Patents

Literature

860results about How to "Flexible replacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

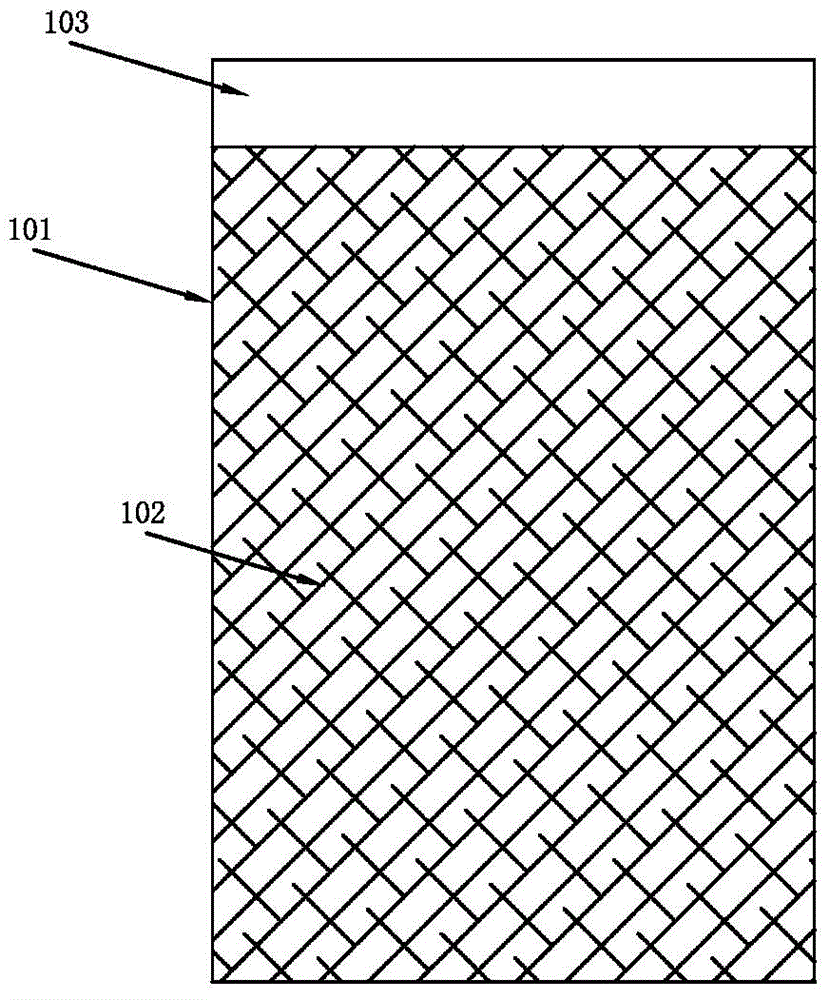

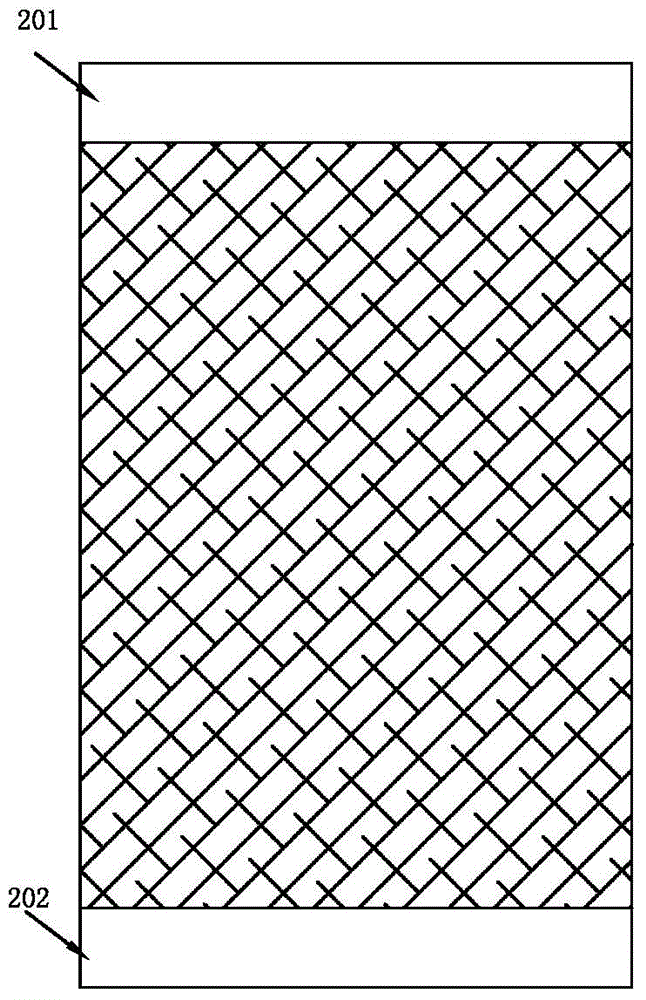

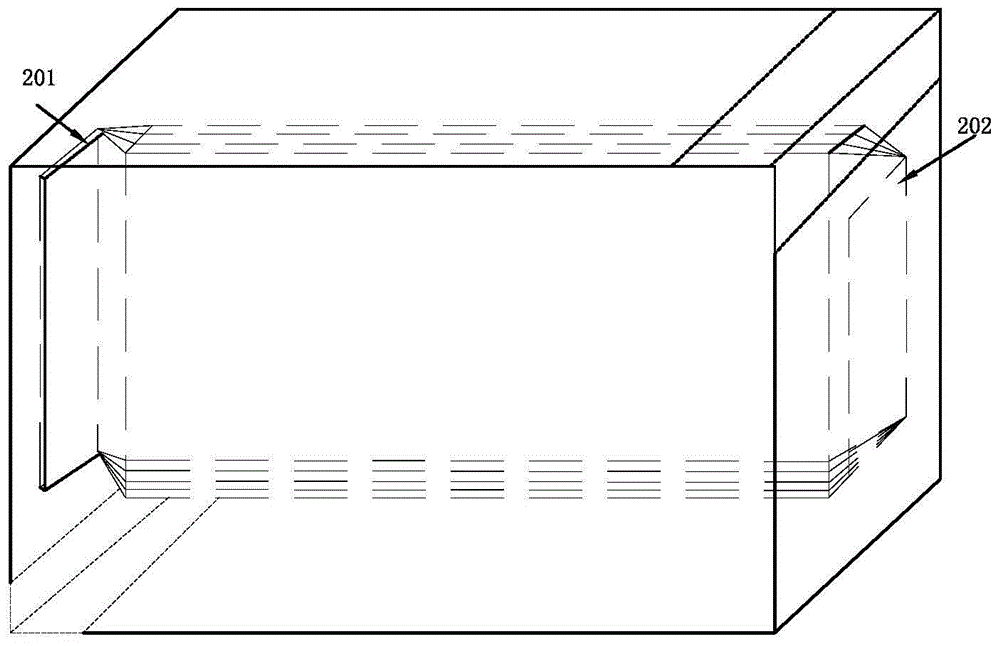

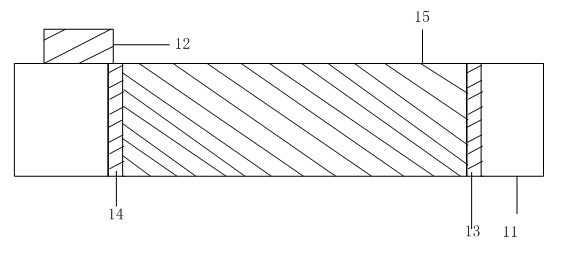

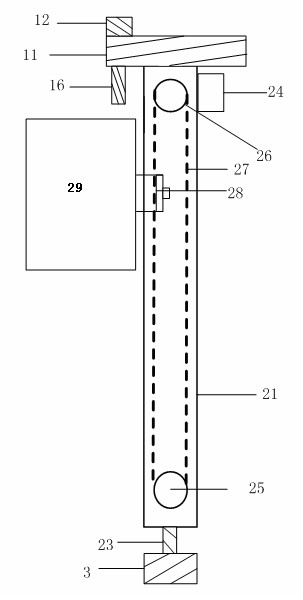

Laminated lithium ion battery, battery pack comprising same and pole piece of laminated lithium ion battery

InactiveCN104882635AImprove cooling effectReduce welding processFinal product manufactureElectrode carriers/collectorsInternal resistanceElectrical battery

Disclosed are a laminated lithium ion battery, a battery pack comprising the same and a pole piece of the laminated lithium ion battery. The pole piece comprises a current collector and an active material layer, wherein the current collector is coated with the active material layer. A section of continuous uncoated area is arranged at the tail end of a first width end portion of the pole piece, the top face and the bottom face of the uncoated area are not coated with the active material layer, the current collector is exposed in the uncoated area, and the exposed current collector serves as a pole lug of the pole piece. By the pole piece, internal resistance of the lithium ion battery is reduced and heat dissipation performance of the battery is improved.

Owner:SHENZHEN GREPOW BATTERY CO LTD

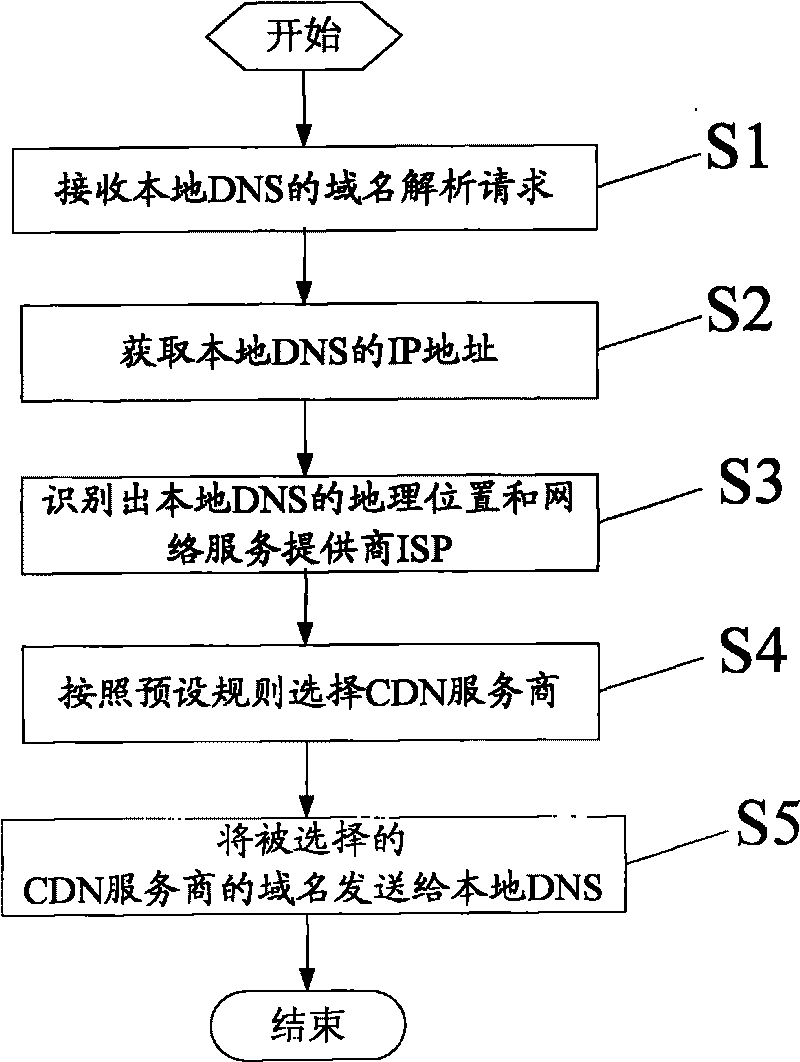

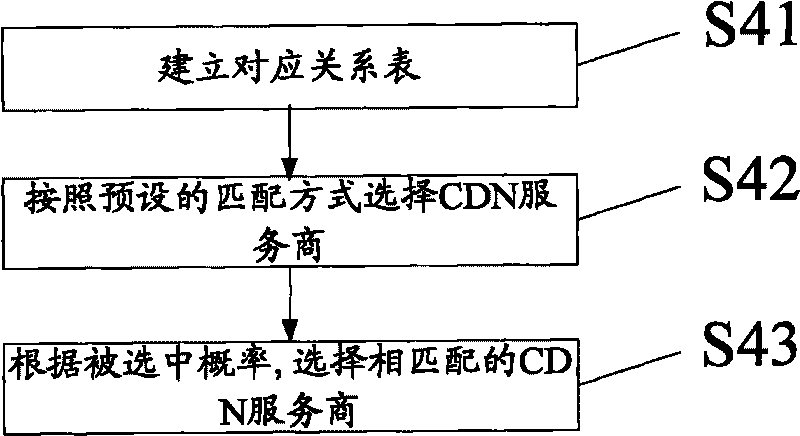

Intelligent dispatching method, device and system of content delivery network flow

The invention discloses an intelligent dispatching method, a device and a system of content delivery network flow. The intelligent dispatching method comprises: receiving a domain name resolution request which is sent by a local DNS through a subdomain which is provided by a website domain authority DNS; according to the domain name resolution request, obtaining the IP address of the local DNS; utilizing the IP address to indentify the geographic location of the local DNS and network service provider ISP information; according to the geographic location and the ISP information, selecting a CDN service provider on the basis of a preset rule; sending a domain corresponding to the name of the selected CDN service provider to the local DNS. The invention builds an intelligent dispatching center between the existing CDN network frame and an operator website; when accessing the network of the operator, a netizen selects a proper CDN service provider according to the preset rule. The invention ensures that the operator can flexibly replace the existing CDN service provider so as to lead the operator to obtain CDN service with better cost performance.

Owner:BEIJING 21VIANET DATA CENT

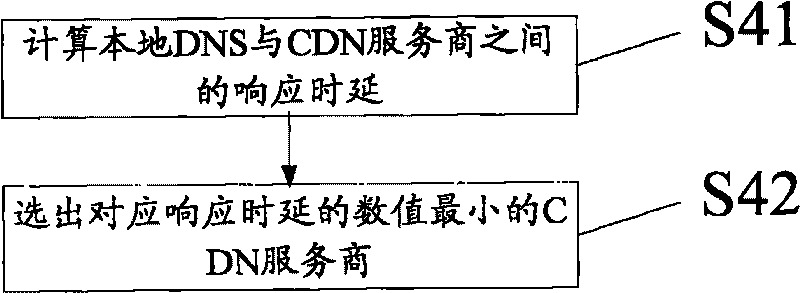

Wireless earphone establishing interaction with earphone box

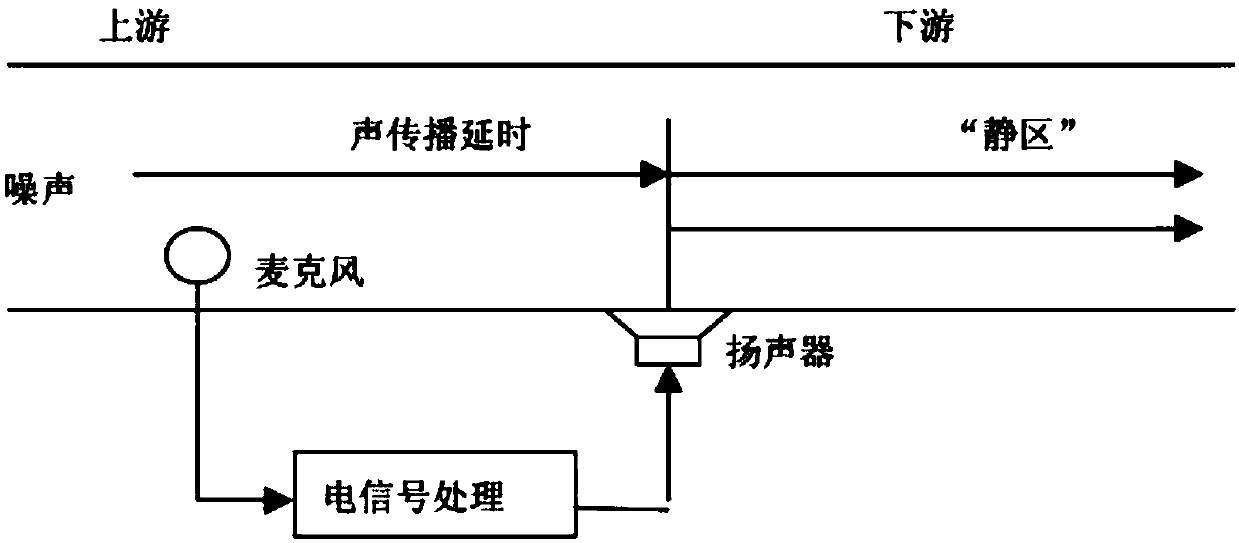

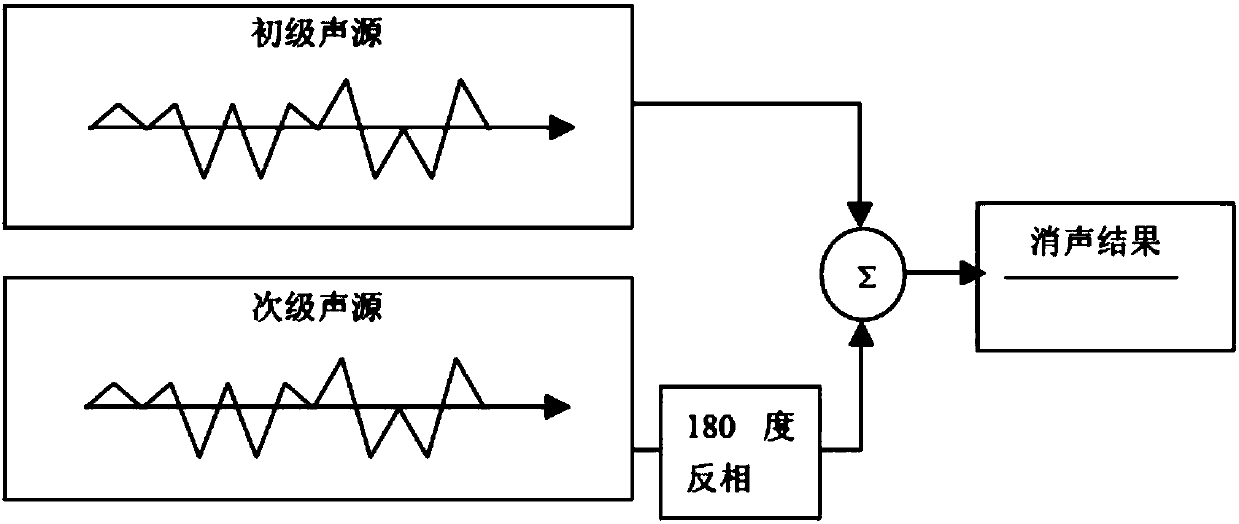

InactiveCN107809696AQuick responseThe system responds quicklyMicrophonesSignal processingLoudspeakerNoise-canceling microphone

The invention relates to a portable listening device, and particularly relates to a wireless earphone establishing interaction with an earphone box. The wireless earphone comprises a shell, a loudspeaker component, a noise reduction microphone, a call microphone, a rechargeable charging unit, an earphone sensor and an earphone processor, and the earphone sensor detects whether a cover of the earphone box is at a closed position or an open position according to a magnet on the cover of the earphone box; the earphone processor receives and marks a cover opening signal sent by the earphone sensorwhen detecting that the cover of the earphone box moves from the closed position to the open position, and transmits the cover opening signal to the box processor. According to the wireless earphone,the earphone sensor detects the cover opening condition of the earphone box and performs data interaction with the earphone box in real time.

Owner:成都必盛科技有限公司 +1

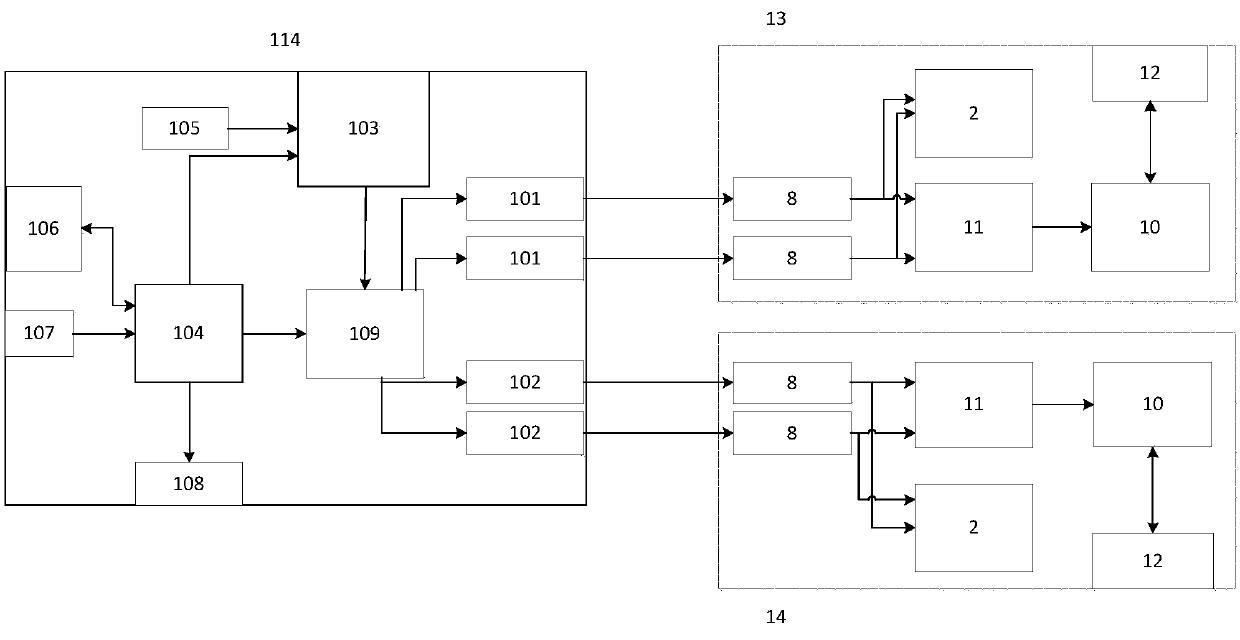

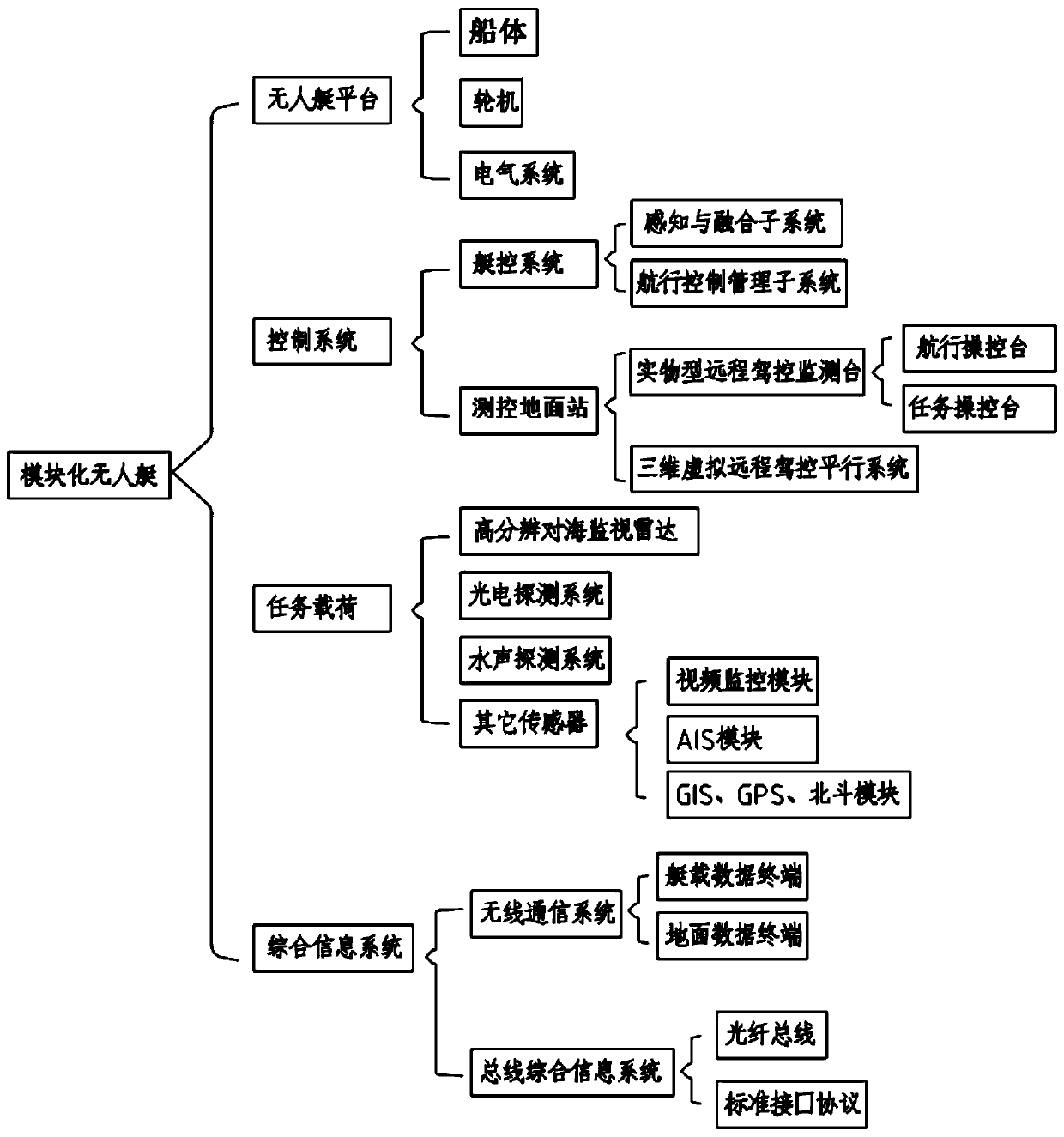

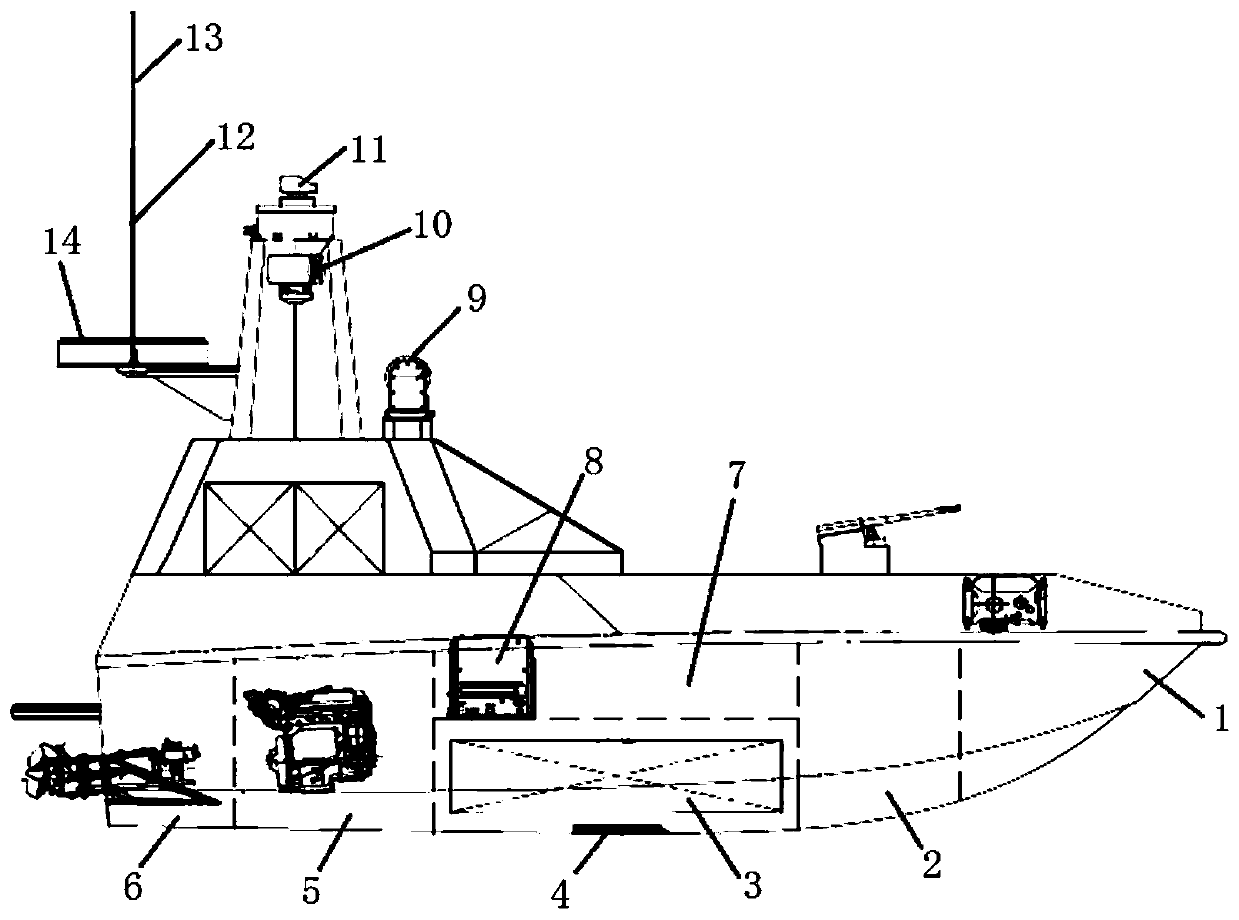

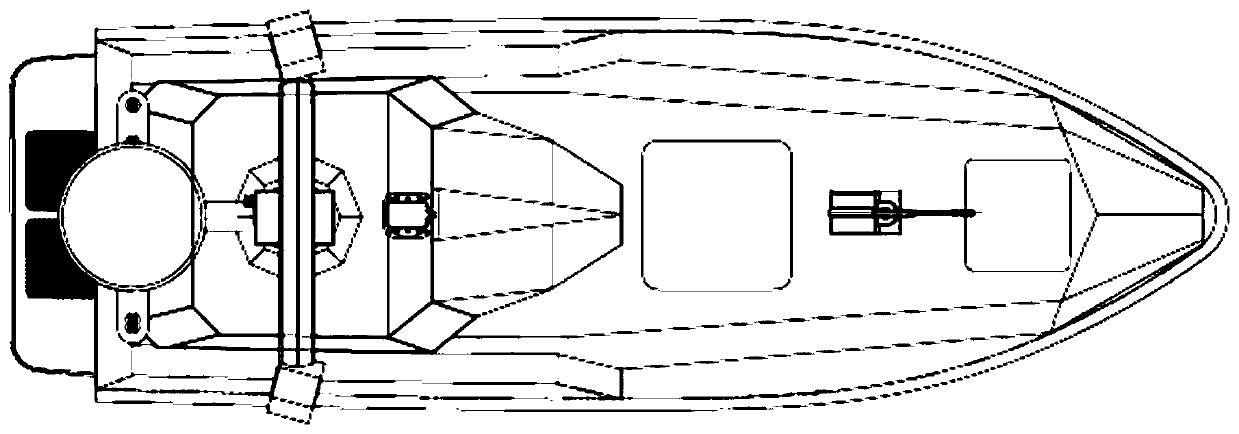

Modularized unmanned boat

InactiveCN110316327AHigh strengthIncreased durabilityNavigational aid arrangementsUnmanned surface vesselsModularityBus interface

The invention belongs to the technical field of unmanned boats and discloses a modularized unmanned boat. The modularized unmanned boat comprises an unmanned boat platform, the unmanned boat platformis provided with a control system, a task load and a comprehensive information system, and all the systems are connected together through an optical fiber bus; the unmanned boat platform is a main body of the modularized unmanned boat and comprises a hull, a marine engine and an electrical system, the marine engine comprises a propulsion mechanical device and a generator set, the marine engine andthe electrical system are installed on the hull, and the hull is sequentially provided with a watertight cabin, a water ballast cabin, a replenishing cabin, a cabin and a spraying pump cabin from thehead to the end. According to the unmanned boat in the invention, an open type system and a modular design are adopted, a unified universal boat body platform is adopted for various types of unmannedboats, an optical fiber bus structure is adopted between boat-loaded task equipment, a form of a standardized module structure and a universal bus interface is adopted for the task equipment, the task equipment is connected into a unified whole through an optical fiber bus, and the people are replaced by the modularized unmanned boat to execute tasks such as patrol protection, marine law enforcement, search rescue, water quality monitoring, hydrological geographic investigation and the like in a severe or dangerous environment.

Owner:SHANDONG CONGLIN MAIER ALUMINUM ALLOY STRUCTURAL ENG

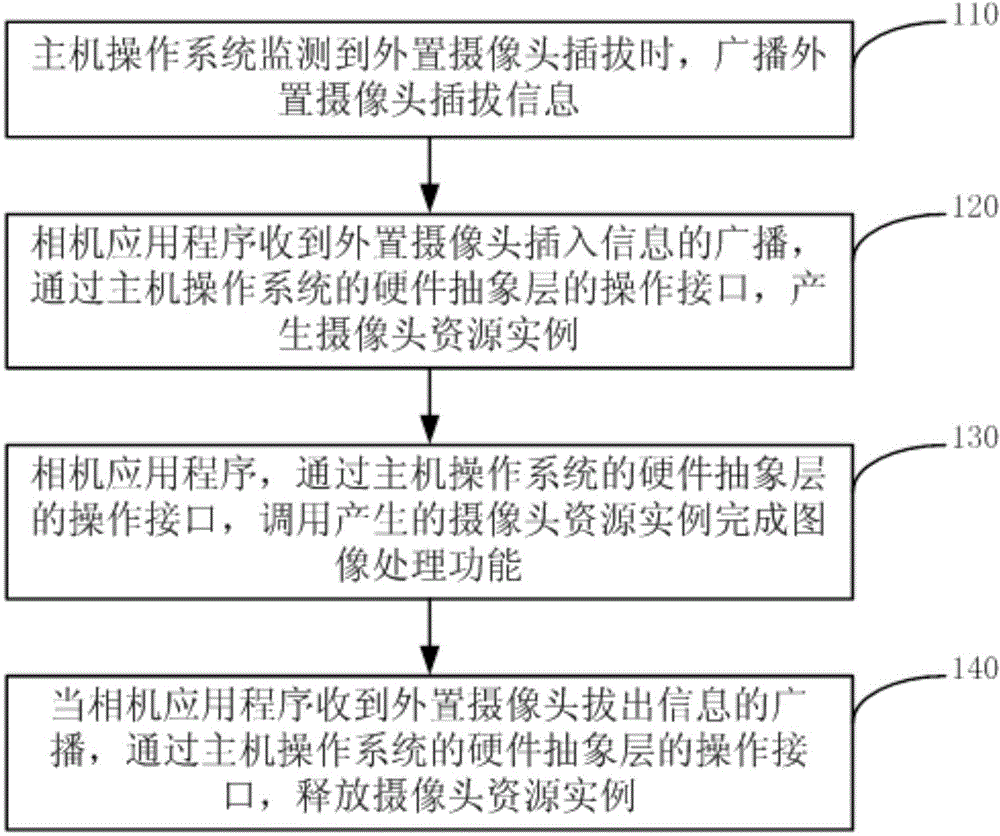

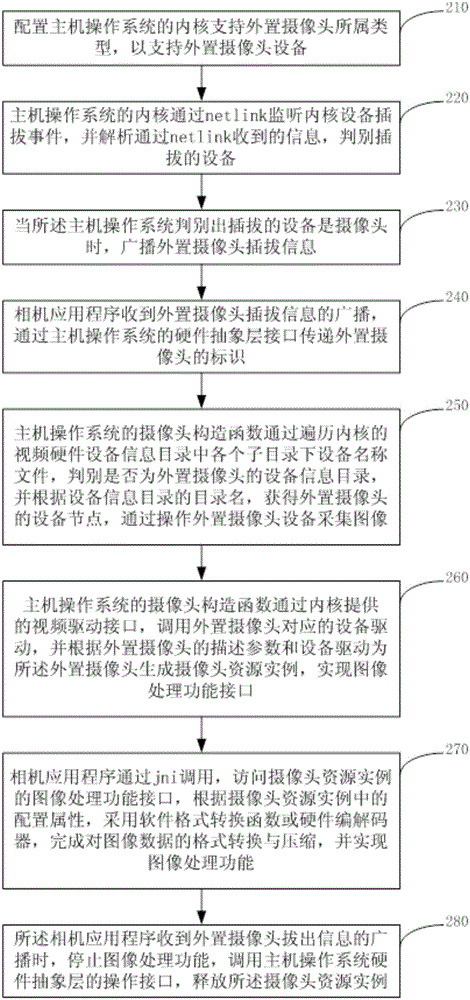

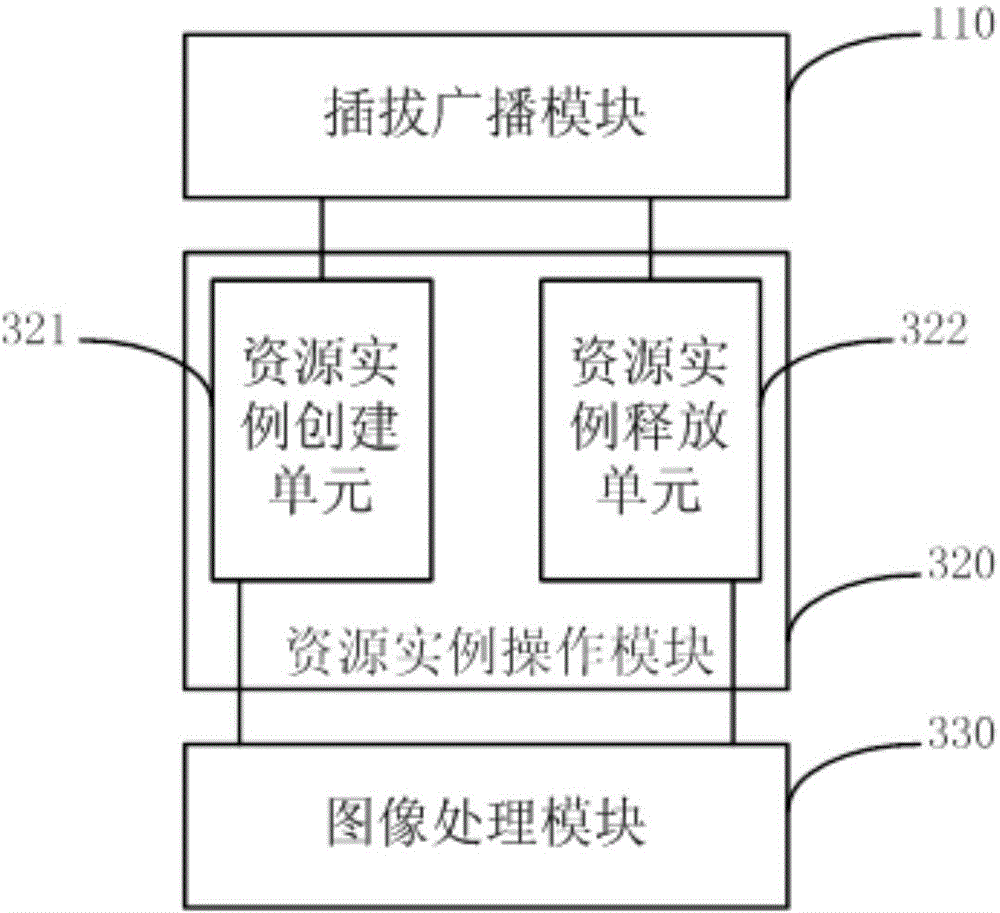

Realizing method and device for external camera of host, and mobile terminal

ActiveCN103559150AEasy to plug and unplugEasy to operateTelevision system detailsColor television detailsOperational systemImaging processing

The embodiment of the invention provides a realizing method and device for an external camera of a host, and a mobile terminal. The method comprises the steps of when a host operation system monitors the condition that the external camera is plugged or unplugged, broadcasting the plugging-unplugging information of the external camera; using a camera application program to receive the broadcasting of the plugging-unplugging information of the external camera, and generating or releasing a camera resource example by the operation interface of a hardware abstraction layer of the host operation system; enabling the camera application program to call the generated camera resource example by the operation interface of the hardware abstraction layer of the host operation system so as to finish an image processing function. The source example of the external camera is realized by software, so the external camera is virtualized to the internal camera of the host, and further the processing function for an image collected by the external camera is realized. As the external camera can be conveniently plugged on or unplugged from the host, so the operation is flexible and convenient, and no extra hardware and software improvement is needed, and the realizing cost is low.

Owner:AUTEL INTELLIGENT TECHNOLOGY CORP LTD

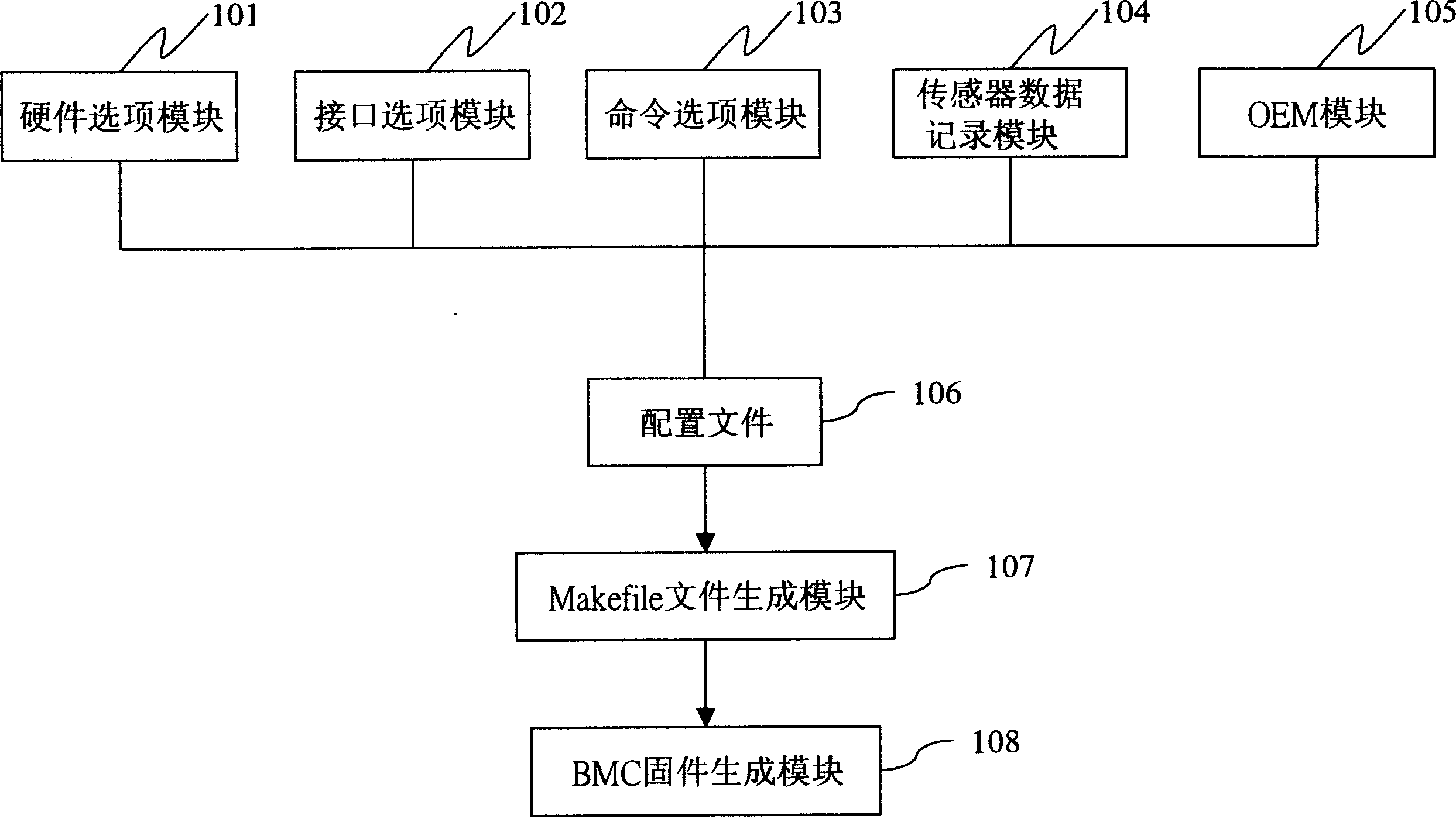

Firmware automatic configuration system and method for substrate management controller

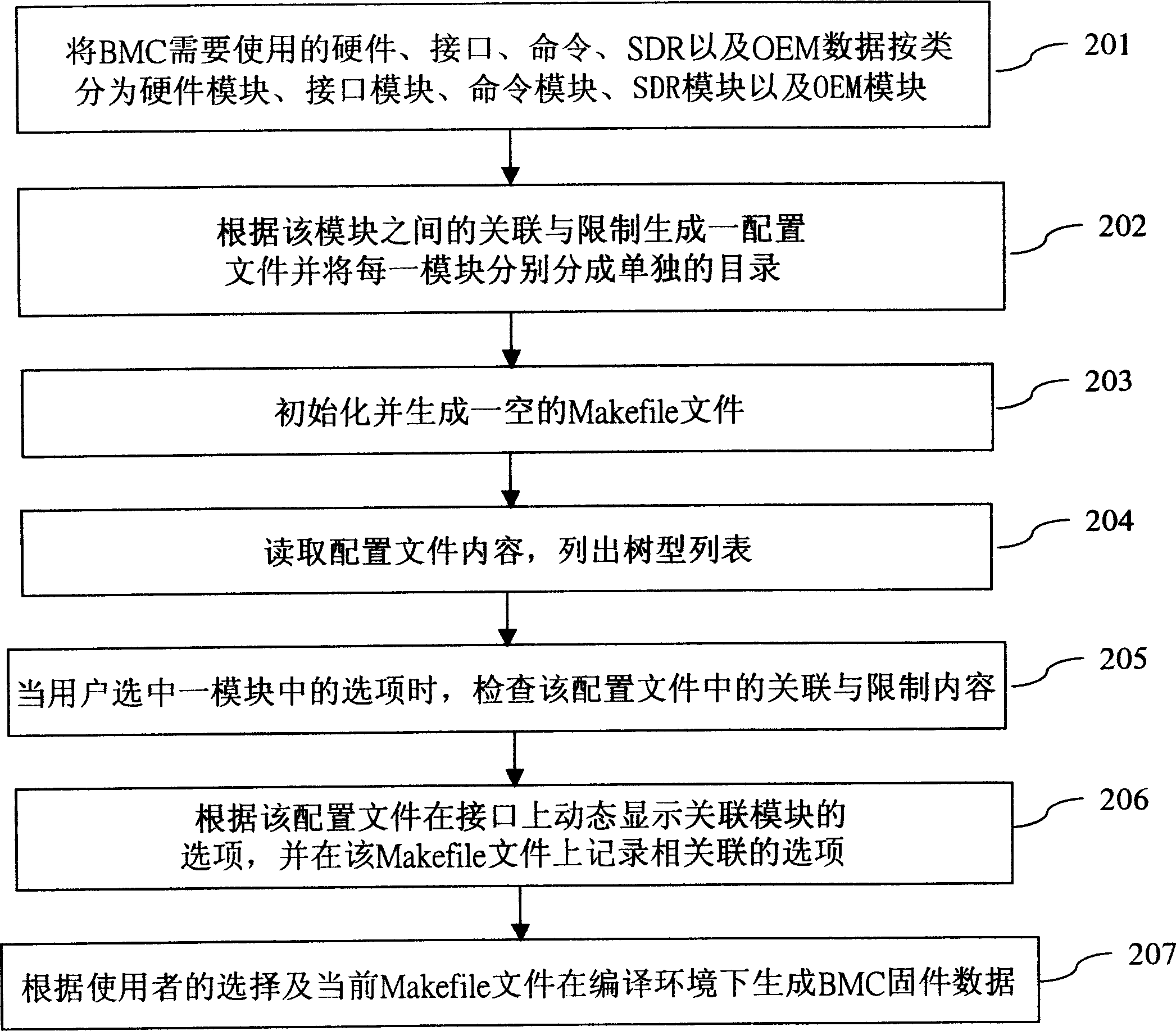

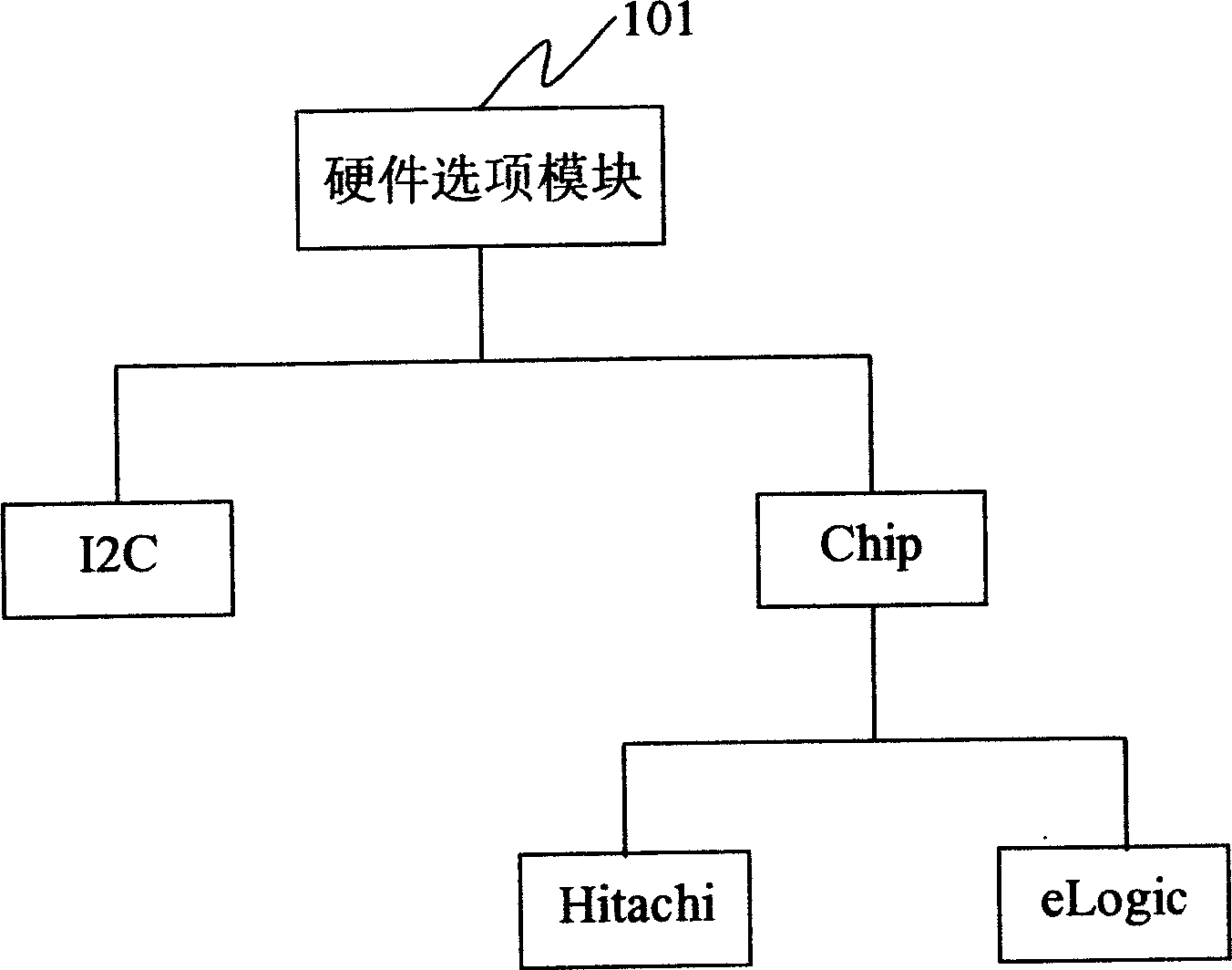

InactiveCN1641568AFlexible replacementFlexible managementSpecial data processing applicationsSpecific program execution arrangementsBaseboardMakefile

The invention discloses a firmware automatic configuration system of baseboard managing controller. It packages the hardware module, interface module, command module, SDR module and OEM module according to species. Then, a configuration file would be created and separated catalog of every module would be gained. A Makefile would be created after initializing. Reading content of the configuration file, when user chooses an option in a module, checking the configuration file and dynamic display the option of the relate module on the interface and register the relative option on the Makefile. Finally, BMC firmware data would be created and automatically finish the configuration of BMC firmware according to the invention.

Owner:INVENTEC CORP

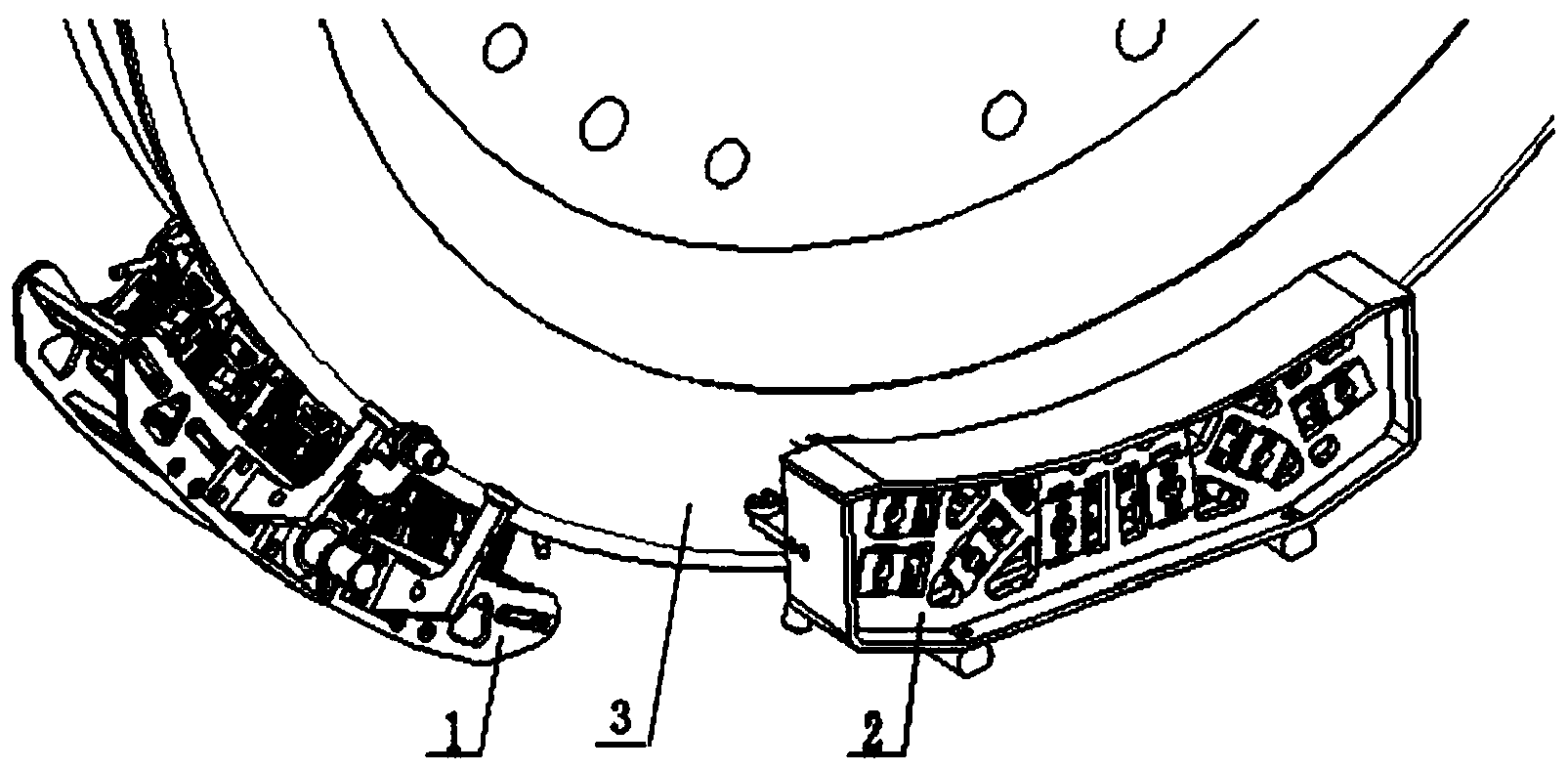

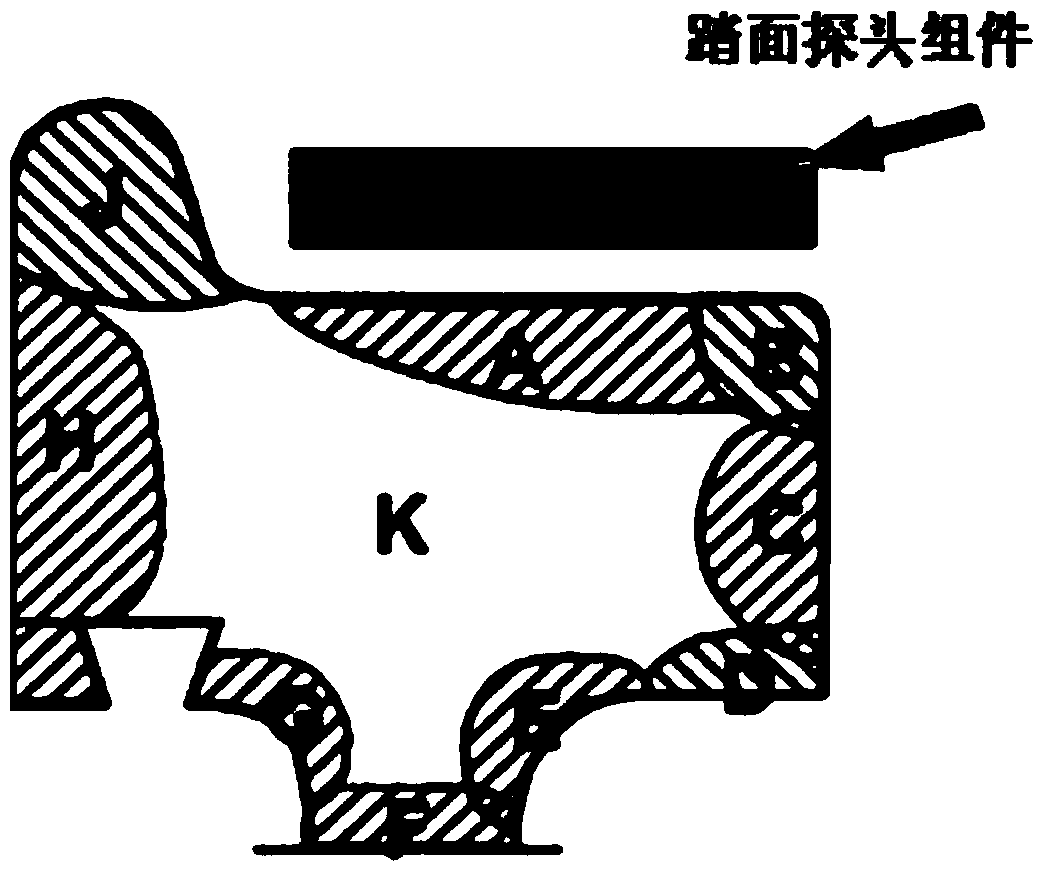

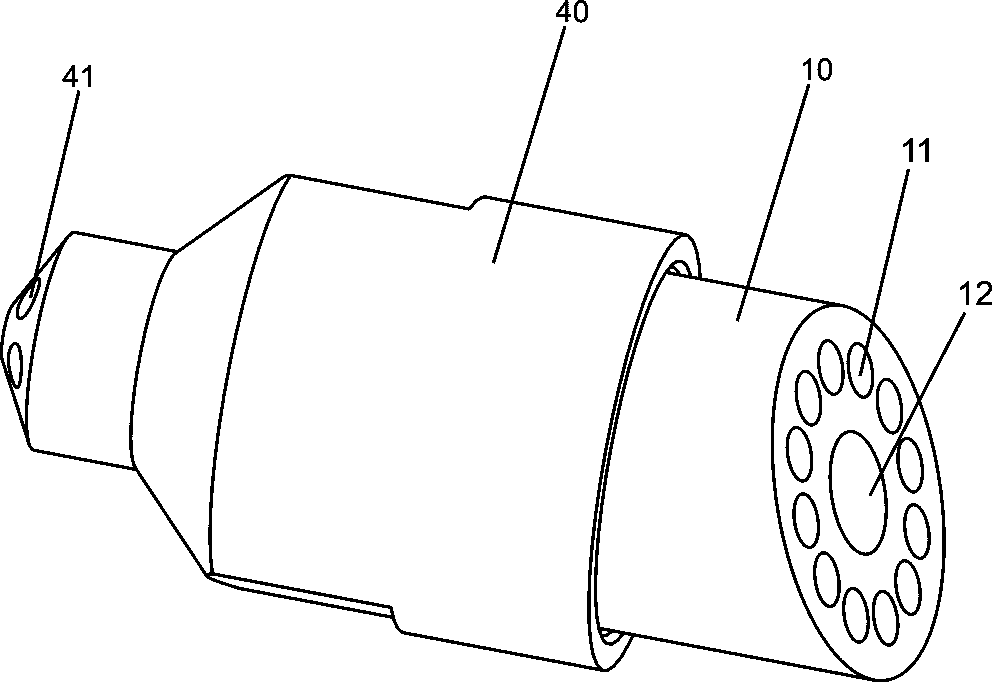

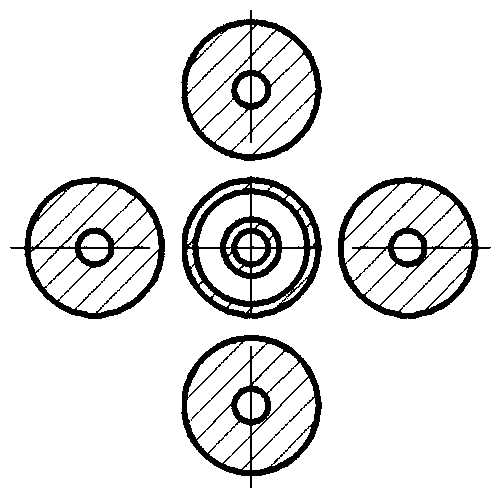

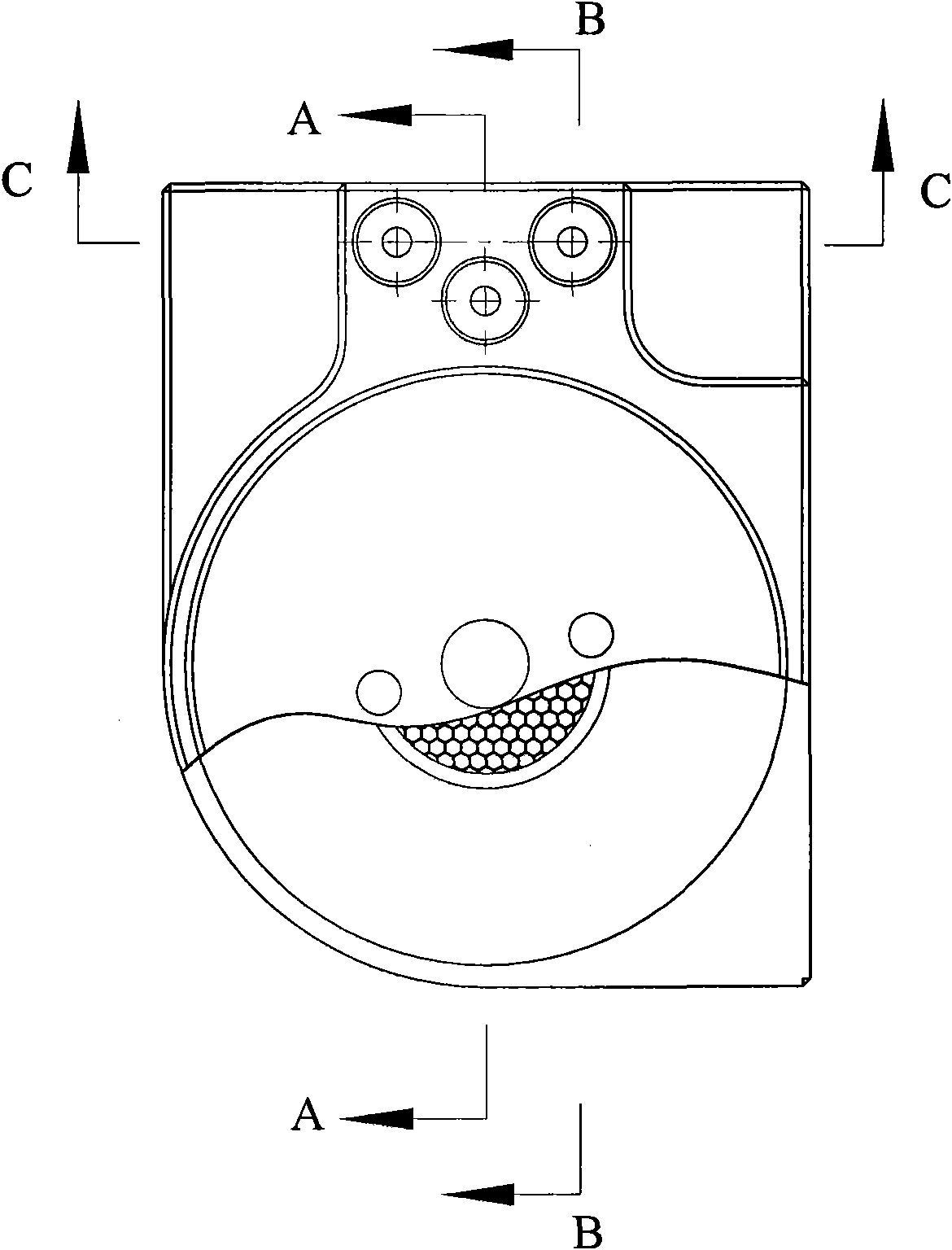

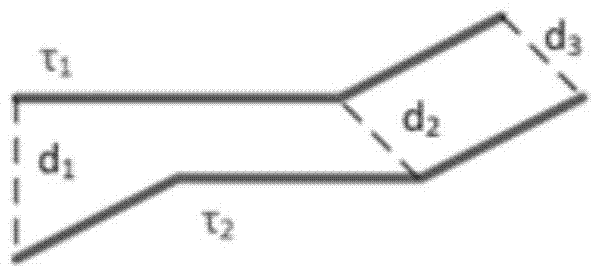

Track vehicle rim and tread flaw detection probe assembly system

ActiveCN103472138AEasy to useProtect the safety of useMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringManipulator

The invention discloses a track vehicle rim and tread flaw detection probe assembly system. The track vehicle rim and tread flaw detection probe assembly system comprises a tread flaw detection probe assembly and a rim flaw detection probe assembly. The tread flaw detection probe assembly leans on the tread of a wheel through a mechanical arm; the rim flaw detection probe assembly leans on the rim surface of the wheel through the mechanical arm; the tread flaw detection probe assembly can automatically detect wheel tread and rim defects from the tread in an online mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate; the rim flaw detection probe assembly can automatically detect wheel rim surface and tread detects from the inner lateral side of the rim in on online-mode and is high in detection efficiency, accurate in detection result, simple in structure and convenient to use and operate.

Owner:BEIJING SHEENLINE GRP CO LTD

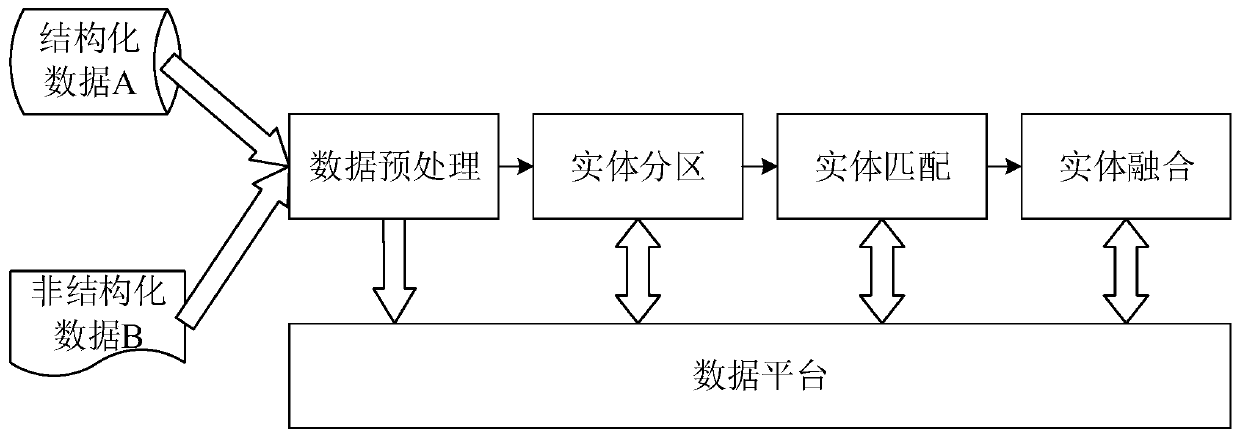

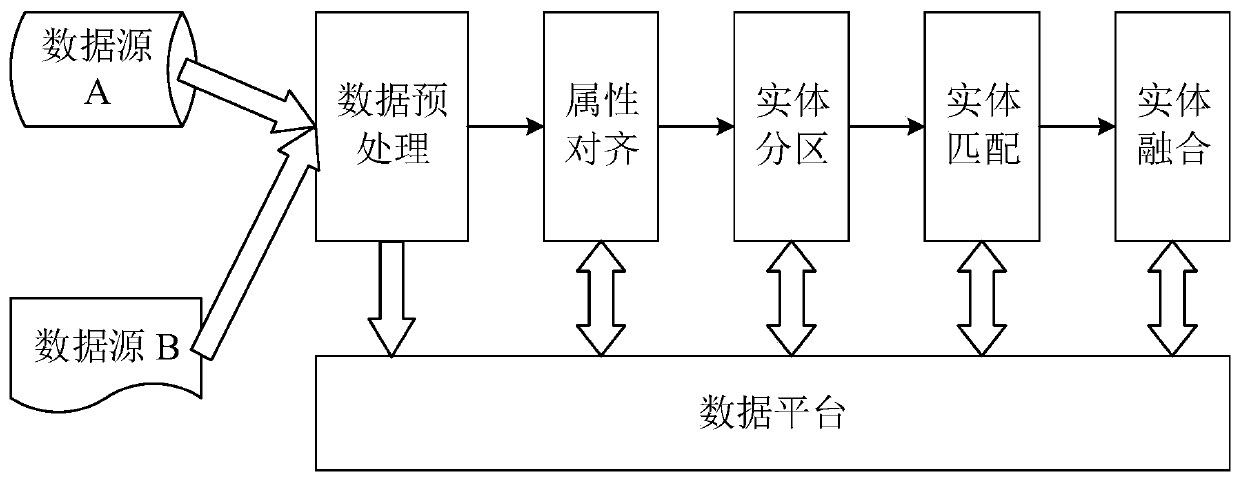

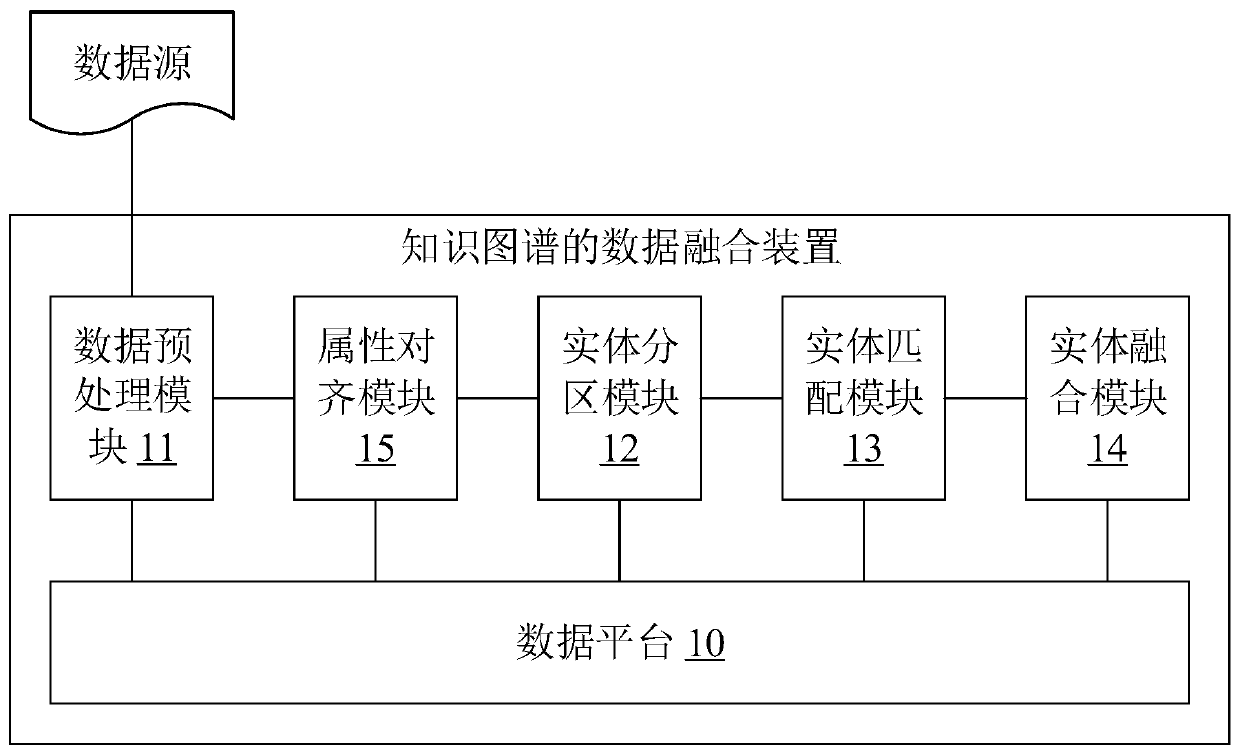

A data fusion method and device for a knowledge graph

PendingCN109739939AFlexible replacementIncrease computing resourcesDatabase modelsSpecial data processing applicationsData platformData source

The invention provides a data fusion method and device for a knowledge graph. The system for executing the method comprises a data platform configured with a unified access interface, and the method comprises the following steps: processing data from different data sources, converting the processed data into a triple format, storing the processed data into the data platform through the unified access interface, and receiving graph data index information returned by the data platform; according to the graph data index information, dividing an entity stored in the data platform into one or moresub-partitions according to attributes; performing similarity calculation on the candidate entity pairs divided into the same sub-partition, and screening out matched entity pairs meeting a preset similarity condition; and supplementing and / or replacing the entity attribute values of the matched entity pairs to generate a unified entity representation. By means of the method, the problem that an existing data fusion technology cannot flexibly adapt to data fusion of different knowledge bases can be effectively solved.

Owner:YINGTOU INFORMATION & TECH SHANGHAI CO LTD

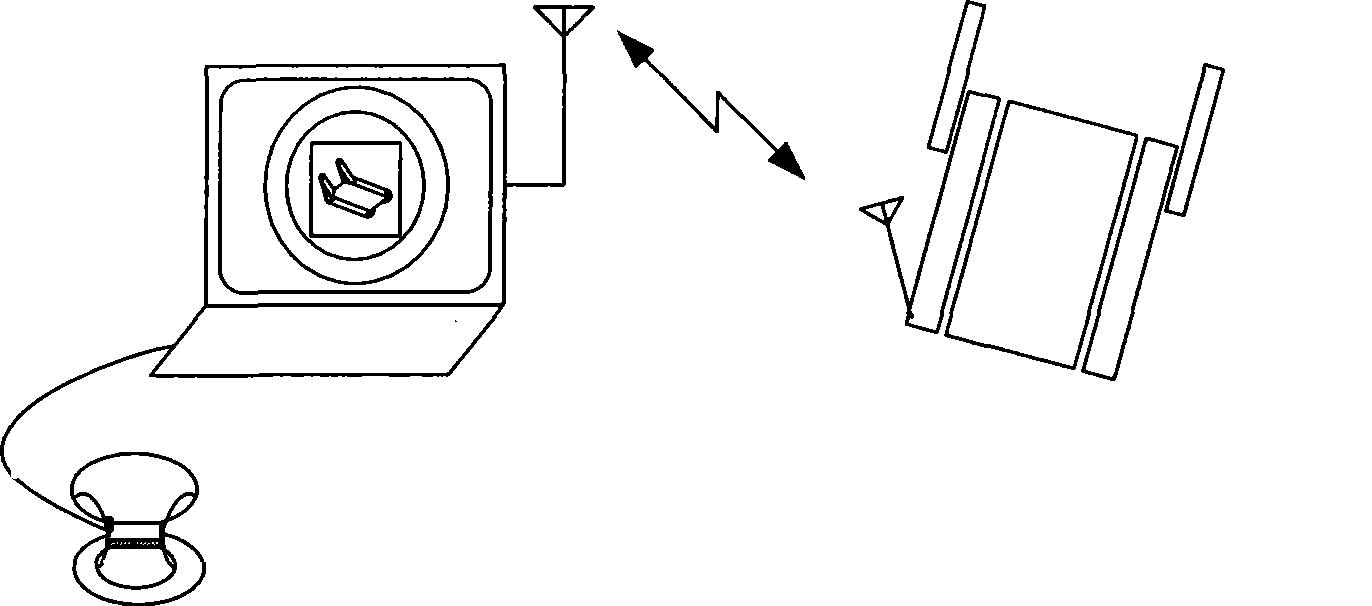

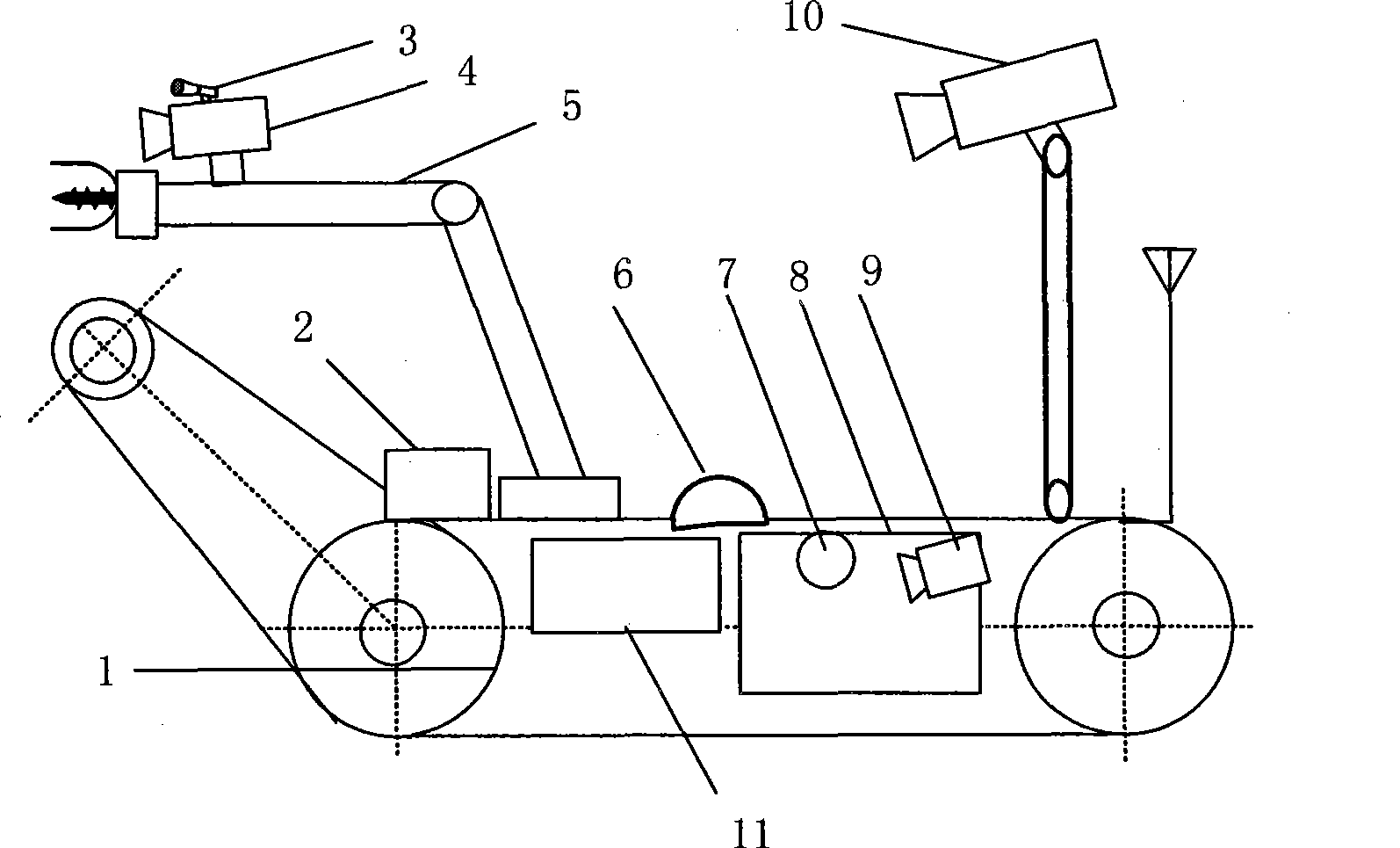

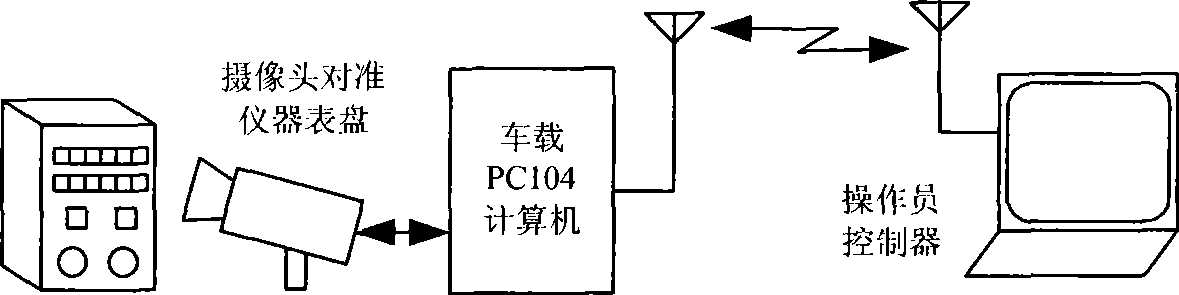

Nuclear pollution detecting method based on remote operating mobile robot

InactiveCN101377547AFlexible searchEasy to findChemical methods analysisRadiation intensity measurementWireless controlWireless transmission

The invention provides a method for testing nuclear pollution and chemical pollution with a remote-controlled movable robot, which aims at the problem of automatic testing under the circumstances of nuclear pollution and chemical pollution. The invention has the following main points: a remote-controlled robot enters a polluted site under the remote wireless control by the operator and transmits the information of an accident site back to a local operation platform through wireless transmission; the movable robot is provided with a nuclear detector and an instrument cabinet; a chemical gas detector, a camera and an illuminating lamp are arranged in the instrument cabinet, and a camera captures the images of the indication panel of a chemical gas detector and transmits the images back to the local operation platform; the pollution source is removed or sampled by mechanical arms after being found; and the movable robot is provided with a GPS navigator to position the pollution source. The invention has the advantages of zero casualty, flexible replacement of instruments in the instrument cabinet and the like, and can be used in highly dangerous accident sites with nuclear pollution and chemical leakage, which can not be detected with normal means.

Owner:江苏亚星波纹管有限公司 +1

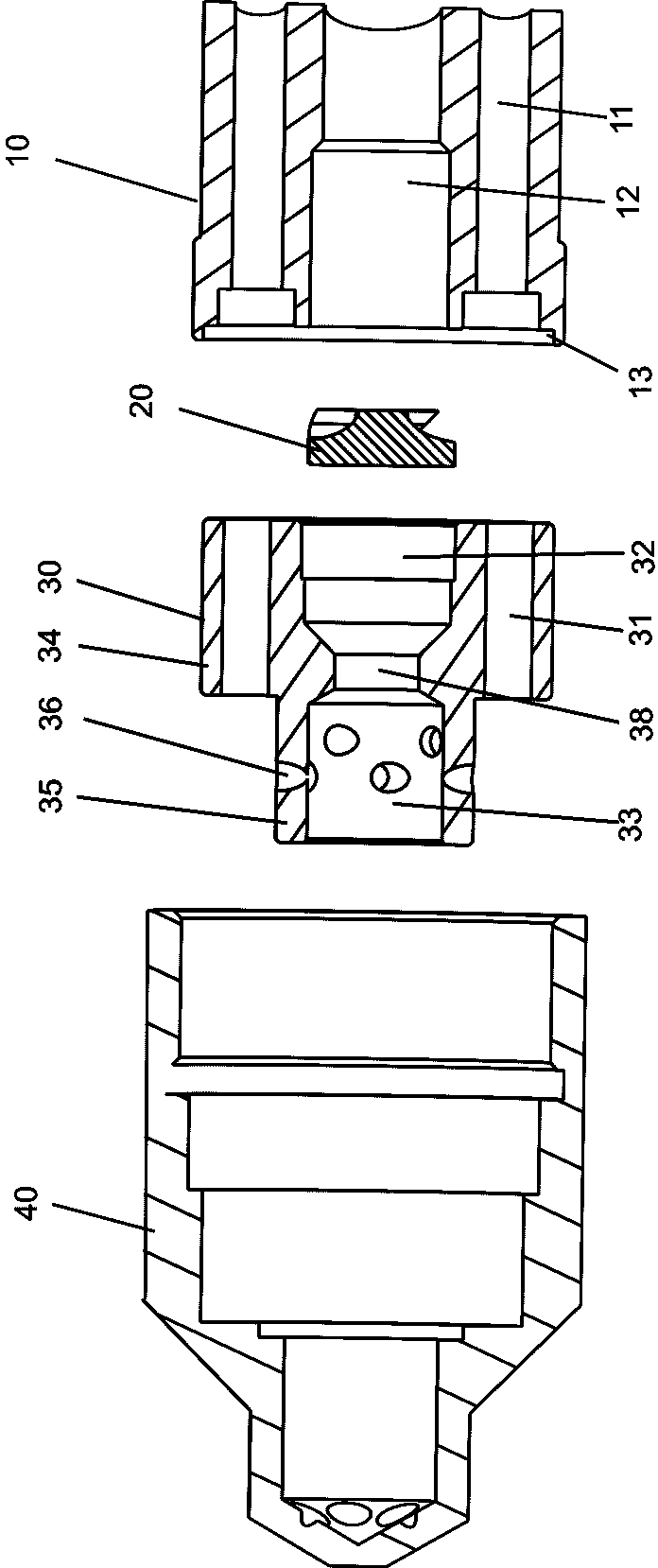

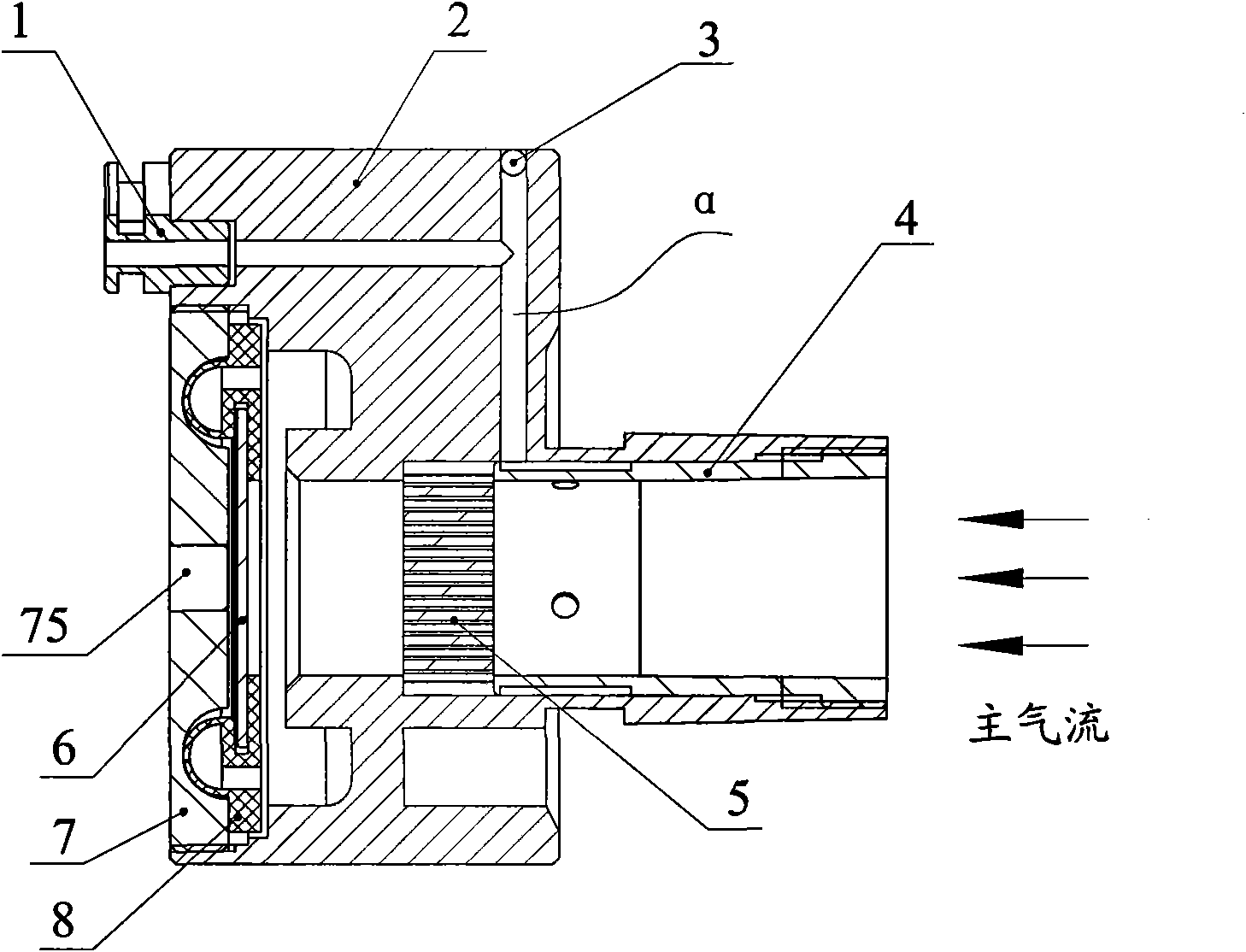

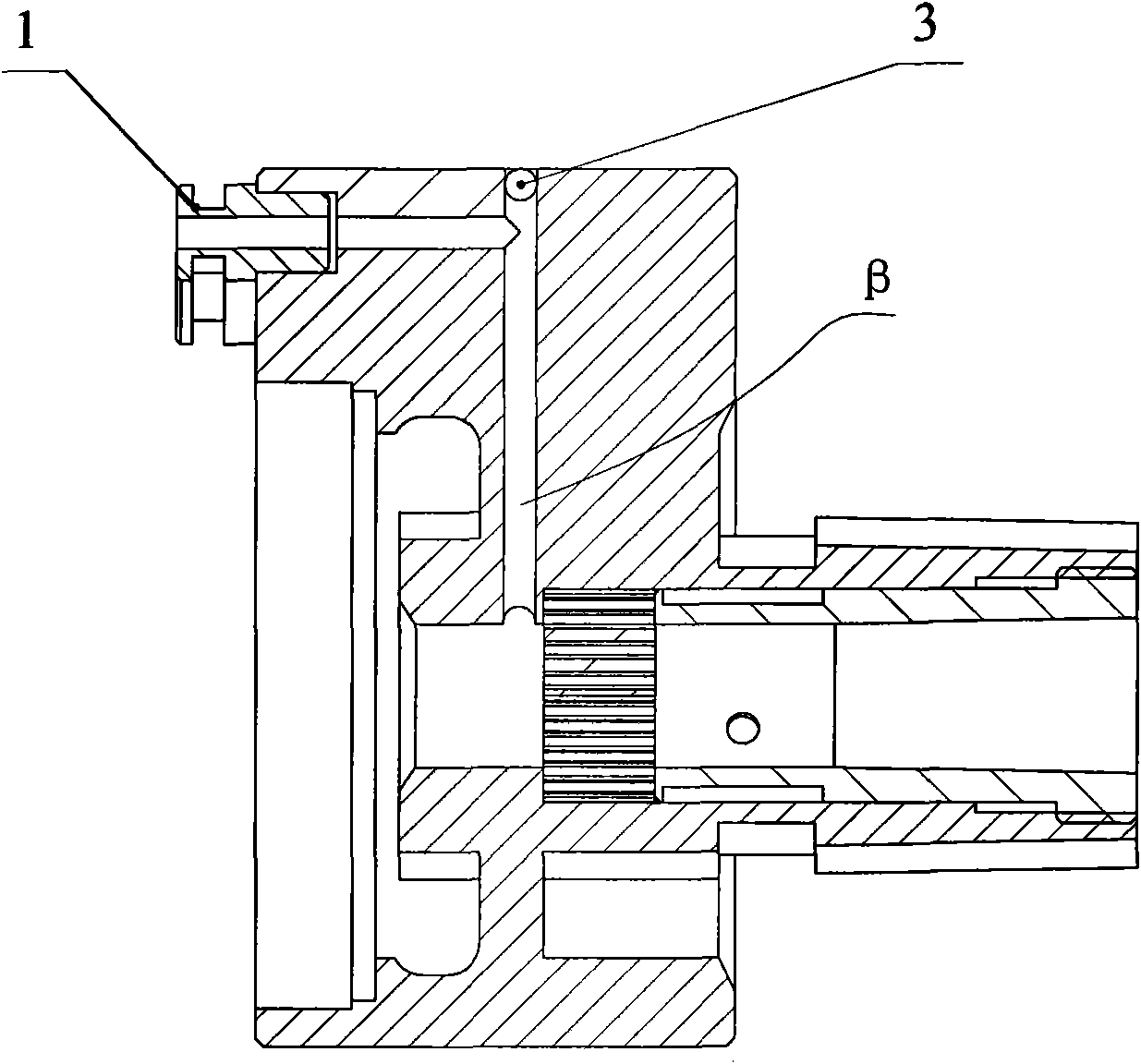

Two-fluid atomization nozzle

ActiveCN104384037AEnsure atomization rateFlexible disassemblyLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a two-fluid atomization nozzle which comprises a fluid joint, a liquid spinning disk, a two-fluid atomization cavity and a sprayer, wherein the sprayer is internally provided with a hollow cavity; one end of the hollow cavity is provided with an opening and the other end of the hollow cavity is provided with spray holes; the two-fluid atomization cavity, the liquid spinning disk and the fluid joint are sequentially assembled towards the opening in the hollow cavity; the two-fluid atomization cavity is internally provided with a first gas runner and a first liquid runner; an atomization cavity is formed at the junction of the first gas runner and the first liquid runner and is communicated with the spray holes; the liquid spinning disk is arranged at the liquid inlet end of the first liquid runner; the liquid joint is internally provided with a second gas runner and a second liquid runner. Therefore, the two-fluid atomization nozzle is formed by detachably assembling multiple split components, so that the replaceability of local atomization components is realized and the maintenance and replacement costs are lowered; furthermore, the two-fluid atomization nozzle can well ensure the high atomization rate and atomization degree of liquids.

Owner:YICHUAN TECH CHENGDU CO LTD

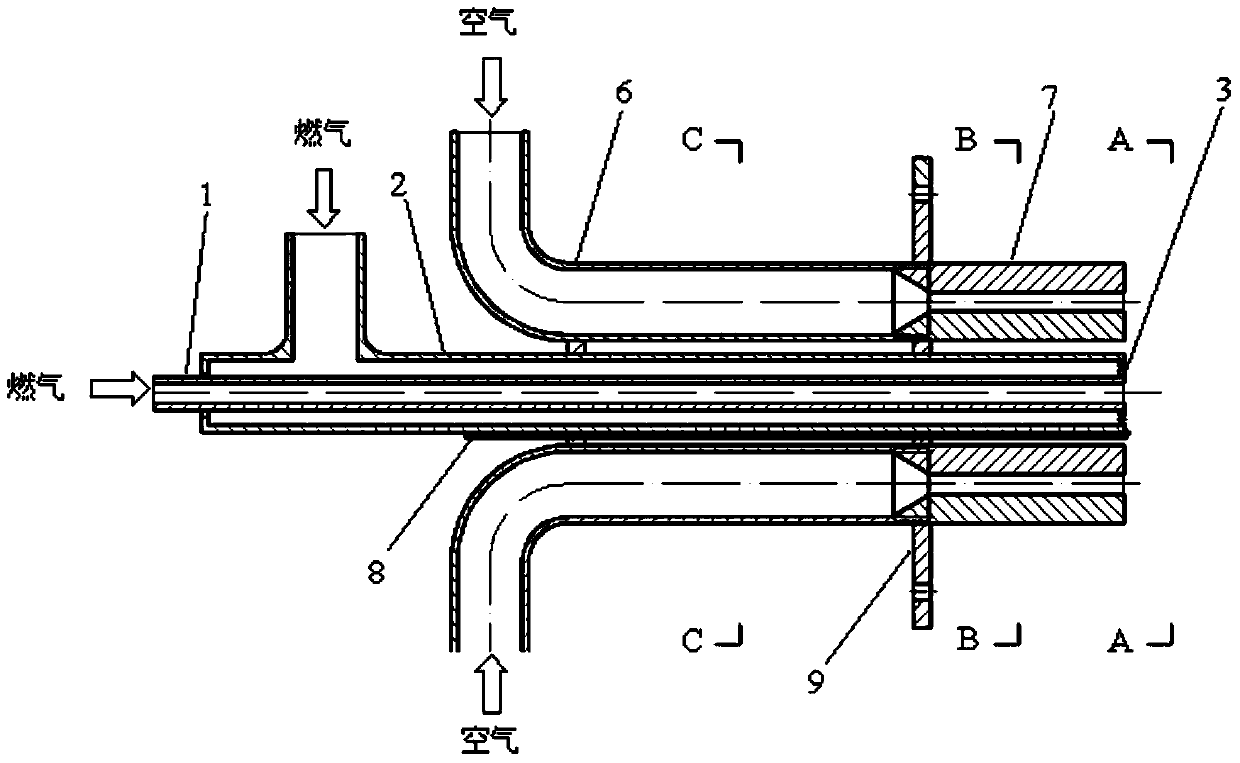

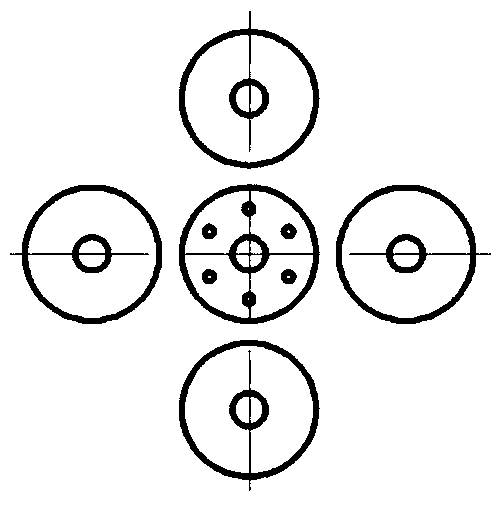

Direct-injection gas burner without flame

InactiveCN103742913AVersatilityEasy to disassembleIndirect carbon-dioxide mitigationGaseous fuel burnerEngineeringFuel gas

The invention relates to a direct-injection gas burner without flame. The burner comprises an inner gas pipe which is arranged horizontally, an outer gas pipe which is sleeved at the outer part of the inner gas pipe in a coaxial way, gas nozzles which are arranged at the outlet ends of the inner gas pipe and the outer gas pipe, a plurality of air pipes which are arranged at the periphery of the outer gas pipe, a plurality of air nozzles which are respectively arranged at the outlet end of each of the air pipes, and an igniting needle which is arranged on one side of the outer gas pipe in parallel, wherein an annular hollow is formed between the inner gas pipe and the outer gas pipe, a center fire hole which is communicated with the inner gas pipe is formed in the center of the gas nozzle, the periphery of the center fire hole is provided with a plurality of peripheral fire holes which are communicated with the center fire hole, and the tail part of the igniting needle is close to the gas nozzle. The burner is in a simple structure and does not need preheating of the air. A stirring reactor and a heat accumulator are arranged in the burner, and therefore the flameless burning in a furnace can be realized.

Owner:PEKING UNIV

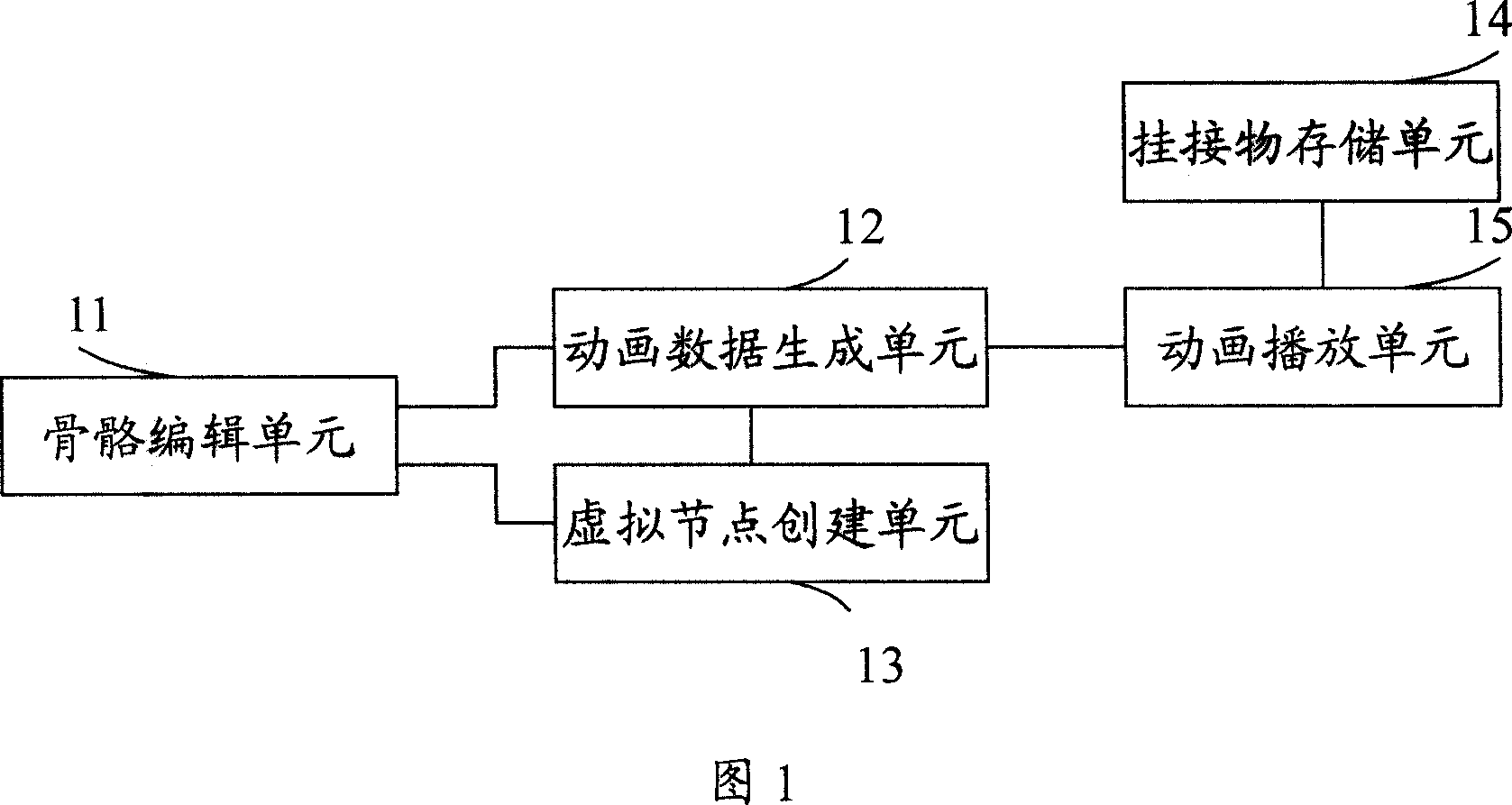

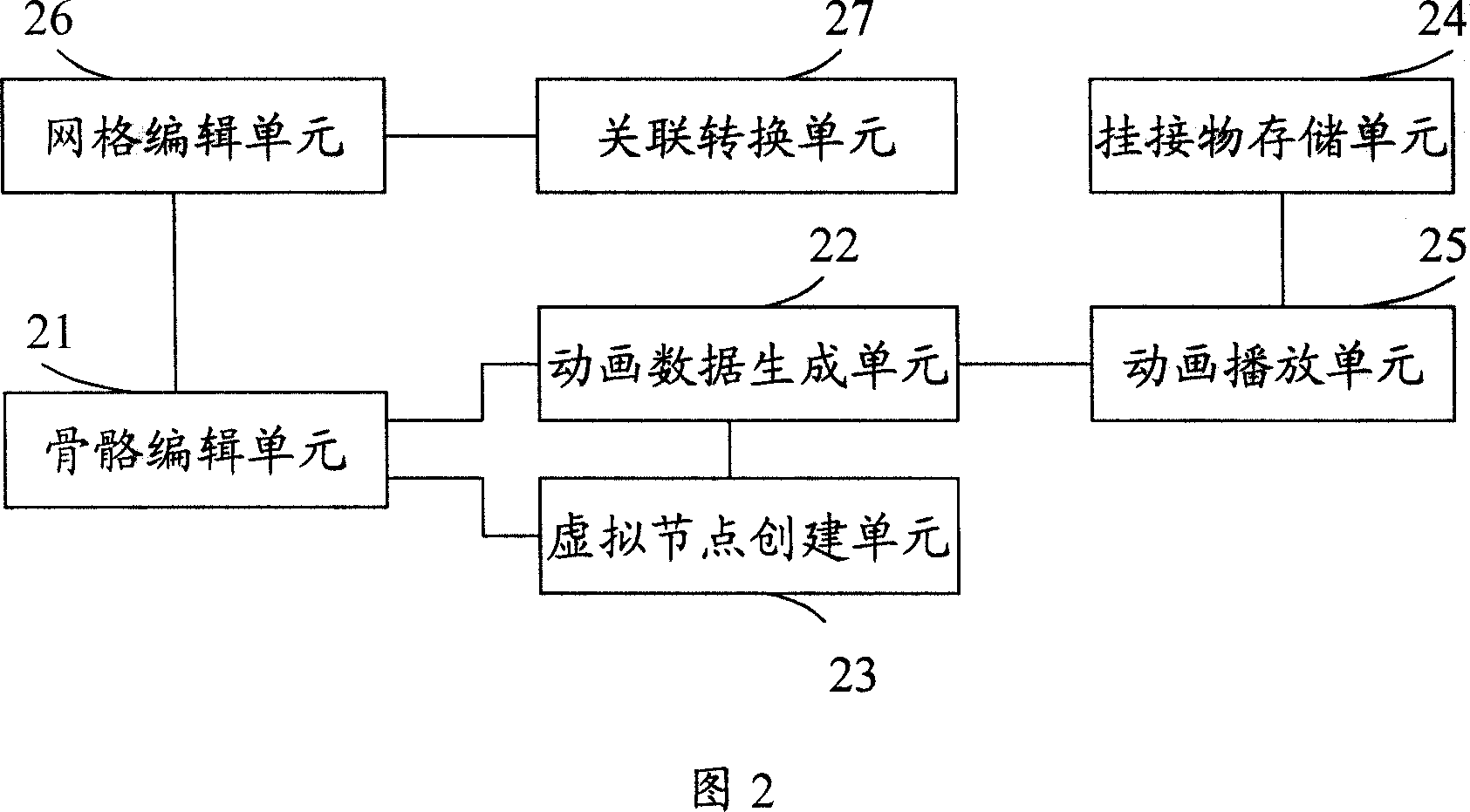

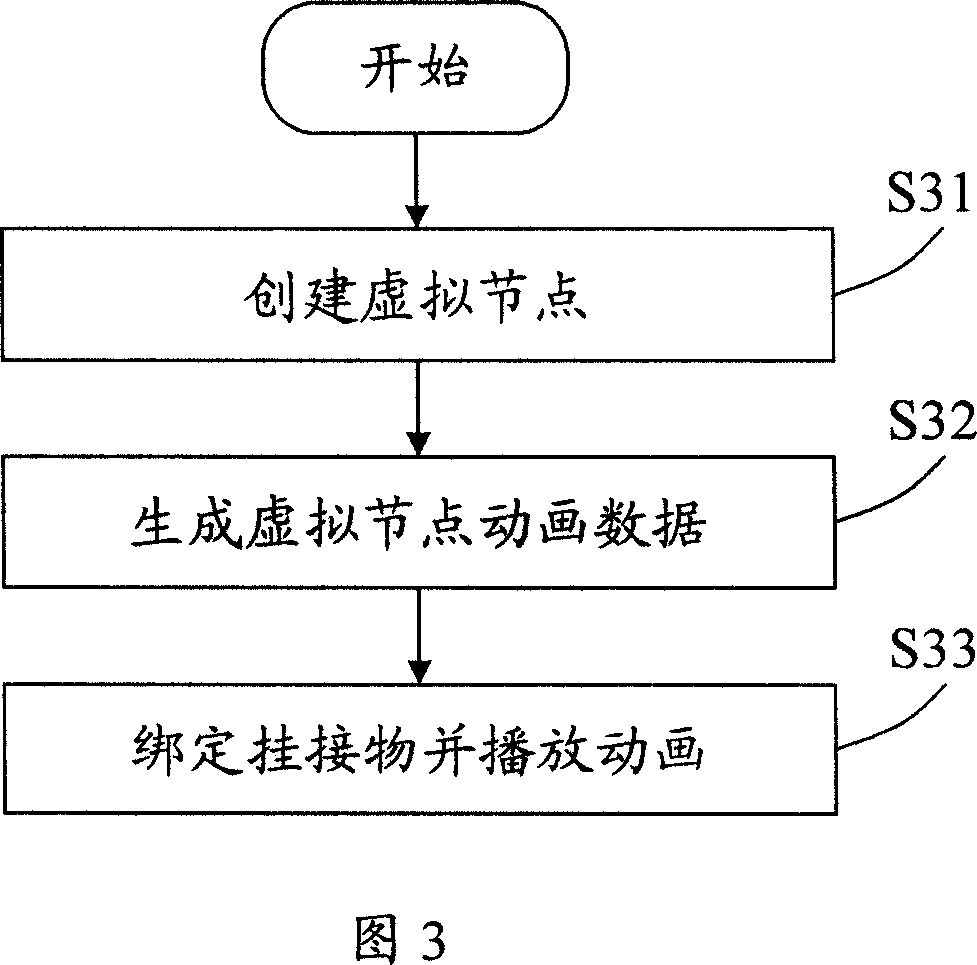

Role animation realization method and system

ActiveCN101079154AImprove reusabilityFlexible replacementAlkaline accumulatorsCell lids/coversAnimationWorld Wide Web

The invention discloses a role cartoon achieving method, which comprises the following steps: (a) establishing one or a plurality of virtual nodes and tying up every virtual code and a role skeleton data; (b) generating the cartoon data of the virtual code according to the cartoon data of the tied role skeleton; (c) tying up the articulated object cartoon data to the cartoon data of the virtual code and playing the articulated object cartoon. The invention also provides a corresponding role cartoon achieving system. The invention makes the skeleton data, the grid data, and the articulated object data independent by the virtual code, which reduces the occupancy of the system resource, and improves the multiple use of the role cartoon.

Owner:TENCENT TECH (SHENZHEN) CO LTD

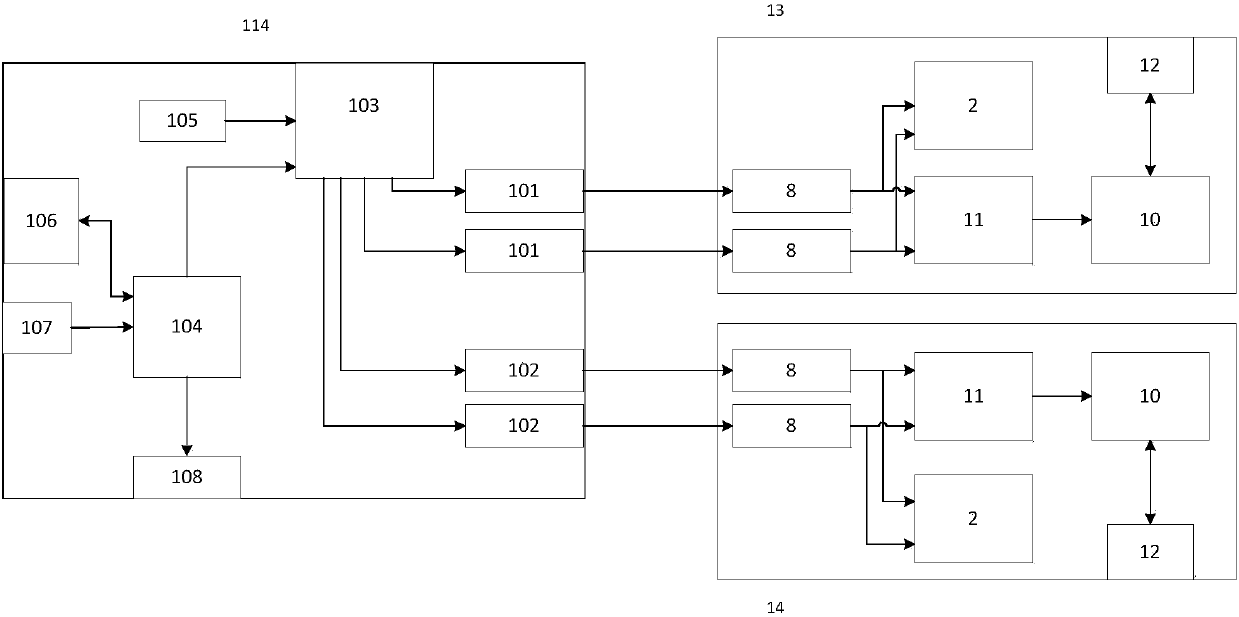

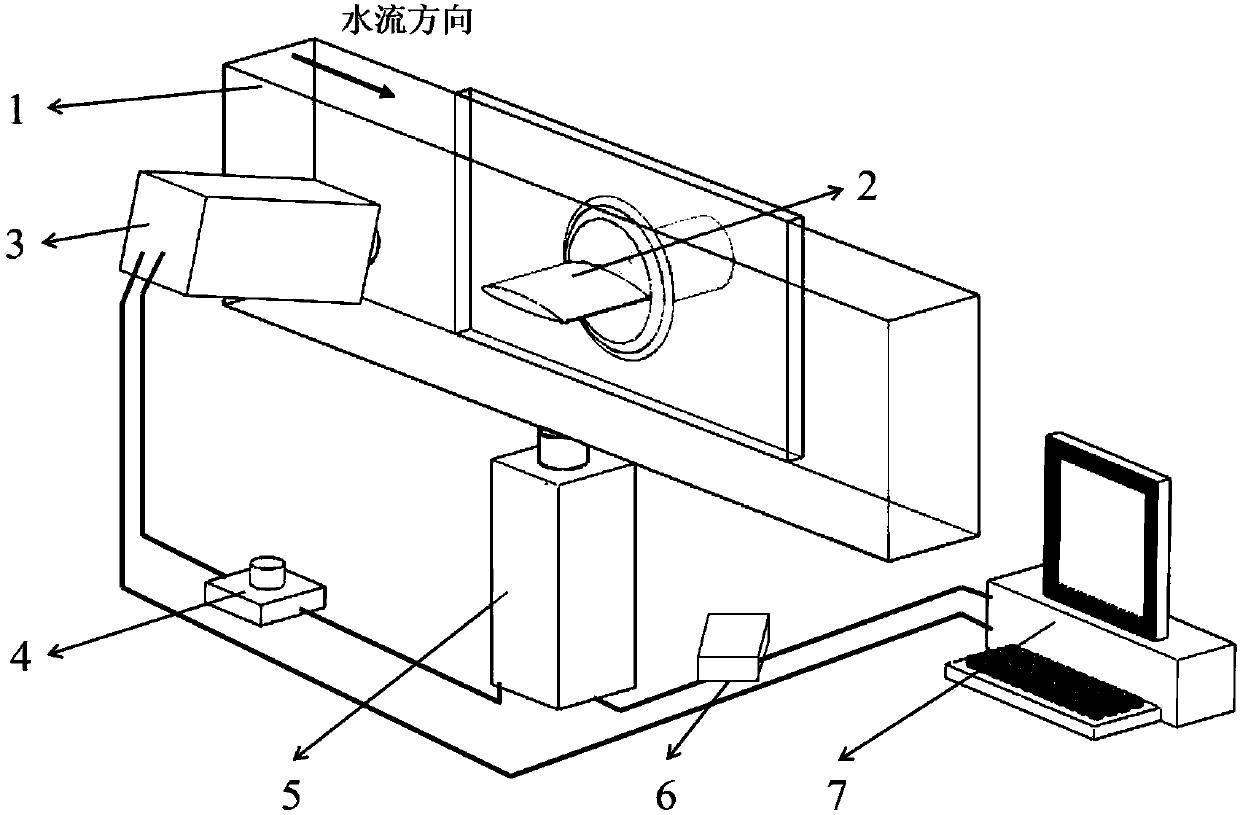

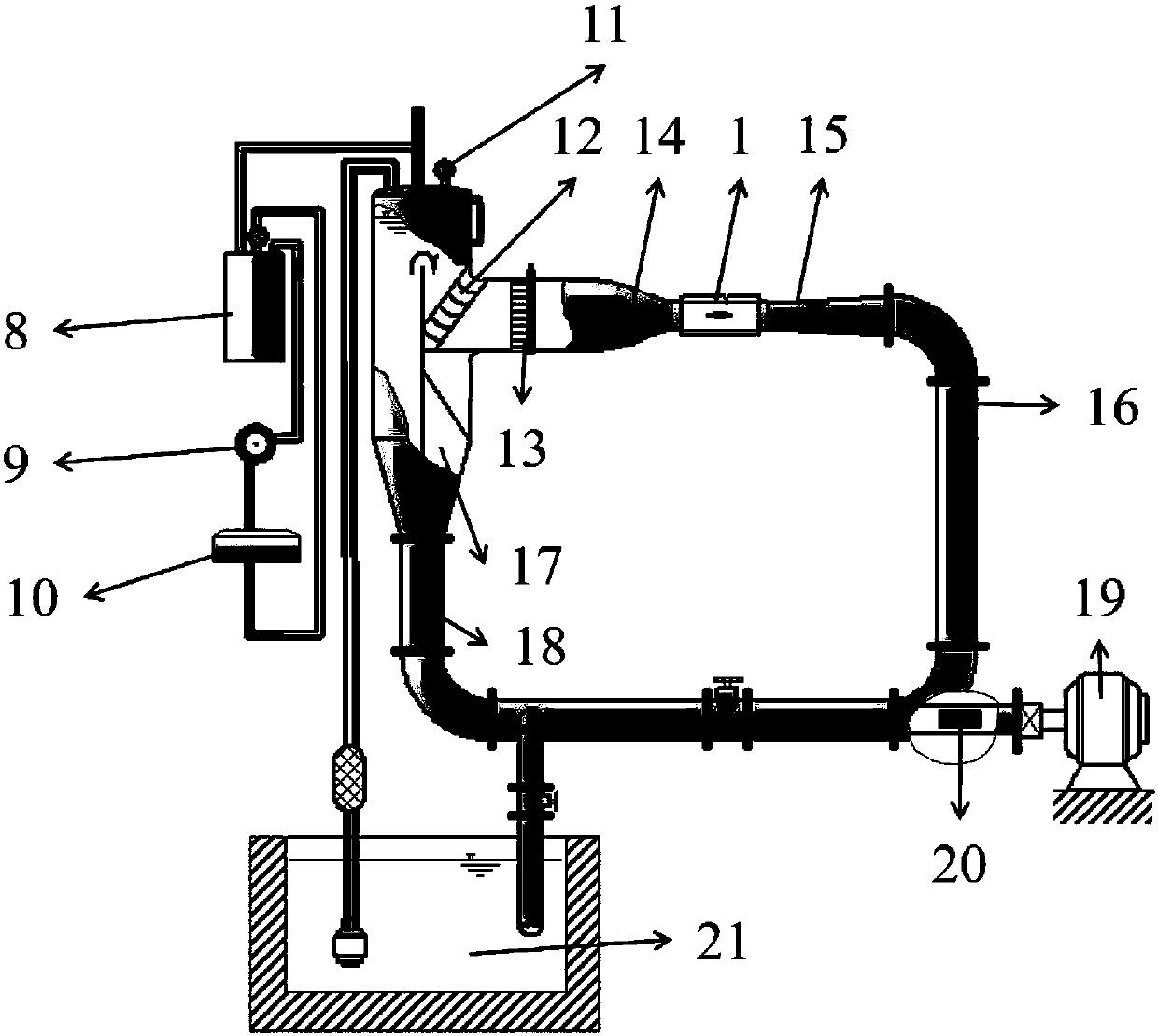

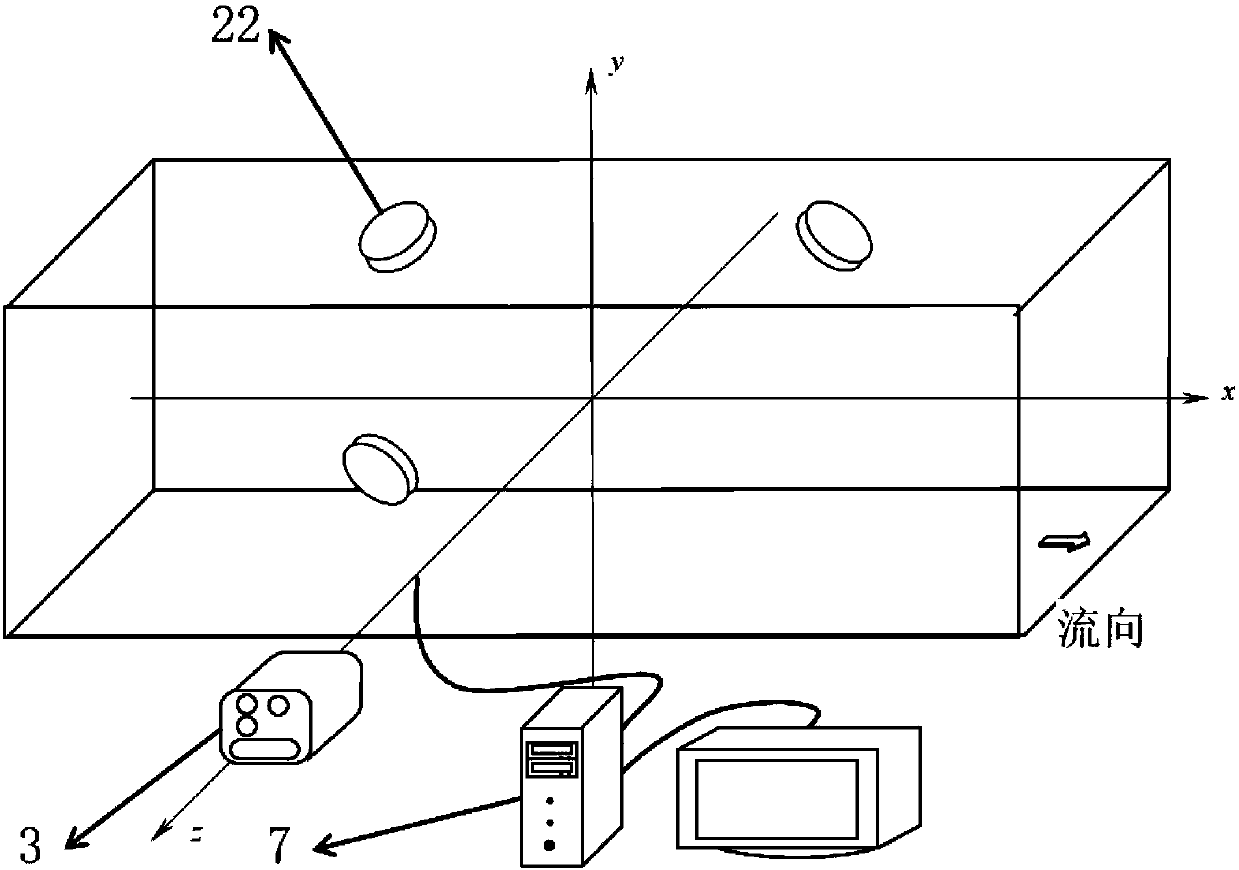

Unsteady cavitation flow-excited vibration multi-field synchronous measurement system for water tunnel experiment

InactiveCN107907296ASimultaneous measurement is preciseSynchronous Analysis FeaturesHydrodynamic testingPhysical fieldMulti field

The invention relates to an unsteady cavitation flow-excited vibration multi-field synchronous measurement system for a water tunnel experiment and belongs to the ship and underwater vehicle engineering and water conservancy and hydropower engineering technology field. The system is composed of an experimental section, an experimental model, a high-speed camera, a synchronous trigger switch, a laser Doppler vibration meter, a data acquisition instrument, a data processing system / computer and display assembly and a light source. According to the system of the invention, rising edge voltage signals are generated through the synchronous trigger switch, trigger signals are controlled by using the voltage signals, and therefore, the signal acquisition starting instructions of the high-speed camera and the laser Doppler vibration meter are controlled quantitatively and precisely, and the quantitative and accurate synchronous measurement of an unsteady cavitation flow field and a structure field can be realized; and data obtained through multi-physical field synchronous acquisition are subjected to preprocessing, time-domain analysis, frequency-domain analysis and time-frequency analysis,and therefore, reliable analysis experimental data can be provided for the study of fluid-structure interaction characteristics.

Owner:TSINGHUA UNIV

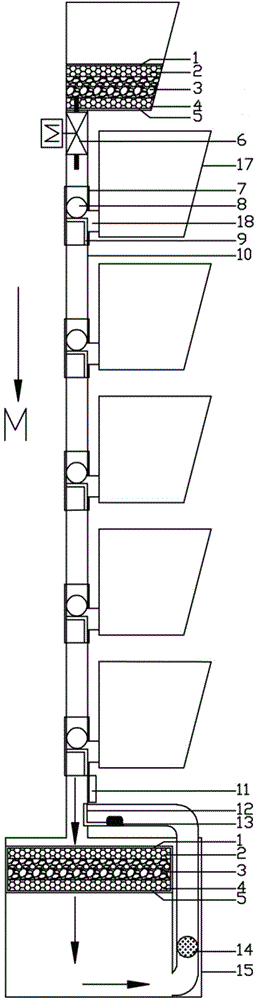

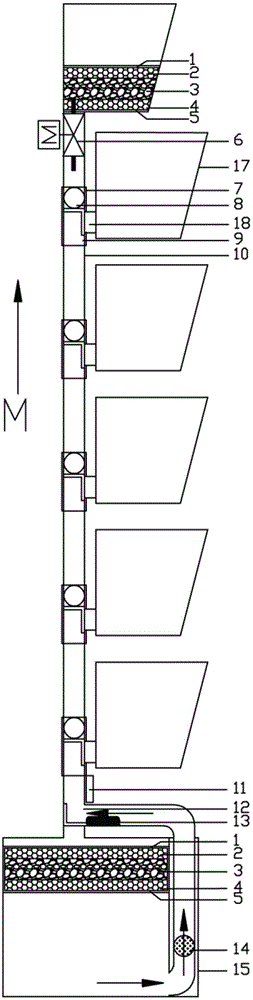

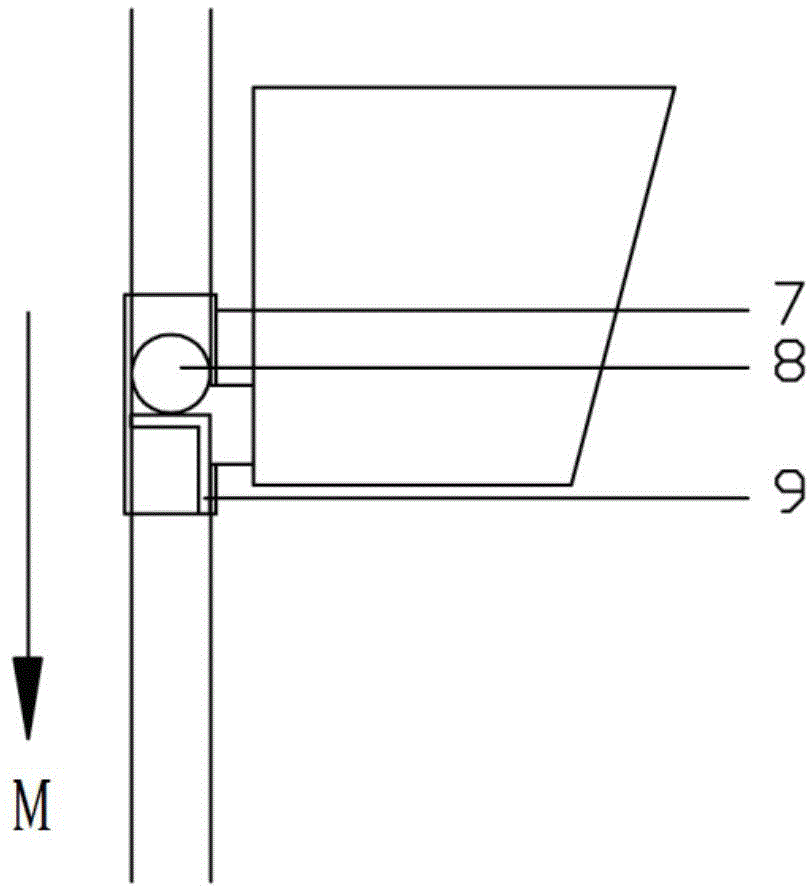

Landscape combined-type stereoscopic greening smart system

ActiveCN104542042ASolve sinkingFlexible replacementGeneral water supply conservationWatering devicesVertical planeSolenoid valve

The invention relates to the technical field of stereoscopic greening, in particular to a landscape combined-type stereoscopic greening smart system. The landscape combined-type stereoscopic greening smart system comprises a rainwater collection and purification system, a water guiding irrigation system, green plant systems, an outer electronic control system and a water storage purification system, wherein the water guiding irrigation system comprises a detachable combined-type water guiding pipeline framework and greening module clamping grooves; the detachable combined-type water guiding pipeline framework is fixed on a construction vertical plane; the greening module clamping grooves are formed in and communicated with the detachable combined-type water guiding pipeline framework; each green plant system is arranged in one of the corresponding greening module clamping groove; the upper end and the bottom end of the detachable combined-type water guiding pipeline framework are respectively connected with the rainwater collection and purification system and the water storage purification system; a solenoid valve is arranged at the water outlet of the rainwater collection and purification system and electrically connected with the outer electronic control system. The landscape combined-type stereoscopic greening smart system is simple in structure, relatively high in practicability and low in use cost, meanwhile, can realize cyclic utilization of water resources, achieves the effects of attractive appearance and environmental protection, and can effectively economize resources.

Owner:辽宁易发成林生态技术有限公司

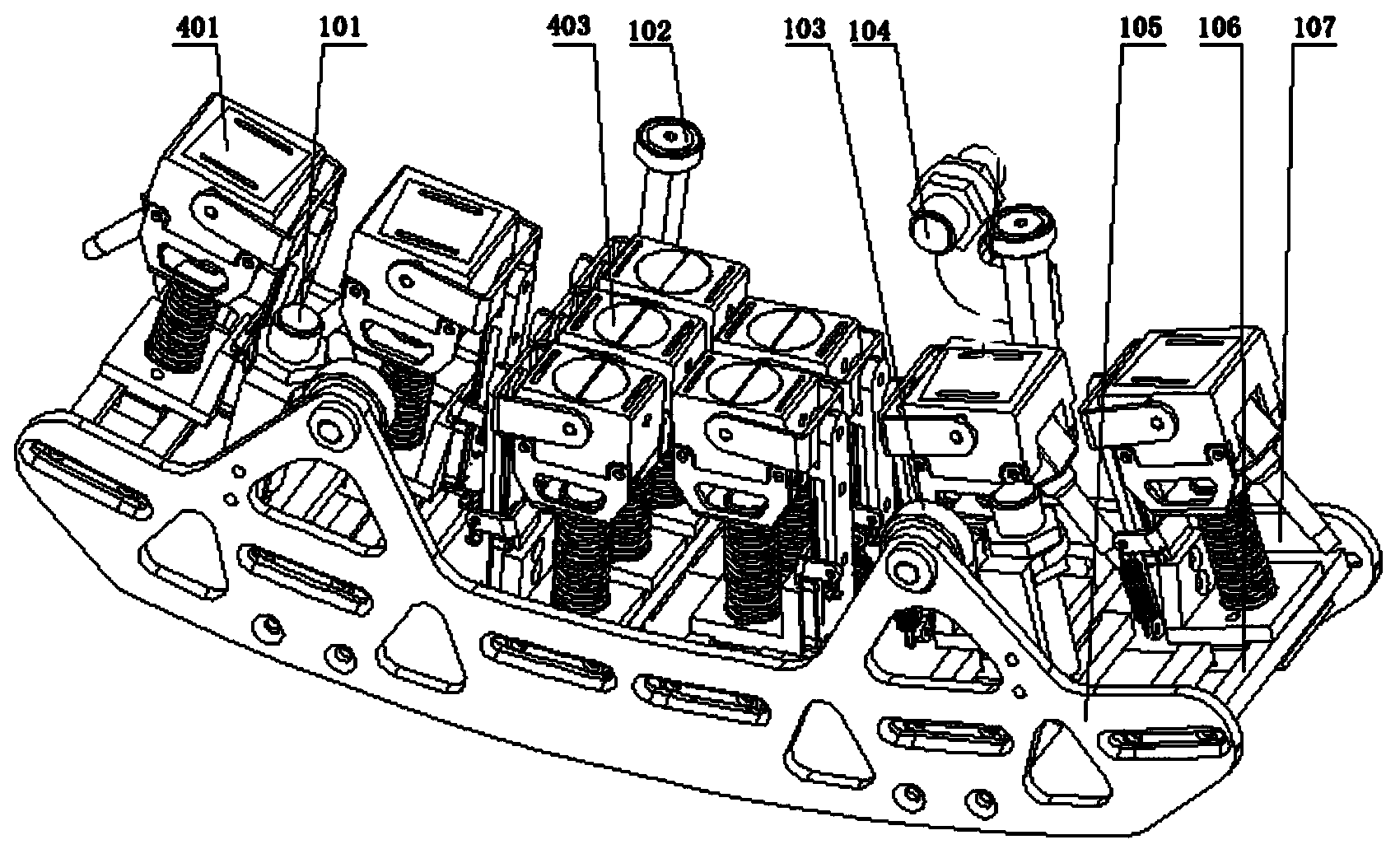

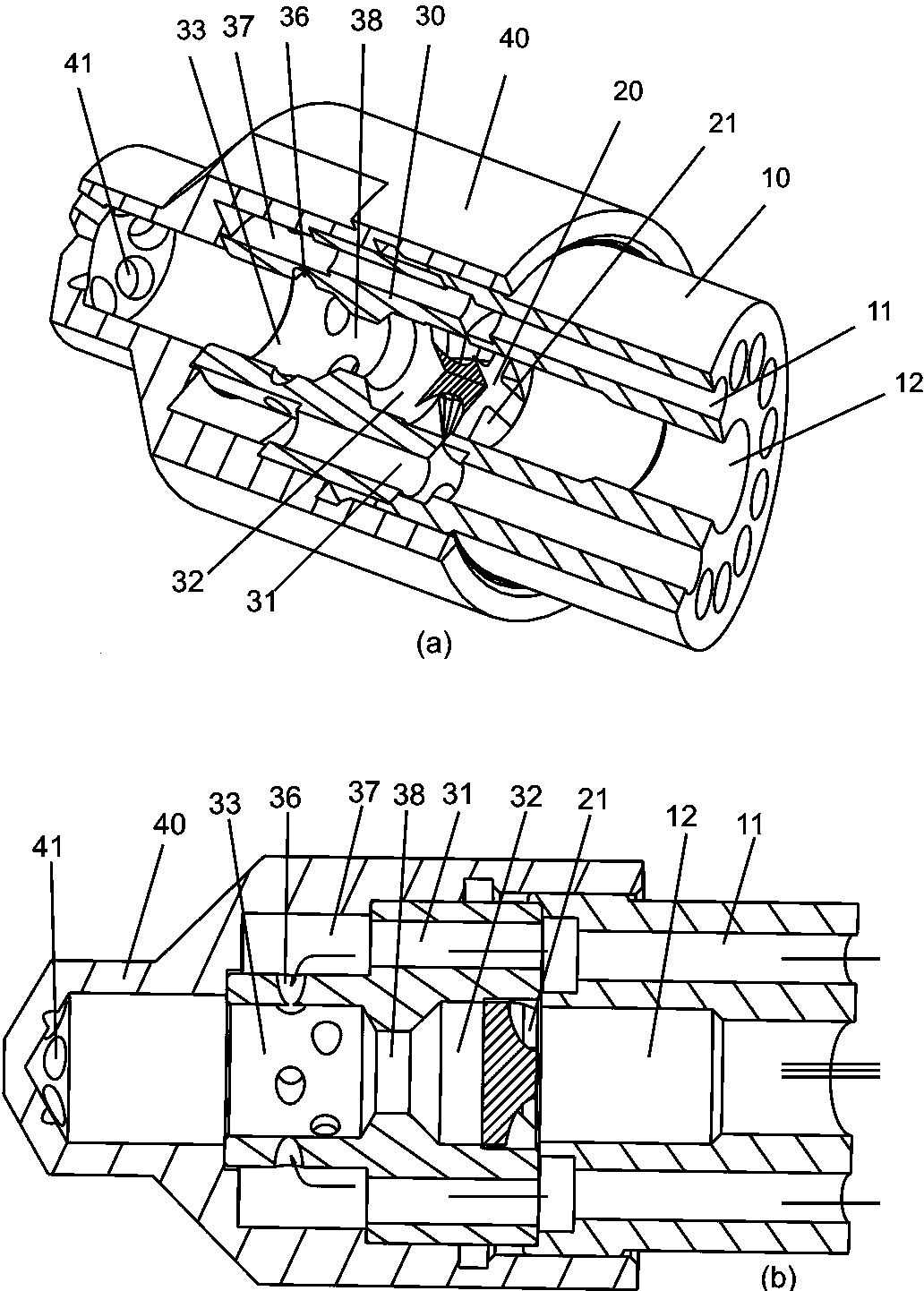

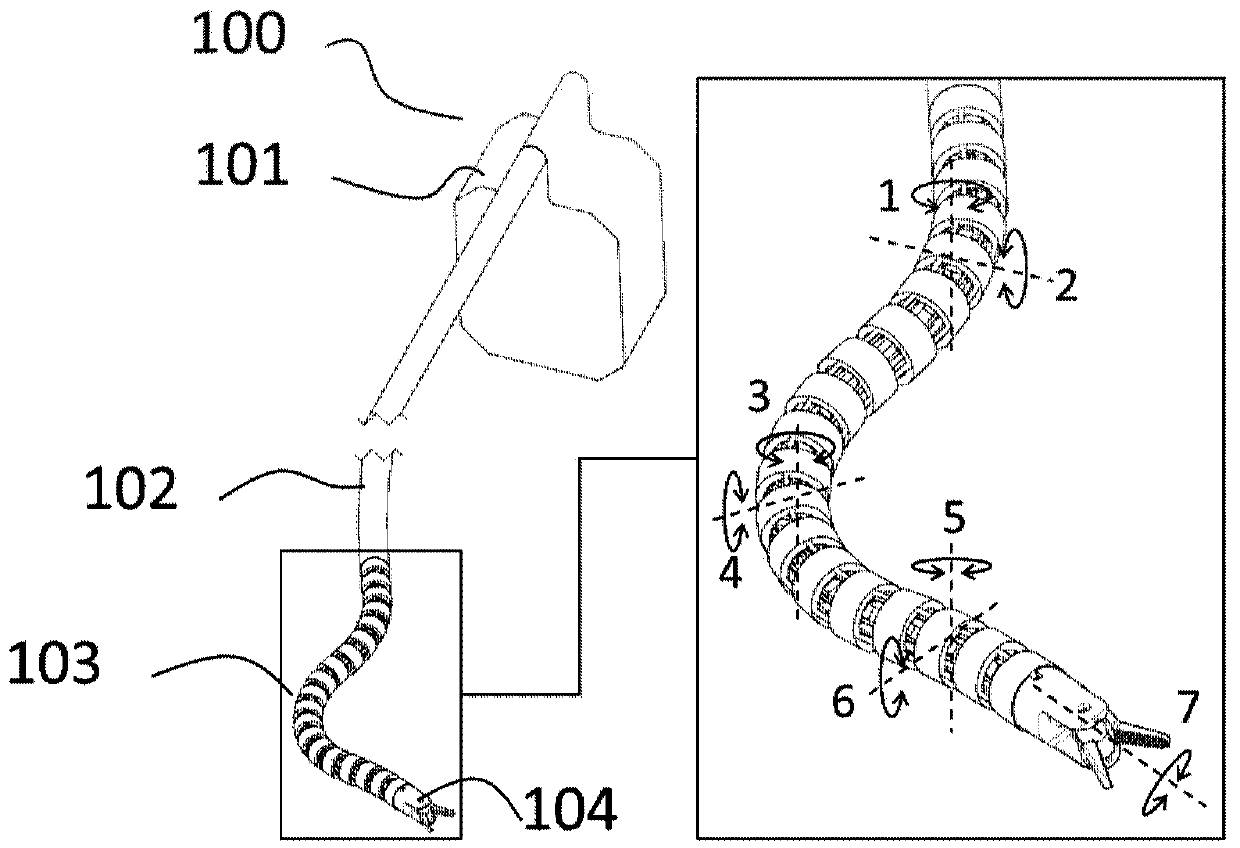

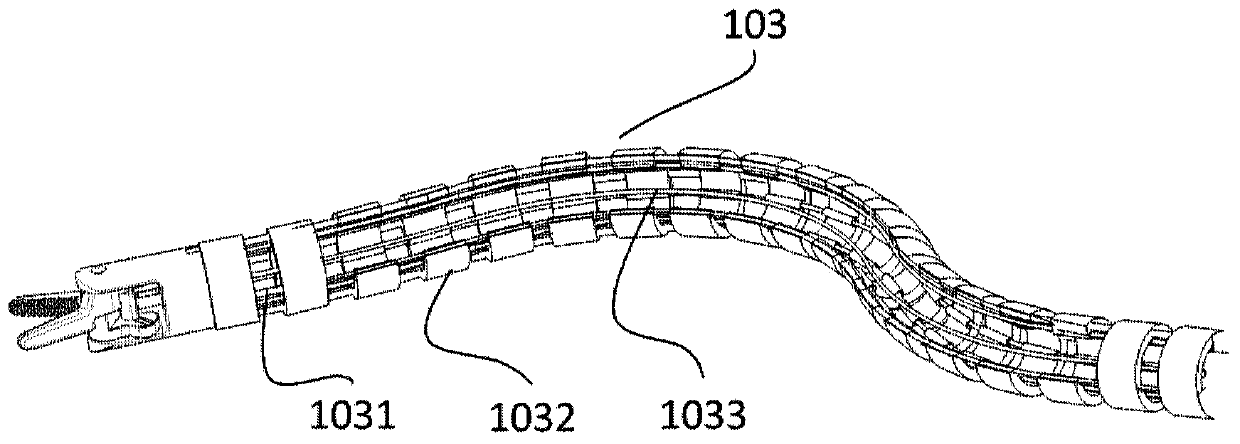

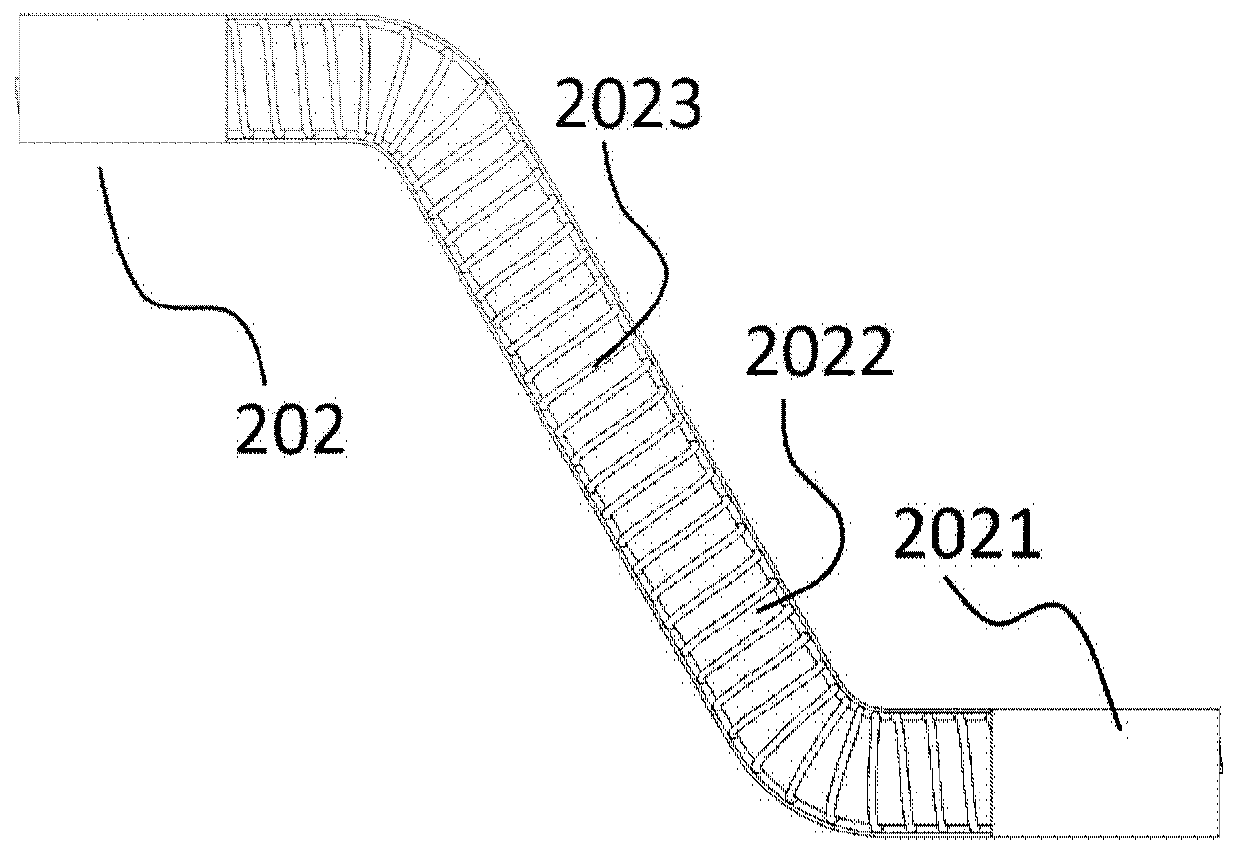

Flexible surgical instrument, operating arm system and minimally invasive surgical robotic slave manipulator system

A flexible surgical instrument, an operating arm system and a minimally invasive surgical robotic slave manipulator system are provided. The flexible surgical instrument includes an instrument drive mechanism, a flexible instrument arm, an active actuator of the flexible instrument arm and an operating forceps. The flexible instrument arm has the first end connected to the instrument drive mechanism and the second end connected to the first end of the active actuator of the flexible instrument arm. The operating forceps is connected to the second end of the active actuator of the flexible instrument arm. The instrument drive mechanism drives the active actuator of the flexible instrument arm to move. The flexible instrument arm moves along with the active actuator of the flexible instrument arm. The instrument drive mechanism also drives the operating forceps to move. The systems are small in size and flexible in layout, a supporting arm and an instrument guide arm can be regulated passively with a large regulation range, the space occupied in an operating room is small, and the systems can be laid out freely according to the environment of the operating room.

Owner:TIANJIN UNIV

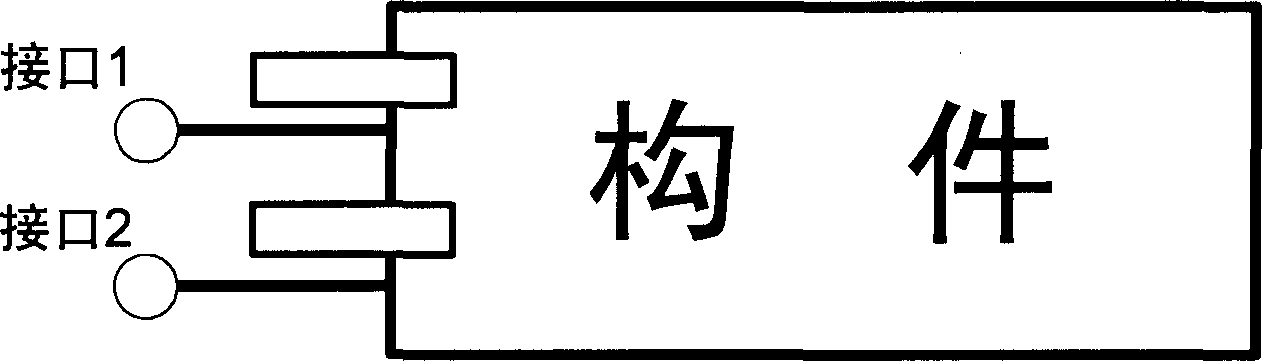

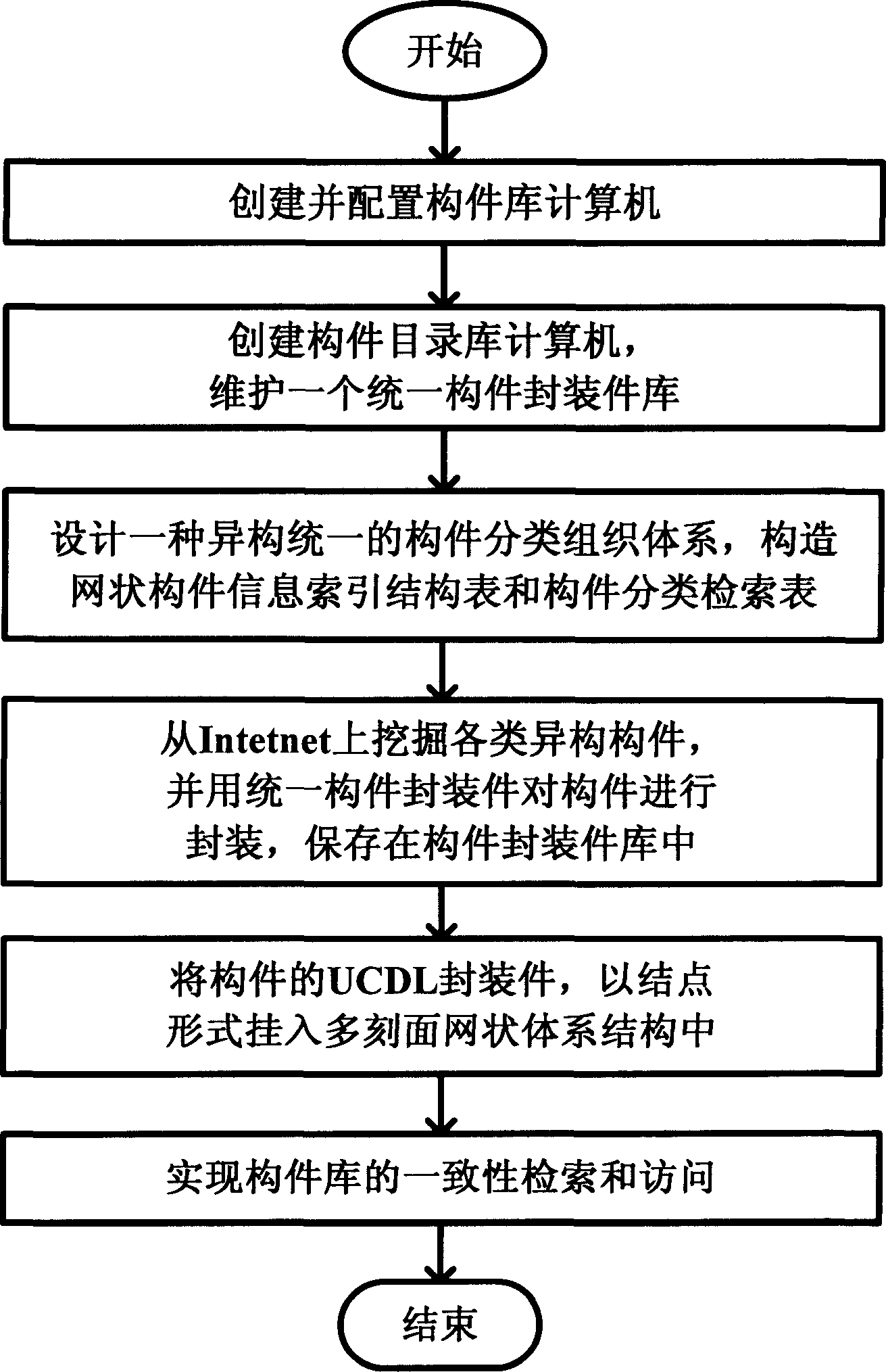

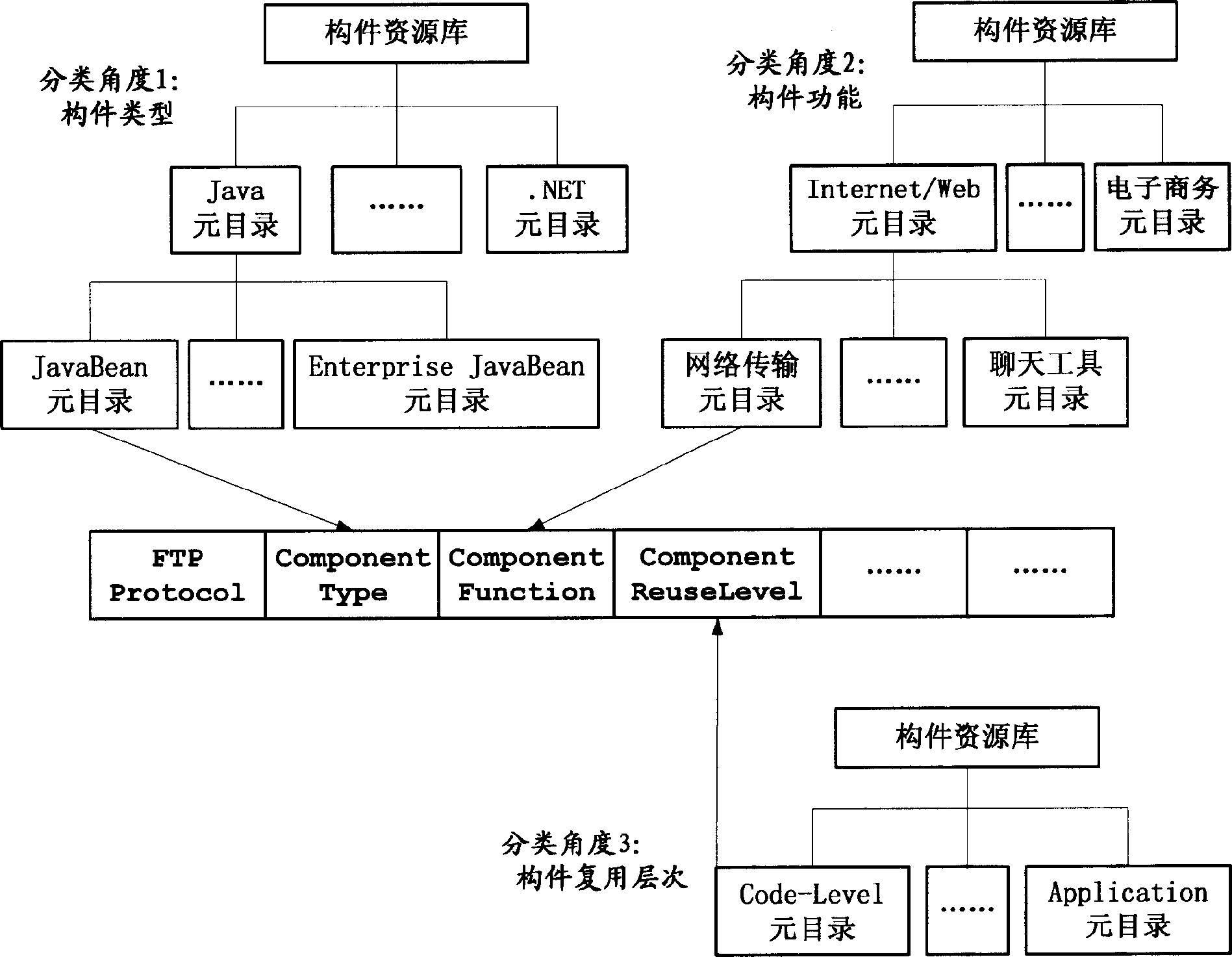

Method for unified management of component library supporting heterogeneous component

InactiveCN1877523AEasy to operateAchieve consistent accessSpecial data processing applicationsSpecific program execution arrangementsThe InternetSql server

The invention relates to a method for managing component library which supports heterogeneous components. The method comprises steps of: on the base of the uniform component package structure of the heterogeneous components, creating a network indexed structure by combining XML with SQL Server database as component library frame; classifying the heterogeneous components; normalizing and storing to the component index library defined by the classified organization mode definition; realizing uniform access and index to the component library on the base of the classification and storage. The invention obtains each component from internet to local efficiently, after verification, information mapping standard, information description, entity storage in library and component indexed access, forms uniform data package, transmits and analyzes standard for providing support on program digging and components package.

Owner:TSINGHUA UNIV

Earphone box for establishing interaction with wireless earphone

The invention relates to an earphone box for storing and charging a portable listening device, and particularly relates to an earphone box for establishing interaction with a wireless earphone. The earphone box comprises a shell, wherein the shell is provided with a first cavity and a second cavity correspondingly receiving a pair of wireless earphones, and the axial line of the wireless earphoneis parallel to the bottom of the earphone box; a cover, wherein the cover is attached to the shell, and the earphone can be operated at a closing position of hiding the earphone in the cover and an opening position of taking out the earphone from the earphone box; and earphone box sensor, wherein the earphone box sensor detects whether the cover is at the closing position or the opening position according to a magnet on the cover; and an earphone box processor, wherein the earphone box processor receives and marks a cover opening signal sent by the earphone box sensor when detecting that the cover moves from the closing position to the opening position, and receives and marks a confirmation signal sent by the earphone sensor when detecting that the cover moves from the closing position tothe opening position; and the second cover opening signal is transmitted to the earphone box processor by the earphone processor in a wireless manner.

Owner:成都必盛科技有限公司 +1

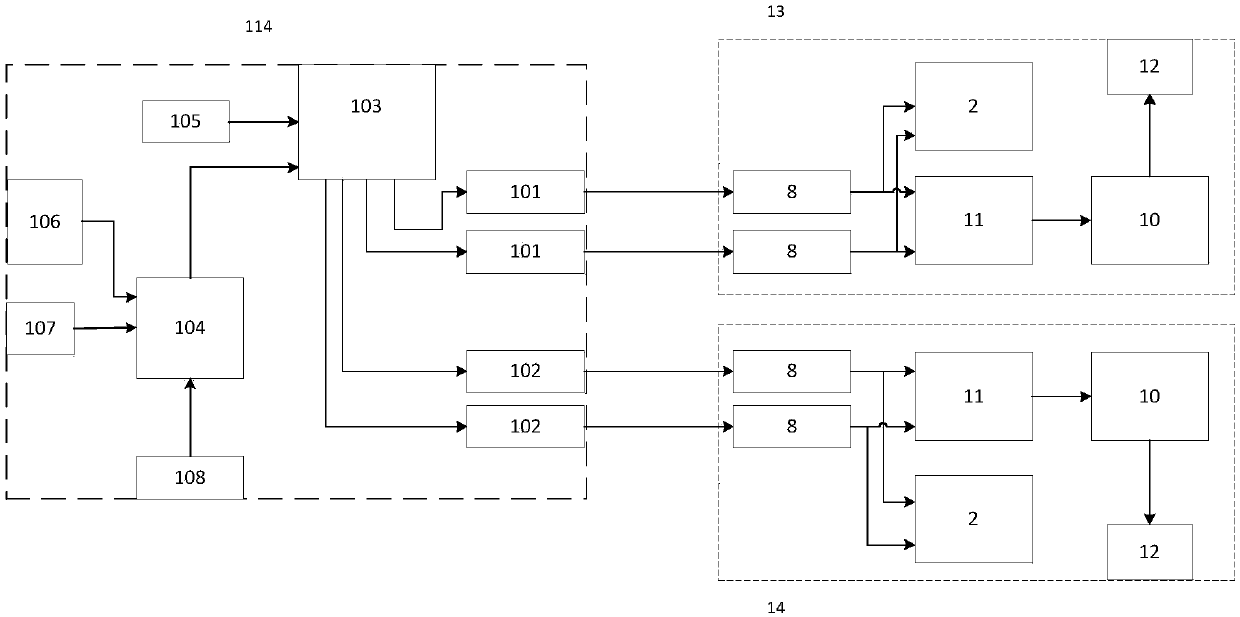

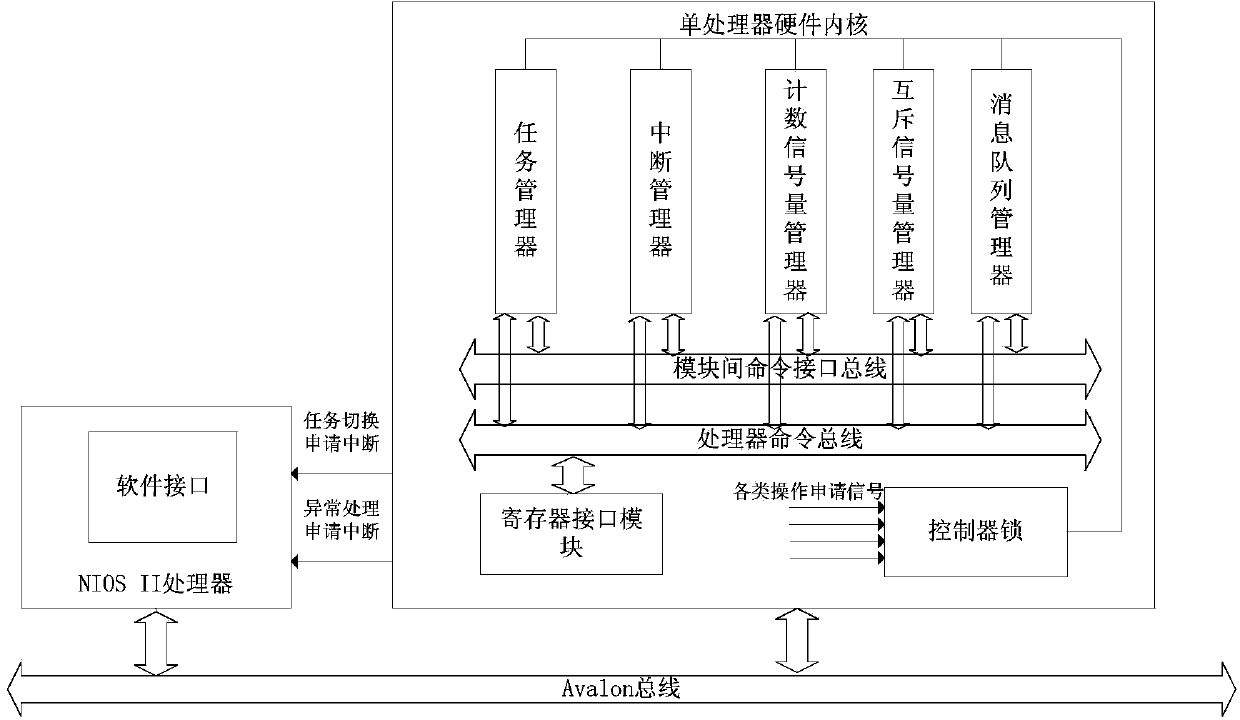

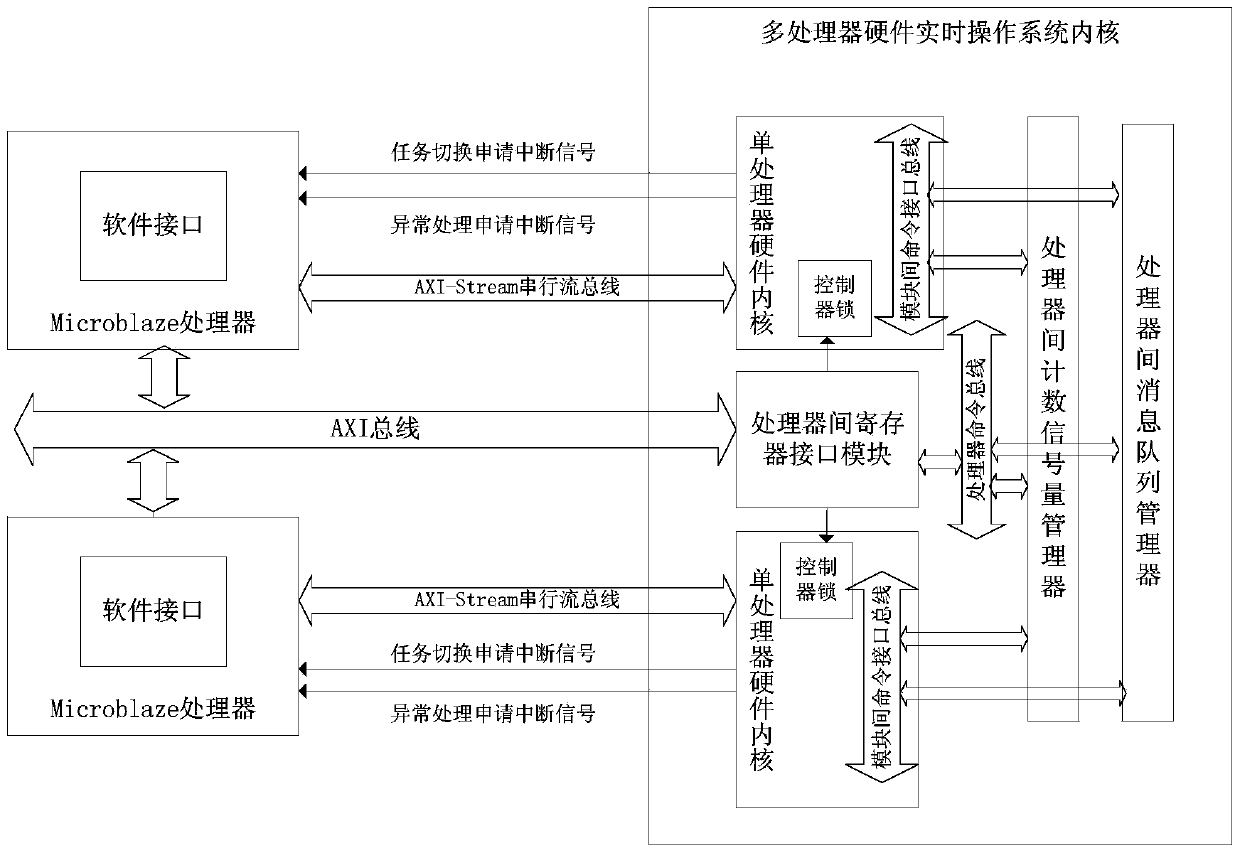

Realization method of real-time operating system of component-based hardware

InactiveCN103440171AReduce overheadImprove performanceProgram initiation/switchingMessage queueProcessor register

The invention discloses a realization method of a real-time operating system of component-based hardware. The method comprises the following steps of: firstly, dividing the real-time operating system into two parts including a hardware inner core and a software interface; then, realizing the communication of a task manager, an interruption manager, a counting semaphore manager, a mutual exclusion semaphore manager and a message queue manager of the real-time operating system by component-based manner in the hardware inner core; enabling the hardware inner core to be communicated with software by a register interface module; synchronizing all the managers by a controller lock; enabling the mangers to be communicated by standard inter-mould command interface buses; and finally, realizing an inter-processor counting semaphore manager and an inter-processor message queue manager and realizing the hardware inner core of a multiprocessor real-time operating system. According to the realization method, the inner core of the hardware real-time operating system is realized by a component-based manner so that the cuttability and the expandability of the system are improved greatly and the flexibility of the software is realized by the real-time operation of the hardware.

Owner:ZHEJIANG UNIV

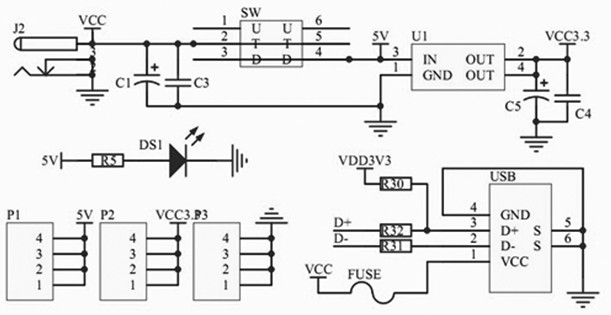

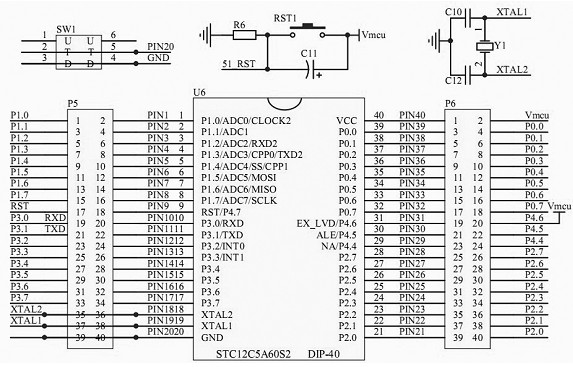

Embedded developing board having strong expansibility

InactiveCN102156515AFlexible replacementStrong ability to upgradeDigital data processing detailsInterface circuitsEEPROM

The invention provides an embedded developing board having strong expansibility, which comprises four components: a system power supply, a processor minimum system, a board-loading base resource and an expansion function module, wherein the system power supply comprises a USB (universal serial bus) power supply interface, an external power source power supply interface, a self-recovering fuse, a voltage stabilizer, a power self-locking switch, a power light; the processor minimum system comprises a 51 single chip, an AVR (automatic voltage regulation) single chip and an ARM (advanced RISC machine) processor; the board-loading base resource comprises a light-emitting diode, a serial shift register, a 4-bit 8-section common cathode nixie tube, a passive buzzer, a matrix keyboard, an independent interruption key, a serial port circuit, a temperature sensor, a keyboard mouse interface, an infrared receiving circuit, an EEPROM (electrically erasable programmable read-only memory) memory, a real-time clock, a PWM (pulse-width modulation) / DA (digital to analog) converter, an ADC (analog to digital converter) sampling circuit, a USB interface, a USB conversion serial port chip, a 1602 dot matrix liquid crystal module interface and a 12864 dot matrix liquid crystal module interface; and the expansion function module comprises an SD / MMC (safety data / multi media card) card interface circuit, a TFT (thin film transistor) color liquid crystal touch screen, an audio module, a wireless communication module and a network module.

Owner:SOUTH CHINA UNIV OF TECH

Expiratory valve

The invention discloses an expiratory valve. The valve comprises a valve body, a top cover, a linear air-resistor, a membrane baffle, a membrane and a valve cover, wherein a first connection part is arranged on the valve body; a second connection part is arranged on the top cover, and the first connection part of the valve body and the second connection part are connected; a plurality of net nest-shaped pores are arranged on the linear air-resistor, and one end of the linear air-resistor is limited by the top cover; the membrane baffle is used for supporting the control external force of a respirator; a groove part for receiving the membrane baffle is arranged on the membrane; and the valve cover is combined with the membrane, and is received in the valve body. Because the expiratory valve is connected and installed in a mode of screw threads, the expiratory valve has low cost, and is convenient for disassembly, cleaning, disinfection and maintenance, so that the expiratory valve can be neatly installed or replaced infinitely, and is suitable for batch production.

Owner:BEIJING AEONMED

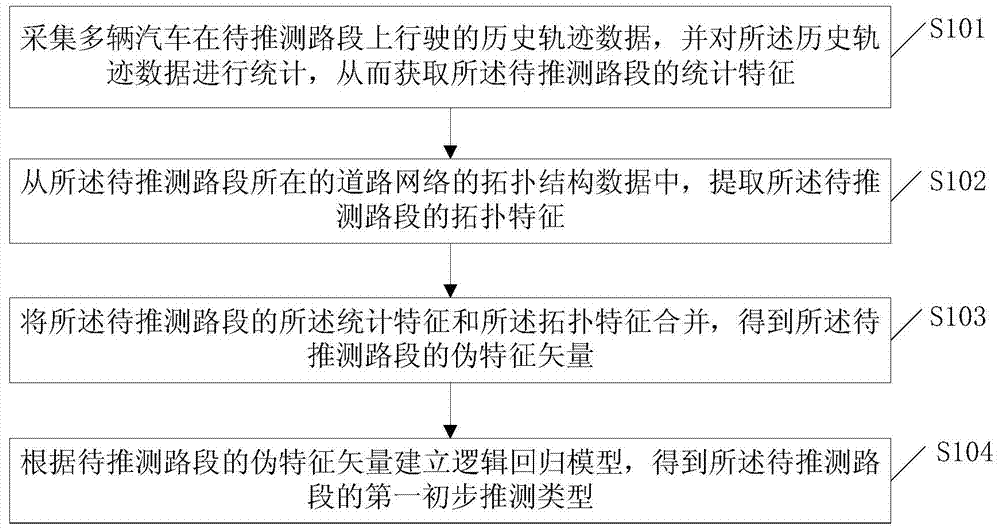

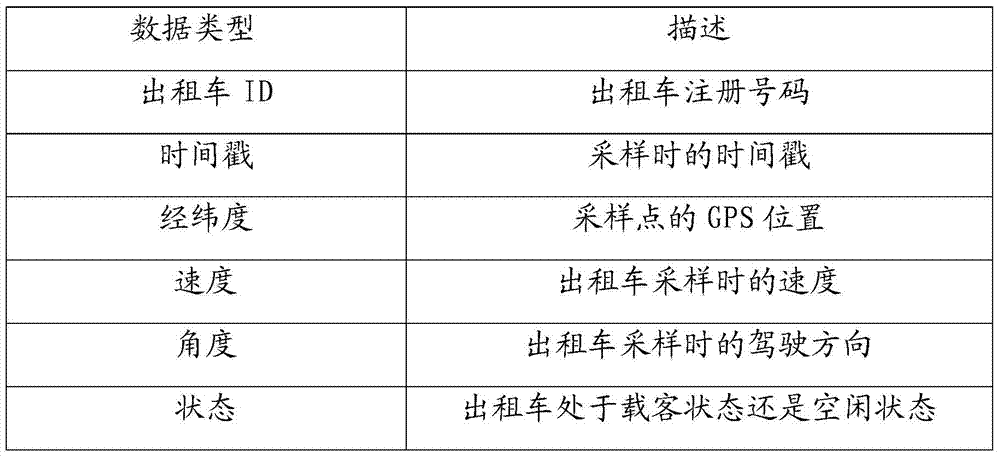

Road section type presumption method

ActiveCN104331422AFlexible replacementPresumed to be highInstruments for road network navigationGeographical information databasesRoad networksEngineering

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

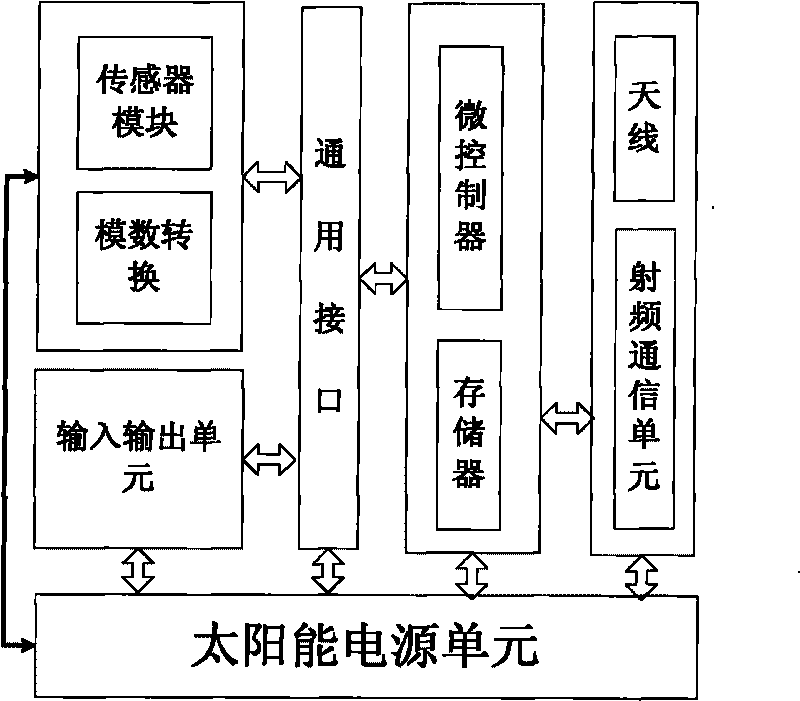

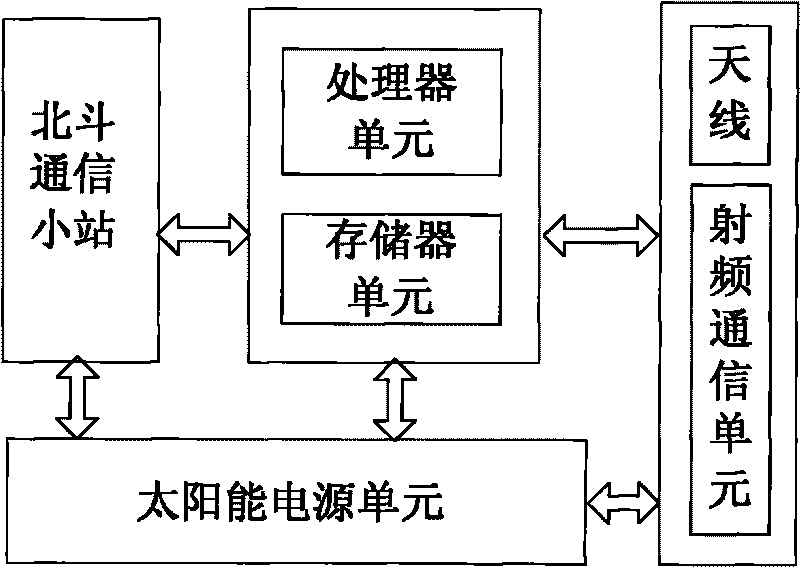

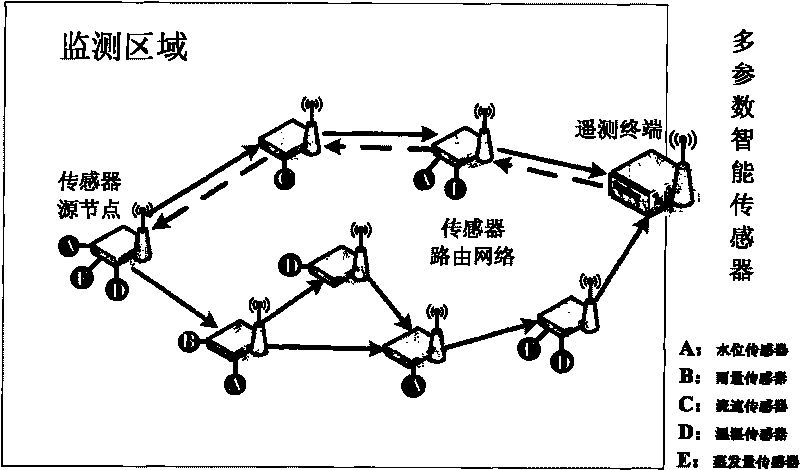

Intelligent multi-sensor system and working method thereof

InactiveCN101713652AWith on-site group information processing functionReport in timeNetwork topologiesIndication of weather conditions using multiple variablesRouting tableWorking set

The invention discloses an intelligent multi-sensor system and a working method thereof. The system comprises a plurality of intelligent sensor nodes for collecting hydrologic information and a telemetering terminal, wherein the intelligent sensor nodes are communicated with each other and communicated with the telemetering terminal through the collision avoidance multi-carrier channel access (CSMA-CA) mode based on the IEEE802.15.4 standard. The method comprises the following steps: the telemetering terminal is initialized; the telemetering terminal creates the intelligent sensor node as a node in a routing table through a distributed routing mode based on the routing table; when a new intelligent sensor node is added to the sensor system, the telemetering terminal determines the new route by radio PREQs grouping information and updates the routing table; and when the telemetering terminal receives hydrologic parameter data sent by the intelligent sensor node, the received hydrologic parameter data is uploaded to a remote base station through a way station of the Beidou satellite communication. The invention has the advantages of reliable hydrologic monitoring and high validity.

Owner:HOHAI UNIV

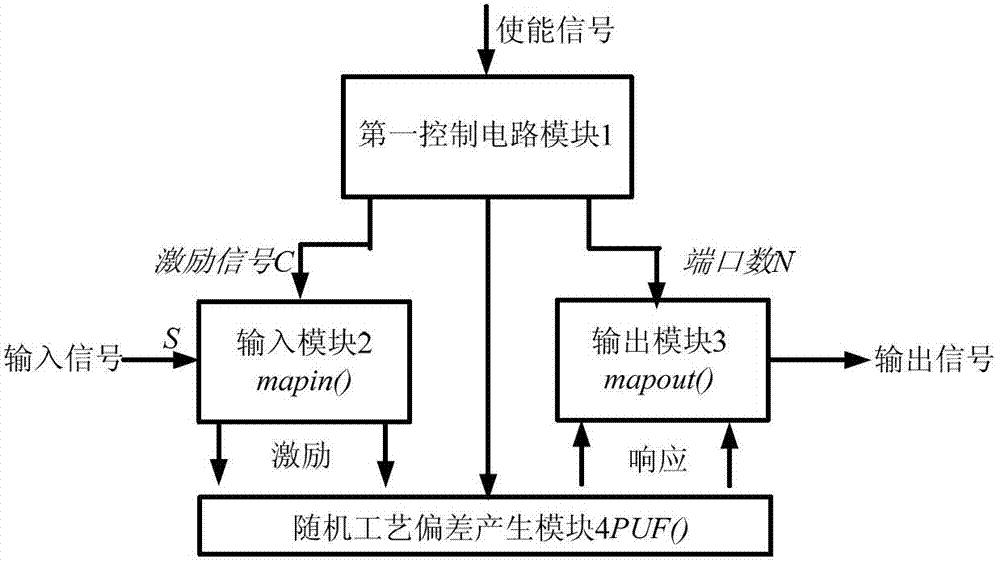

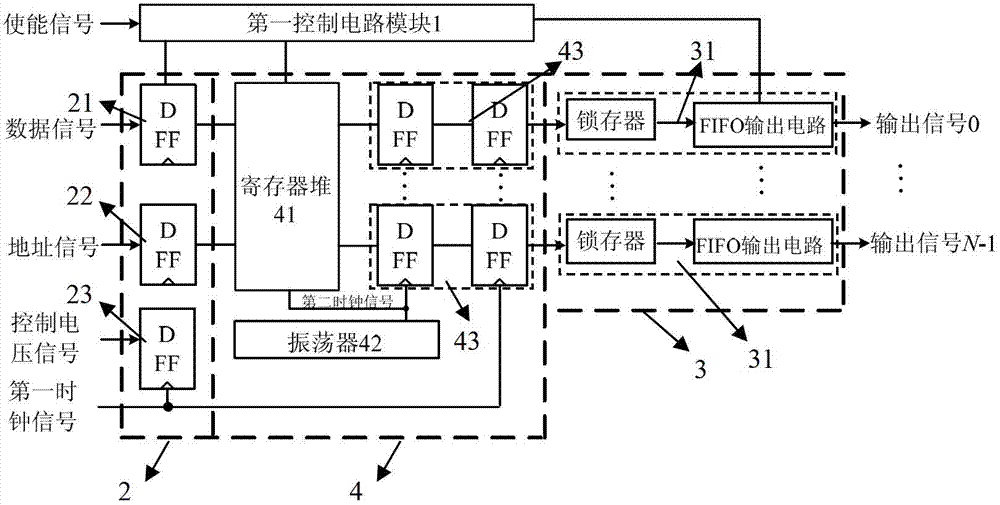

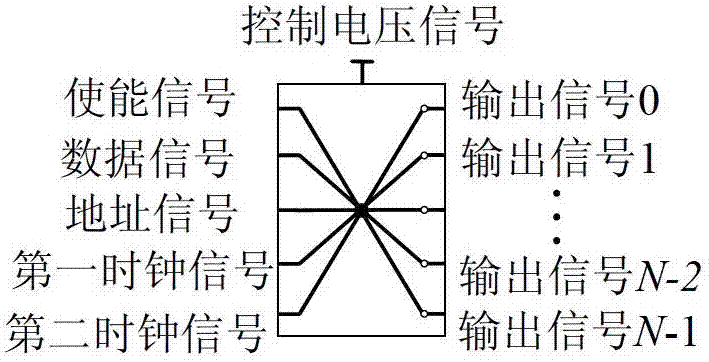

Reconfigurable multi-port physical unclonable functions (PUF) circuit unit

ActiveCN103198267AFlexible replacementImplement refactoringInternal/peripheral component protectionProcess deviationsComputer module

The invention discloses a reconfigurable multi-port physical unclonable functions (PUF) circuit unit. The reconfigurable multi-port PUF circuit unit comprises a first control circuit module, an input module, an output module and a random process deviation generation module, wherein the first control circuit module is connected with the input module, the output module and the random process deviation generation module respectively; the input module is connected with the random process deviation generation module; and the random process deviation generation module is connected with the output module. The reconfigurable multi-port PUF circuit unit has the advantages that the number of output secret keys and ports can be reconfigured; the number of output secret keys and ports can be exchanged flexibly; a plurality of secret keys can be generated within one clock period; the cost is low; and the running speed is high.

Owner:NINGBO UNIV

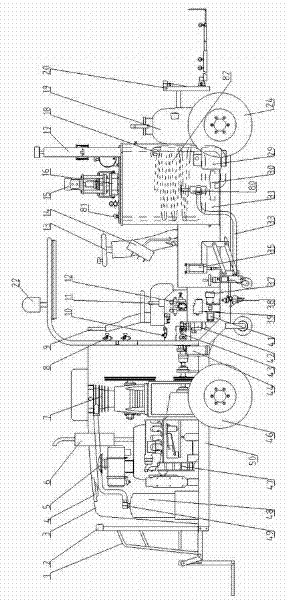

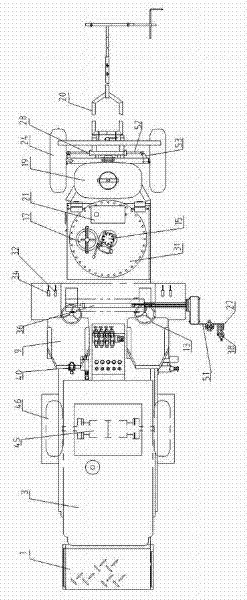

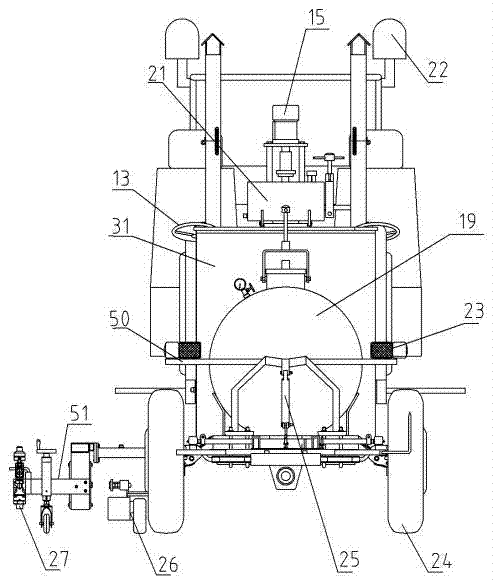

Ride-on Hot Melt Spray Marking Machine

ActiveCN102268855AImprove atomization effectReduce burrsRoads maintainenceHeating systemHeating efficiency

The invention discloses a drive type hot-melt spraying marking machine, which comprises a rack, and the rack is provided with a power-driven system, a heating system, a marking system, a travel system, a hydraulic control system, a pneumatic control system and a steering system, wherein the power-driven system is in drive connection with the travel system, the hydraulic control system and the pneumatic control system respectively; the hydraulic control system is in drive connection with the steering system; and the marking system is in drive connection with the hydraulic control system and the pneumatic control system respectively. In the invention, a hot-melt spraying coating is heated to be a molten condition through an infrared heating system and a heat-conduction-oil heat preservationcyclic system, and then is sprayed to specified positions through a hot-melt gun, and the like. The drive type hot-melt spraying marking machine has the advantages of high marking efficiency, no needof removing existing lines for redintegration, adjustable width and thickness of marking lines, high heating efficiency, sufficiency for combustion and flexible control of flames.

Owner:天途路业集团有限公司

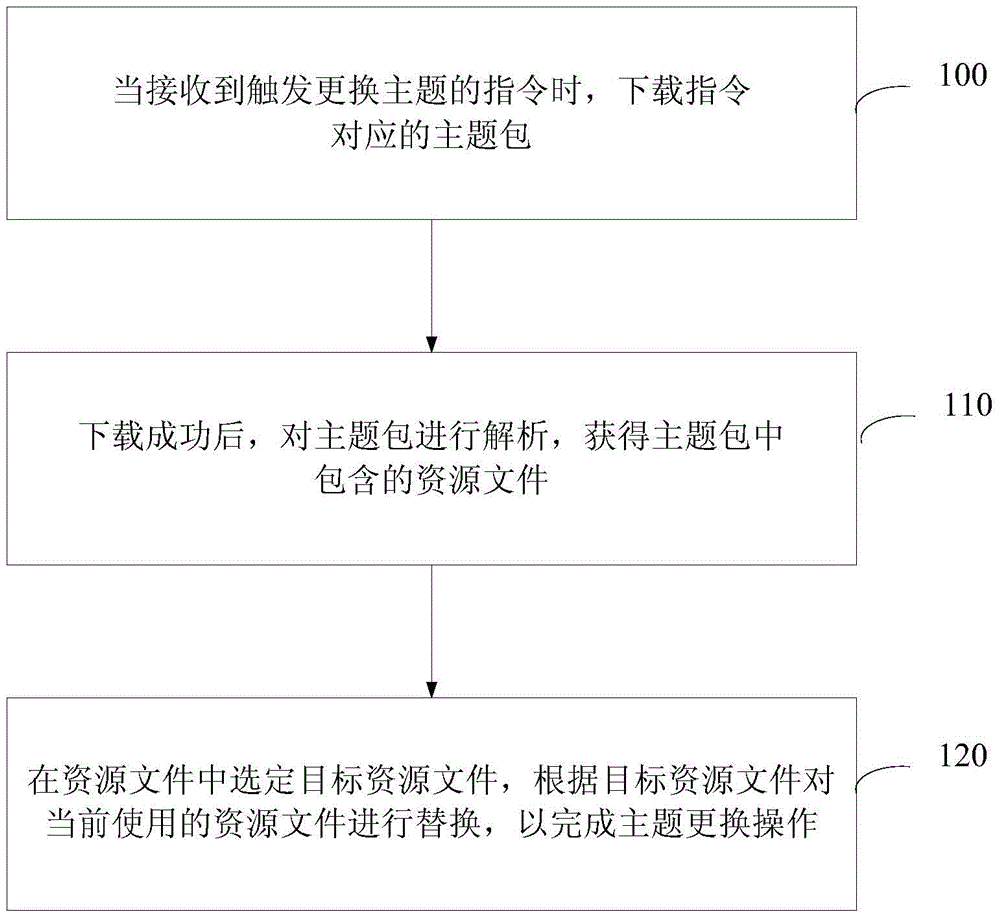

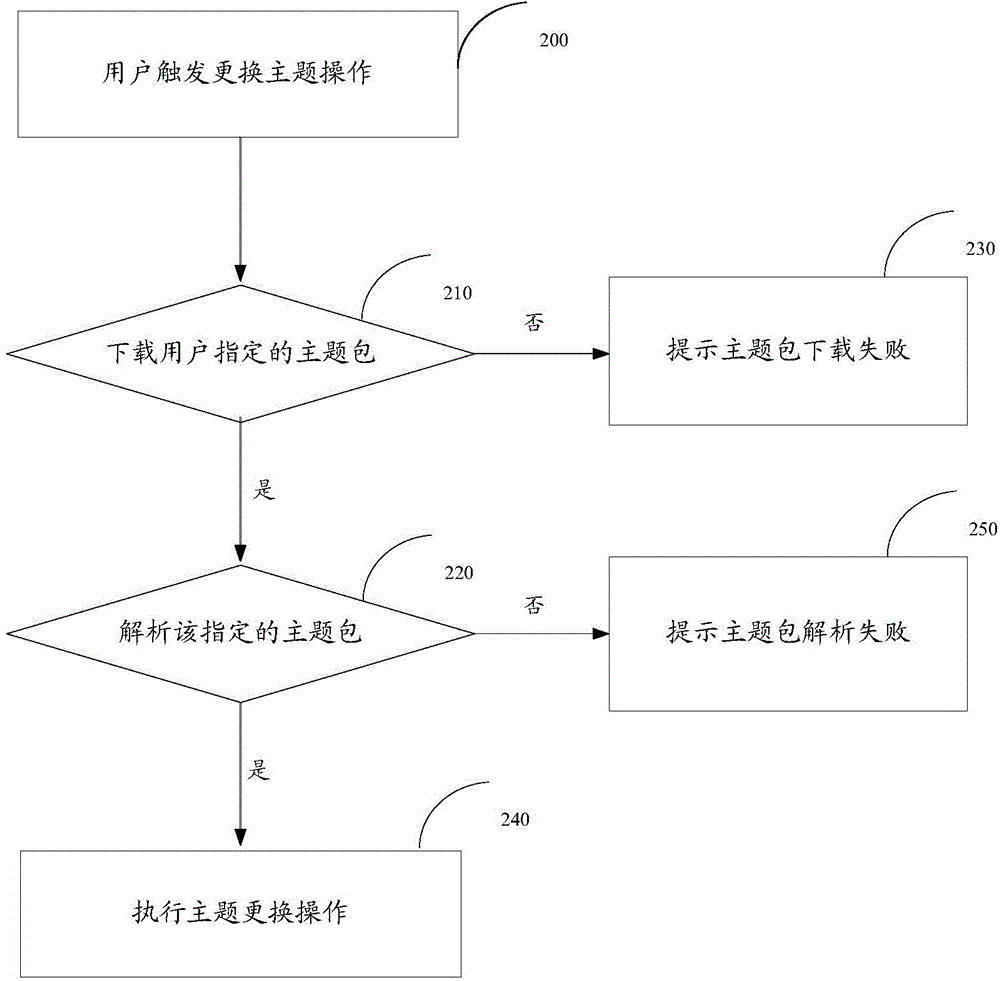

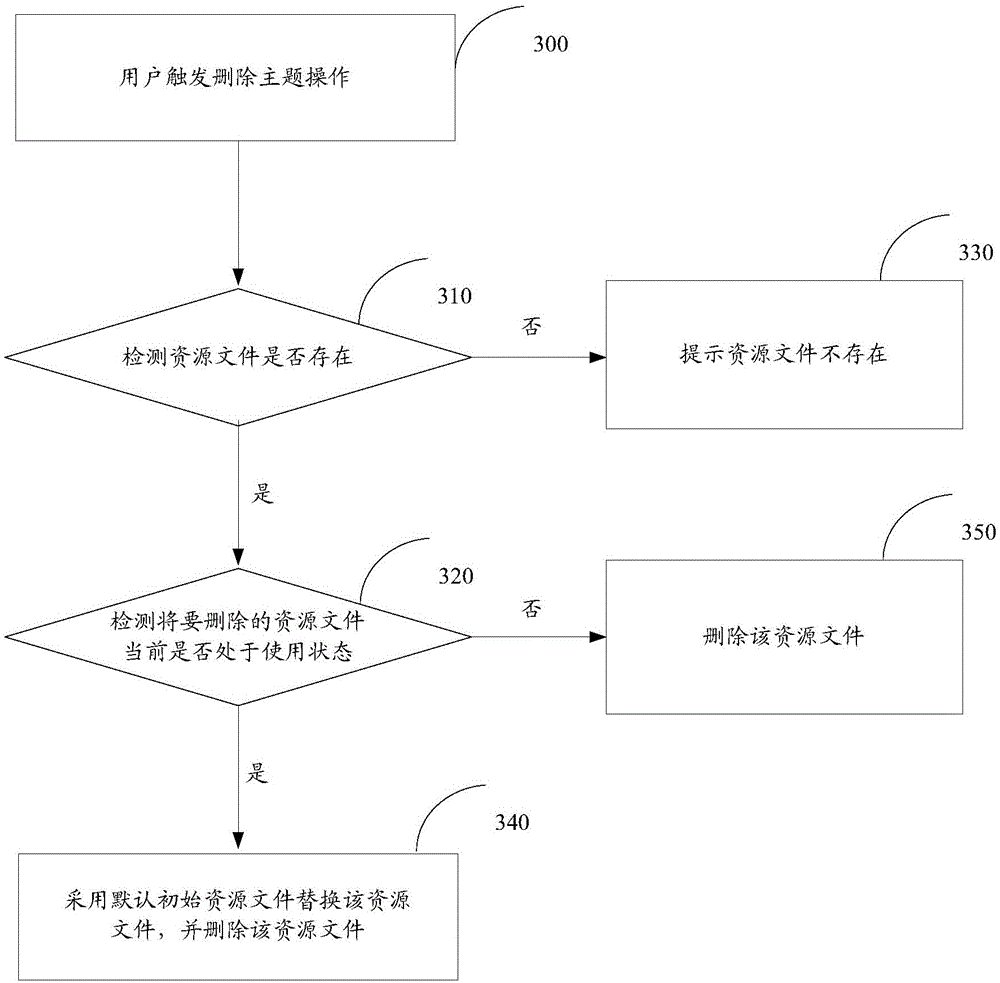

Method and device for replacing theme based on Android system application

InactiveCN104915257AFast replacementEasy to operateProgram initiation/switchingSoftware engineeringComputer engineering

The invention relates to the field of communication and discloses a method and device for replacing a theme based on Android system application. The scheme is that when an instruction for triggering theme file replacement is received, a corresponding theme packet corresponding to the instruction is downloaded; after the downloading is successful, the theme packet is analyzed, a resource file contained in the theme packet is obtained; a target resource file is selected in the resource file, and the resource file contained in the theme file used currently is replaced according to the target resource file, so as to finish the theme replacement operation. Therefore, after being downloaded, the theme packet does not need to be installed and directly undergoes analysis operation, and the method not only can accelerate theme packet analysis speed and improve theme replacement speed, but also is convenient to operate and flexible in theme replacement mode.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

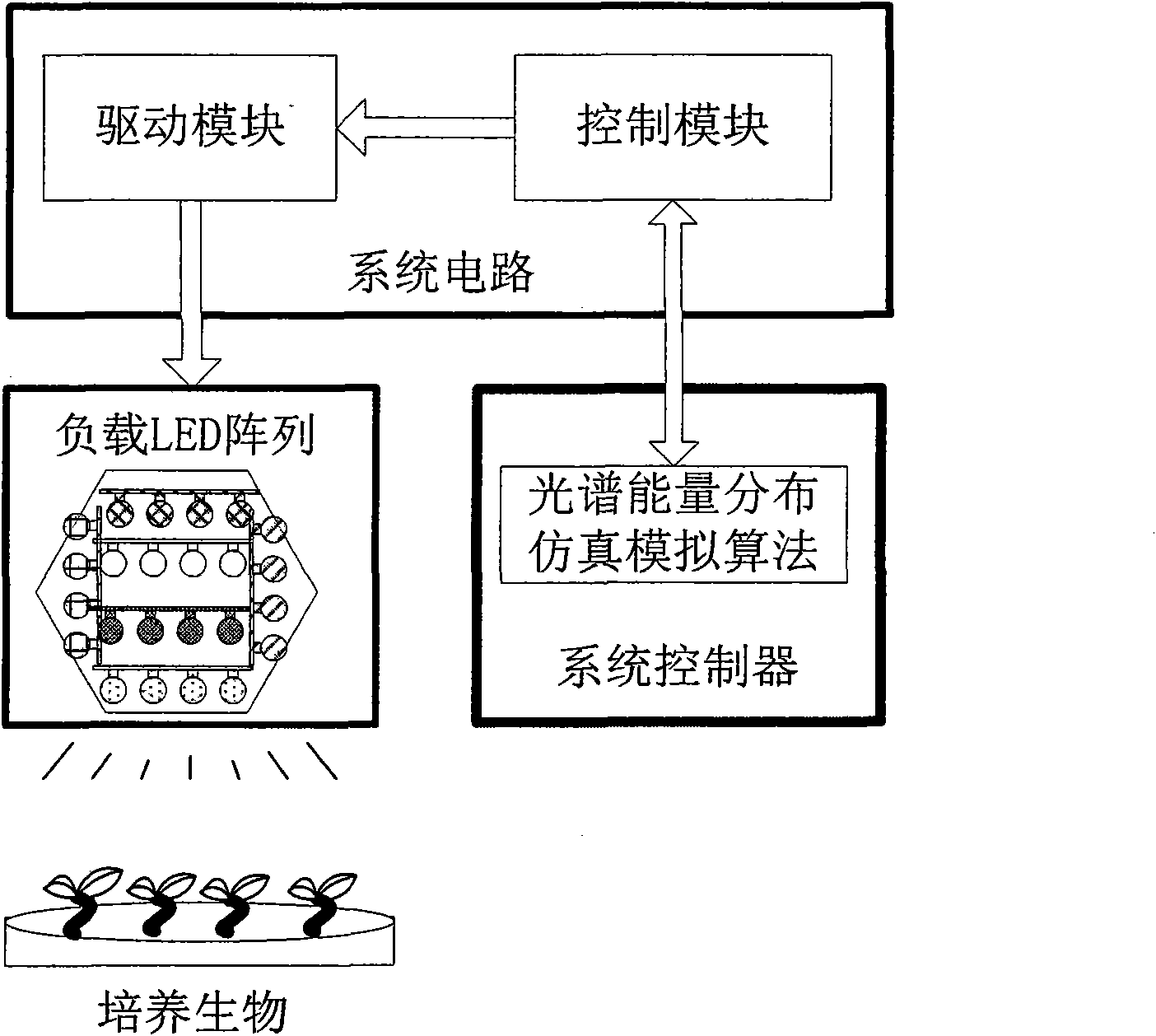

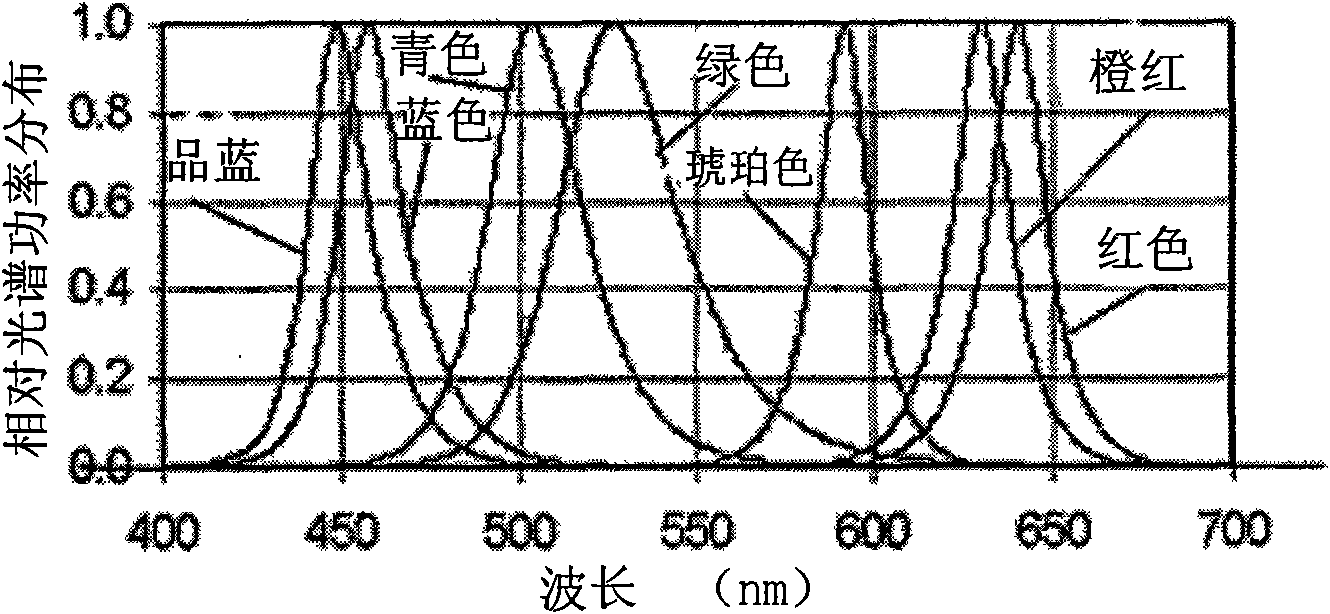

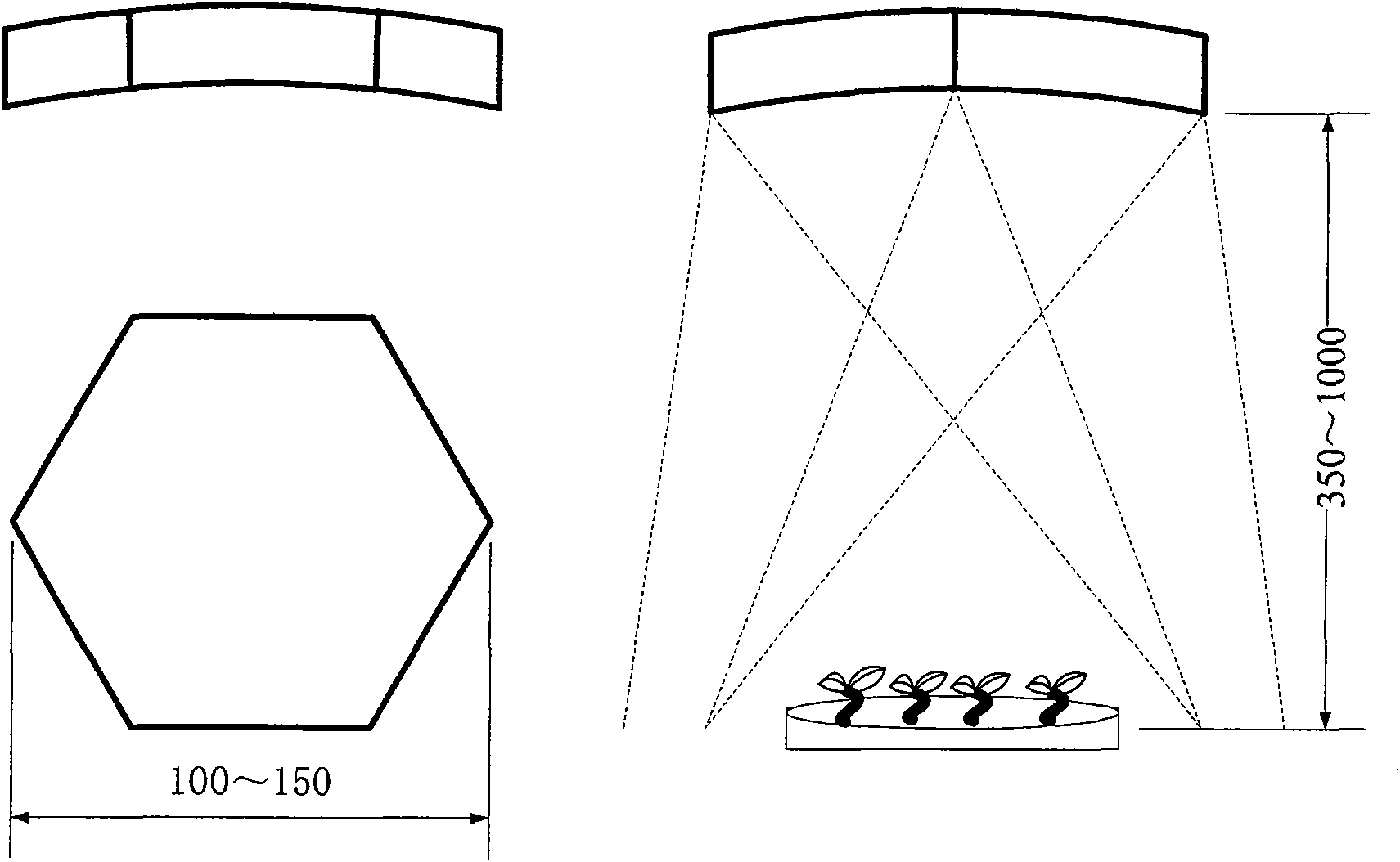

Special spectrum simulation illumination device for plant cultivation and simulation method

InactiveCN101644395AStrong noveltySimulation is accuratePoint-like light sourceElectric circuit arrangementsMicrocontrollerScientific study

The invention discloses a special spectrum simulation illumination device for plant cultivation and a simulation method. In the invention, the design idea of single light source is broken through; a hexagonal extensible light source array is designed based on LED combination; control power supply is realized by signal chip computer control and inductance switch stabilized current; the configuration parameter of a light source is determined by a monochrome calibration method; and the simulation of a special spectrum is realized by a nonlinear least squares curve fitting. The device has the advantages of special spectrum simulation, light-reliable-efficient performances, convenient extension and strong commonality. The simulation test result shows that the invention can pointedly and flexibly simulate the visible light absorption spectrum of special plants, solves the technical problem that how to supply light efficiently and flexibly for biological culture and provides a new technical solution for biological scientific study, biological culture and fresh-keeping in special environment and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

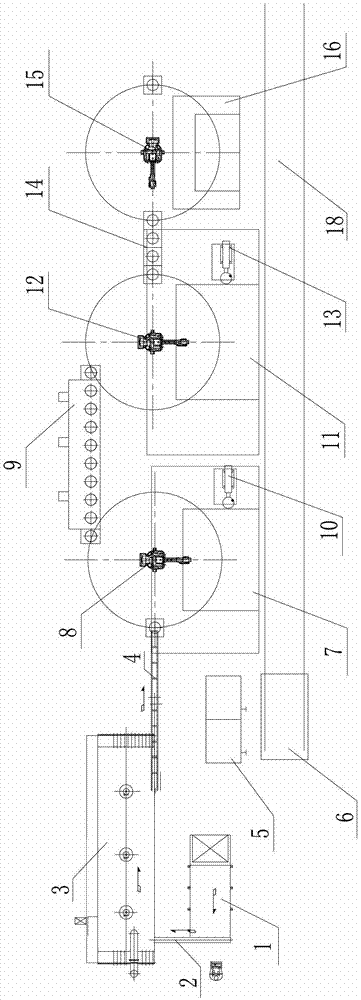

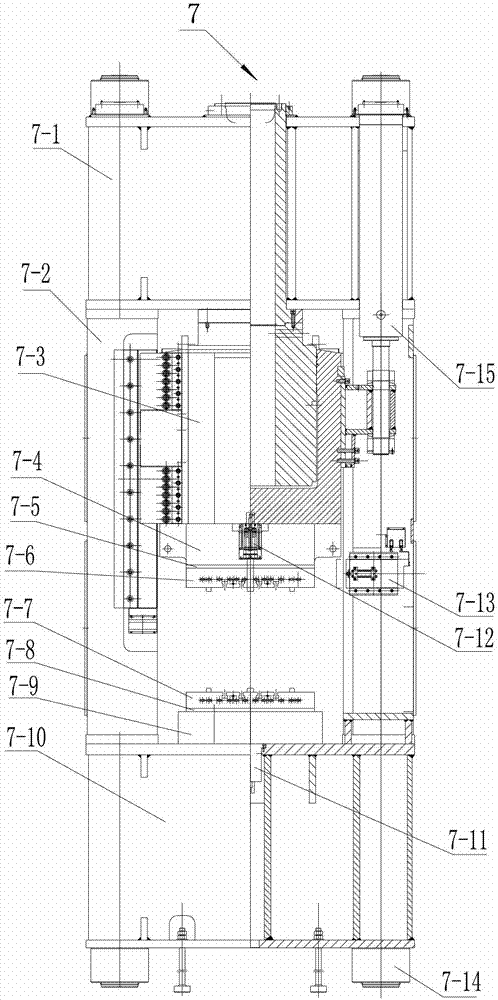

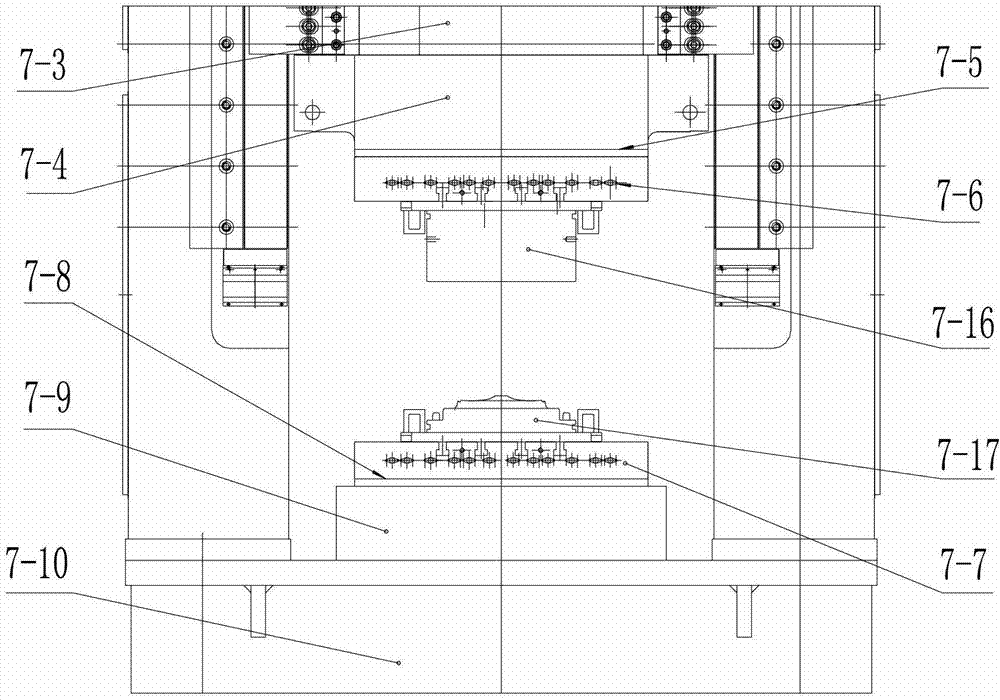

Large-scale aluminum alloy hub isothermal forging production line

ActiveCN102873253ASimplify the pressing processRealize visual operationShaping safety devicesForging/hammering/pressing machinesProduction lineHeating furnace

The invention relates to a large-scale aluminum alloy hub isothermal forging production line. The large-scale aluminum alloy hub isothermal forging production line is characterized by comprising a bar cutting machine, a bar heating furnace, a plurality of delivery manipulators, a pre-forging hydraulic press, a hub finish-forging hydraulic press, an aluminum alloy hub broaching and trimming hydraulic press and a pressing die. A cold material conveying roller table is arranged between the bar cutting machine and the bar heating furnace, a hot material conveying roller table is arranged between the other end of the bar heating furnace and the delivery manipulators, a die heating furnace, a die change trolley and a change trolley rail are arranged on one side of the pre-forging hydraulic press, a pre-forging lubrication spraying device is arranged on the other side of the pre-forging hydraulic press, a middle heating furnace or a delivery roller table is arranged between each two manipulators, and a finish-forging lubrication spraying device is arranged on one side of the hub finish-forging hydraulic press. The large-scale aluminum alloy hub isothermal forging production line has the advantages that by means of structural and technical combination of hot die forging, broaching and trimming, one-time pressing of aluminum alloy hubs can be realized, the pressing process of the aluminum alloy hubs is simplified, cost, time and labor for later-stage secondary processing and shaping can be greatly saved, and production efficiency is improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

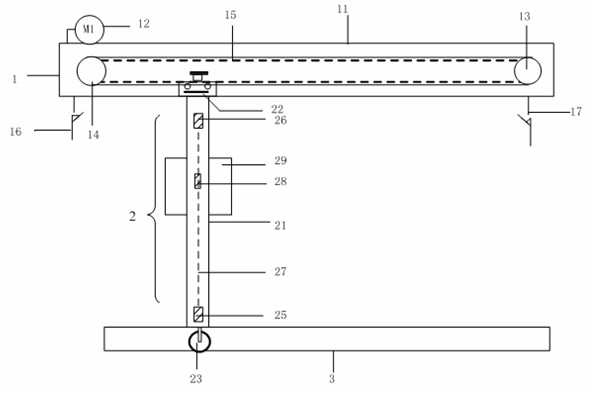

Waterless cleaner for photovoltaic cell panel

InactiveCN102601068AClean thoroughlyClean and comprehensiveCleaning using toolsCells panelClassical mechanics

The invention relates to a waterless cleaner for a photovoltaic cell panel, which comprises a horizontal mechanism, a cleaning mechanism arranged below the horizontal mechanism and a horizontal track. The upper and lower ends of the cleaning mechanism are respectively connected with the horizontal mechanism and the horizontal track. The horizontal mechanism consists of a horizontal bracket, a horizontal moving motor, a horizontal moving driven wheel, a horizontal moving driving wheel, a horizontal moving transmission belt, a forward rotation control stroke switch and an inverse rotation control stroke switch. The cleaning mechanism consists of a vertical rod, a horizontal fixing clamp, an idler wheel, a horizontal track, a vertical moving motor, a vertical moving driven wheel, a vertical moving driving wheel, a vertical moving transmission belt, a vertical fixing clamp and a cleaning brush. By controlling a small brush to move up and down and right and left on the solar cell panel, the waterless cleaner for the photovoltaic cell panel fully cleans the solar cell panel. The cleaning brush is provided with a dust suction device inside, so that the waterless cleaner for the photovoltaic cell panel can clean the cell panel without a water source. Therefore, the waterless cleaner for the photovoltaic cell panel is particularly appropriate for the solar cell panels in western regions that are short of water and with sand blown by the wind frequently.

Owner:SOUTHEAST UNIV

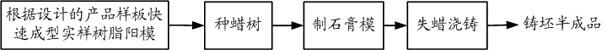

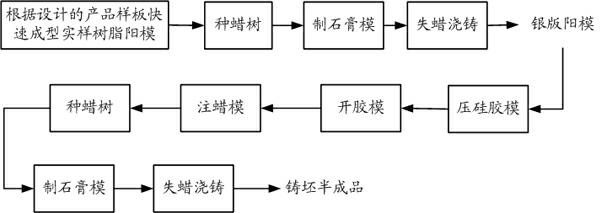

Simplified process method of lost wax casting

InactiveCN102248125ASimple processing methodSimple methodFoundry mouldsFoundry coresParaffin oilsProduct pattern

The invention discloses a simplified process method of lost wax casting, which comprises the following steps in sequence: wax tree planting, plaster mold preparation, and lost wax casting; before the wax tree planting step, the following steps are included: (1) directly molding a resin female mold by a rapid molding device, wherein the resin female mold comprises a mold cavity which has the same shape as the product to be prepared by the simplified process method of lost wax casting; (2) injecting a wax mold: melting paraffin and performing heat insulation, filling the resin female mold with the paraffin in a wax injector, cooling, and finishing to obtain a wax mold. The method of the invention omits a plurality of procedures for mold turnover, saves the cost, and prevents the problem that dimensions and styles deviates the initial design due to multiple male mould-female mold conversion; and the resin female mold is directly molded by the rapid molding device, and thus product pattern replacement is very flexible and rapid.

Owner:SHENZHEN INST OF TECH

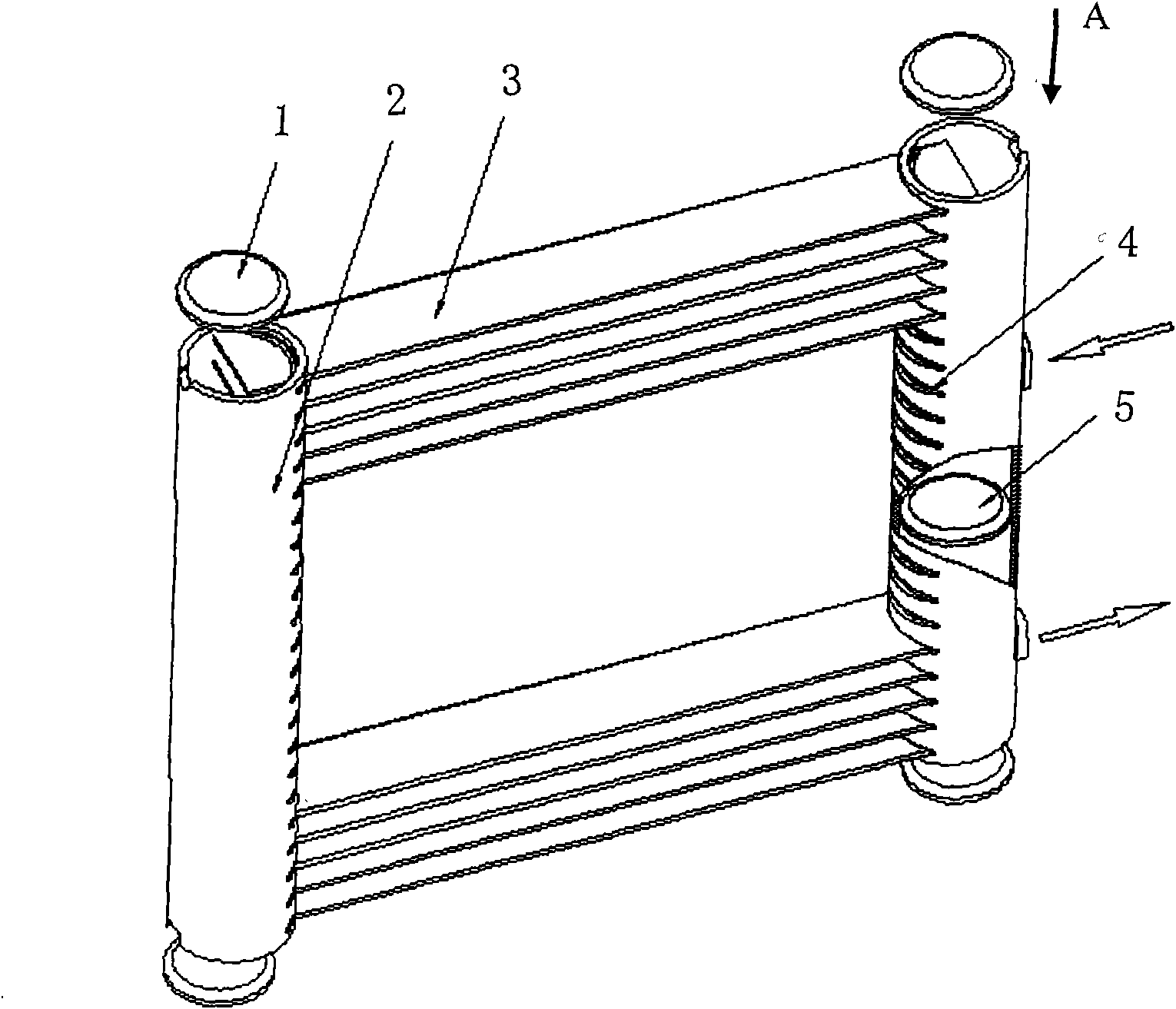

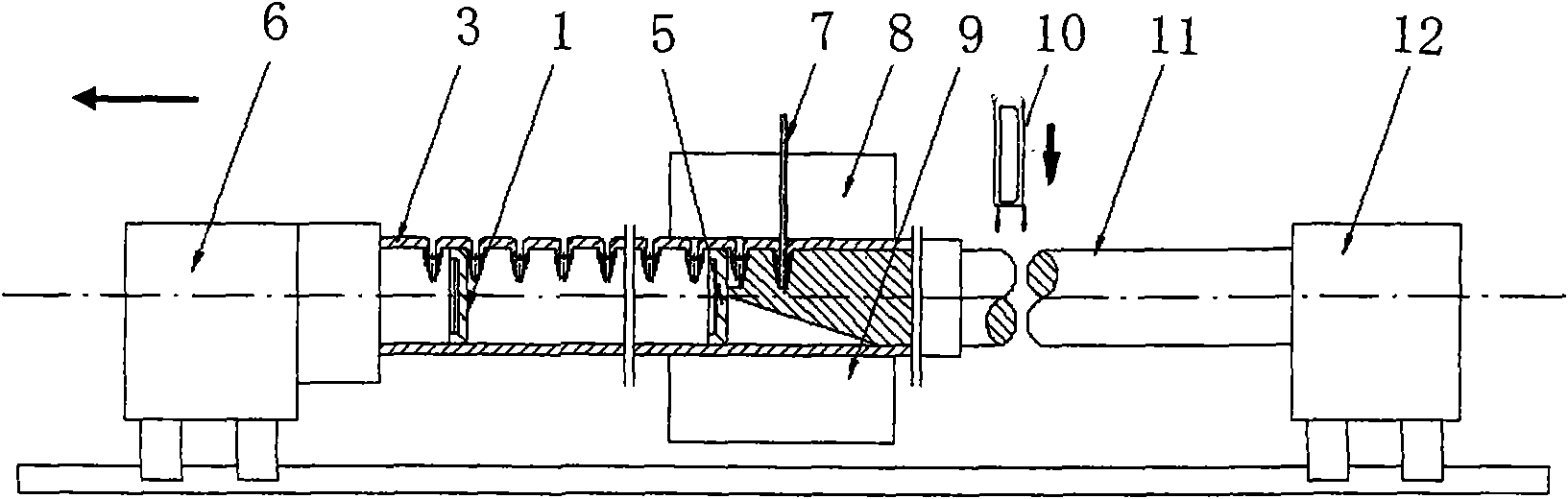

Method for processing collecting tube of heat exchanger

InactiveCN101590502ALow costCost savingsHeat exchange apparatusOperational costsPlate heat exchanger

The invention provides a method for processing a collecting tube of a heat exchanger, which is characterized in that: 1) the collecting tube is limited between a demoulding press block and a lower base, one or more sets of punching knives are arranged in the vertical direction right above the collecting tube, and one end of the collecting tube is connected with a slide block; and 2) when the punching knives press downward, and after one or more punching holes are punched, the punching knives move upward to be lifted, the slide block drives the collecting tube to move toward the front end, by taking the hole spacing of the collecting tube as a stepping stroke, when the collecting tube reaches the punching position of the next punching hole, the punching operation is repeated until all punching holes are punched. The inside of the collecting tube is provided with a core rod in order to avoid the inward caving of the punching holes. The method has the advantages that: the operating process is simple; and the size of the punching knives can be flexibly replaced according to the actual size of the punching holes, and the hole spacing of the punching holes is adjusted by the stepping distance of the slide block, so that the method is suitable for processing collecting tubes of the heat exchangers in different specifications as well as the mechanical mass production, and simultaneously saves a great deal of mould cost, punching equipment cost and operational cost.

Owner:JIANGSU KANGTAI HEAT EXCHANGE EQUIP ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com