Feeding device of exposure machine

A technology of an exposure machine and a power device, which is applied to the field of the feeding device of the exposure machine, can solve the problems of complex, irregular manual placement and unreasonable feeding of the exposure machine, etc., and achieves the effect of a reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

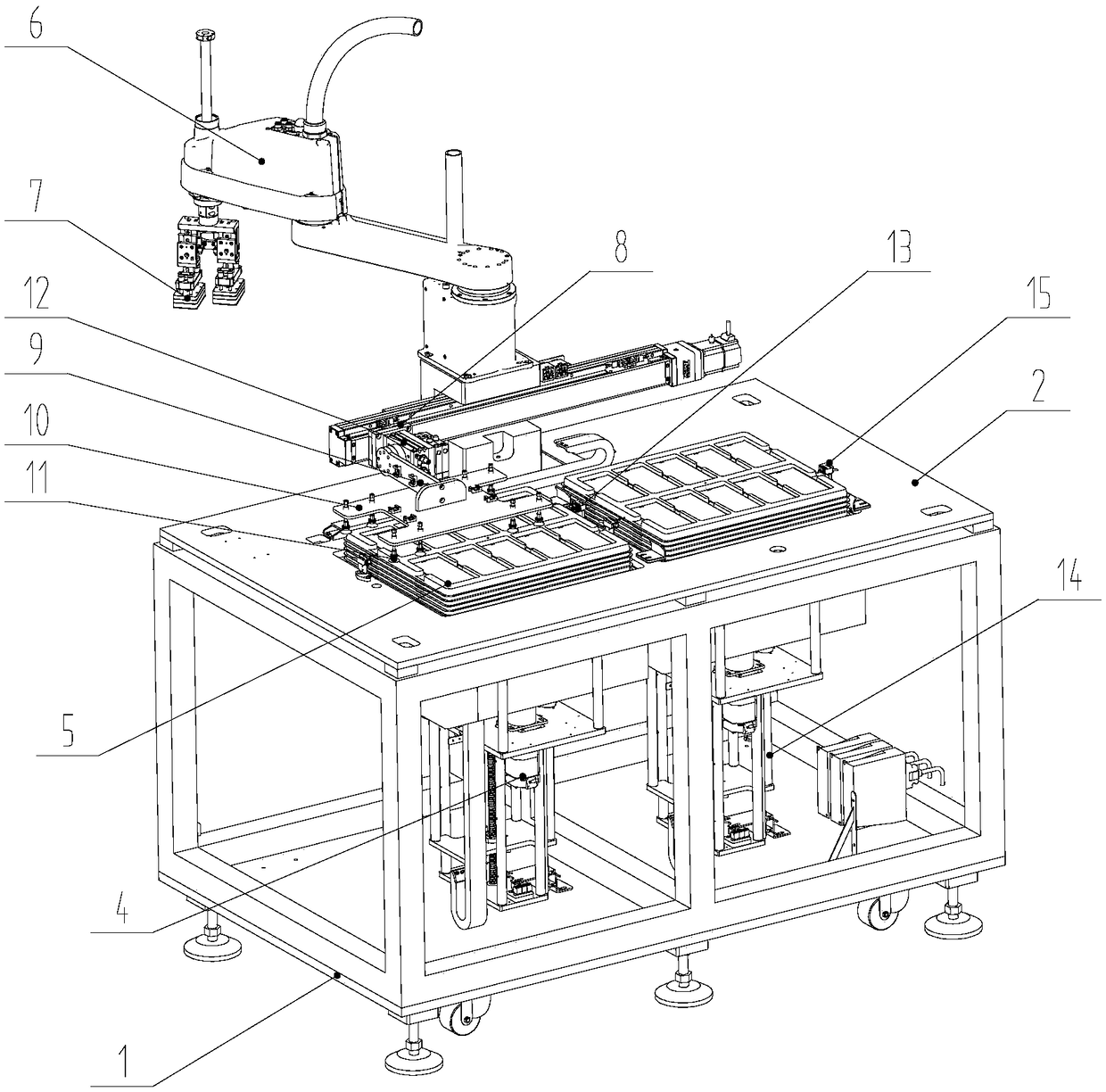

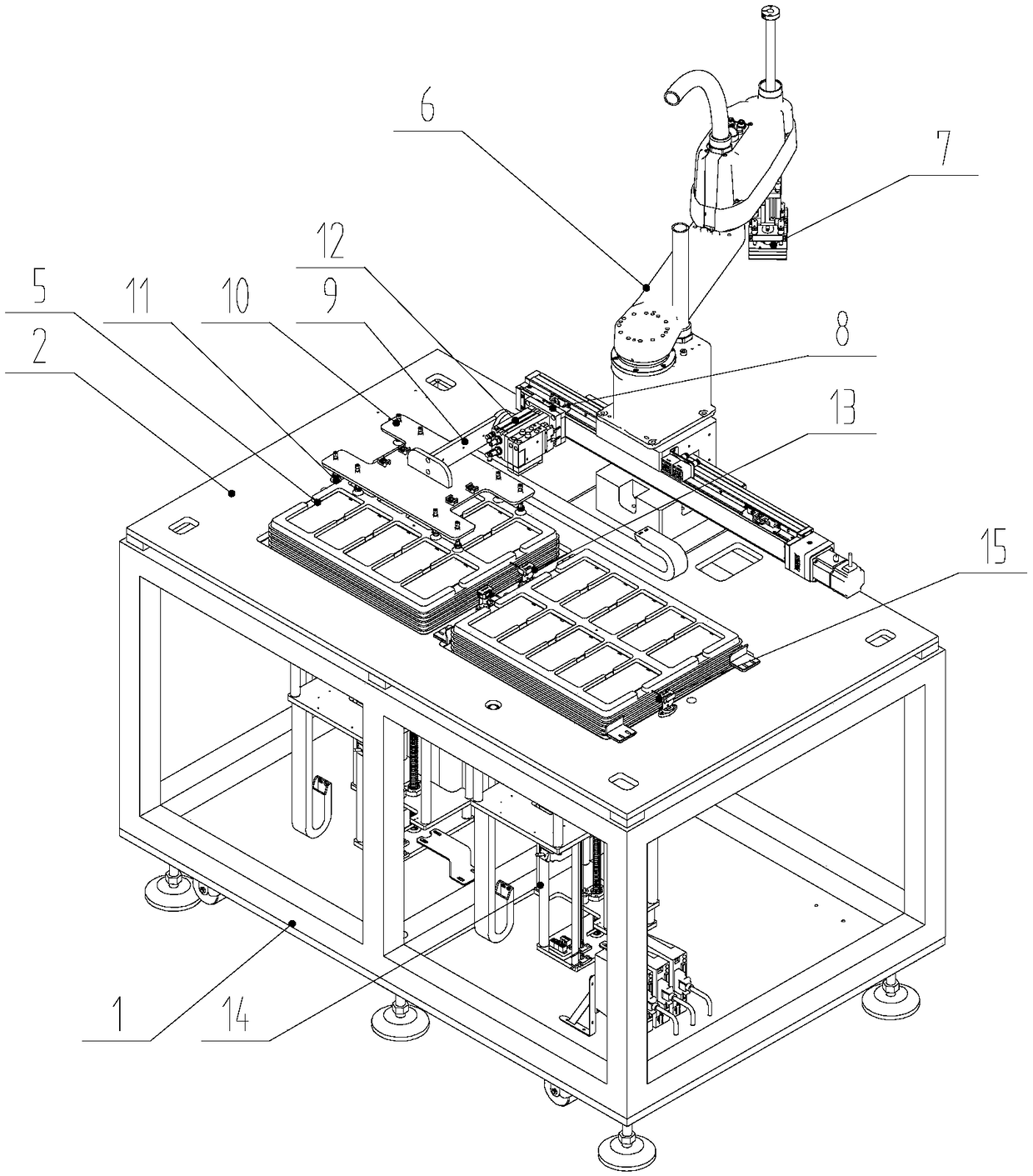

[0026] Such as Figure 1-2 As shown, a feeding device of an exposure machine includes a frame 1, a feeding platform 2 is arranged on the frame 1, a feeding station and a finished product storage station are arranged on the feeding platform 2, and the feeding station The filling station is provided with a feeding hole, and the feeding station is vertically slid to install a lifting table that can extend from the feeding hole. The lifting table is driven by the feeding lifting power device 4. A material tray 5 for placing mobile phone cases to be exposed; a manipulator 6 is installed on the feeding platform 2, and two first sucker assemblies 7 for absorbing the mobile phone case are installed on the terminal of the manipulator 6, and are installed on the workbench There is a transfer device for transferring the tray 5 to the finished product storage station.

[0027] In this embodiment, the transfer device includes a transfer slide 8 slidably installed between the feeding stati...

Embodiment 2

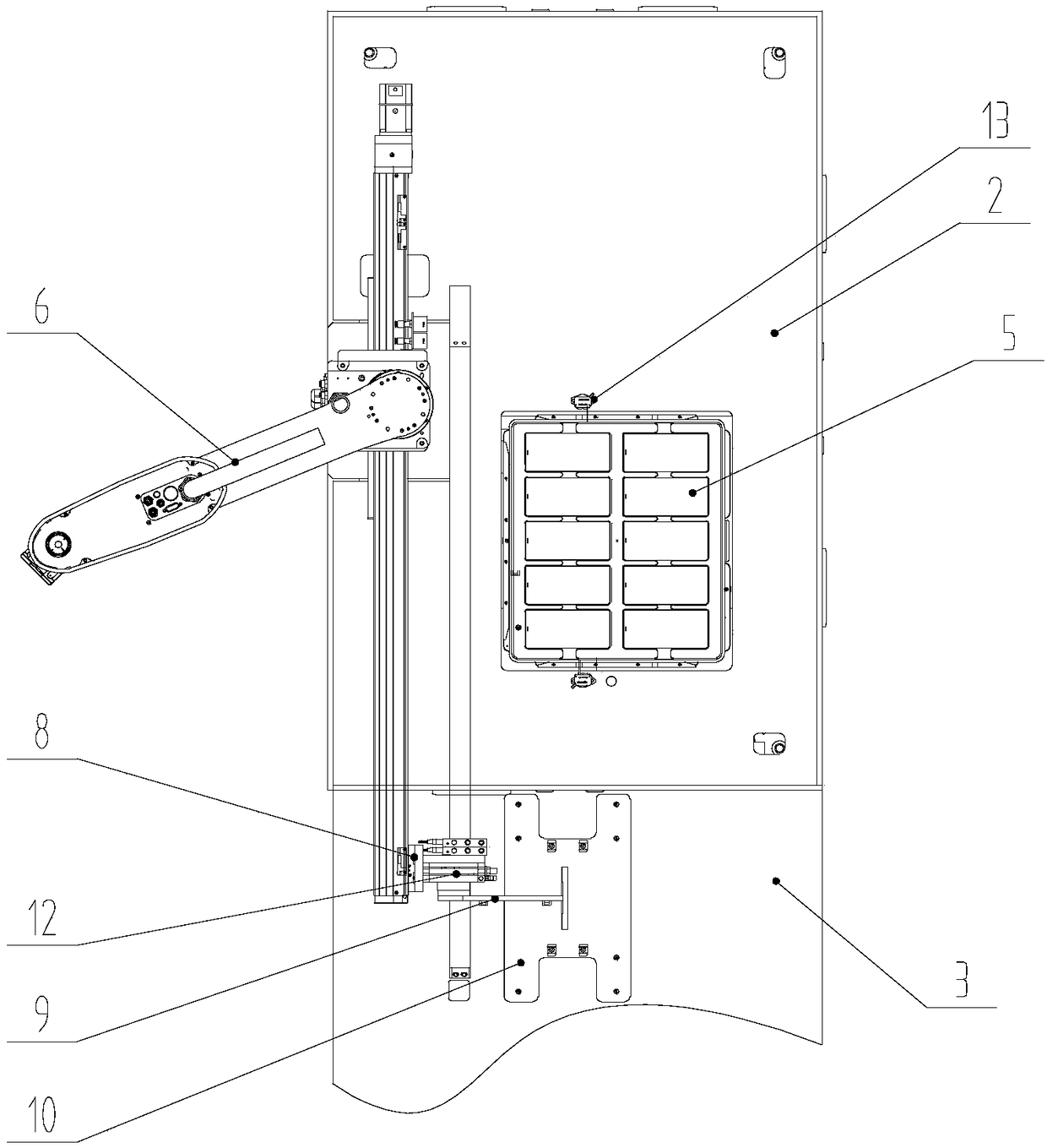

[0032] Such as image 3 As shown, a feeding device of an exposure machine includes a frame 1. A feeding platform 2 is arranged on the frame 1. A feeding station and a finished product storage station are arranged on the feeding platform 2. On the feeding station, There is a feeding hole, and the feeding station is vertically slid to install a lifting platform that can protrude from the feeding hole. The lifting platform is driven by the feeding lifting power device 4. There are multiple Place the material tray 5 of the mobile phone case to be exposed, a manipulator 6 is installed on the feeding platform 2, and two first sucker assemblies 7 for absorbing the mobile phone case are installed on the terminal of the manipulator 6, and are installed on the workbench for The transfer device that transfers the material tray 5 to the finished product storage station, the transfer device includes a transfer slide 8 that is slidably installed between the feeding station and the finished ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com