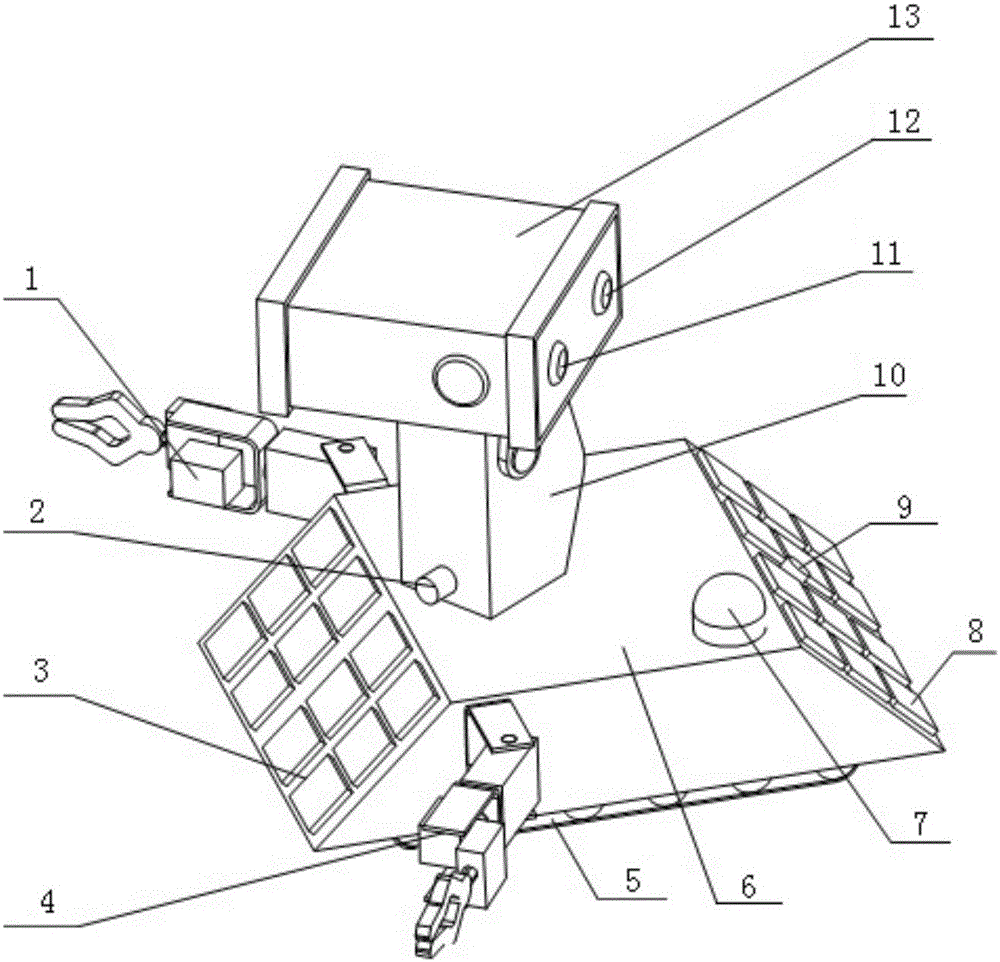

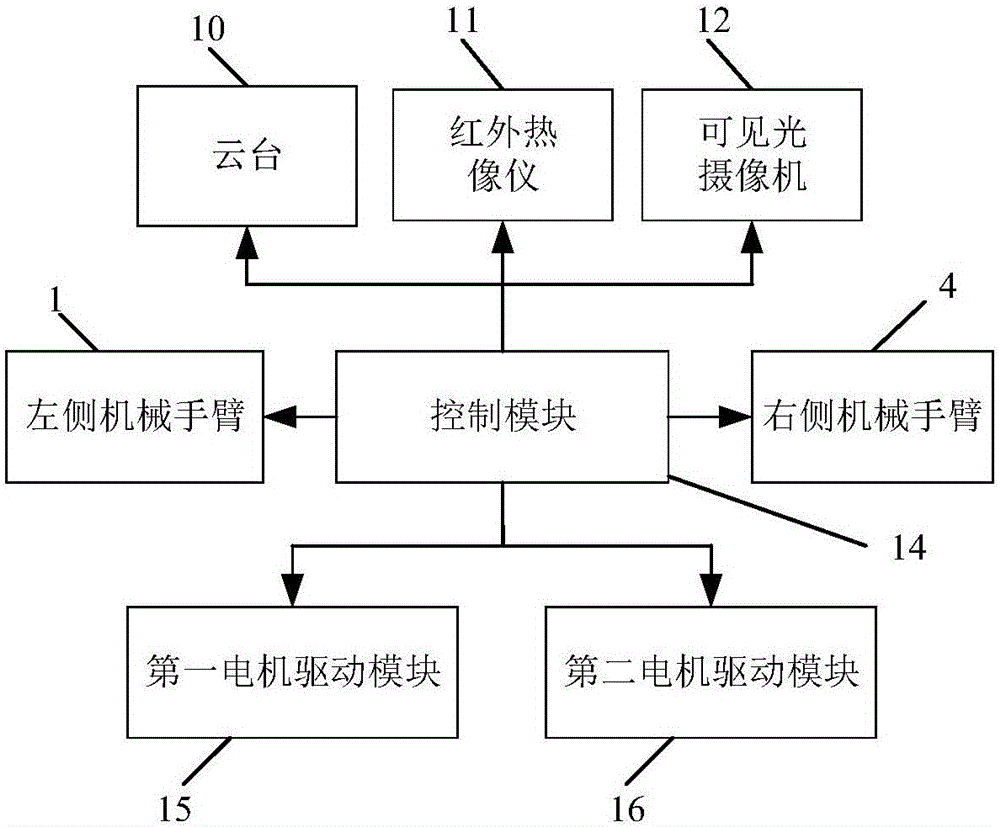

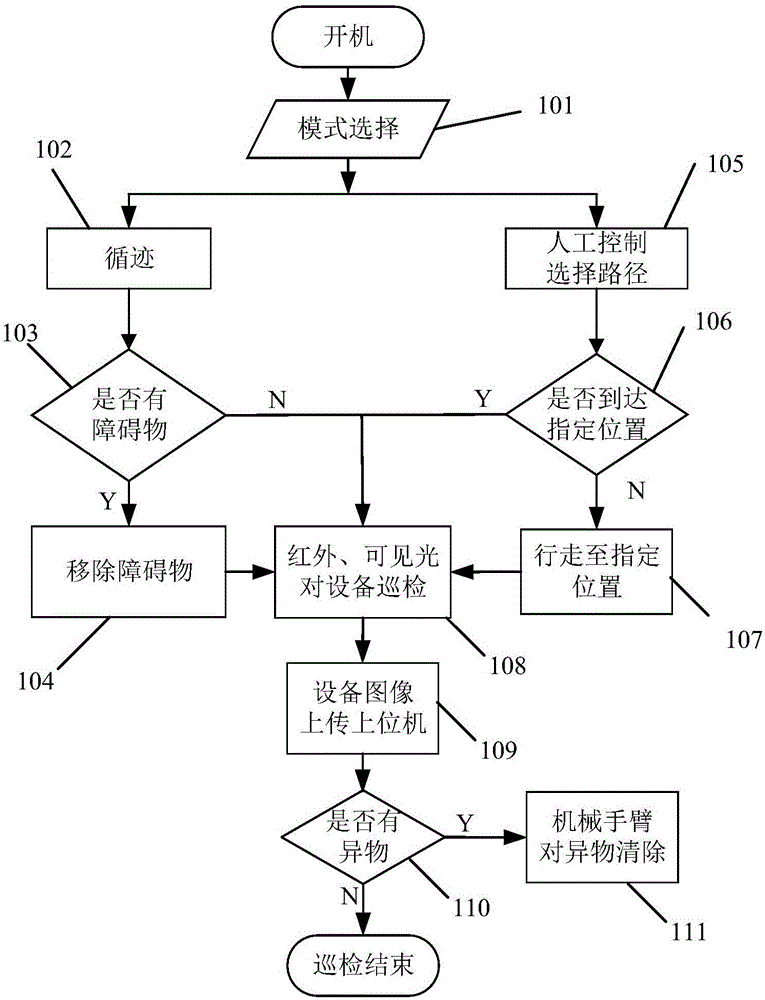

Transformer substation intelligent patrol robot with mechanical arms and patrol method thereof

InactiveCN105856186AHigh degree of intelligenceRealize opening and closingProgramme-controlled manipulatorForeign matterTransformer

The invention relates to a transformer substation intelligent patrol robot with mechanical arms and a patrol method thereof. The patrol robot comprises a walking chassis, patrol equipment and a control module (14). The patrol equipment is installed on the walking chassis. The control module (14) is connected with the walking chassis and the patrol equipment. The patrol robot further comprises the two mechanical arms which are symmetrically installed on the two sides of the walking chassis. The mechanical arms are both connected with the control module (14). Compared with the prior art, the intelligent patrol robot is capable of achieving patrol and meanwhile capable of removing foreign matter and controlling on and off of mechanical switches through the mechanical arms, thereby having a high intelligent level.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Nylon and preparation method thereof

ActiveCN103102486AHigh degree of polymerizationReduce the degree of polymerizationPolymer scienceAntioxidant

The invention belongs to the technical field of polymer processing, and relates to nylon and a preparation method thereof. The nylon is prepared from the following components: 1 part of dicarboxylic acid, diamine, a catalyst, a blocking agent, exchange reaction inhibitor, a nucleating agent and antioxidant, wherein the diamine and the dicarboxylic acid are equal in molar weight; the catalyst accounts for 0.001-0.1wt% of the total weight of the dicarboxylic acid and diamine; the blocking agent accounts for 0.05-1mol% of the total molar weight of the dicarboxylic acid and diamine; the exchange reaction inhibitor accounts for 0.1-5wt% of the total weight of the dicarboxylic acid and diamine; the nucleating agent accounts for 0.1-1wt% of the total weight of the dicarboxylic acid and diamine; and the antioxidant accounts for 0.001-1wt% of the total weight of the dicarboxylic acid and diamine. According to the invention, a primary polymerization product is low in viscosity, and the pressure in a kettle is high, so that pressure spray can be easily realized to prepare dry nylon polymer powder; and further polycondensation can be performed on the low-polymerization-degree nylon through melt polycondensation. Thus, the materials do not need to be further subjected to a long-time solid-phase tackifying process, thereby shortening the reaction time and improving the performance of the high-temperature nylon.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

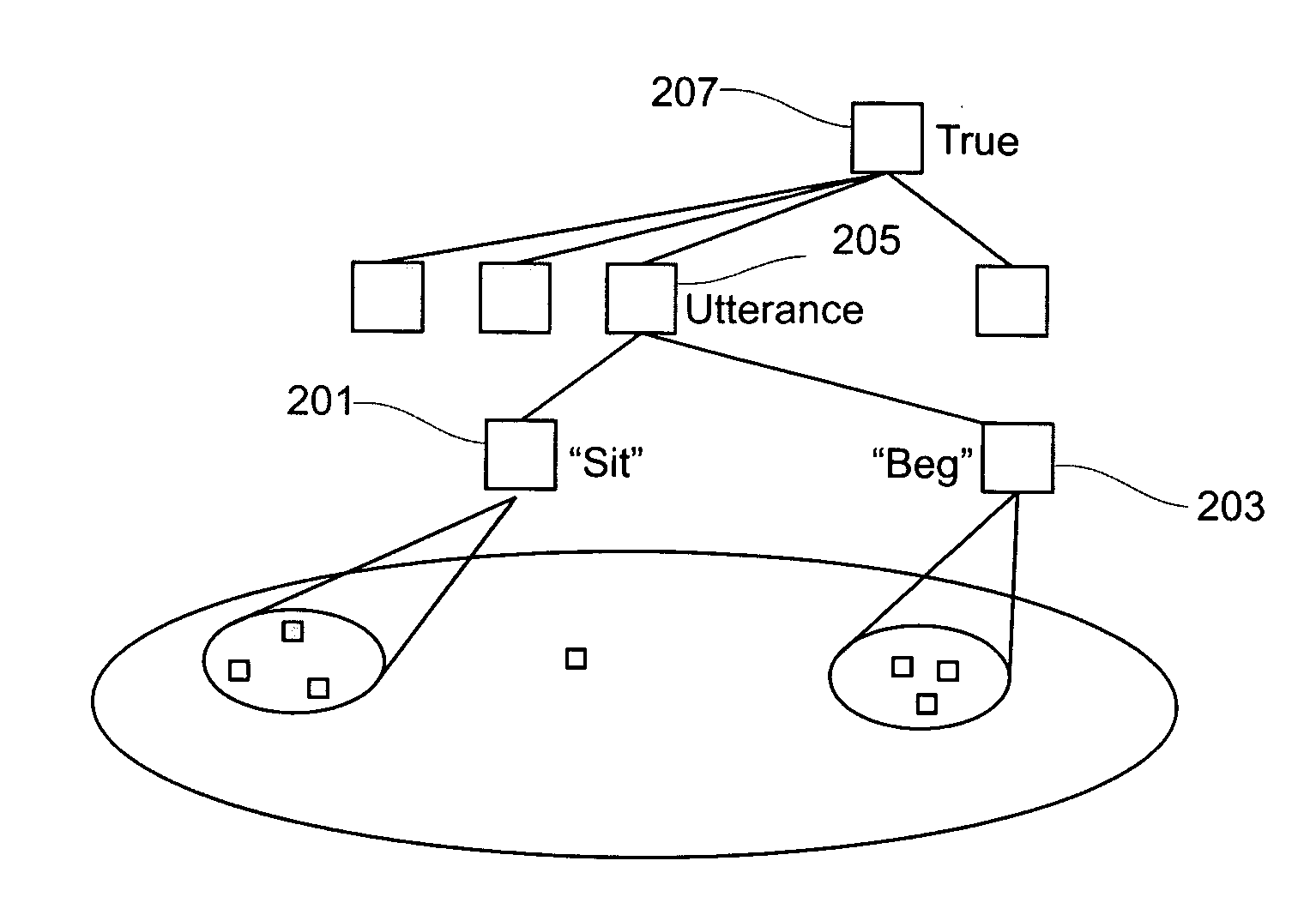

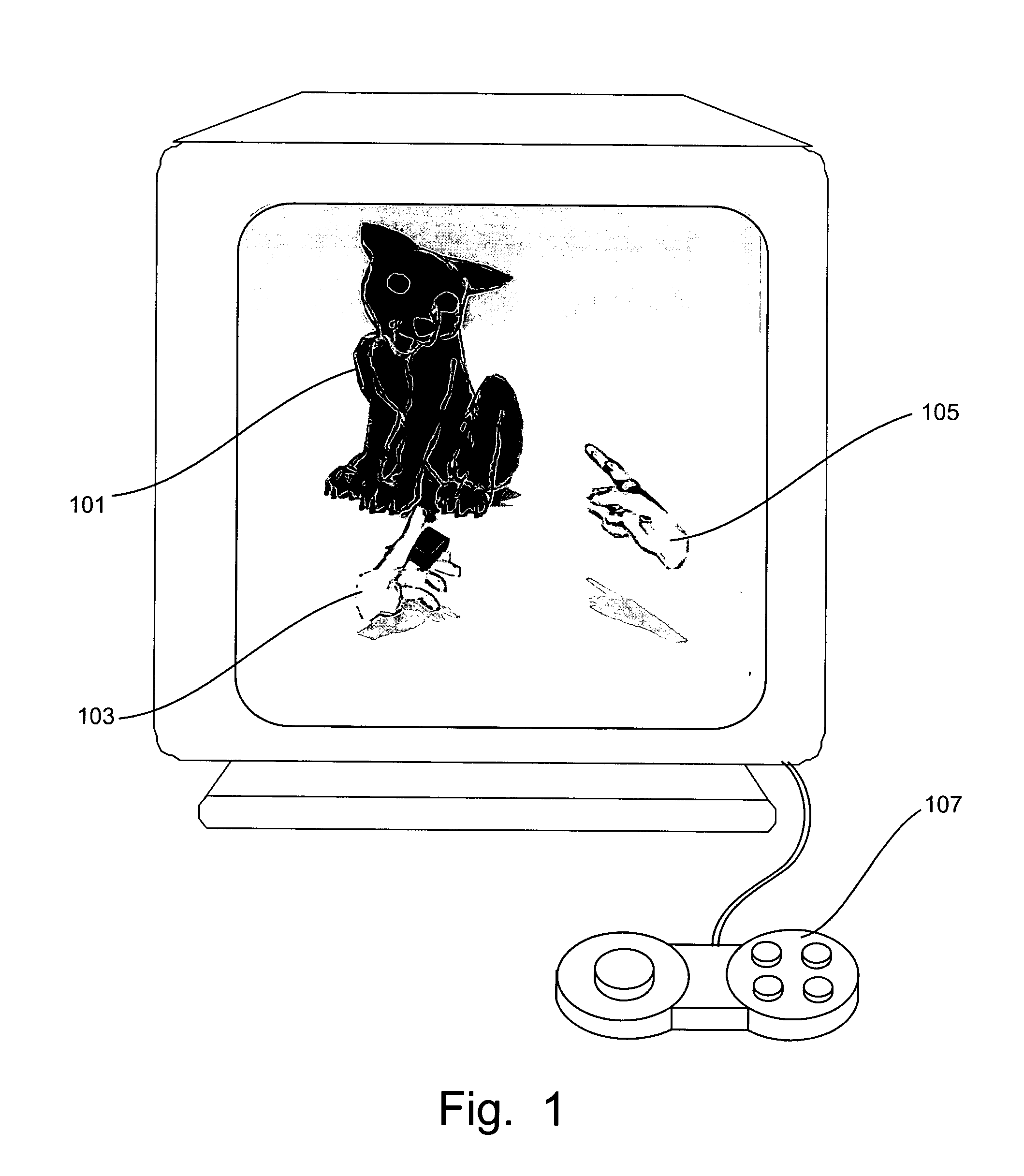

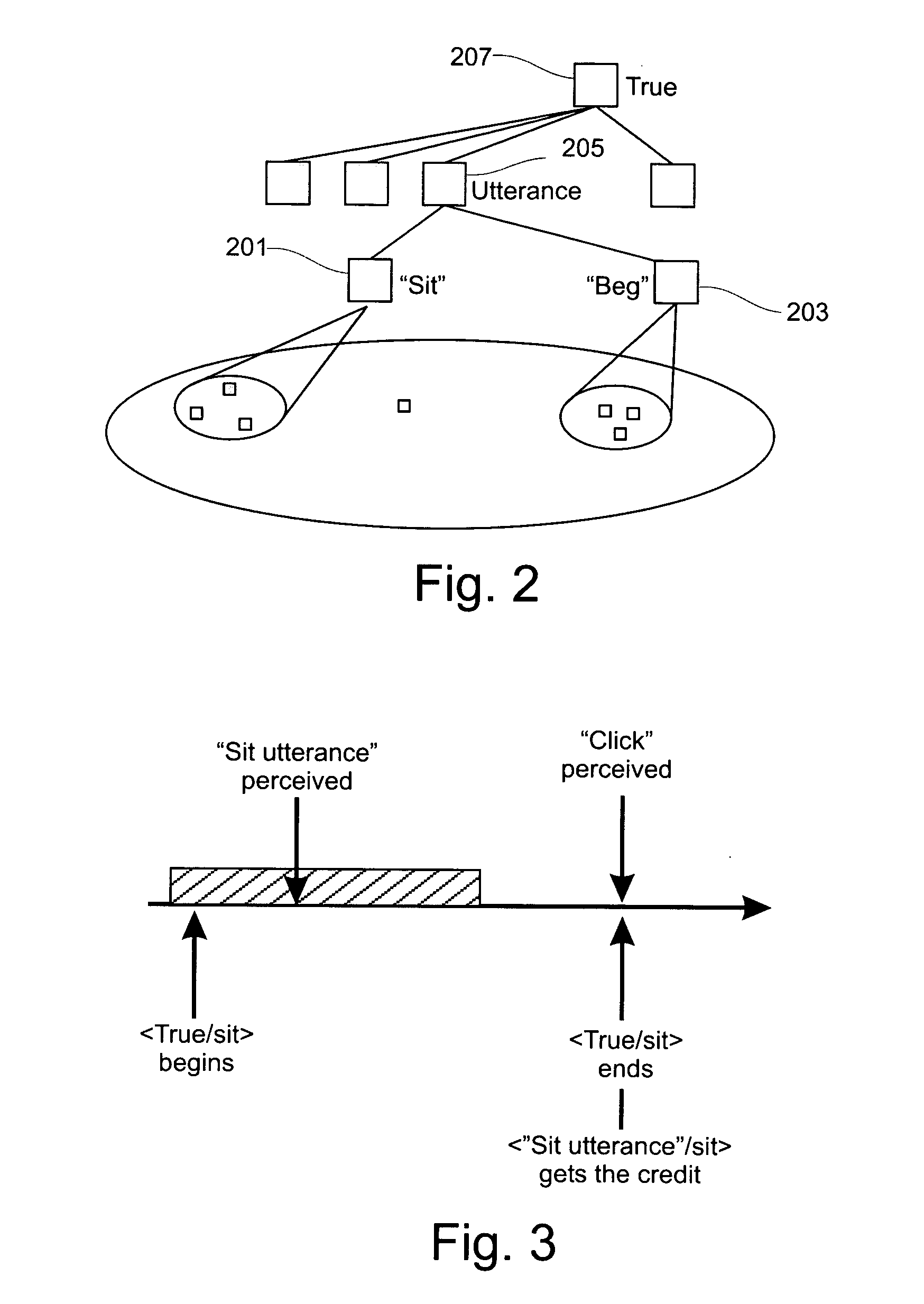

Integrated learning for interactive synthetic characters

InactiveUS20110099130A1High operational reliabilityBig advantageDigital computer detailsElectrical appliancesAnimationClicker training

A practical approach to real-time learning for synthetic characters grounded in the techniques of reinforcement learning and informed by insights from animal training. The approach simplifies the learning task for characters by (a) enabling them to take advantage of predictable regularities in their world, (b) allowing them to make maximal use of any supervisory signals, and (c) making them easy to train by humans. An autonomous animated dog is described that can be trained with a technique used to train real dogs called “clicker training.”

Owner:MASSACHUSETTS INST OF TECH

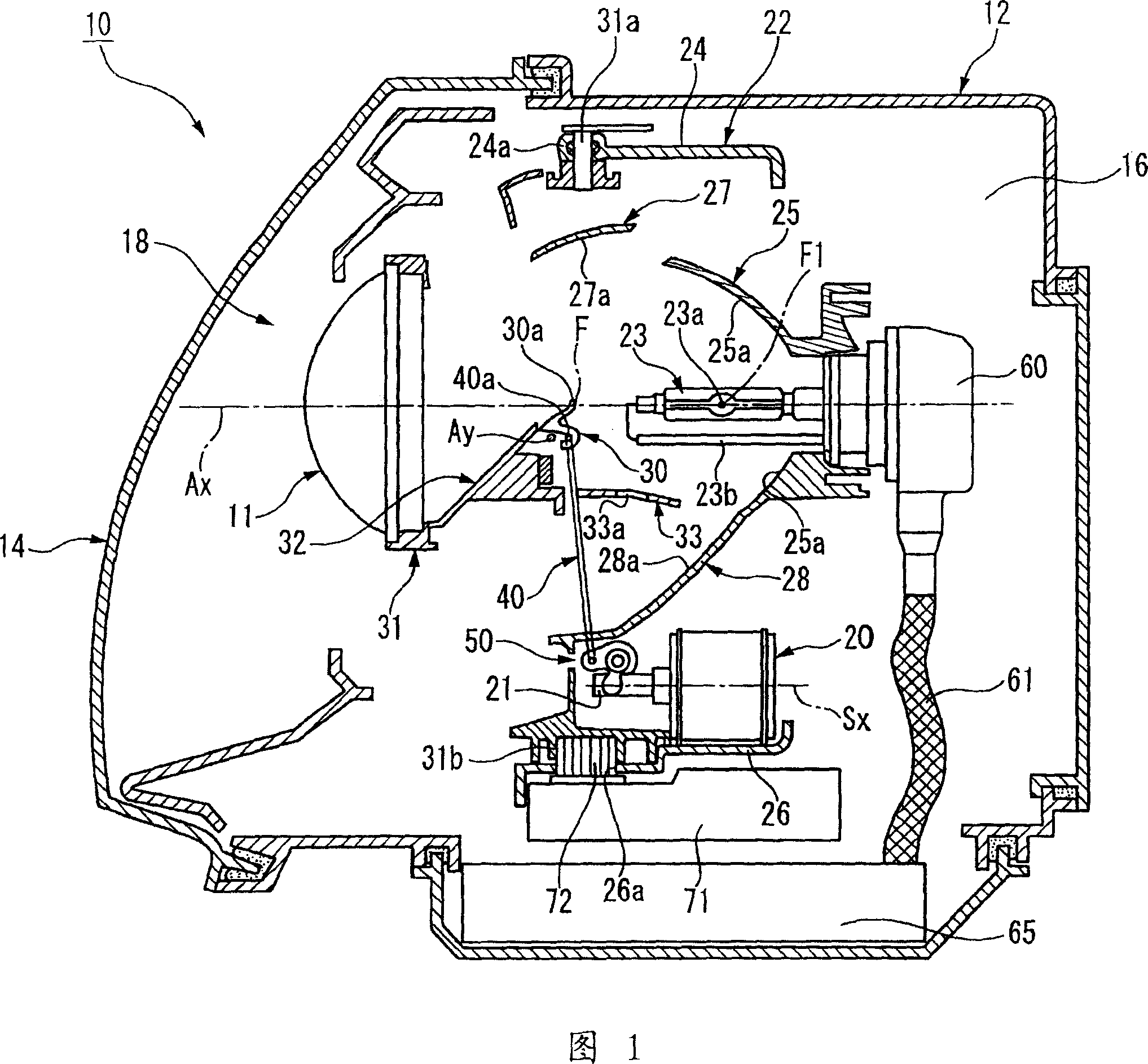

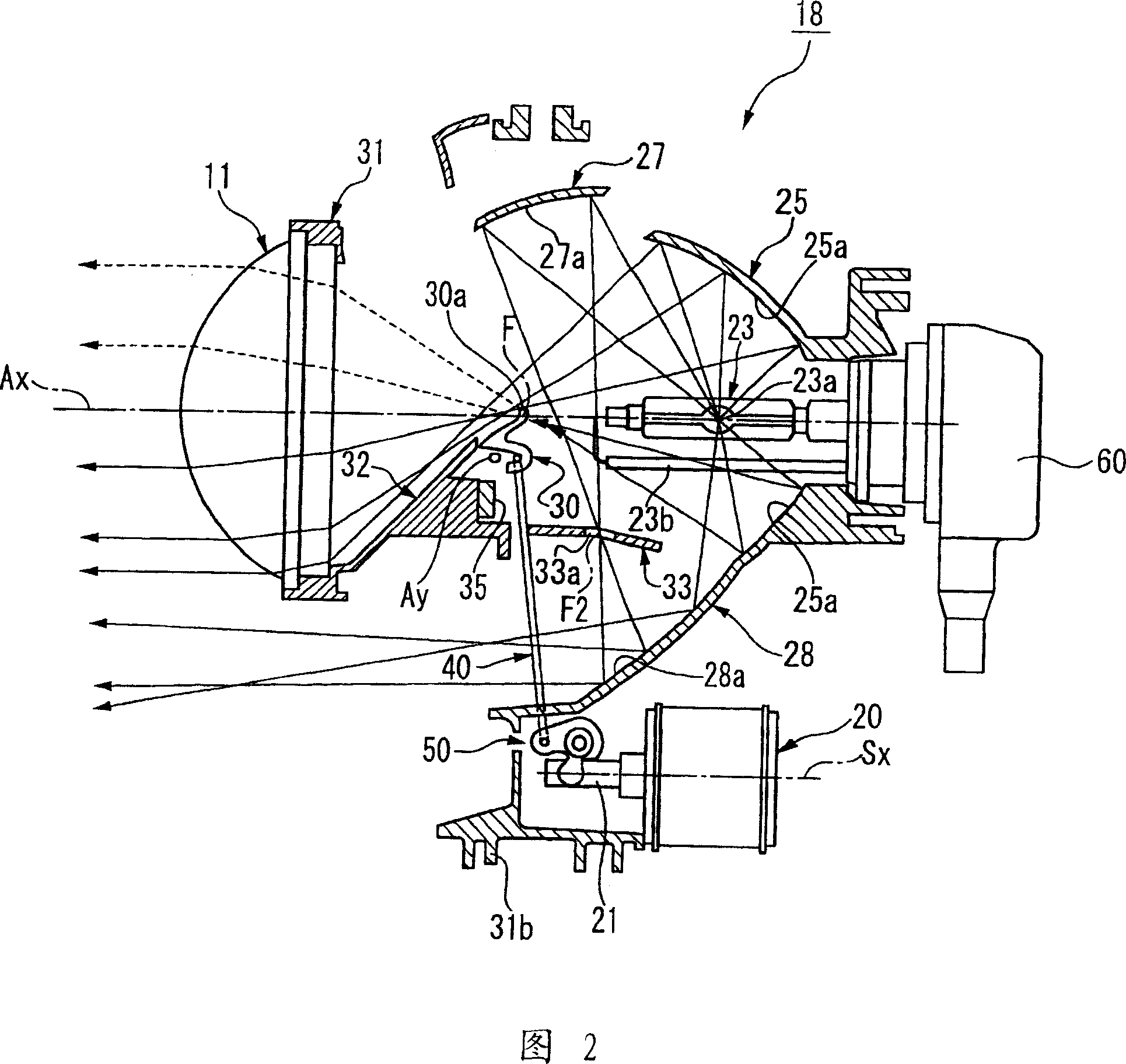

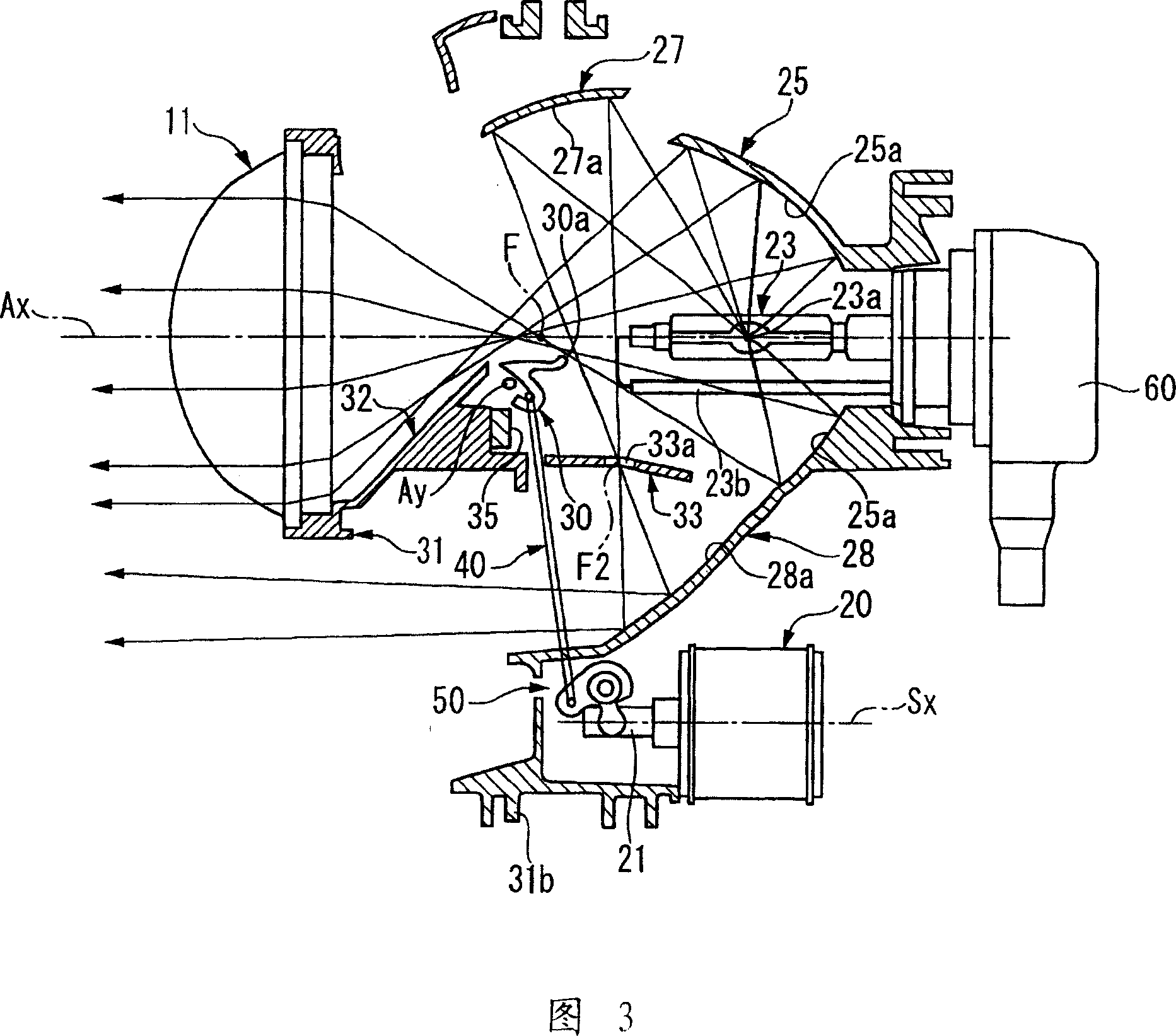

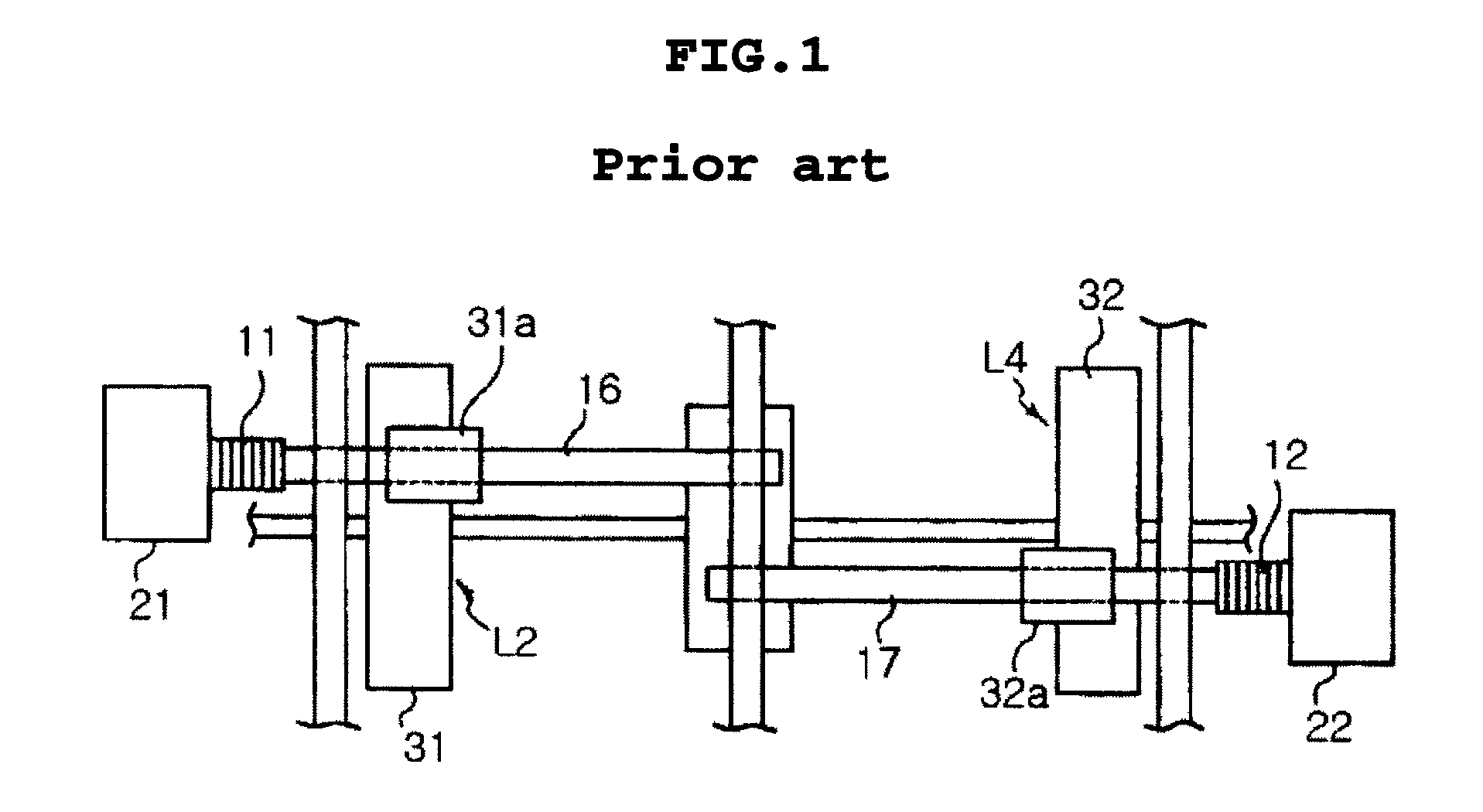

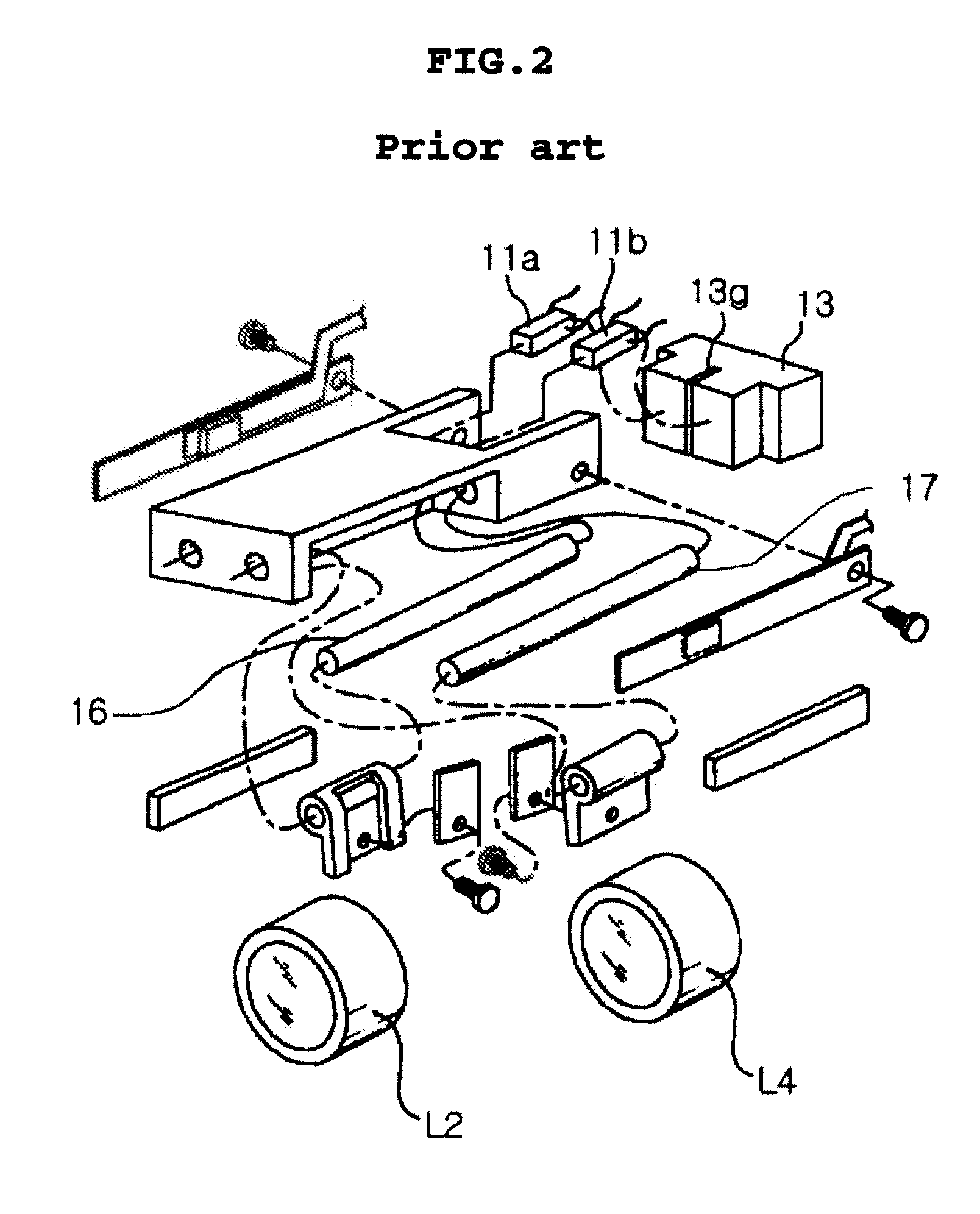

Vehicle headlamp

InactiveCN1928422AImprove rigidityReduce vibrationVehicle headlampsPoint-like light sourceRotational axisFree rotation

The invention provides a vehicle headlight with an actuator miniaturized and weight-saved and with luminance at irradiation effectively enhanced without adversely affecting on formation of a low-beam light distribution pattern, in a projector type one equipped with a movable shade. The vehicle headlight (10) is provided with a projection lens (11), a light source bulb (23), a reflector (25) reflecting direct light from the light source bulb (23) toward front, a movable shade (30), an actuator (20) moving the movable shade (30) between a shielding position and a shielding relaxation position. The movable shade (30) is installed in free rotation around a rotational axis line extended in a car width direction in the vicinity of a lens center axis (Ax), and the actuator (20) gives driving force to an end of a rod member (40) with the other end coupled with the movable shade (30) in a length direction through an operation direction changing mechanism (50) to rotate the movable shade.

Owner:KOITO MFG CO LTD

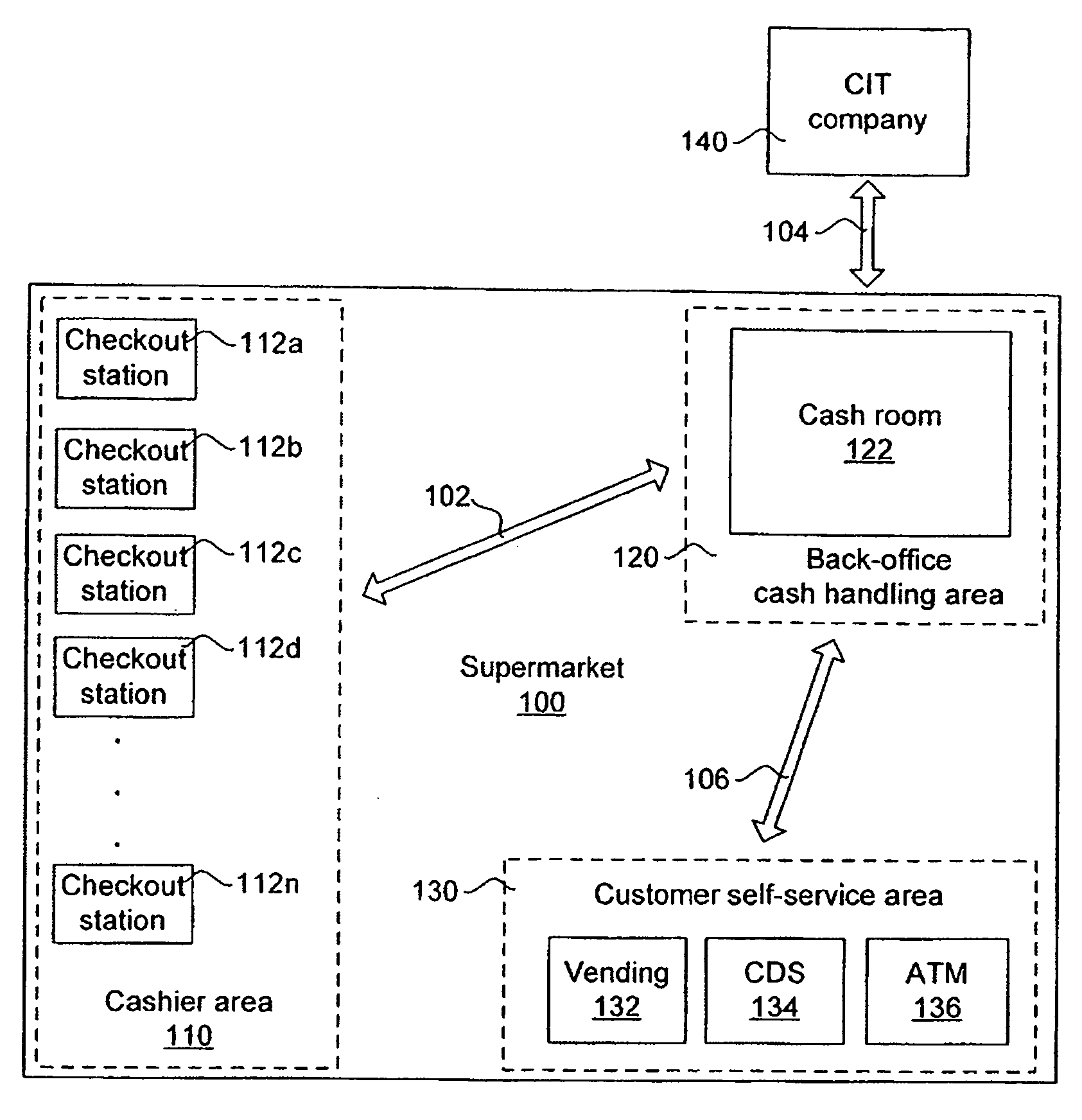

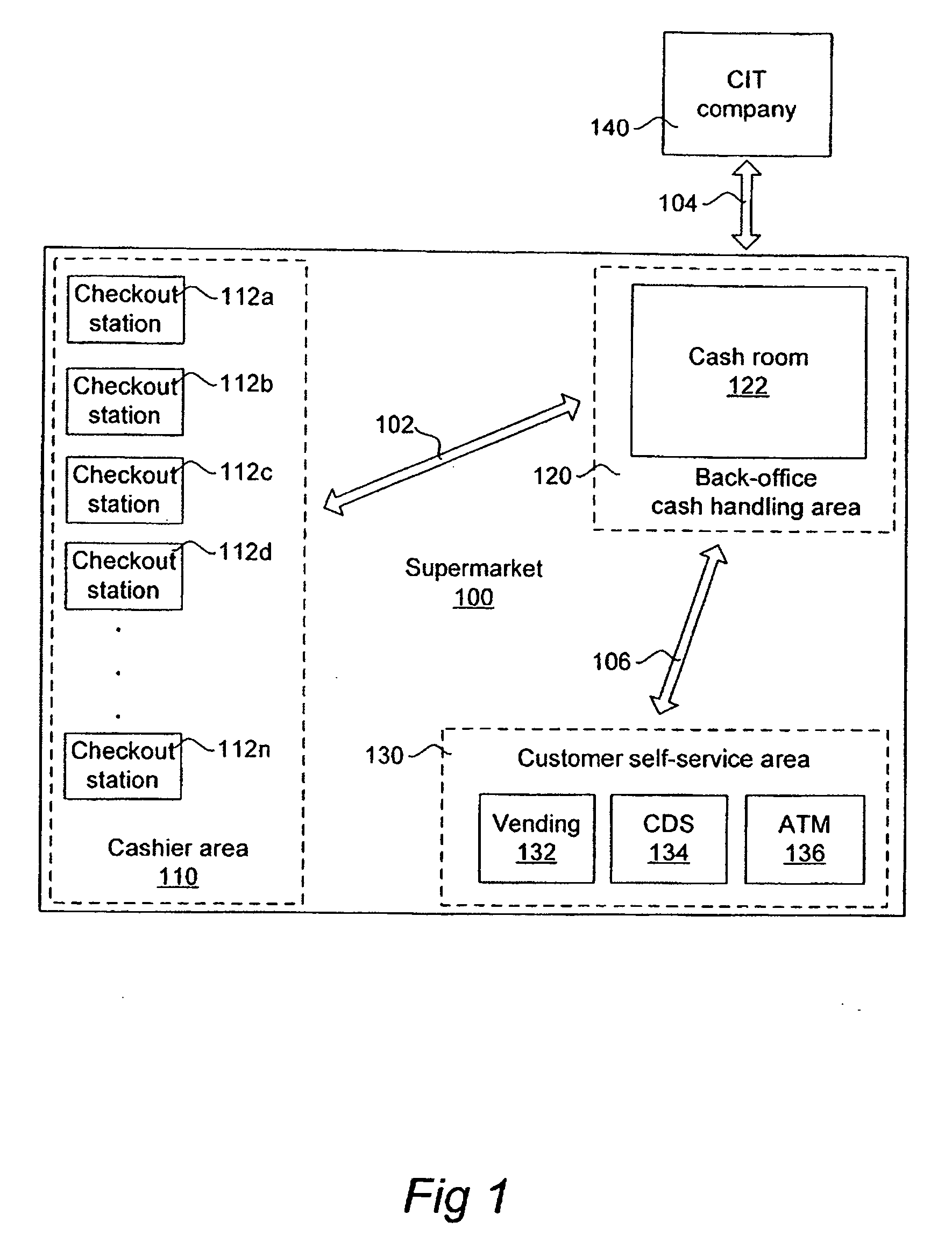

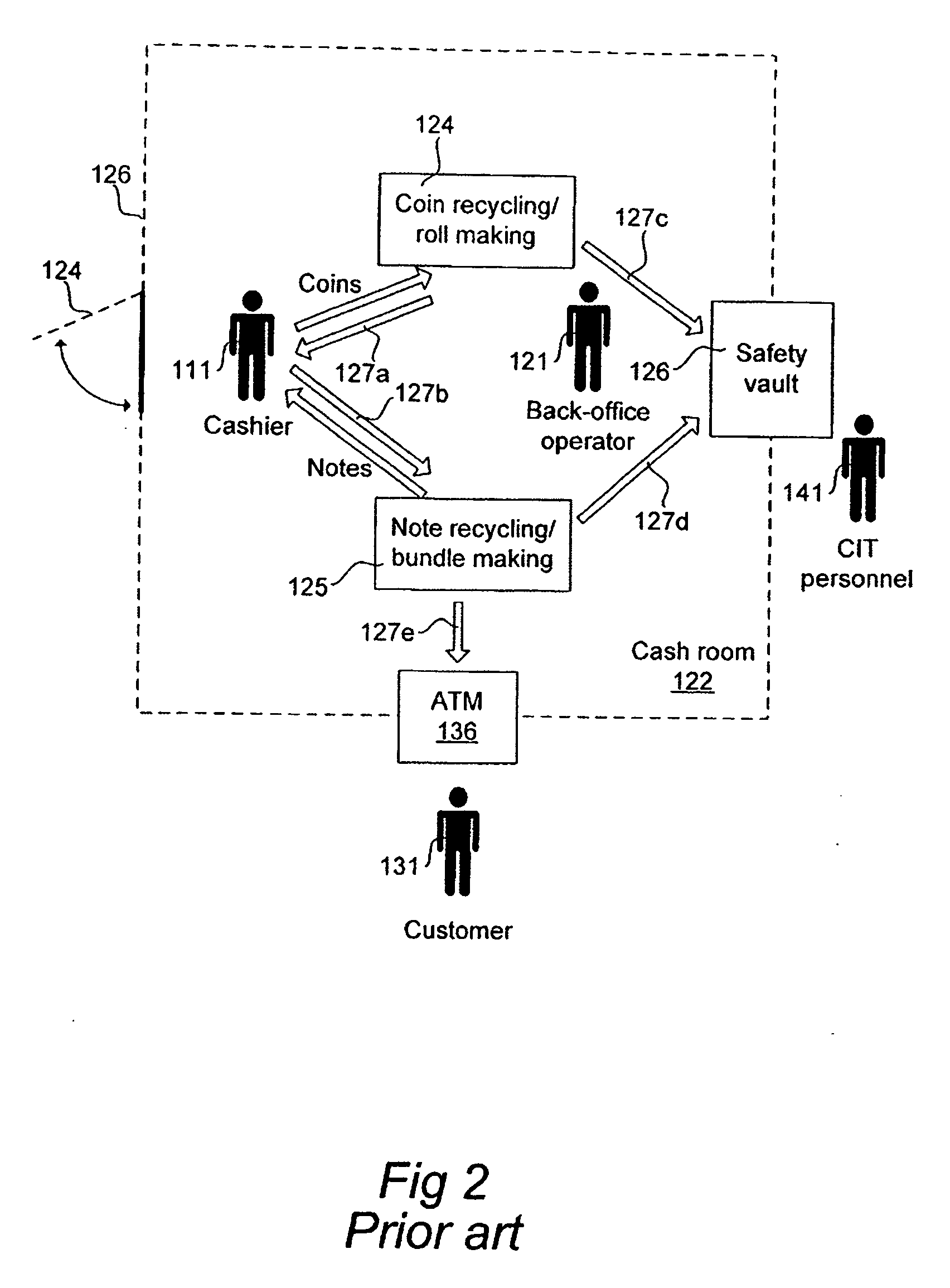

Cash recycling system having a cash receiving unit and a cash dispensing unit

InactiveUS20070151827A1High operational reliabilityImprove throughputComplete banking machinesCoin/currency accepting devicesEngineeringMechanical engineering

A cash recycling system is presented which has a cash receiving unit, the cash receiving unit has a cash input module, a cash processor, a cash output module, and a cash dispensing unit. The cash dispensing unit has a cash input module, a cash processor, and a cash output module. The cash input module of the cash receiving unit and the cash output module of the cash dispensing unit are accessible to a first type of user. The cash dispensing unit and the cash receiving unit are physically separate from and operative independently of each other. The cash output module of the cash receiving unit is adapted to supply cash, as processed by the cash processor, in a form which is sorted in denomination and therefore directly suitable for loading into the cash input module of the cash dispensing unit.

Owner:SCAN COIN IND AB

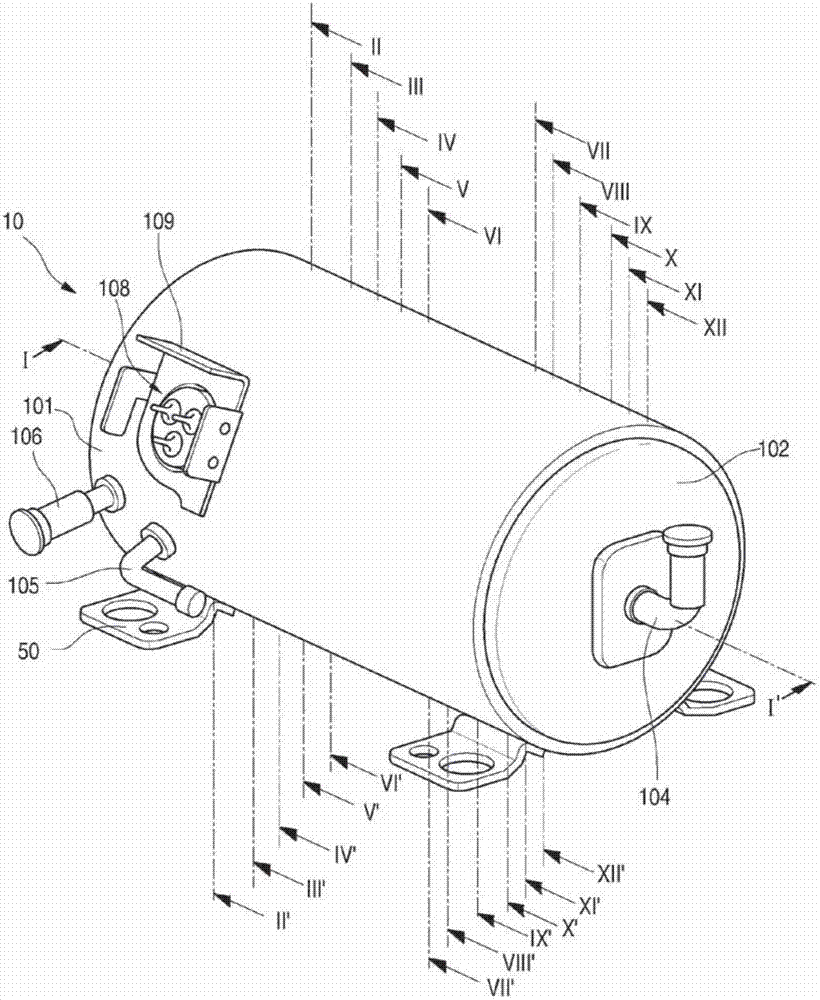

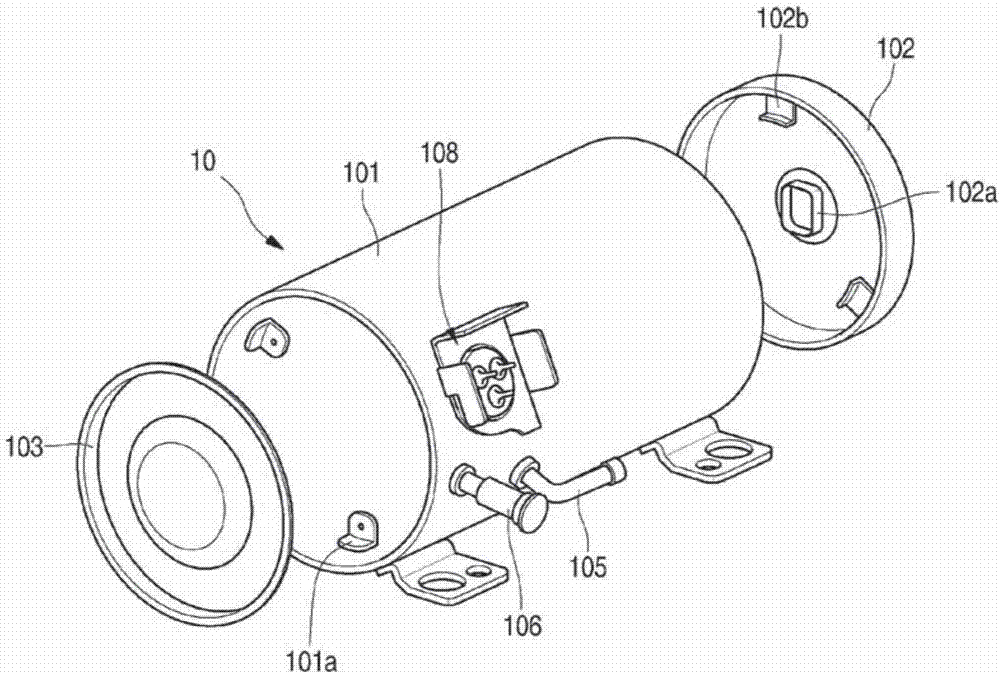

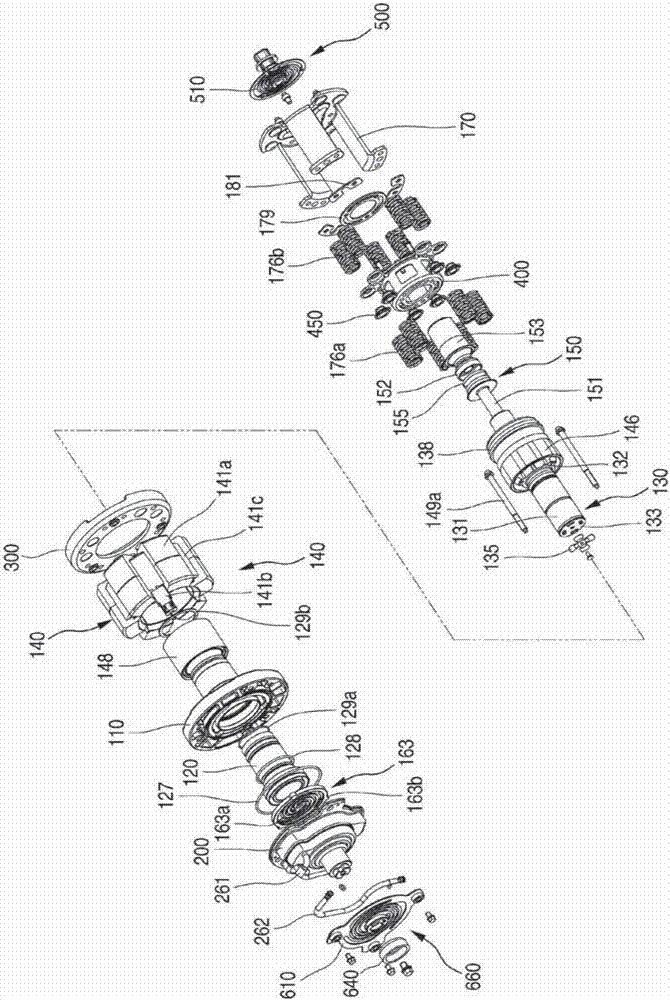

Linear compressor

ActiveCN107304759AImprove assembly work efficiency and mass production efficiencyMaintain rigidityPositive displacement pump componentsPiston pumpsRefrigerantLinear compressor

Owner:LG ELECTRONICS INC

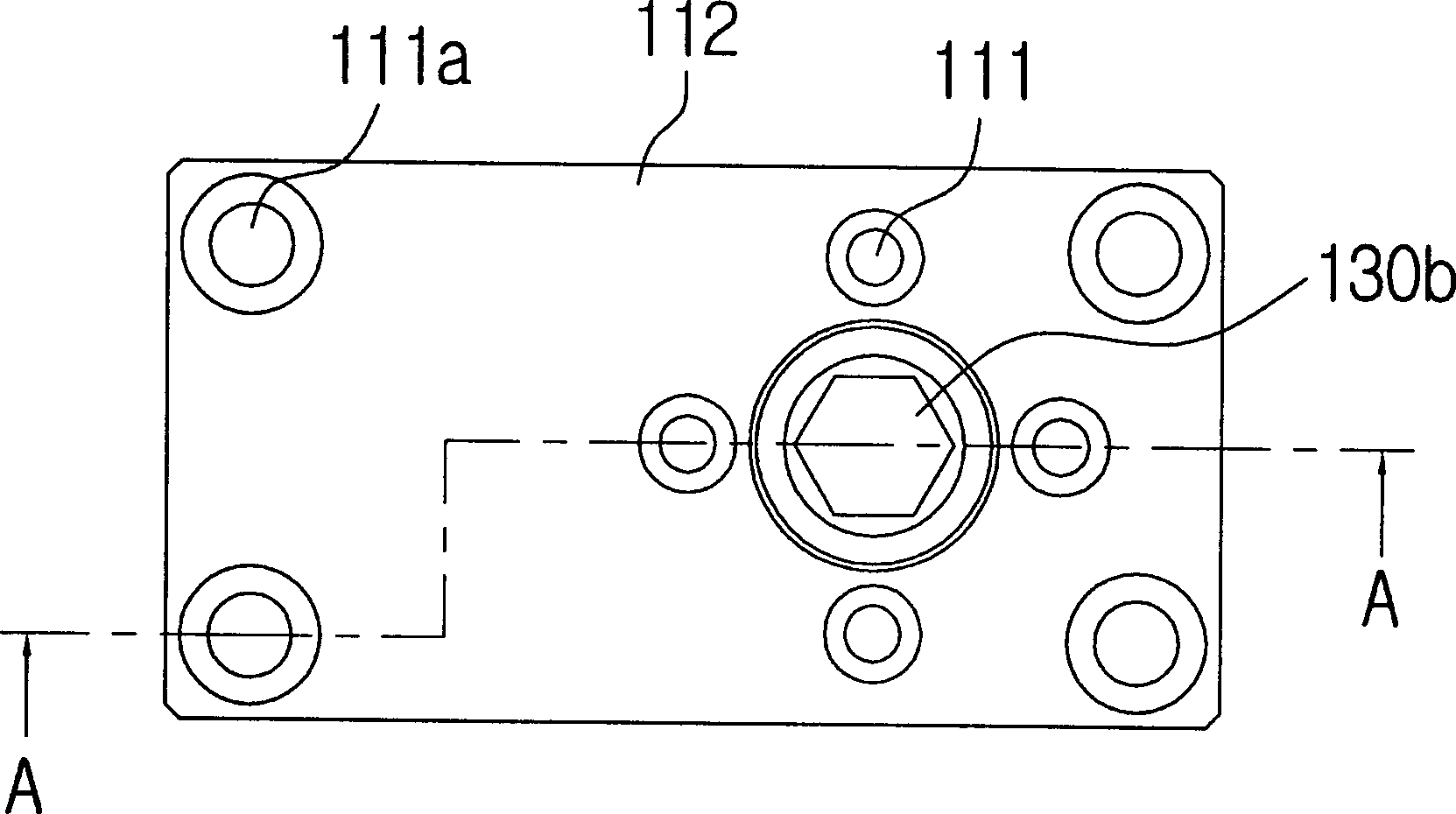

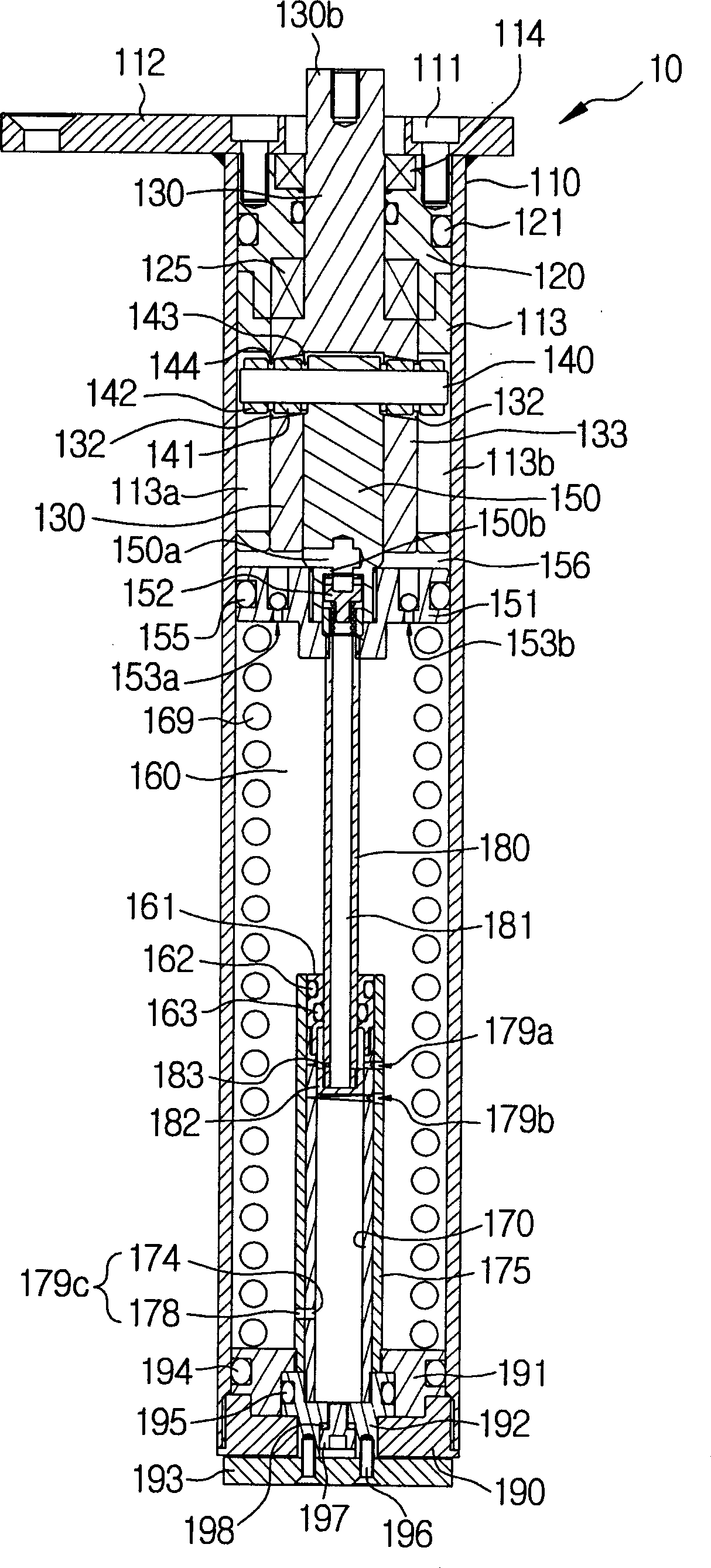

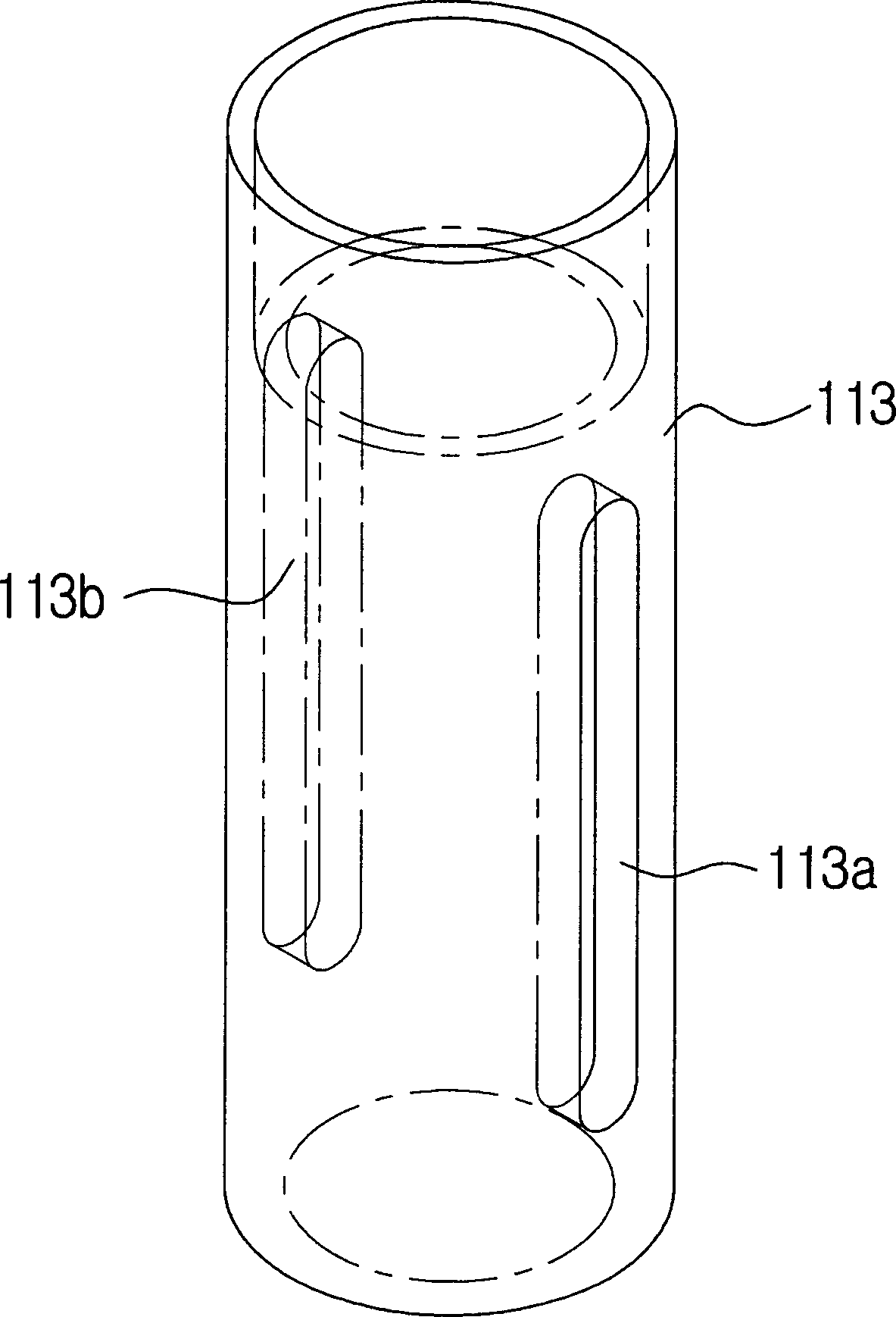

Lens actuating module

Disclosed herein is a lens actuating module. The module includes a housing having an accommodating space and a bush guide. A lens barrel is accommodated in the accommodating space and includes a lens and a barrel hook. A driving unit applies a driving force to a bush such that it is moved up in the direction of the optical axis, by pulling force of contraction of a shape memory alloy wire. The bush is guided by the bush guide and engages with the barrel hook. A rotary member is interposed between the housing and the lens barrel. A preload unit pulls the lens barrel in the direction of the optical axis such that the lens barrel moves down to an original position, and pulls the lens barrel in a direction perpendicular to the optical axis to maintain a contact of the lens barrel with the rotary member.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

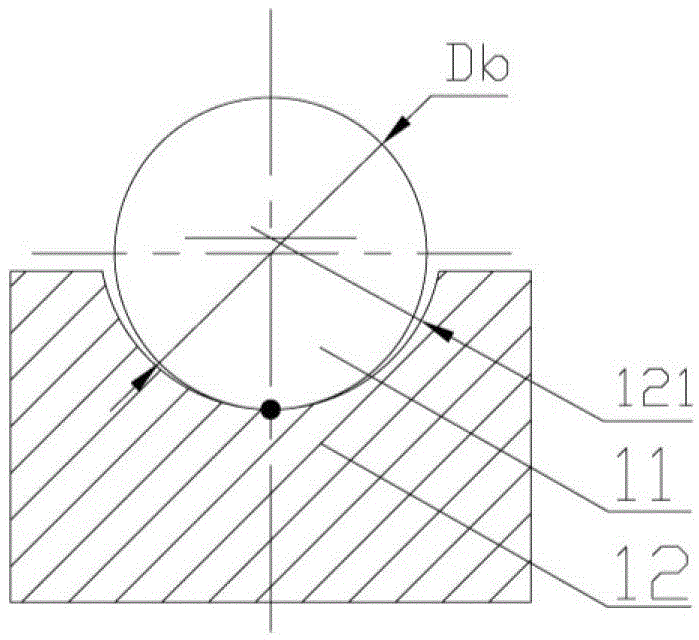

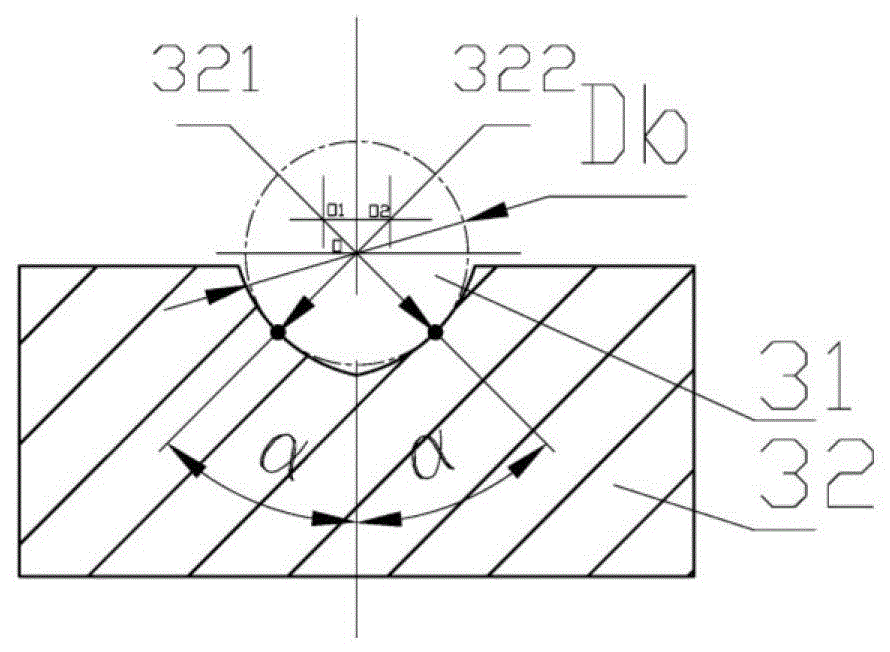

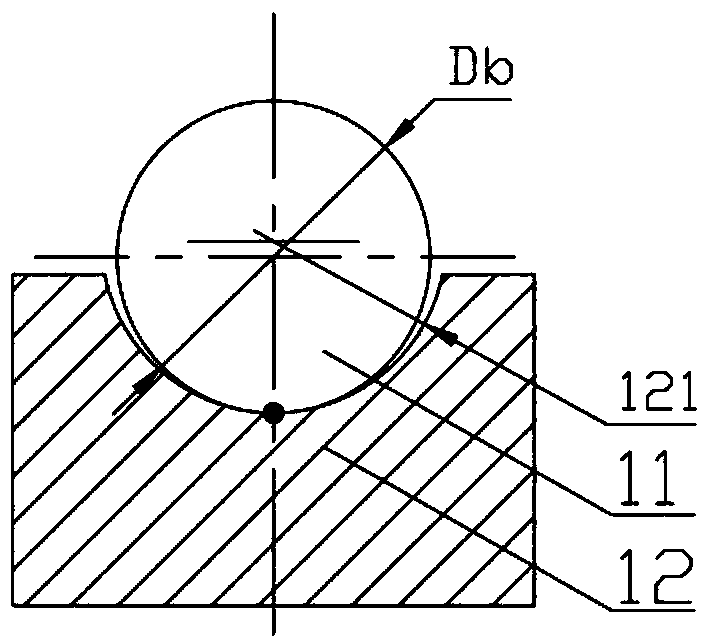

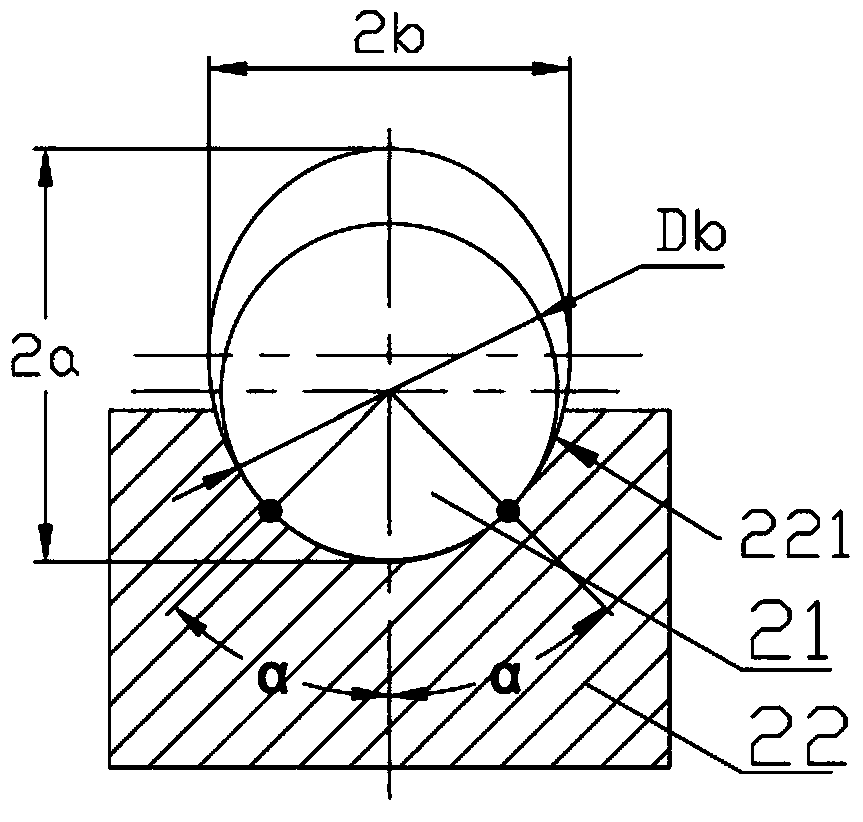

Machining method of rolling bearing formed by whole and precise hard turning and molding of sleeve ring

InactiveCN103331456AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesParticle adhesionEnvironmental resistance

The invention provides a machining method of a rolling bearing formed by whole and precise hard turning and molding of a sleeve ring. The machining method is characterized by comprising the following steps: after quenching and annealing heat treatment of the sleeve ring, carrying out the whole and precise hard turning and molding; and then combining and assembling a rolling body, wherein a sleeve ring rolling path comprises a fixed-curvature-groove-shape rolling path, a non-groove-shaped rolling path, a variable-curvature-shaped rolling path and a non-groove-shaped rolling path according to section shapes. The machining method disclosed by the invention overcomes the defects in the prior art that (1) performance defects on a machining surface, including grinding burn, a grinding metamorphic layer, grinding tensile stress, abrasive particle adhesion, scratches and the like, are caused by grinding and molding the sleeve ring; (2) shape defects on the machining surface that mutual position precision of all parts is not high, the shape of the rolling path cannot be accurately guaranteed and the like, are caused by carrying out a plurality of times of machining on different surfaces, even the same surface; (3) the defects that large investment of equipment, a tool clamp and personnel, and high machining cost are caused; and (4) the defects that a cutting solution needs to be used and the machining method is not environment-friendly enough are caused. The invention provides an anti-fatigue and green machining method which has the very great engineering actual meanings.

Owner:SHANGHAI F&S BEARING TECH

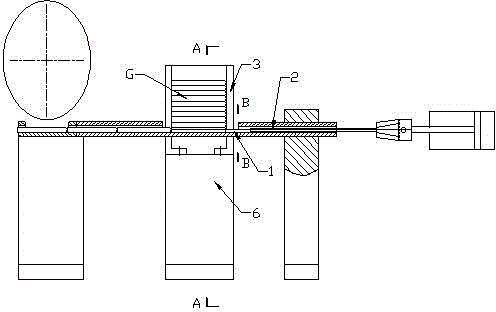

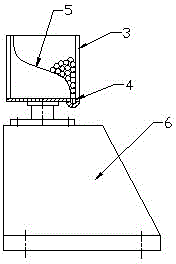

Feed device of minor-diameter rodlike workpiece processing equipment

ActiveCN102873614AStable outputSmall diameterGrinding machine componentsGrinding machinesEngineeringUltimate tensile strength

The invention relates to a feed device of minor-diameter rodlike workpiece processing equipment. The feed device comprises a horizontal feed channel, the front end of which is connected with a part of a cutting device; a pushing mandril which is driven by a power unit and can axially move in the feed channel is arranged at the rear section of the feed channel; a feed box is arranged above the feed channel; a discharge port which directly faces the feed channel is arranged at the bottom of the feed box and rodlike workpieces can pass through the discharge port one by one; a guide slope which enables the rodlike workpieces to roll to the discharge port under the actions of gravities is arranged inside the feed box; and the feed box is installed on a vibrating device and can vibrate up and down along with the vibrating device. The feed device has the advantages that: 1, with the feed device, the workpieces with small diameter and light weight can be discharged successfully, clamping stagnation is reduced, and the movement reliability is improved; 2, the strength of the pushing mandril and the structural strength of the entire guide structure are improved, and the fault of breakage of a small-size pushing mandril is reduced.

Owner:丹阳市盛力机械有限公司

Machining method for rolling bearing with ring precisely shaped by hard finishing

ActiveCN103737024AHigh mutual position accuracyImprove shape and position accuracyRolling contact bearingsTurning machinesRolling-element bearingBurn injury

Disclosed is a machining method for a rolling bearing with a ring precisely shaped by hard finishing. The machining method is characterized in that an inner ring and an outer ring of the bearing are integrally precisely shaped by hard finishing or the key surface of a ring part is precisely shaped by hard finishing; the key surface comprises raceways, raceway flanges, raceway oil grooves, seal grooves, ring flanges, grooved raceway edge chamfers and the like; precise shaping by hard finishing takes the place of grinding (such as the raceways) shaping and shaping by soft finishing (such as the sealing grooves), so that technical and quality problems of limited shape design of a raceway section, grinding badness even burn injuries and the like are solved; the technical and quality problems of low machining precision, heat treatment distortion and the like existing in shaping surfaces of the sealing grooves, the grooved raceway edge chamfers and the like by soft finishing are solved by precise hard finishing, so that the surfaces of the ring can be designed according to the operating condition and can be shaped precisely in a quite high mode, and the key surface of the ring can be controlled in shape and performance, and designing and manufacturing of the high-performance rolling bearing high in sealability and reliability and the like are of great practical engineering significance.

Owner:SHANGHAI F&S BEARING TECH

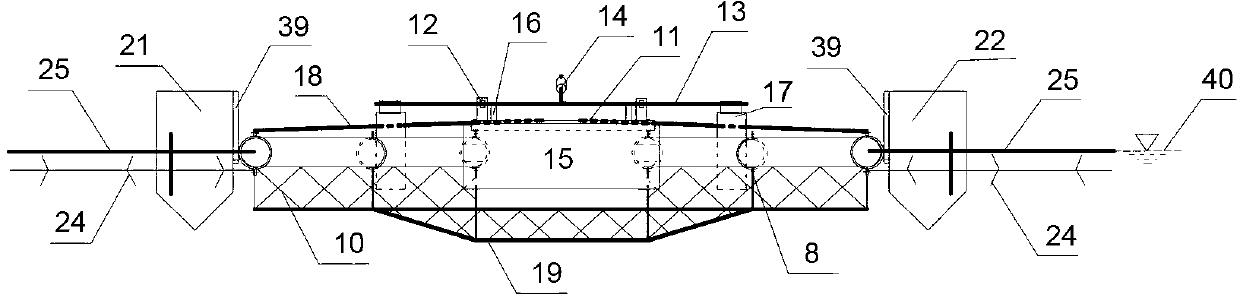

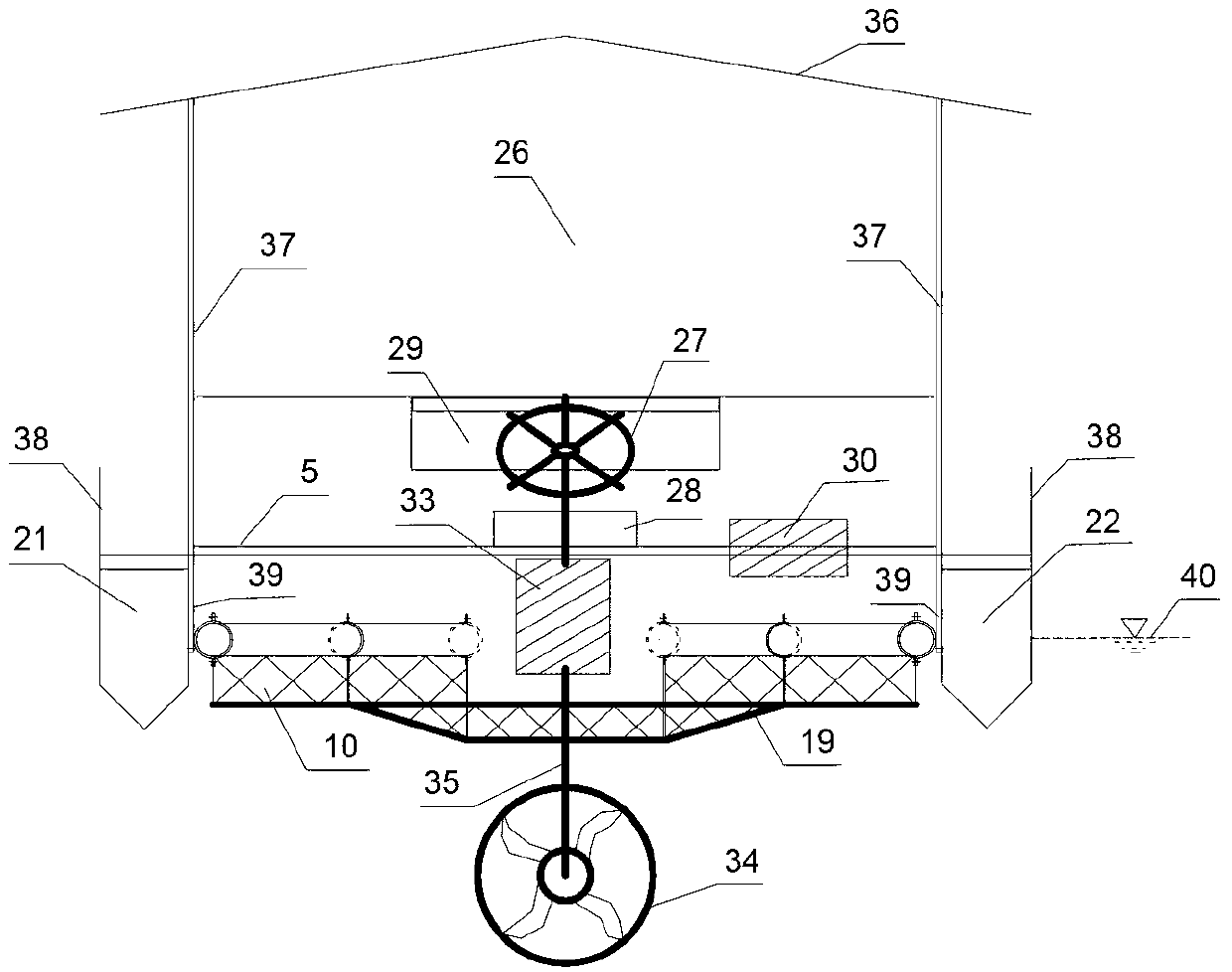

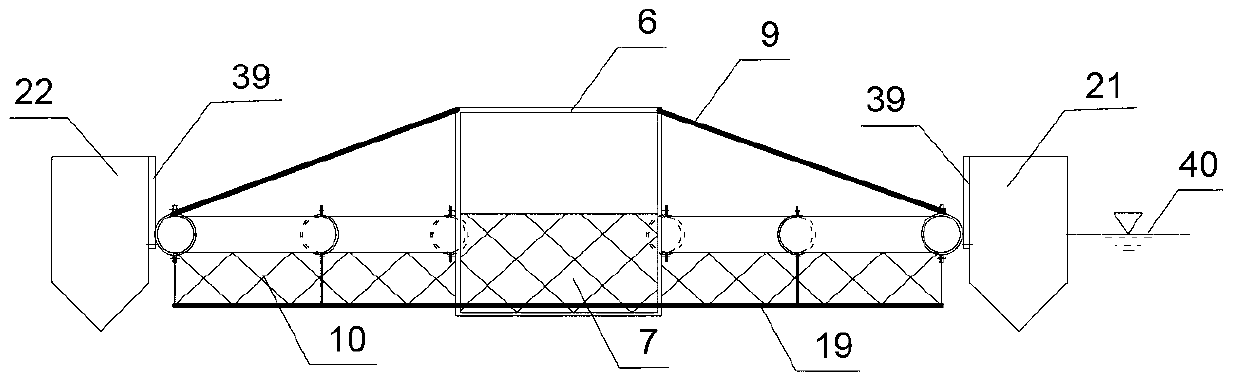

Automatic water floating object collecting device

ActiveCN103318382ARealize automatic collectionSimple structureWater cleaningWaterborne vesselsMarine engineeringPower equipment

The invention belongs to the technical field of water floating object collecting devices, and relates to an automatic water floating object collecting device. The main body structure of the automatic water floating object collecting device comprises a boat body, a bilateral wheel adjustable horn-shaped inlet section, a floating object inlet automatic door system, a ship power equipment operation system and a floating object outlet gate system. The bilateral wheel adjustable horn-shaped inlet section is arranged at the head end of the boat body, the floating object inlet automatic door system is arranged between the boat body and the bilateral wheel adjustable horn-shaped inlet section, the ship power equipment operation system is arranged in the middle section of the boat body, and the floating object outlet gate system is arranged on the tail portion of the boat body. The automatic water floating object collecting device is simple in structure, reliable in principle, high in operation reliability, simple and convenient to manage and maintain and low in cost, and does not need a machine driven system for collecting rubbish.

Owner:光大理工环境技术研究院(青岛)有限公司

Multipurpose hinge apparatus having automatic return function

InactiveCN1573003AHysteresis auto reset speedPrevent automatic resetSpringsLighting and heating apparatusReturn functionClosed chamber

A multipurpose hinge apparatus having an automatic return function is provided in which the apparatus is installed between the door and a main body. The apparatus includes a driving mechanism for ascending and descending a piston rod according to opening and closing of the door which is installed in the upper portion of a cylindrical housing. A piston is connected with the piston rod, in which a one-direction check valve is installed in the piston. The piston partitions an upper chamber and a lower chamber and ascends and descends in association with the piston rod. A first oil path communicates with the upper and lower chambers via the lower portion of the piston rod in the central portion of the piston. A compression spring which makes the piston ascend is inserted into the lower chamber. Oil is filled in the chamber. Thus, the hinge apparatus is automatically returned to the initial position with return speed in multiple steps by controlling an amount of oil flowing from upper chamber to lower chamber in multiple steps when a door is closed.

Owner:I ONE INNOTECH

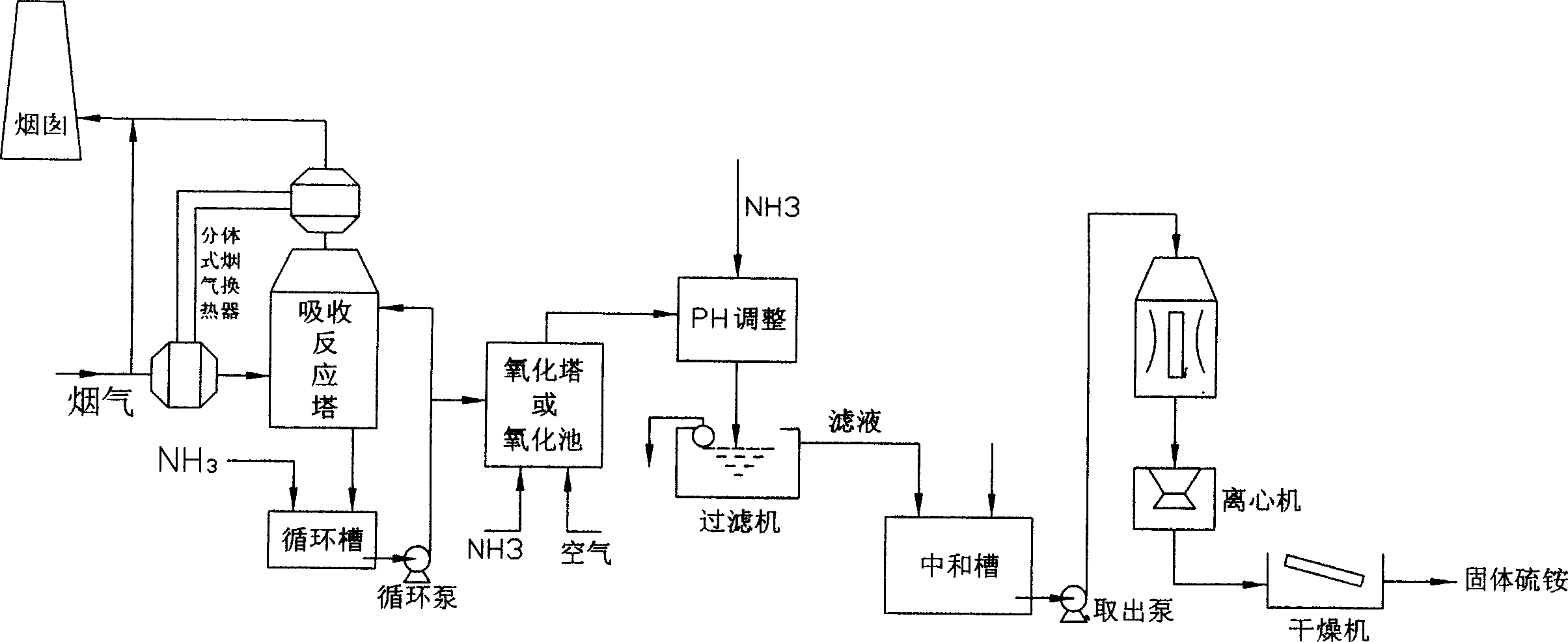

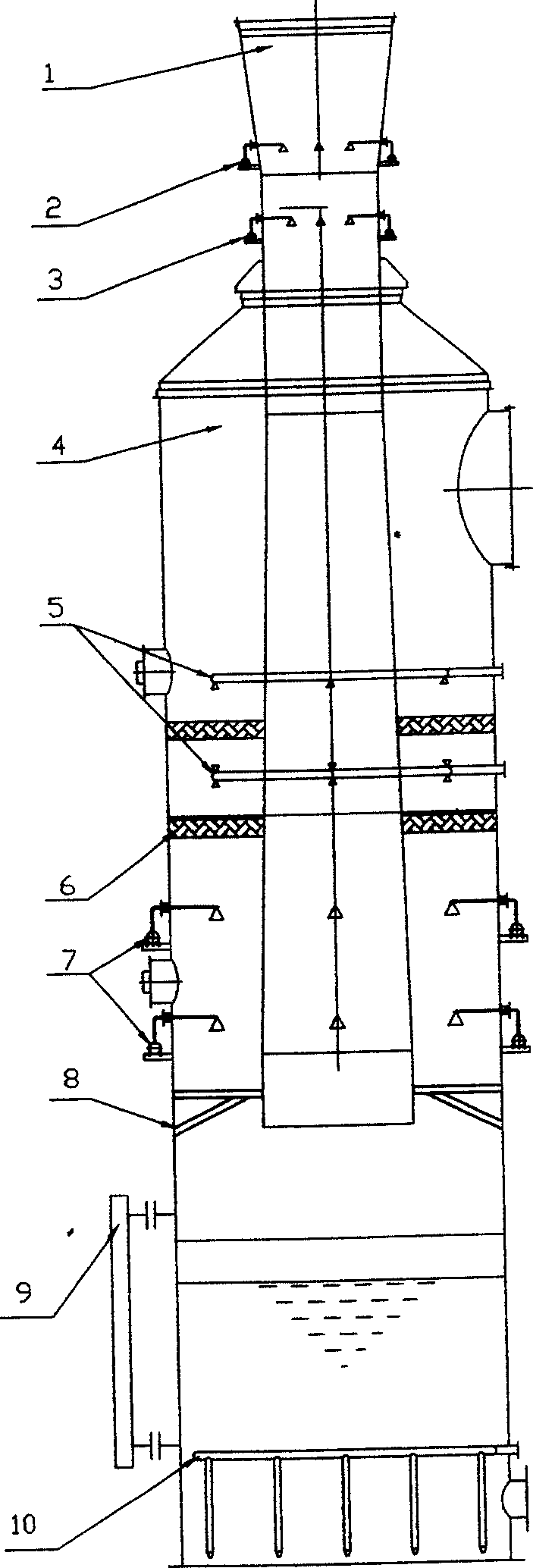

Smoke desulfurizing method by amino-thiamine method

InactiveCN1647849AIncrease profitImprove reaction efficiencyDispersed particle separationThiamineAmmonium bisulfite

Owner:JIANGSU HEYICHANG ENVIRONMENTAL PROTECTION ENG & TECH

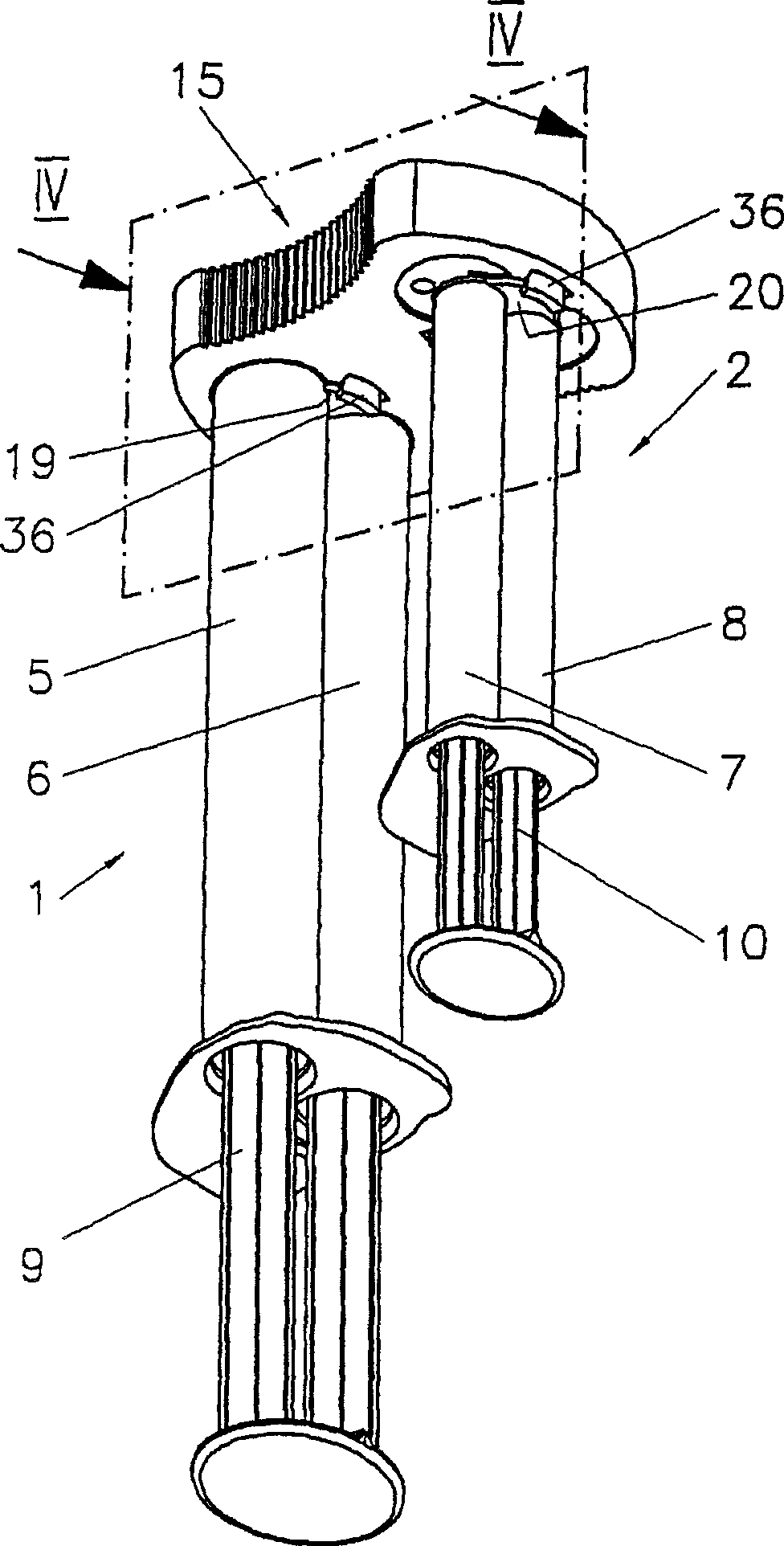

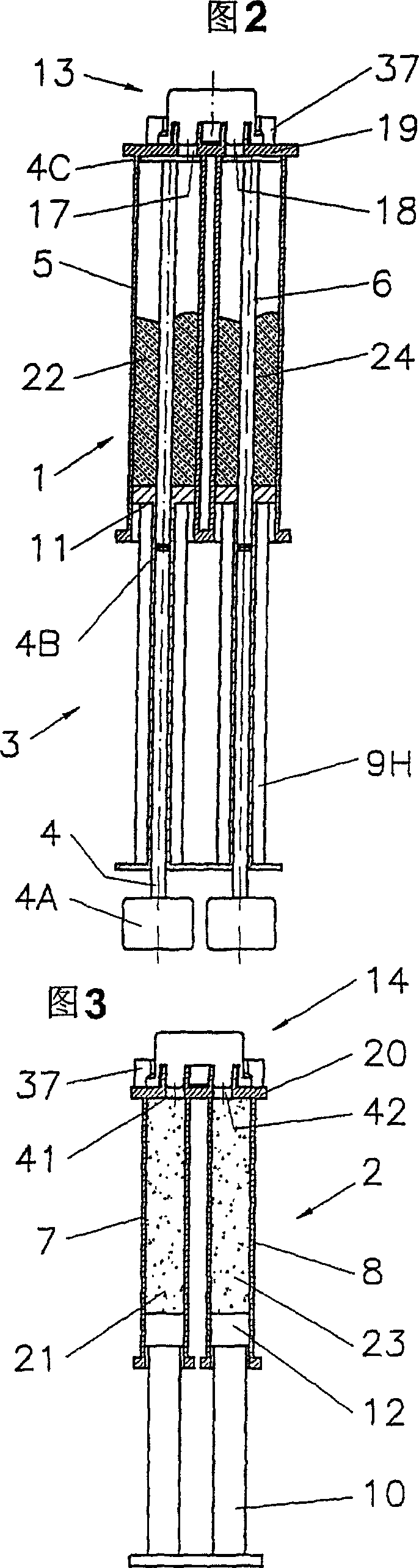

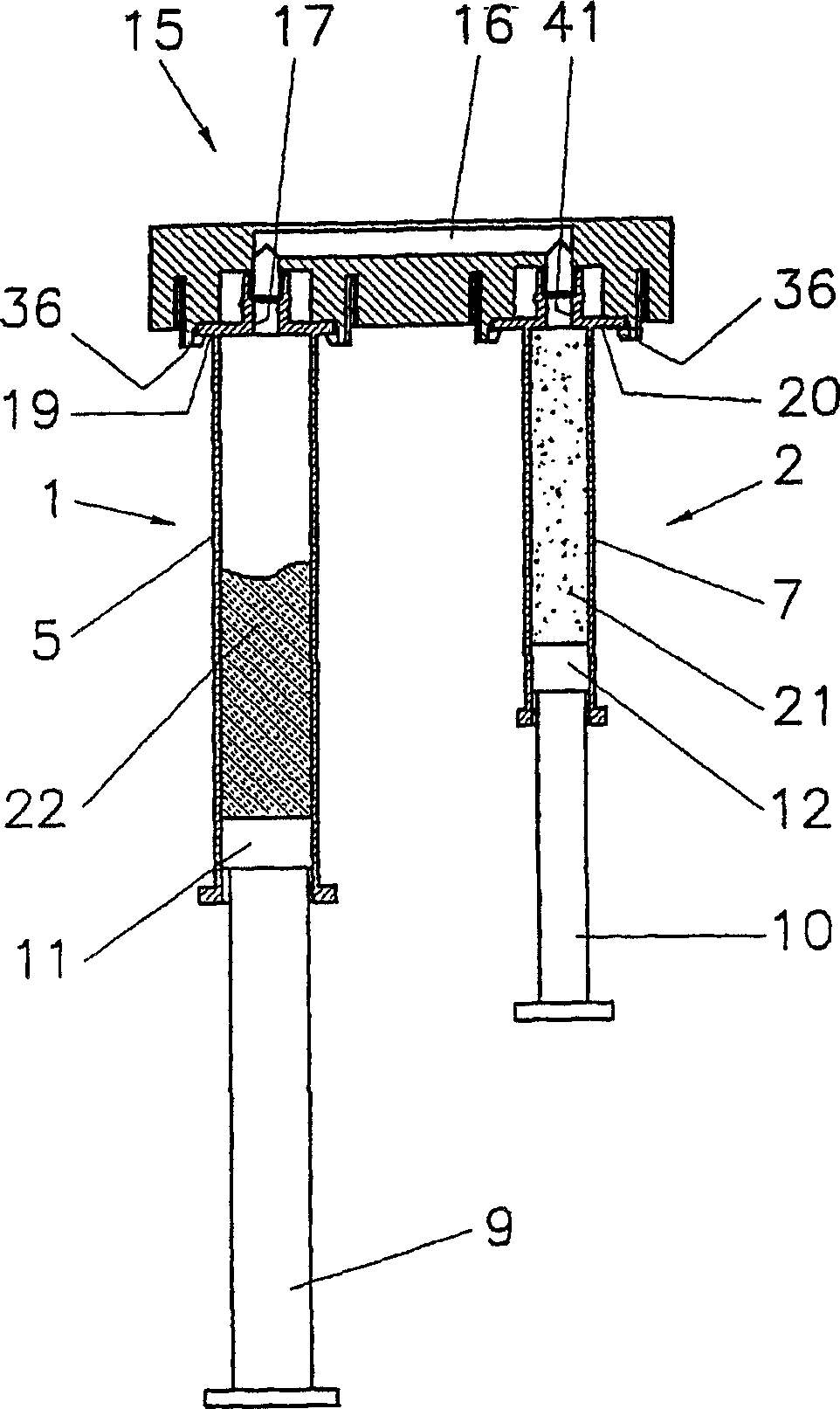

Device and method for transferring, mixing and delivering components

InactiveCN1838997AEasy to operateMix thoroughlyLiquid surface applicatorsShaking/oscillating/vibrating mixersNicrophorus distinctusBone cement

The invention relates to a transferring, mixing and delivering device preferably comprising at least two delivering devices (1, 2) one of which contains liquid components (21, 23) and a transferring unit (15) for connecting said delivering devices (1, 2). The transferring unit comprises connecting channels (16, 38) between outputs (17, 18; 41, 42) for components (21, 23; 22, 24) contained in the reservoirs (5, 6, 7, 8) of the delivering devices (1, 2). The aim of said invention is to increase the reliability of said transferring, mixing and delivering device. For this purpose, the transferring unit (15, 31, 39) is provided with locking elements (36) for receiving the flanges (19, 20) arranged on the delivering devices (1, 2). Such an injection system makes it possible without any problems to store, easily and softly blend and deliver the mixtures by means of double syringes. The inventive device provides exceptional advantages when a powder or granulate material, for example a bone cement or a bone substitute material is contained in the first syringe.

Owner:MEDMIX SYST

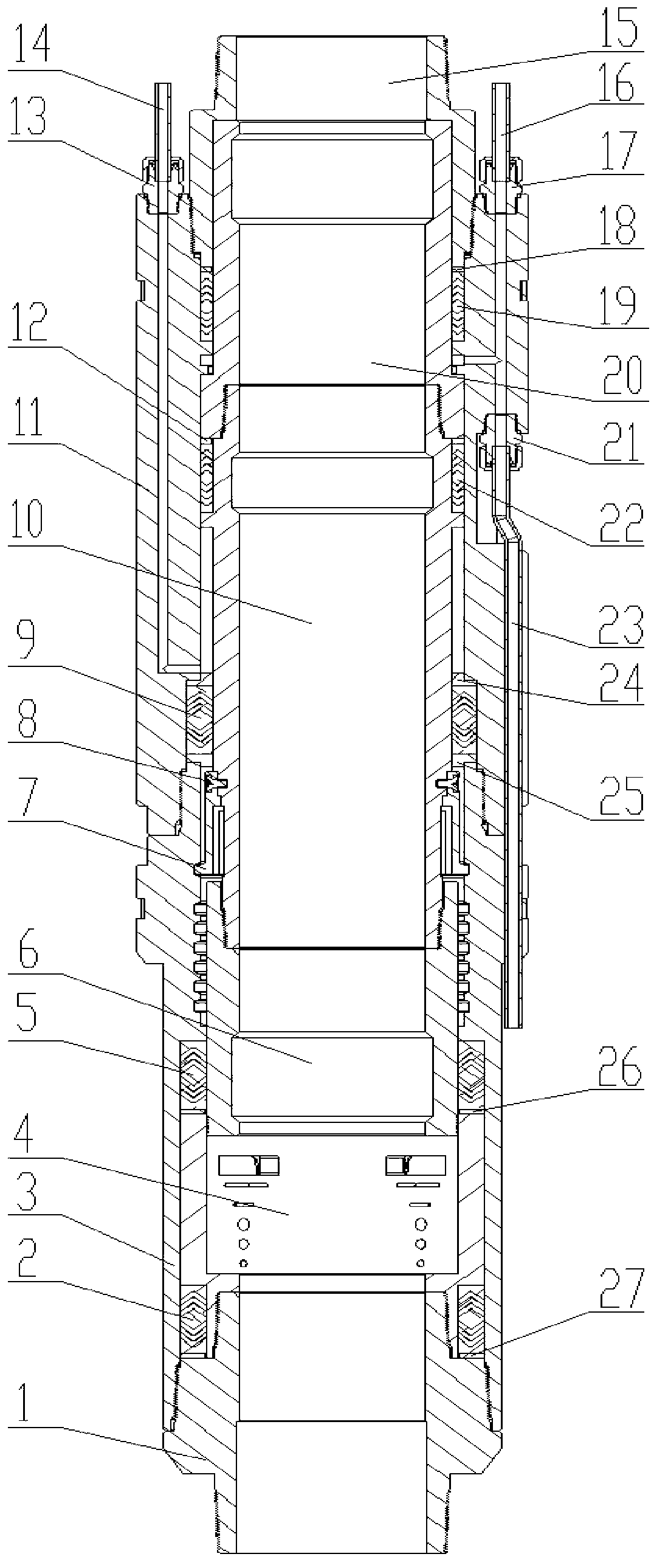

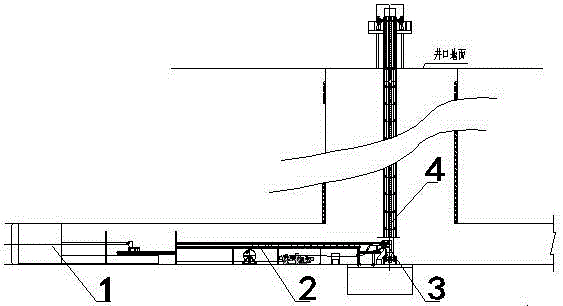

Smart well interval control valve

InactiveCN103244075AHigh operational reliabilityImprove reliabilityWell/borehole valve arrangementsSealing/packingEngineeringFormation fluid

Provided is a smart well interval control valve. A sliding sleeve is arranged in a fluid throttler, and the sliding sleeve and the fluid throttler are matched to open / close different throttling holes. The fluid throttler is connected onto a lower joint, and the lower joint is connected onto a lower cylinder body of the interval control valve. All sealing groups are compact in structure and form good dynamic / static sealing together with an upper piston, a lower piston, the sliding sleeve, an interval control valve lower cylinder body and an interval control valve upper cylinder body in conditions of underground high temperature and high pressure through Teflon materials. Two liquid inlet hole ducts are arranged at the position of the end surface of the interval control valve upper cylinder body, wherein one liquid inlet hole duct is used for controlling the valve to be opened, the other liquid inlet hole duct is public and is used for controlling the valve to be closed, and both the two liquid inlet hole ducts are in threaded sealing connection with the interval control valve upper cylinder body through 1 / 4 inch National (American) Pipe Thread (NPT) joints. The fluid throttler is provided with a plurality of throttling holes with different opening degrees, a hydraulic piston is adopted to push the sliding sleeve to move, the liquid inlet amount of formation fluid is adjusted through multistage throttling, and the smart well interval control valve has the advantages of being long in service life, good in sealing performance and the like.

Owner:XI'AN PETROLEUM UNIVERSITY

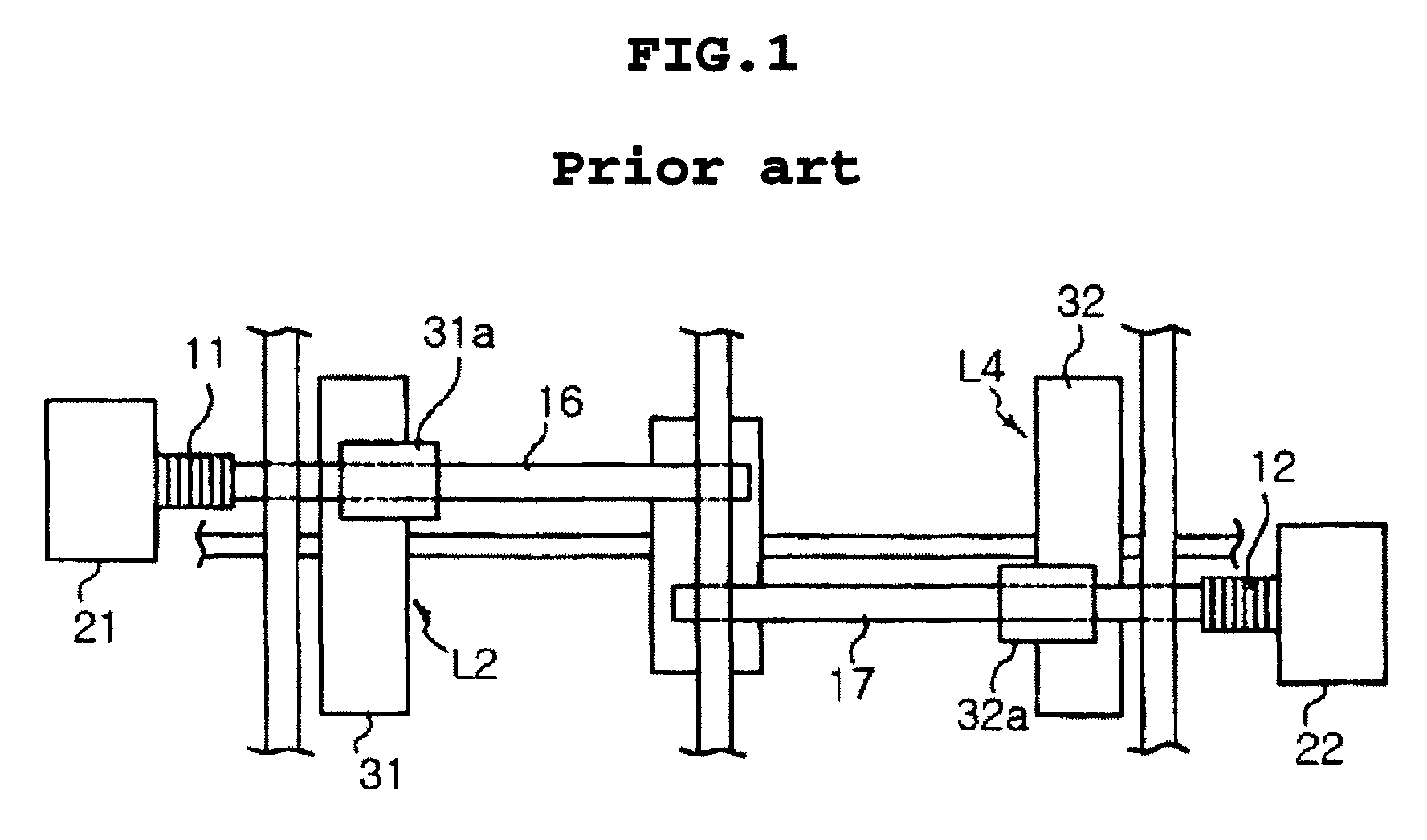

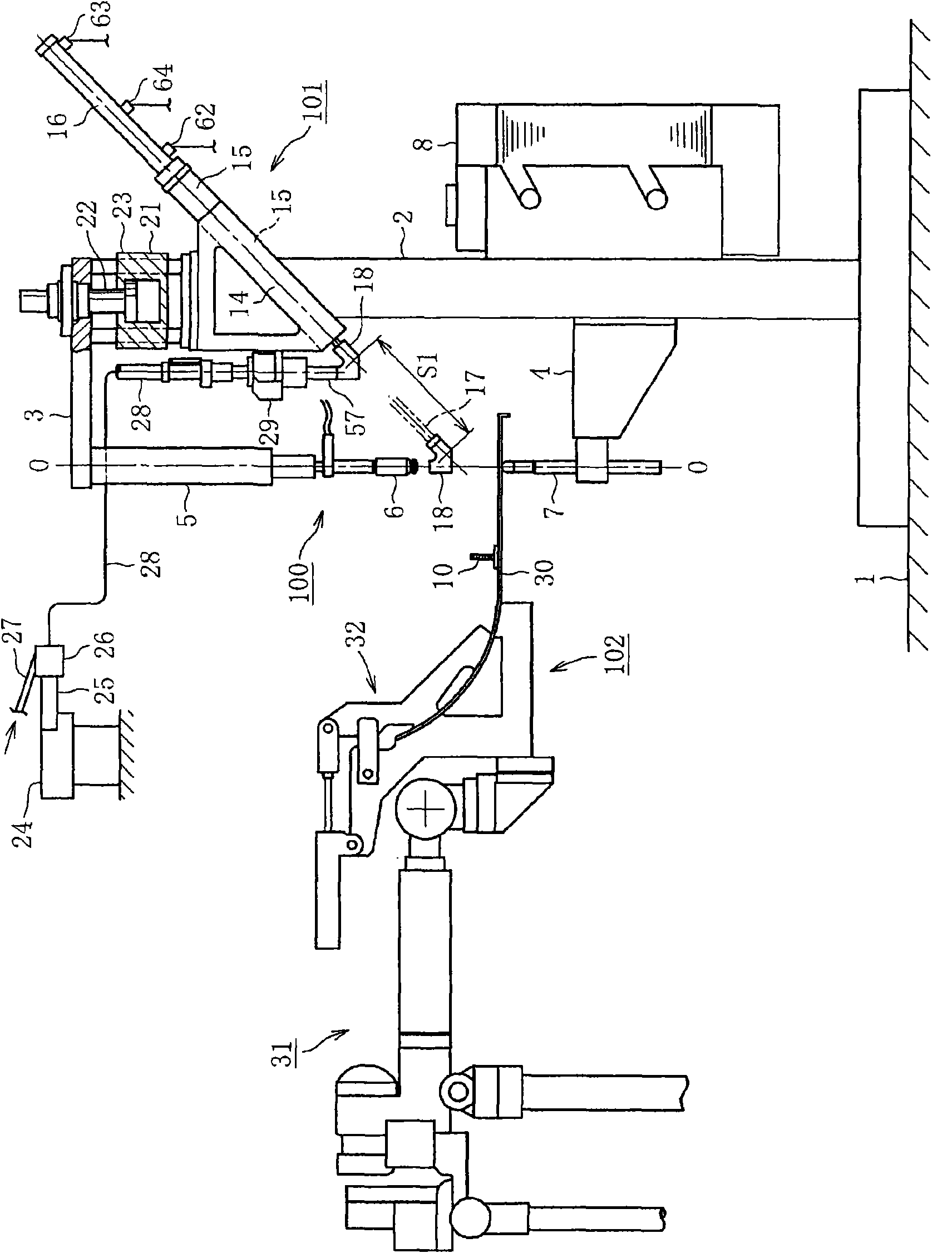

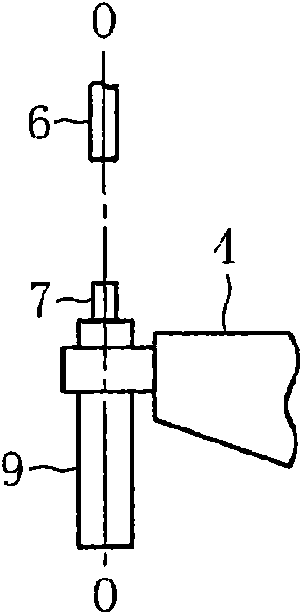

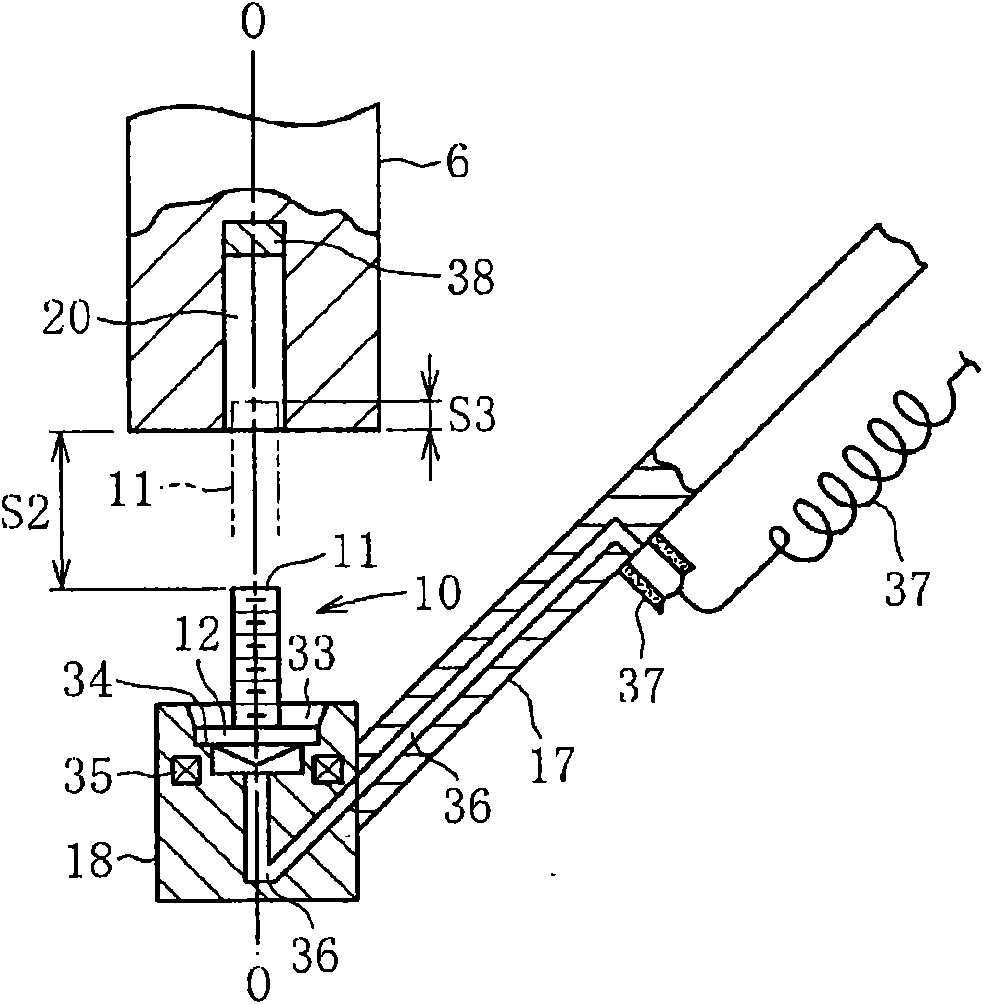

Projection bolt welding method, and welding apparatus

ActiveCN101622092AReduce sizeEasy to insertWelding/cutting auxillary devicesArc welding apparatusElectrical resistance and conductanceSheet steel

Provided are a welding method and a welding apparatus, which can start the proper advance of an electrode on the basis of both the positioning of the welded portion of a projection bolt with respect to a steel sheet and the completing state of the feed of the projection bolt with respect to the electrode. In the welding method, a bolt (10) held by a feed rod (17) is inserted into a receiving hole (20) of an electrode (6). Air is injected from a holding head (18) thereby to complete the bolt insertion into the receiving hole (20). Then, the feed rod (17) is retracted. After this, the electrode (6) is advanced to weld the bolt to a steel sheet (30) by the electric resistance method. In response to the signal issued by the insertion of the bolt and the signal issued by the positioning of the welded portion of the steel sheet (30), the electrode (6) is advanced relative to the steel sheet (30), and the pressurization and the power feed are then performed.

Owner:青山好高

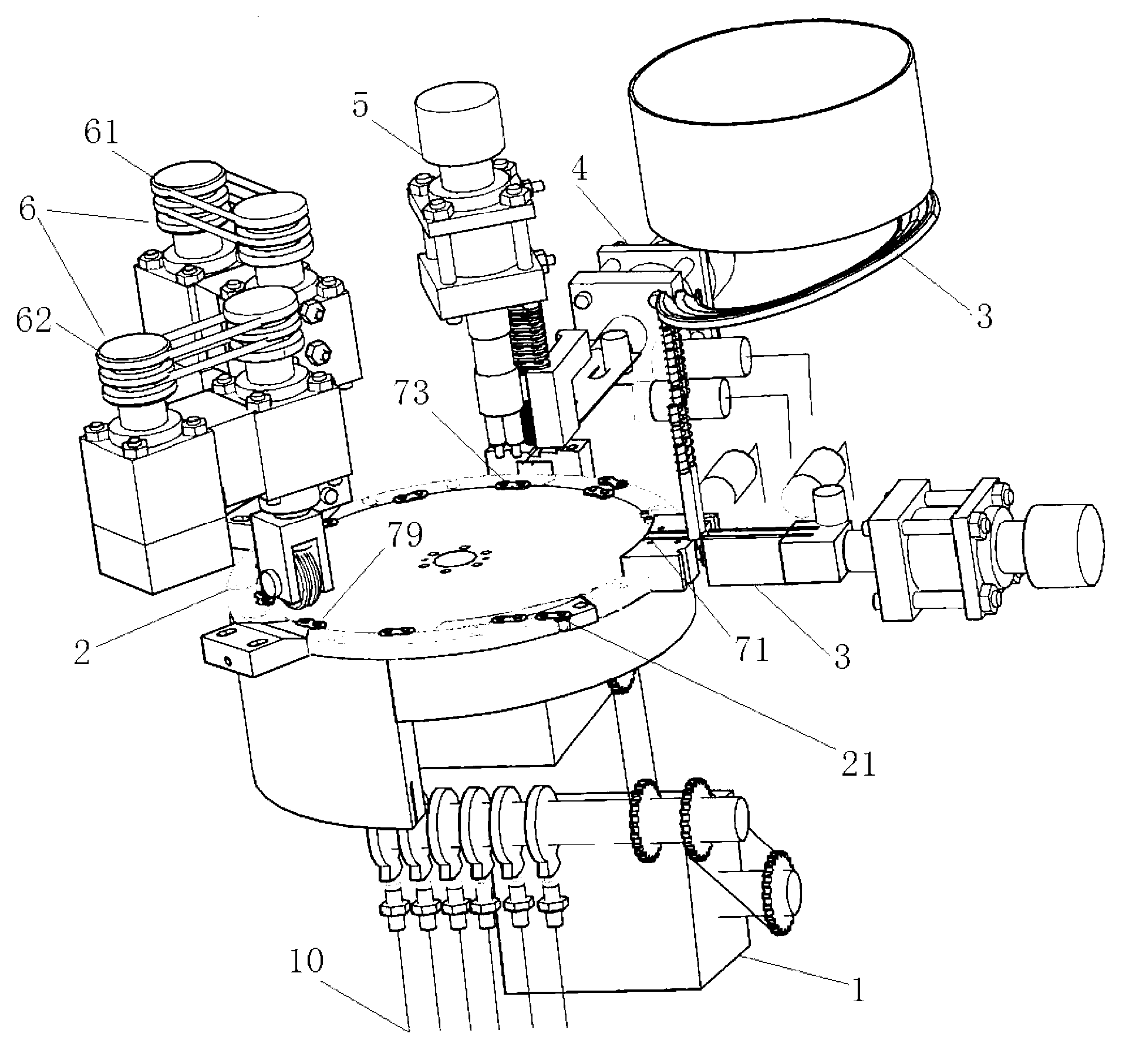

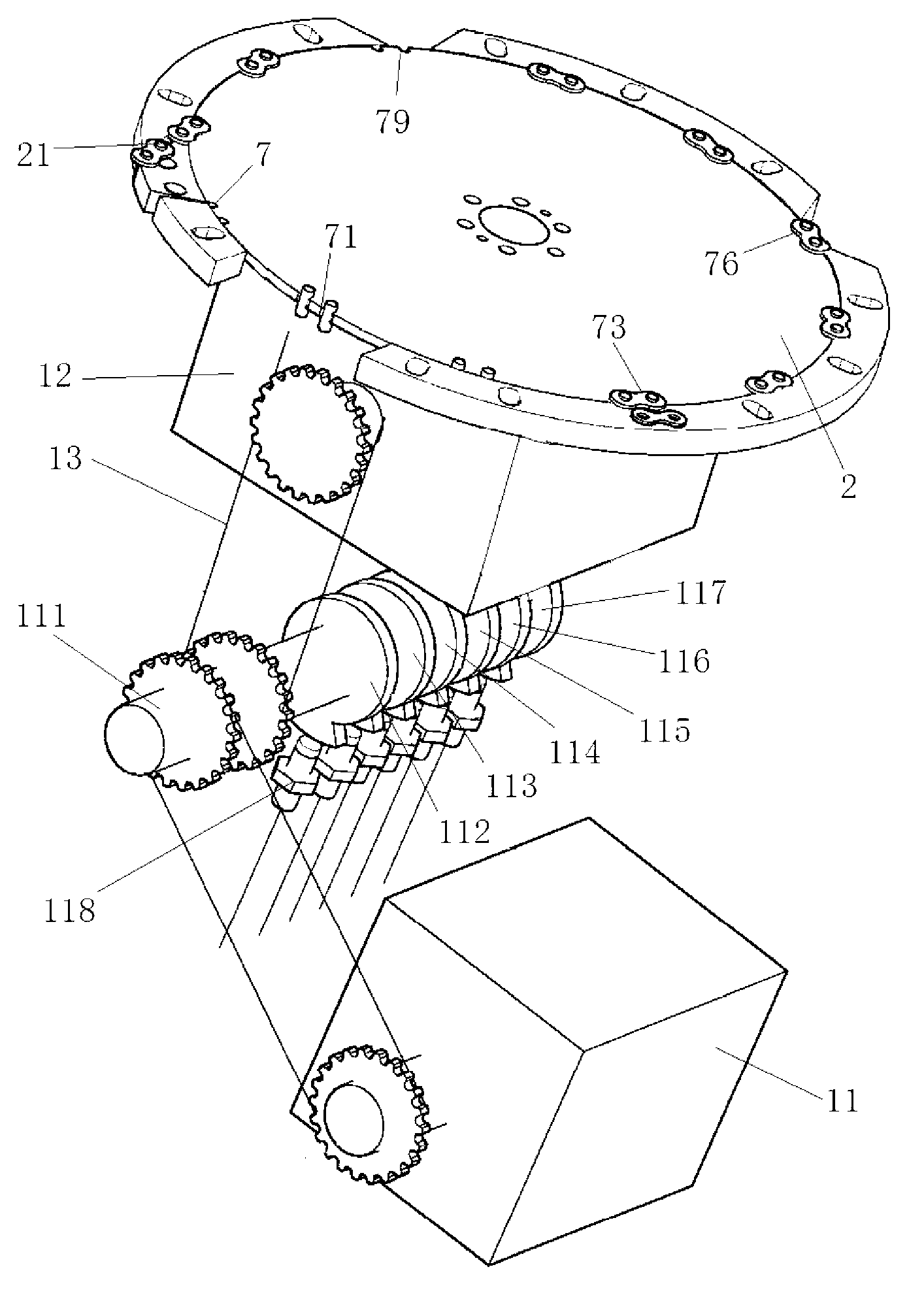

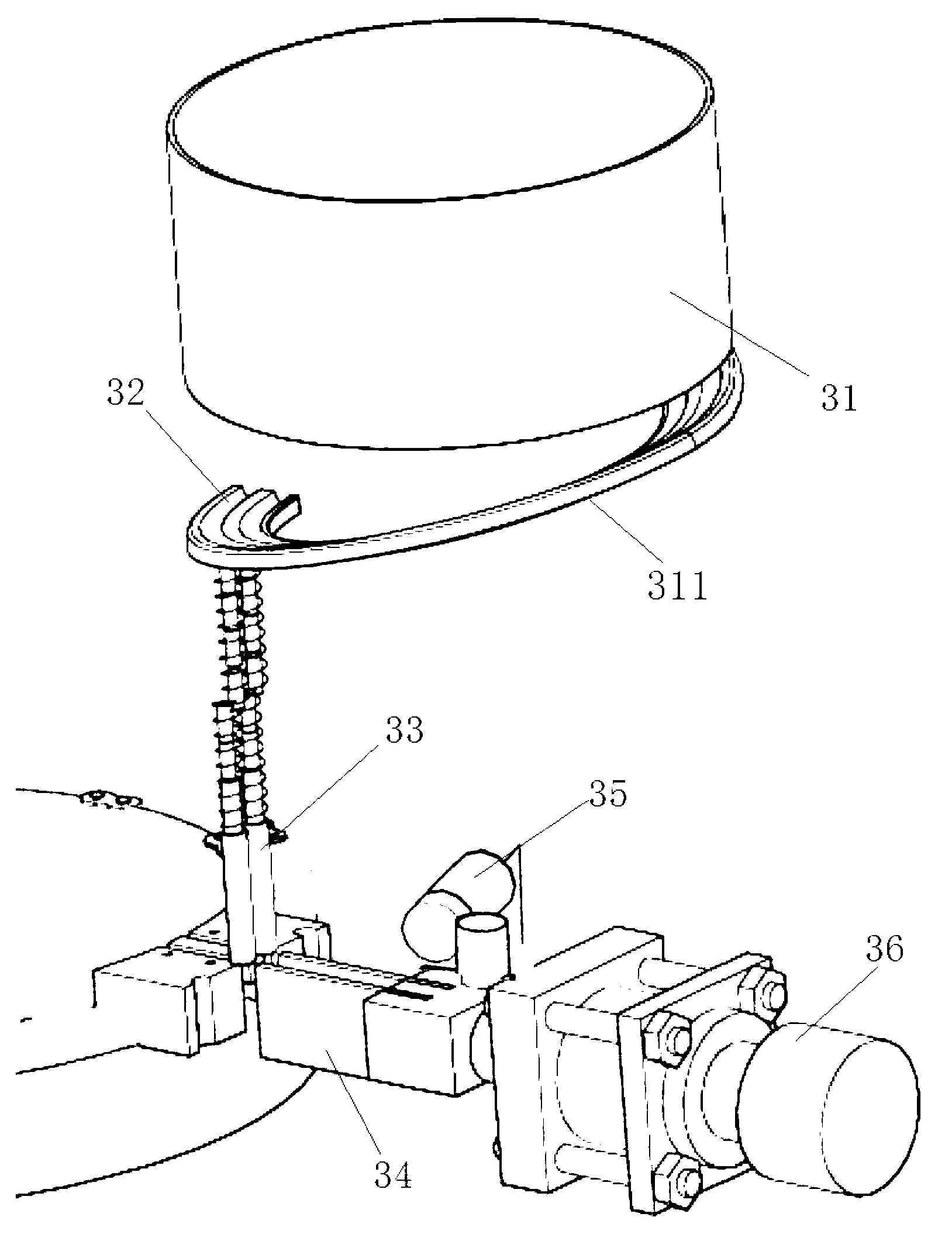

Chain connector assembly machine

ActiveCN102847867AAvoid subsequent lossesHigh operational reliabilityMetal chainsSynchronismAssembly machine

A chain connector assembly machine comprises a driving device, a working rotating disc, a pin roll delivery device, an outer piece delivery device, a piece assembly device, a round riveting device and a control device. The round riveting device comprises a first round riveting device and a second round riveting device. The driving device is connected with the working rotating disc, 12 pairs of grooves are evenly arranged outside the working rotating disc, the pin roll delivery device is connected with a first pair of grooves, the outer piece delivery device and the piece assembly device are connected with a third pair of grooves, the first round riveting device is connected with a sixth pair of grooves, the second round riveting device is connected with a ninth pair of grooves, and a finished product outlet is arranged at the position of the eleventh pair of grooves. The control device controls the driving device, the pin roll delivery device, the outer piece delivery device, the piece assembly device, the first round riveting device and the second round riveting device. The chain connector assembly machine improves reliability and action synchronism in the production process and avoids loss caused in the production process.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

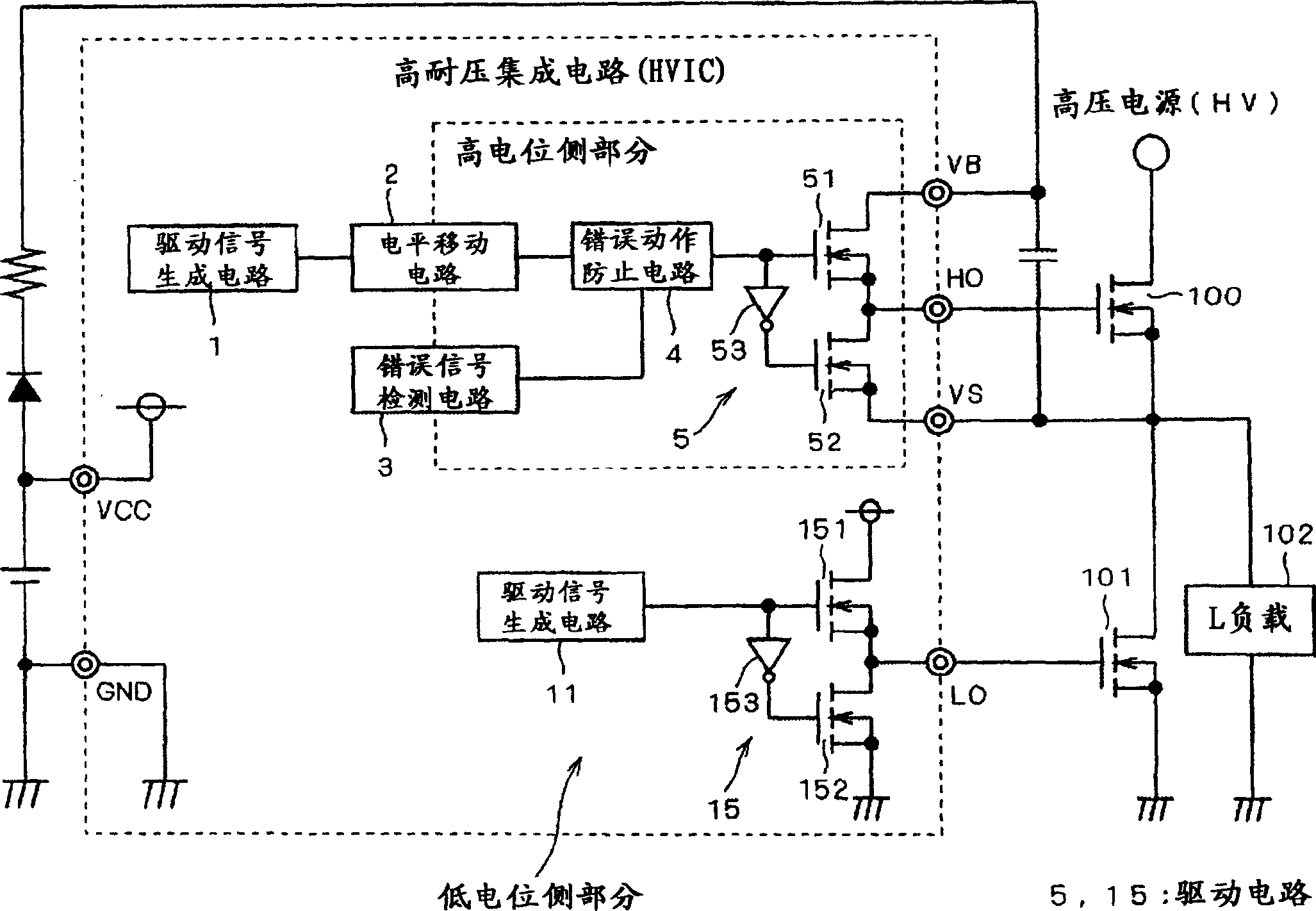

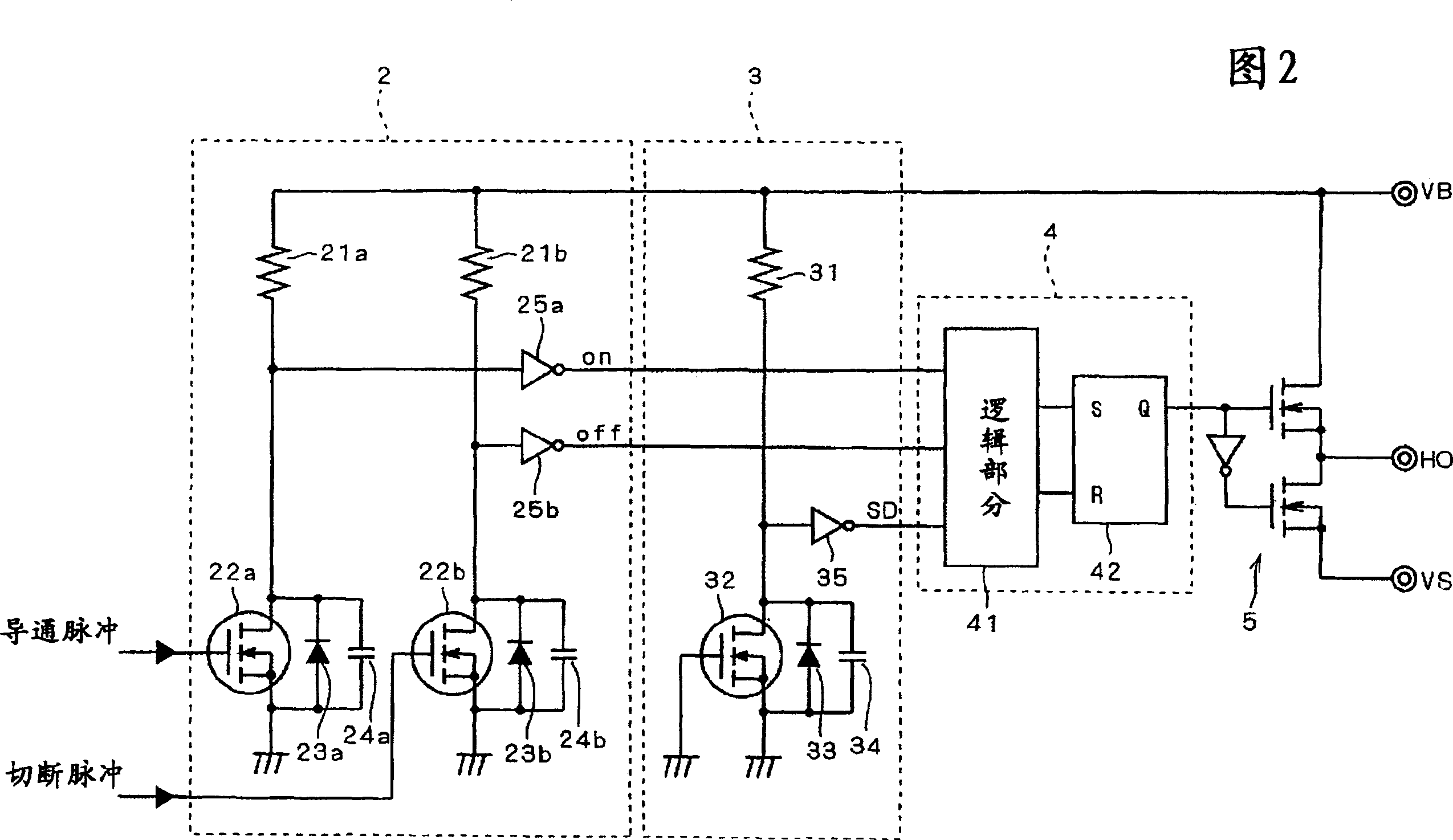

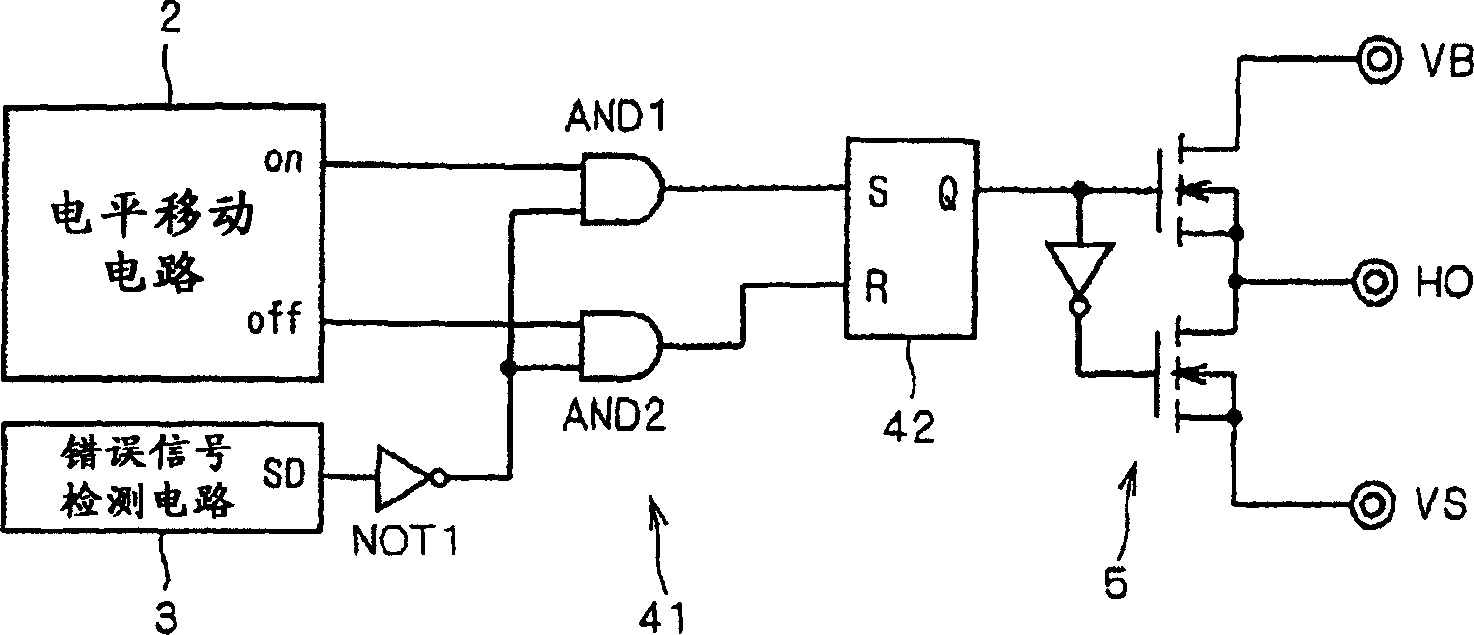

Semiconductor device

InactiveCN1630172AAvoid actionHigh operational reliabilityTransistorError detection/correctionSemiconductorSemiconductor device

The semiconductor device of the present invention can prevent erroneous operation due to an erroneous signal generated in a level shift circuit. The error signal detection circuit (3) is connected in parallel with the level shift circuit (2), and the HVMOS (32) of the error signal detection circuit (3) is a dummy switching element fixed to an off state in a normal use state, It has the same structure as the two level shift circuits for on and off included in the level shift circuit (2). The voltage drop of the error signal detection resistor (31) is used as an error signal generation signal (SD) indicating the occurrence of an error signal in the level shift circuit (2), and is input to the error operation prevention circuit (4) through the NOT gate (35). )middle. A malfunction prevention circuit (4) performs predetermined malfunction prevention processing based on the malfunction signal generation signal (SD).

Owner:MITSUBISHI ELECTRIC CORP

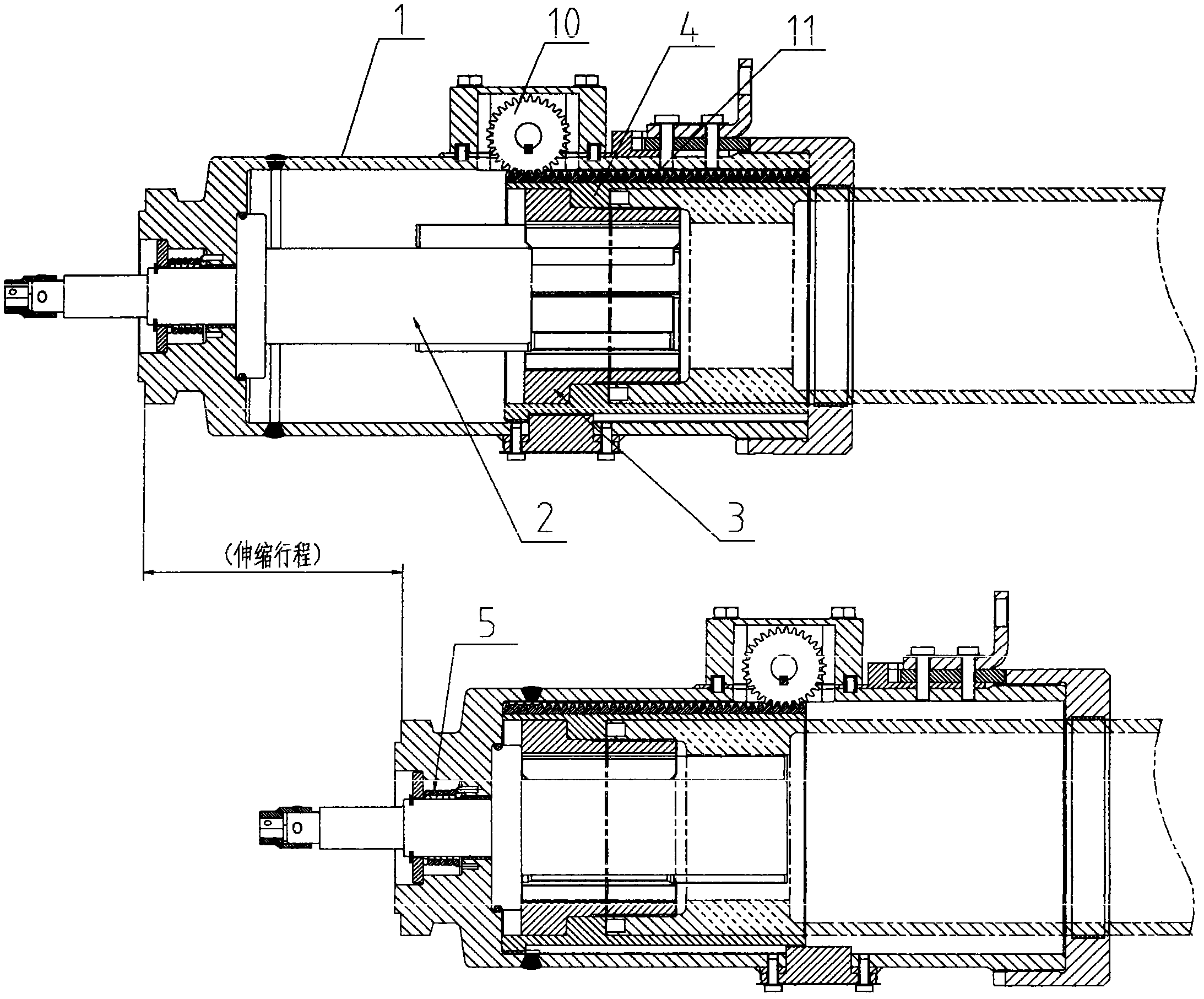

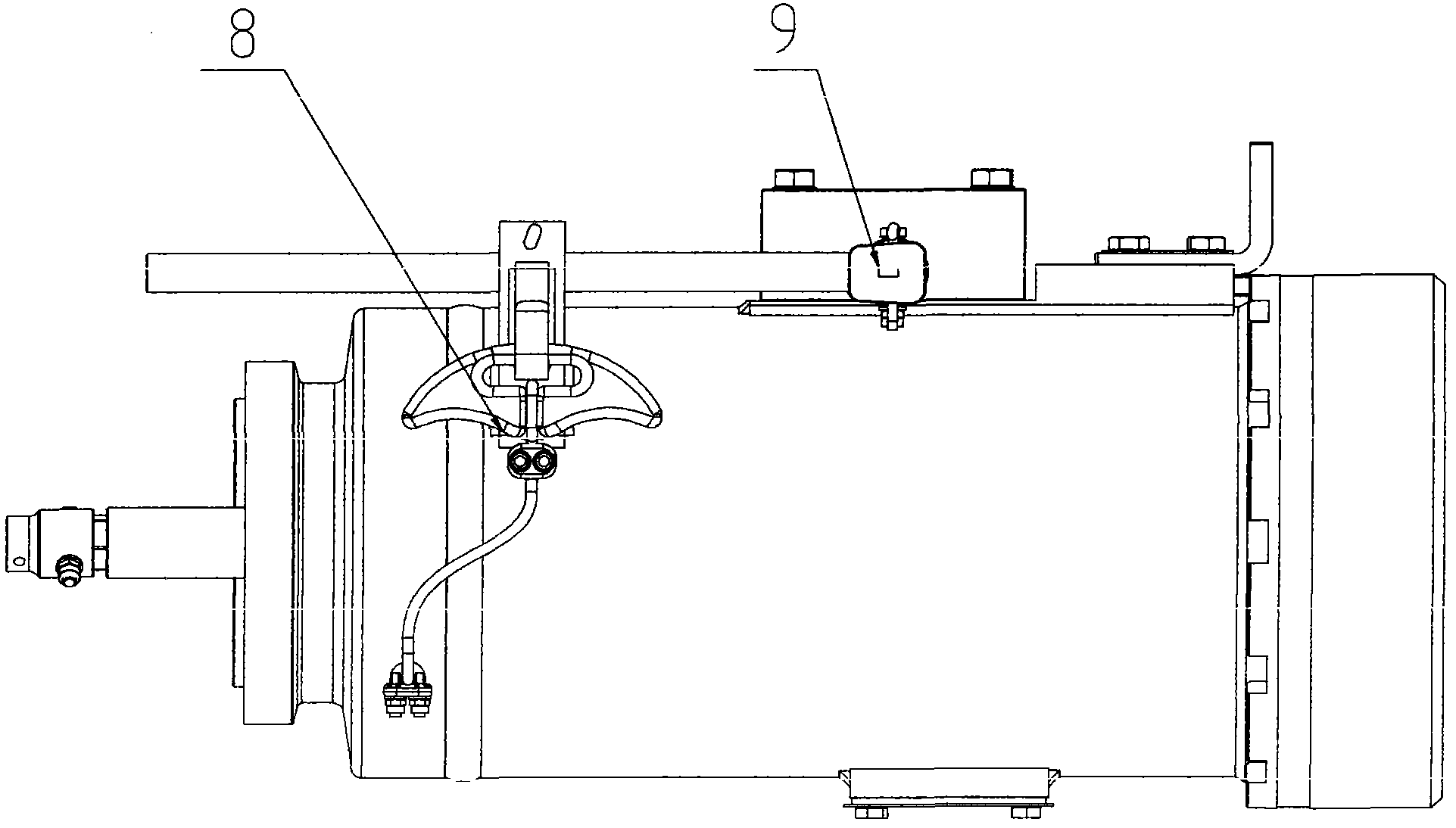

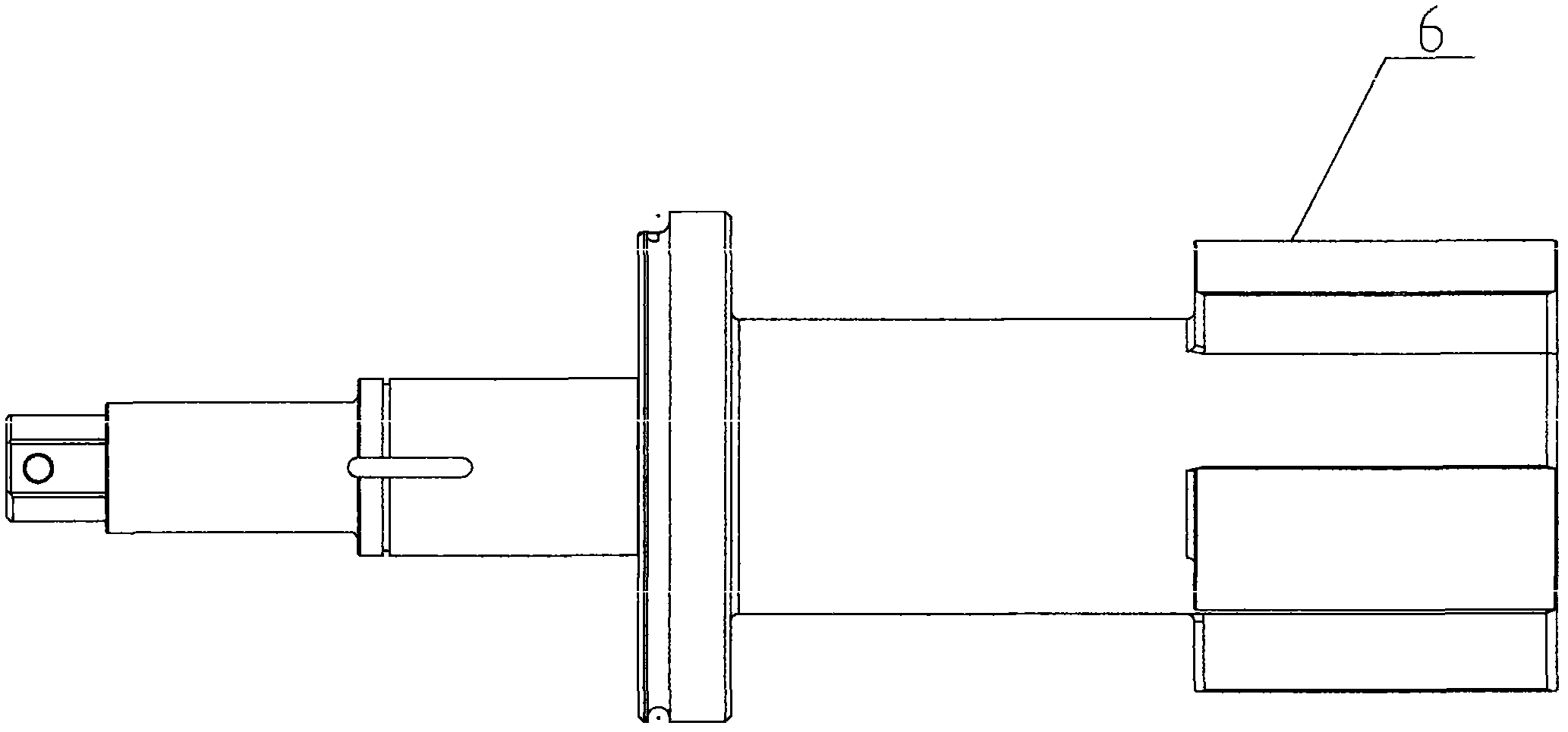

Telescopic mechanism of telescopic coupler and buffer device for high-speed motor train unit

The invention relates to a telescopic mechanism of a telescopic coupler and buffer device for a high-speed motor train unit. The telescopic mechanism comprises a pressed rod which is positioned at one end in a movable shell of the coupler and buffer device and connected with the movable shell, and a bearing joint sleeved on the pressed rod, wherein a guide cylinder is fixedly arranged outside the bearing joint; a telescopic driving mechanism is arranged between the guide cylinder and the movable shell; one end of the pressed rod is connected with the movable shell through a torsion spring; the pressed rod and the bearing joint are locked; a locking mechanism comprises convex heads which are positioned at the other end of the pressed rod and distributed at intervals, and grooves which are positioned on the inner wall of the bearing joint and fitted with the convex heads; when the convex heads are opposite to the grooves, the pressed rod and the bearing joint are unlocked and can relatively slide; and an unlocking driving mechanism is arranged outside the movable shell. The corresponding parts are arranged in the movable shell, so the occupied space is small, and the corresponding parts are well protected; meanwhile, the telescopic mechanism and the locking mechanism have relatively simple structures, are labor-saving and high in action reliability and can bear a high longitudinal load, and the impact energy absorption capacity of a buffer system is relatively high. After the telescopic mechanism is applied, the telescopic coupler and buffer device can be localized and completely replaces imported products.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

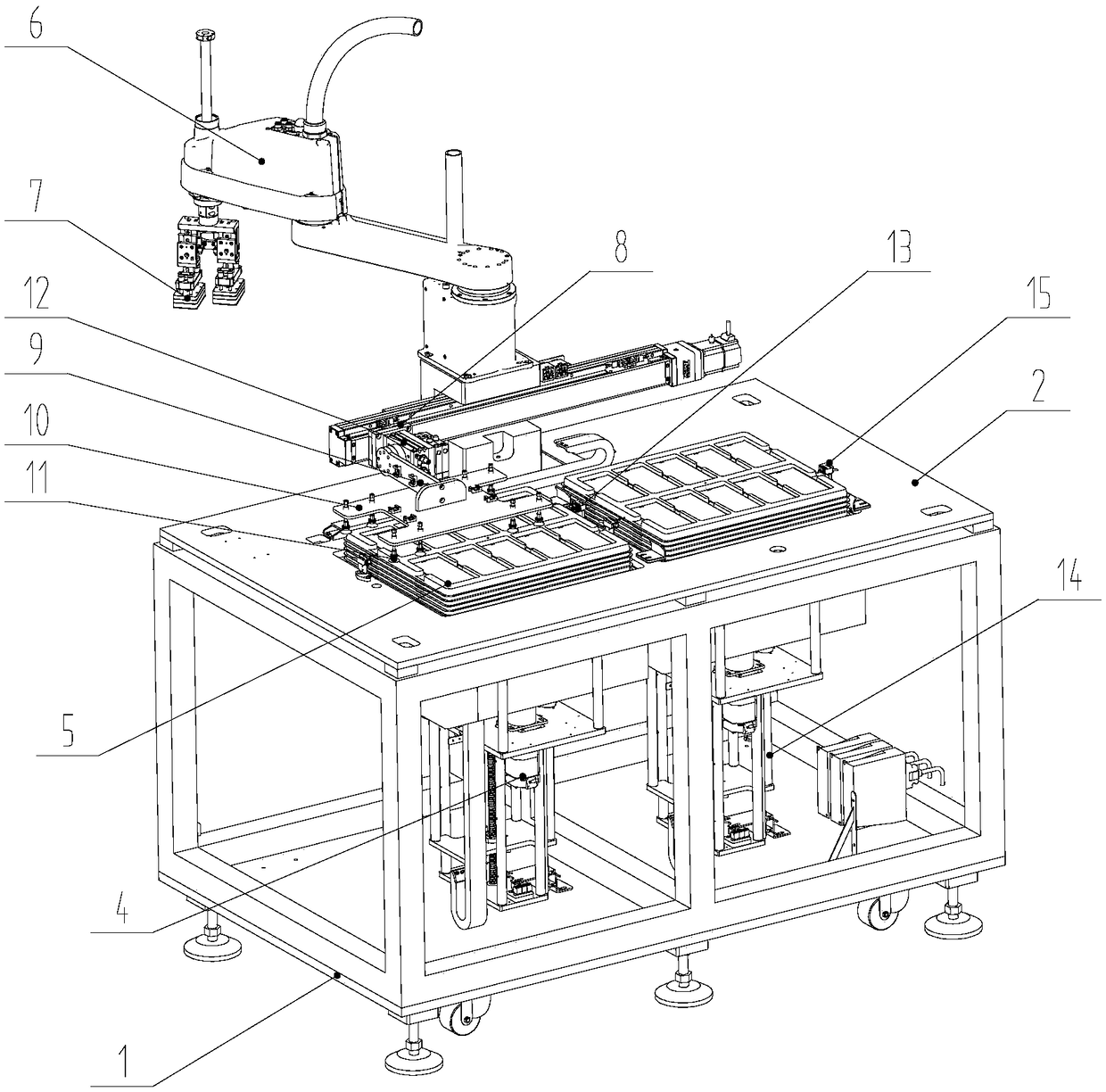

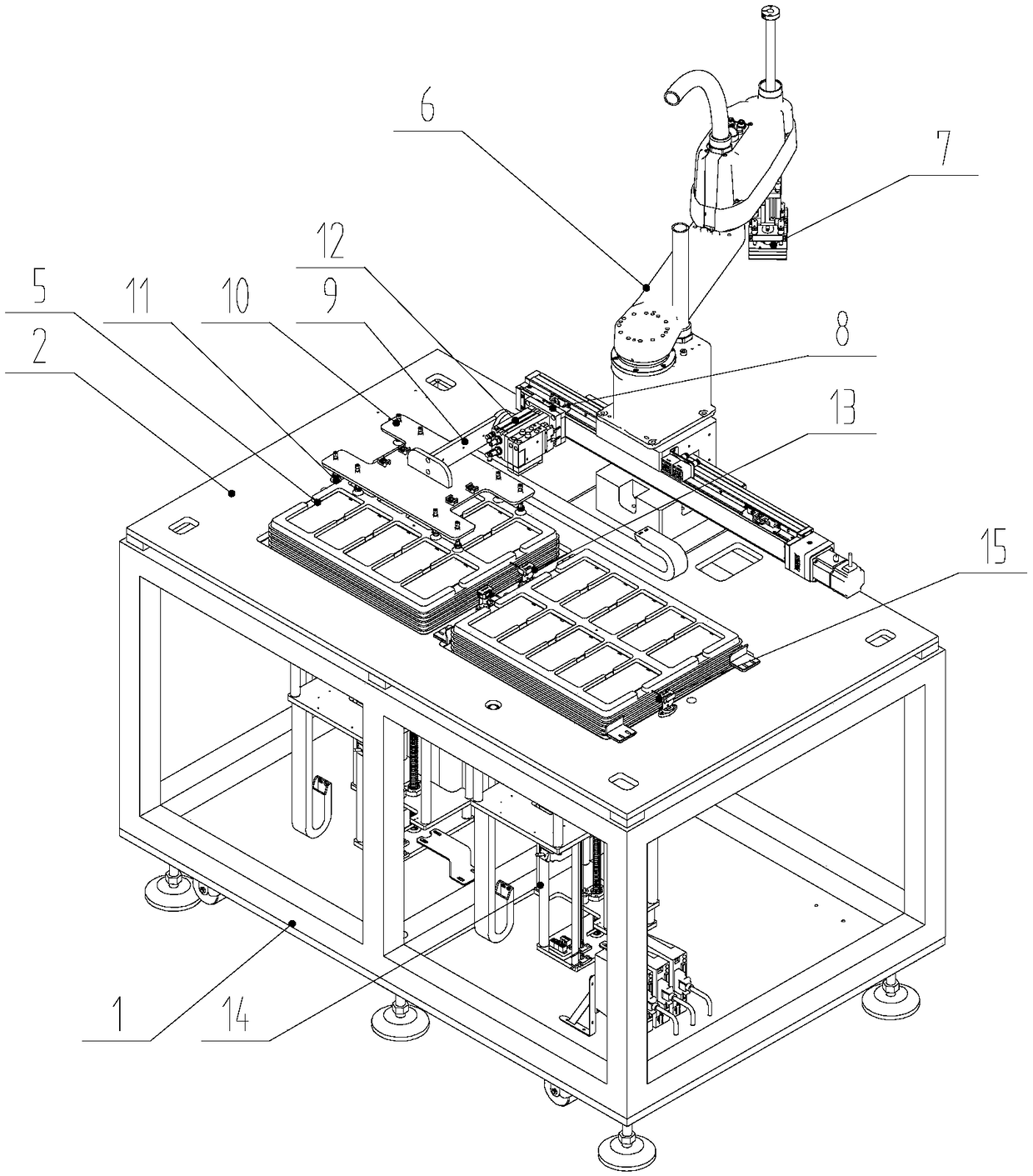

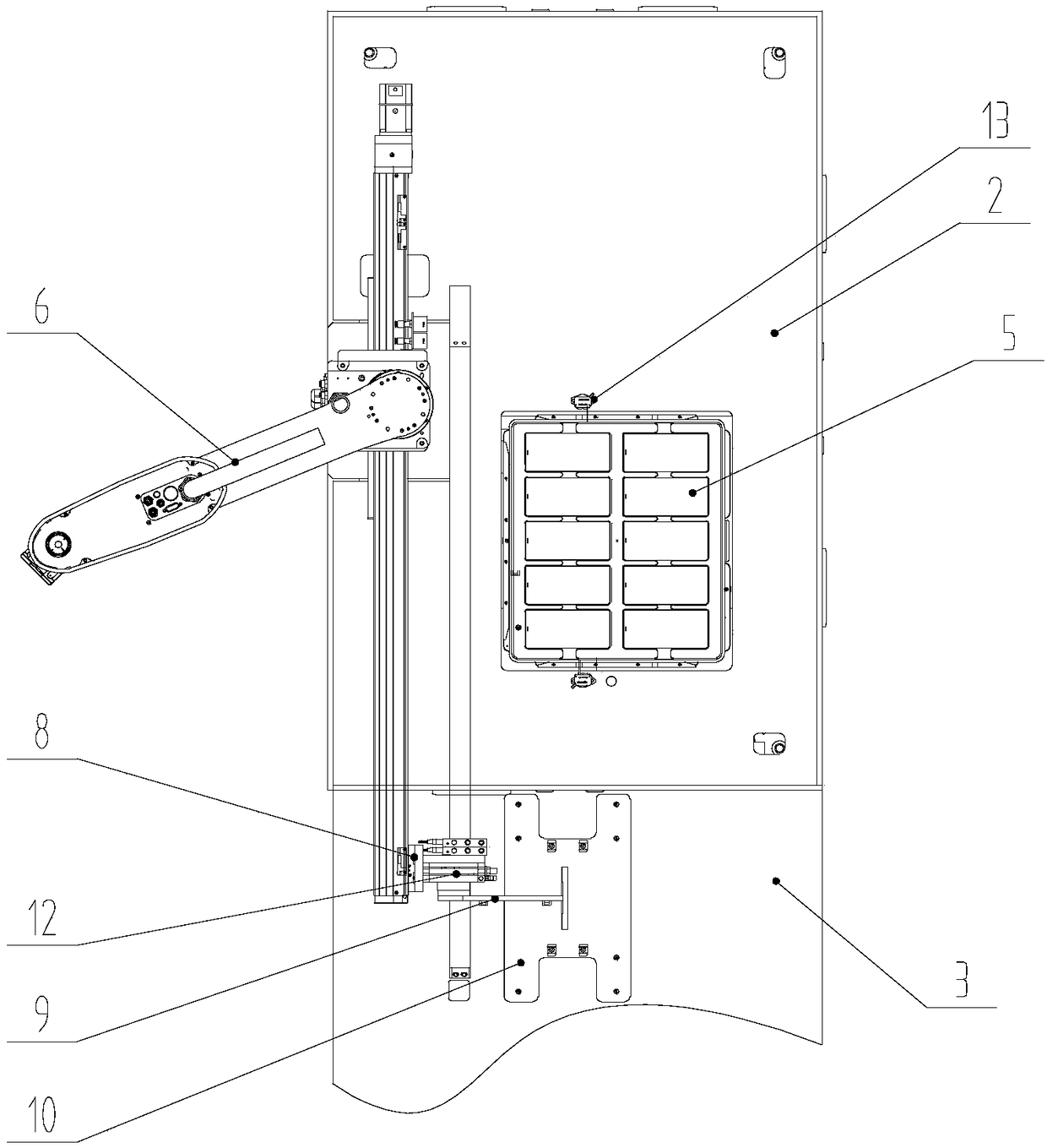

Feeding device of exposure machine

PendingCN109292450AEasy loadingReasonable structureConveyorsControl devices for conveyorsEngineeringManipulator

The invention discloses a feeding device of an exposure machine. The feeding device comprises a machine frame, a feeding platform is arranged on the machine frame, a supplement station and a finishedproduct storage station are arranged on the feeding platform, the supplement station is provided with a supplement passing hole, a lifting platform which can extend out of the supplement passing holeis vertically and slidably arranged at the supplement station, the lifting platform is driven by a supplement lifting power device, a plurality of trays used for placing to-be-exposed mobile phone shells are stacked on the lifting platform, a mechanical arm is arranged on the feeding platform, two first sucker assemblies used for sucking the mobile phone shells are arranged at the tail end of themechanical arm, and a working table is provided with a transferring device used for transferring the trays to the finished product storage station. The feeding device can realize automatic feeding ofthe mobile phone shells, the feeding efficiency is improved, and the labor cost is reduced.

Owner:JIANGSU GIS LASER TECH INC

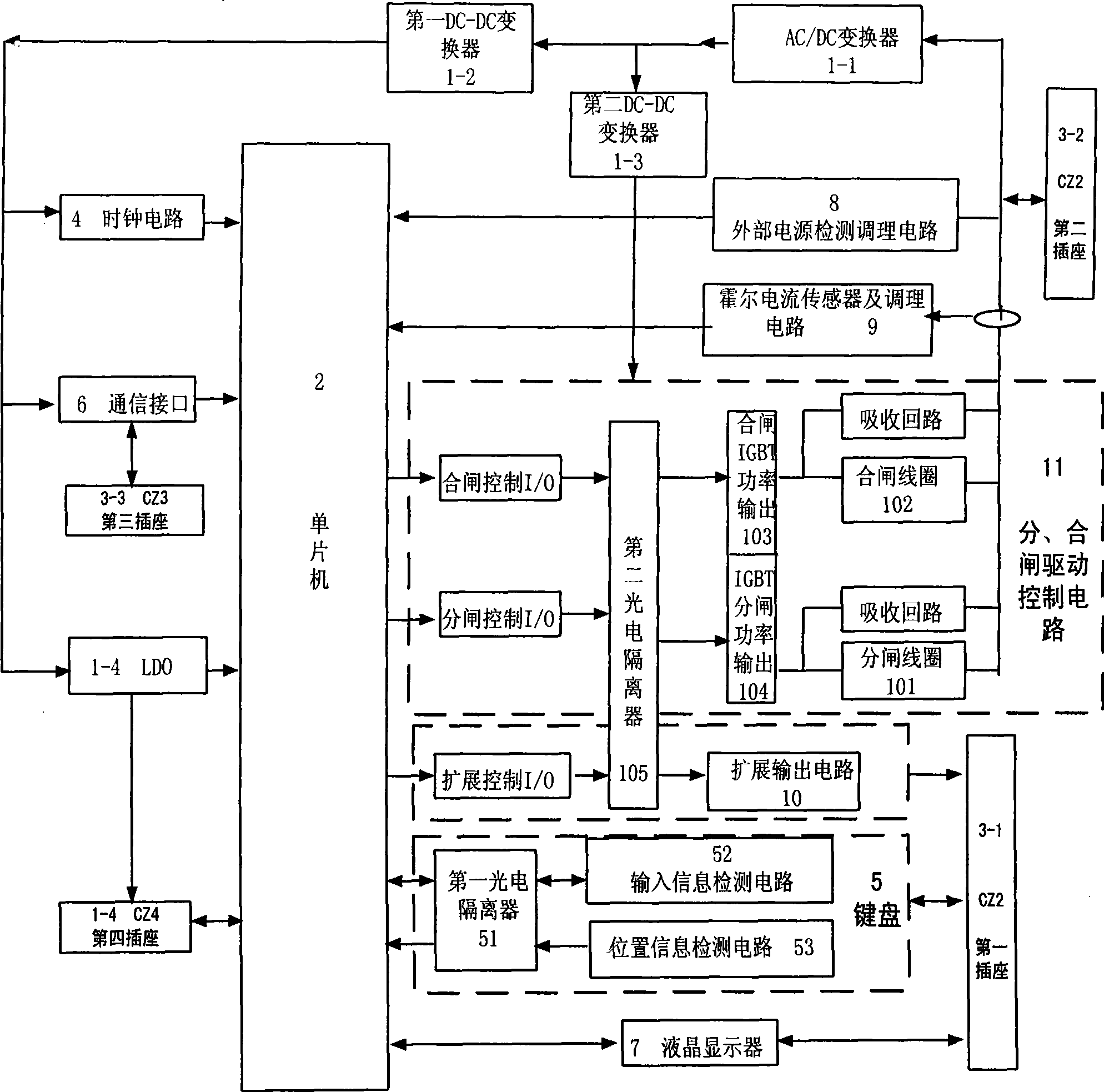

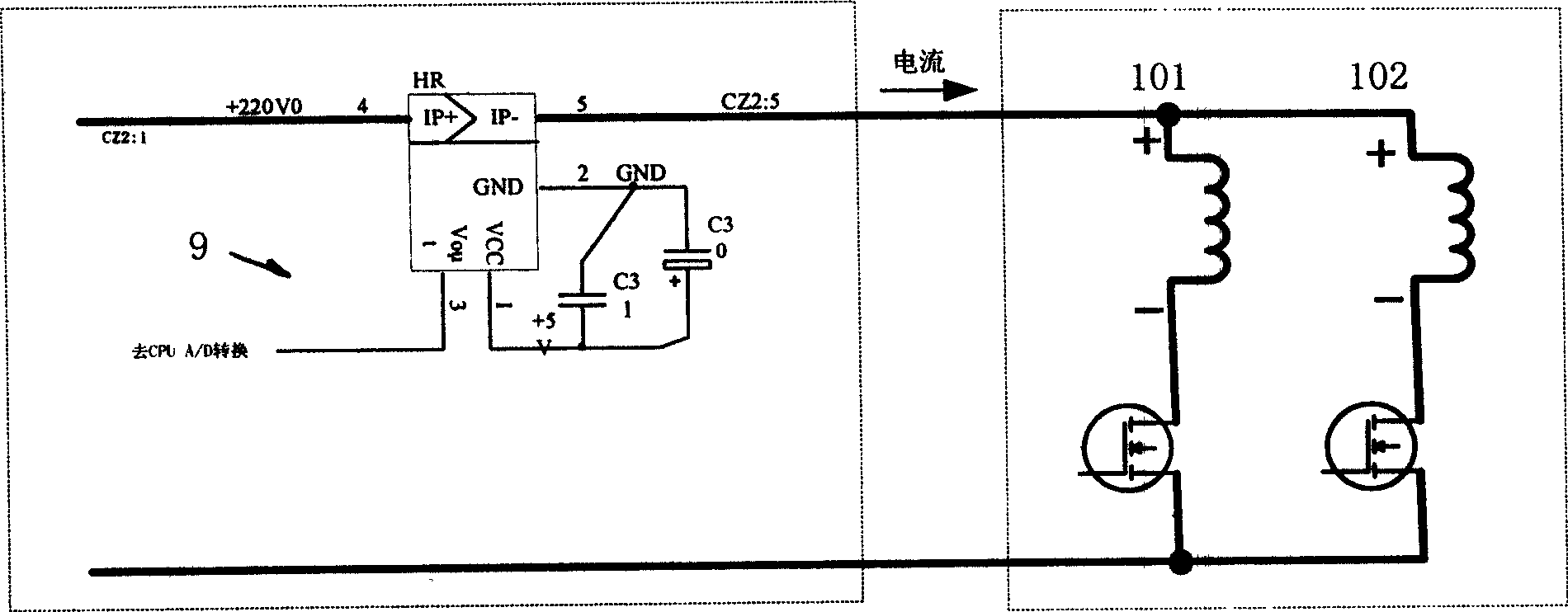

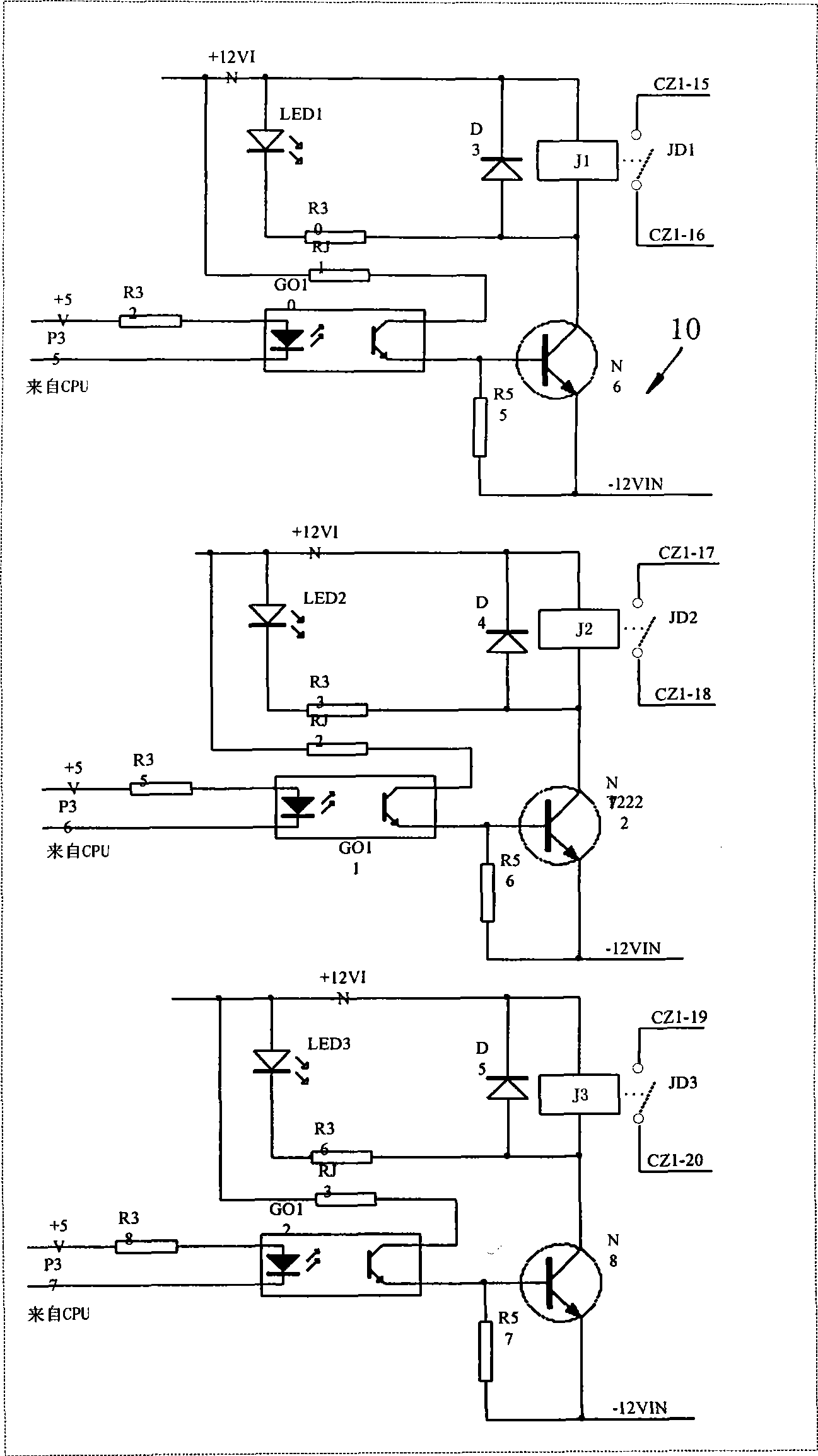

Permanent magnet mechanism controller

InactiveCN101477903AReduce agingHigh operational reliabilitySwitch power arrangementsHigh-tension/heavy-dress switchesLocation detectionReference current

The invention provides a permanent magnetic controller, which comprises a trip and a closing coils and a position detecting circuit and a driving control circuit thereof, and a single chip microcomputer and a keyboard thereof; wherein, the detecting circuit adopts a hall current sensor, and is used for collecting current waveform signals of the trip and closing coils, transforming the current waveform signals to voltage signals through a conditioning circuit, and transmitting the voltage signals to the single chip microcomputer; the keyboard is used for inputting tripping and closing instructions; and the single chip microcomputer analyzes and compares the current waveform detection signals with a reference current waveform, and outputs tripping and closing driving signals through the driving control circuit respectively to the trip and the closing coils. The permanent magnetic controller has the advantages that as the closing and trip coil current waveform intercomparison technology is adopted, the reliability of movements of a circuit breaker is improved; furthermore, as heights of waveforms on the trip and the closing coils cannot reach saturation, the aging degree of the coils is reduced, and the service life of a permanent magnetic coil is prolonged.

Owner:北京龙源开关设备有限责任公司

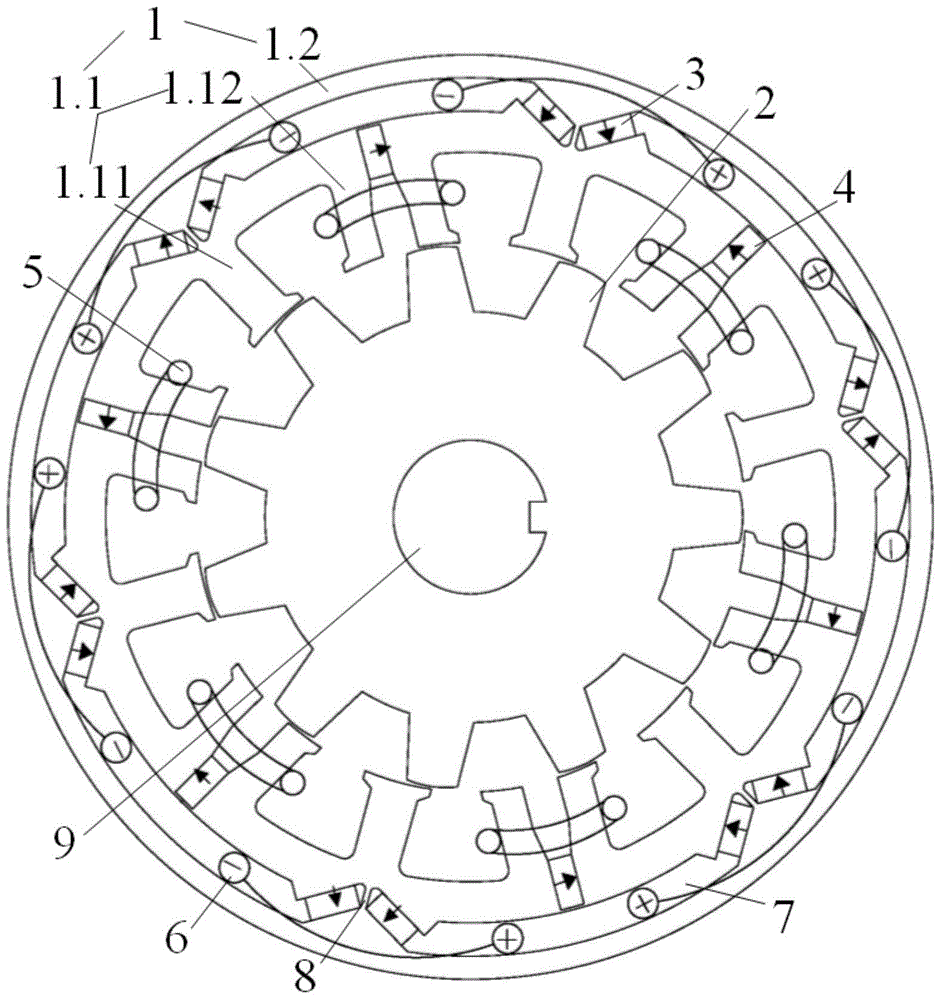

E-shaped stator core flux switching type hybrid permanent magnet memory motor

InactiveCN104410180ASimple structureStable structureMagnetic circuit stationary partsElectric machineMemory motor

The invention discloses an E-shaped stator core flux switching type hybrid permanent magnet memory motor and belongs to the field of flux-adjustable permanent magnet motors. Both rotor and stator cores of the motor adopt a salient pole structure. A stator of the motor comprises six E-shaped stator cores, V-shaped aluminum-nickel-cobalt permanent magnets, tangential-magnetizing rectangular neodymium iron boron permanent magnets and a whole layer of stator yokes, wherein adjacent neodymium iron boron permanent magnets with opposite polarities are inlaid between the two adjacent E-shaped stator cores, and a three-phase concentrated winding armature winding is wound across a sandwich-shaped unit composed of the core edges of adjacent E-shaped stator units and the neodymium iron boron permanent magnets; a groove between two adjacent V-shaped aluminum-nickel-cobalt permanent magnets is used for placing a concentrated single-phase pulse winding. The E-shaped stator core flux switching type hybrid permanent magnet memory motor greatly alleviates a space conflict between electromagnetic loading in the stator cores and pulse magnet-adjustment capacity, can realize flexible online magnet adjustment and has little loss of excitation, the torque density and the force and energy expression of the motor can be improved, and the fault-tolerant fault operation ability is good.

Owner:SOUTHEAST UNIV

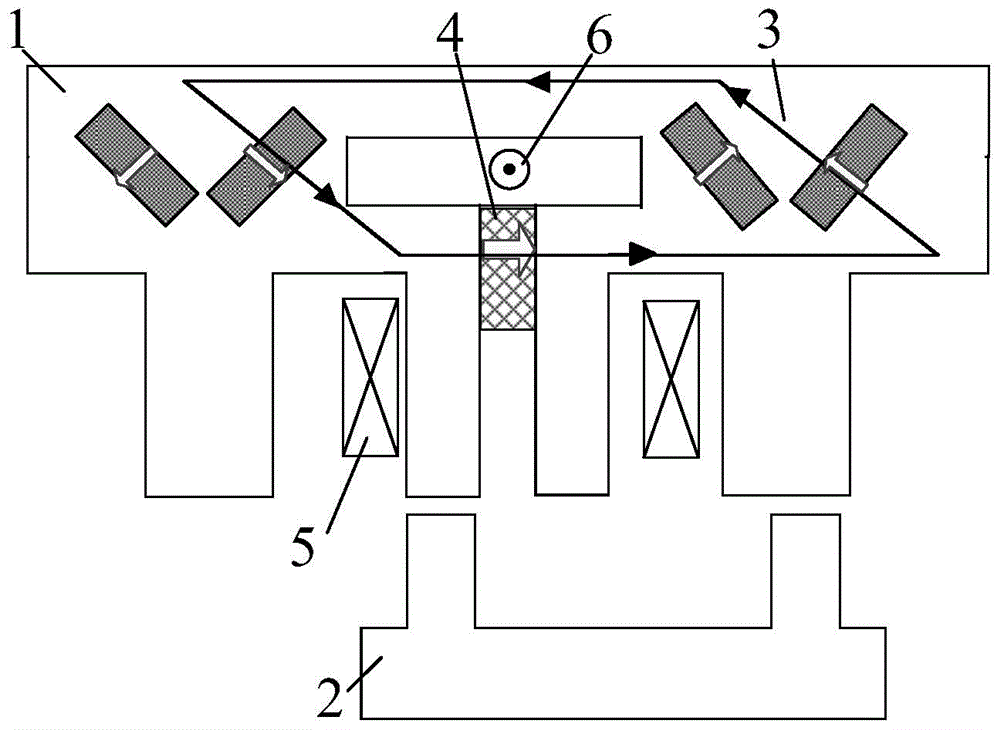

Device for continuously deslagging in subway construction and deslagging method utilizing device

InactiveCN106089231AShorten the construction periodCompact structureTunnelsSlagTunnel boring machine

The invention discloses a device for continuously deslagging in subway construction and a deslagging method utilizing the device. The device comprises a tunnel boring machine (1), a continuous belt conveyor (2) and a vertical lifting belt conveyor (4), wherein the tunnel boring machine (1) is mounted on a rail in a tunnel; a machine tail of the continuous belt conveyor (2) is fixedly mounted on the tunnel boring machine (1); a machine body of the continuous belt conveyor (2) is fixedly mounted on a tunnel hole wall; a machine head of the continuous belt conveyor (2) is fixedly mounted on the ground of the tunnel; the vertical lifting belt conveyor (4) is fixedly mounted on the ground of the tunnel, a vertical shaft hole wall and the ground of a wellhead; and a slag transferring funnel (3) is fixedly mounted between an unloading section of the continuous belt conveyor (2) and a material receiving section of the vertical lifting belt conveyor (4). With the adoption of the structure, the effects of compact structure, continuous conveying, high production efficiency, high operation reliability, safety and stability, high automation degree and capability of shortening construction duration of the tunnel are realized.

Owner:车新宁 +2

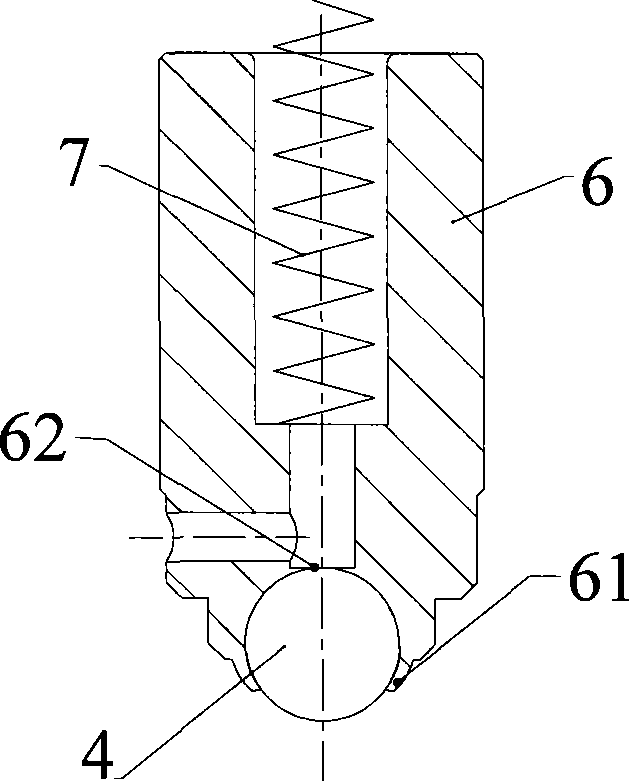

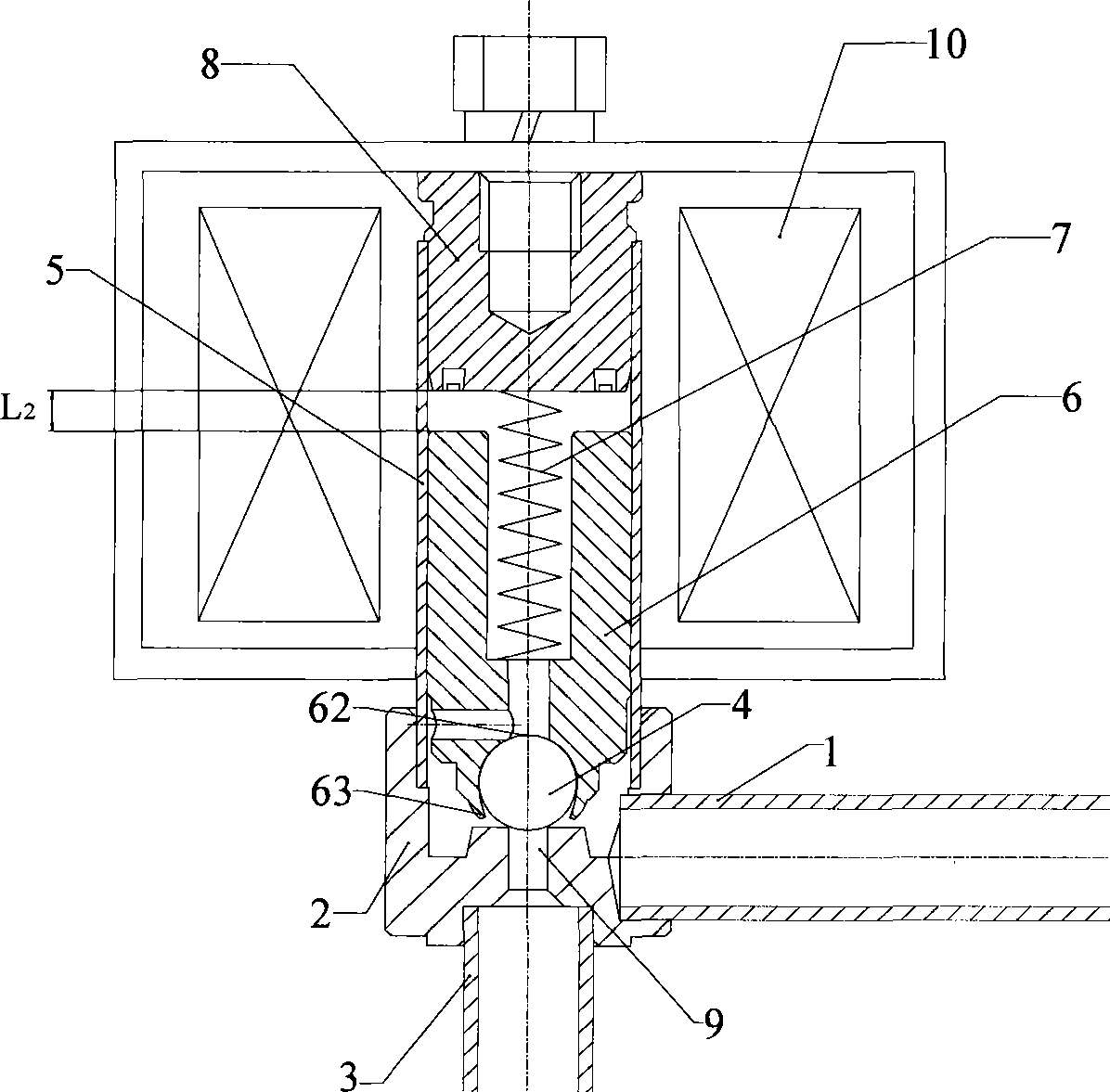

Electromagnetic valve

ActiveCN101498379ASmall sizeChange structureOperating means/releasing devices for valvesLift valveSolenoid valveEngineering

The invention discloses an electromagnetic valve, comprising a valve base (2), a sleeve (5) connected with the valve base (2), and a coil (10) outside the sleeve (5). The valve base (2) is provided with a valve opening (9) and is fixed with a medium inlet pipe (1) and a medium outlet pipe (3); a static iron core (8) and a movable iron core (6') are arranged in the sleeve (5), a spring is arranged between one end of the movable iron core (6') and the static iron core (8), a containing part (62') and an end part (63') are arranged at the other end of the movable iron core (6'), the containing part (62') contains a sealing element (4) that opens or closes the valve opening (9), and a gap is arranged between the end part (63') and the sealing element (4). In the invention, the reliable operation of the electromagnetic valve is guaranteed without increasing the diameter of the iron core or the cost.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

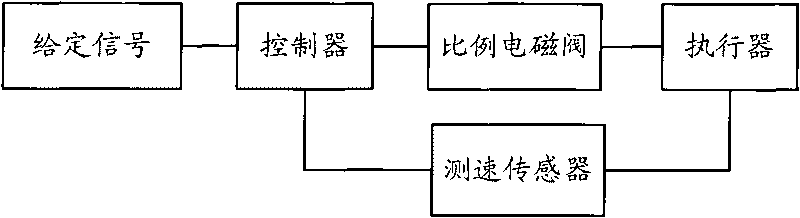

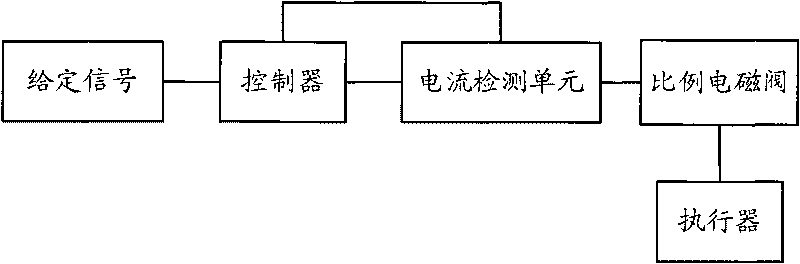

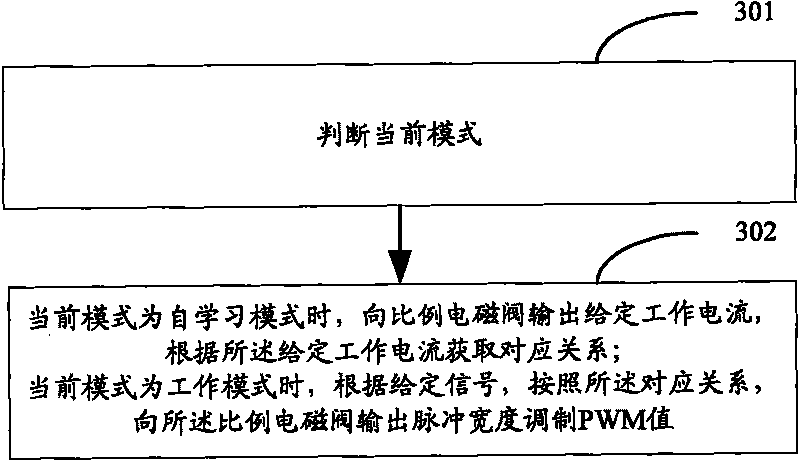

Control method and device of proportional solenoid and engineering machinery using device

ActiveCN101718368AEliminate individual differencesHigh precisionOperating means/releasing devices for valvesSolenoid valveControl engineering

The embodiment of the invention discloses a control method and device of a proportional solenoid and engineering machinery using the device. The method comprises the step of judging the current mode, and if the current mode is a self-learning mode, outputting the given working current to the proportional solenoid, and acquiring the corresponding relation according to the given working current; and if the current mode is a working mode, according to the given signal and the corresponding relation, outputting the pulse width to the proportional solenoid to modulate the PWM value. The invention improves the accuracy and the reliability of the system action.

Owner:益阳市科技成果转化服务中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com