Semi-rigid abnormal beam anchor cable truss roadway supporting system

A technology of anchor cable truss and roadway support, which is applied to support the roof beam of the mine roof, the installation of anchor rods, mining equipment, etc., and can solve the problems of high support cost, roof shearing and slipping, and roof separation deformation. Achieve the effect of avoiding the loss of bearing capacity, ensuring integrity and large adjustment space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

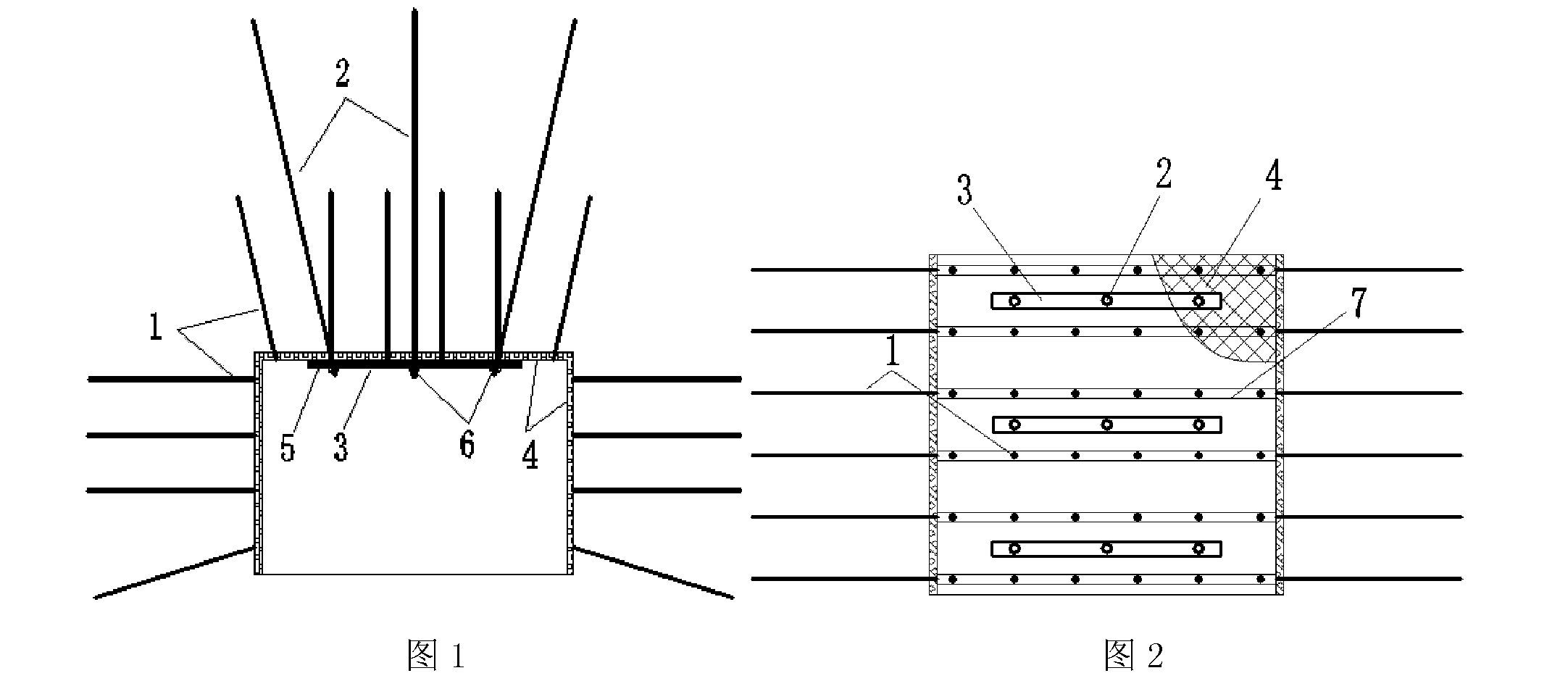

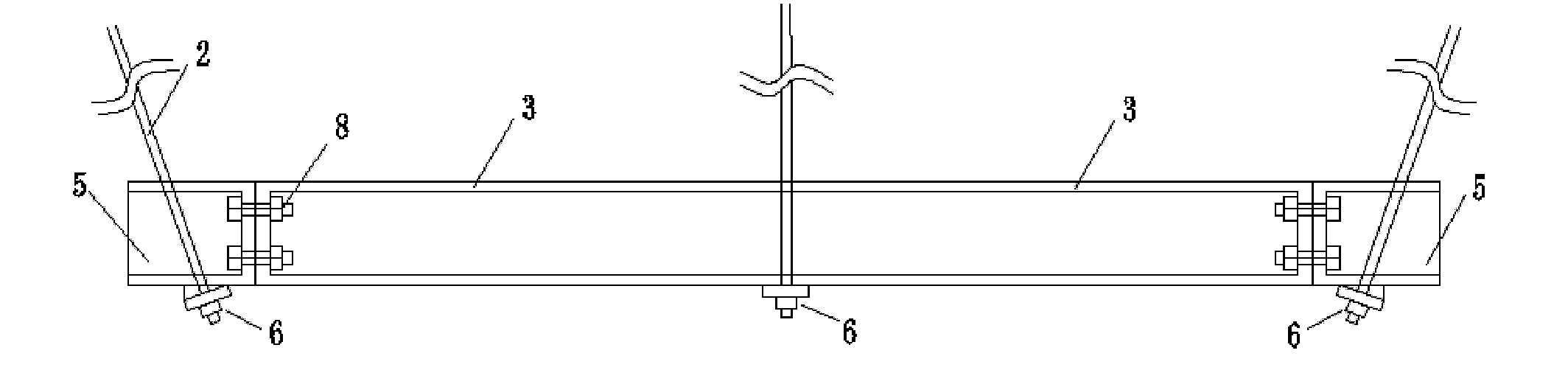

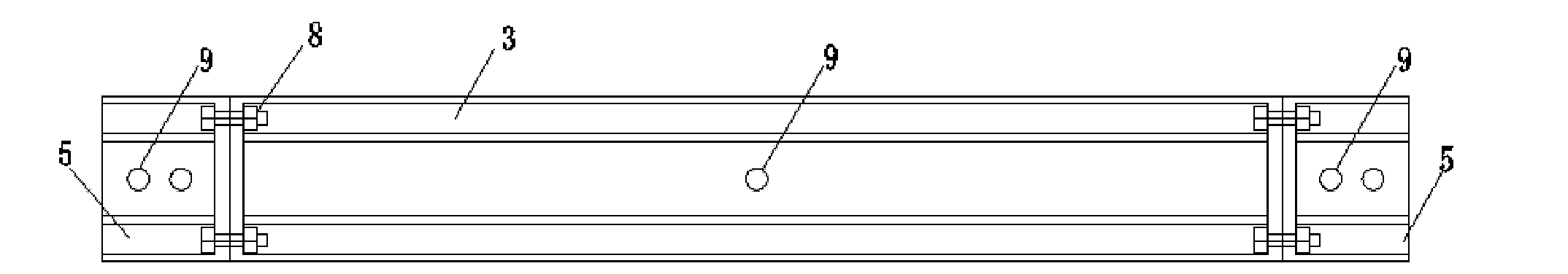

[0022] Such as Figure 1-5 As shown, metal mesh 4 is laid on the surface of the roadway, and special-shaped beams 3 and steel belts 7 are arranged at intervals under the coal rock roof. The anchor cable 2 passes through the special-shaped beam 3 and the metal mesh 4 and is anchored into the rock formation. It is connected with the special-shaped beam 3 and its semi-rigid node 5 through the tray and the lock 6 to form a prestressed force and form an extrusion protection effect on the roof. When the surrounding rock condition of the two sides of the roadway (referred to as the roadway side) is poor, the roadway side can also be equipped with special-shaped beams 3, which can be fixed with the anchor rod 1 or the anchor cable 2 to realize the coupling and matching of the roof side support strength, and jointly control the deformation of the surrounding roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com