Smoke desulfurizing method by amino-thiamine method

A flue gas and ammonium sulfate technology, applied in the field of ammonia-ammonium sulfate flue gas desulfurization, can solve the problems of high ammonia consumption, difficult recovery of by-products, large flue gas resistance, etc., so as to improve reaction efficiency, improve utilization rate, and efficiently collect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

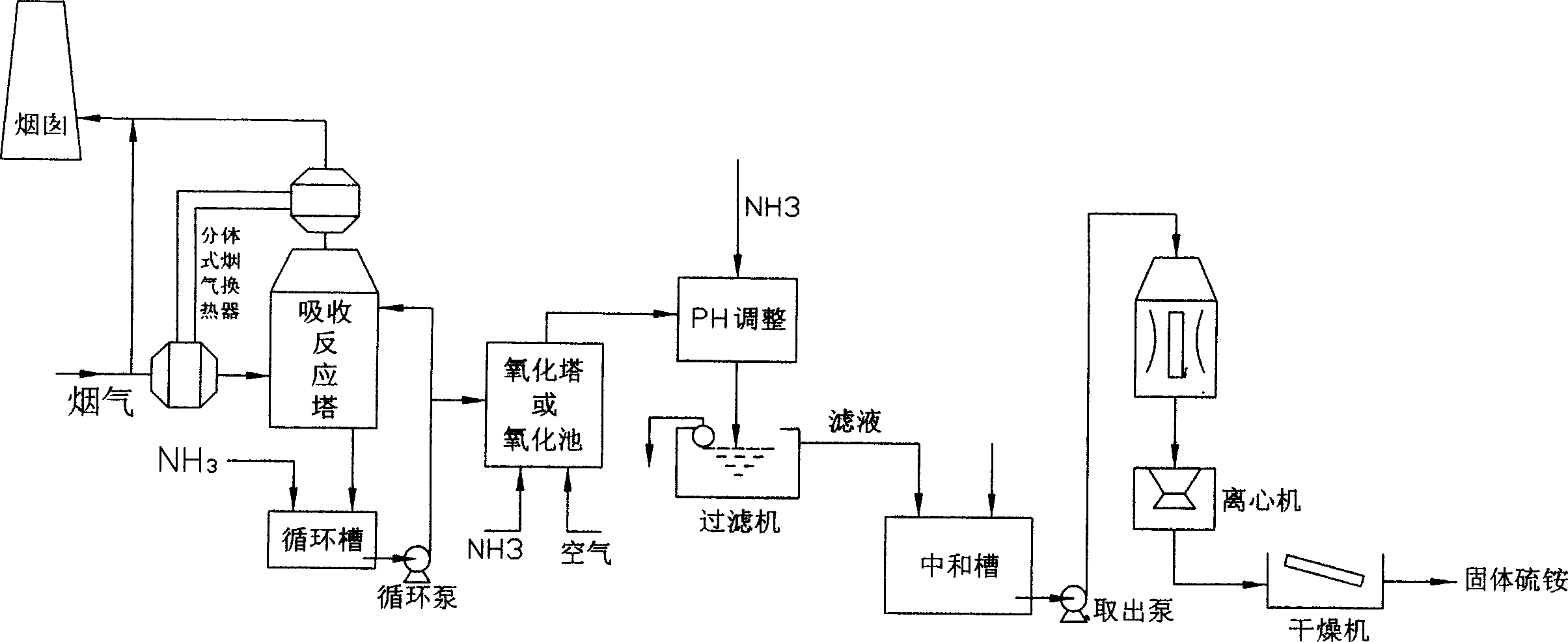

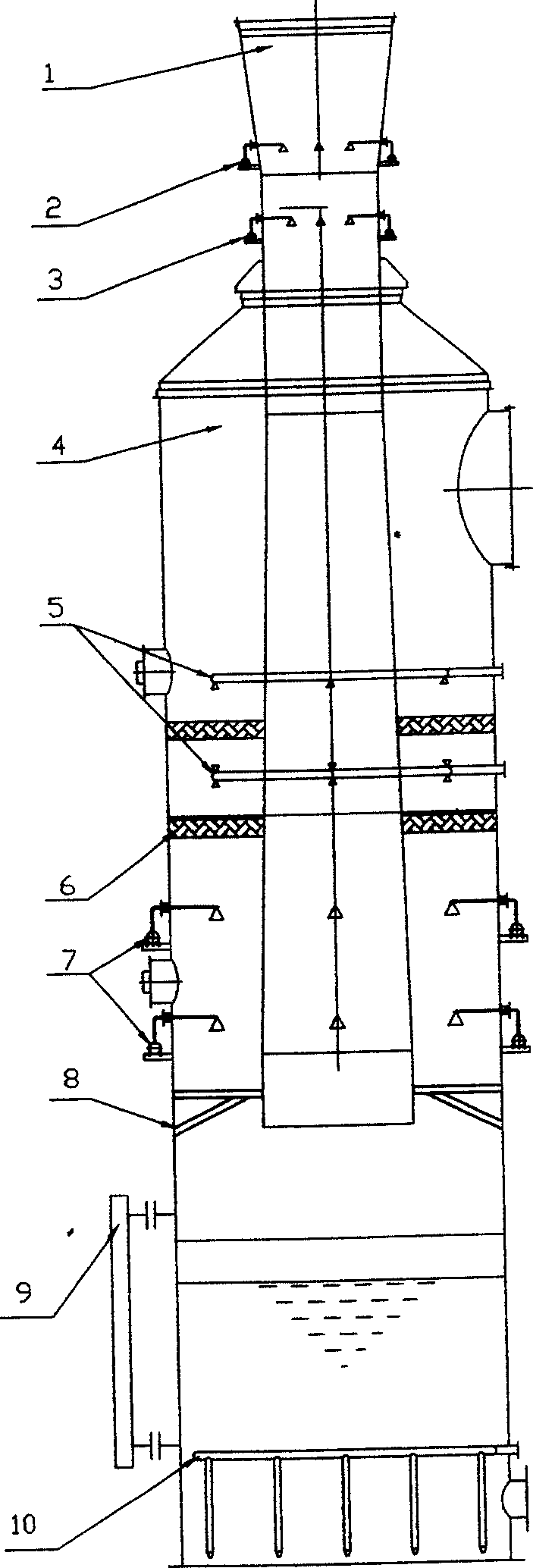

[0043] Such as figure 1 As shown, the present invention includes a separated flue gas heat exchanger, an absorption reaction tower, a circulating liquid tank, a circulating pump, an oxidation tank, compressed air, pH adjustment, a filter, a neutralization tank, a slurry pump, a crystallization evaporator, and a centrifuge , Dryer, etc. Specific steps are as follows:

[0044] 1) Absorption: A flue gas desulfurization tower is installed between the boiler outlet and the chimney, and the desulfurization tower uses ammonia as a carrier to absorb SO in the flue gas of the coal-fired boiler. 2 absorbed to form ammonium sulfite (NH 4 ) 2 SO 3 ;

[0045] 2) Circulation: the absorption liquid in the desulfurization tower enters the circulation tank, and NH is added 3 , a part of the absorption liquid enters the oxidation tower or oxidation pool through the circulating pump, and the other part enters the desulfurization tower for recycling;

[0046] 3), adjust the pH value: add N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com