High-performance vane-inserted single-leaf casement screen door

A high-performance, swing door technology, applied in the direction of door leaf, window/door, wing leaf arrangement, etc., can solve the problems of undisclosed gold reed fixing method, high failure rate of mass production, and short life of door leaf shaft, etc., to achieve It is easy to replace and repair, guarantees shielding effectiveness, and does not require high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

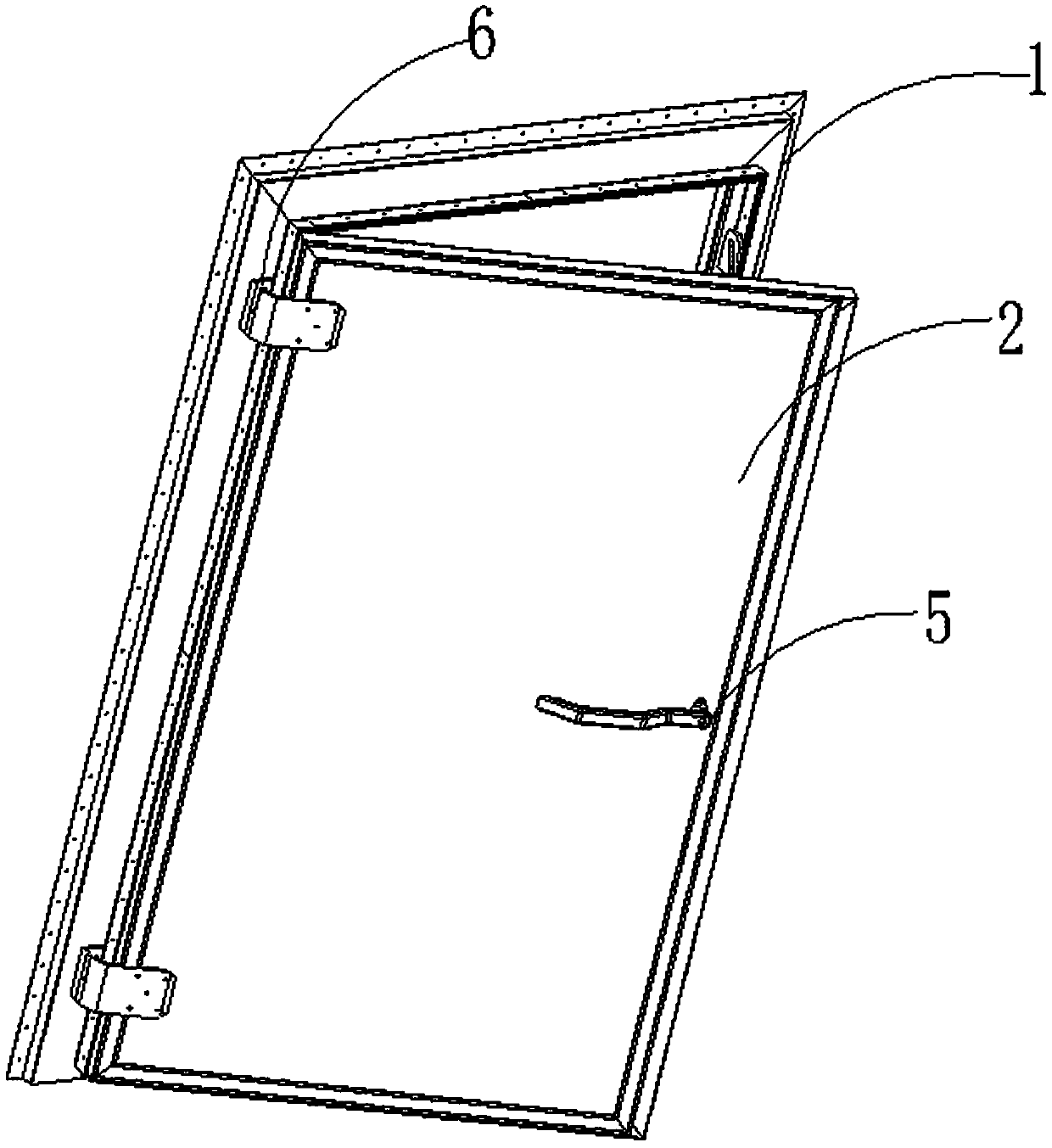

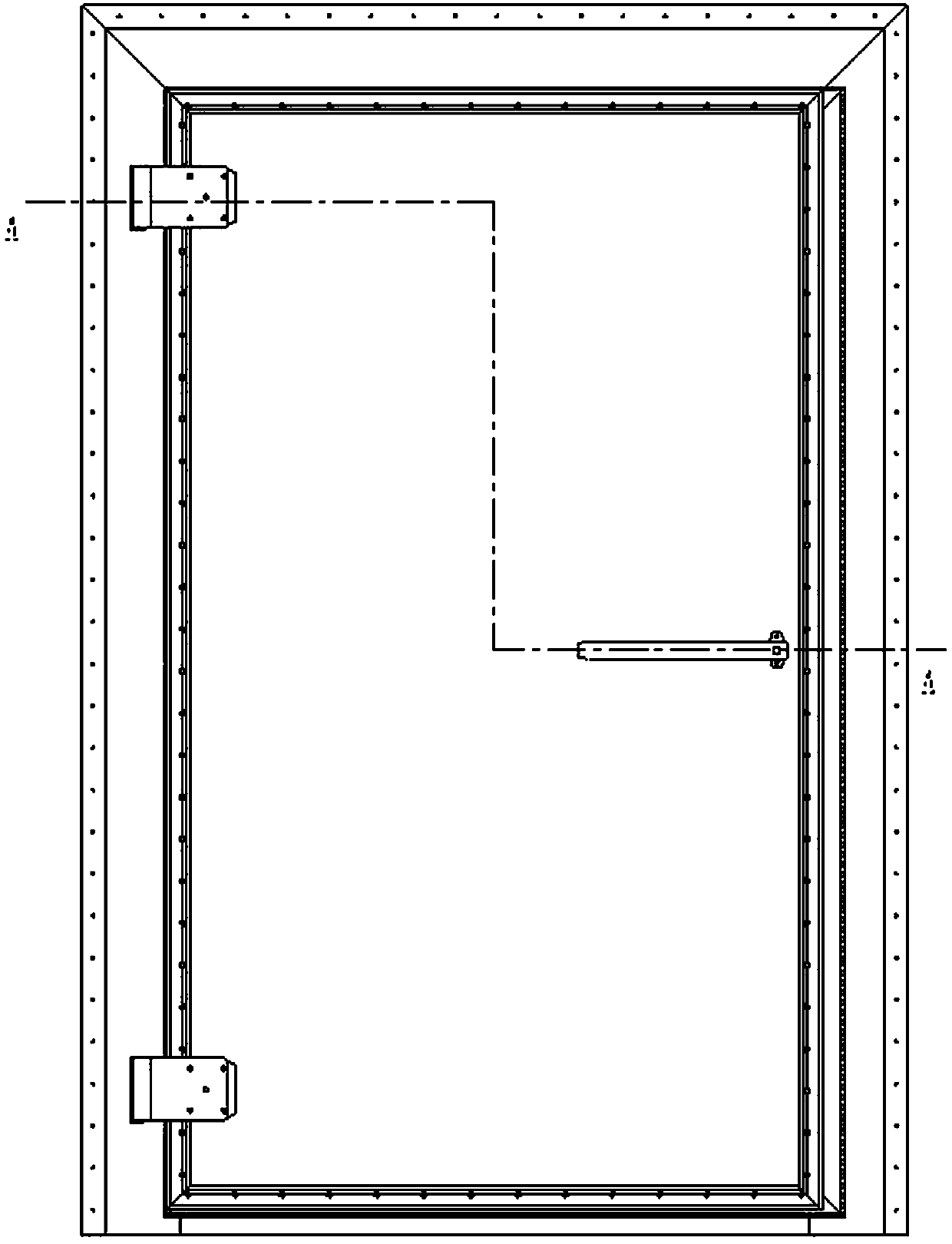

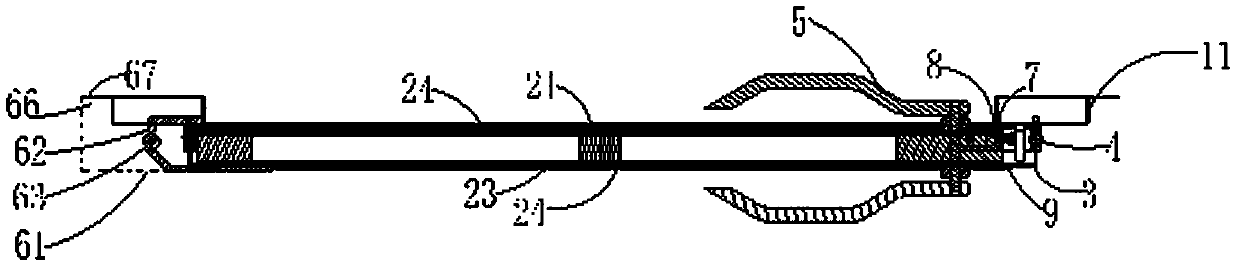

[0040] like Figure 1-9 As shown, the present embodiment provides a high-performance knife-inserted single-leaf shielded side-hung door, including a door leaf 2 and a door frame 1, the left and right ends of the door leaf 2 are provided with door knives 3, and the left and right ends of the door frame 1 are provided with door knives. 3 Spring elements 4 for interfitting use, such as Figure 7 As shown, the spring member 4 includes a reed 41, a reed buckle 42 and a reed seat 43, the inner wall of the reed seat 43 is provided with a relatively abutting reed 41, and the reed buckle 42 fixes the reed 41 on the reed seat 43 On the inner wall, it is close to contact, and the spring seat 43 is also provided with a conductive elastic body 44, which is preferably conductive foam in this embodiment, and the conductive elastic body 44 is located in the deformation direction when the door knife 3 is inserted into the reed 41, and the door leaf 42 and the door frame 41 is closed and locke...

Embodiment 2

[0054] like Figure 10 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the door leaf 2 is provided with two door knives 3, and the door frame 1 is provided with two spring members 4 that are used in conjunction with the two door knives 3. In the prior art, the door leaf 2 and the door frame 1 of this embodiment reserve space for the composite door knife 3, and if necessary, a "double knife and four spring structure" is added to continuously improve the shielding performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com