Track vehicle rim and tread flaw detection probe assembly system

A technology for rail vehicles and components, which is applied in the direction of material analysis, measuring devices, and instruments using sonic/ultrasonic/infrasonic waves, and can solve the problems of continuous detection in undetectable areas, unstable detection working conditions, and large consumption of coupling fluid, etc. It achieves the effect of compact, simple and practical structure, improved space utilization, and simple and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

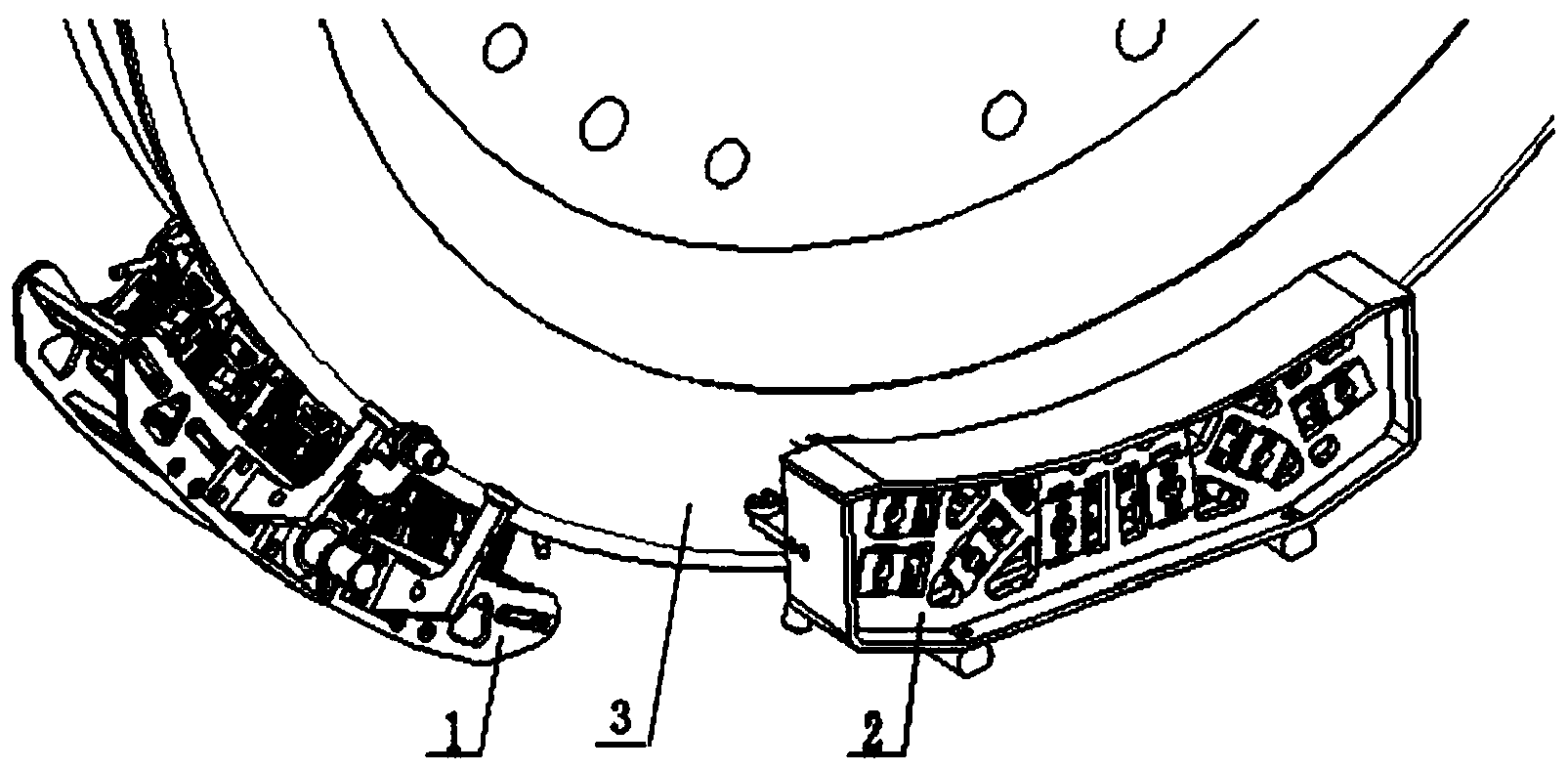

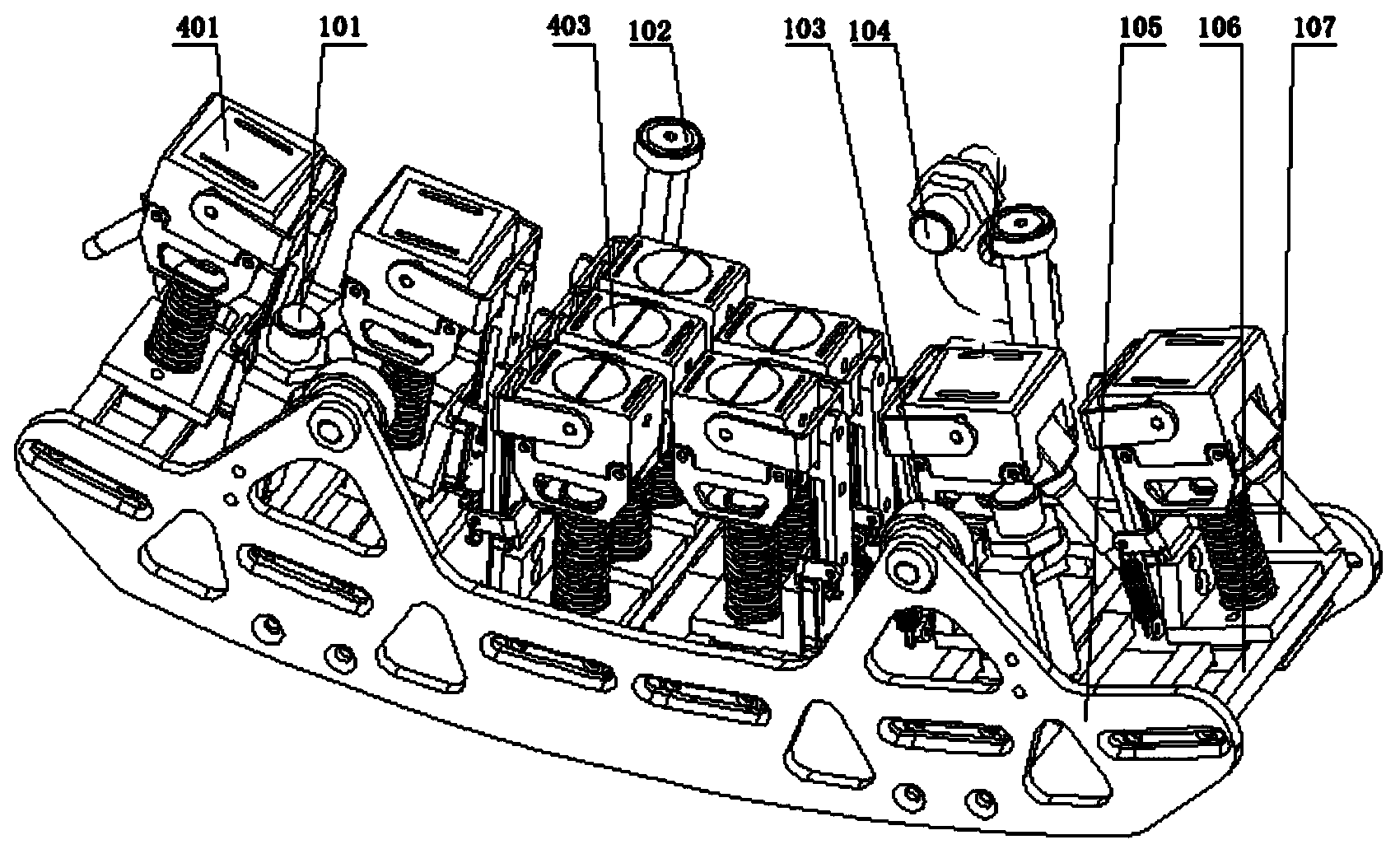

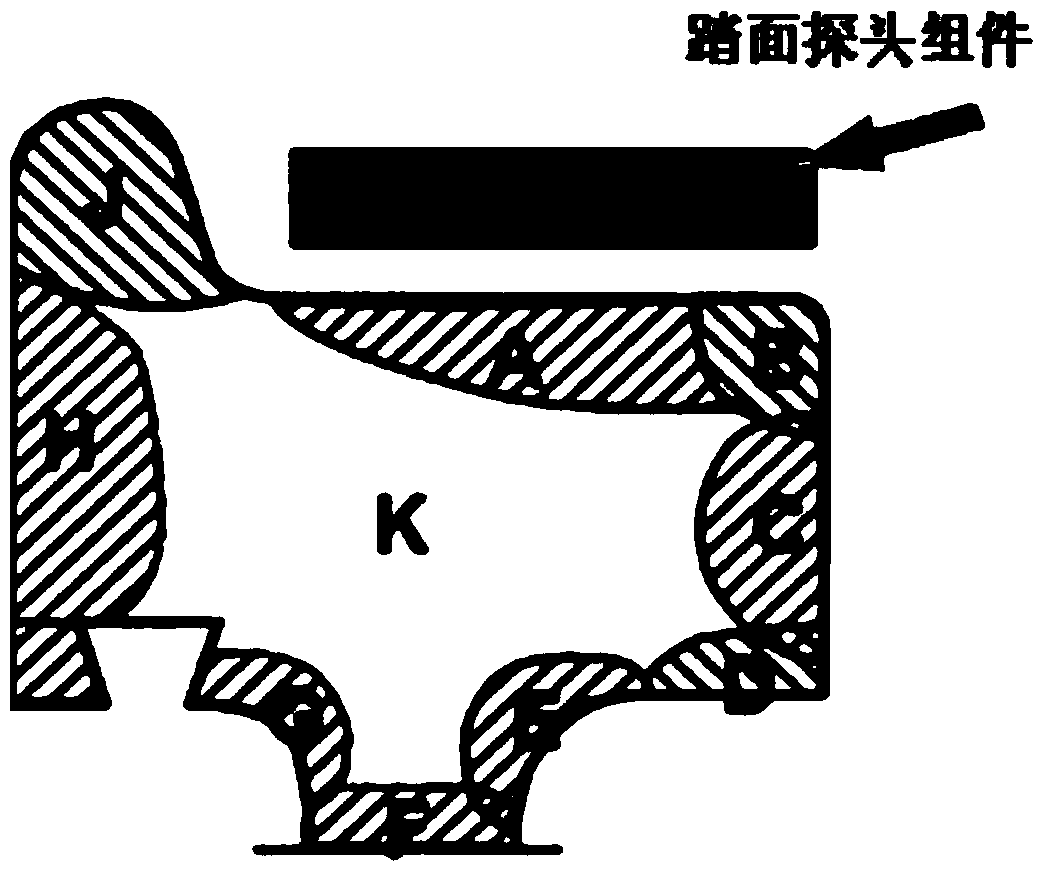

[0028] Such as figure 1 The shown is a rail vehicle wheel rim and tread flaw detection probe assembly system, which is the core component of ultrasonic wheel flaw detection equipment, and overcomes the defects of existing models. The basic idea of the scheme is that each wheel is equipped with a tread flaw detection probe assembly and a rim flaw detection probe assembly, the manipulator clamps the tread flaw detection probe assembly, cooperates with the rim flaw detection probe assembly, and continuously detects the same wheel at the same time. And the structure is optimized, so that the height of the probe components is low, and it is easy to overcome the obstacles at the bottom of the vehicle during the movement, so as to realize the compatibility of all models. The improved telescopic structure of the cage makes the telescopic cage more flexible and reliable. The coupling liquid spray structure is added, and the coupling liquid outlet is directly designed on the probe fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com