Karst cave backfilling method and tunnel construction method

A technology for tunnel construction and karst caves, which is used in tunnels, tunnel linings, and earthwork drilling and mining, etc. It can solve the problems of difficult protection during construction of karst treatment measures, large scale development of giant karst caves in alpine tunnels, and large thickness of slump deposits at the bottom of karst caves. problems, to avoid concrete cracking, improve the grouting range and grouting compactness, and avoid the loss of grout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

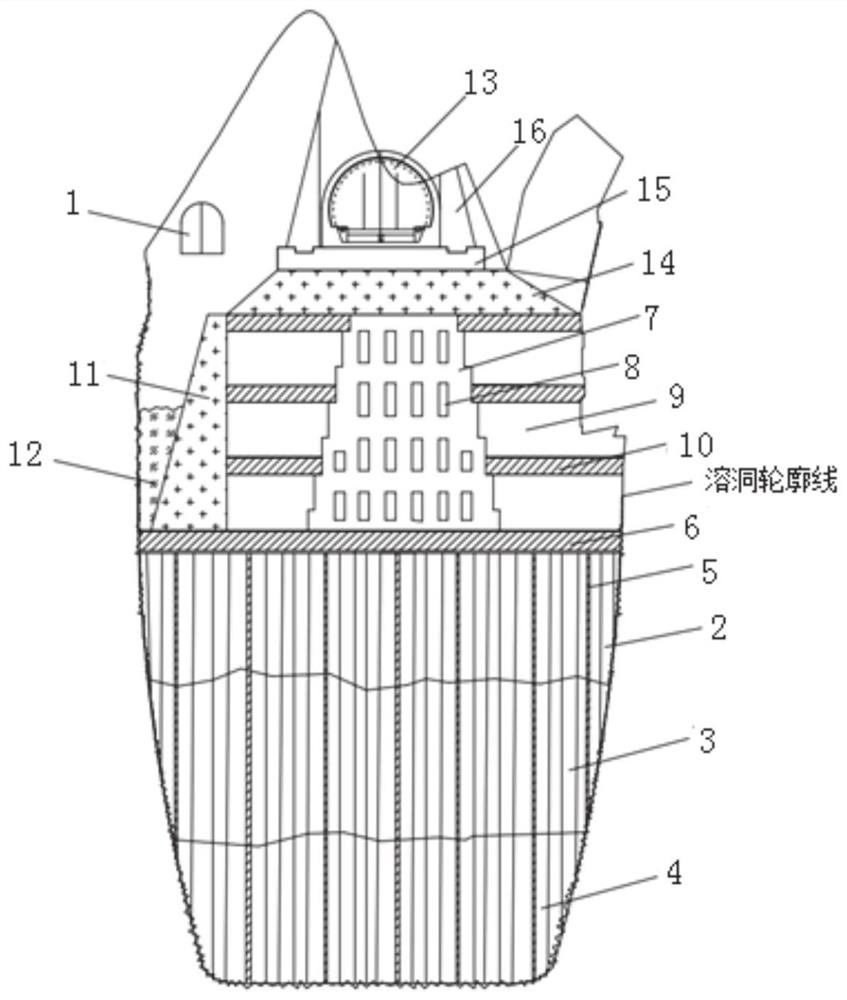

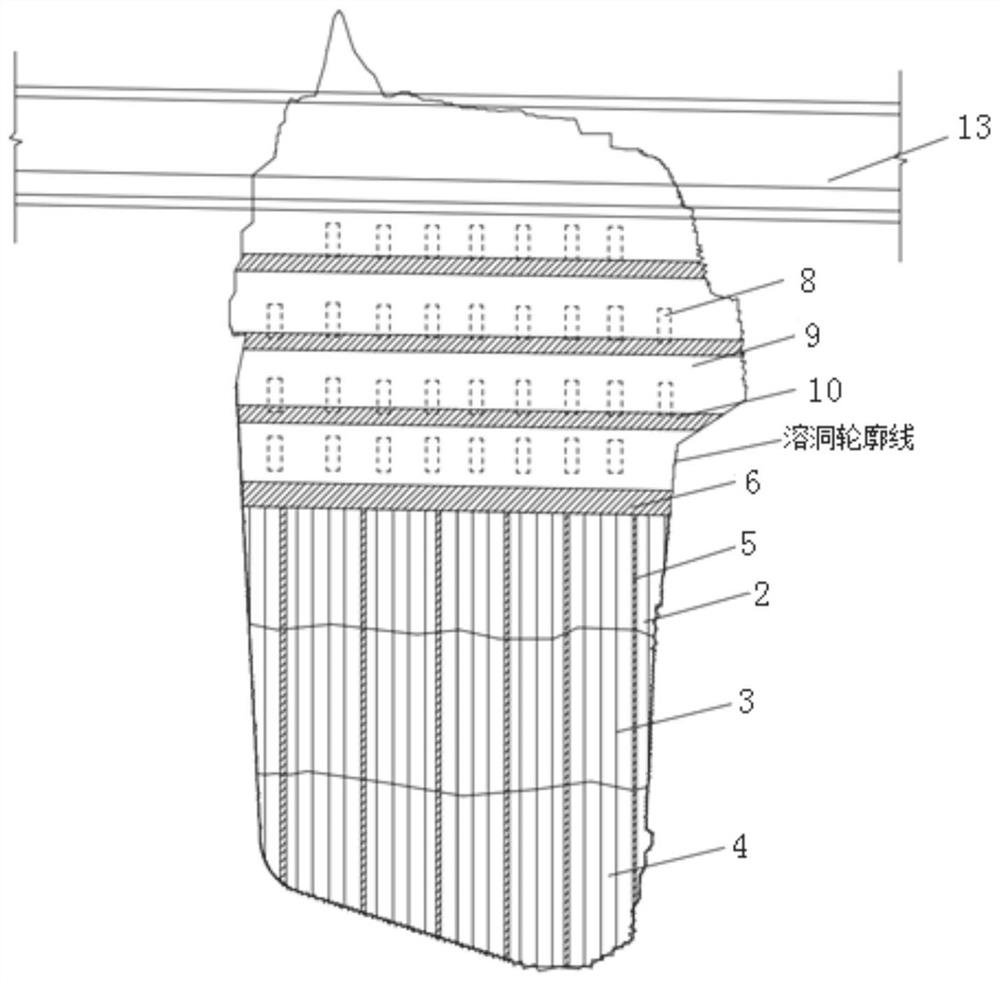

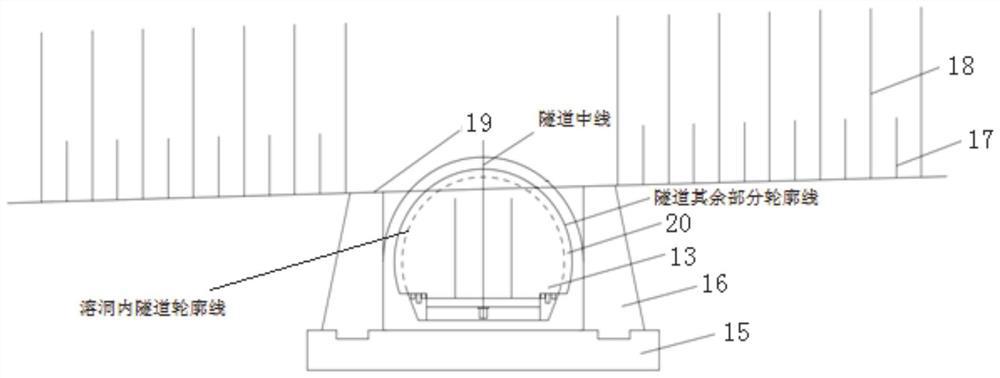

[0065] This embodiment discloses a tunnel construction method. When the tunnel construction encounters a karst cave and needs to pass through the karst cave, the karst cave backfilling method described in Embodiment 1 is first used to backfill the karst cave to form a tunnel foundation, and then the tunnel is constructed on the tunnel foundation. 13.

[0066] After backfilling is completed, a graded crushed stone layer 14 is constructed on the top of the tunnel foundation reinforcement plate and the upper surface of the concrete foundation structure at a slope ratio of 1:1.5, and the two sides of the graded crushed stone layer and the two sides of the tunnel foundation have set The specific construction method of the graded gravel layer is as follows: Vibration rolling method is used to backfill in layers about 5m mixed with 5-7% graded gravel layer, and the thickness of the layers is about 30cm. After testing to meet the compaction requirements, continue to construct the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com