Device for continuously deslagging in subway construction and deslagging method utilizing device

A subway and slag technology, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve problems such as safety risks, long tunnel construction period, low efficiency, etc., achieve high operation reliability, shorten tunnel construction period, continuous delivery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

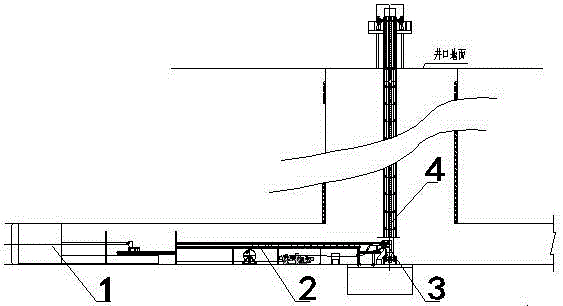

[0012] according to figure 1 As shown, the present invention relates to a device for continuous slag removal in subway construction, which includes a shield machine 1, a continuous belt machine 2, and a vertical lifting belt machine 4. The shield machine 1 is installed on the track in the tunnel, The tail of the continuous belt conveyor 2 is fixedly installed on the shield machine 1, the fuselage of the continuous belt conveyor 2 is fixedly installed on the tunnel wall, and the head of the continuous belt conveyor 2 is fixedly installed on the ground of the tunnel Above, the vertical lifting belt conveyor 4 is fixedly installed on the tunnel floor, shaft wall and wellhead ground, and a slag transfer funnel 3 is fixedly installed on the unloading section of the continuous belt conveyor 2 and the receiving section of the vertical lifting belt conveyor 4 between.

[0013] The present invention also relates to a slagging method using the device for continuous slagging in subway c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com