Construction method for tunnel crossing through backfilling zone of super high-rise buildings

A technology for tunnel construction and high-rise buildings, applied in tunnels, tunnel linings, earth-moving drilling, etc., can solve problems such as ground subsidence, save construction costs, improve safety, environmental protection and economic benefits, and reduce safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

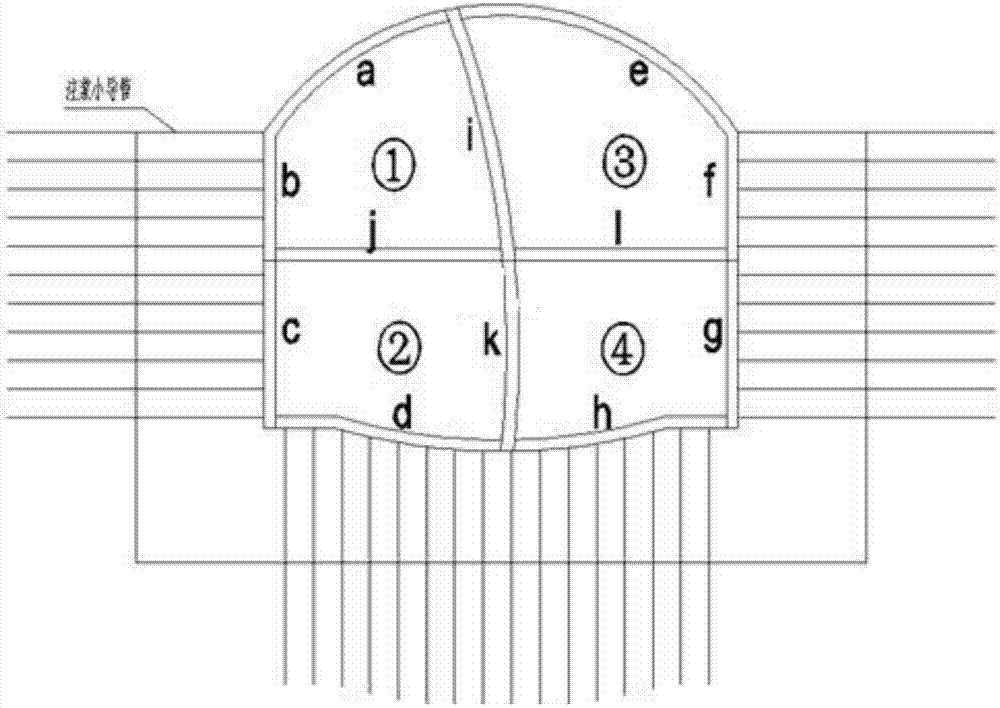

[0025] A construction method for tunnels passing through the backfill area of super high-rise building groups, the construction is carried out according to the following steps:

[0026] The first step is construction preparation.

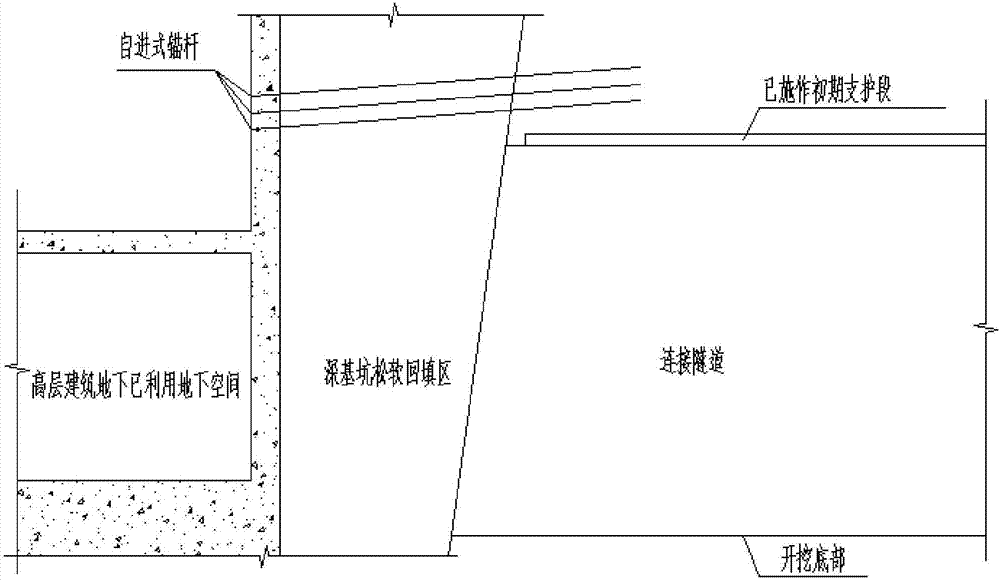

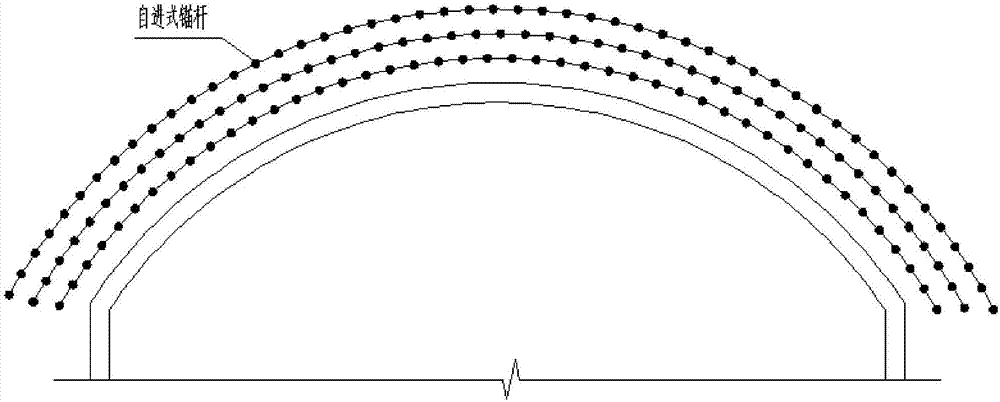

[0027] The second step is multi-level self-advancing bolt advance support. to combine figure 1 , figure 2 As shown, the high-rise building has used the underground space (such as the garage) and the interface of the connecting tunnel as a section of deep foundation pit soft backfill area, which is formed when the deep foundation pit soft backfill area is built. This construction method is aimed at the construction method of the soft backfill area of this section of deep foundation pit, and effectively solves the problem of subsidence of the bottom surface caused by the fall of backfill soil during the construction proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com