Soil and comprehensive construction waste prepared automatic water-absorption automatic luminous type sponge road

A technology of automatic lighting and construction waste, applied in the directions of buildings, roads, roads, etc., to prevent the support keel from sinking, solve the strength, and facilitate the processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

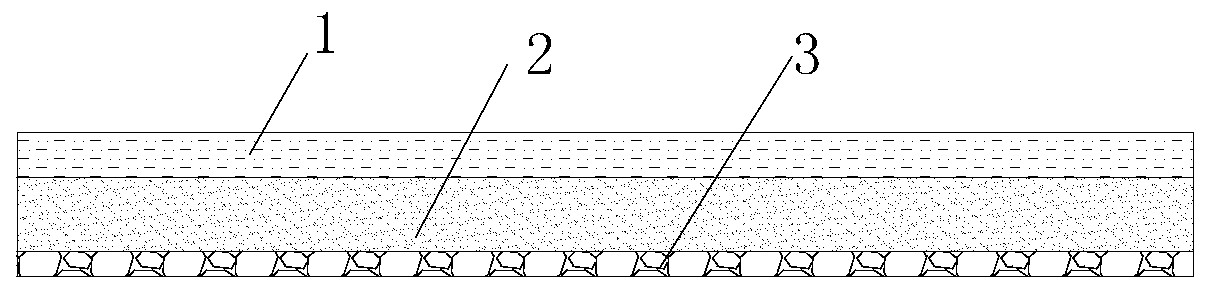

[0034] see figure 1 , the embodiment of the present invention provides an automatic drinking water automatic luminescent sponge road prepared from soil and comprehensive construction waste, including: a permeable surface layer 1, a permeable base layer 2 and an isolation layer 3 laid sequentially from top to bottom, the permeable base layer It is a polymer water permeable body layer.

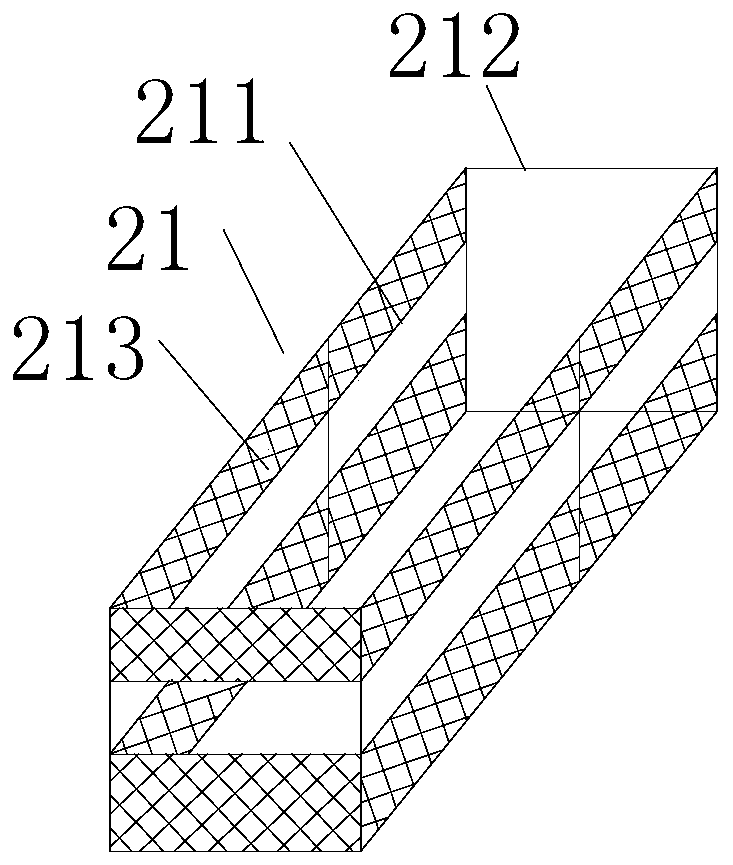

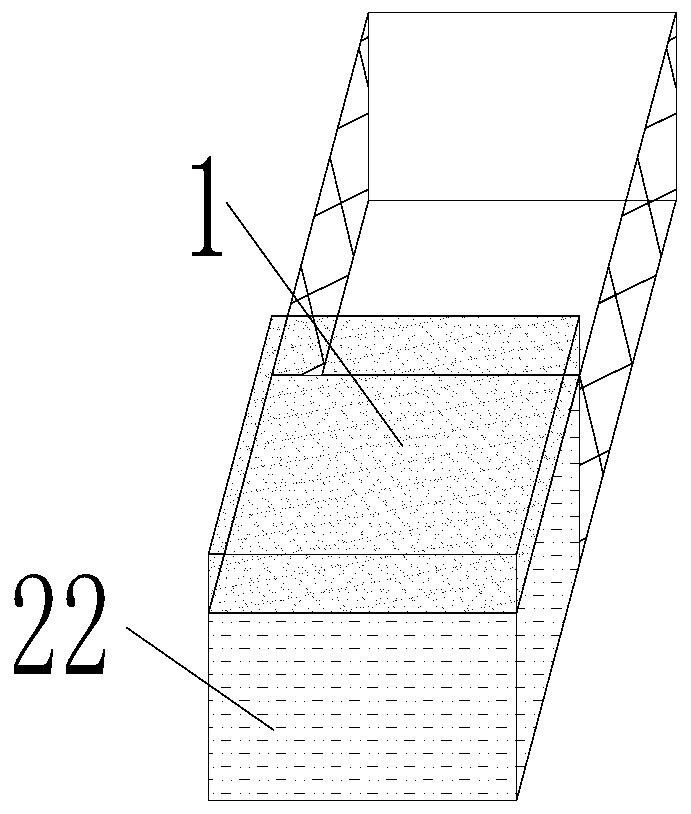

[0035] Preferably, the permeable base layer 2 includes a support keel 21 and a polymer permeable material 22 coated on the support keel 21 .

[0036] Preferably, the polymer permeable material 22 includes the following raw materials in weight percentage: 40-70% of pebble charcoal slag powder, 10-30% of unsaturated polyester resin, 5-10% of curing agent, 3-8% of aluminum powder, Strengthening agent 0.5-1.5%, accelerator 0.5-1.5%, cement 10-20%, water 15-30%.

[0037] Preferably, the permeable surface layer 1 includes the following raw materials in weight percentage: 30-60% of mudstone charcoal ...

Embodiment 2

[0042] see Figure 2-3 1. A preparation method for preparing automatic drinking water and automatic luminescent sponge road, comprising the following steps:

[0043] 1) laying isolation layer 3 on the original soil layer;

[0044] 2) Preparation of polymer water-permeable material 22: Weigh 40-70% mud rock charcoal powder, 10-30% unsaturated polyester resin, 5-10% curing agent, 3-8% aluminum powder, 15-30% by weight Pour % water into the automatic mixing station, turn on the automatic mixing station for 5-10 minutes and stop stirring, put 10-20% cement into the automatic mixing station and stir for 1-3 minutes, then add 0.5-1.5% reinforcing agent in turn , 0.5-1.5% accelerator, continue to stir, stir for 10-20 minutes and then grind to prepare a polymer water-permeable material for later use;

[0045] 3) Preparation of permeable surface layer: Weigh 30-60% pebble charcoal slag powder, 5-20% unsaturated polyester resin, 2-10% curing agent, 0.5-1.5% reinforcing agent, 1-5% lumin...

Embodiment 3

[0051] A sidewalk, which is prepared by the preparation method for preparing automatic drinking water and automatic luminous sponge roads. The difference from the sponge road is that the thickness of the water-permeable surface layer and the water-permeable base layer of the sidewalk are different from those of the sponge road. In this embodiment, the sidewalk and the sponge road can be poured in one piece, which simplifies the pavement manufacturing process and increases the anti-torsion and anti-seismic effects of the overall pavement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com