Telescopic mechanism of telescopic coupler and buffer device for high-speed motor train unit

A technology of high-speed EMUs and telescopic mechanisms, applied in traction devices, transportation and packaging, railway car body parts, etc., can solve the problems of complex telescopic and locking structures and large space occupation, and achieve simple structure and low occupation of telescopic and locking mechanisms. The effect of small space and high operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

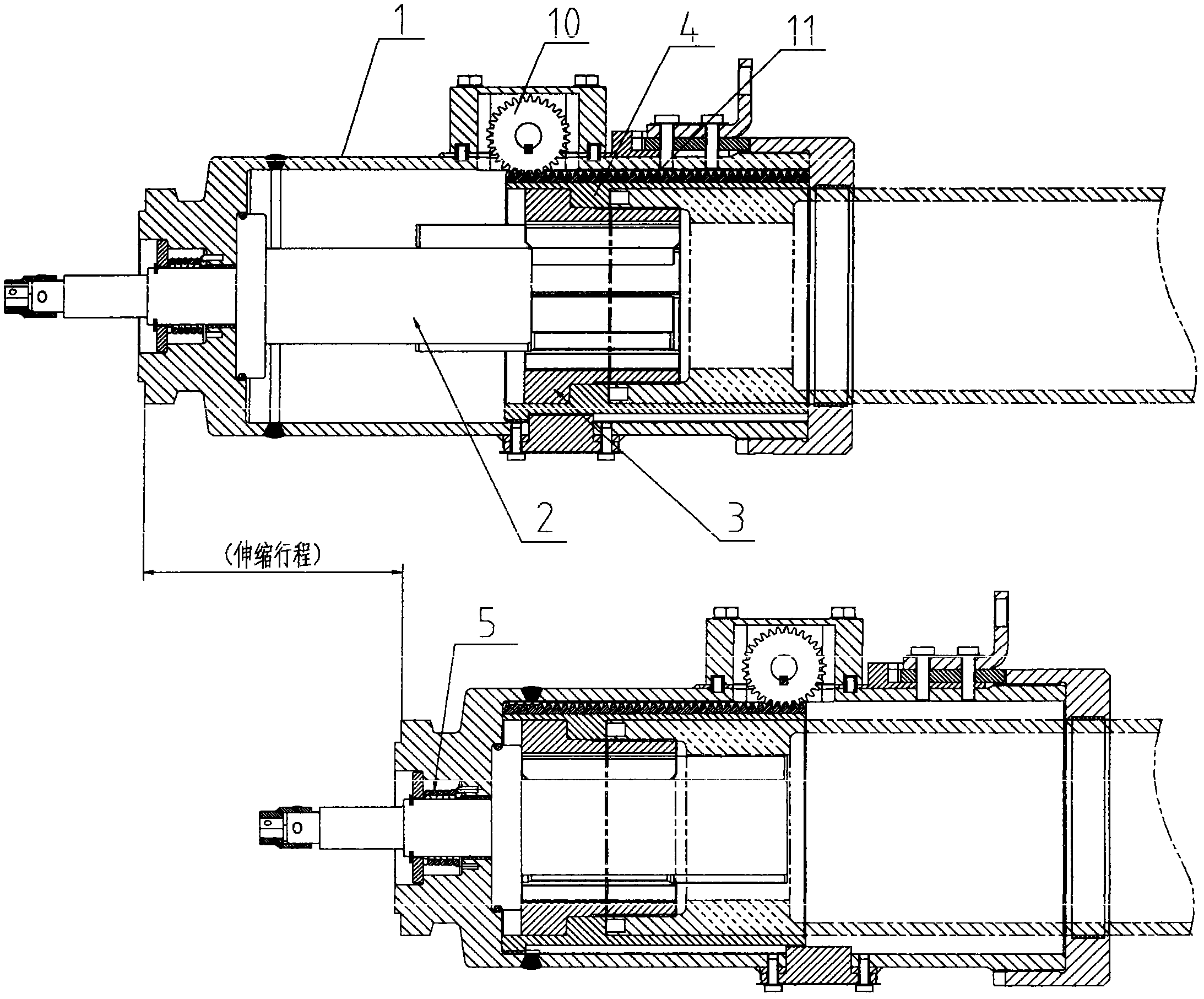

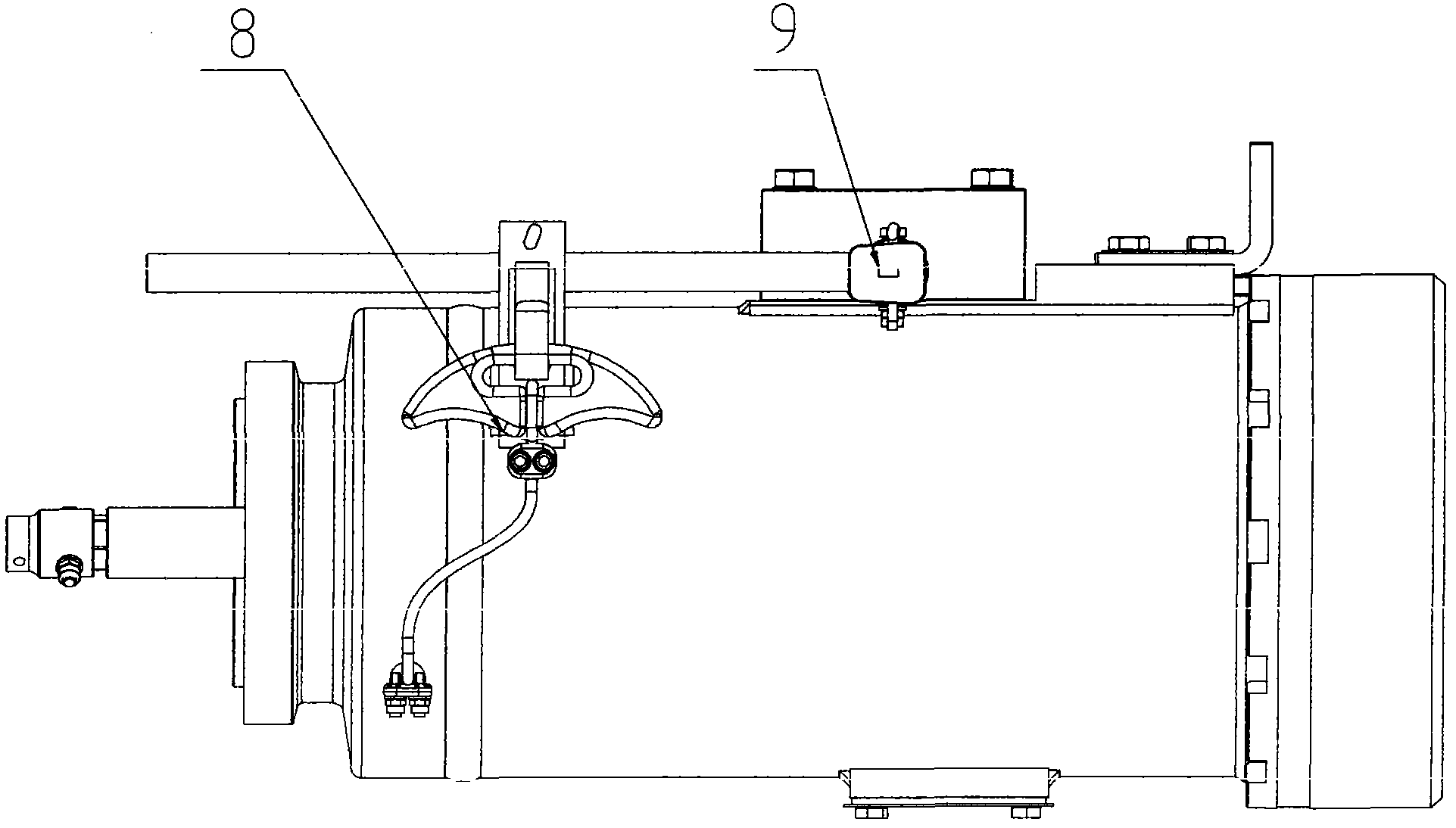

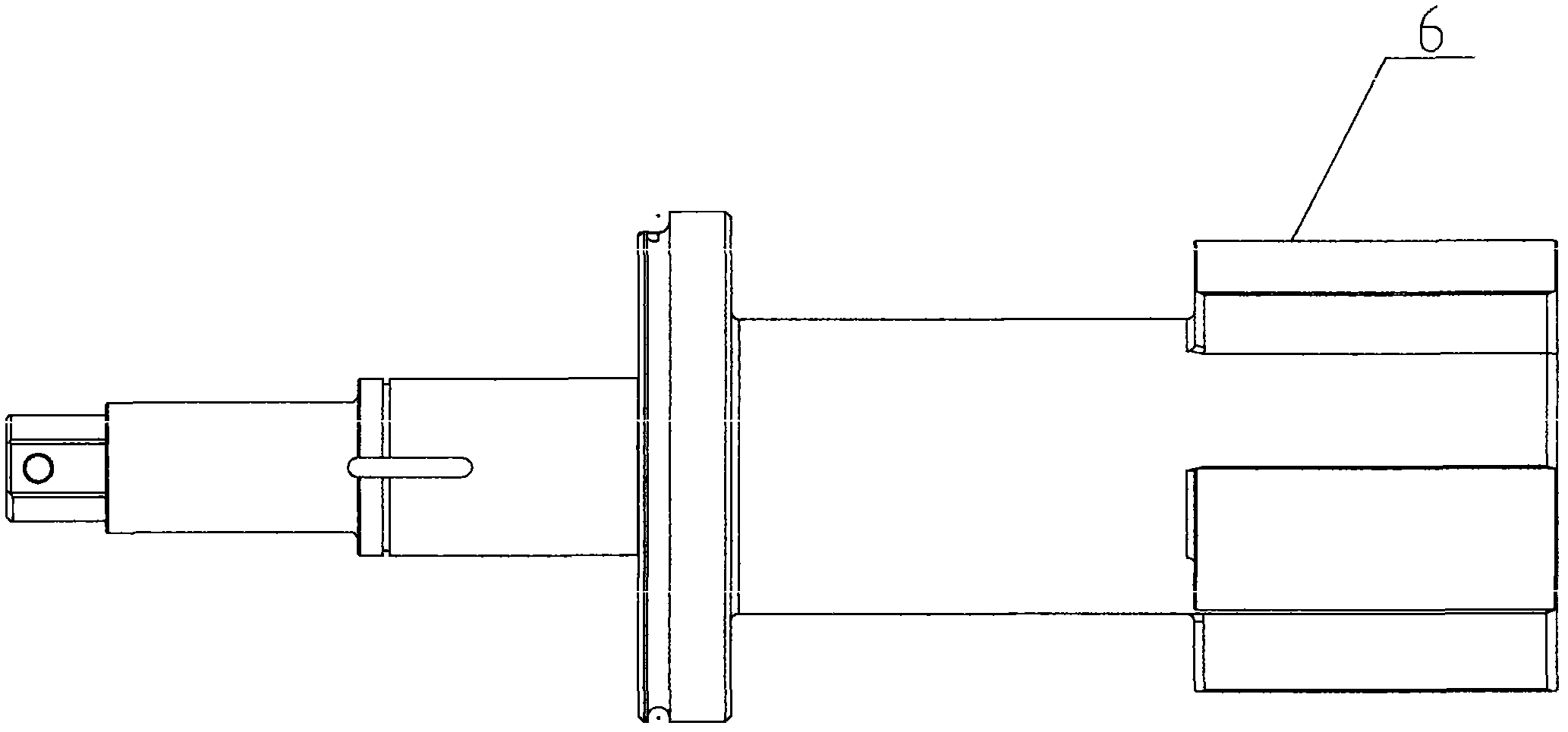

[0021] A telescopic mechanism for a telescopic hook buffer device for high-speed EMUs. The telescopic mechanism includes a pressure rod 2 connected to the movable housing 1 at one end inside the movable housing 1 of the hook buffer device, and a pressure rod 2 sleeved on the pressure rod 2. The bearing joint 3 is fixed with a guide cylinder 4 on the outside of the bearing joint 3, and a telescopic drive mechanism 9 is arranged between the guide cylinder 4 and the movable housing 1. The telescopic drive mechanism includes a telescopic gear 10 located on the movable housing 1 and The telescopic rack 11 is fixed on the guide cylinder 4; one end of the pressure rod 2 is connected to the movable housing 1 through the torsion spring 5 to keep the pressure rod 2 and the bearing joint 3 in a locked state; the locking mechanism includes a The protruding heads 6 distributed at intervals at the other end of the rod 2, the grooves 7 matching the protruding heads 6 on the inner wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com