Patents

Literature

68results about How to "Solve sinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

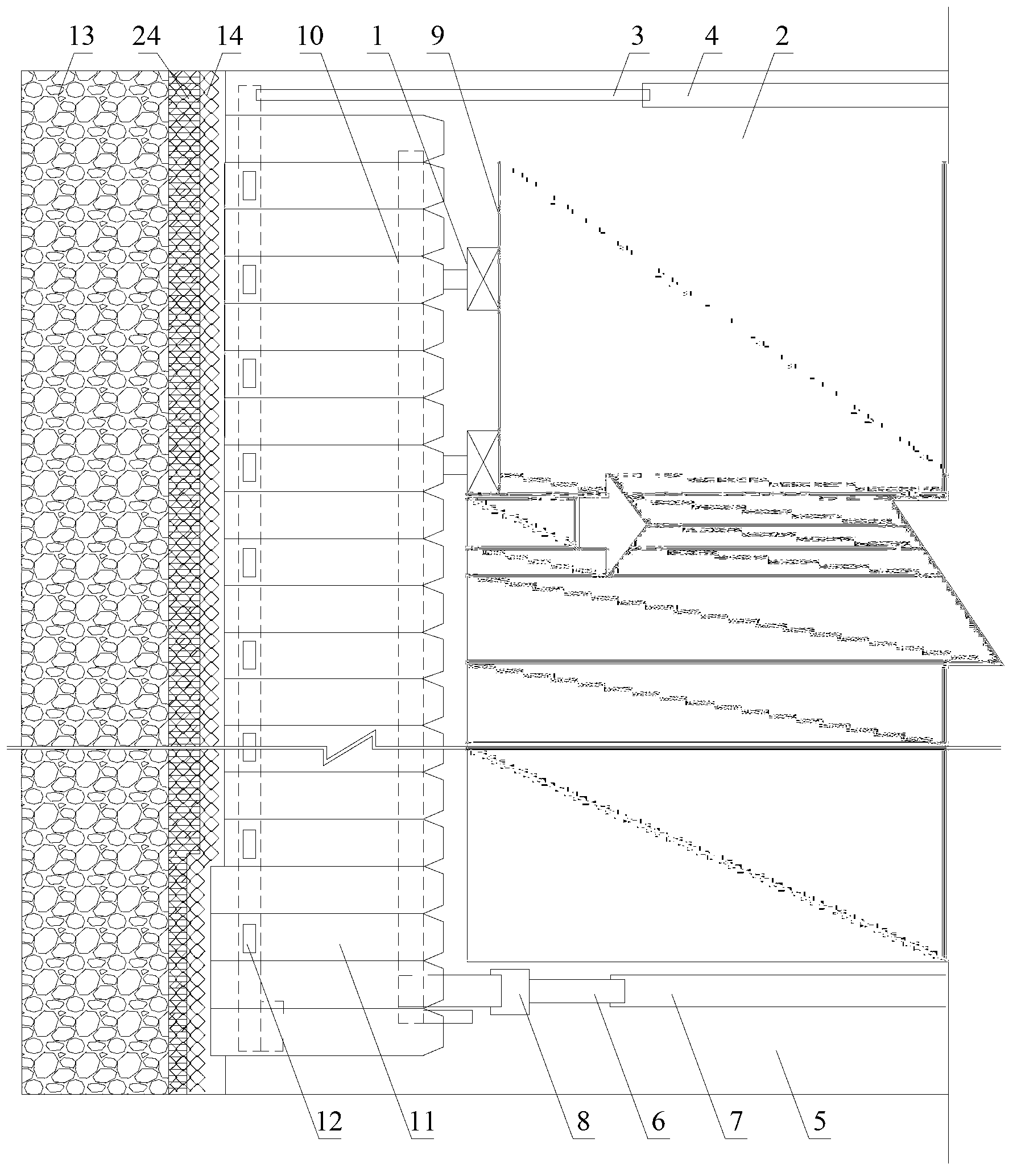

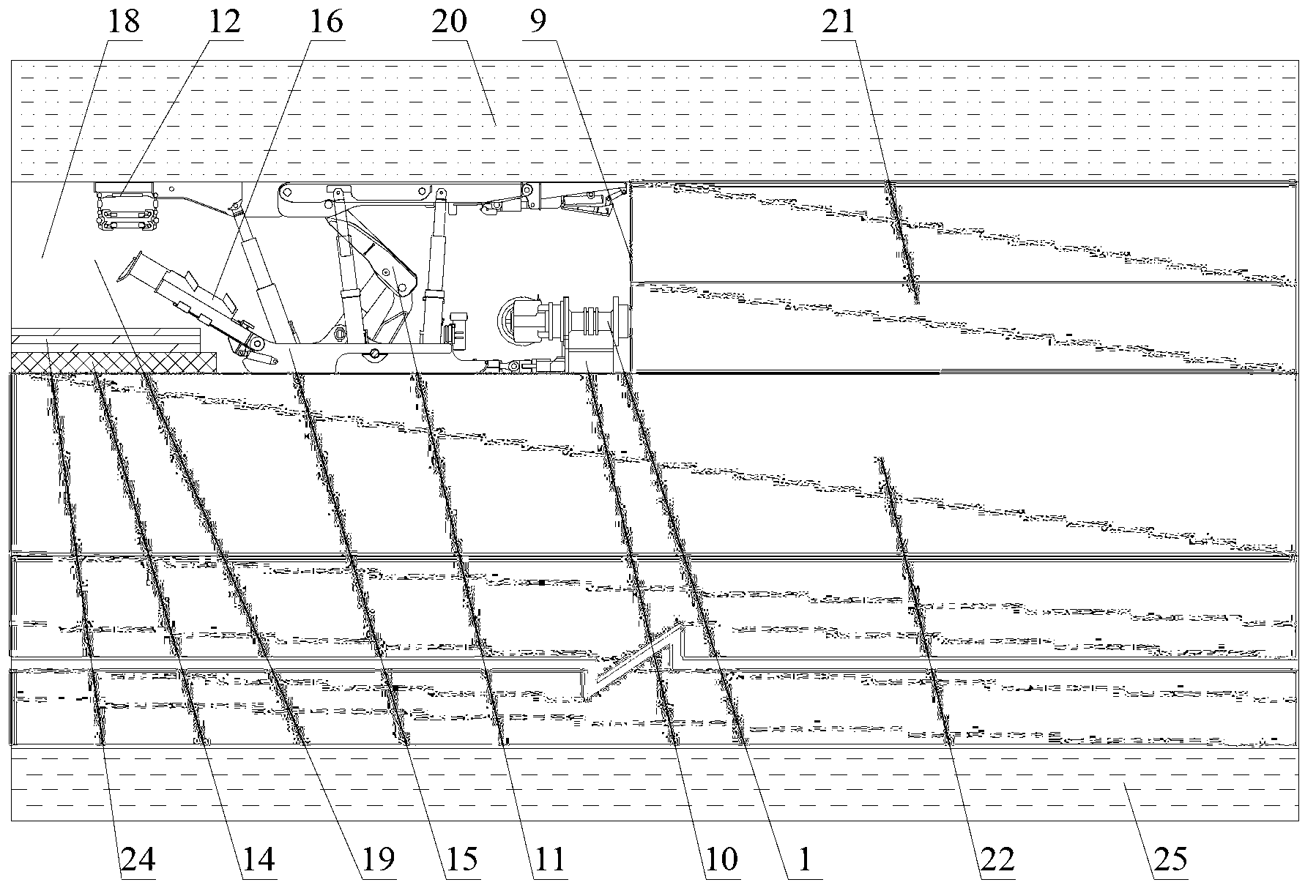

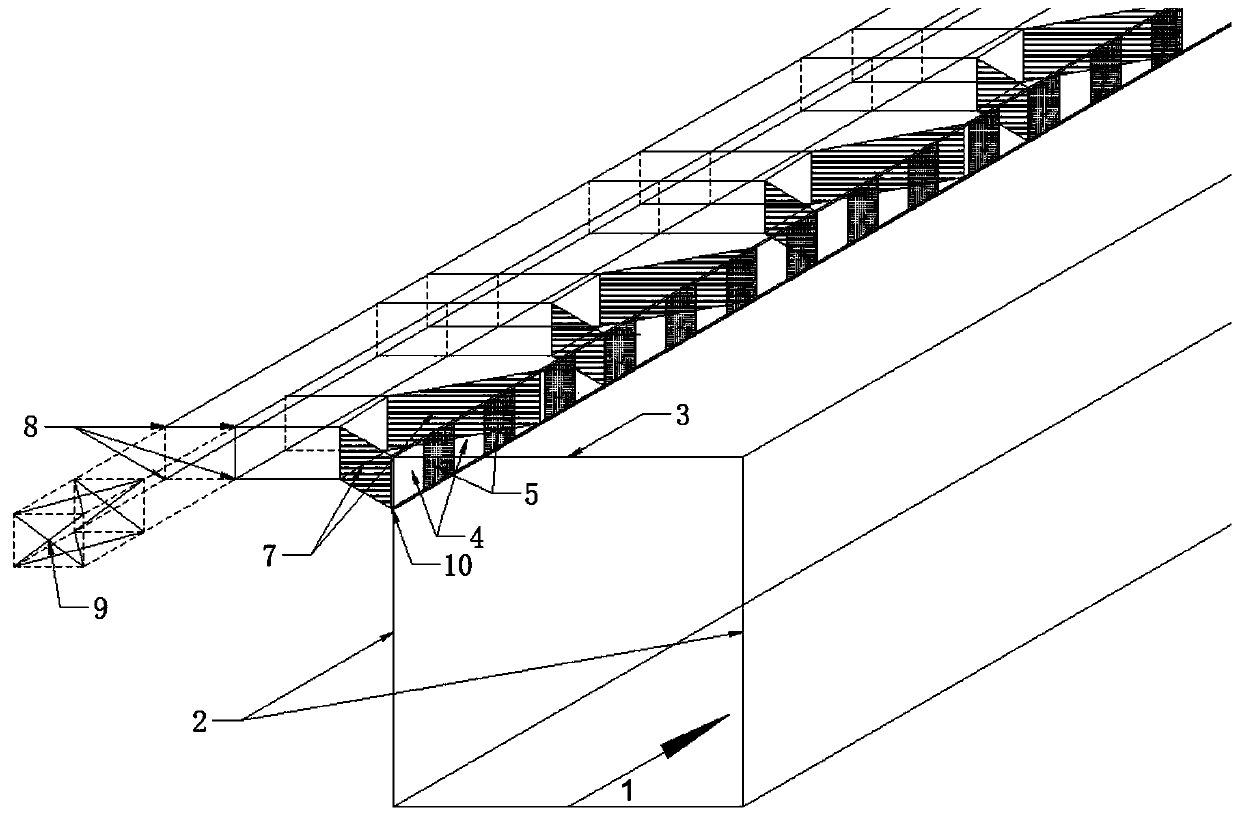

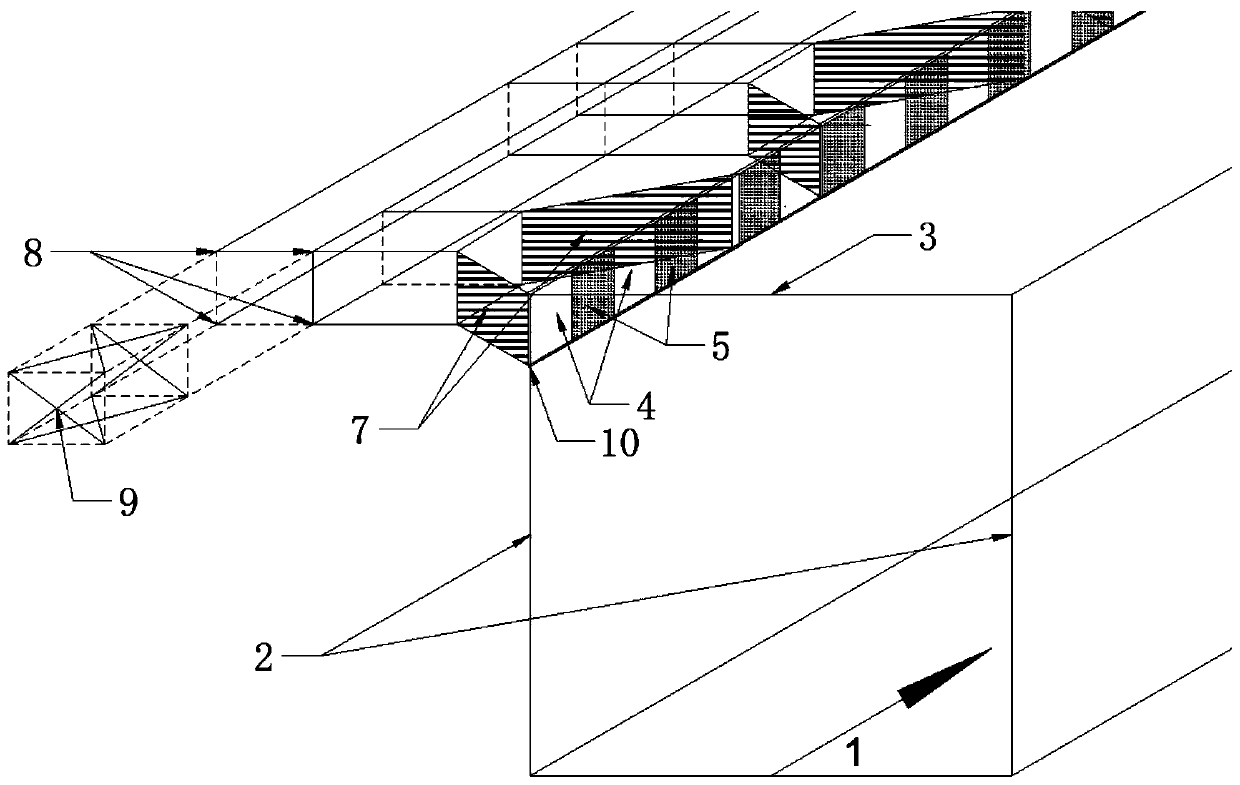

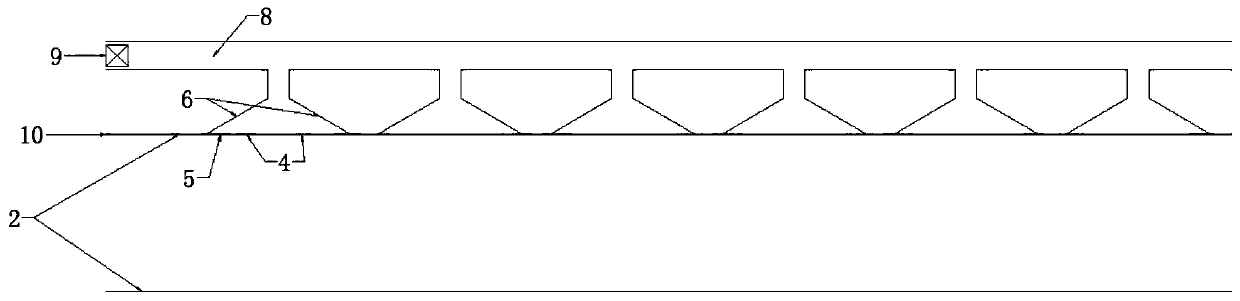

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

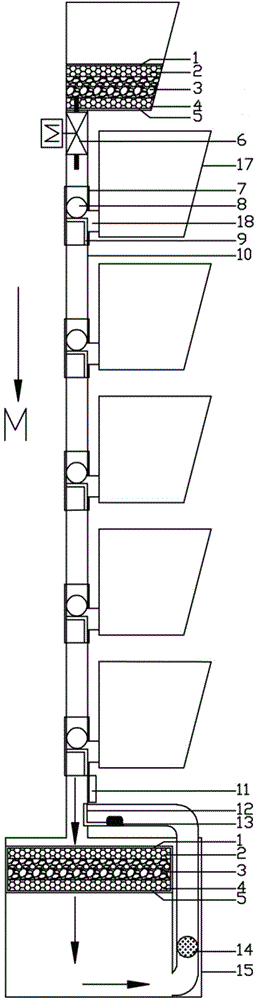

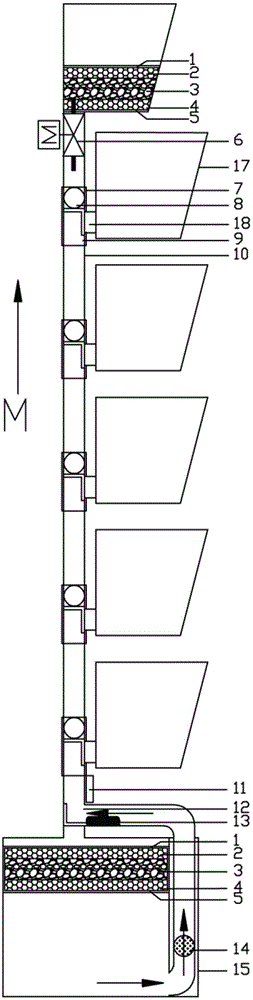

Landscape combined-type stereoscopic greening smart system

ActiveCN104542042ASolve sinkingFlexible replacementGeneral water supply conservationWatering devicesVertical planeSolenoid valve

The invention relates to the technical field of stereoscopic greening, in particular to a landscape combined-type stereoscopic greening smart system. The landscape combined-type stereoscopic greening smart system comprises a rainwater collection and purification system, a water guiding irrigation system, green plant systems, an outer electronic control system and a water storage purification system, wherein the water guiding irrigation system comprises a detachable combined-type water guiding pipeline framework and greening module clamping grooves; the detachable combined-type water guiding pipeline framework is fixed on a construction vertical plane; the greening module clamping grooves are formed in and communicated with the detachable combined-type water guiding pipeline framework; each green plant system is arranged in one of the corresponding greening module clamping groove; the upper end and the bottom end of the detachable combined-type water guiding pipeline framework are respectively connected with the rainwater collection and purification system and the water storage purification system; a solenoid valve is arranged at the water outlet of the rainwater collection and purification system and electrically connected with the outer electronic control system. The landscape combined-type stereoscopic greening smart system is simple in structure, relatively high in practicability and low in use cost, meanwhile, can realize cyclic utilization of water resources, achieves the effects of attractive appearance and environmental protection, and can effectively economize resources.

Owner:辽宁易发成林生态技术有限公司

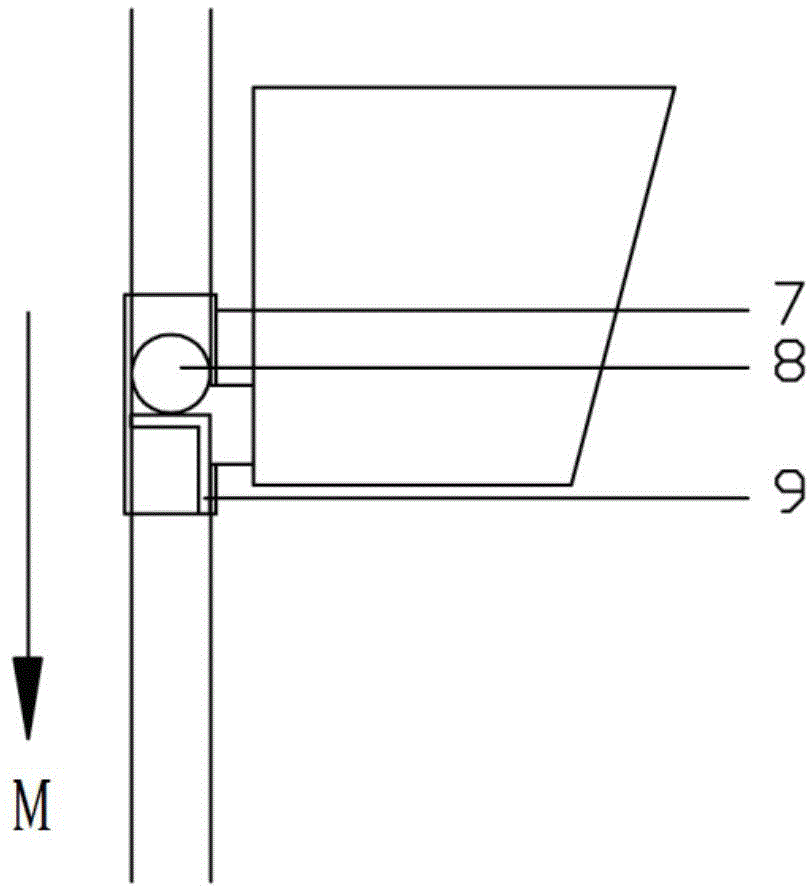

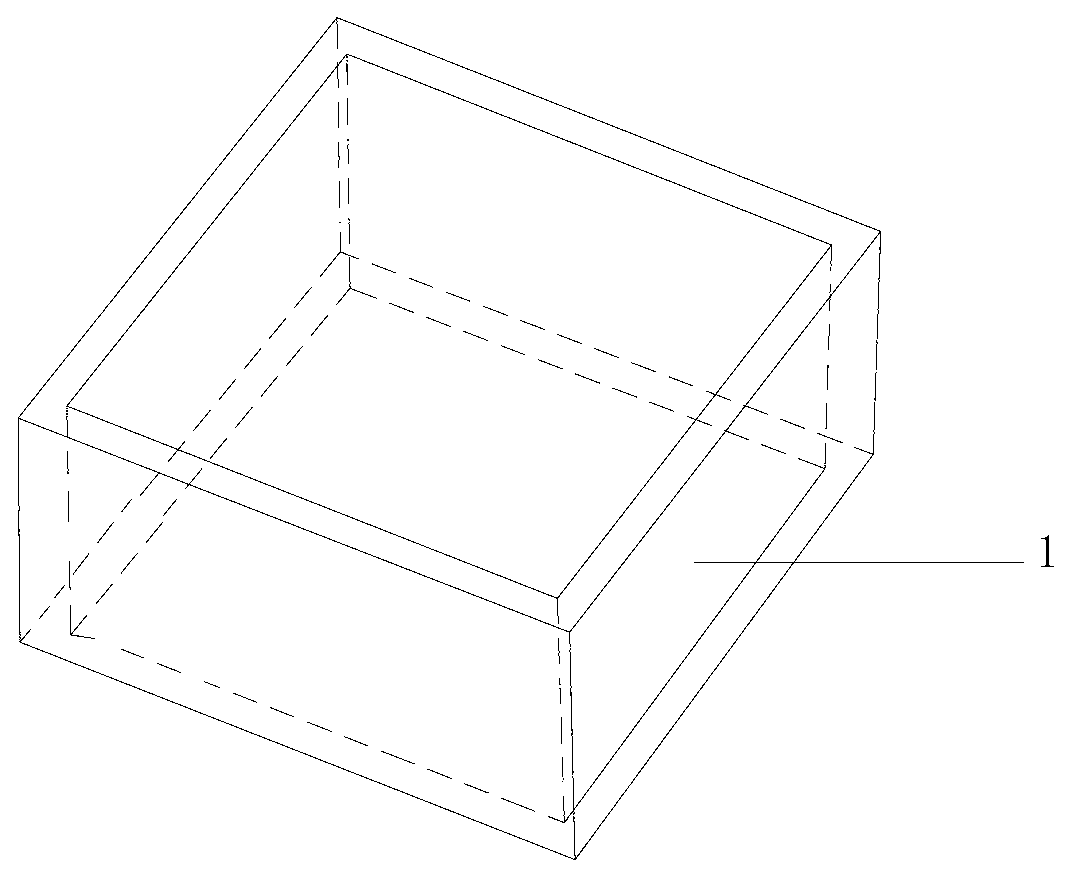

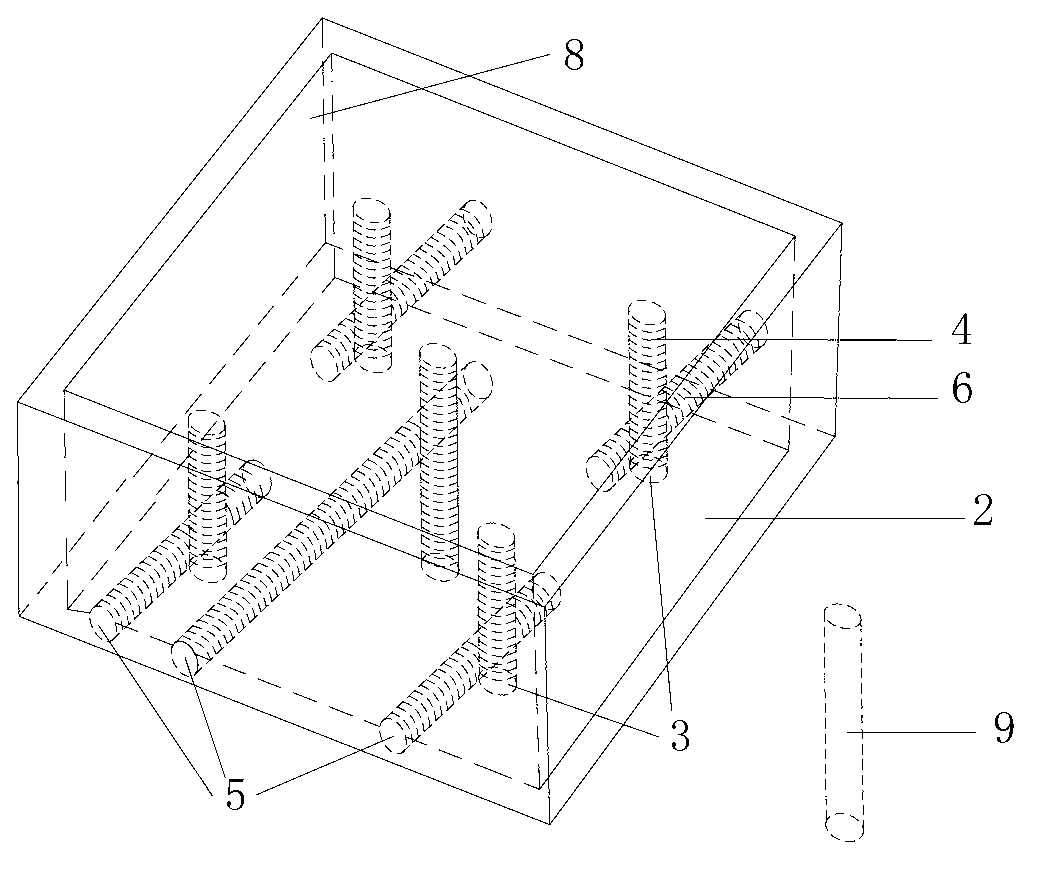

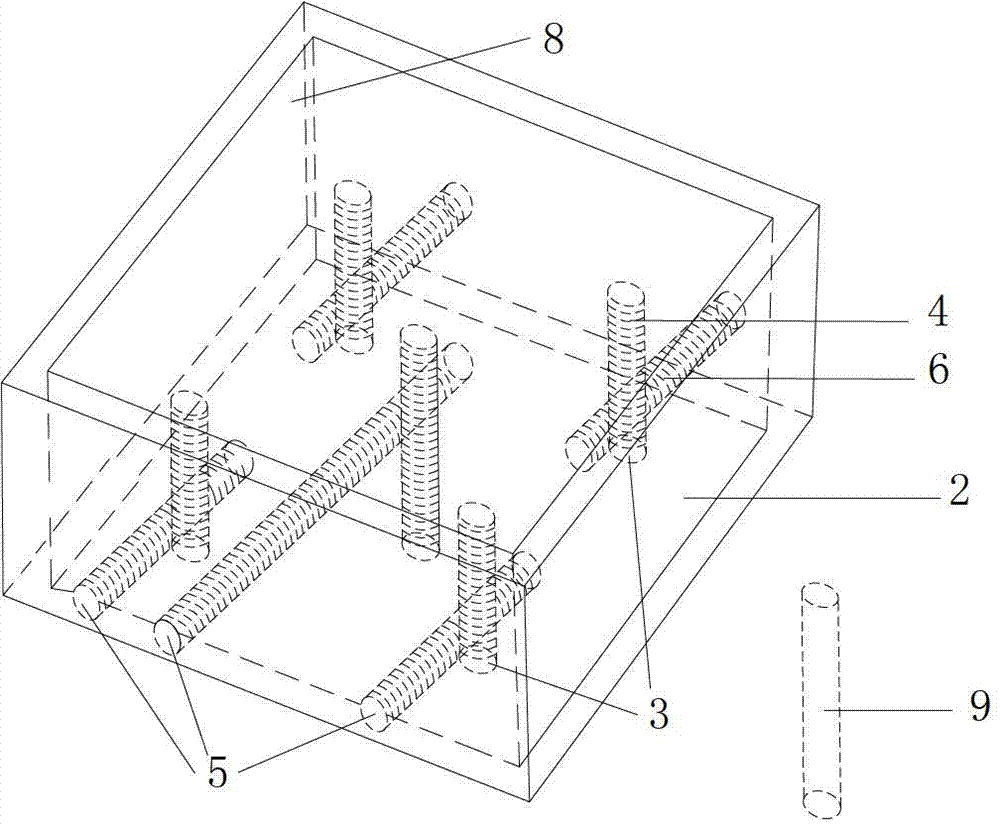

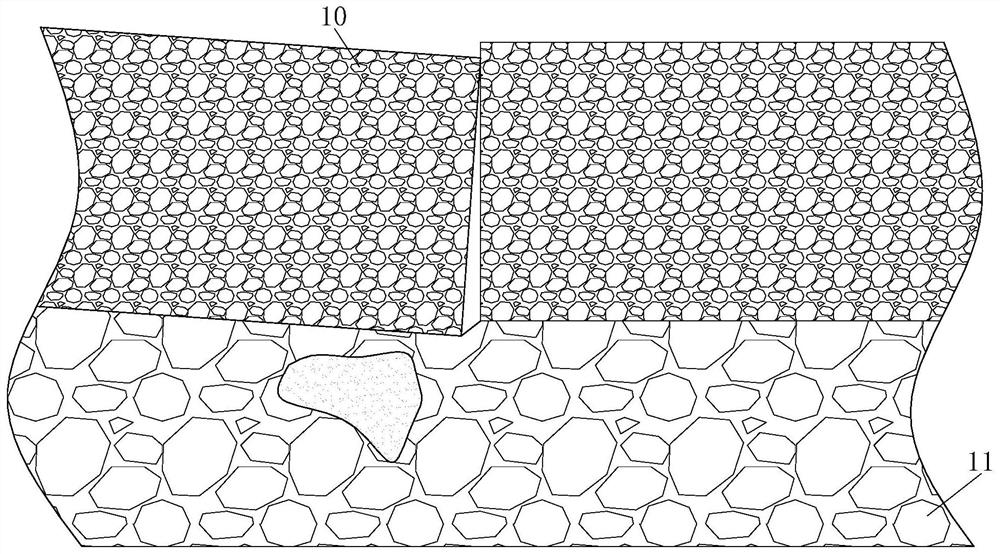

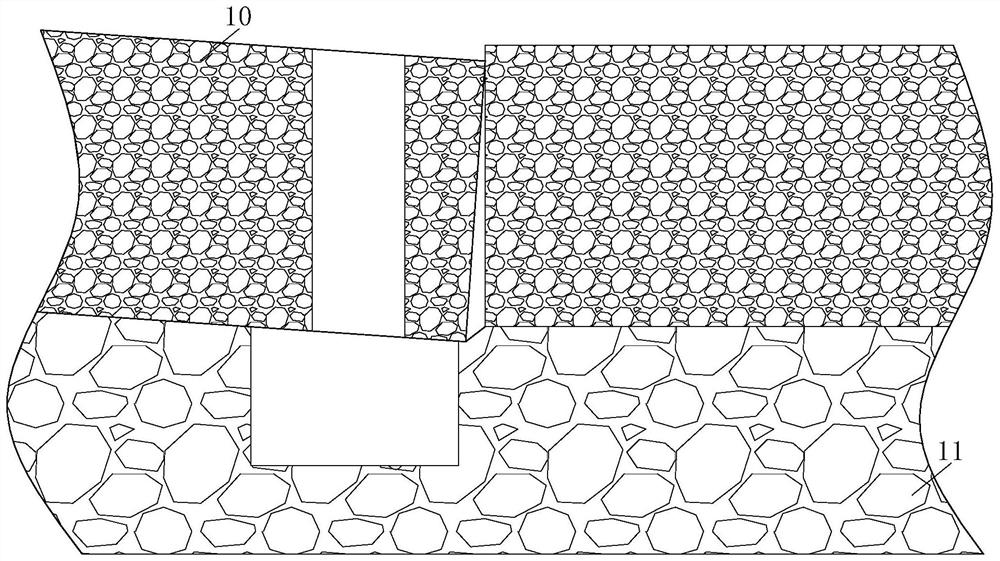

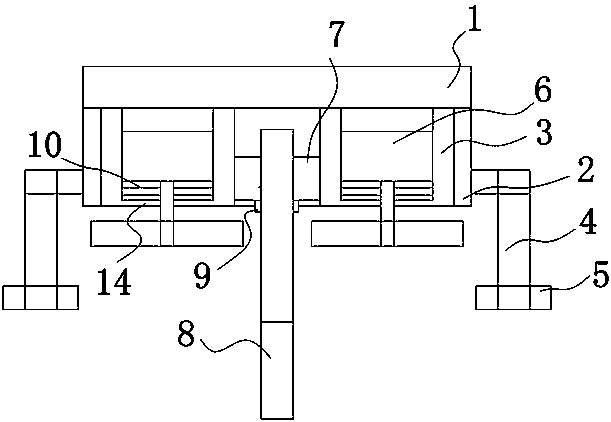

Experimental method and apparatus for shearing of structural surface of columnar jointing

ActiveCN103234838ASolve sinkingFast coolingMaterial strength using steady shearing forcesEpoxyExperimental methods

The invention discloses an experimental method for shearing of a structural surface of a columnar jointing. The method comprises adjusting a rock structural surface to be located in a shearing seam of upper and lower shearing boxes; sleeving screw sleeves to five internally-inserted vertical screws, using plastic films to separate and wrap; vertically moving the internally-inserted vertical screws through adjusting rods, so that the structural surface of the columnar jointing rock is located between the shearing seam; selecting proportional epoxy resin mortar to form epoxy resin mortar; and pouring the epoxy resin mortar into the upper and lower shearing boxes for cooling and solidification. The invention further discloses an experimental apparatus comprises the upper and lower shearing boxes, the internally-inserted vertical screws and the adjusting rods, wherein a bottom of the lower shearing box is provided with vertical screw holes, walls of the lower shearing box are provided with horizontal screw holes, and contacted parts of the adjusting rods and the internally-inserted vertical screws form worm structures. According to the invention, fine adjustment of the rock position can be realized, a surface of the epoxy resin mortar can be always maintain as a plain, a molding is relatively good, problems of rock sinking in cement mortar can be solved, and thus the structural surface of the rock can be easily positioned.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

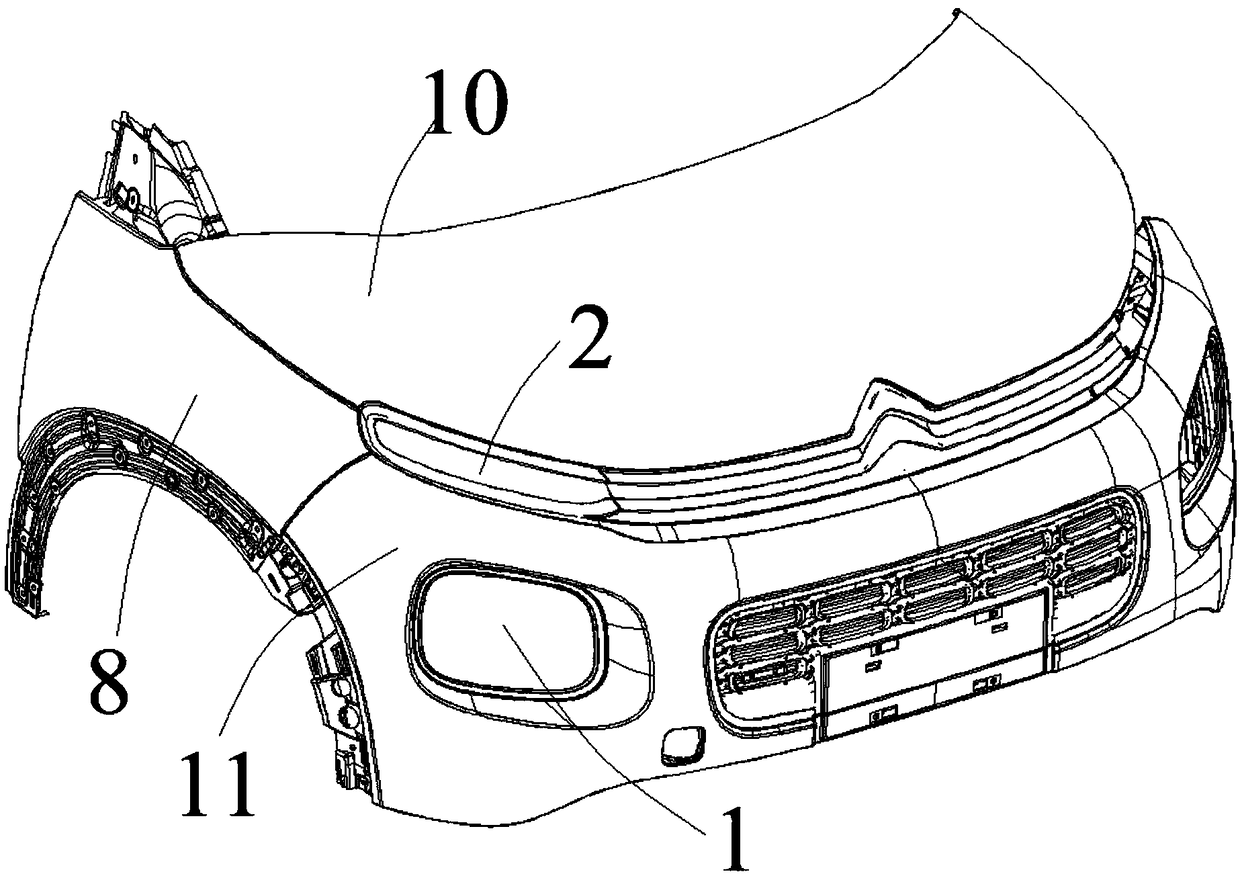

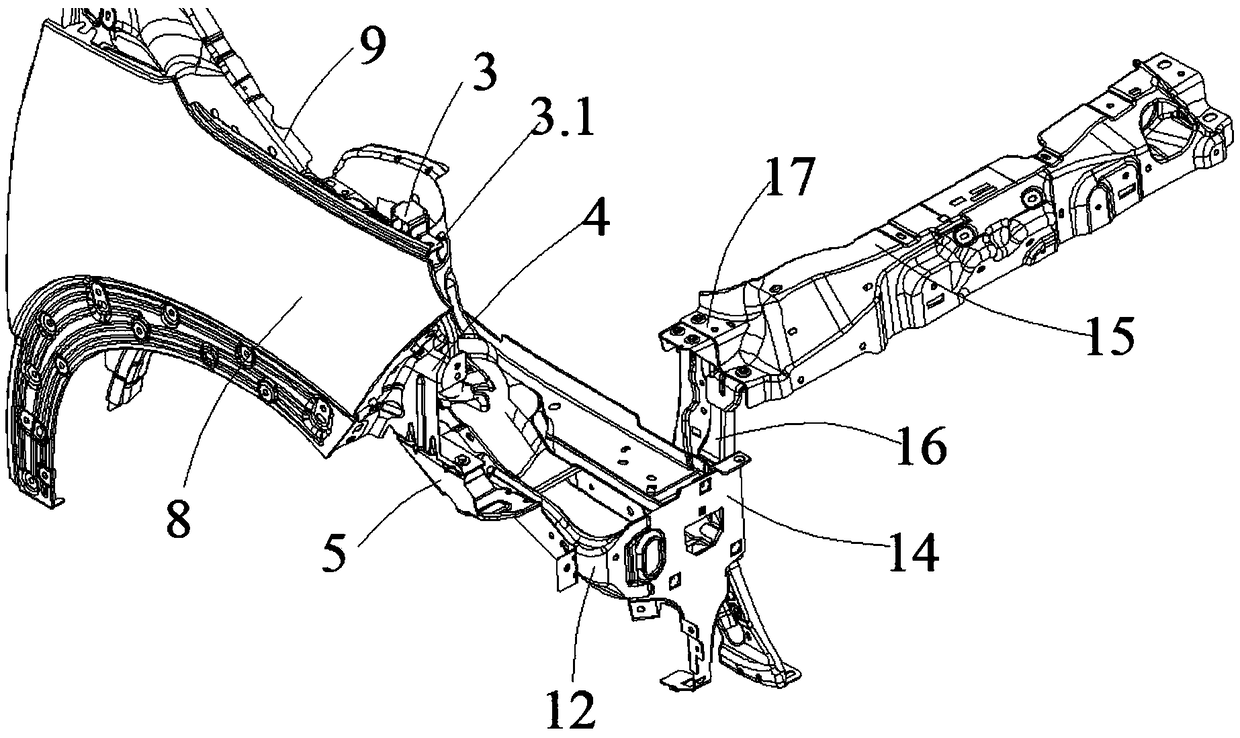

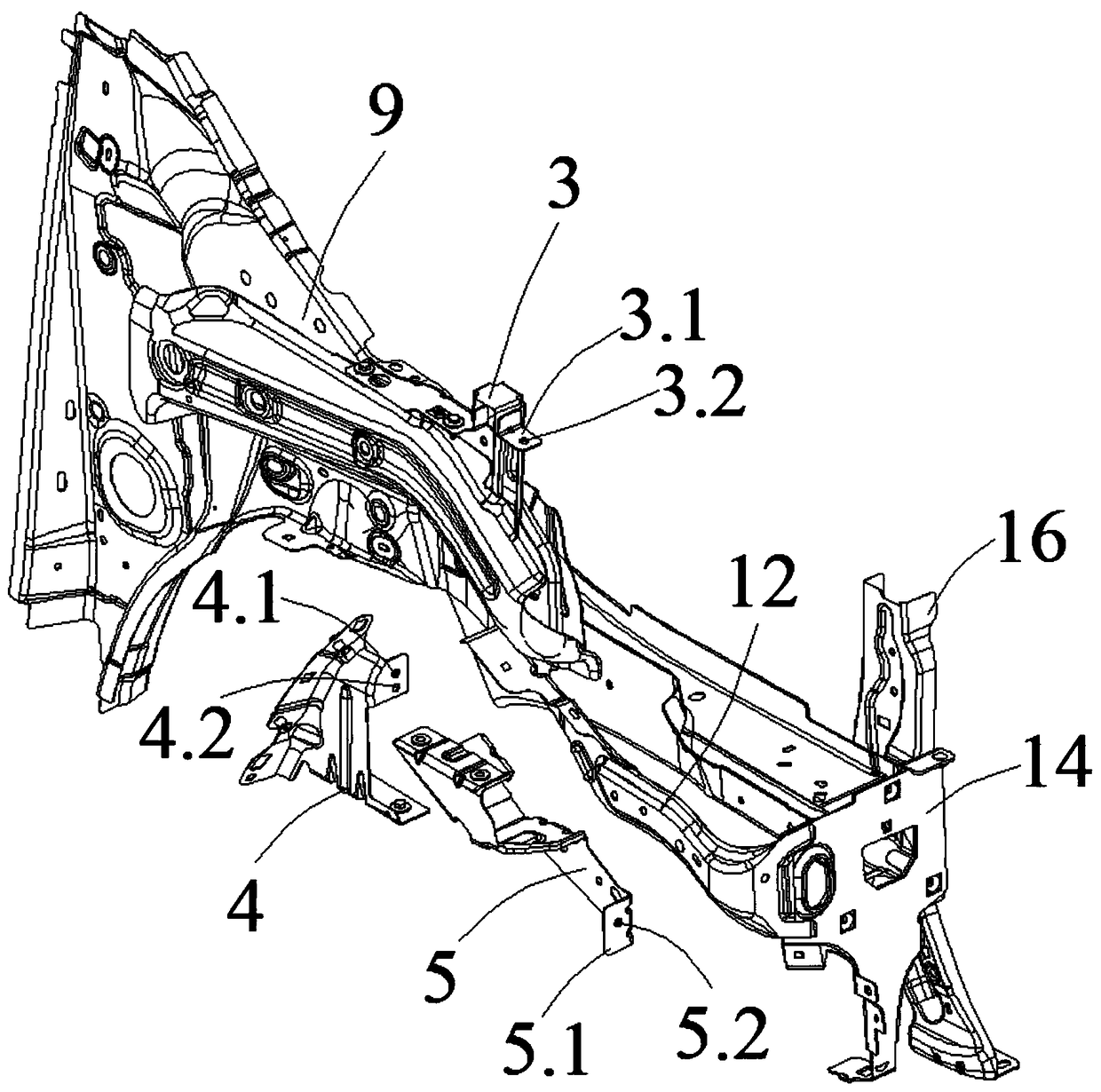

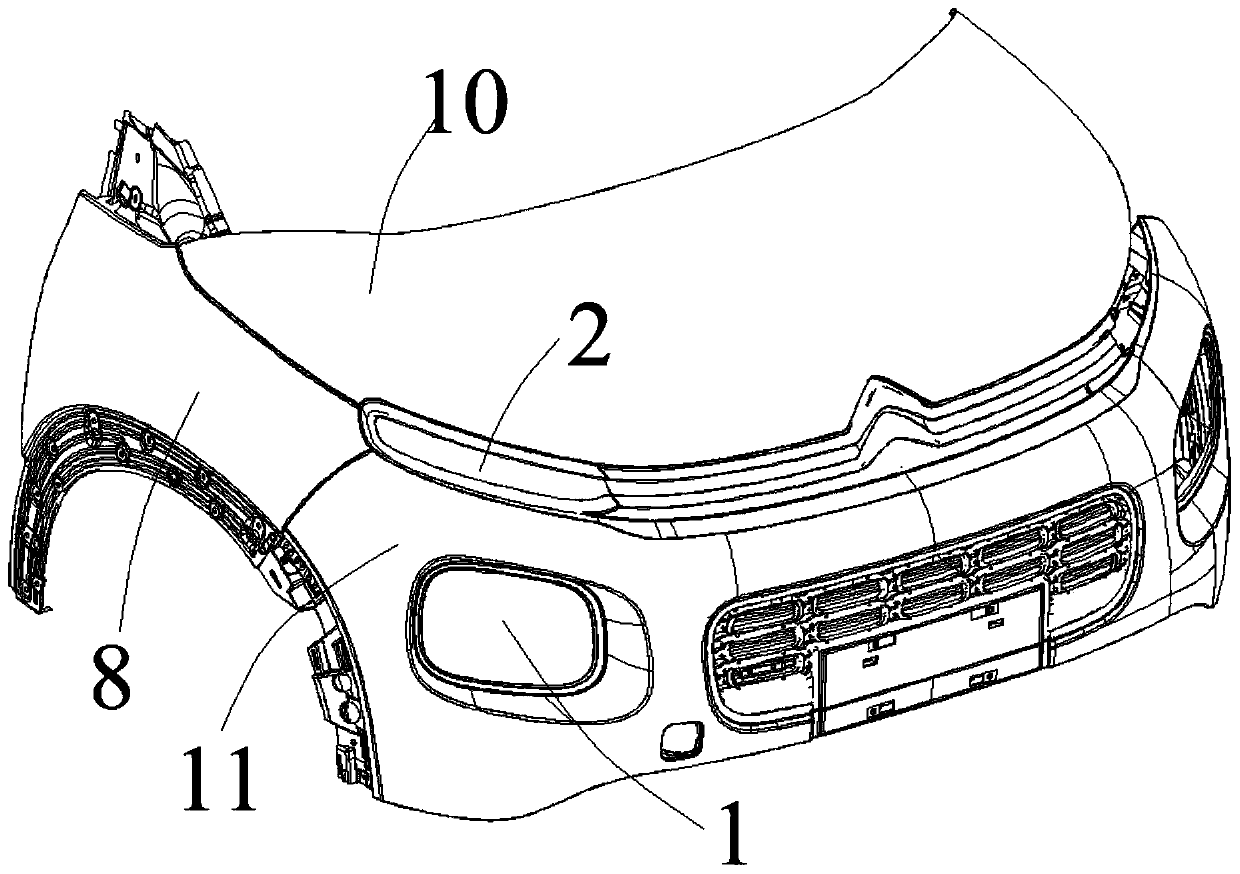

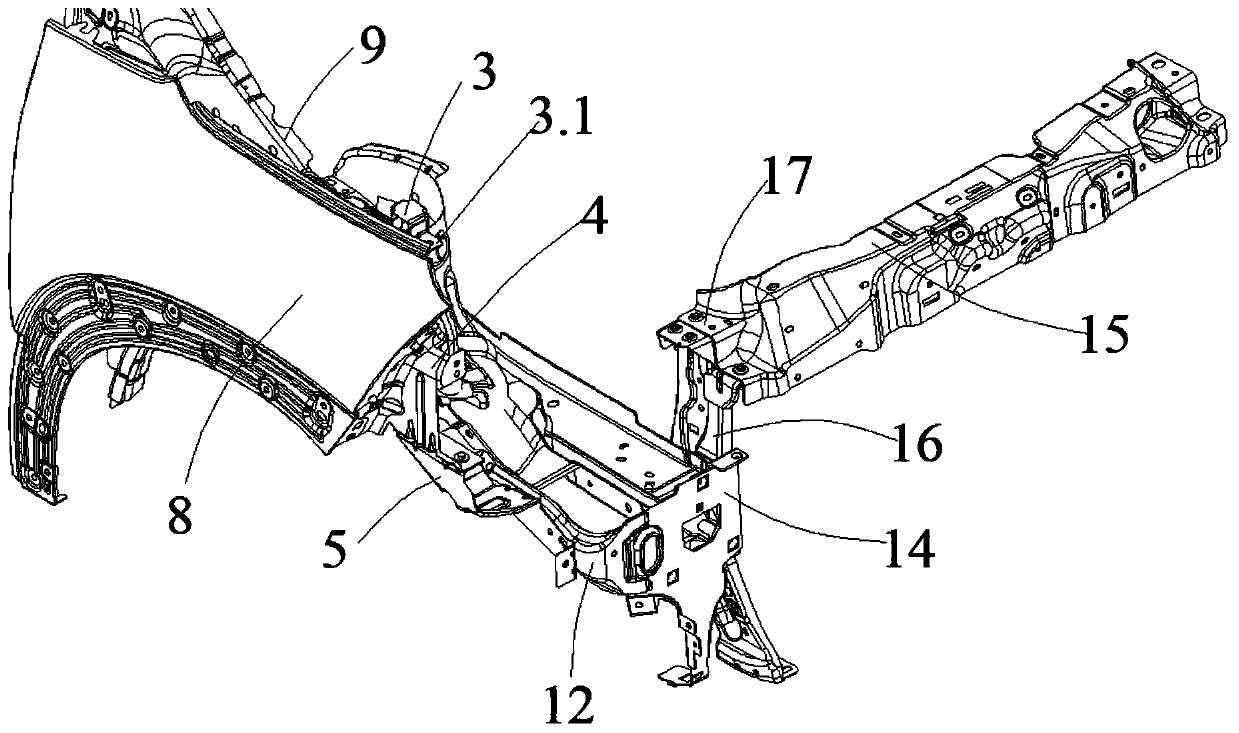

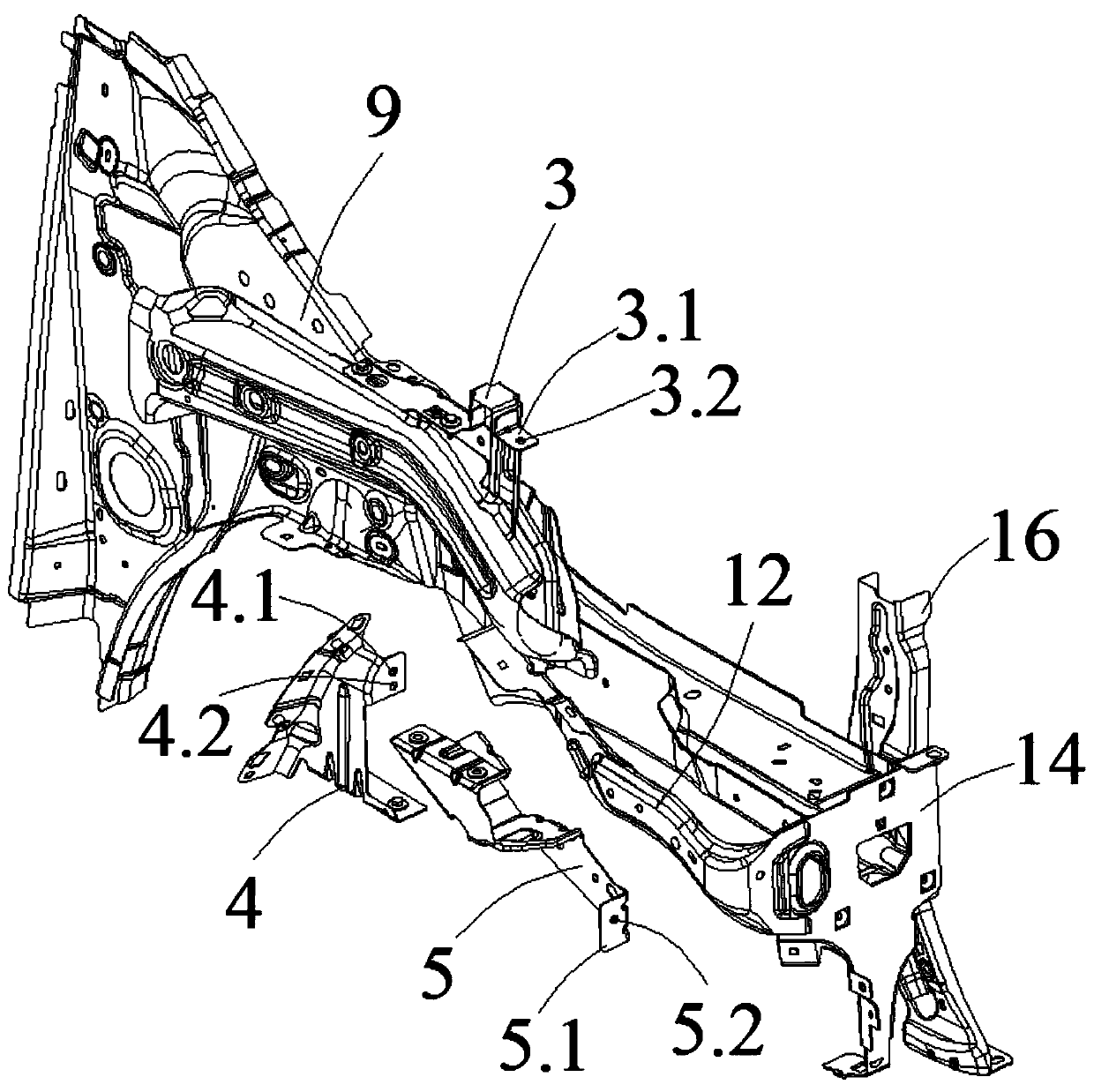

Vehicle front face structure

ActiveCN109466422AImprove stabilityEfficient sharingSuperstructure subunitsOptical signallingSurface layerStructural stability

The invention relates to the technical field of vehicle part structures, in particular to a vehicle front face structure. The vehicle front face structure comprises a fender support, the fender support is fixed to the two sides of a vehicle body in the Y direction and used for supporting a fender and an engine hood, and a front bumper upper framework is fixed to the front end of the vehicle body in the X direction and used for supporting a front bumper surface layer and the engine hood; the vehicle front face structure further comprises a headlamp assembly covered with the front bumper surfacelayer; the fender support comprises a fender front support body used for supporting a fender outer plate and a fender lower support body fixed to an edge beam of the side of the vehicle body; the headlamp assembly is fixedly connected with the fender lower support body through a lower fixing structure at the Z-direction lower end, fixedly connected with the front bumper upper framework through aside fixing structure at a Y-direction side part and fixedly connected with the fender front support body through a rear fixing structure at the X-direction rear end. The vehicle front face structureis reasonable in distribution, improves the structural stability of the headlamp assembly and a daytime driving lamp, and solves the submerging problem caused by concentration of weight.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

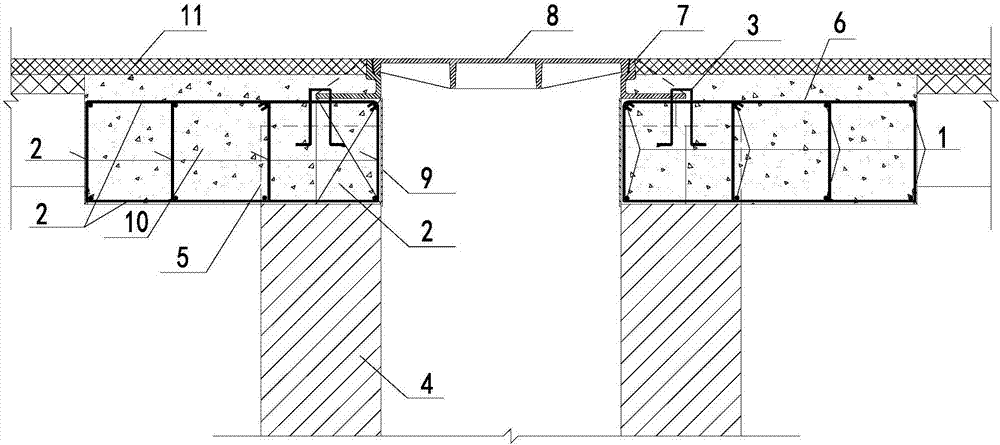

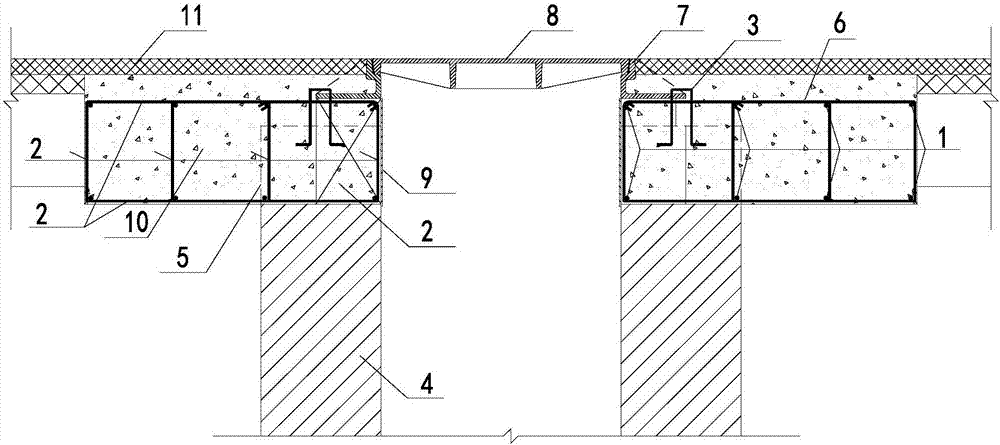

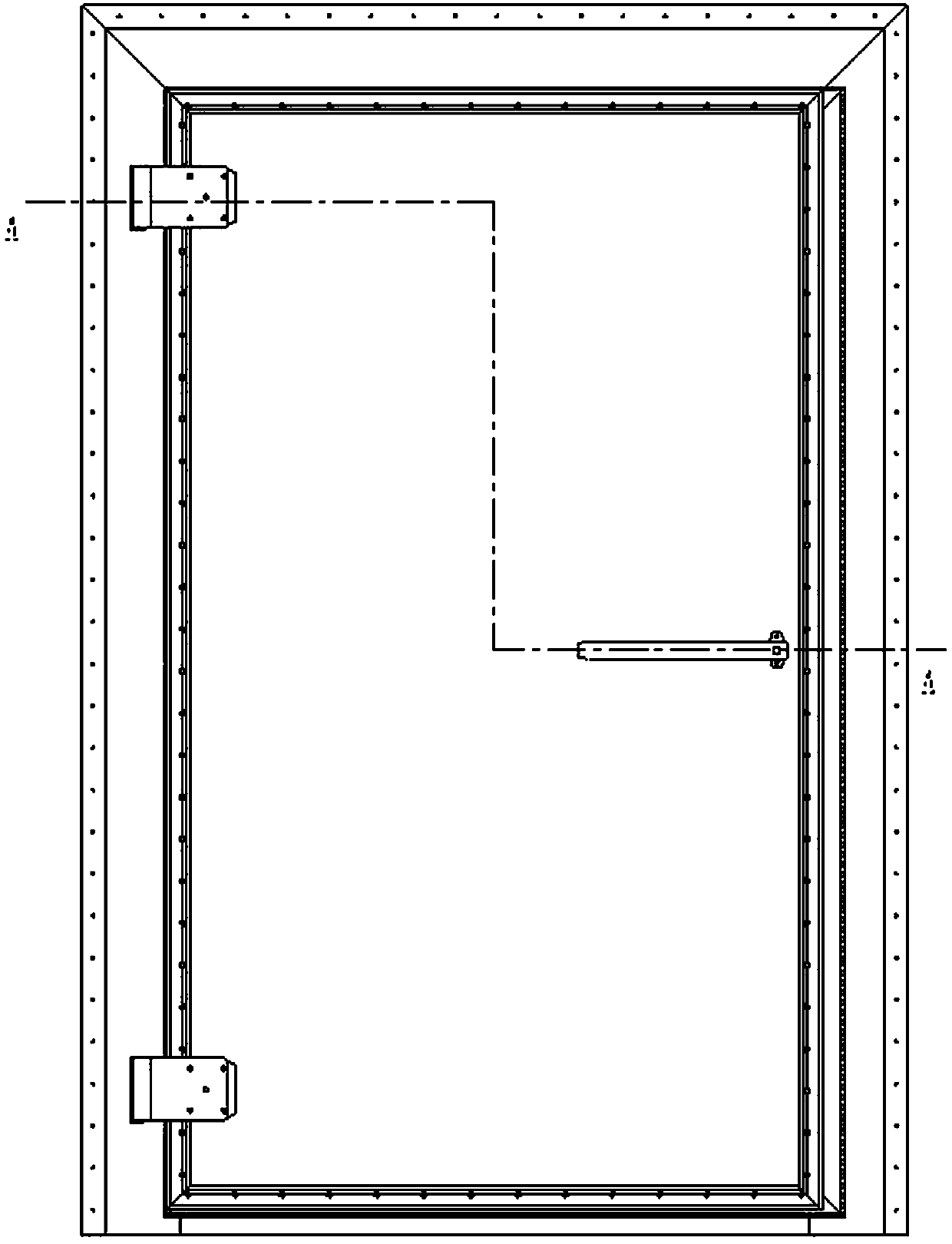

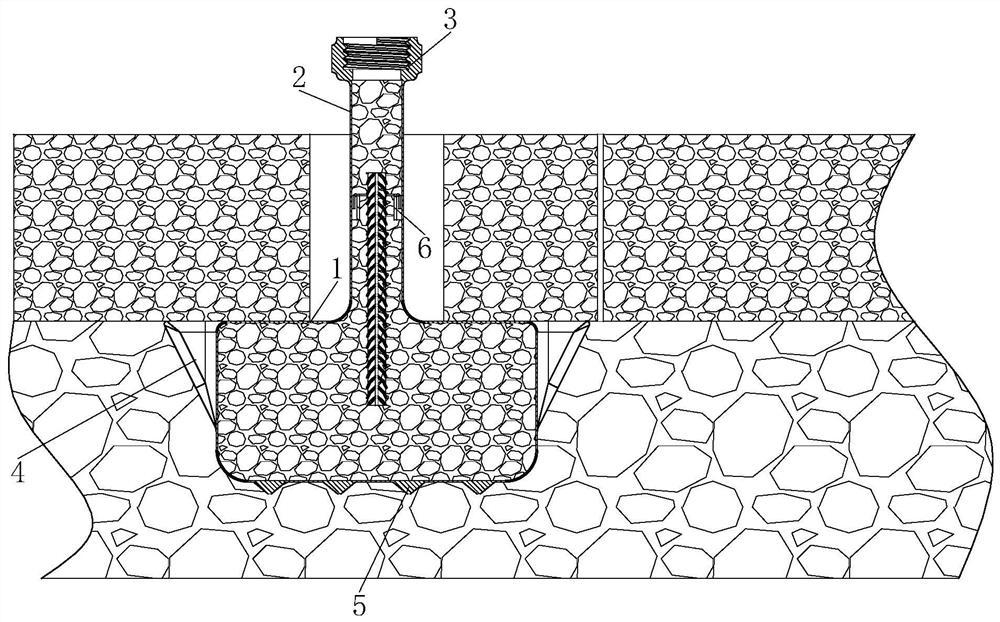

Bearing platform type safety manhole

InactiveCN1970899ASolve sinkingNot easy to pull outArtificial islandsUnderwater structuresTraffic accidentEngineering

The invention discloses a desk safety and inspection well, comprising well base (1) set at the bottom of inspection well, well cylinder, well seat (4) and well cover (6). Its well cylinder is divided into fixed well cylinder (2) and active well cylinder (3). The fixed well cylinder (2) is fixed on the well base (1) and presetting active well cylinder (3) is set on the fixed well cylinder (2) vertically. Pre-buried well ring (11) is set on the well seat (4), which is covered on the active well cylinder (3) flatly. Under the well cover (6) there is a desk (5), which covers on the active well seat (3). The well cover (6) is set in the well ring (11) of well seat (4). The well cover (6) and desk (5) are locked together by screw cap (3) and screw bar (9). The inspection well in the invention can solve the repairing problem when inspection well goes down or declines under pressure and the well cover is connected with the well seat by hinge so that it is opened freely and not easy to be stolen. Abnormal well cover is not easy to be turn out when it is extruded by wheel. If one well cover is lost, the reflectorized paint on the desk can take a caution to foot passenger or traveling crane so as to avoid the traffic accident.

Owner:姜静怡

Imaging diagnosis equipment

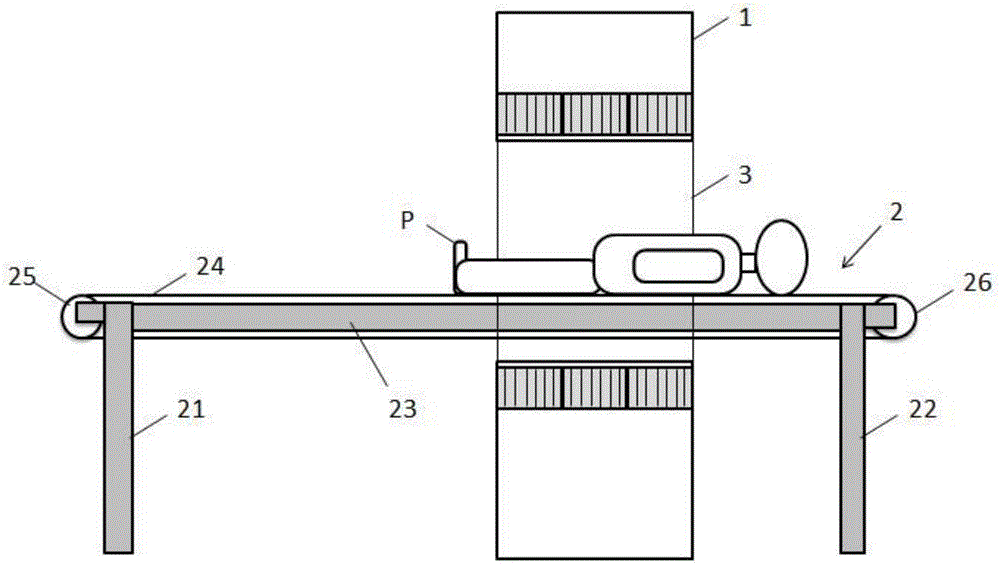

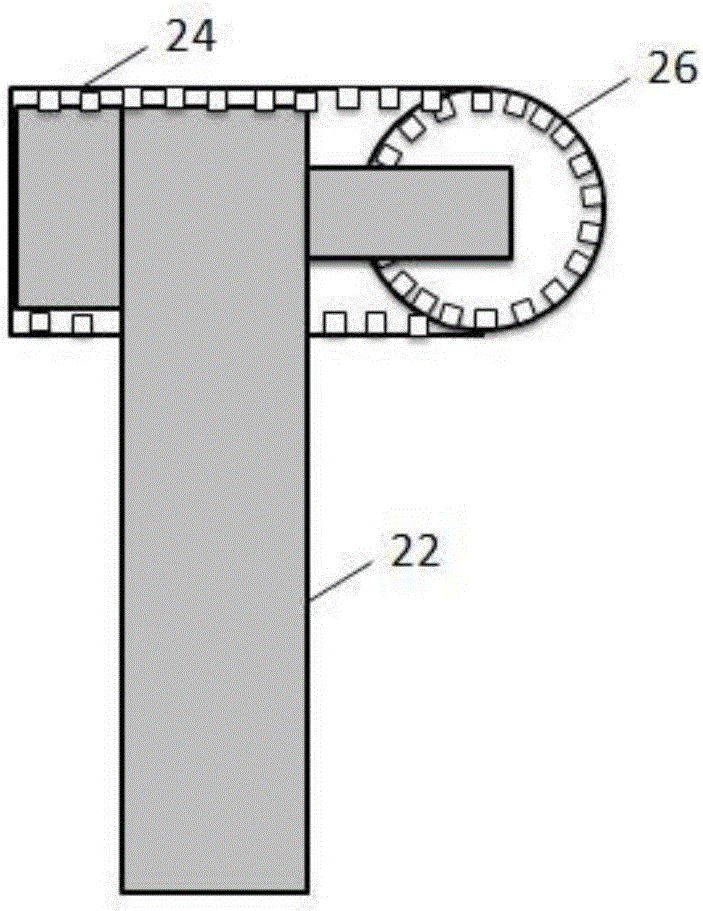

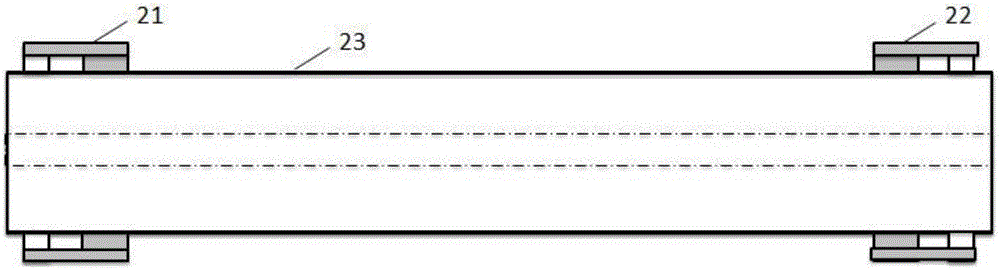

InactiveCN106419943ASolve sinkingPatient positioning for diagnosticsComputerised tomographsImage diagnosisEngineering

The invention provides imaging diagnosis equipment. The imaging diagnosis equipment comprises imaging equipment and a scanning bed, wherein the scanning bed comprises a first support platform, a second support platform, a bed board and a conveying device; the first support platform and the second support platform are arranged on two sides of a scanning area of the imaging equipment; the bed board is arranged above the first support platform and the second support platform; the conveying device comprises a conveyer belt which is arranged above the bed board and a driving device which is arranged to be correlated to the conveyer belt; and the driving device is used for driving the conveyer belt to conveying tested subjects to the scanning area.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

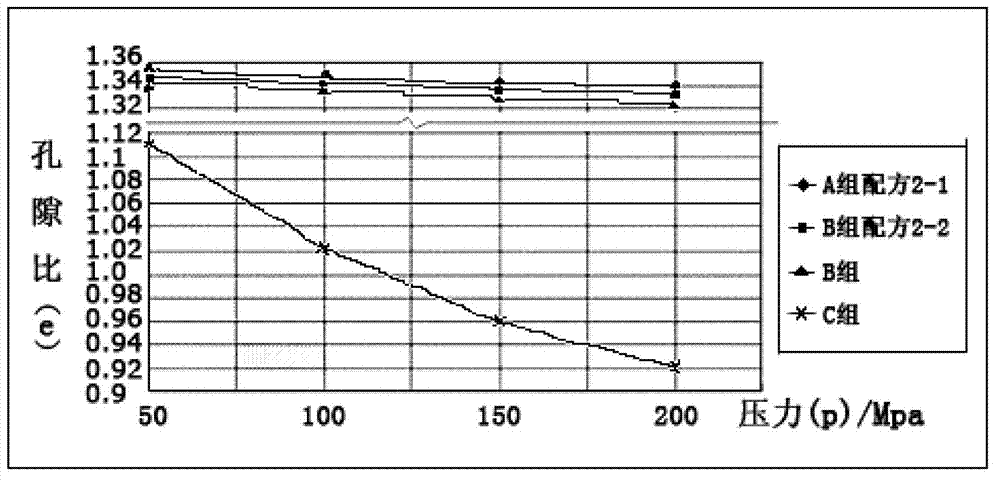

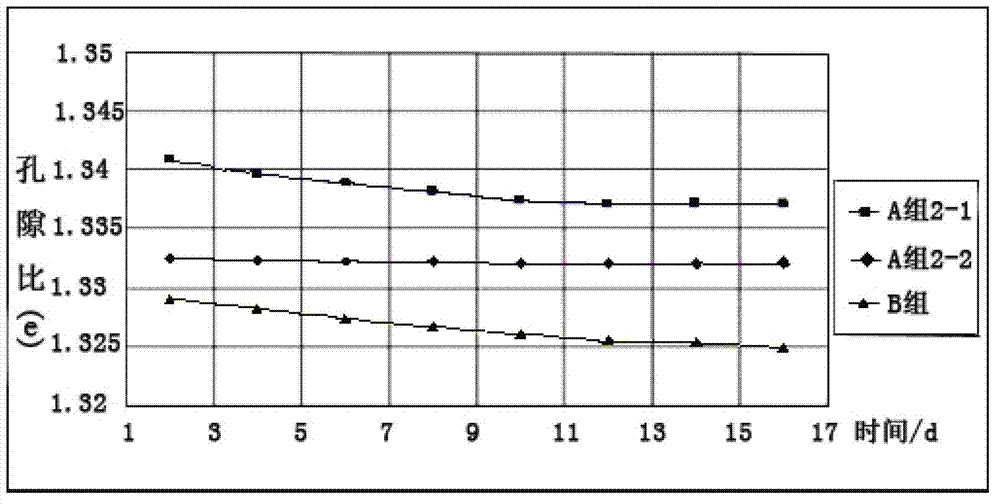

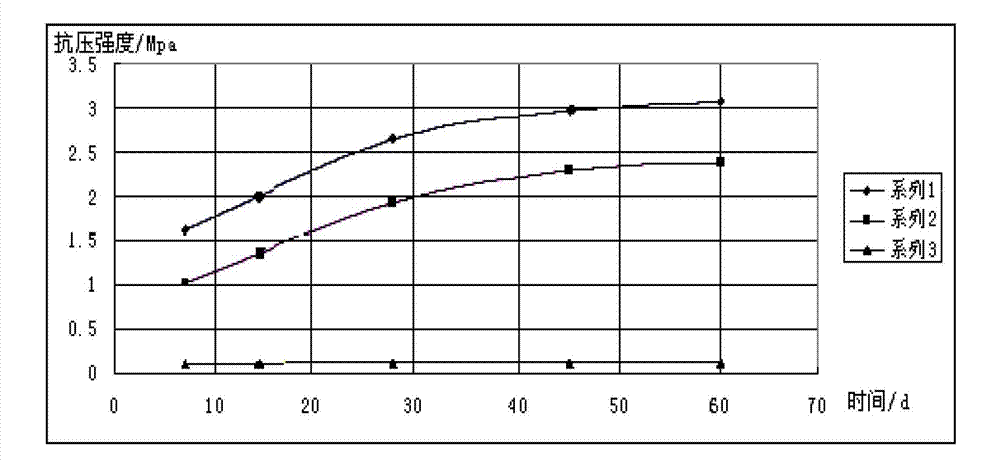

Novel formula for reclamation shoal soft soil suitable for ultra soft soil hydraulic reclamation method

InactiveCN102786281AHigh compressive strengthImprove early compressive strengthOrganic fertilisersSoil conditioning compositionsSludgeMaterials science

The invention provides a novel formula for reclamation shoal soft soil suitable for ultra soft soil hydraulic reclamation method. The formula comprises the following components, by mass part: 10 parts of dry soil powder, 2.40 parts of cement, 0.72 part of water glass, 0.576 parts of fly ash, 0.132 part of silicone powder, 0.12 part of gypsum powder, 6.08 parts of water, and 0.072 part of py4 composite admixture. According to a large number of indoor orthogonal experiments by the invention, reinforcement soft soil for hydraulic reclamation and water drainage method in Wenzhou coast, which mainly includes sludge reclamation, is mixed with cement and a plurality of admixtures and compound additives, and pressure resistance, shear resistance and compression performance of the soil can be greatly changed; and compared with s conventional cement formula, the novel formula consumes less supplies, but can greatly improve pressure resistance, shear resistance and compression performance of cement shoal soft soil, especially improve early compressive strength and significantly reduce settlement after construction. Therefore, the formula has important meaning for large area utilization and construction of ultra soft soil hydraulic reclamation coastal reclamation land in coastal southeastern industrial belt.

Owner:WENZHOU UNIVERSITY

Urban road inspection well

PendingCN106906847ACustomer service construction time is limitedExpress traffic processingArtificial islandsUnderwater structuresAsphaltSurface layer

The invention discloses an urban road inspection well. The urban road inspection well comprises a shaft, a concrete precast block, a well periphery reinforcement cage, a well base, a well lid, a template, an early strength concrete layer and an asphalt surface layer. A well periphery support structure of the inspection well mainly includes two parts of the well periphery reinforcement cage and the earth strength concrete layer; the two parts are organically combined to effectively treat such more general and frequent diseases as well periphery sinking and well periphery road surface destruction of the inspection well frequently generated in urban road pavements; and the inspection well not only solves the frequent generation problems of well periphery sinking and local destruction, but also can overcome the limited difficulty of the construction time of urban roads. The inspection well structure is also suitable for repairing and transforming the destructed inspection well, and can achieve the effects of quick repair of the inspection well with urban road well periphery sinking and local destruction, quick traffic opening and thorough treatment of well periphery diseases.

Owner:北京特希达交通勘察设计院有限公司

Construction method for preventing surrounding subsidence and local damage of urban road manhole

InactiveCN107012760AQuick fixSolve sinkingArtificial islandsTemporary pavingsStructure of the EarthRoad surface

The invention discloses a construction method for preventing surrounding subsidence and local damage of an urban road manhole. The construction method for preventing the surrounding subsidence and the local damage of the urban road manhole comprises the steps of determining a manhole surrounding treatment range; digging and removing old pavement structures within the range; mounting a manhole surrounding reinforcement cage; mounting a cast iron manhole seat; adjusting the elevation of the manhole seat; supporting a template; pouring concrete; protecting a finished product; and laying an asphalt concrete surface course. According to the construction method for preventing the surrounding subsidence and the local damage of the urban road manhole, a problem that the surrounding subsidence and local damage frequently occur because the traditional material cannot be compacted in the traditional manhole surrounding treatment method is solved; as early strength concrete and the manhole surrounding reinforcement cage are organically combined, the difficulty that urban road construction time is limited can be overcome; the urban road manhole with the surrounding subsidence and the local damage can be rapidly repaired and can be rapidly open to traffic; and a manhole surrounding disease treatment effect is complete.

Owner:北京特希达交通勘察设计院有限公司

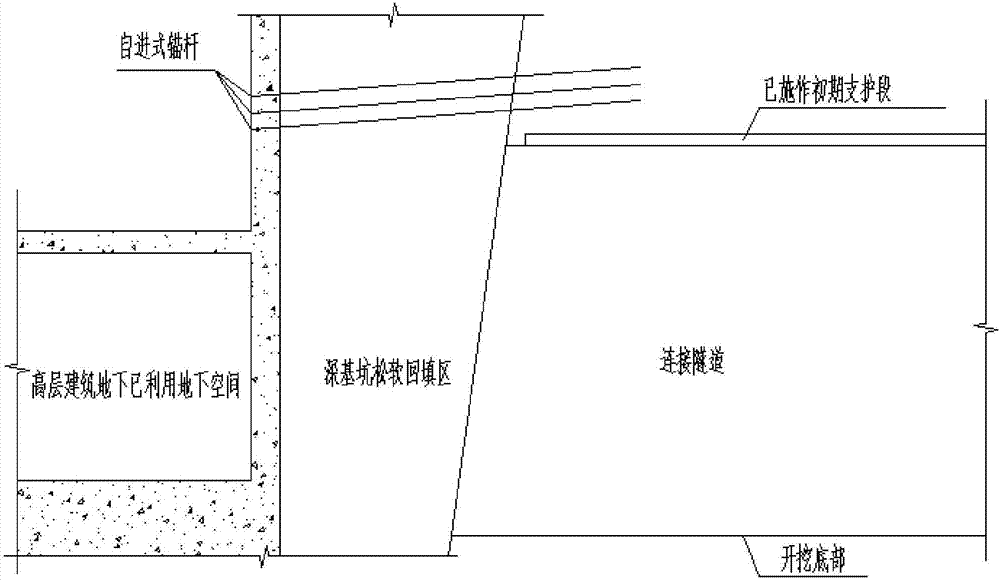

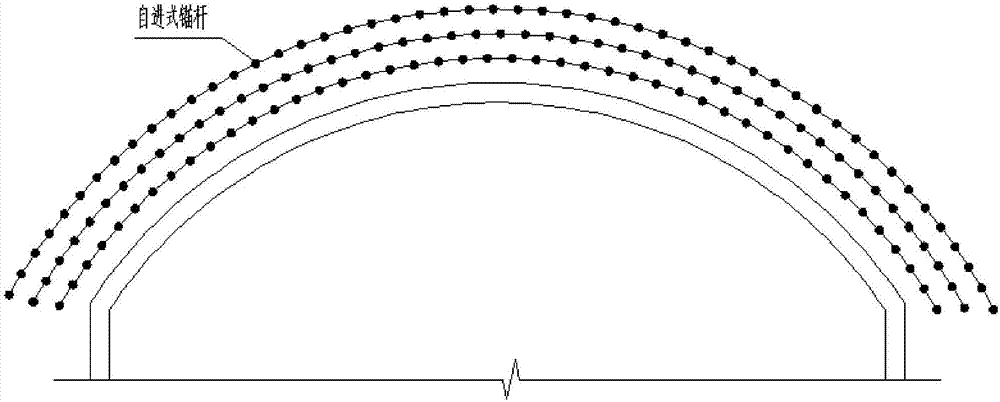

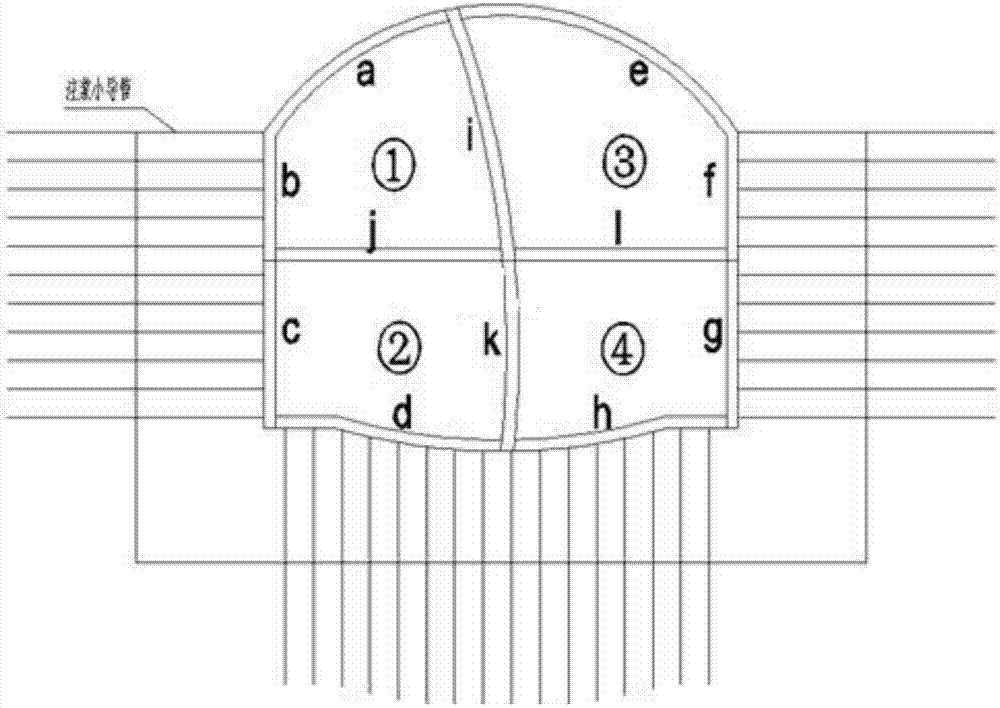

Construction method for tunnel crossing through backfilling zone of super high-rise buildings

ActiveCN107060778ASolve sinkingReduce security risksUnderground chambersTunnel liningGround subsidenceEconomic benefits

The invention discloses a construction method for a tunnel crossing through a backfilling zone of super high-rise buildings. The construction method includes the following steps of conducting construction preparation; conducting advanced support on multi-layer self-advancing anchor bolts; conducting construction of sectional drift headings; and conducting construction of a similar cantilever reinforcing liner structure. By adopting advanced support of the multi-layer self-advancing anchor bolts, annular grouting reinforcement of small pipes and construction of the similar cantilever reinforcing liner structure, the problem that ground subsidence caused by backfill falling down in the tunnel construction process is effectively solved, safety risks are greatly reduced, constriction period cost is saved, and safety, environment protection, and economic benefits are improved dramatically.

Owner:中铁十一局集团第五工程有限公司

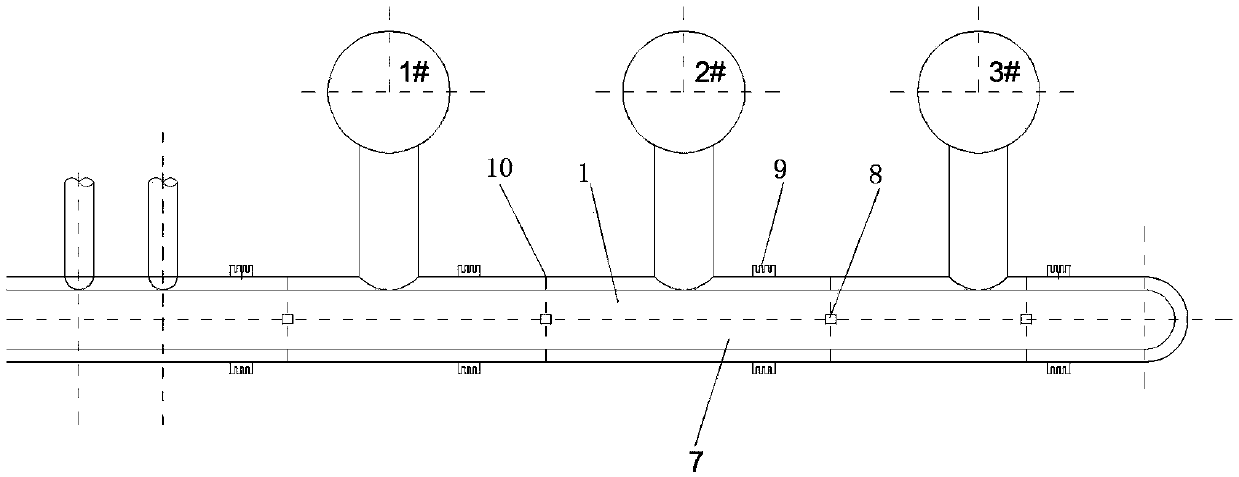

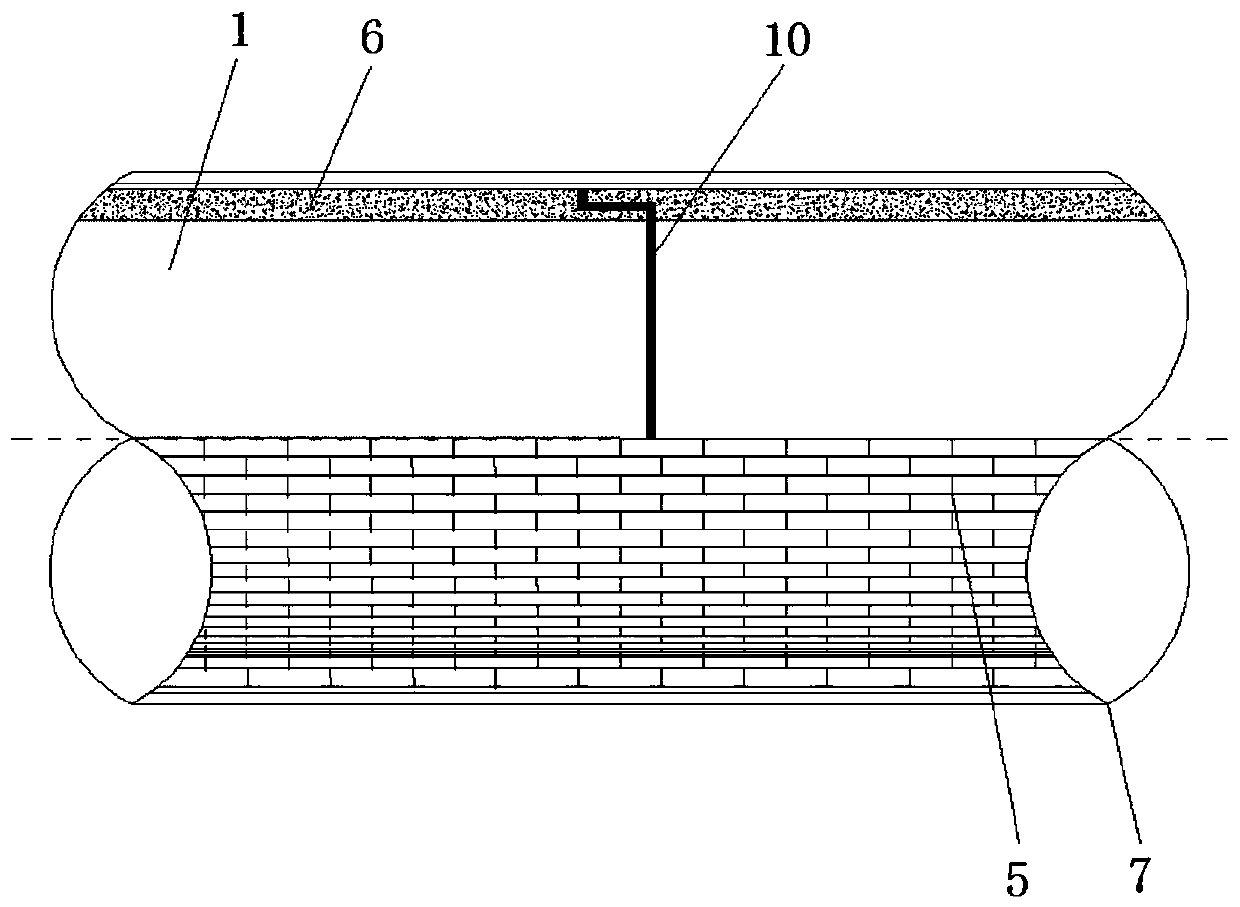

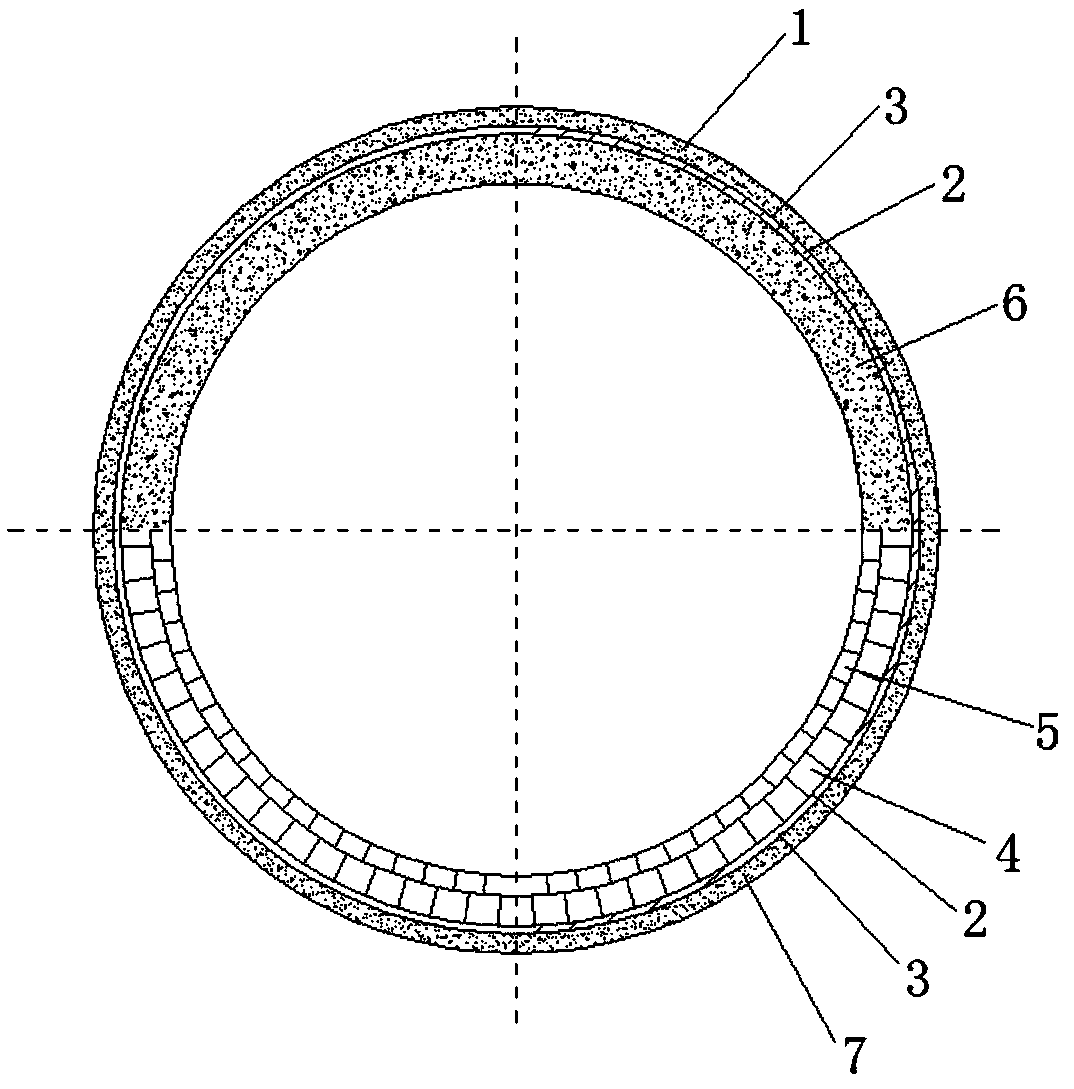

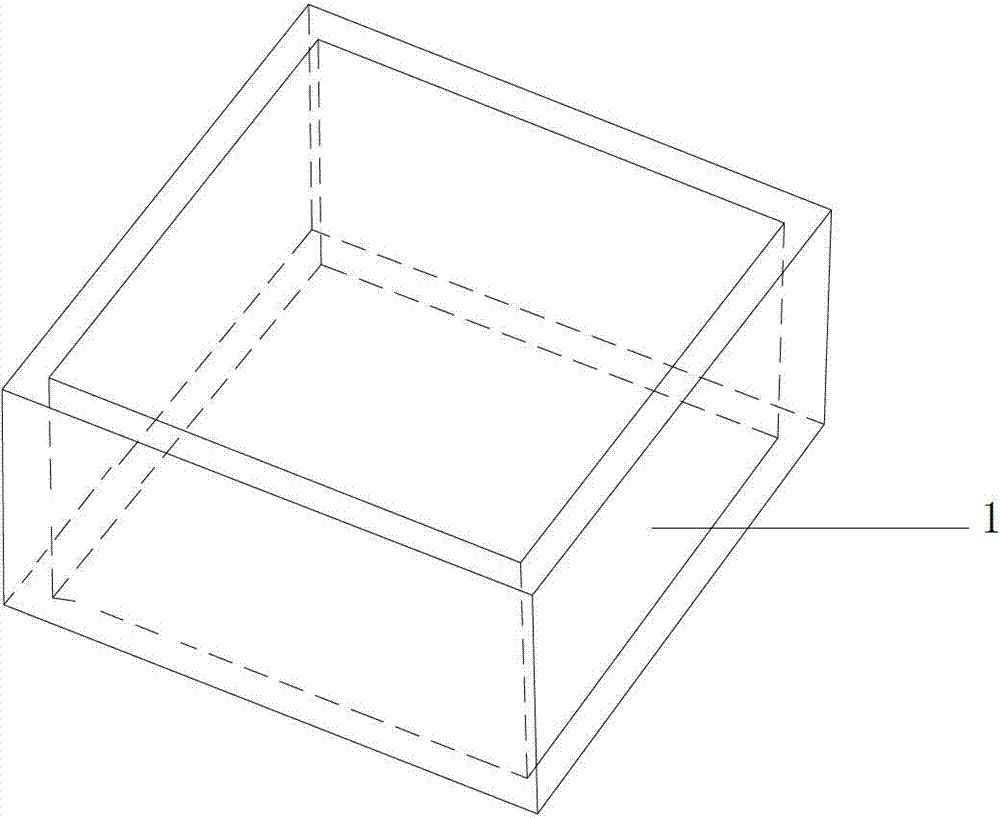

Semi-cast blast furnace hot blast stove pipe and construction method thereof

The invention discloses a semi-cast blast furnace hot blast stove pipe. The semi-cast blast furnace hot blast stove pipe comprises a steel shell composed of an upper steel shell and a lower steel shell; a masonry structure layer is laid in the lower steel shell; and an integrally-cast castable layer is arranged in the upper steel shell. The invention further discloses a construction method of thesemi-cast blast furnace hot blast stove pipe. The method comprises the steps that a whole reserved casting hole is sprayed; a fiber felt layer, an insulating brick layer and a working lining brick layer are sequentially laid on the surface of a sprayed layer of the lower steel shell; fiber felt layers are sequentially laid on the surface of the sprayed layer of the upper steel shell; an upper steel shell casting template is mounted; an expansion gap template is mounted; and casting construction is conducted. The pipe and the construction method have the beneficial effects that a lower lining of the hot blast stove pipe adopts a traditional masonry material and a traditional masonry method, an upper lining is casted and molded by casting a castable once, gaps in traditional pipe structurescan be reduced, a weak area is avoided, and the phenomena of sinking, breaking or even collapse of upper brick linings which often occur in the using process of the hot blast stove can be effectivelyavoided.

Owner:中冶武汉冶金建筑研究院有限公司

Experimental method and apparatus for shearing of structural surface of columnar jointing

ActiveCN103234838BSolve sinkingFast coolingMaterial strength using steady shearing forcesEngineeringStructural engineering

The invention discloses an experimental method for shearing of a structural surface of a columnar jointing. The method comprises adjusting a rock structural surface to be located in a shearing seam of upper and lower shearing boxes; sleeving screw sleeves to five internally-inserted vertical screws, using plastic films to separate and wrap; vertically moving the internally-inserted vertical screws through adjusting rods, so that the structural surface of the columnar jointing rock is located between the shearing seam; selecting proportional epoxy resin mortar to form epoxy resin mortar; and pouring the epoxy resin mortar into the upper and lower shearing boxes for cooling and solidification. The invention further discloses an experimental apparatus comprises the upper and lower shearing boxes, the internally-inserted vertical screws and the adjusting rods, wherein a bottom of the lower shearing box is provided with vertical screw holes, walls of the lower shearing box are provided with horizontal screw holes, and contacted parts of the adjusting rods and the internally-inserted vertical screws form worm structures. According to the invention, fine adjustment of the rock position can be realized, a surface of the epoxy resin mortar can be always maintain as a plain, a molding is relatively good, problems of rock sinking in cement mortar can be solved, and thus the structural surface of the rock can be easily positioned.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Investment casting process for complex thin-wall hollow aluminum alloy aviation part

InactiveCN112139451ASolve sinkingSpeed up the flowFoundry mouldsFoundry coresInvestment castingSlurry

The invention belongs to the technical field of investment casting processes, and relates to an investment casting process of a complex thin-wall hollow aluminum alloy aviation part. The investment casting process comprises the following steps that a water-soluble ceramic core is manufactured by adopting a 3D printing mode, the water-soluble ceramic core is coated with an organic waterproof coating, and drying is carried out on the water-soluble ceramic core; a wax injection mold is manufactured according to the shape of a casting, a water-soluble ceramic core is placed in the wax injection mold, a wax material is injected into the wax injection mold after mold closing to form a wax mold, the wax mold is coated with gypsum slurry, and after the gypsum slurry is hardened, heating dewaxing and roasting are carried out to obtain a gypsum casting mold; and molten metal is poured into the gypsum casting mold by adopting a vacuum pouring and pressurizing solidification method to obtain a casting mold, and finally the casting mold is put into clear water to dissolve and remove the water-soluble ceramic core to obtain the needed complex thin-wall hollow aluminum alloy aviation part. According to the investment casting process of the complex thin-wall hollow aluminum alloy aviation part, the water-soluble ceramic core and the gypsum casting mold are combined, so that the problem that along and narrow inner cavity of the gypsum casting mold sinks is solved, and forming of looseness, cold shut and hot cracks in the casting is reduced through vacuum pouring and pressurizing solidification.

Owner:HENAN ZHENGXU TECH CO LTD

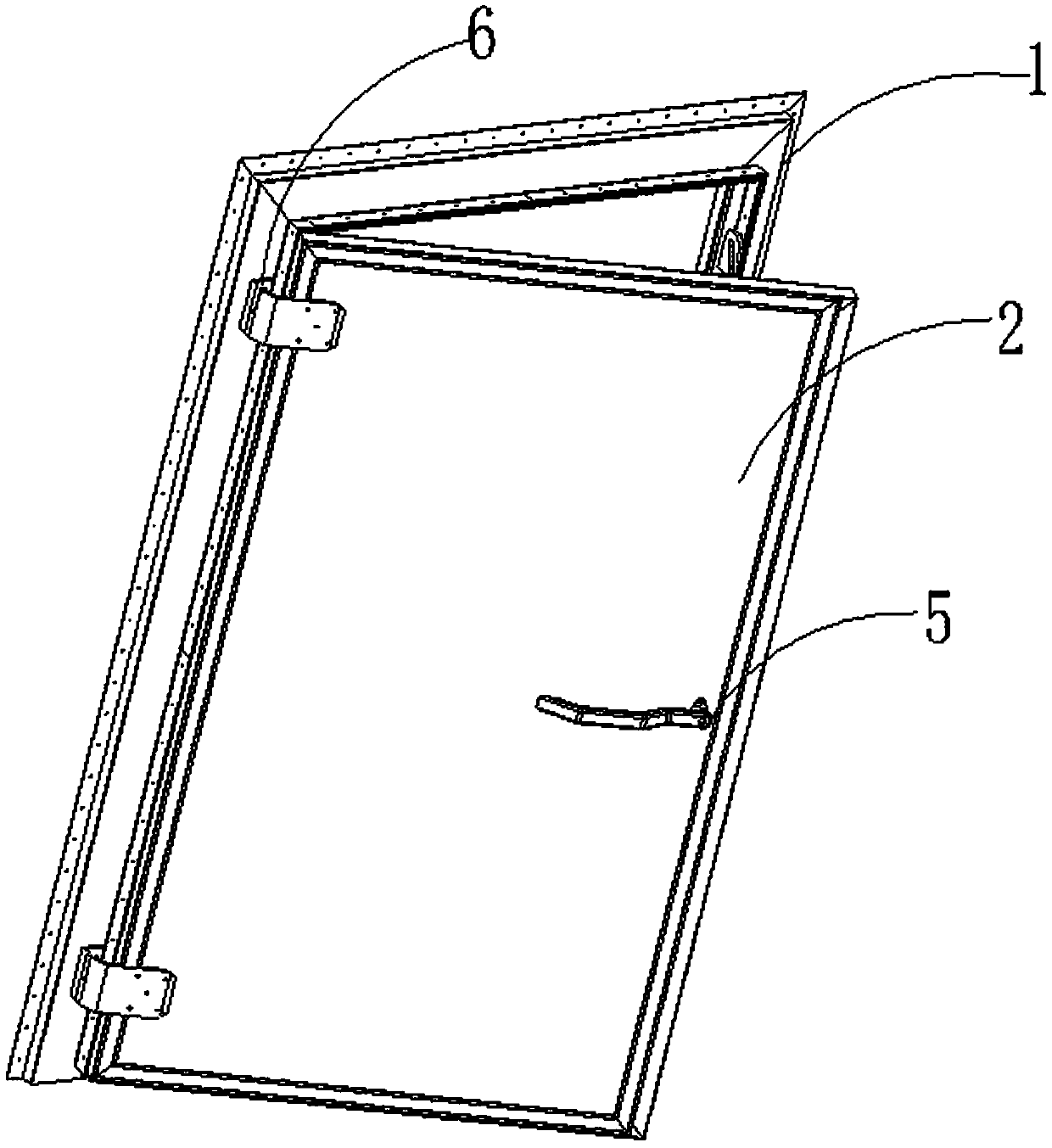

High-performance vane-inserted single-leaf casement screen door

PendingCN107724909AAchieve fixationRealize detachableRadiation protectionConnector applicationsEngineeringField strength

The invention relates to the technical field of screening and discloses a high-performance vane-inserted single-leaf casement screen door, comprising a door leaf and a door frame; the door leaf is provided with a door vane, the door frame is provided with a spring part used with the door vane, the spring part comprises a spring, a spring fastener and a spring seat, the inner wall of the spring seat is provided with spring plates abutted to each other, the spring plates are fixed to the inner wall of the spring seat through the spring fastener, a conductive elastic part is arranged in the spring seat and is arranged in a deformation direction where the door vane is inserted into the spring plates, the door leaf and the door frame are closed and locked in wedged manner, and contact between the spring plates and the door vane is ensured. The high-performance vane-inserted single-leaf casement screen door has high screening efficiency, good performance stability, good convenience of opening and closing, good operation stability and zero noise, the screening efficiency under 40-600 MHz may reach 100 dB and above; the high-performance vane-inserted single-leaf casement screen door is applicable to a screen room with MR (magnetic resonance) equipment having high field strength of 7 T and above.

Owner:ZHUZHOU HELI ELECTROMAGNETIC TECH

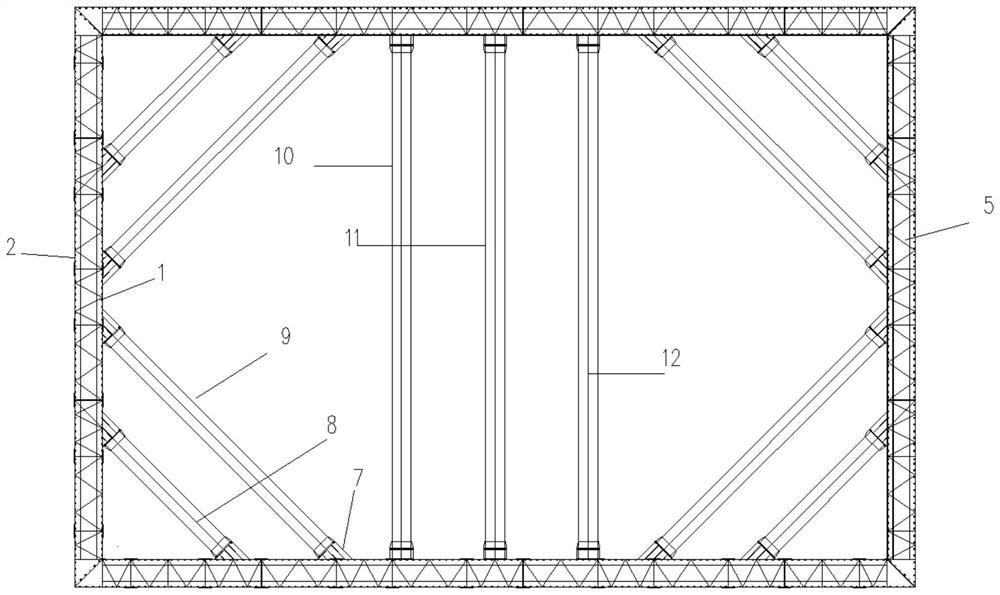

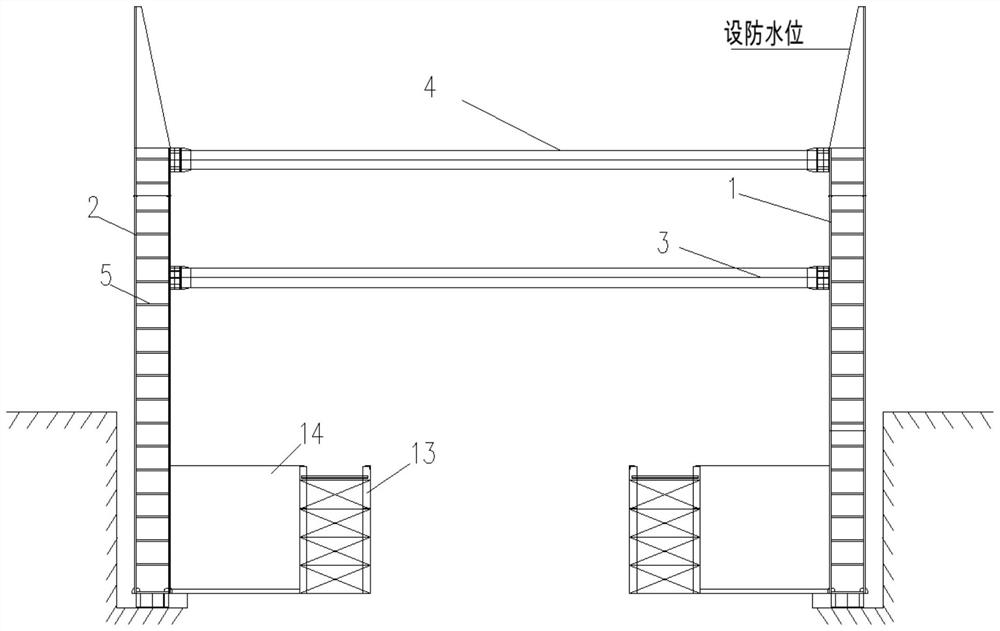

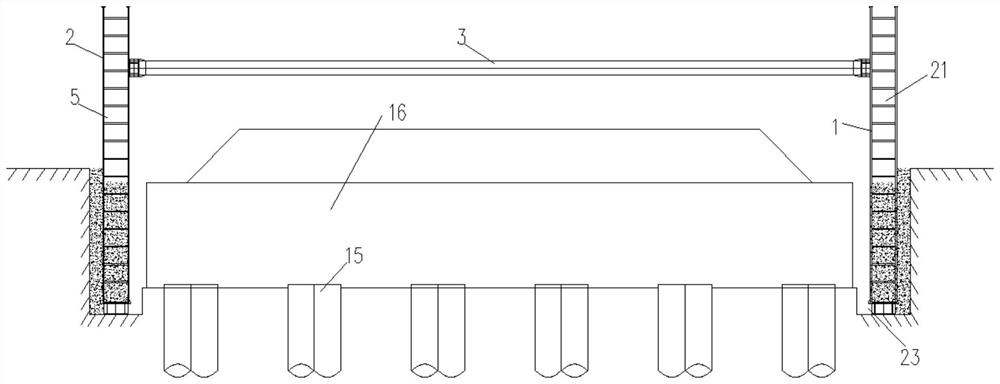

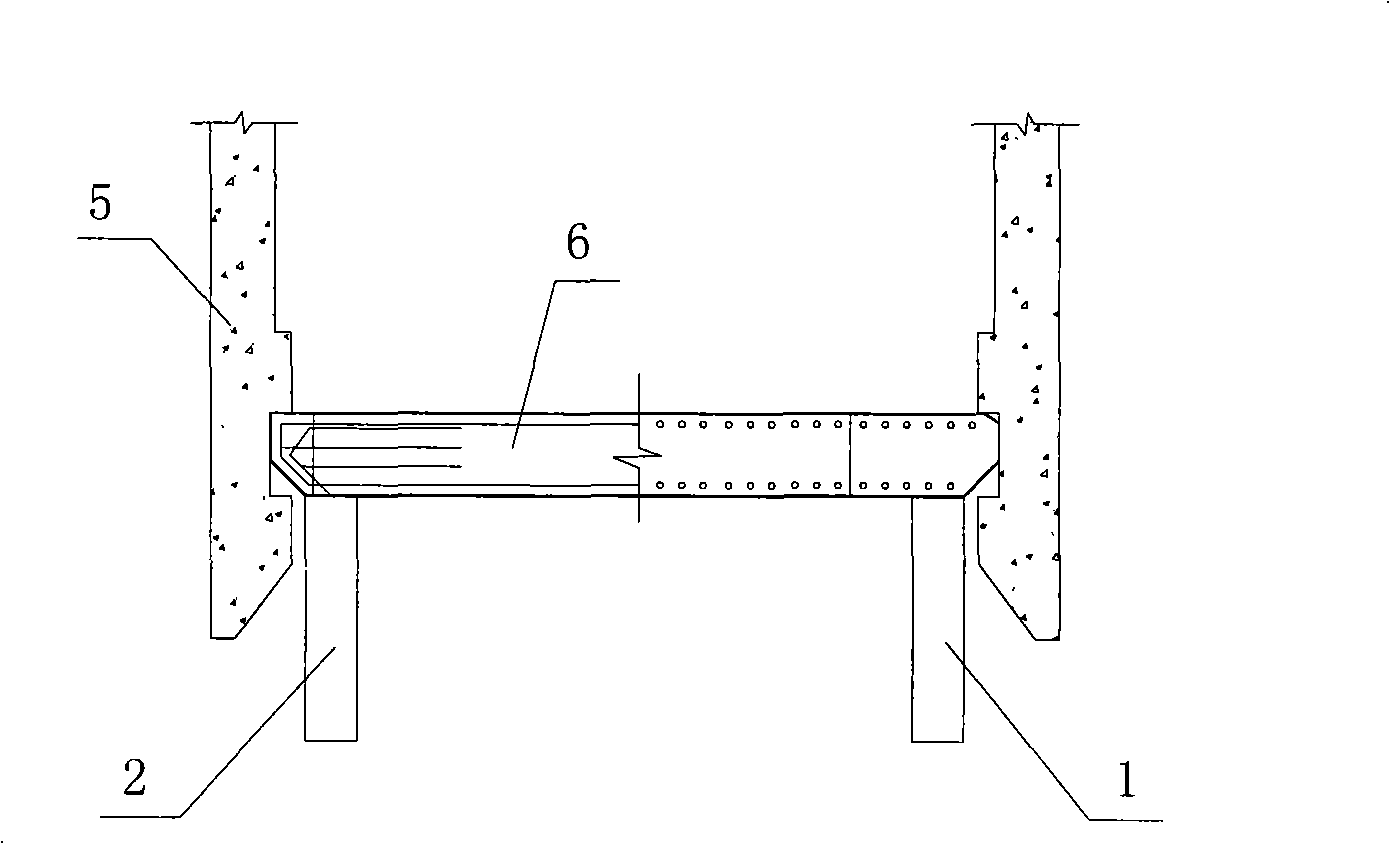

Construction method of steel jacket box for rock-socketed bearing platform construction under water level change

The invention provides a construction method of a steel jacket box for rock-socketed bearing platform construction under water level change. The construction method comprises the following steps thata groove is dug in rock at a designed bridge position, a double-wall steel jacket box is manufactured, assembled and floated to a site, concrete or water is injected into inner and outer side steel wall plates to enable the double-wall steel jacket box to sink to a specified position, according to requirements, in order to increase the gravity, a partition plate can be welded on the inner wall ofthe double-wall steel jacket box to form partition bins, concrete or water is injected into the partition bins, the gravity is increased, and the sinking requirement is met. Compared with the prior art, the construction method has the advantages that a blade angle does not need to be arranged at the lower end of the double-wall steel jacket box, an air suction dredger does not need to be adopted,the equipment circulating cost is reduced, the construction cost is reduced, and the problem that the double-wall steel jacket box sinks under the condition that geological conditions are not suitablefor soil cutting sinking, no covering layer or few covering layers is solved.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP +1

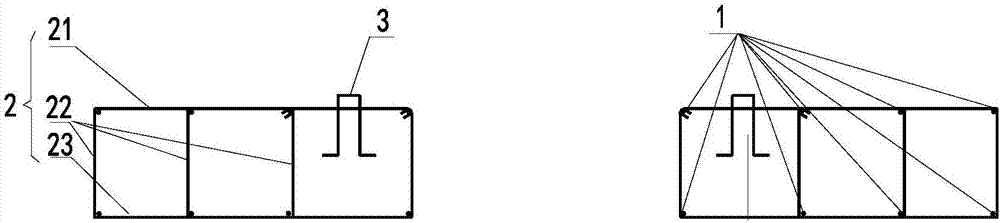

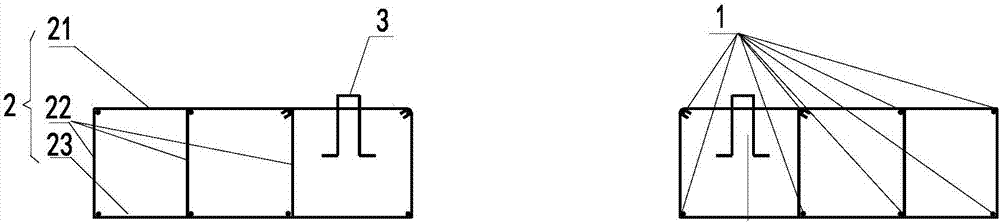

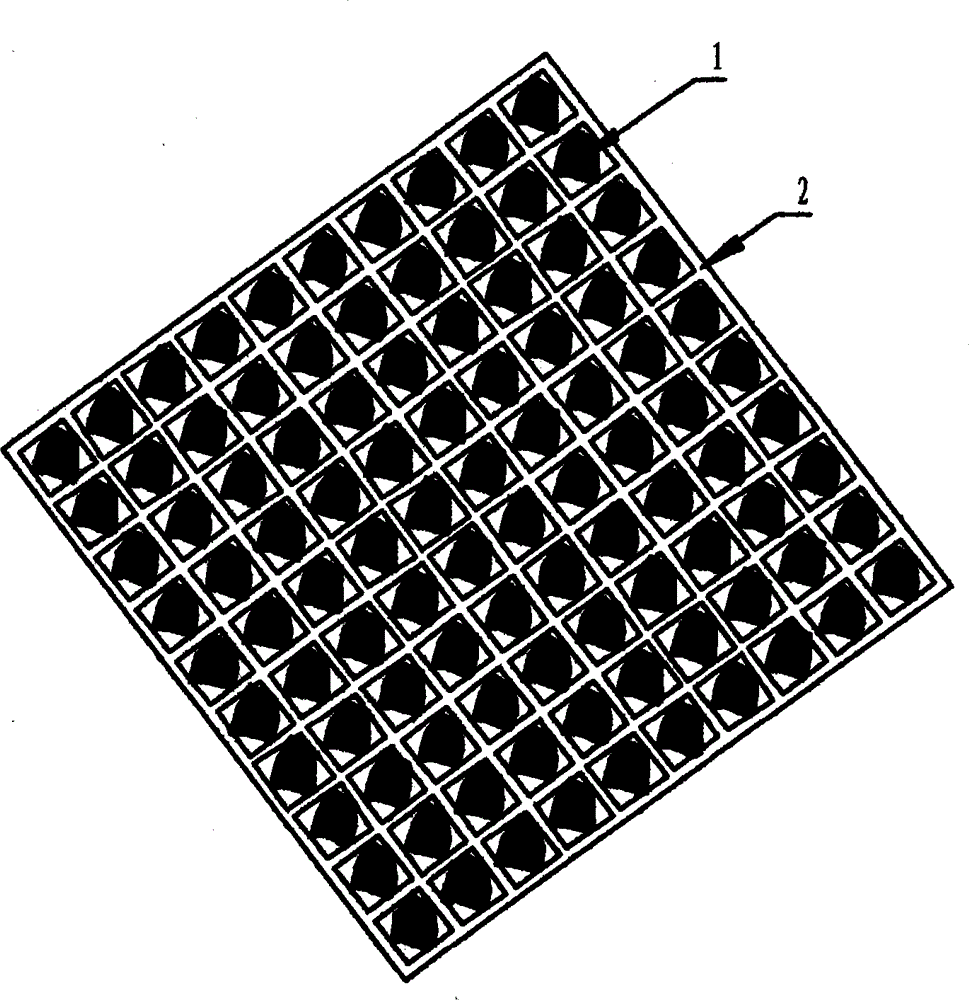

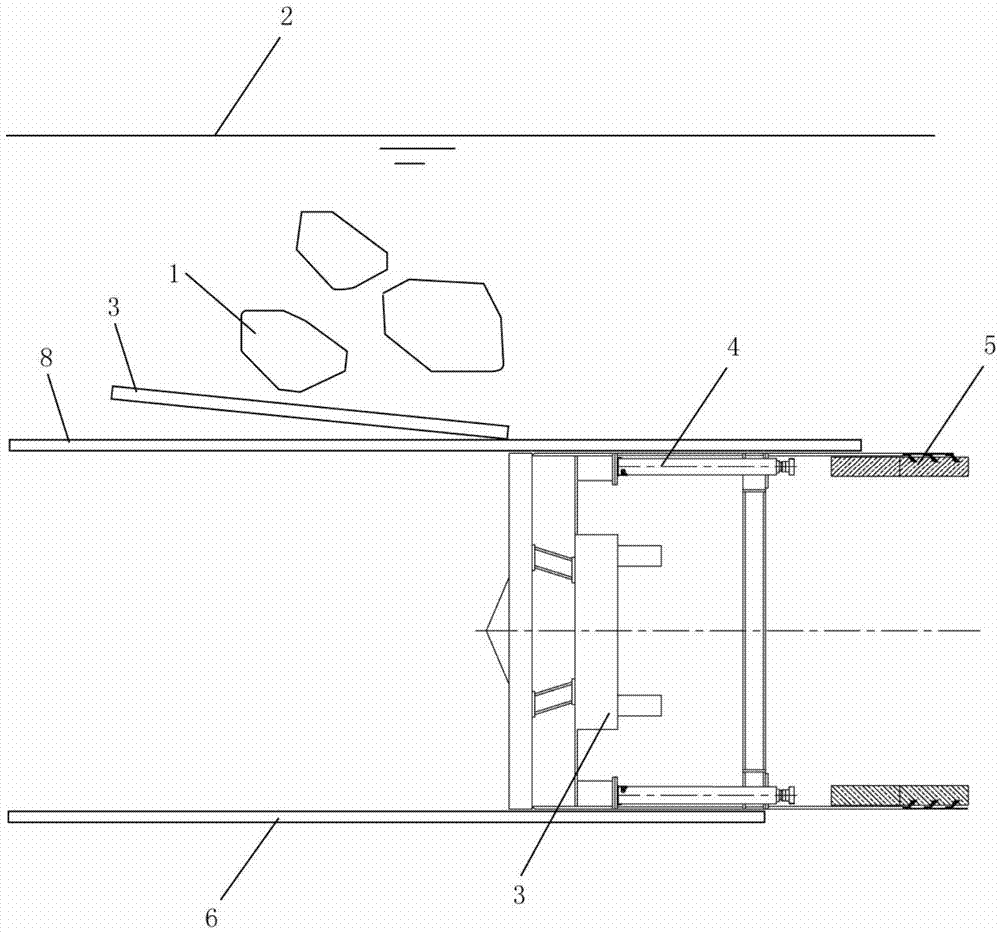

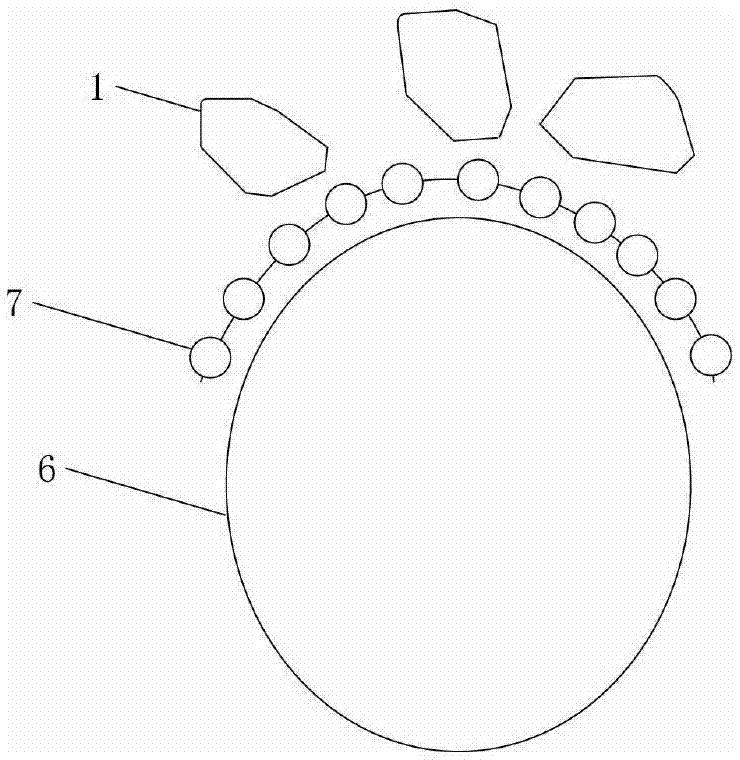

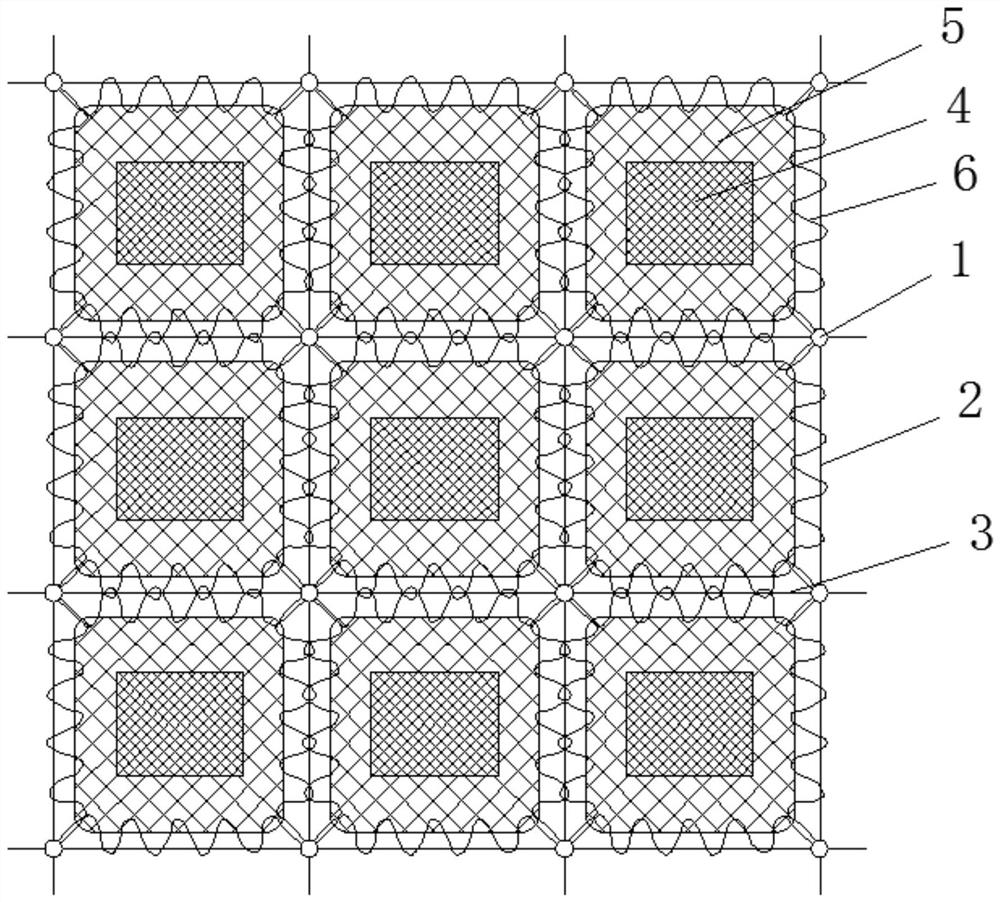

Casting method for fusing metal gridding reinforcing body and a metal matrix

The invention provides a casting method for fusing a metal gridding reinforcing body and a metal matrix. The casting method comprises the following steps of fixing reinforcing bodies (1) by using metal grids (2); mounting the reinforcing bodies (1) in corresponding positions of a foam mould; injecting pre-foamed foam beads in the foam mould to obtain a bright and clean foam mould with reinforcing body metal grids; accurately positioning the reinforcing bodies (1); uniformly coating foam mould clusters by using foam mold casting coatings; performing vibratory modeling on the foam mould clusters in a casting sand box; connecting a vacuumizing system to the casting sand box; pouring qualified smelted liquid metal on the foam mould; performing vacuumizing while pouring; and taking out the foam mould after cooling down the foam mold so as to obtain a casting on which the reinforcing bodies (1) are fused at accurate surface positions of the metal matrix. By the casting method, the reinforcing bodies (1) can be accurately positioned and uniformly distributed on the casting of the metal matrix; after the metal grids (2) and the metal matrix are fused, a transitional layer is formed; the reinforcing bodies (1) can be firmly fused with the metal matrix; the yield of products is improved; the cost is effectively reduced; and the quality of products is guaranteed.

Owner:吴建化

Movable lateral smoke exhaust device in tunnel

PendingCN110566260AOptimize the connection methodEfficient exclusionTunnel/mines ventillationSustainable transportationDrive motorFlue

The invention discloses a movable lateral smoke exhaust device in a tunnel. Funnel-shaped smoke exhaust ducts are arranged on the upper part of the side wall of the tunnel at equal intervals; double sliding rails are arranged at the bottoms of smoke inlets of the funnel-shaped smoke exhaust ducts and the intervals between every two funnel-shaped smoke exhaust ducts, and movable baffles are arranged on the double sliding rails in parallel by pulleys; drive motors are arranged on the movable baffles, through the cooperation of the pulleys and the sliding rails, the movable baffles arranged in parallel form a shielding structure at the smoke inlets, and smoke exhaust ports are formed at the unshielded smoke inlets. Smoke can be quickly and efficiently exhausted from the tunnel, human casualties and loss can be reduced, and the rescue efficiency is improved.

Owner:HEFEI UNIV OF TECH

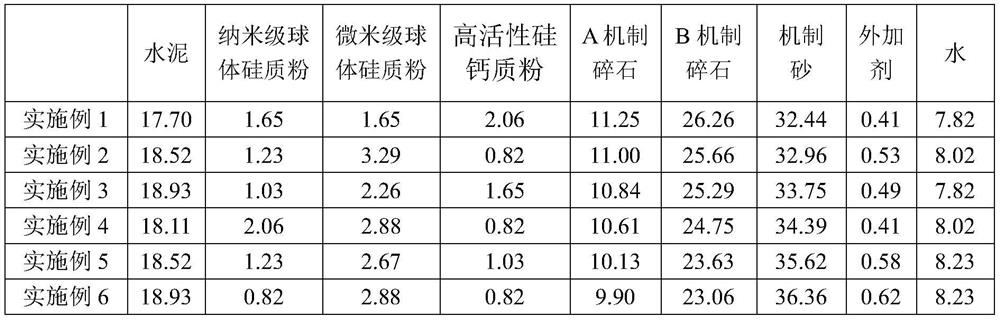

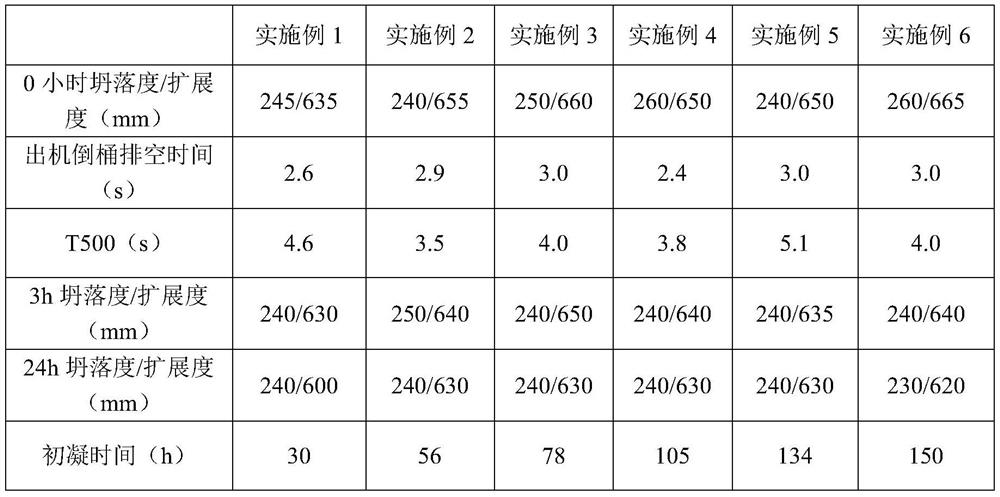

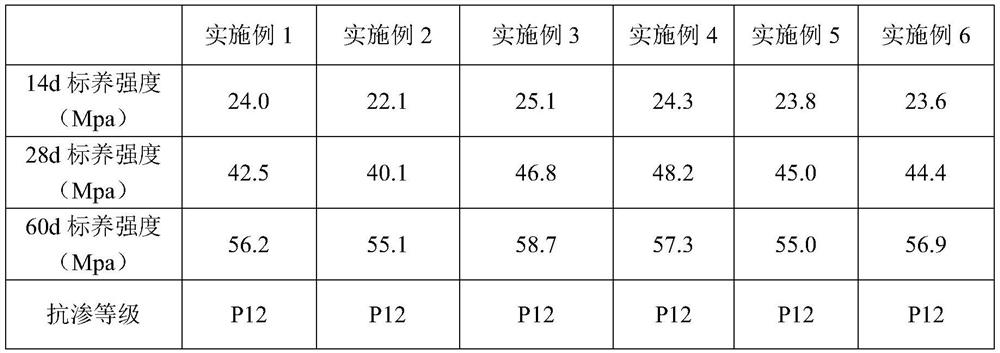

Super-long underwater pile foundation machine-made sand self-compacting concrete and preparation method thereof

ActiveCN111620630AClotting time achievedInhibits hydration processCrushed stoneStructural engineering

The invention discloses super-long underwater pile foundation machine-made sand self-compacting concrete and a preparation method thereof. The mass ratio of the components of the concrete is as follows: 17.70-18.93 of cement, 0.82-2.06 of nano-scale spherical siliceous powder, 1.23-1.65 of micron-sized spherical siliceous powder, 0.82-2.06 of high-activity siliceous-calcareous powder, 9.90-11.25 of machine-made broken stone A, 23.09-26.26 of machine-made broken stone B, 32.44-36.36 of machine-made sand, 0.41-0.62 of admixture and 7.82-8.23 of water. High-quality raw materials are preferably selected in the invention, indexes such as cement fineness, setting time and standard consistency are controlled; the cement can meet the adjustable control requirement of the ultra-long underwater pilefoundation setting time from 30 hours to 150 hours under the action of the admixture, and the concrete is suitable for underwater pile foundation concrete construction without flowing water and withthe length of 70 m or above, especially for underwater pile foundation concrete construction with the length of 100 m.

Owner:中建西部建设贵州有限公司 +1

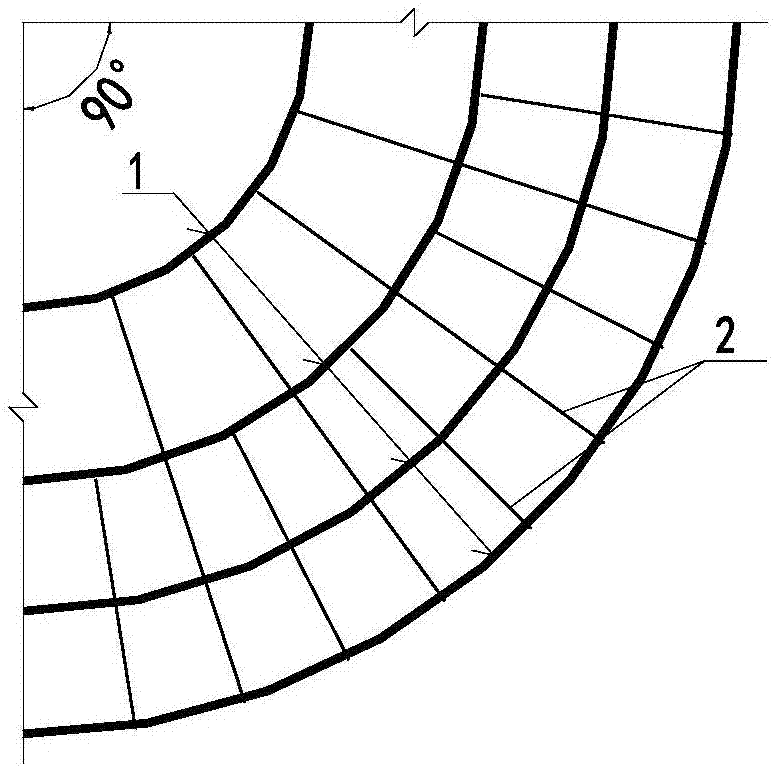

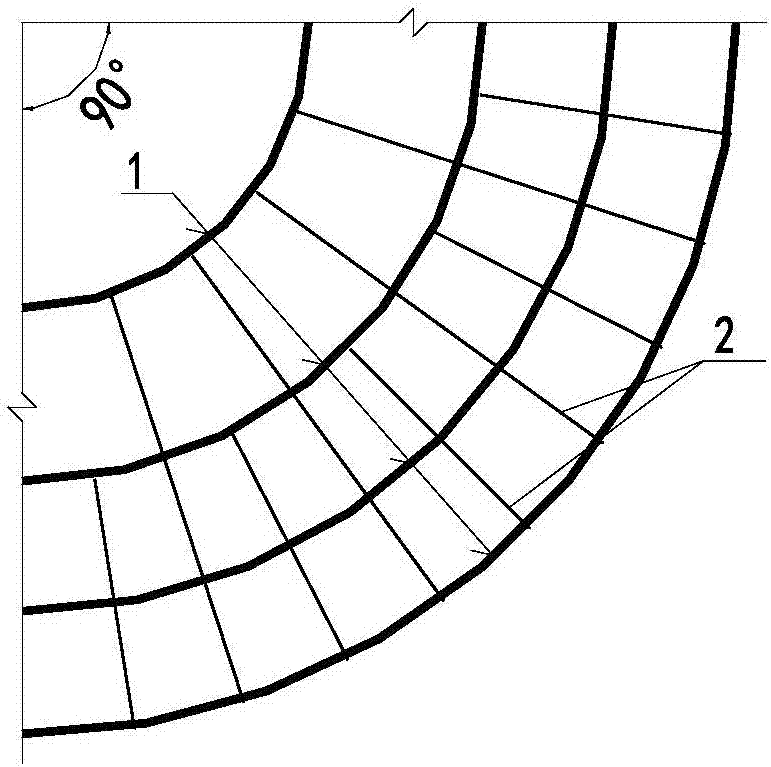

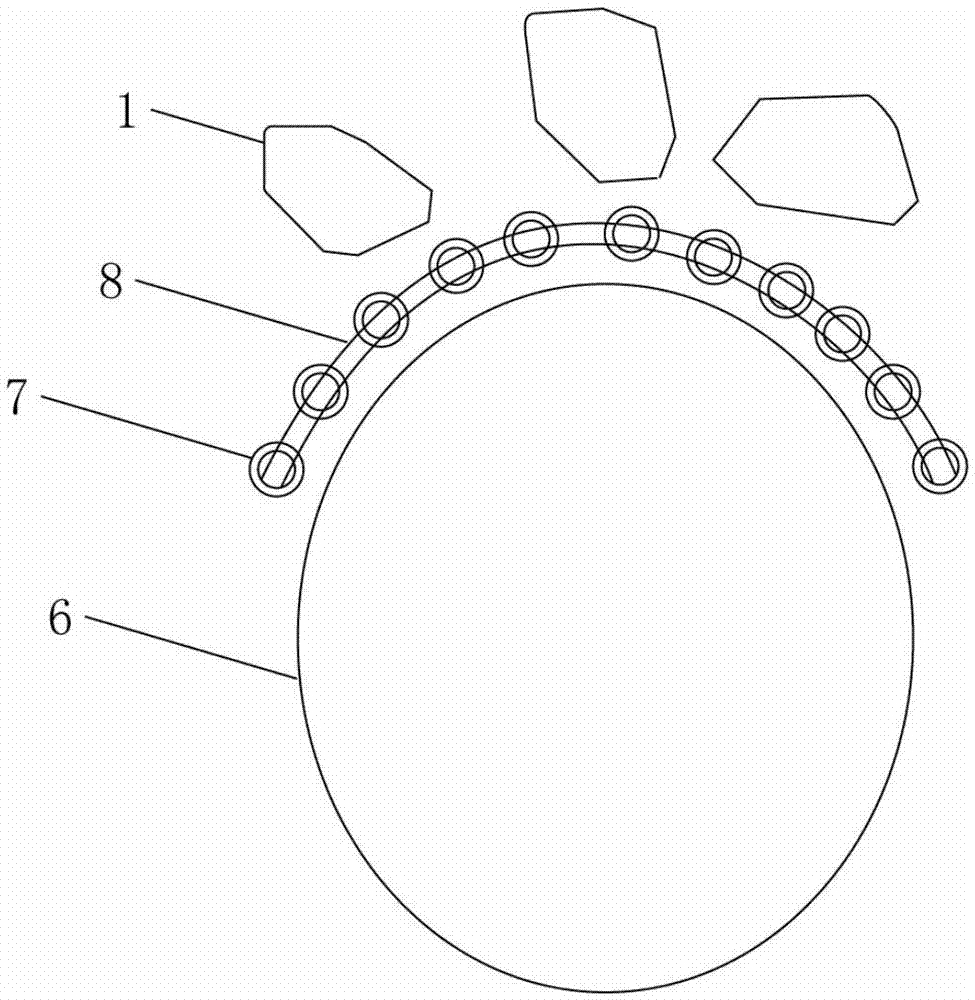

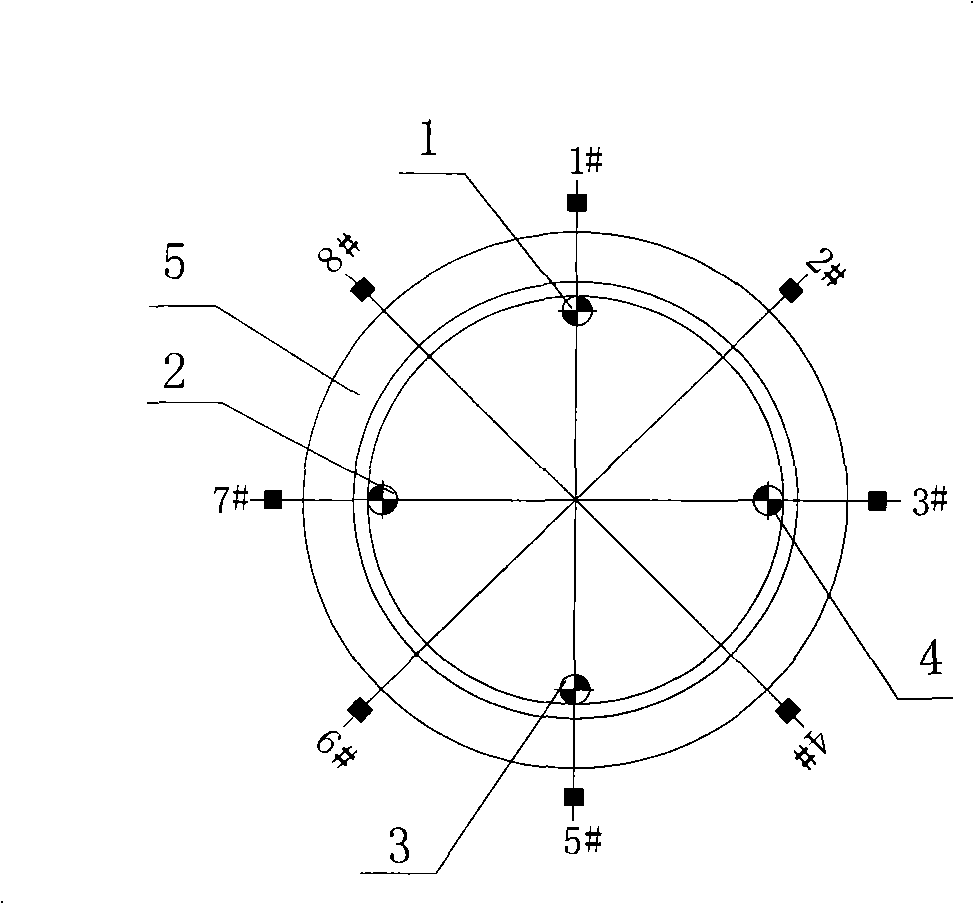

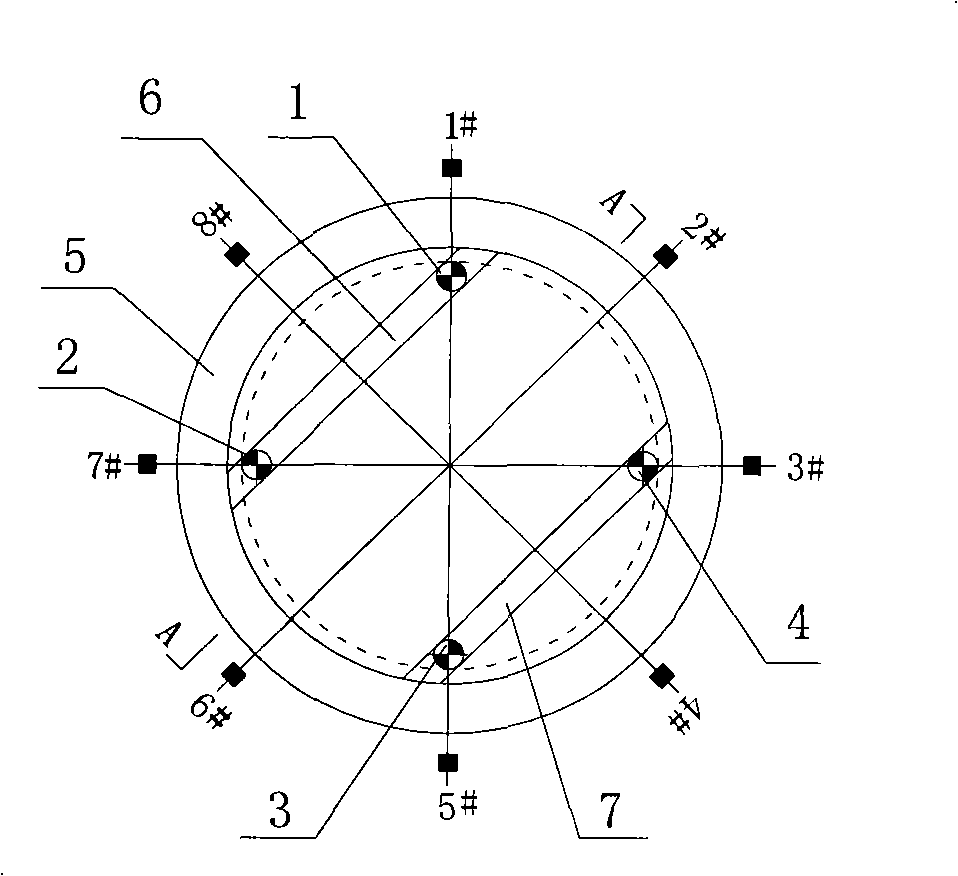

Method for isolating solitary stone group on upper portion of shield tunnel through advance pipe shed

The invention belongs to the technical field of shield tunneling, and in particular relates to a method for isolating boulder groups with an advanced pipe shed above the shield tunnel, which is characterized in that the following steps are followed: (1) The shield tunnel is shut down, and the tunnel is passed through the opening of the cutter head Excavate the advanced pipe shed hole above the contour line; (2) Use quick-setting high-pressure concrete to inject grout into the said advanced pipe shed hole, until the said advanced pipe shed hole is fluidized, stop grouting; (3 ) Repeat steps (1) and (2) until the 30°-90° range on both sides of the tunnel center is completed; (4) Form a concrete pipe shed above the tunnel with a range of 60°-180° from the center, and isolate Upper boulder group; (5) Shield excavation to safely pass through the tunnel section of the upper boulder group. Aiming at the boulder group above the shield tunnel, the invention forms a pipe shed through advanced grouting, which solves the problem of subsidence or subsidence of the boulder group in the soil above the shield tunnel, and enables the shield to smoothly pass through the boulder group above the tunnel.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

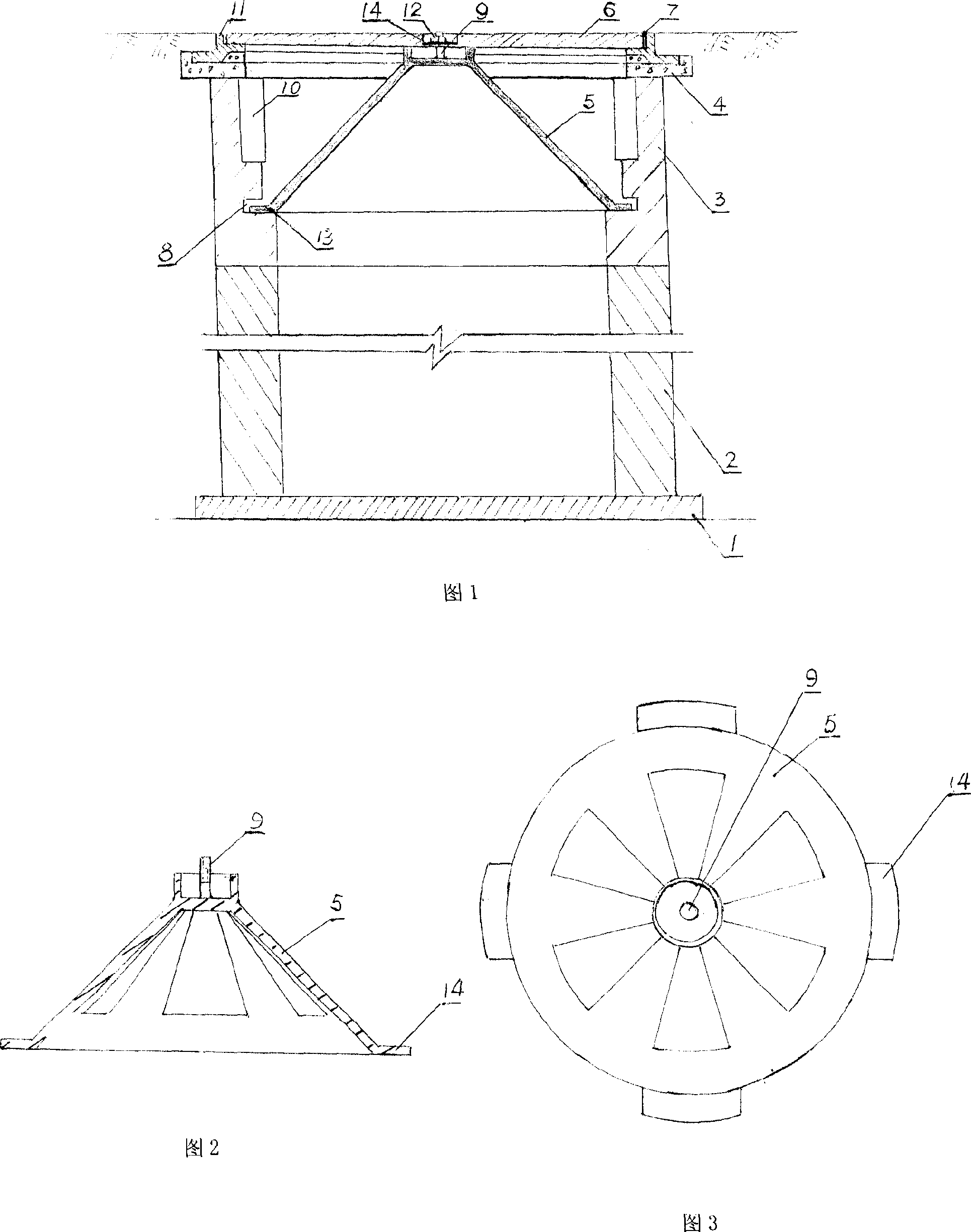

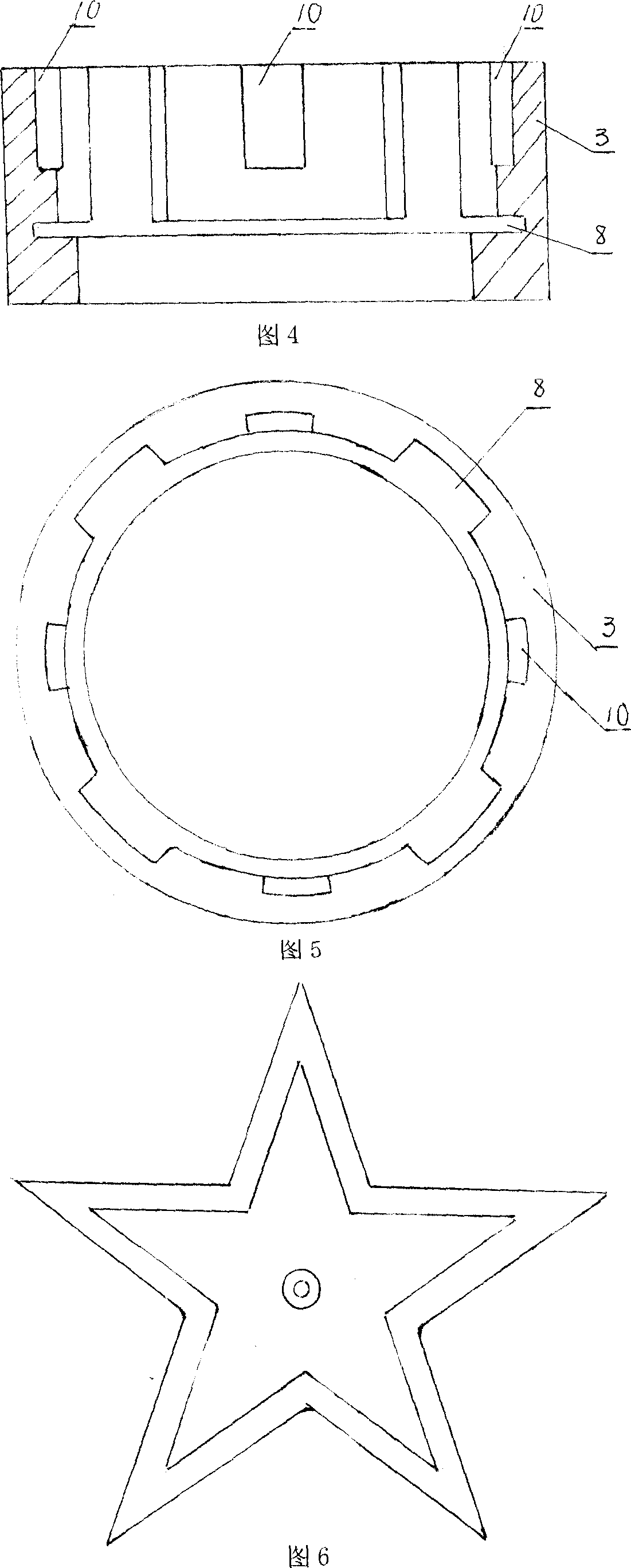

Method for preventing cyclone well from sinking when sealing bottom

The invention belongs to the technical field of construction of a cyclone well and particularly relates to a method for preventing the cyclone well from sinking when sealing bottom. The method is characterized by comprising the following steps (1) when the cyclone well is excavated to the bottom designed elevation of the sealing bottom, 4 to 20 grouting piles are drilled in the well and the depth of each grouting pile meets entering-rock condition respectively; and (2) then simple beams are poured on the 4 to 20 grouting piles and the sealing bottom is sealed from the bottoms of the simple beams till the top designed elevation of the sealing bottoms. The bearing capacity of 4 to 20 grouting piles is large than or equal to the difference value of the self weight and the frictional resistance of the well wall and the frictional resistance is equal to the frictional resistance between the well wall and the soil layer. The method can solve the problem of sinking of the cyclone well when sealing bottom (the bearing capacity is not enough when the bearing layer is the soil layer).

Owner:CHINA FIRST METALLURGICAL GROUP

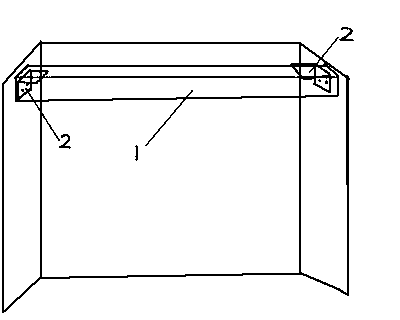

Hidden supporting structure of plaster board ceiling

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

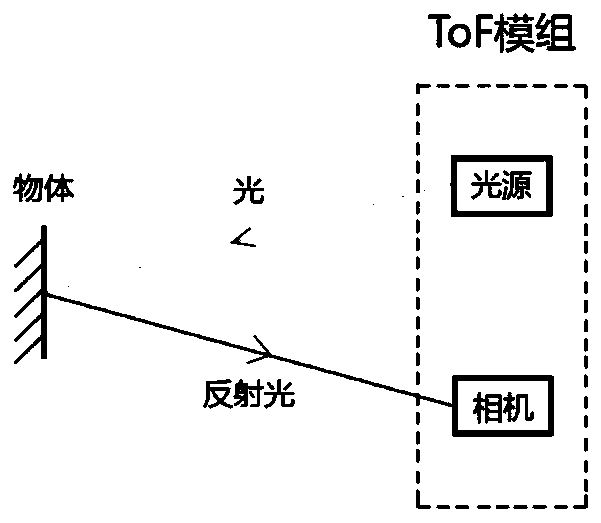

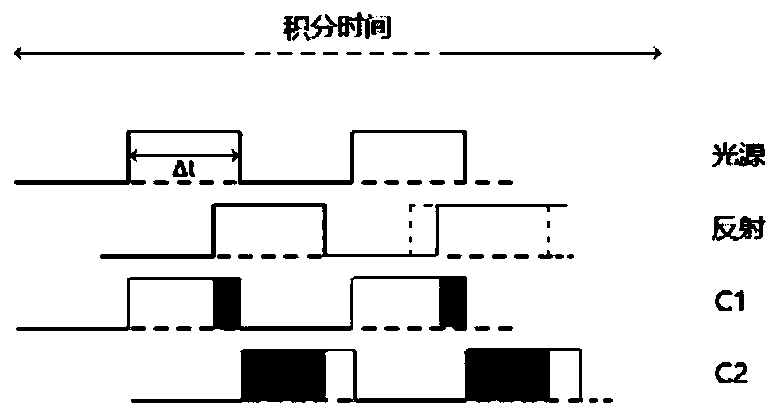

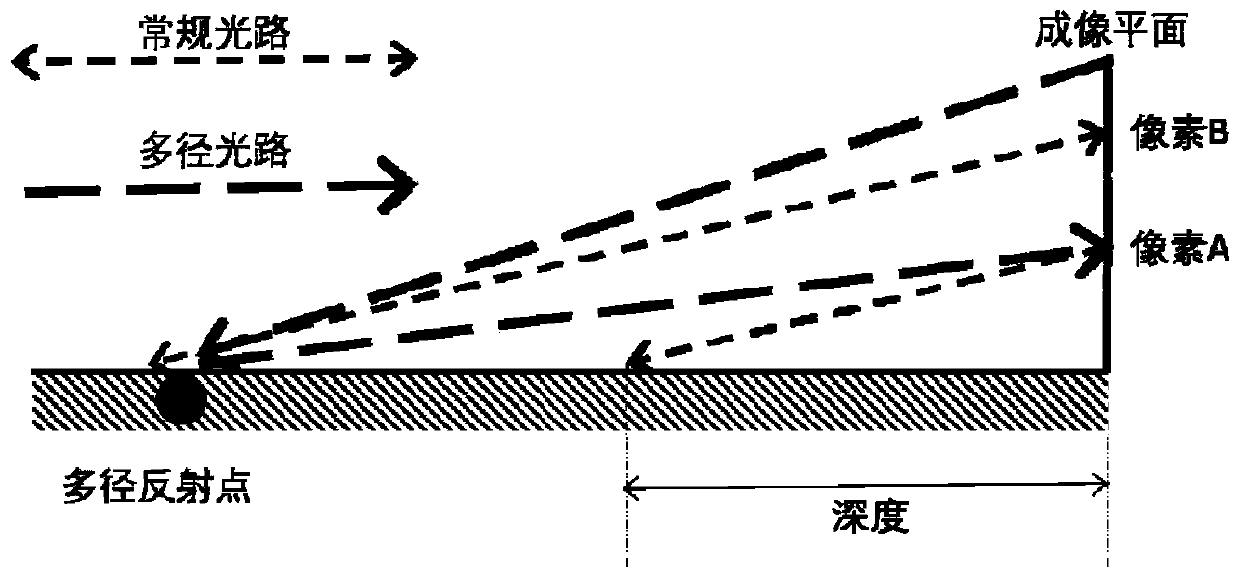

Installing method for TOF module for robot

The invention discloses an installing method for a TOF module for a robot. The installing method for the TOF module for the robot comprises the step of adjusting an inclination angle between an optical axis of the TOF module and the ground so that the height H of an optical center of the TOF module from the ground, the field of view angle in the vertical direction of the module VFoV, the shortestmeasurable distance L2 of the module and the shortest demand detection range Rmin of the robot meet corresponding constrained relationship. The installing method for the TOF module for the robot effectively solves the problems about ground point cloud sinking and large measured plane error.

Owner:BESTECHNIC SHANGHAI CO LTD

Cement pavement repairing method

ActiveCN114032750AReduce volumeEasy to carryClimate change adaptationRoads maintainenceRoad engineeringArchitectural engineering

The invention belongs to the technical field of road engineering, and particularly relates to a cement pavement repairing method which comprises a bag body, an extension part and a connecting part. According to the method, a repairing bag is placed in the area needing to be grouted before grouting, then grouting is conducted in the repairing bag, filled grout is wrapped by the arranged repairing bag, leakage of the grout is prevented, then the grouting pressure is guaranteed, a settled panel can be lifted, and smooth pavement repairing is guaranteed; when grouting is not carried out, the repairing bag is in a folded state, the size is small, the repairing bag is more convenient to carry, meanwhile, the bag body of the repairing bag is folded into a cylindrical shape, the folded repairing bag is more attached to a drilled hole, and then the repairing bag can enter a damaged part of a roadbed through a hole in a pavement slab more easily; and by arranging the extension part, the repair bag is prevented from being blocked in the hole of the pavement slab, the repair bag can be better unfolded during grouting, and the repairing quality is improved.

Owner:中国安能集团科工有限公司

Sewage monitor suitable for use under various water quality conditions

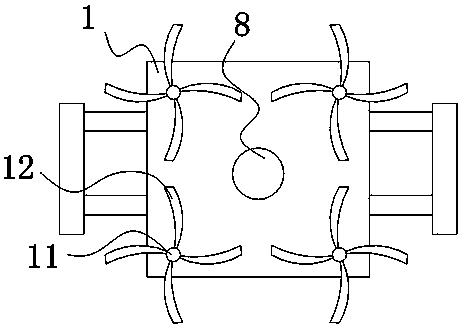

PendingCN107831292ASolve the problem of not being able to moveAchieve the purpose of normal workTesting waterRolloverMotor drive

The invention relates to a sewage monitor suitable for use under various water quality conditions, comprising a cover plate, the bottom of the cover plate is fixedly connected with a side plate, the side of the side plate is fixedly connected with a fixed plate, and the side plate is far away from the lower part of the side of the fixed plate A connecting rod is fixedly connected, the bottom of the connecting rod is fixedly connected with a stabilizing block, the side of the fixed plate far away from the side plate is provided with a motor, the side of the fixed plate is fixedly connected with a storage plate, and a monitoring rod runs through the axis of the storage plate, and the motor A baffle is arranged at the bottom, and a drive shaft is fixedly connected to the outside of the output shaft of the motor, and the drive shaft is away from the inherent blades of the outer sheath at one end of the motor. The advantages of the present invention are: by setting the motor to drive the blades so that they can rotate and work, break through the high-density sewage and duckweed, solve the problem of not being able to move in the high-density sewage, thereby achieving the purpose of normal work, and setting a stable block to solve the problem of sinking and duckweed. The problem of rollover is provided to ensure the collection of sewage samples.

Owner:聚数科技成都有限公司

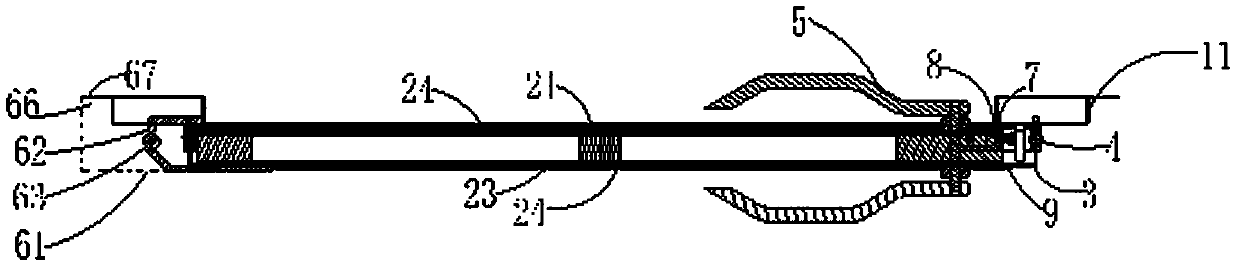

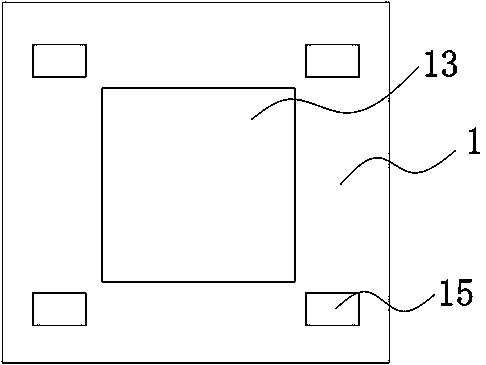

Invisible supporting structure of gypsum board ceiling

InactiveCN102936935ASolve sinkingSolve the problem of edge crackingCeilingsEngineeringDropped ceiling

The invention discloses an invisible supporting structure of a gypsum board ceiling, comprising a cross beam and a supporting leg, wherein the supporting leg is arranged at a contact part of the gypsum board ceiling and an indoor wall; the cross beam is inserted on the supporting leg to form a stable supporting structure of the gypsum board ceiling; and the cross beam, the supporting leg and the gypsum board ceiling are sprayed with a decoration color with the same color of the same brand, so as to achieve the aim of invisible decoration and fitment relative to vision to a certain extent under the condition of fixing and supporting the ceiling. The invisible supporting structure has an ingenious design and utilizes simple materials; the problems that the gypsum board ceiling is sunk or the edge is cracked after the gypsum board ceiling is hung for several days or several months can be solved; and the invisible supporting structure is convenient to implement and is convenient to apply.

Owner:姬志刚

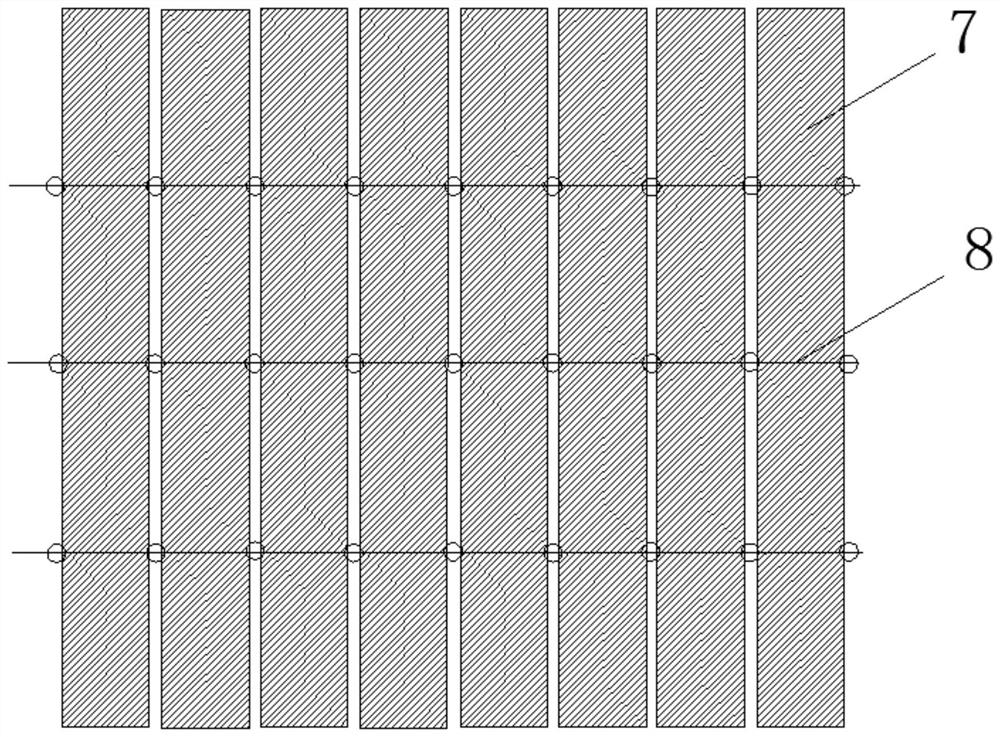

Construction method for ecological restoration of high and steep rock surface and ecological vertical bag used thereof

PendingCN112854265ASolve sinkingGuaranteed growthExcavationsCultivating equipmentsEnvironmental resource managementRock bolt

The invention relates to the technical field of ecological slope protection, and discloses a construction method for ecological restoration of a high and steep rock surface and an ecological vertical bag used thereof. The construction method comprises the following steps of clearing slope surfaces, determining anchor rod hole positions, drilling anchor rod holes, grouting and inserting steel rope anchors, installing longitudinal support ropes and transverse support ropes, paving grid nets, paving steel rope nets and hanging ecological vertical bags. The ecological vertical bag further comprises a planting bag, the planting bag is filled with a soil dressing material and nursery stocks, and the soil dressing material is prepared by uniformly stirring and mixing a soil improvement fertilizer, planting soil and water. The construction method has the characteristics of good vegetation growth condition, good applicability and environmental protection.

Owner:中矿复绿(北京)生态科技发展有限公司

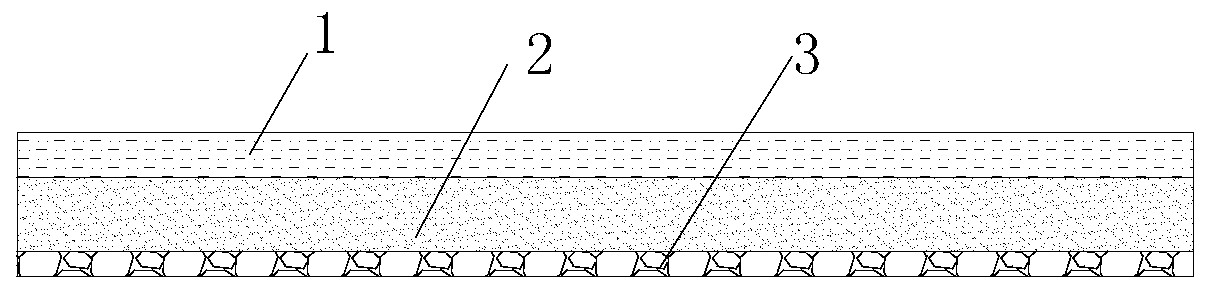

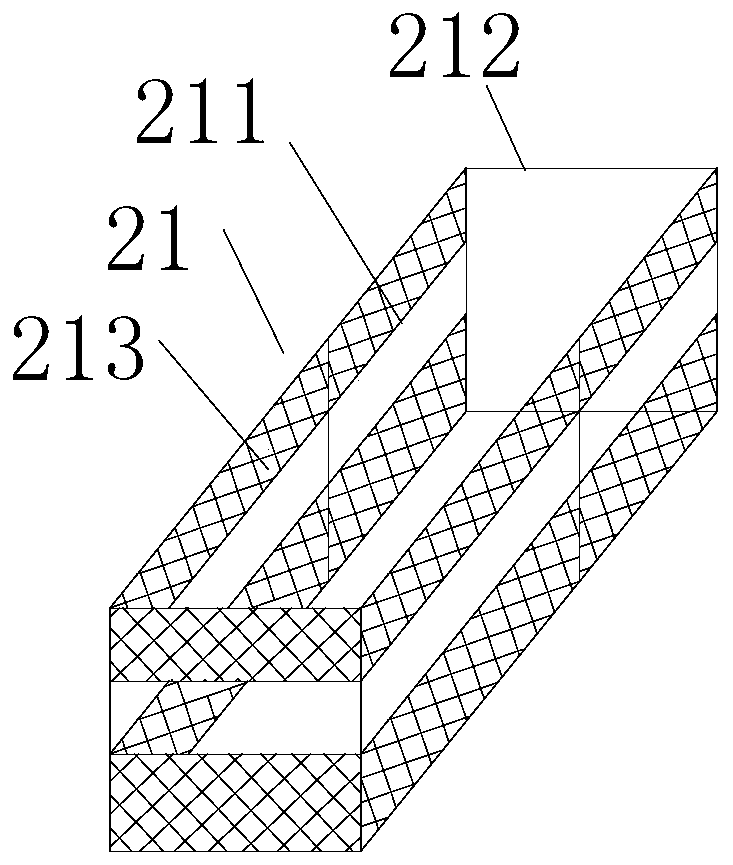

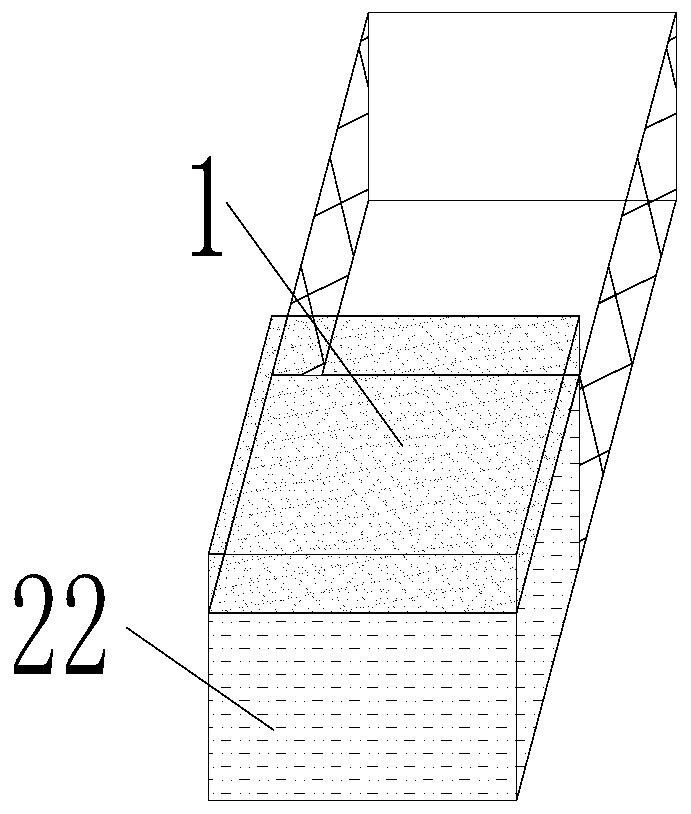

Soil and comprehensive construction waste prepared automatic water-absorption automatic luminous type sponge road

PendingCN110273345AImprove support strengthPrevent sinkingIn situ pavingsPaving gutters/kerbsWater sourceRoad surface

The invention relates to a soil and comprehensive construction waste prepared automatic water-absorption automatic luminous type sponge road. The soil and comprehensive construction waste prepared automatic water-absorption automatic luminous type sponge road comprises a permeable surface layer, a permeable base layer and an isolation layer which are laid in sequence from top to bottom. The permeable base layer is a macromolecule permeable body layer. Accumulated water on the road surface is permeated into an original soil layer through the macromolecule permeable body layer, and water flow permeates directly into the soil base layer after permeating through the road surface layer to the porous road base layer for permeating to realize the water source in-situ mutual compensation of natural precipitation and air mutual compensation, while the rapid permeation of water, reducing water accumulation and protecting the environment are ensured, the quality problems of easy damage and poor durability of a road compact and closed structure system in the prior art are solved, moreover, road performance is higher, and the natural permeability function is achieved; while the environment is beautified, the recyclable use of resources is realized, and the overall strength and carrying capacity of the road are improved.

Owner:沈志勇

Stabilizing agent and preparation method thereof, cereal milk prepared by using stabilizing agent, and preparation method of cereal milk

InactiveCN108308595AImprove hydrophilicityGood suspensionMilk preparationMilk preservationFiberFood additive

The invention relates to a stabilizing agent and a preparation method thereof, cereal milk prepared by using the stabilizing agent, and a preparation method of the cereal milk, and belongs to the technical field of food additives. The stabilizing agent comprises the following components in percentage by mass of 5%-20% of citrus fibers, 10%-30% of sodium carboxymethyl cellulose, 40%-80% of mono / di-glyceride fatty acid esters and 5%-10% of carrageenan. The cereal milk prepared by using the stabilizing agent comprises the following components in percentage by mass of 35%-90% of fresh milk, 0.5%-5% of cereal powder, 1%-6% of white granulated sugar, 0.15%-0.25% of a suspension emulsion stabilizer and the balance of water. According to the stabilizing agent and the preparation method thereof, the cereal milk and the preparation method thereof disclosed by the invention, the insoluble citrus fibers are used as a main suspending agent, and through the food additive, the hydrophilicity of the insoluble citrus fibers is increased, the network structure of the insoluble citrus fibers is stabilized, the suspension and the thickening property of a system are promoted, the situation that the cereal milk does not have the phenomena of precipitation, layering and bleeding in the 6-month quality guarantee period can be guaranteed, and a favorable stable state is reached.

Owner:HEBEI BROS ILONG FOOD TECH LLC

A car front face structure

ActiveCN109466422BImprove stabilityEfficient sharingSuperstructure subunitsOptical signallingFenderHeadlamp

The invention relates to the technical field of vehicle part structures, in particular to a vehicle front face structure. The vehicle front face structure comprises a fender support, the fender support is fixed to the two sides of a vehicle body in the Y direction and used for supporting a fender and an engine hood, and a front bumper upper framework is fixed to the front end of the vehicle body in the X direction and used for supporting a front bumper surface layer and the engine hood; the vehicle front face structure further comprises a headlamp assembly covered with the front bumper surfacelayer; the fender support comprises a fender front support body used for supporting a fender outer plate and a fender lower support body fixed to an edge beam of the side of the vehicle body; the headlamp assembly is fixedly connected with the fender lower support body through a lower fixing structure at the Z-direction lower end, fixedly connected with the front bumper upper framework through aside fixing structure at a Y-direction side part and fixedly connected with the fender front support body through a rear fixing structure at the X-direction rear end. The vehicle front face structureis reasonable in distribution, improves the structural stability of the headlamp assembly and a daytime driving lamp, and solves the submerging problem caused by concentration of weight.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

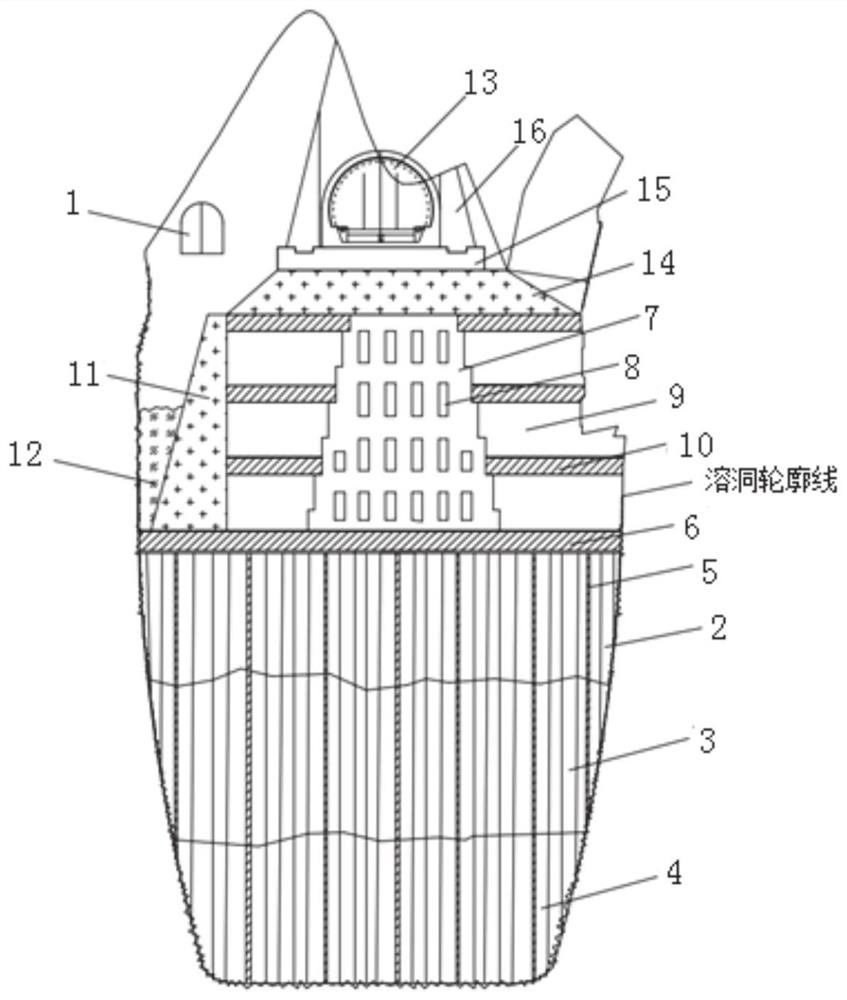

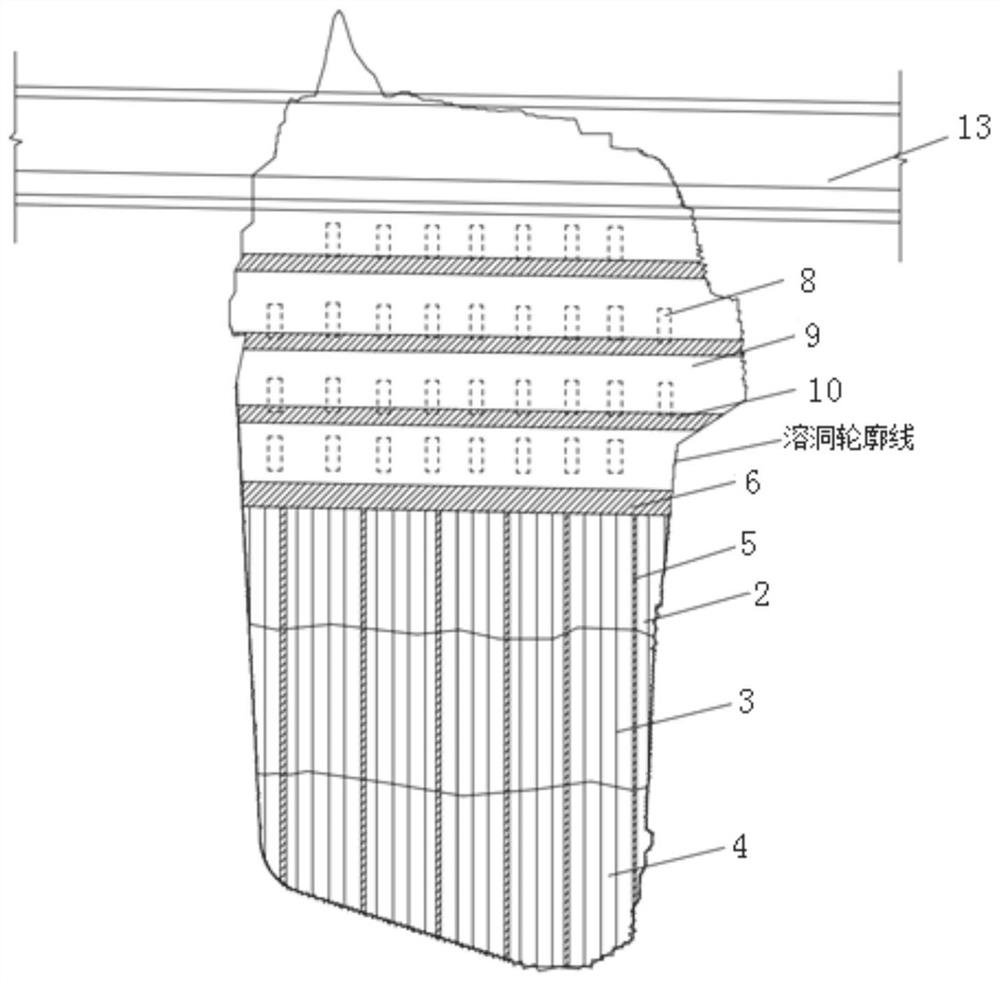

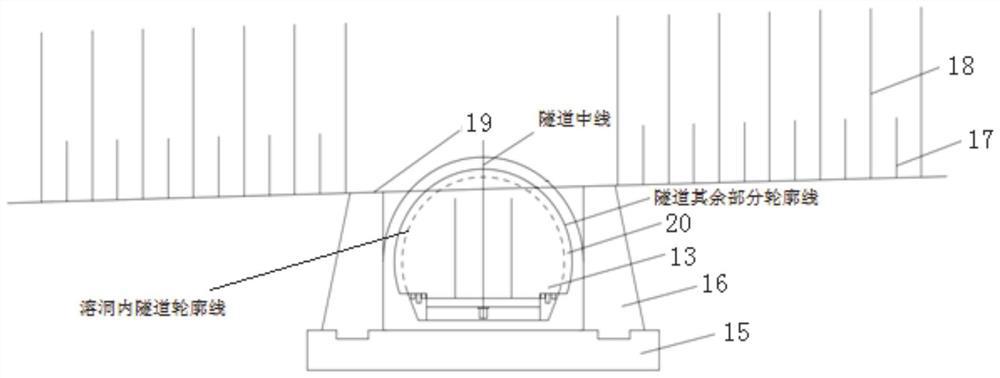

Karst cave backfilling method and tunnel construction method

ActiveCN112610222AMeet backfill processing requirementsSuitable for backfill processing requirementsUnderground chambersTunnel liningLap jointKarst

The invention relates to a karst cave backfilling method and a tunnel construction method. The karst cave backfilling method comprises the following steps that a karst cave is backfilled with lower graded cave ballasts, and grouting reinforcement is conducted on the backfilled lower graded cave ballasts and collapsed bodies and accumulated bodies in the karst cave; first reinforcing plates are constructed on the backfilled lower graded cave ballasts, and concrete foundation structures are constructed on the first reinforcing plates; and the positions between the two sides of the concrete foundation structures and the cave wall of the karst cave are backfilled with inter-plate graded cave ballasts in a graded mode, grouting reinforcement is conducted on the inter-plate graded cave ballasts, second reinforcing plates are arranged between the adjacent inter-plate graded cave ballasts, one end of each second reinforcing plate is connected to the corresponding concrete foundation structure in a lap joint mode, and the other end of each second reinforcing plate supports the cave wall of the karst cave. The backfilling method is low in cost and good in economic efficiency.

Owner:中铁十四局集团建筑工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com