A car front face structure

A front face and automobile technology, applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of headlight falling off, difficult assembly, and far-reaching seams, so as to improve structural stability and facilitate assembly Reasonable effect of assembly and structure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

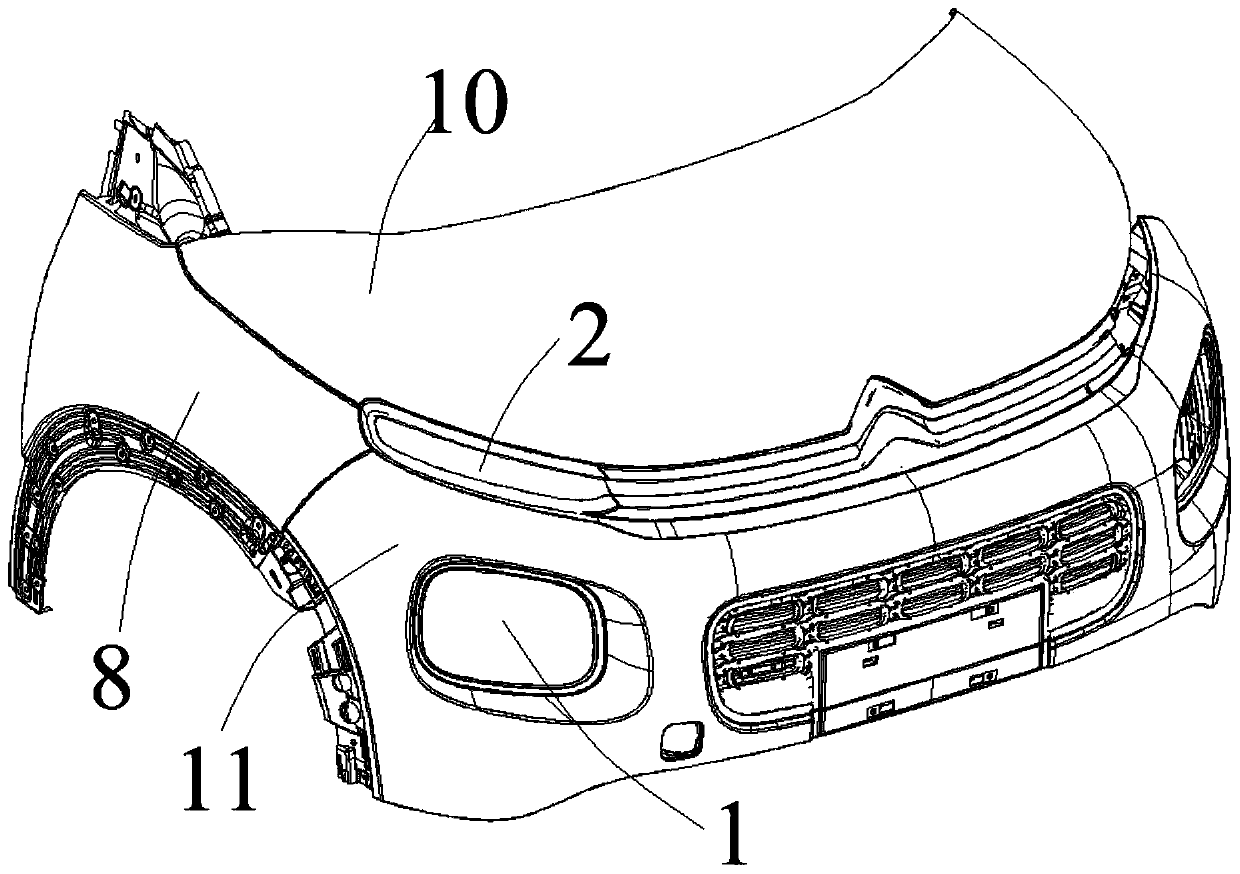

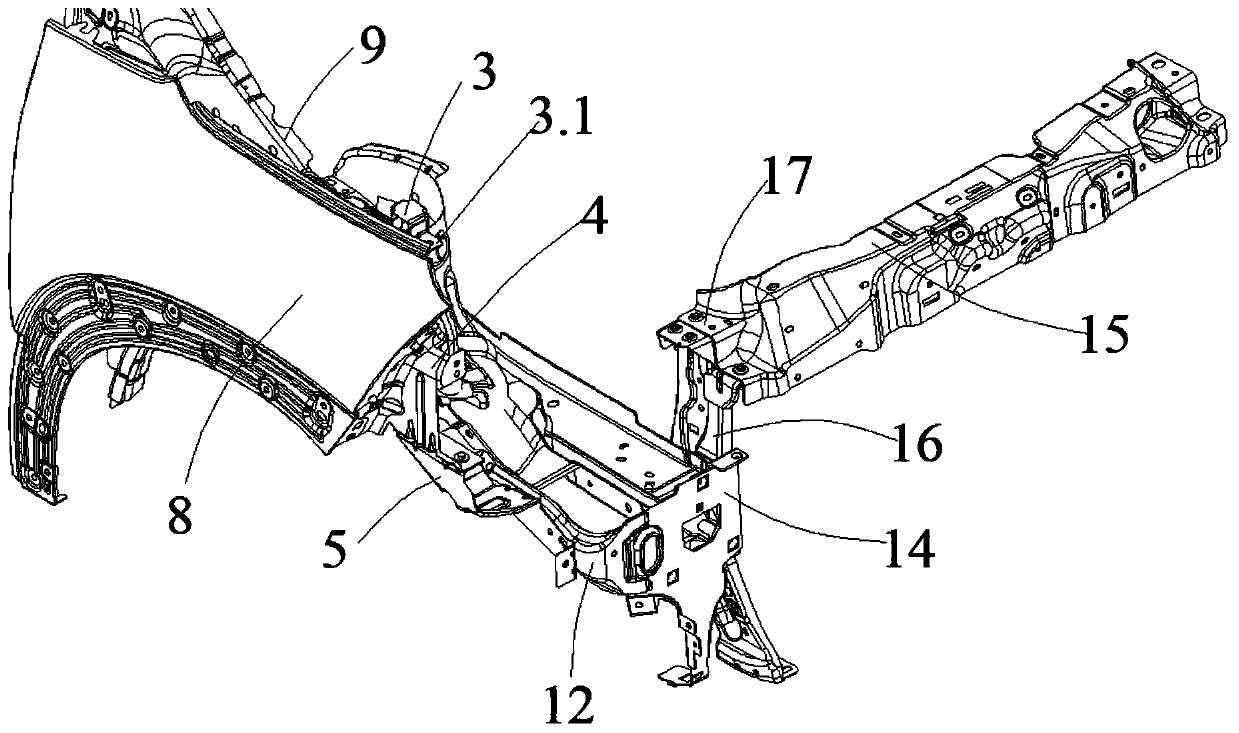

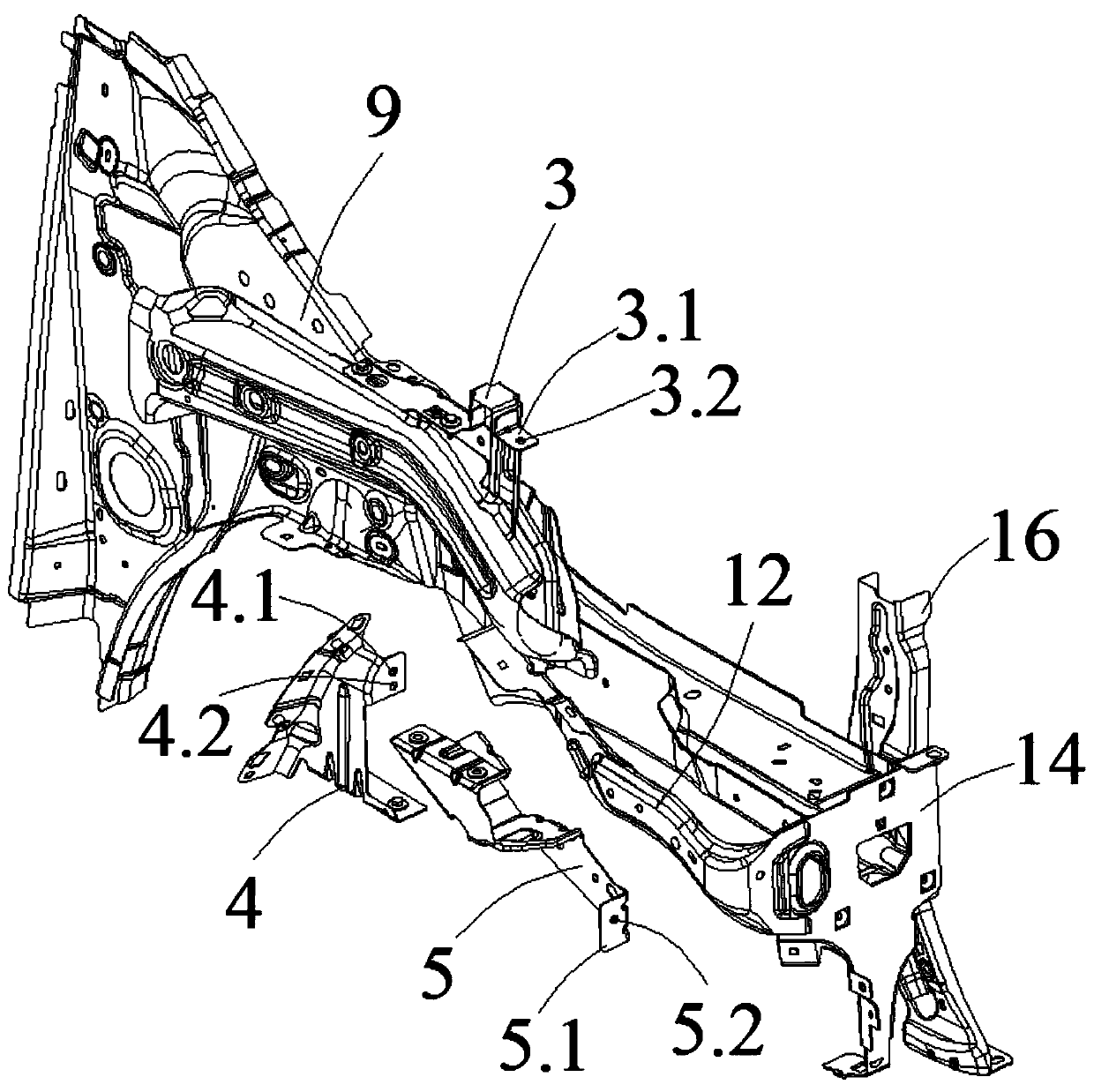

[0038] Such as Figure 1-11 As shown, the front face structure of the automobile in this embodiment includes a split headlight structure, including a headlight assembly 1 and a daytime running light 2, and the headlight assembly 1 is wrapped in the front protection skin 11, The daytime running lights 2 are located at the junction of the engine cover 10 , the front bumper skin 11 and the fender outer panel 8 , and the daytime running lights 2 are above the headlight assembly 1 .

[0039] In order to avoid the sinking problem caused by the heavy weight of the headlight assembly 1 , in this embodiment, the headlight assembly 1 is respectively fixed on several supporting components to share the weight and avoid excessive weight concentration. The supporting components for fixing the headlight assembly 1 include a fender bracket and a fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com