Patents

Literature

114results about How to "Sinking smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

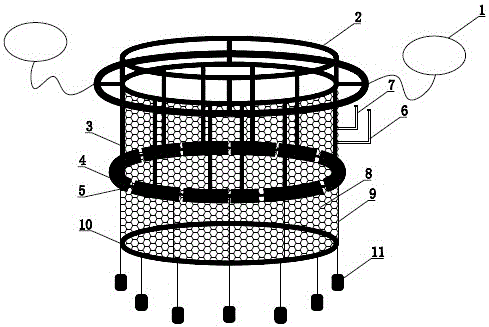

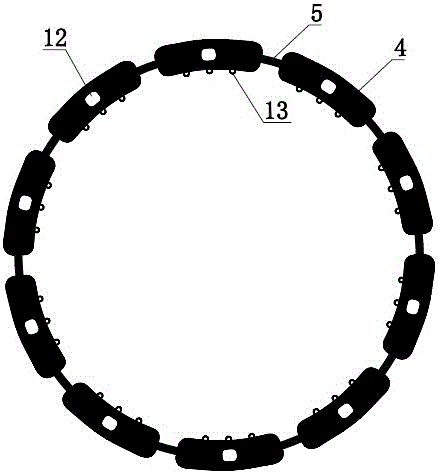

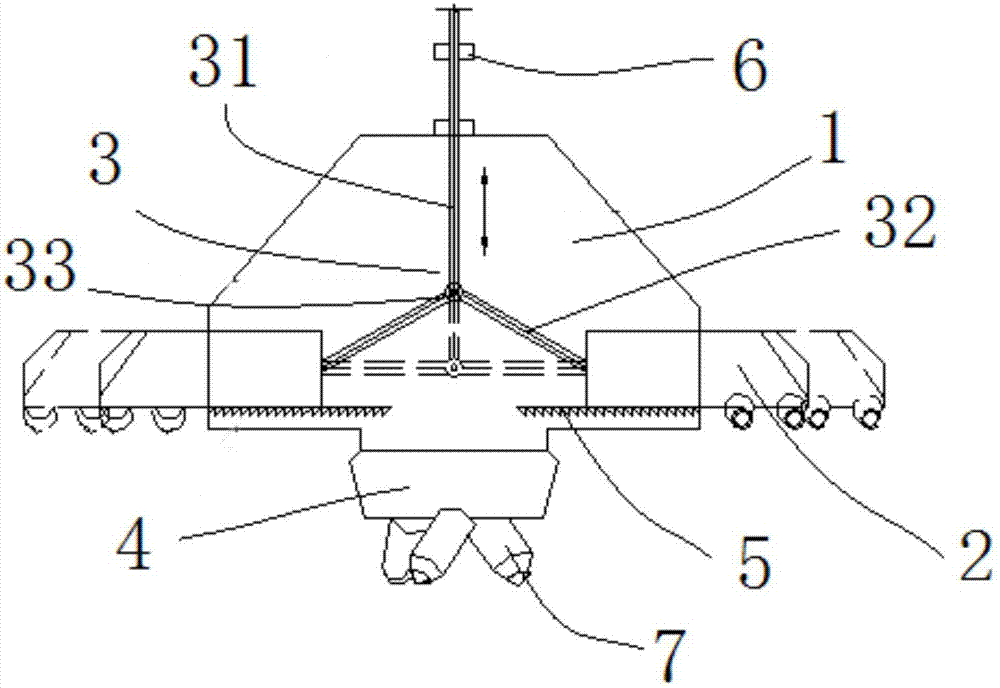

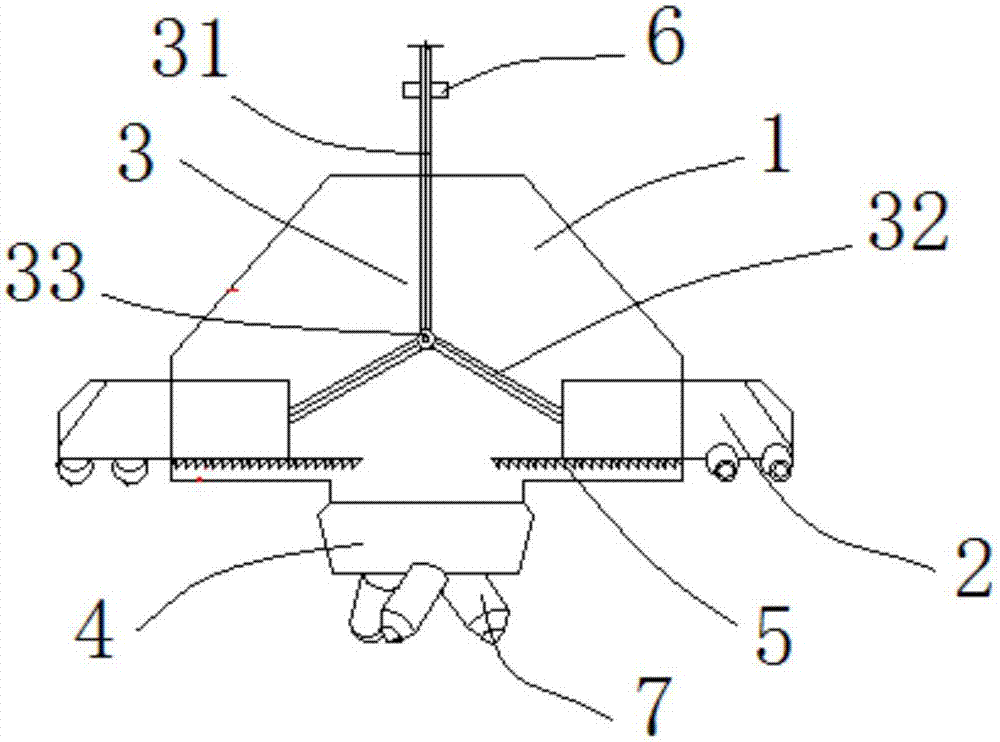

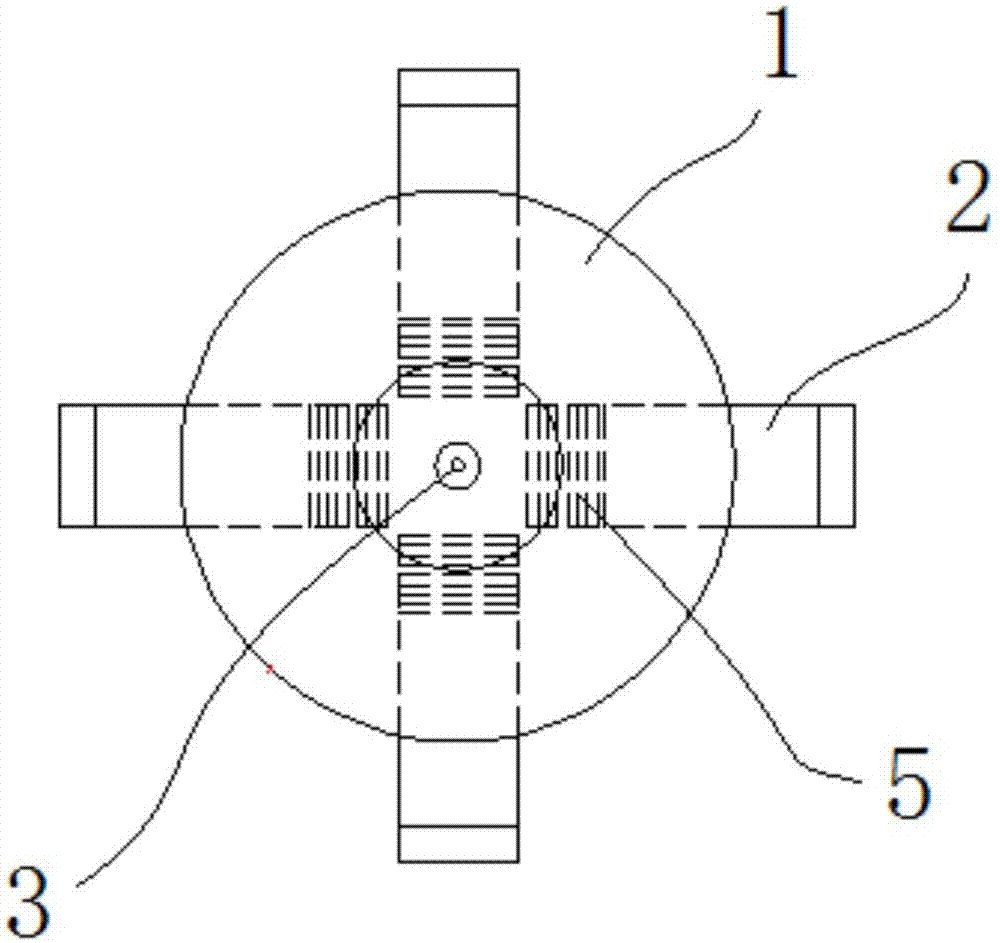

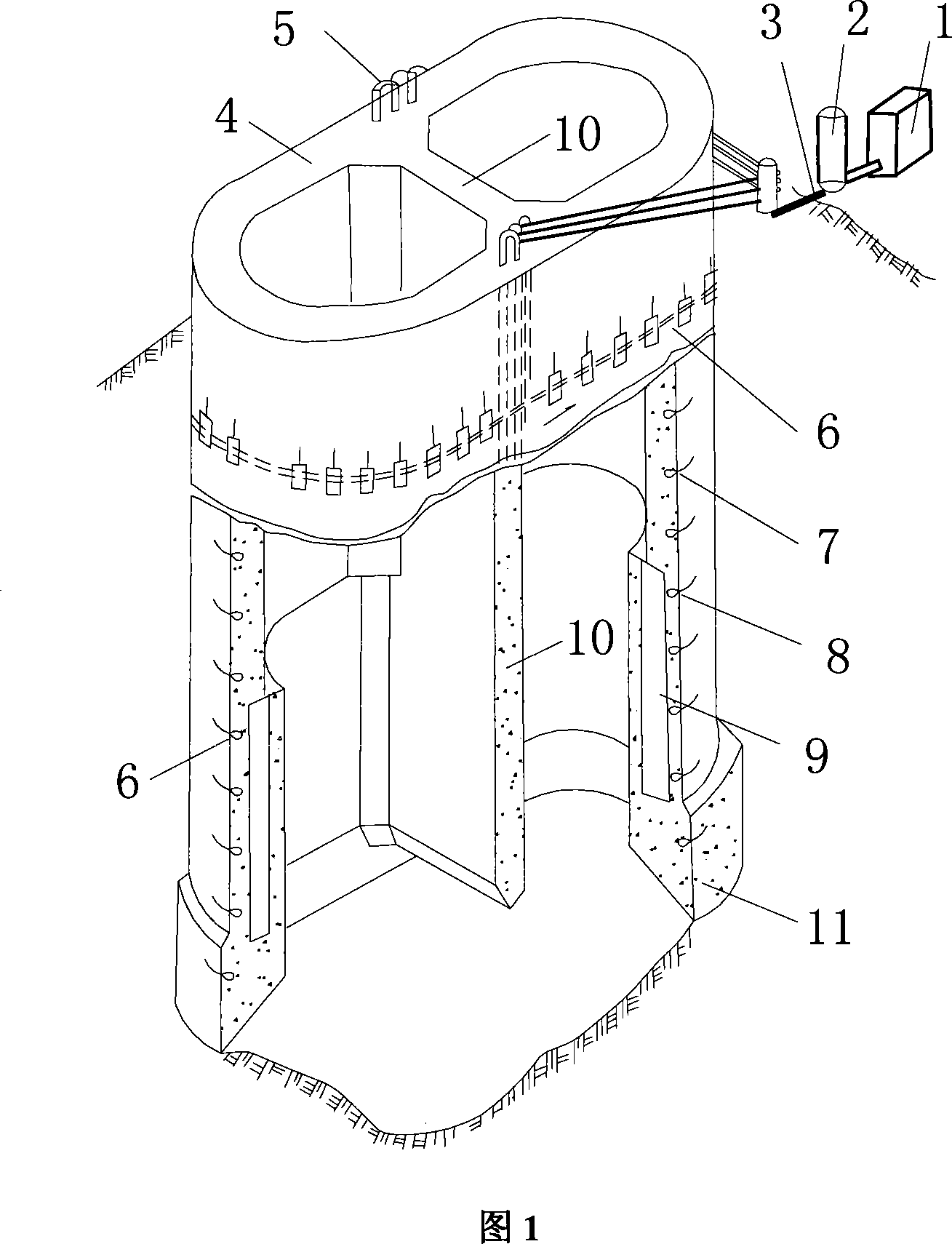

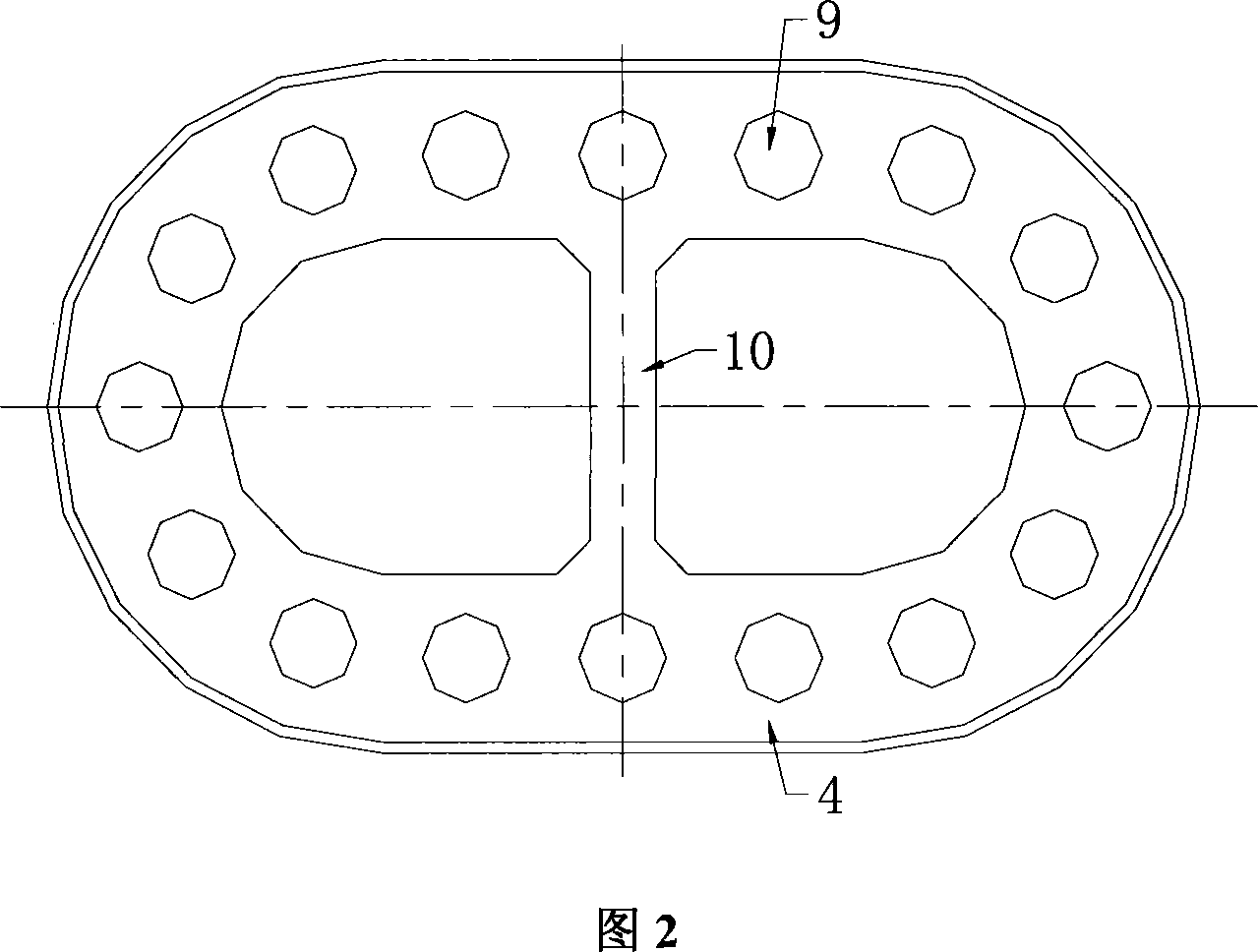

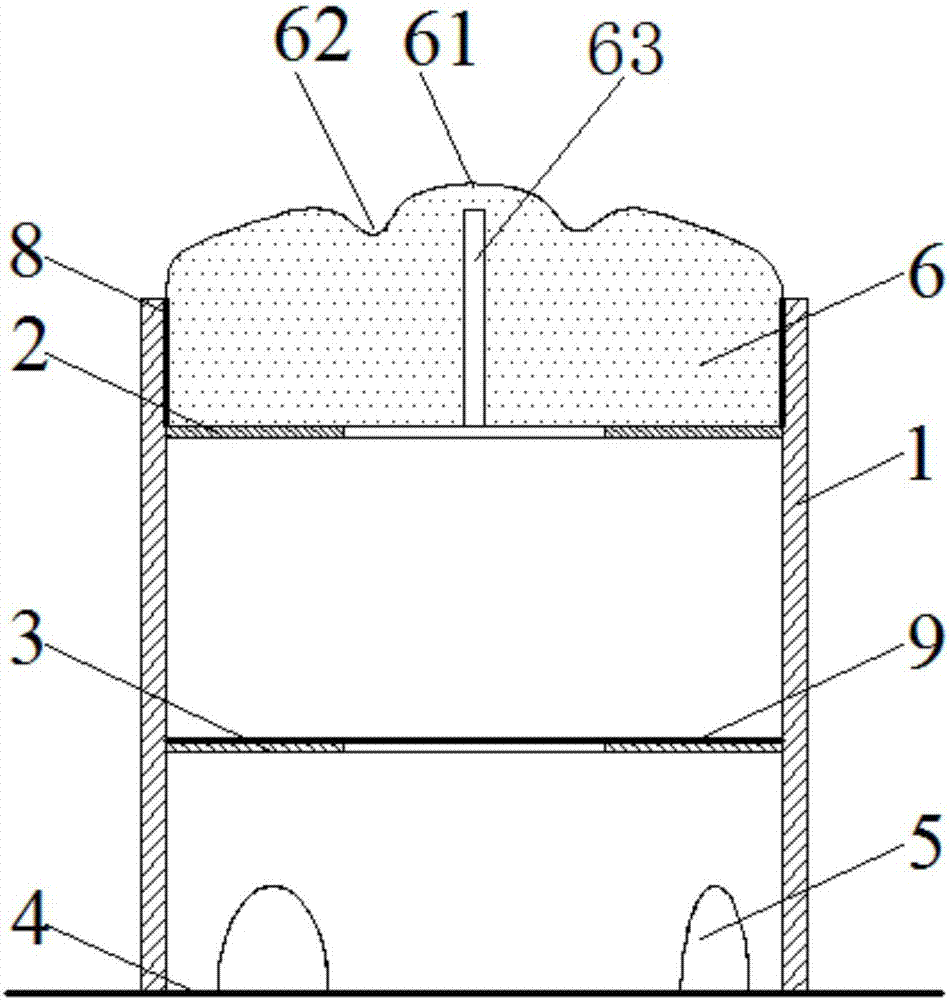

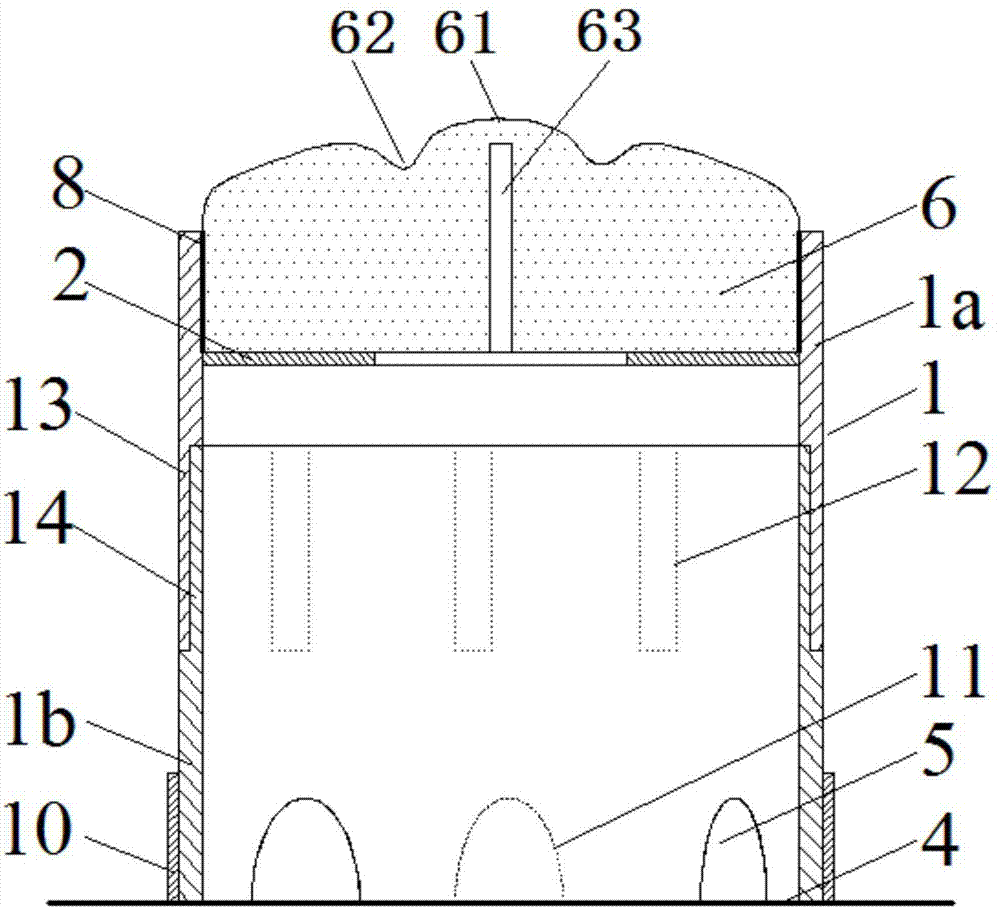

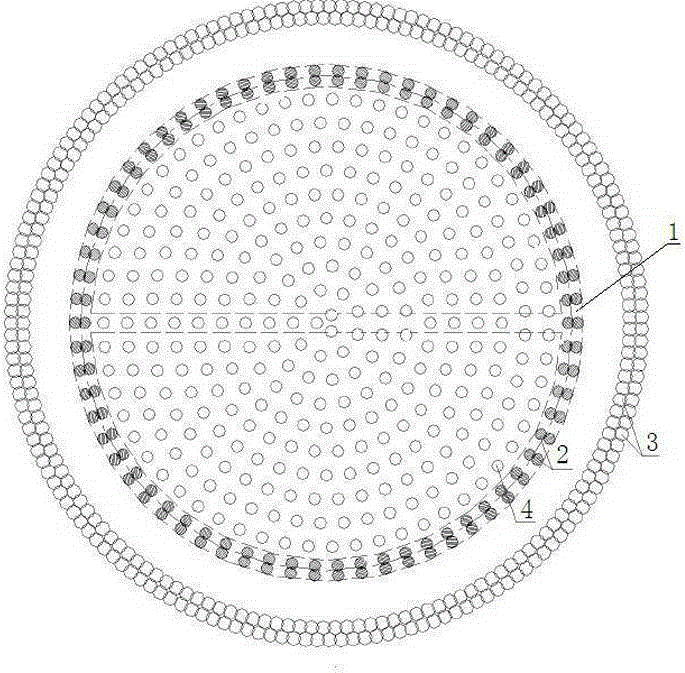

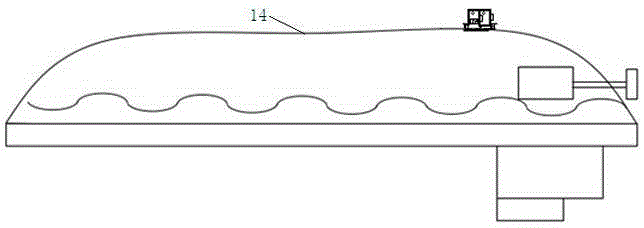

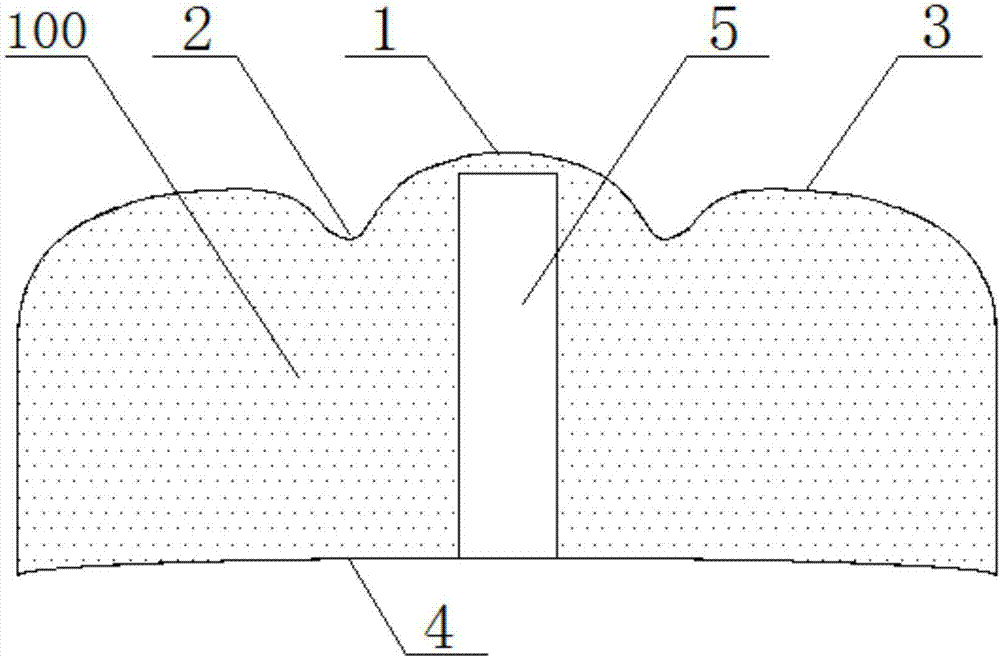

Floating and sinking type culturing net cage subjected to isobaric control and control method

ActiveCN106472379ASinking smoothlyLower center of gravityClimate change adaptationPisciculture and aquariaUnderwaterEngineering

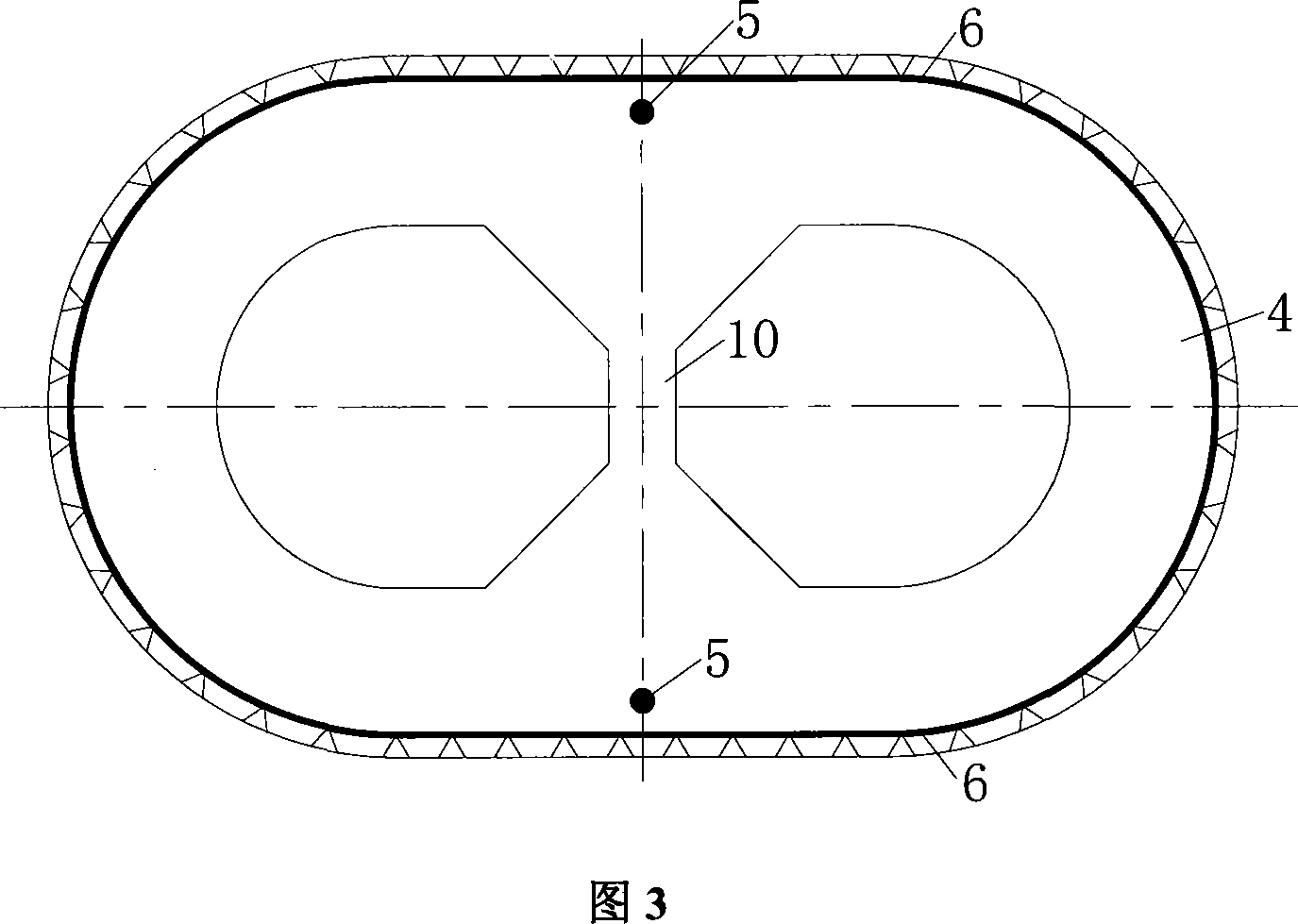

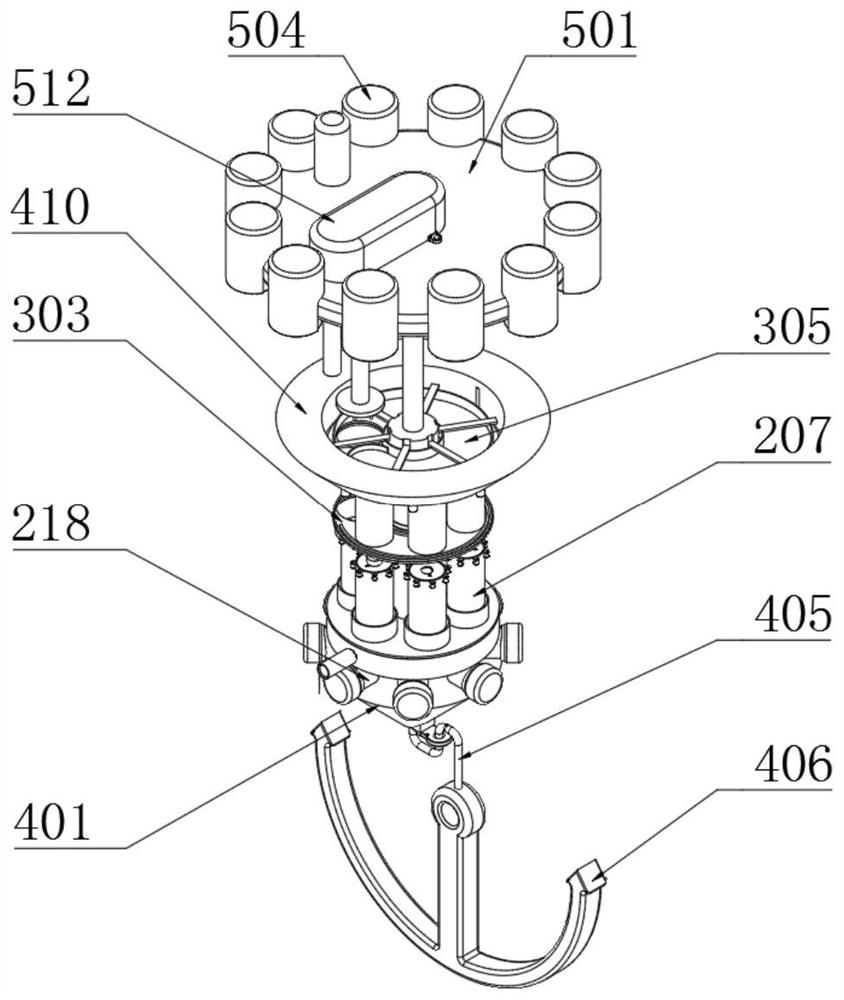

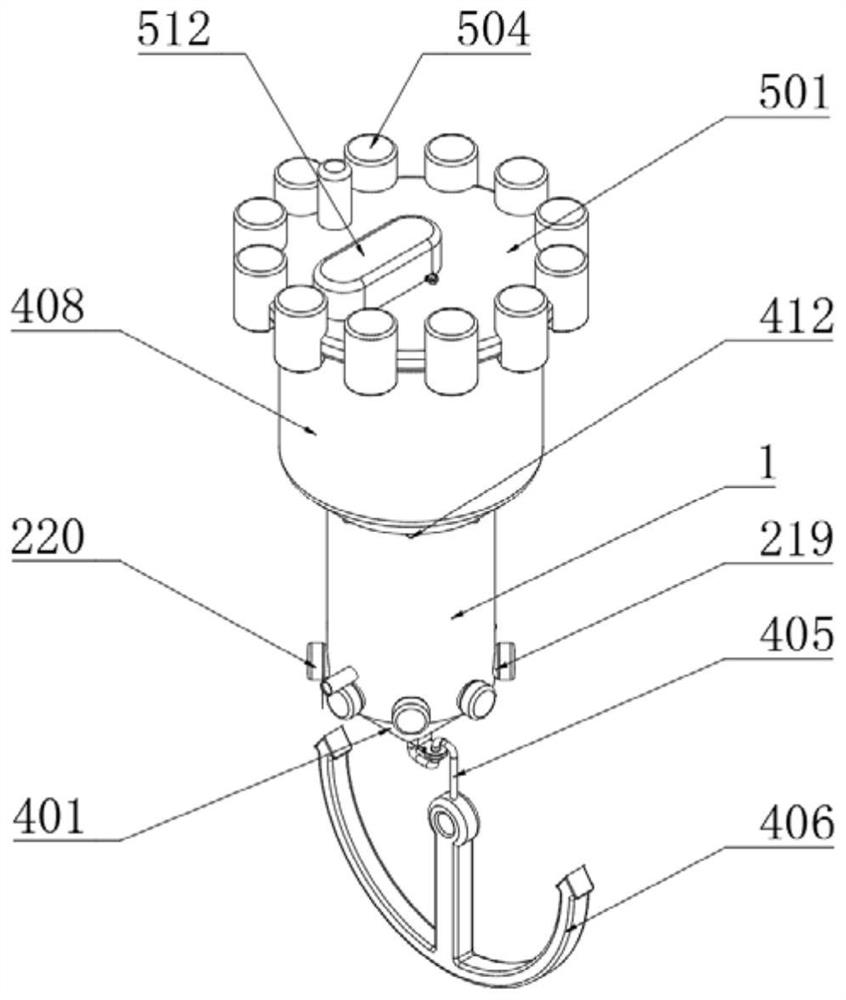

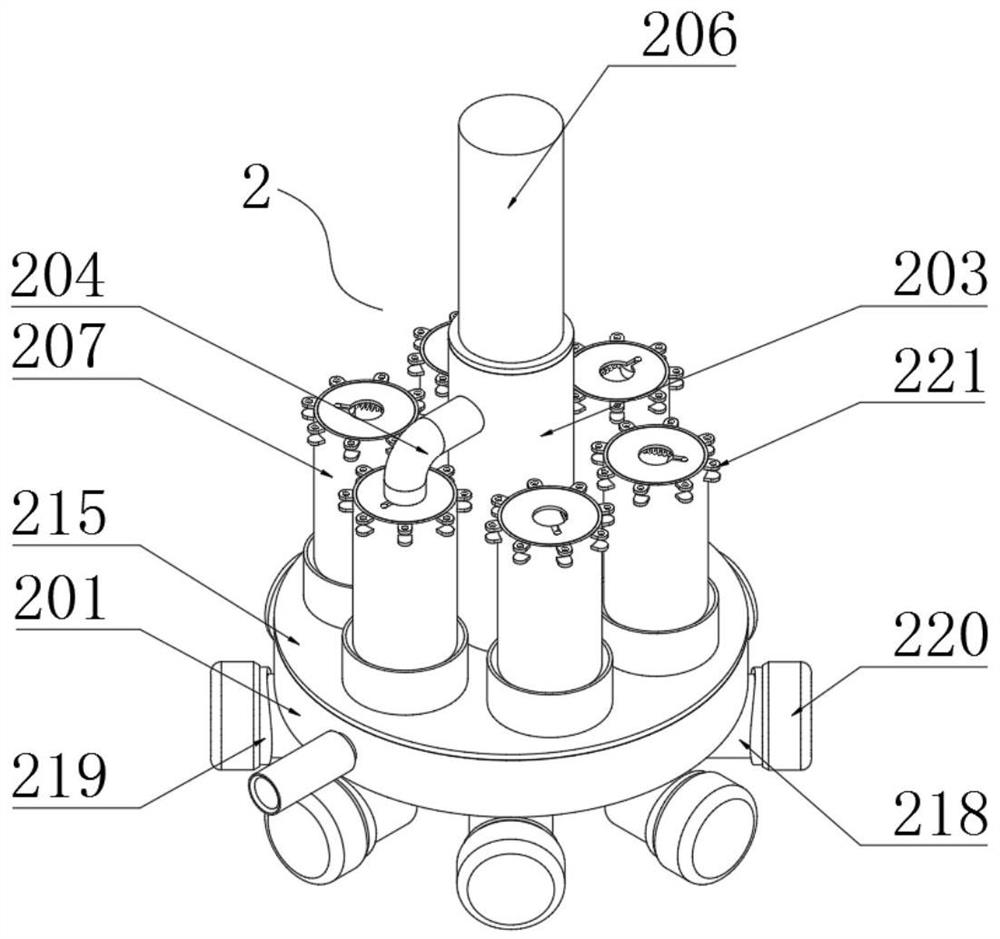

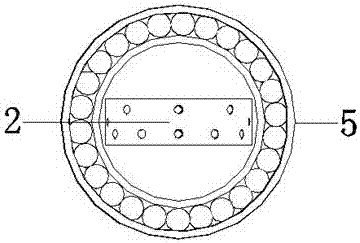

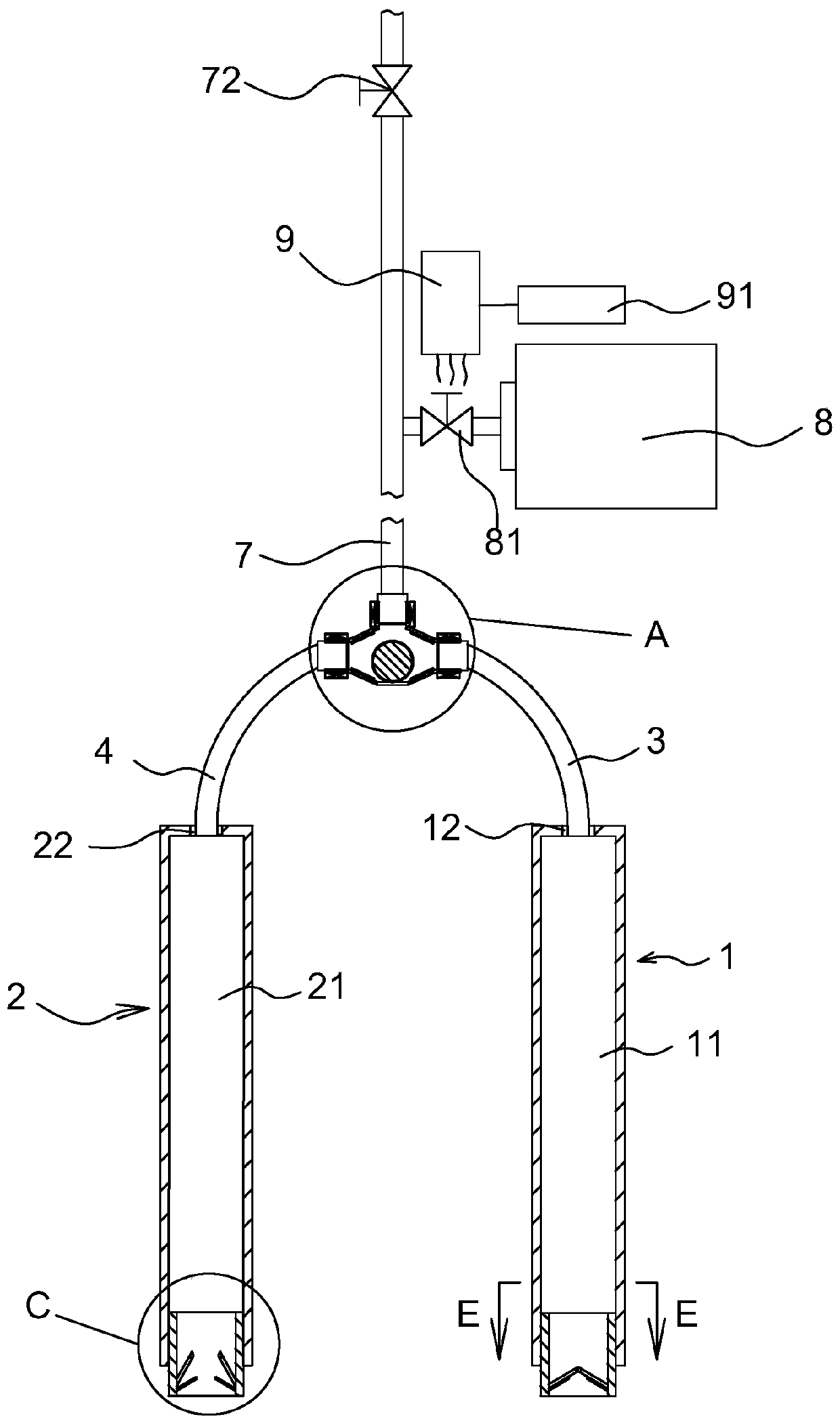

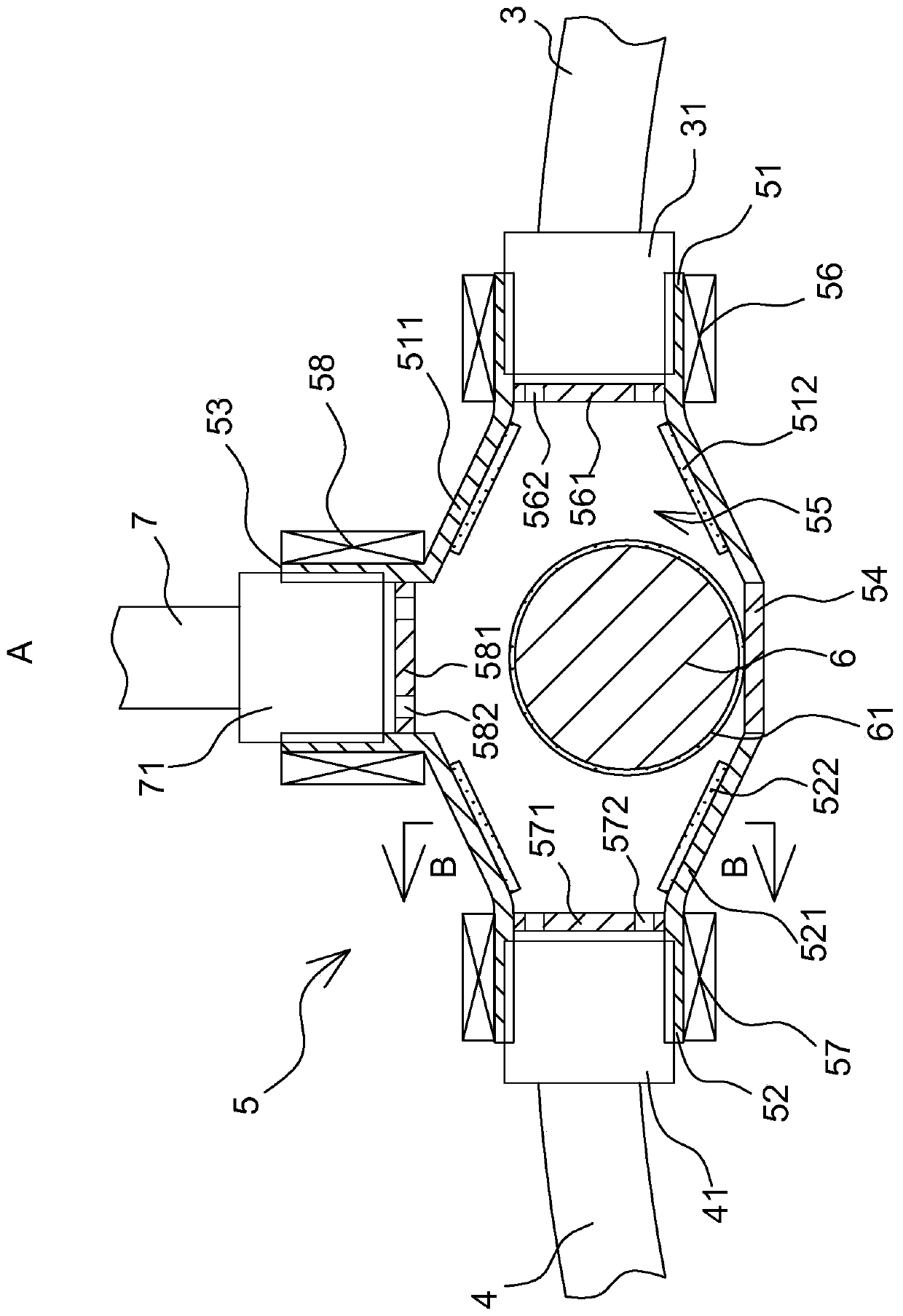

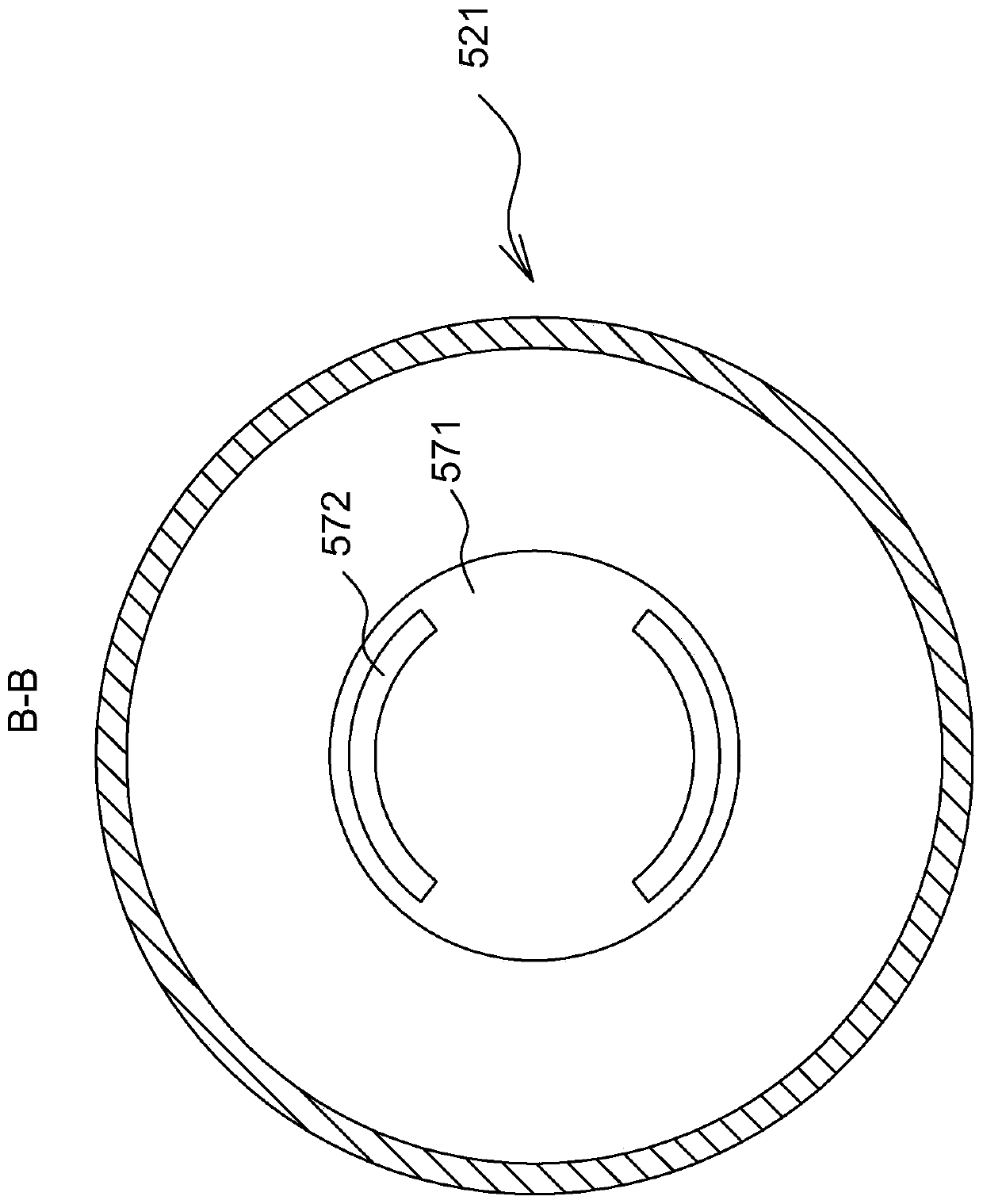

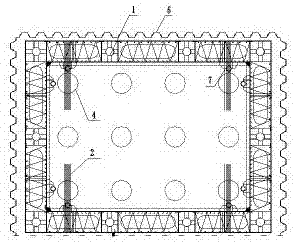

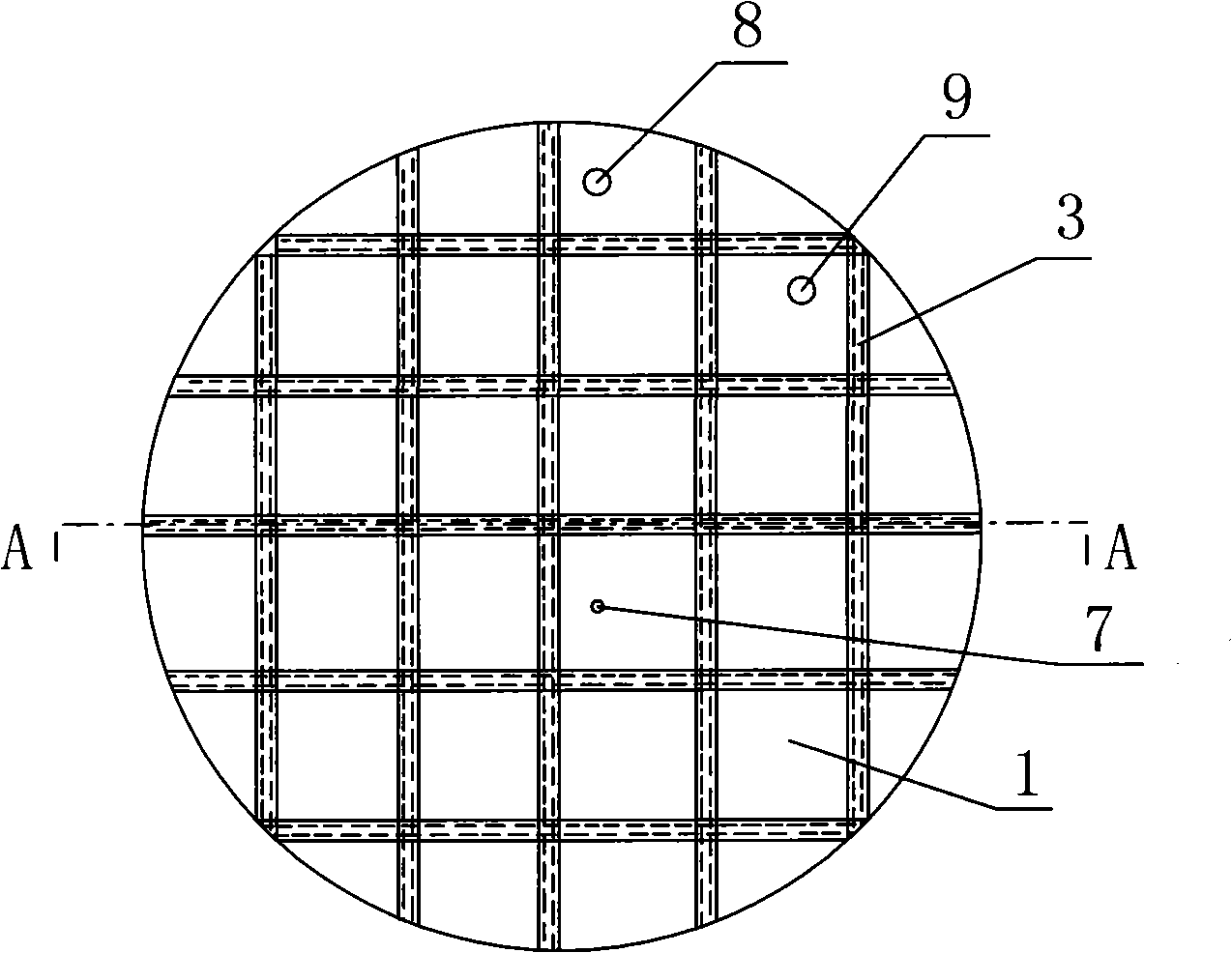

The invention discloses a floating and sinking type culturing net cage subjected to isobaric control and a control method. The floating and sinking type culturing net cage comprises floating balls, a main floating body frame, vertical supporting pipes, a sinking and floating control body, netting, a water inlet-discharge pipe and an air inlet-exhaust pipe, wherein the floating balls are fastened to the main floating body frame by flexible ropes; the main floating body frame, the vertical supporting pipes and the sinking and floating control body form one rigid whole; the sinking and floatation control body is of an annular structure which is formed by connecting multiple sinking and floatation cabins by communicating pipes, so as to form an isobaric cavity; the sinking and floating control body is located at the 1 / 2 position of a net cage, and is fastened to and connected with the vertical supporting pipes by the sinking and floating cabins and a buffering cabin. The sinking and floating control body of the floating and sinking type culturing net cage subjected to the isobaric control replaces a conventional integral separating sub-cabin; the whole sinking and floating control body is enabled to form the isobaric cavity underwater; the smooth and steady sinking of the net cage is realized; the main floating body frame, the vertical supporting pipes and the sinking and floating control body are enabled to form the rigid whole; the structural strength of the net cage is improved; deformation of the netting is avoided.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI +1

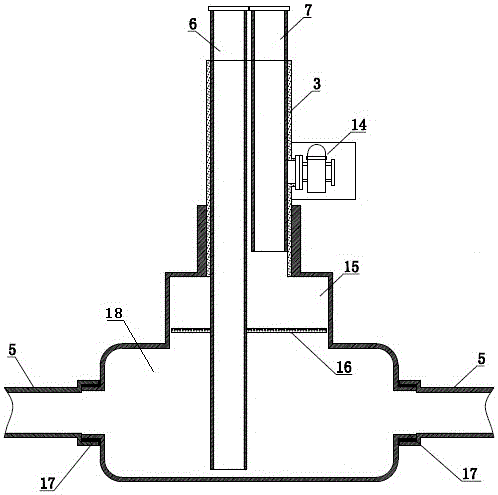

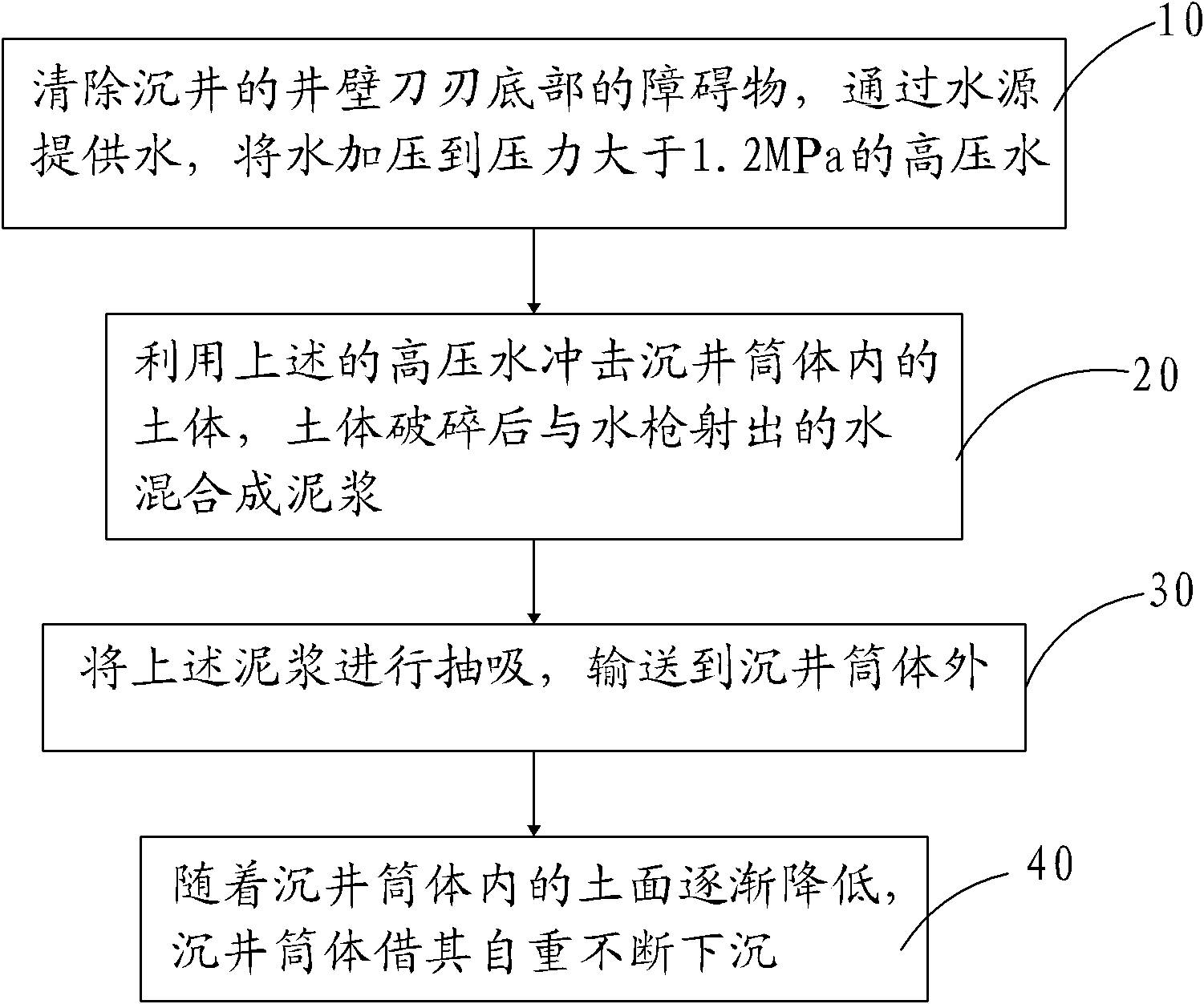

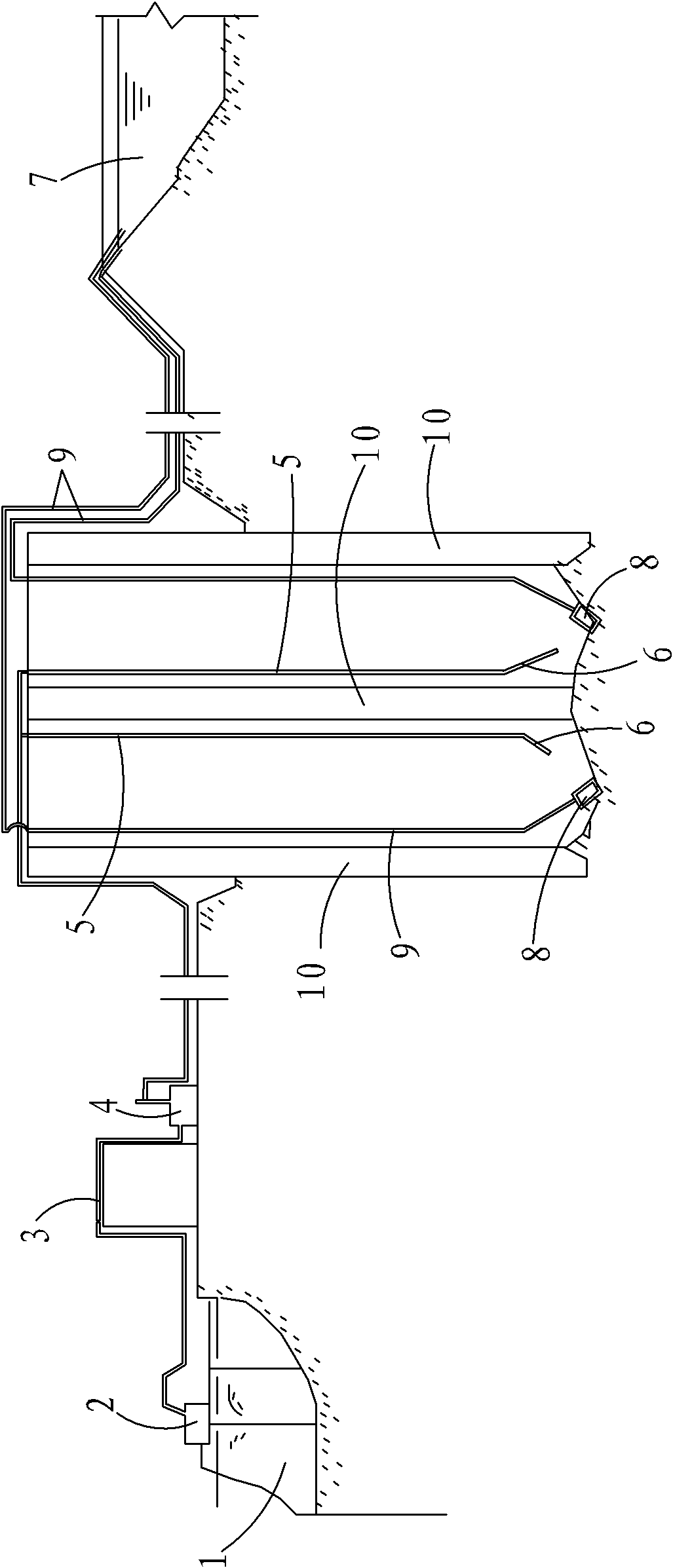

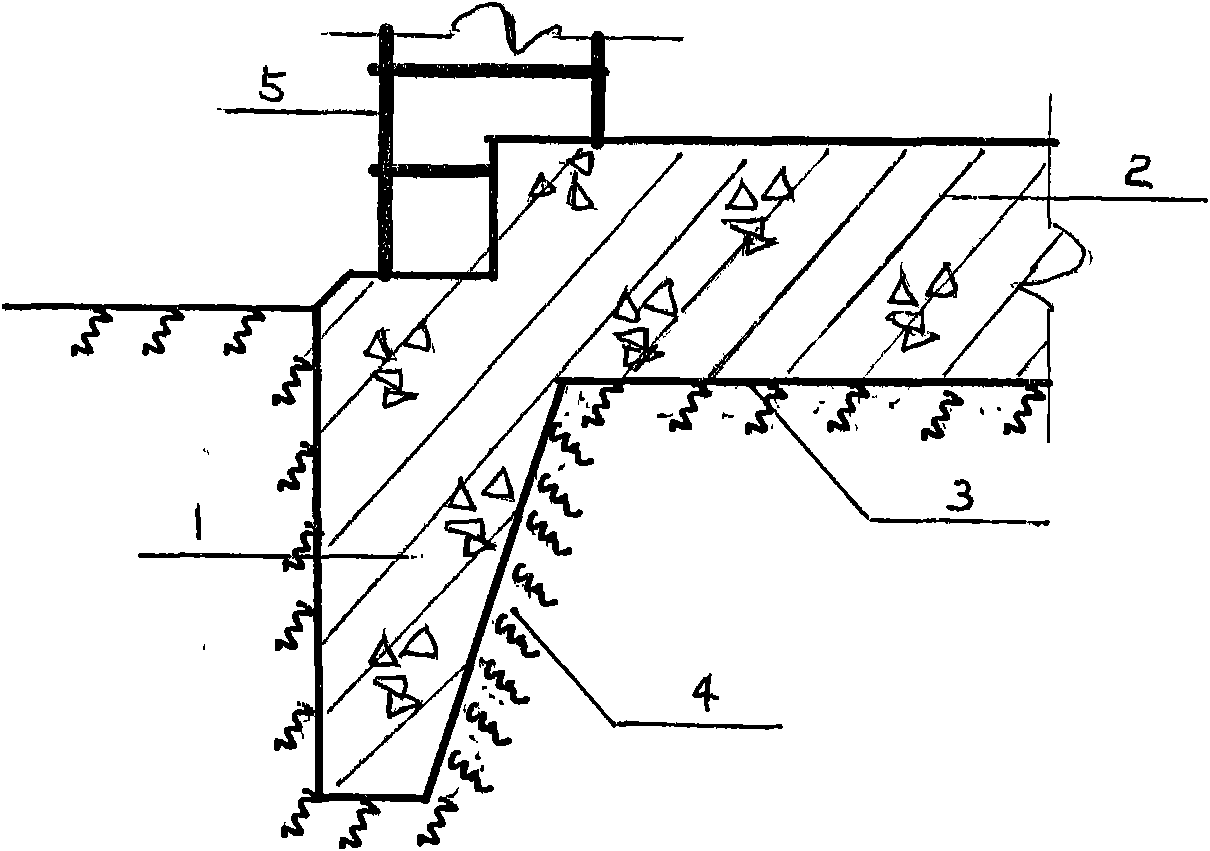

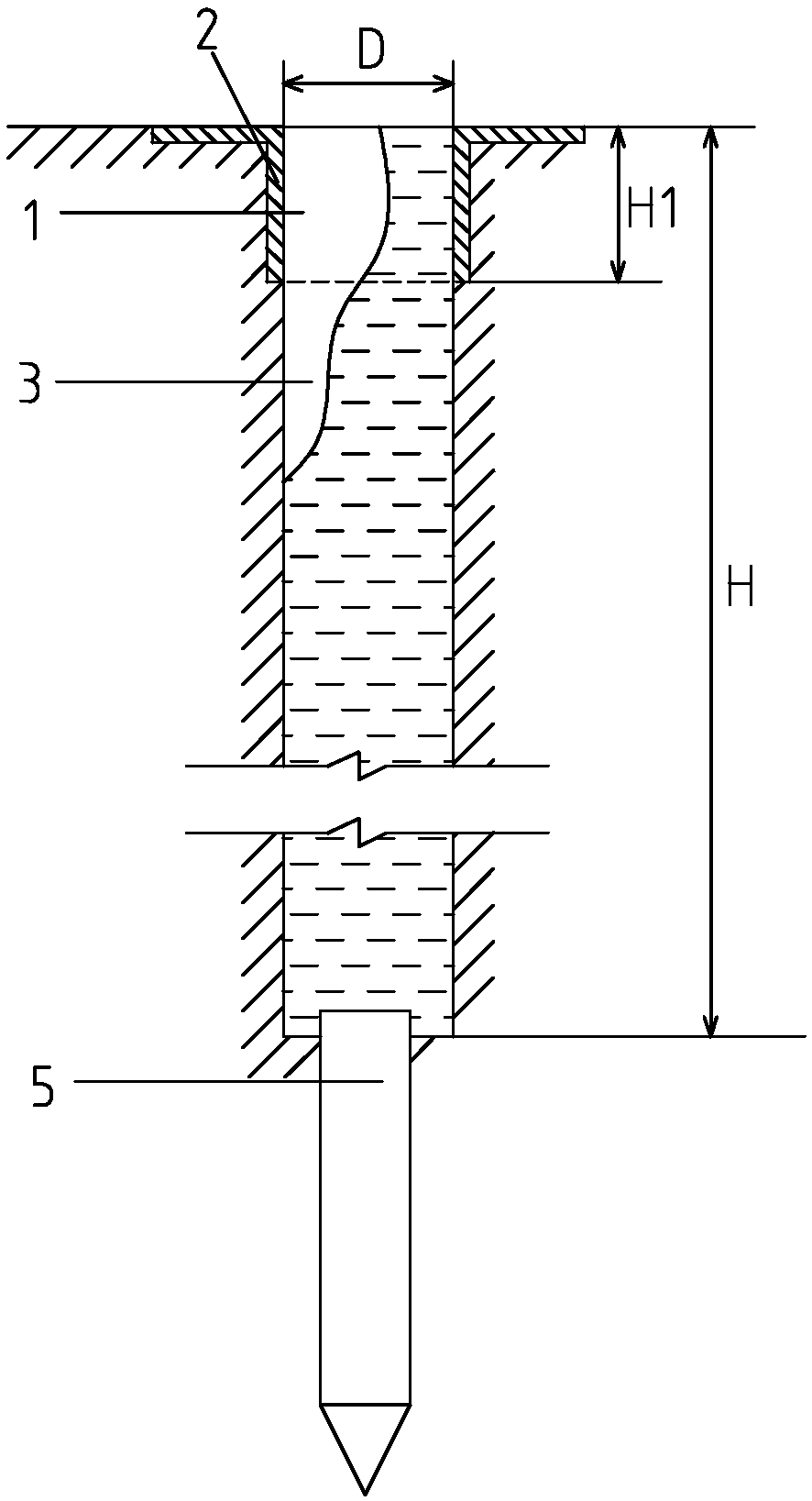

Open caisson construction method of reinforced concrete for soft soil layer

The invention provides an open caisson construction method of reinforced concrete for a soft soil layer. The open caisson construction method specifically comprises the followings steps: 10, barriers on the bottom of a wall blade of an open caisson are removed, water is supplied from a water source, and the water is pressurized to a pressure higher than 1.2 MPa; 20, the high-pressure water is utilized to impact soil mass in a tube body, and the broken soil mass and water sprayed from a water gun are mixed into slurry; 30, the slurry is pumped and delivered to the outside of the tube body of the open caisson; and 40, the tube body of the open caisson subsides gradually due to self gravity along with gradual reduction of soil surface in the tube body of the open caisson. The open caisson construction method disclosed by the invention can avoid over-digging of the bottom and the phenomena of sudden subsidence of the open caisson because hydraulic power is utilized to break oil, is easy to ensure the construction quality of the open caisson, can effectively control the soil breaking program and position, can enable the open caisson to subside steadily, is convenient for controlling the final subsiding elevation of the open caisson, and reduces the engineering cost.

Owner:FUJIAN UNIV OF TECH

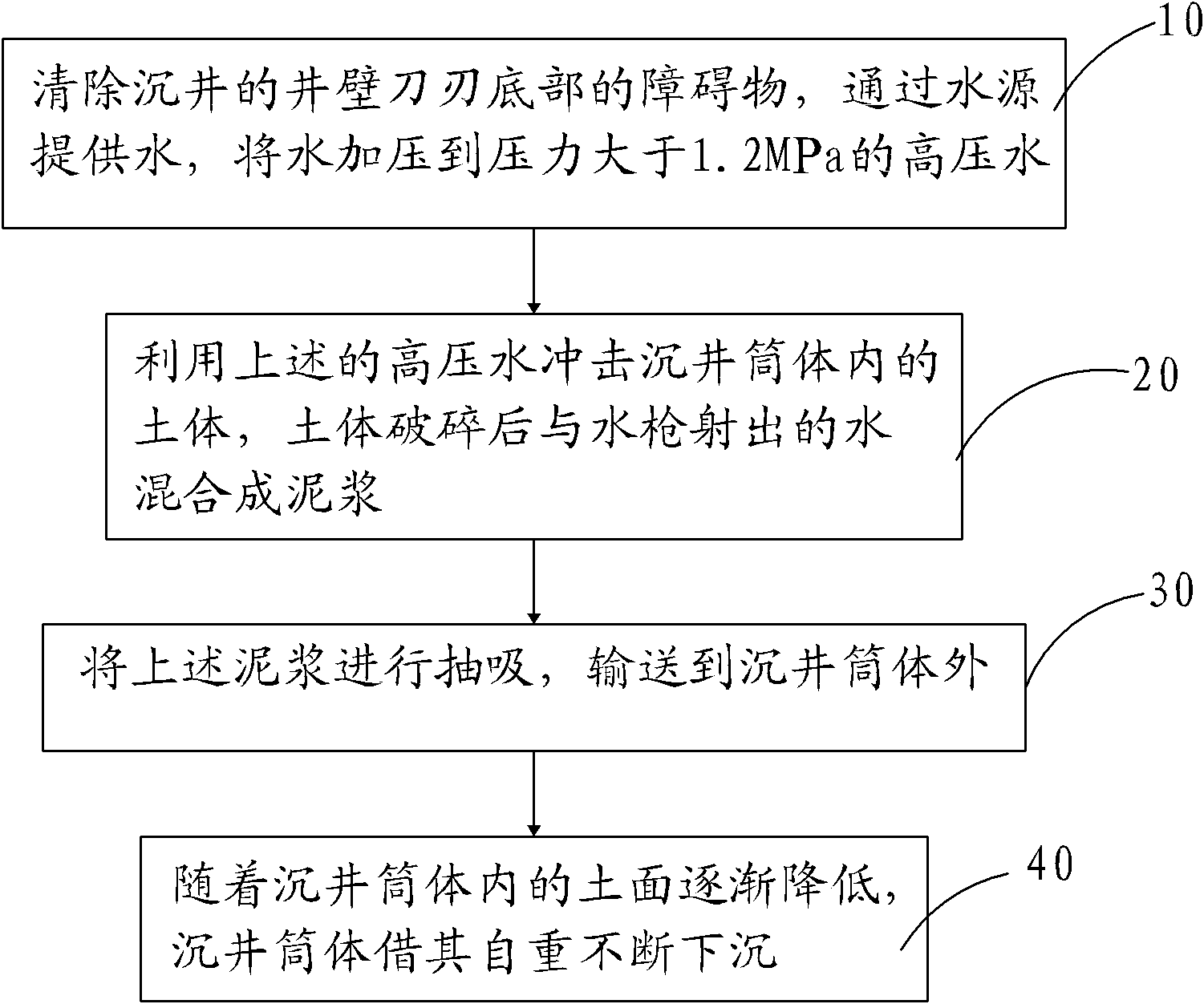

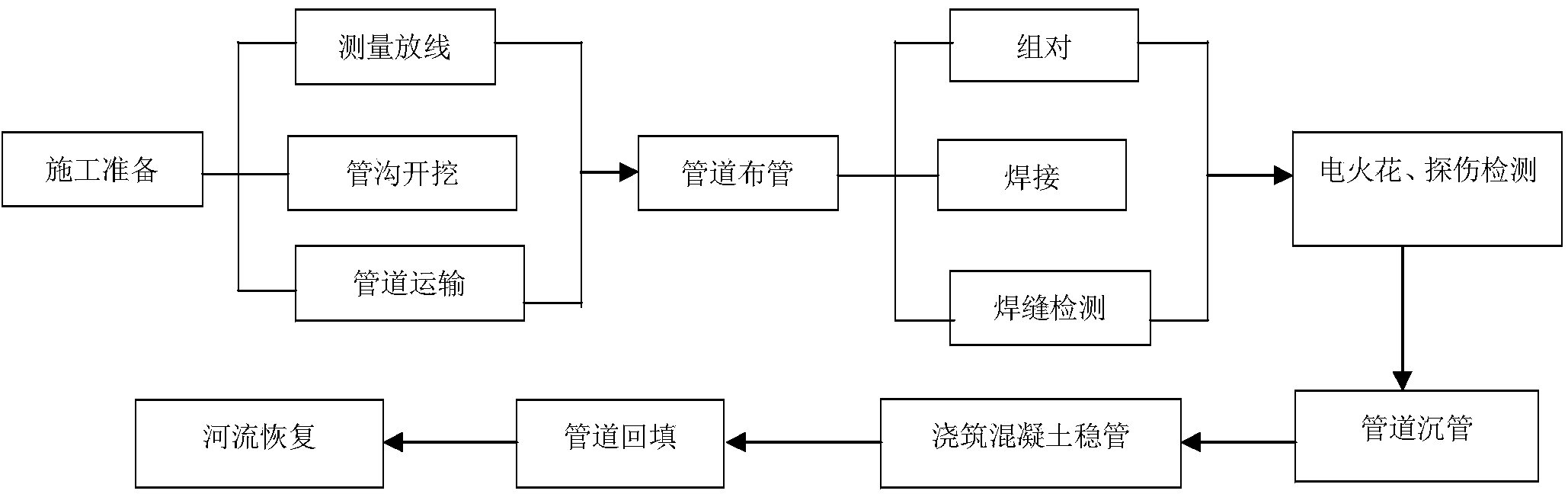

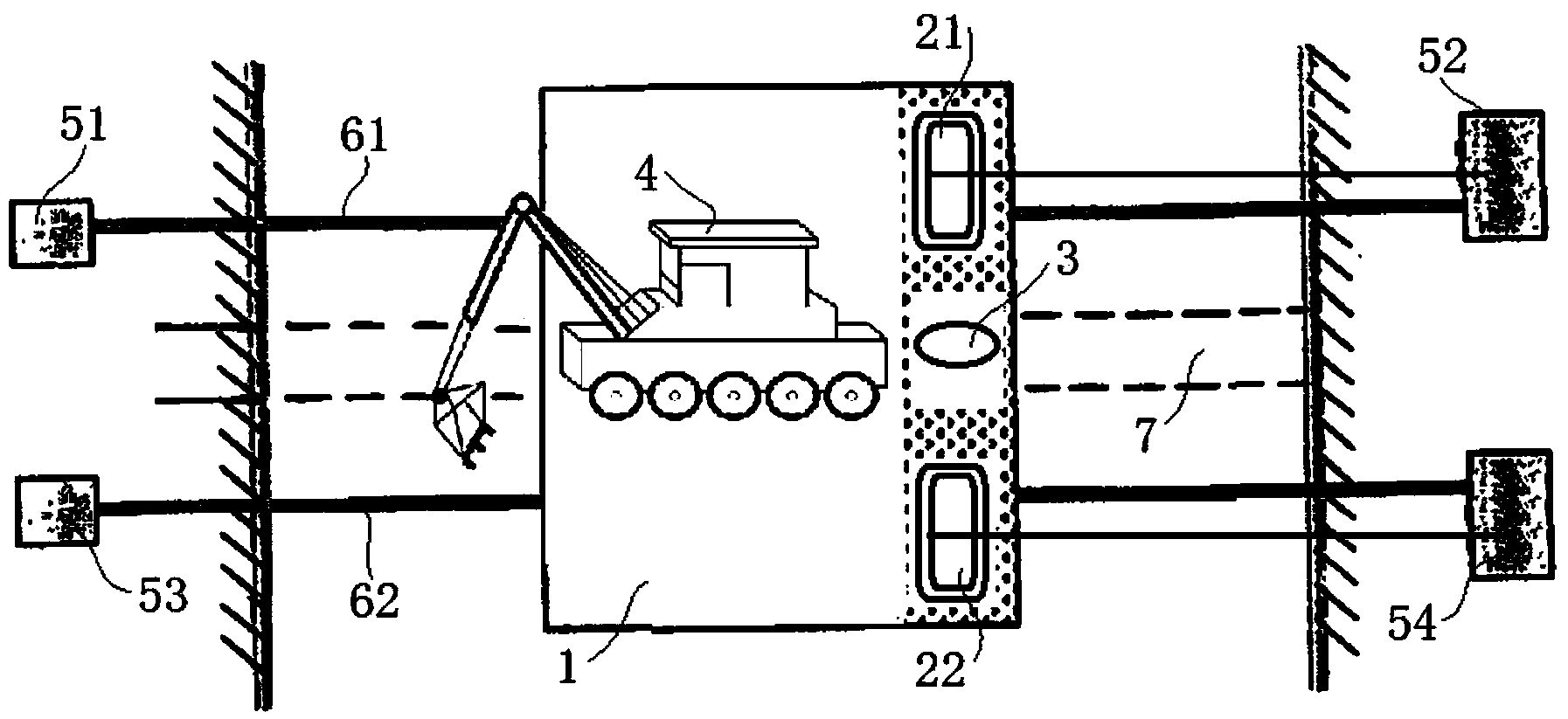

Underwater grooving and pipe sinking river traversing construction method

ActiveCN103912721AImprove pairing accuracyGuarantee smooth constructionWater resource protectionPipe laying and repairEngineeringFluvial

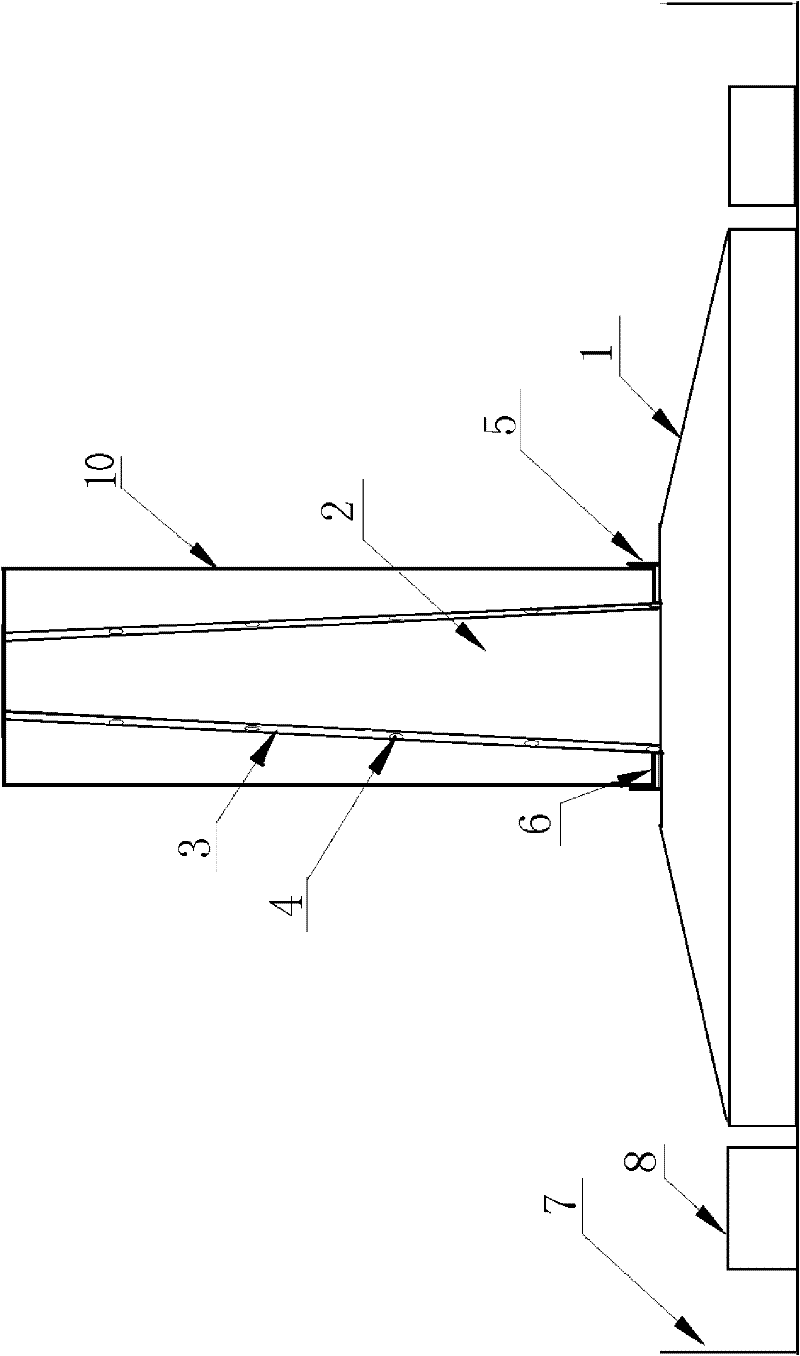

The invention discloses an underwater grooving and pipe sinking river traversing construction method, and belongs to the field of underwater pipeline laying technologies. The underwater grooving and pipe sinking river traversing construction method includes steps of preparing for construction; arranging pipes of pipelines, performing preliminary assembling procedures and photon assembling procedures in assembling procedures for arranging the pipes of the pipelines, particularly, preliminarily assembling the first pipelines to be preliminarily assembled and the second pipelines to be preliminarily assembled on river banks, marking location point information on the end surfaces of the pipelines, and assembling straight pipe sections of first river beds and straight pipe sections of second river beds on platforms of photons; sinking the pipes of the pipelines, implementing an integral pipeline sinking technology in procedures for sinking the pipes of the pipelines, tying first buoys at first elbow sections on the pipelines, tying second buoys on second elbow sections on the pipelines, and controlling first valves, second valves, the first buoys and the second buoys to always keep the first valves, the second valves, the first buoys and the second buoys on the center lines of pipe trenches so as to guarantee that the pipelines are accurately sunken in the pipe trenches; pouring concrete and stabilizing the pipes; refilling the pipelines and restoring rivers. The underwater grooving and pipe sinking river traversing construction method has the advantage that the integral pipelines can be accurately and stably sunken in the specified pipe trenches under the control of the underwater grooving and pipe sinking river traversing construction method.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

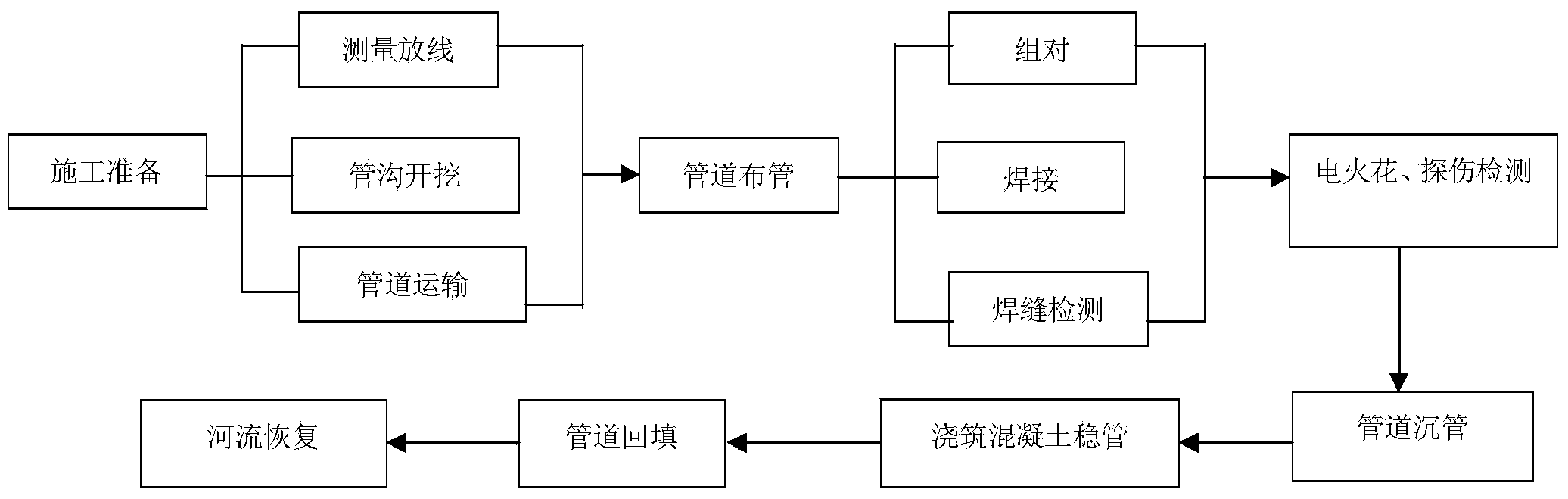

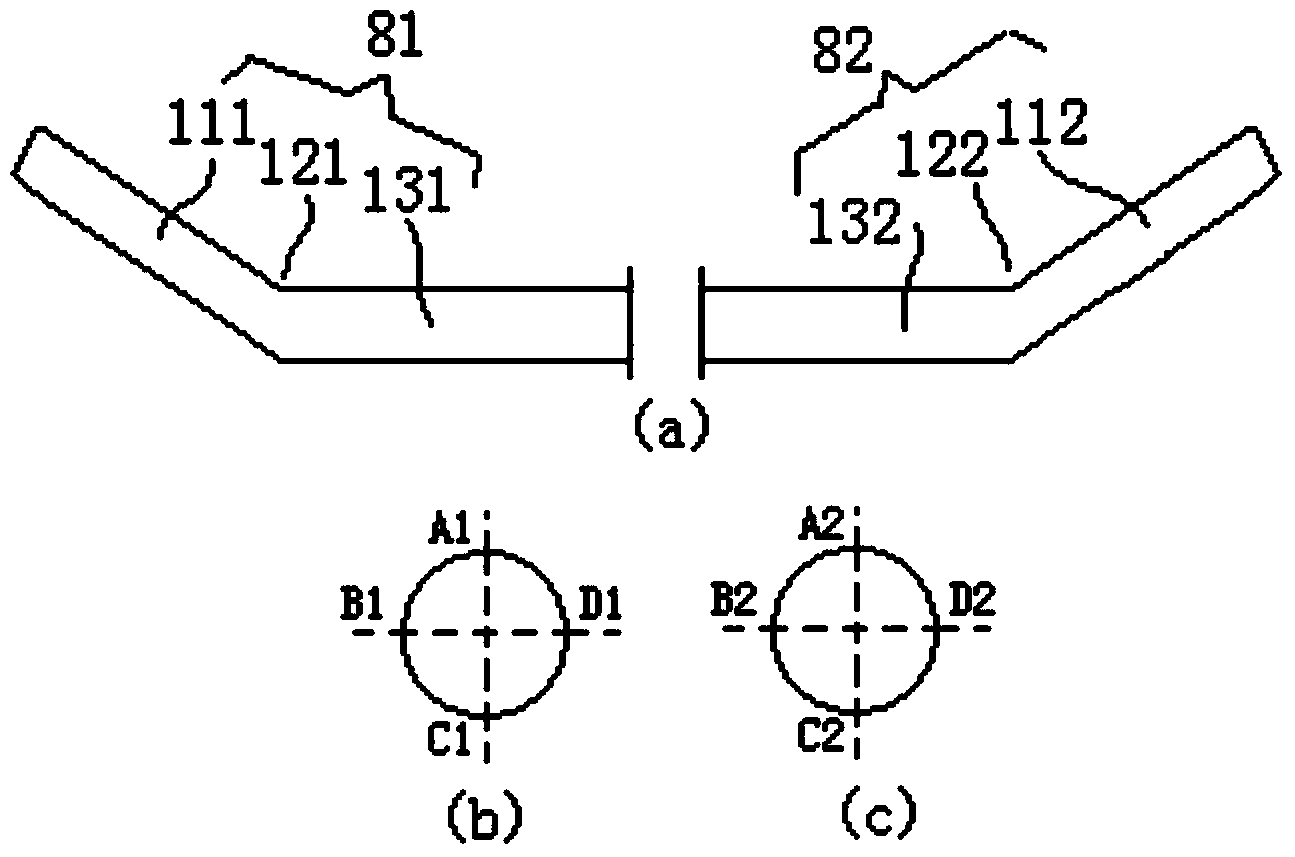

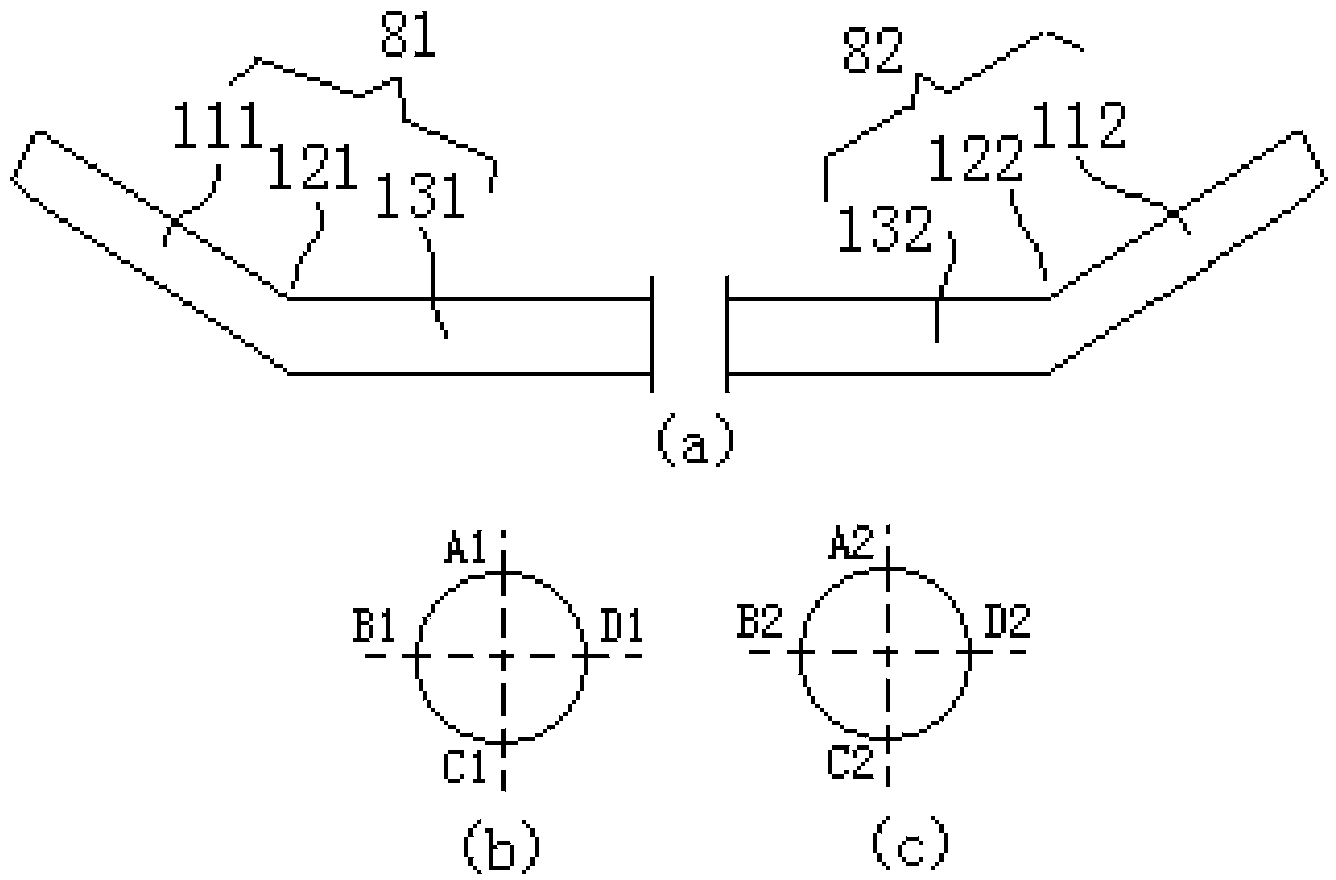

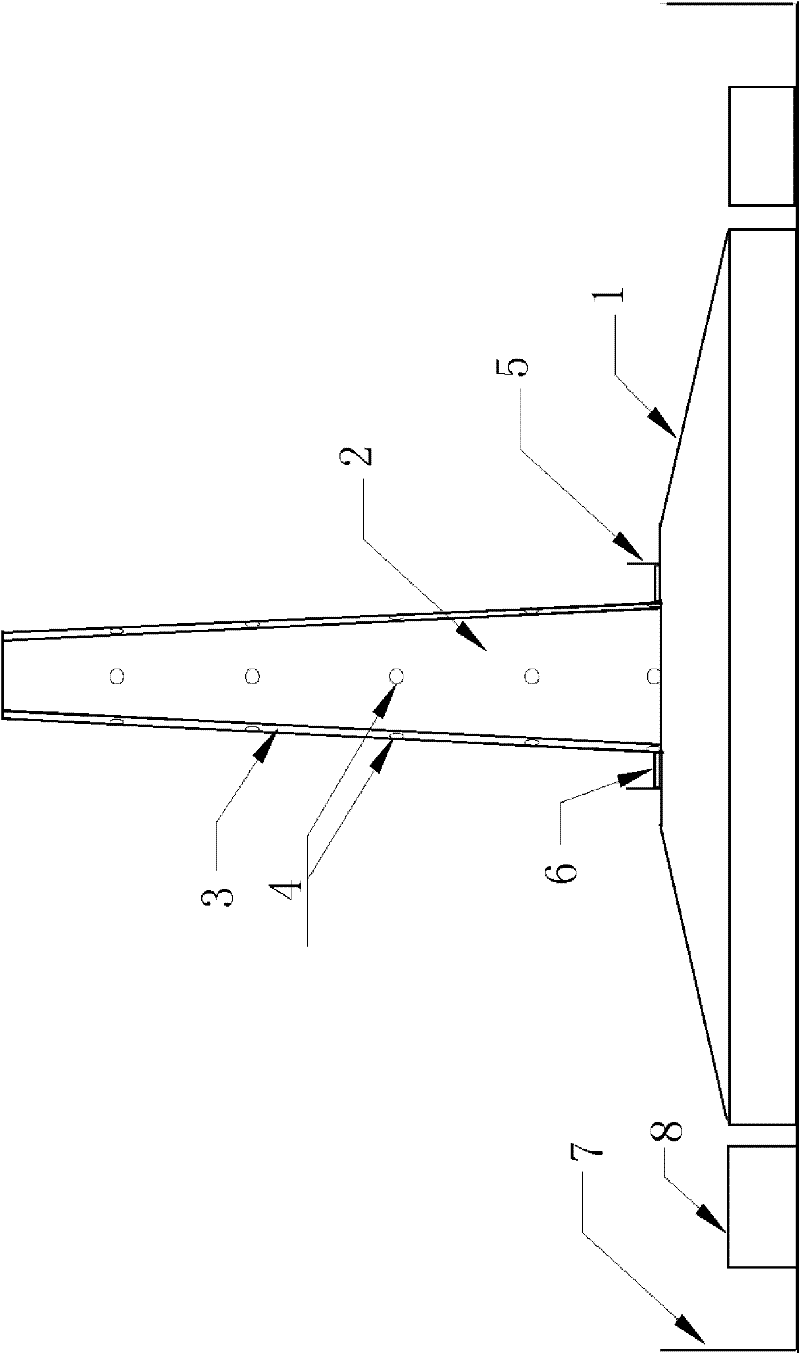

Sunken pipe assembling method for making pipeline pass through river

ActiveCN103912722AImprove pairing accuracySinking smoothlyPipe laying and repairEngineeringAssembly line

The invention discloses a sunken pipe assembling method for making a pipeline pass through a river, and belongs to the technical field of underwater pipeline laying. The method includes the steps that first, pipes are arranged for the pipeline, the assembly procedure includes the pre-assembly process and the pontoon assembly process, the first pre-assembly pipeline and the second pre-assembly pipeline are assembled beside the bank of the river, position point information is marked on the end face of each pre-assembly pipeline, and a first river bed straight pipe segment and a second river bed straight pipe segment are assembled on a platform of a pontoon; second, pipe sinking is performed for the pipeline, the overall pipeline sinking technology is adopted in the pipeline sinking process, a first buoy is tied to a first elbow segment on the pipeline, a second buoy is tied to a second elbow segment, and by controlling a first valve, a second valve, the first buoy and the second buoy always in the center line of a pipe ditch, it is guaranteed that the pipeline accurately sinks into the pipe ditch. With the method, the whole pipeline can be accurately controlled to sink into the assigned pipe ditch, and the control accuracy is high.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

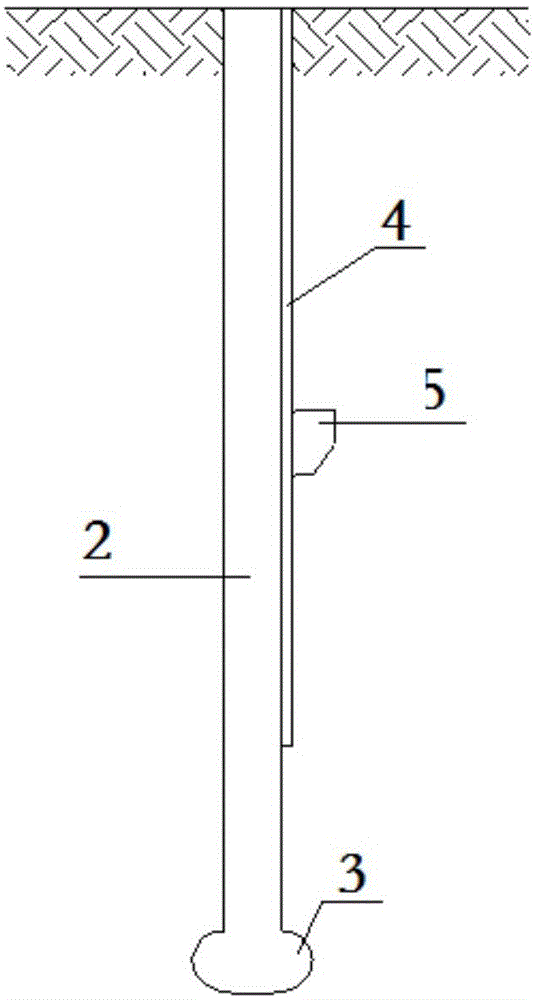

Rock breaking chambering drilling head used for pile sinking and construction method of pile sinking

The invention discloses a rock breaking chambering drilling head used for pile sinking. The rock breaking chambering drilling head includes a drilling body, multiple cutting blades and an articulatedmechanism. The drilling body is of a hollow structure, and the bottom of the drilling body is provided with cutting teeth. The multiple cutting blades are arranged on the drilling body in a surrounding mode, and each cutting blade can do reciprocating motion horizontally. The articulated mechanism includes a main supporting rod and multiple branch rods. The multiple branch rods are arranged corresponding to the multiple cutting blades one by one. One end of each branch rod is connected with the corresponding cutting blade, and the other end of each branch rod is connected with an articulated joint. The articulated joint is connected with the main supporting rod. The main supporting rod extends towards the exterior of the drilling body. The drilling body can slide up and down along the mainsupporting rod. The main supporting rod is provided with a positioning piece, and the positioning piece is located outside the drilling body. By controlling the up-and-down motion of the main supporting rod, the cutting blades are driven to move horizontally. According to the rock breaking chambering drilling head, the diameter of the drilling head can extend and retract automatically; drilling head chambering and recycling can be achieved conveniently; and rock breaking forming hole diameter is expanded, a tubular pile is made to be capable of sinking or entering-rock smoothly.

Owner:GUANGXI UNIV

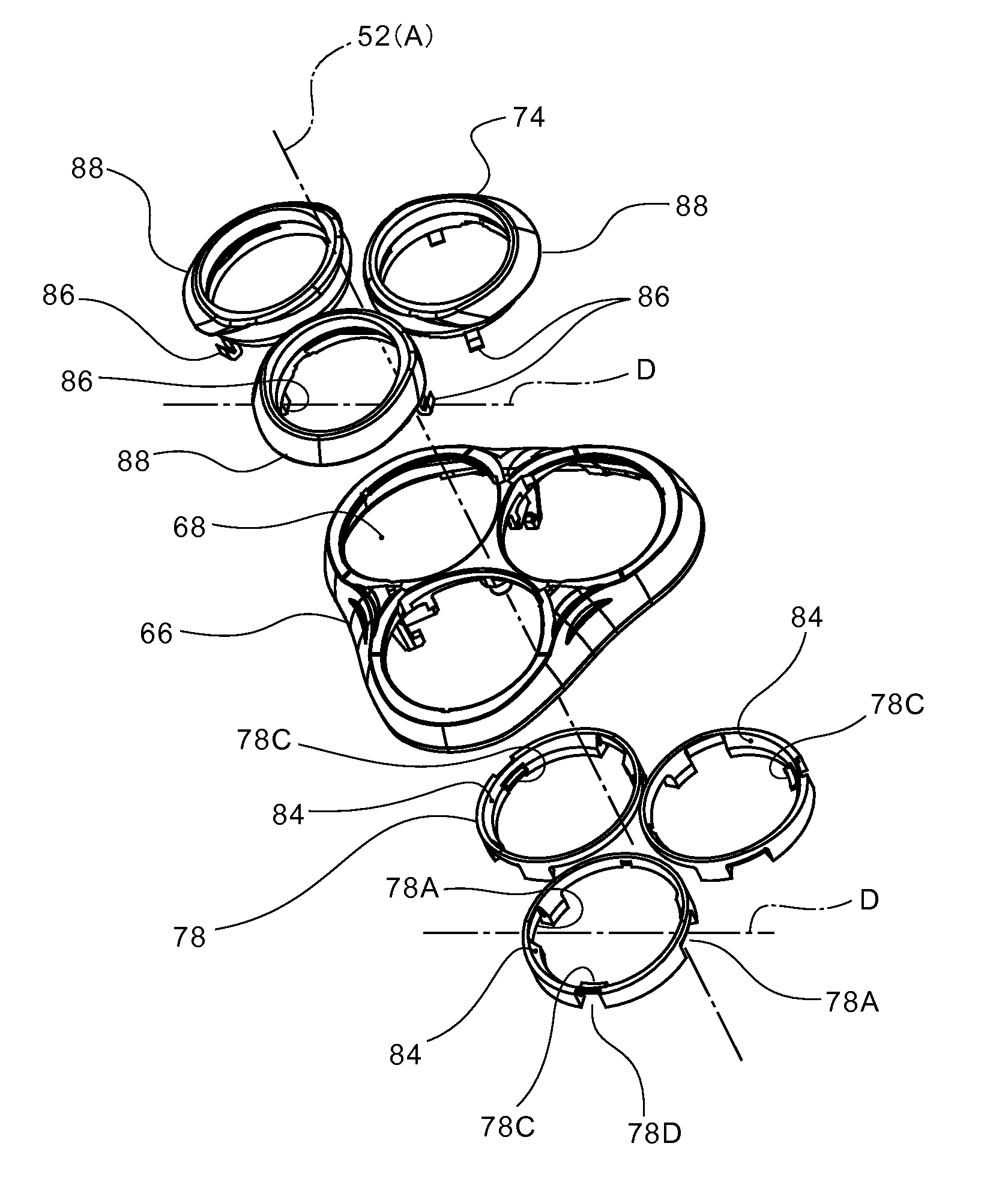

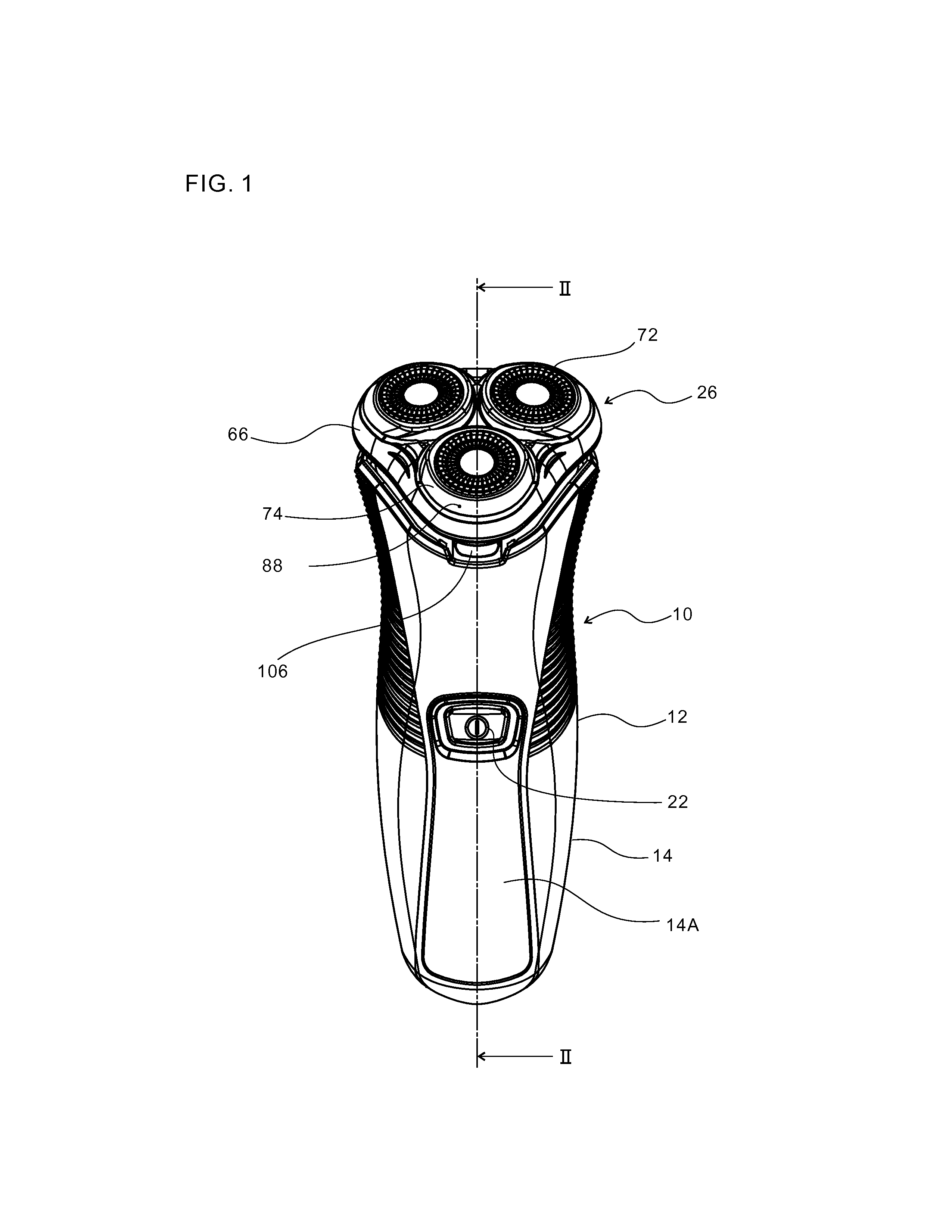

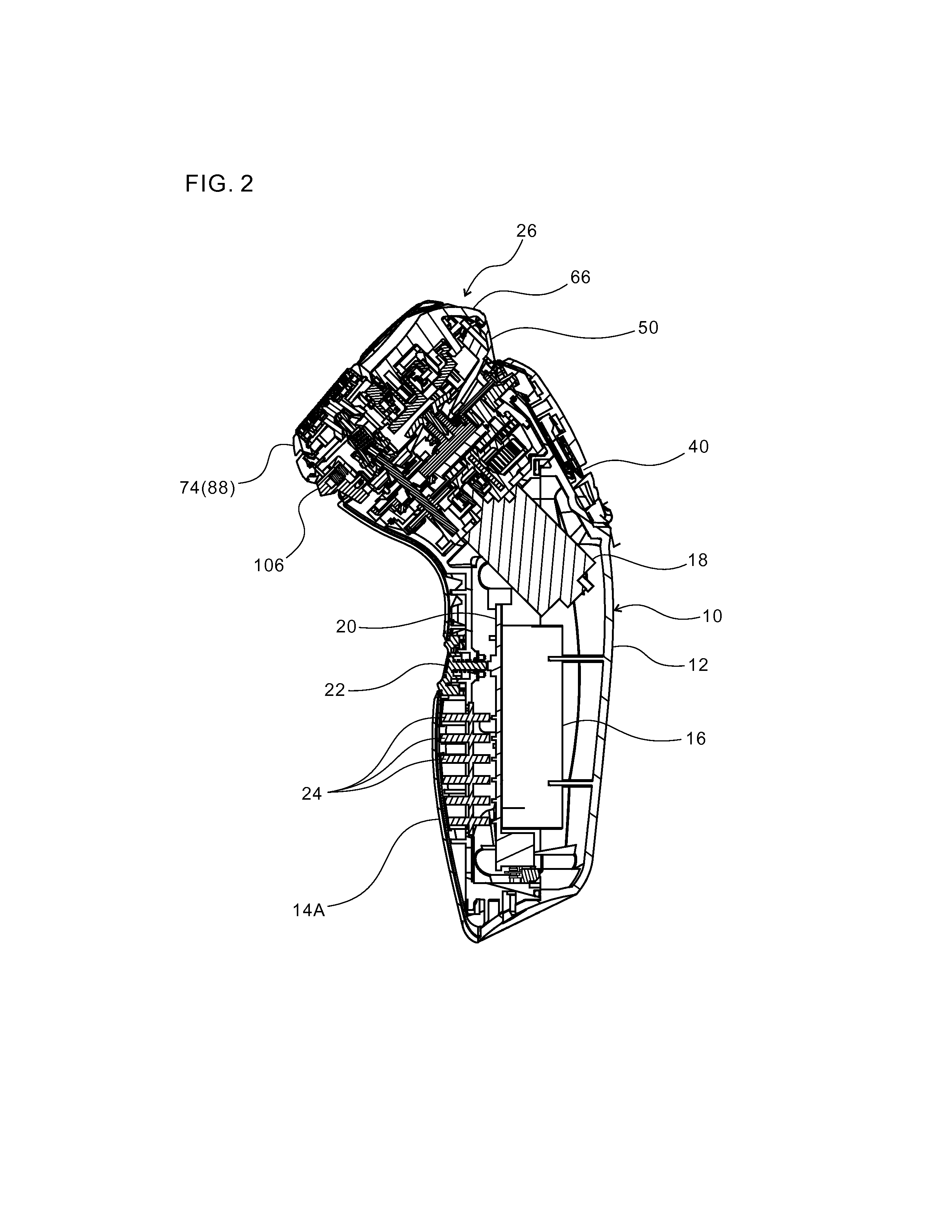

Rotary electric shaver

InactiveUS20130180112A1Improve performanceImproved closeness of outer cuttersMetal working apparatusElectric razorsKnife holder

A rotary electric shaver includes an outer cutter case secured to the outer periphery of an outer cutter and having a sliding surface formed on the outer periphery. An outer cutter case holder is fitted in a mounting port to vertically move with an upper limit position restrained and pivotably holds the outer cutter case to guide the sliding surface. A pushup plate imparts an upward return tendency to an outer cutter case assembly including the outer cutter, the outer cutter case and the outer cutter case holder. The outer periphery of the outer cutter case is provided with a projection extending to the upper surface of the outer cutter frame, serving as a stopper which prevents the outer cutter case from sinking into the mounting port. This arrangement prevents the outer cutter from being caught by the inner edge of the mounting port and improves shaving performance.

Owner:IZUMI PROD CO

Air curtain sunk shaft foundation and construction method thereof

The invention relates to a foundation for air curtain caisson and the construction method, belonging to the bridge foundation construction technology field. Air curtain caisson makes use of pipes pre-buried in caisson wall and air shrine on external wall to apply high-pressure air to peripheral circumstance so that frictional resistance between caisson wall and soil is decreased and the caisson sinks smoothly. The construction method for foundation of air curtain caisson comprises casting caisson in segment and in place, sucking mud and sinking, height addition, air curtain sinking, caisson absorbing mud and sinking, caisson rectification technology, clearing foundation, and closing bottom so on. The invention is suitable for construction of caisson foundation with all kinds of usage, especially sand formation and clayey stratum with certain water content. The construction method for foundation of air curtain caisson can be used on bank and on water. It can not be constrained by water depth.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

A tower structure suitable for ocean engineering and its installation method

ActiveCN102296629AReduce transportation and installation costsRelief swingFoundation engineeringTowersEngineeringWind power generator

The invention discloses a tower-drum structure suitable for ocean engineering and an installation method thereof, which are used for solving the problems of high installation and construction operation difficulty and high transportation and installation costs existing in the conventional tower-drum structure. The tower-drum structure comprises a concrete gravity foundation pedestal, a foundation tray, a guide pipe and a tower drum, wherein an injection pipe is arranged inside the guide pipe; the tower drum is sleeved on the outer side of the guide pipe; and the bottom edge of the tower drum is arranged in a tower drum collar of the concrete gravity foundation pedestal. The tower-drum structure has a simple structure, and is convenient to install; the requirement on the bearing force of a natural soft soil foundation can be met by adjusting the size of the foundation tray; and overall water haulage is adopted, so that the installation cost can be reduced effectively. The invention is particularly suitable for tower-drum structures such as sea areas with large water depths, wind generator sets and tide generator sets on soft soil foundations, and the like.

Owner:POWERCHINA ZHONGNAN ENG

Marine detection device convenient for sampling

InactiveCN113008626AScientific and reasonable structureEasy to useWithdrawing sample devicesTesting waterWater storageBuoy

The invention discloses a marine detection device convenient for sampling. A fixed collecting plate is welded to the inner side of a mounting pipe, an ascending pipe penetrates through the top end of the fixed collecting plate, an extraction block is placed on the inner side of the ascending pipe, an extraction electric push rod is connected to the top end of the extraction block, a connecting rope is slidably clamped to one end of the inner side of a storage cylinder, and a buoy is connected to one end of the connecting rope. The other end of the connecting rope is connected with a U-shaped clamping plate, and a sealing limiting block is clamped to the inner side of the sliding opening. Sea water is discharged into the storage cylinder through the water outlet pipe, the needle cylinder principle is utilized, the sea water stably enters the storage cylinder, meanwhile, the injection height of the sea water is limited, the situation that the sea water overflows due to the fact that the sea water is injected from the top end is avoided, the service life of the sea water storage device is prolonged, and the service life of the sea water storage device is prolonged. The water inlet is limited through the limiting spring and the sealing limiting block, seawater is prevented from spilling out when the storage barrel moves, and therefore the sealing effect of the storage barrel is guaranteed, internal parts are protected, and the parts are prevented from being soaked in the seawater.

Owner:杨高盛

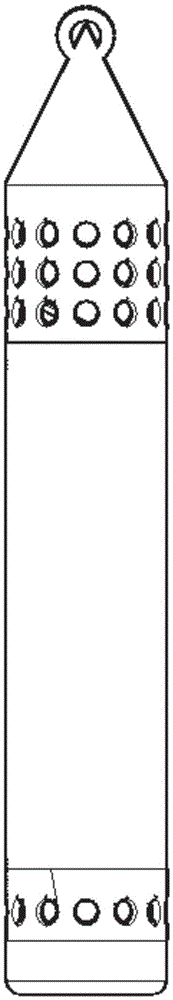

Moxa-moxibustion tool and preparation process thereof

ActiveCN107280965AAdvantages of preparation processWon't fallDevices for heating/cooling reflex pointsPharmaceutical product form changeEngineeringMaximum size

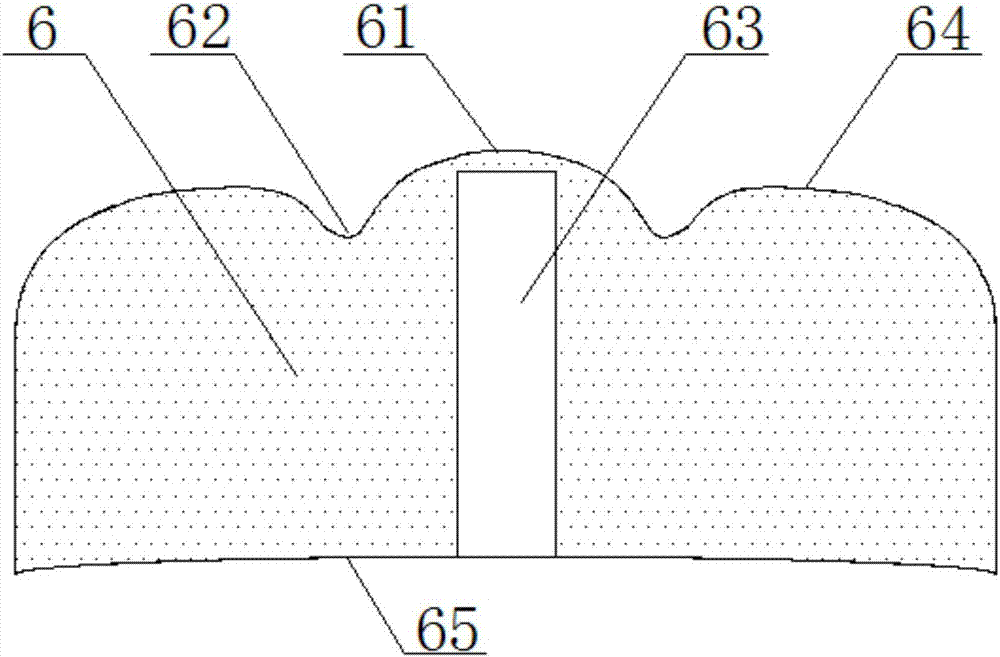

The invention relates to a moxa-moxibustion tool and a preparation process thereof. The moxa-moxibustion tool comprises a moxibustion tool and a moxibustion core, wherein an air hole is formed in the bottom end of the moxibustion tool, the moxibustion tool is of a cylindrical structure, the moxibustion core is fixed to the upper portion of the inner cavity of the moxibustion tool, the upper surface of the moxibustion core protrudes out of the moxibustion tool, and the portion, in contact with a moxa cake, of the inner surface of the moxibustion tool is a flame-retardant face and is of a wedge surface structure. The moxibustion core is the moxa cake, the maximum size of the bottom surface of the moxa cake is 1-5 times of the height of the moxa cake, the bottom surface of the moxa cake is a cambered surface protruding upwards, the center of the upper surface of the cambered surface protrudes and is higher than the upper surface of the cambered surface, the bottom surrounding of the protrusion is downwards sunken and is lower than the upper surface of the moxa cake, a blind hole with a downward opening is formed in the moxa cake, and the hole bottom of the blind hole is located in the protrusion. The invention also correspondingly provides the preparation process of the moxa-moxibustion tool. The moxa-moxibustion tool is aligned during the moxa cake releasing, releasing and installation of the moxa cake can be simultaneously achieved, and working processes are saved. A central hole of the moxa cake is the blind hole, and the blind hole blocks an upper-end outlet of a flue, so that moxibustion smoke only flows downward, and the moxibustion utilization rate is improved.

Owner:湖北蕲艾堂科技有限公司

Bottom-connected reinforced concrete open caisson water-washed sinking construction method

The invention discloses a bottom-connected reinforced concrete open caisson water-washed sinking construction method which comprises the steps of open caisson construction, open caisson sinking and the like. The construction method has the advantages of simple process, stable sinking rate and safe operation.

Owner:南通宏华建筑安装有限公司

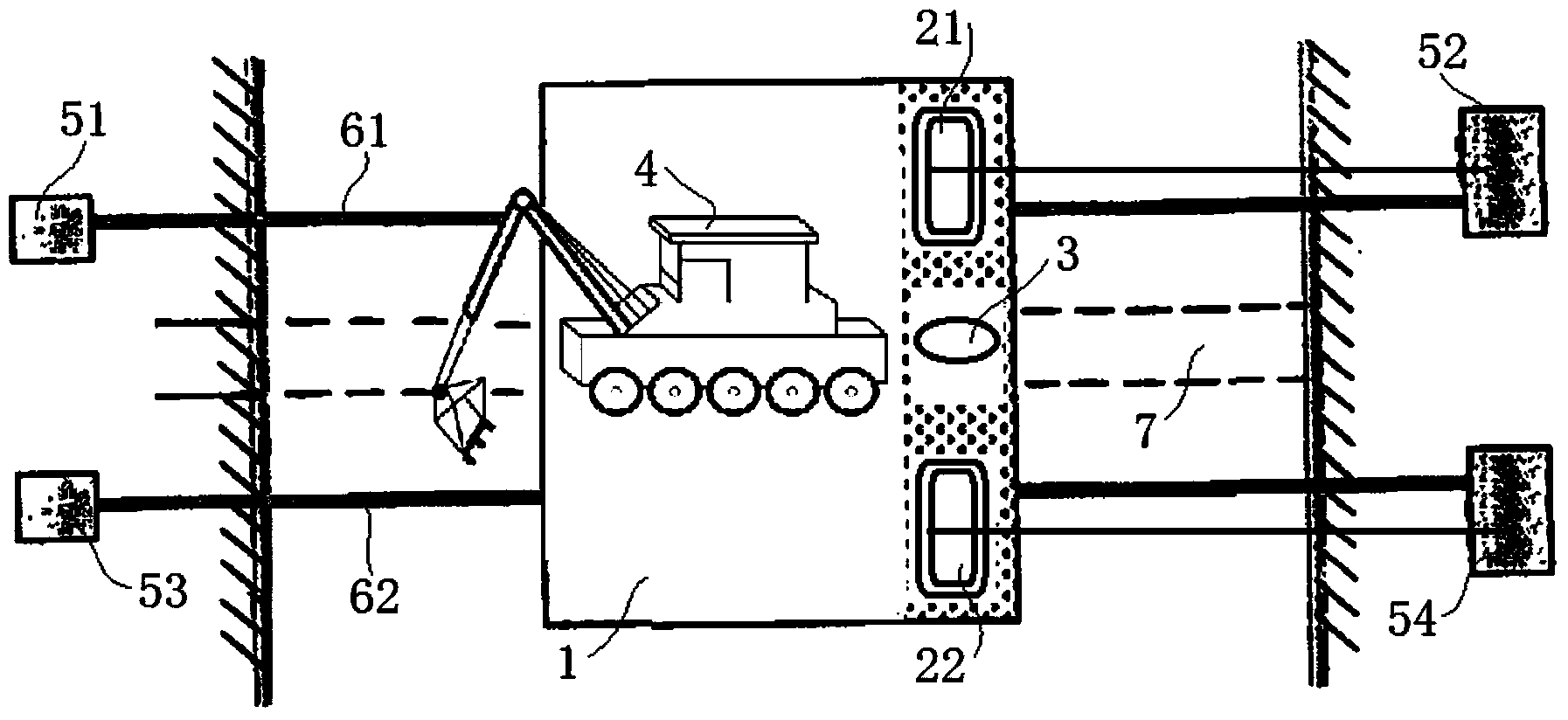

Steel sheet pile support construction method for building underground garage open caisson

ActiveCN106013053AReduce the risk factorAvoid cumbersomeArtificial islandsExcavationsPurlinArchitectural engineering

The invention discloses a steel sheet pile support construction method for building an underground garage open caisson to reduce the construction complexity and improve the construction efficiency during open caisson building and reduce the building expenditure for the open caisson. According to the construction method, open caisson construction is carried out in an area defined by a steel sheet wall, wherein building of a wall of the open caisson is carried out in a manner of segment-by-segment construction from bottom to top. The building method comprises the steps that steel sheet piles are sunk, and the continuous steel sheet pile wall is formed; a certain of earthwork is excavated in the area defined by the steel sheet pile wall, then, a pile block enclosure purlin is erected on the top of the steel sheet pile wall, and horizontal braces are built on the inner side of the pile block enclosure purlin; and then, open caisson building is finished through a method that earthwork is excavated segment by segment, the wall is poured segment by segment and sinking is carried out.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

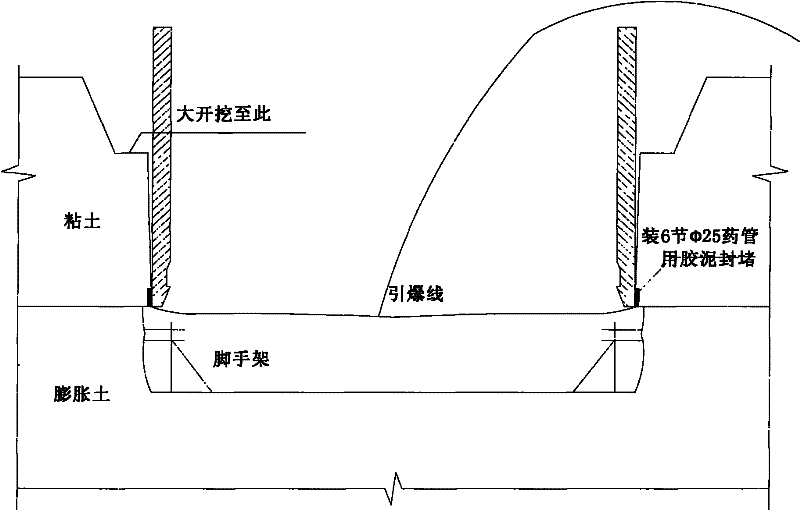

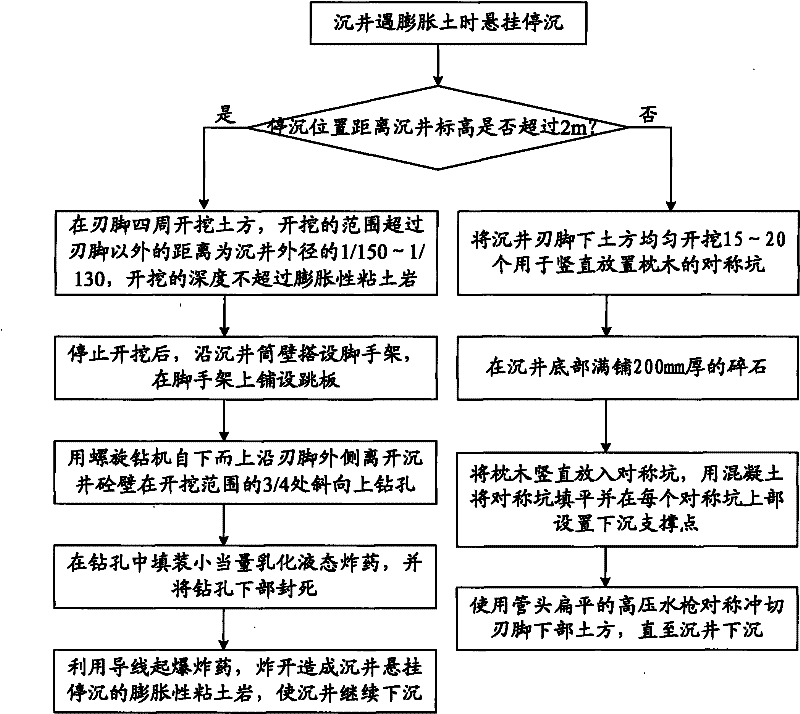

Treatment method for hanging sinking stop due to expansive soil in well sinking

ActiveCN102235010ASinking smoothlyRelax and sink smoothlyBlastingCaissonsHydrologyHigh pressure water

The invention provides a treatment method for hanging sinking stop due to expansive soil in well sinking. When the hanging sinking stop is caused by the expansive soil in the well sinking construction process, if the distance between the sinking stop position and the well sinking elevation exceeds 2 meters, blast holes are uniformly distributed in the surrounding earthwork of the lower part of a blade foot, the expansive soil which causes hanging stop is subjected to small equivalent blast, and the expansive soil is blasted; and if the distance between the sinking stop position and the well sinking elevation is less than 2 meters, a blast working face cannot be established, sinking support points are uniformly arranged at the well sinking blade foot, and then the earthwork at the lower part of the blade foot is symmetrically punched by using a high-pressure water gun with flat tube head till the sunken well is sunken. By the method, the contact area of the earthwork and the tube wall is effectively reduced on the premise that the outer wall structure of the sunken wall is not affected, and the super-normal lateral frictional resistance is eliminated, so that the sunken well is uniformly loosened and sunken, the sunken well is prevented from deviating, the construction period is not delayed, and the engineering quality and the construction efficiency of well sinking construction are effectively improved.

Owner:CHINA HUAYE GROUP

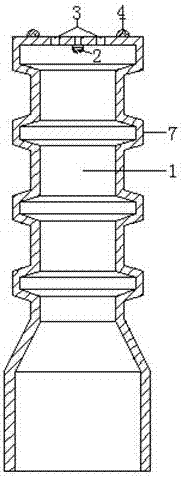

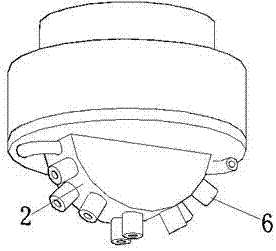

Deep-sea bamboo joint type suction anchor

ActiveCN107299645ALarge amount of waterBig impactArtificial islandsBulkheads/pilesJoints typesResistance force

The invention discloses a deep-sea bamboo joint type suction anchor. The deep-sea bamboo joint type suction anchor comprises a bamboo joint type anchor cylinder, a bearing and a rotatable nozzle. The bamboo joint type anchor cylinder is a cylinder body with an open bottom and a closed top. A plurality of convex bamboo-joint-shaped structures around the cylinder body are arranged at the middle upper portion of the cylinder body of the anchor cylinder at fixed intervals. The middle lower portion of the cylinder body of the anchor cylinder is in an expanded cylinder shape, and the external diameter of the expanded portion of the cylinder is larger than that of each bamboo-joint-shaped structure. A drainage hole communicated with the internal portion of the cylinder body is formed in a top cover of the anchor cylinder. The rotatable nozzle is located in the cylinder body, is connected with the inner wall of the top cover of the anchor cylinder through the bearing and is fixed to the circle center of the top cover of the bamboo joint type anchor cylinder, and therefore the needed suction anchor is formed. According to the suction anchor, side friction resistance force can be increased, it is ensured that the suction anchor can sink to a preset designed depth, and the vertical bearing capacity and ultimate anti-uplifting bearing capacity of the suction anchor are significantly improved.

Owner:OCEAN UNIV OF CHINA

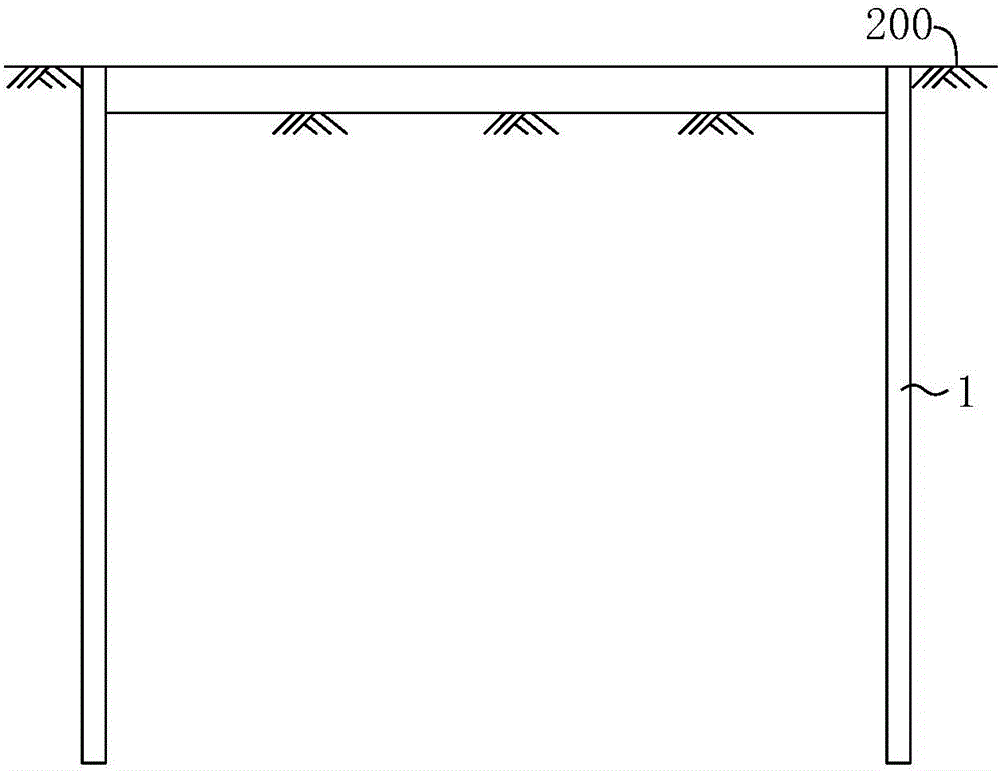

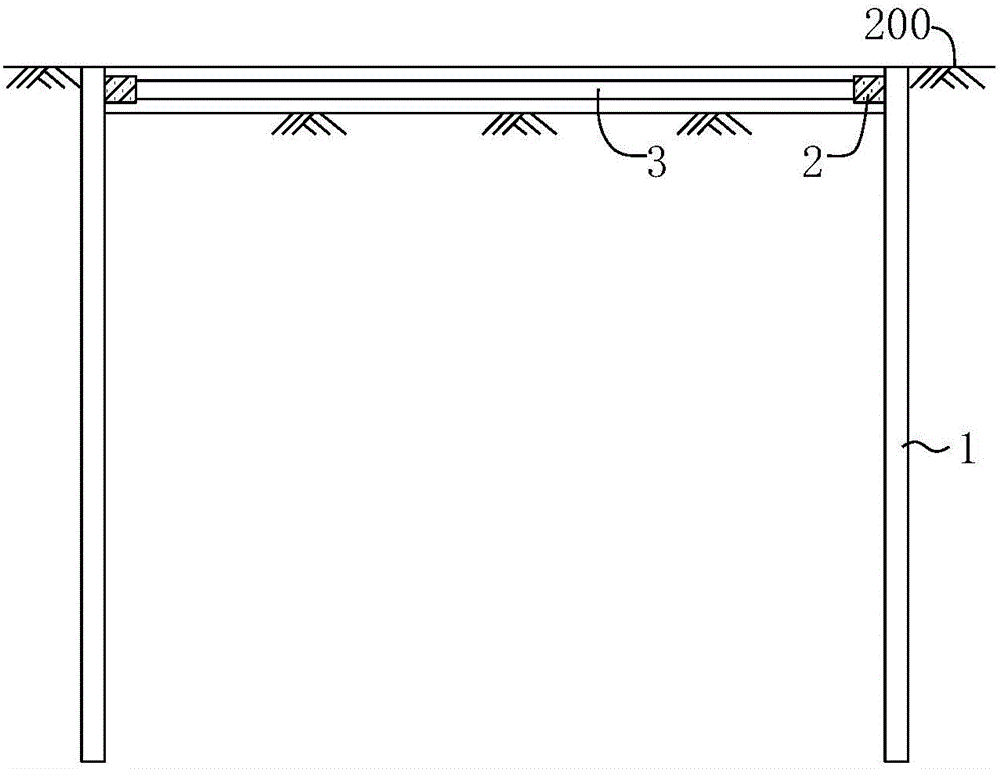

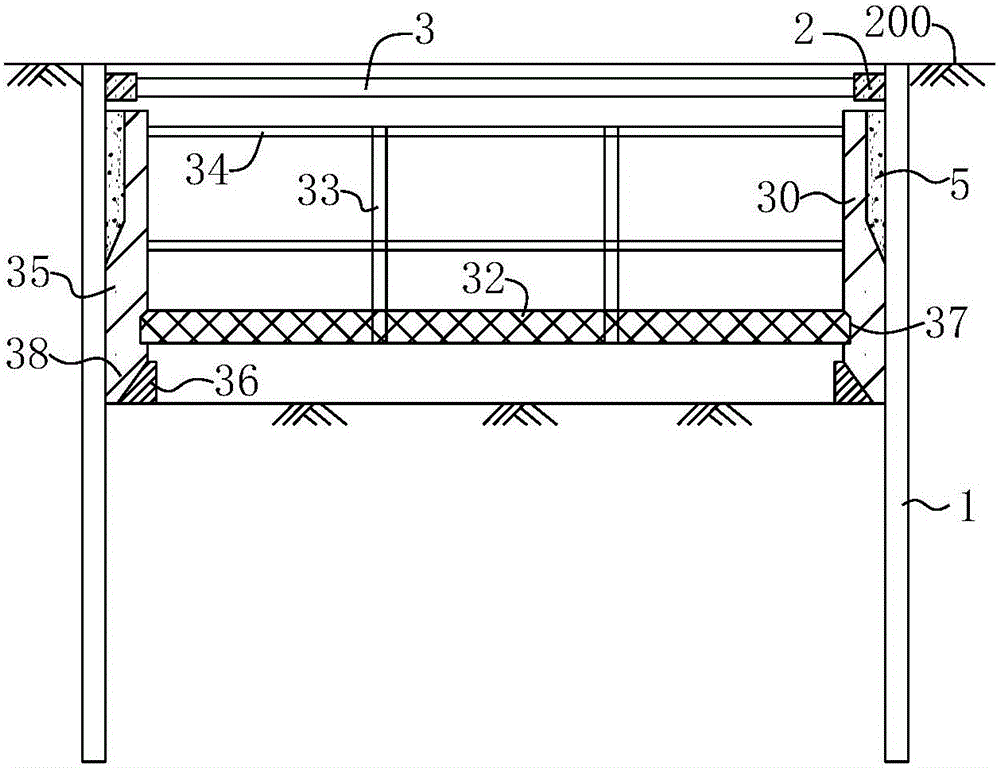

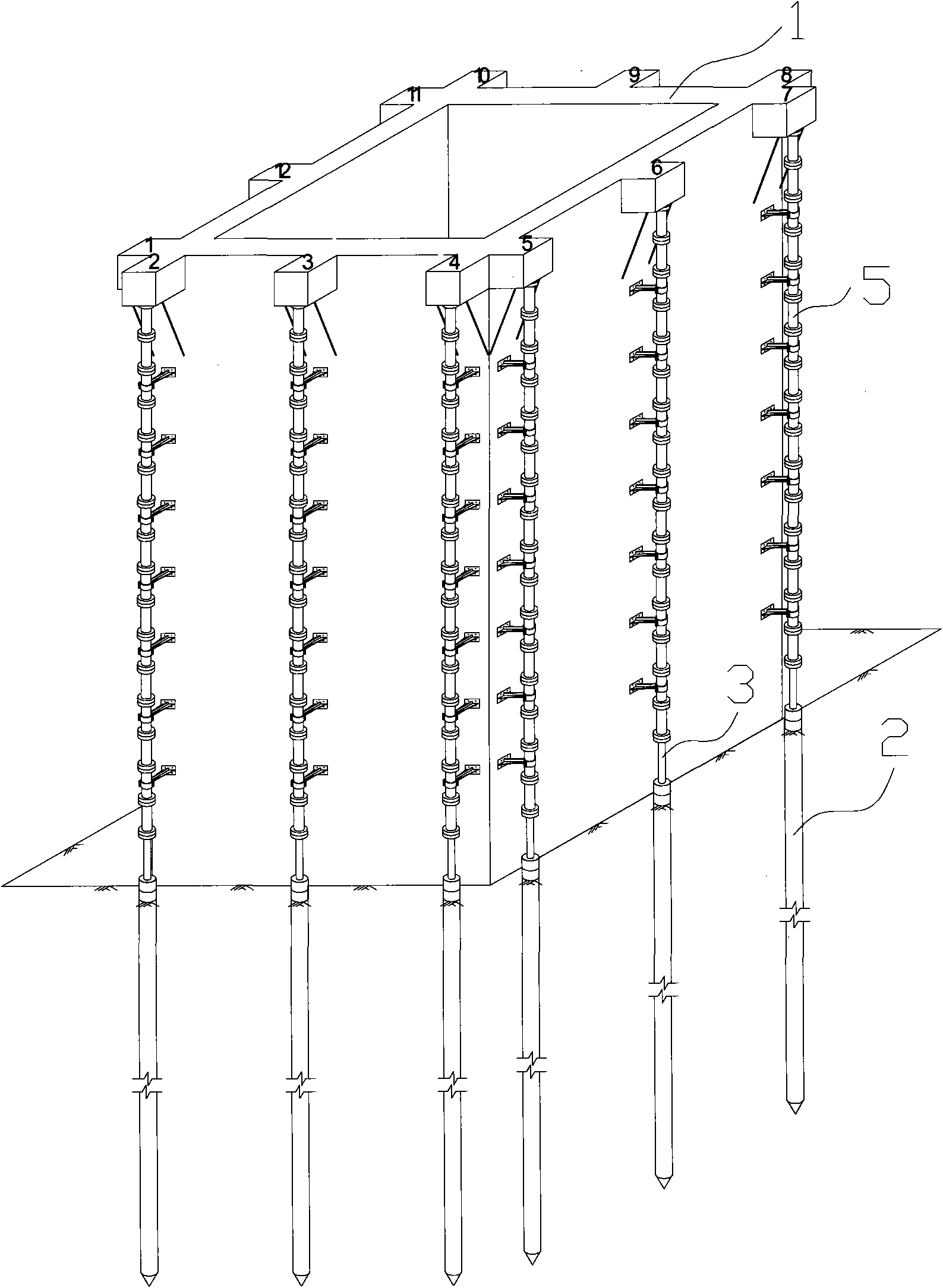

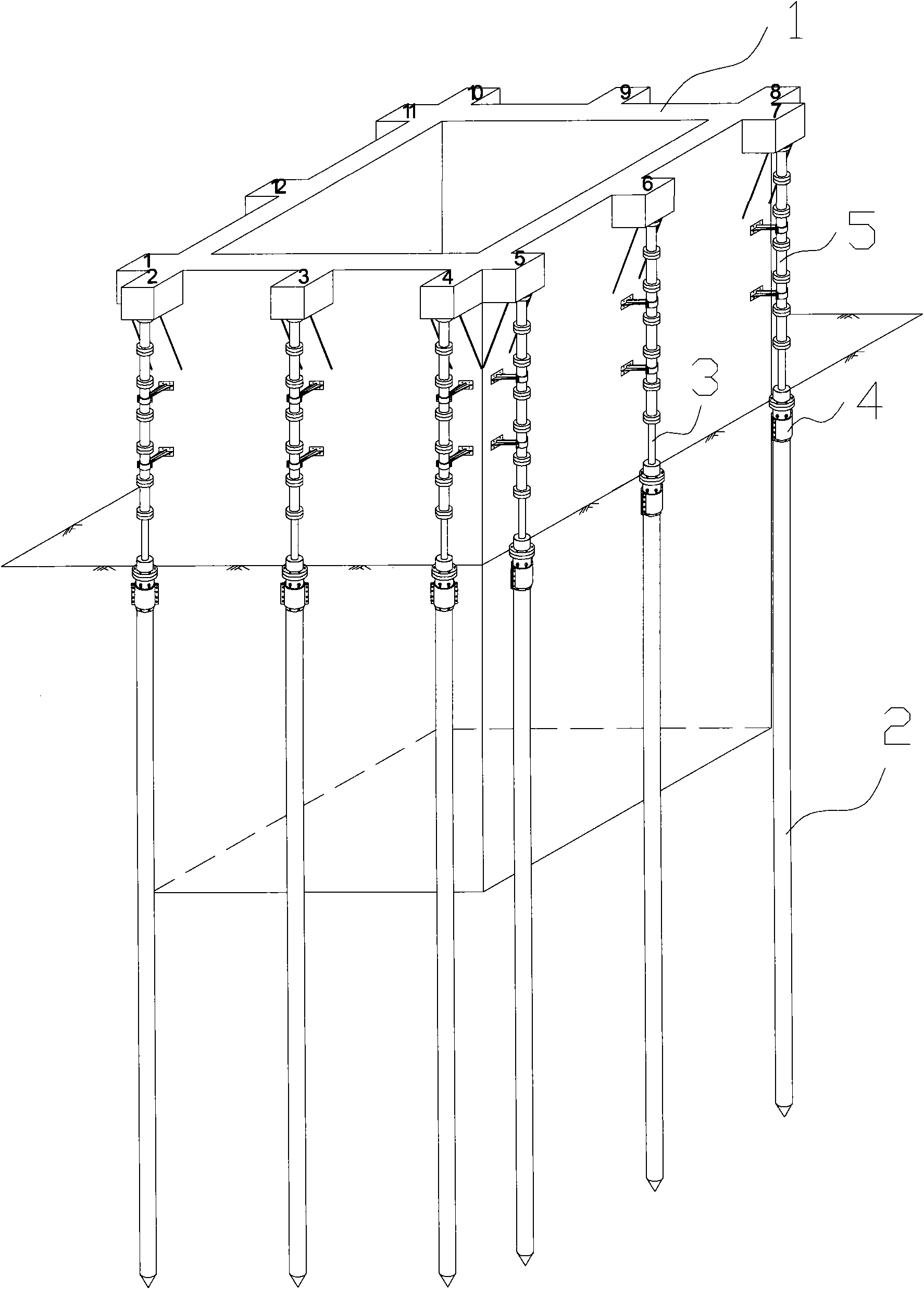

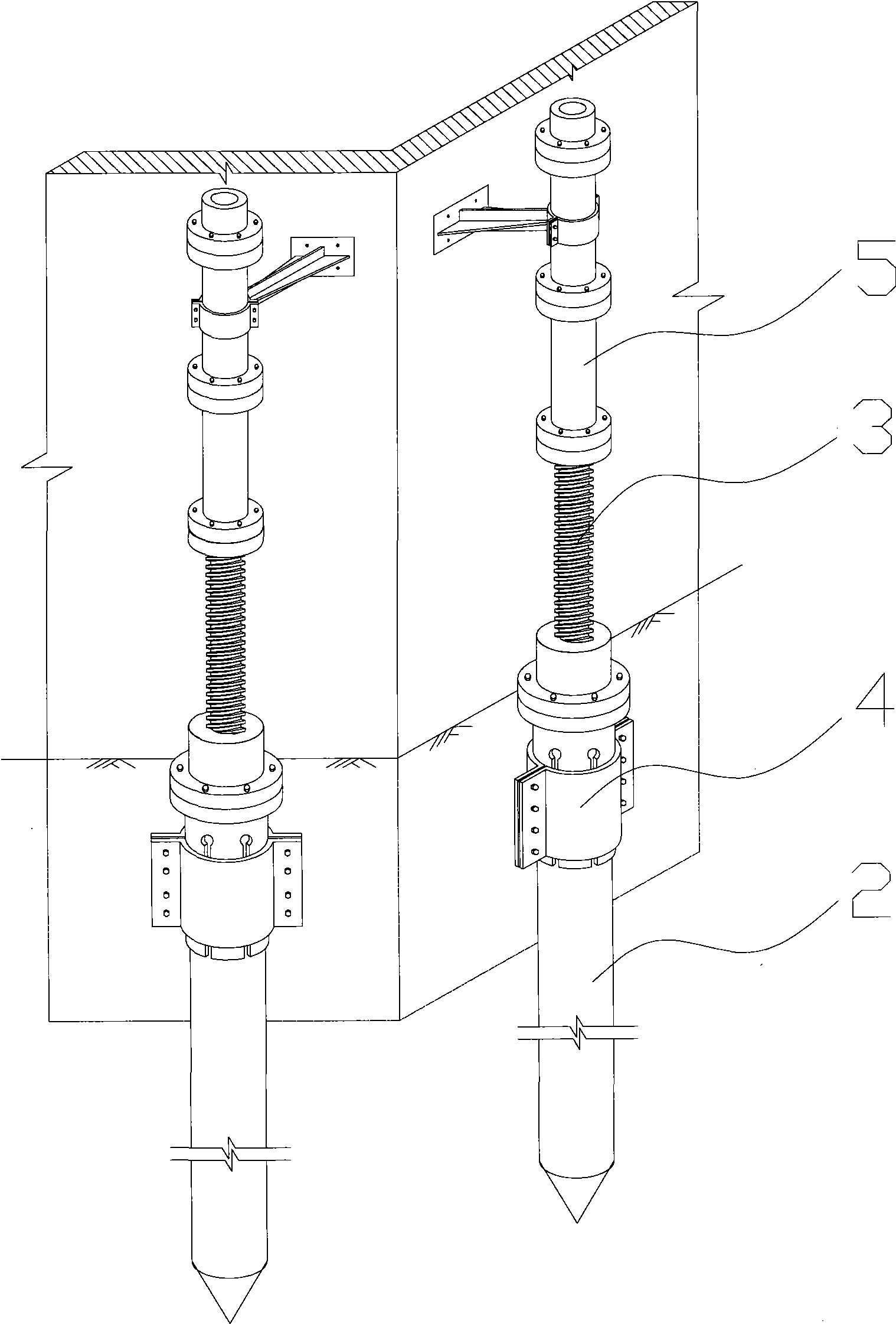

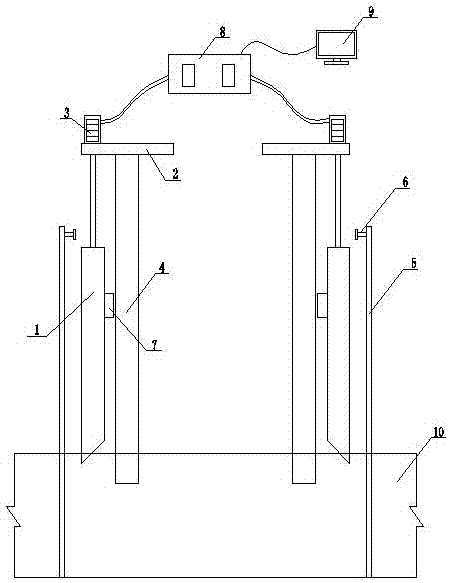

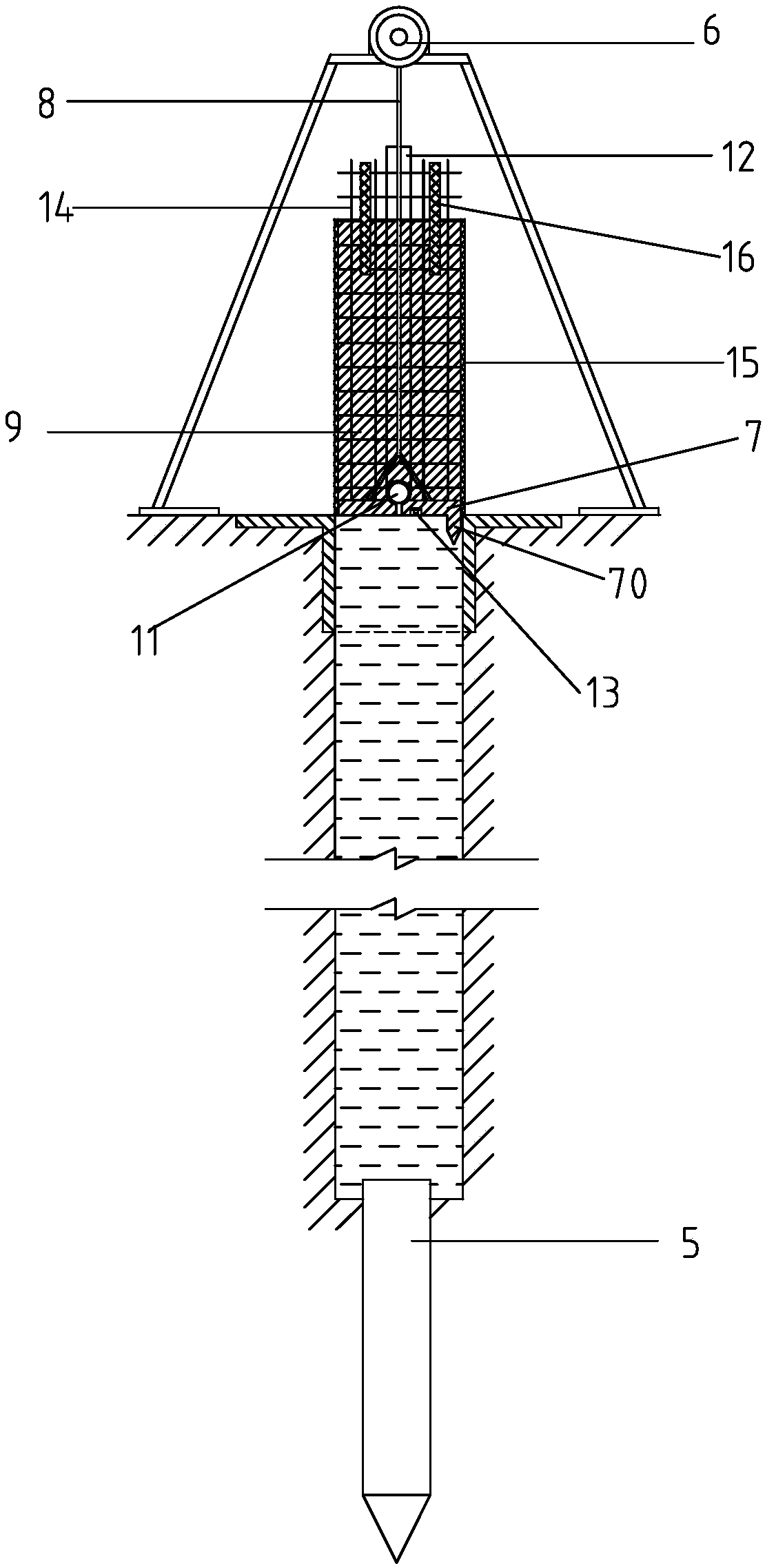

Sinking device of open caisson and sinking method of open caisson with same

The invention discloses a sinking device of an open caisson, comprising a precast pile used for supporting an open caisson structure main body. The sinking device of the open caisson is characterized by comprising a bidirectional stress jack and an axial connector, wherein the bidirectional stress jack is tightly and fixedly connected with the open caisson structure main body and positioned between the open caisson structure main body and the precast pile, and the bidirectional stress jack is used for upwards supporting and downwards drawing the open caisson structure main body; and the axial connector is used for tightly and fixedly connecting the bidirectional stress jack with the precast pile. Because the invention utilizes the bidirectional stress jack tightly and fixedly connected with the open caisson structure main body and the precast pile, the sinking device of the open caisson can be used for supporting the open caisson structure main body in the sinking process of the open caisson and also can be used for drawing the open caisson structure main body. Therefore, the dead weight of the open caisson is reduced, and the controllable, precise and stable sinking of the open caisson is realized; in addition, the invention further discloses a sinking method of the open caisson with the sinking device.

Owner:丁慈鑫 +1

Underwater sample collection device and sampling method thereof

ActiveCN109916669AAccurate collectionEfficient analysisWithdrawing sample devicesUnderwaterEngineering

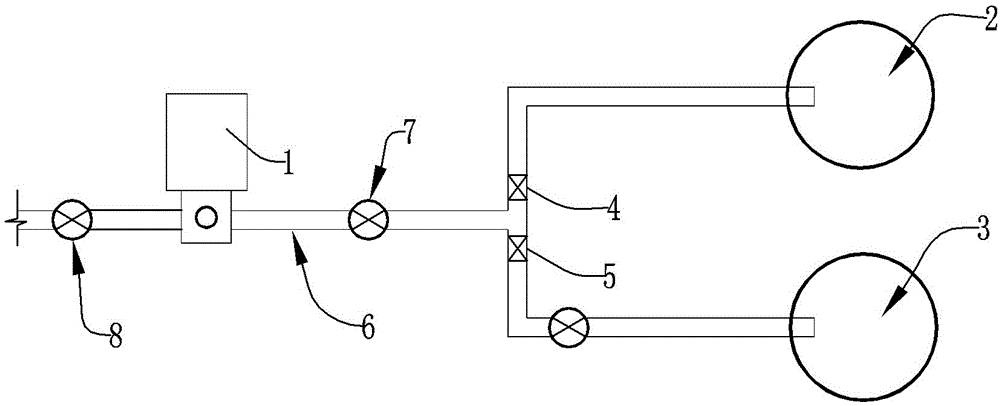

The present invention belongs to the technical field of sample analysis, and relates to an underwater sample collection device and a sampling method thereof. The device comprises a t-branch pipe consisting of a first straight pipe, a second straight pipe and a third straight pipe, a holding cavity for mutual communication is formed among the first straight pipe, the second straight pipe and the third straight pipe, the holding cavity is internally provided with a moving ball capable of blocking the first straight pipe or the second straight pipe or the third straight pipe, the first, second and third straight pipes are all provided with electromagnet modules capable of driving movement of the moving ball, the third straight pipe is connected with a drainage pipe, the drainage pipe is provided with an air inflation mechanism capable of air inflation for the drainage pipe, and the first straight pipe and the second straight pipe are respectively connected with a first sampling barrel anda second sampling barrel. The underwater sample collection device and the sampling method thereof can collect water in special depth to improve the collection efficiency of soil ore sands at the bottom of the underwater.

Owner:ZHEJIANG OCEAN UNIV

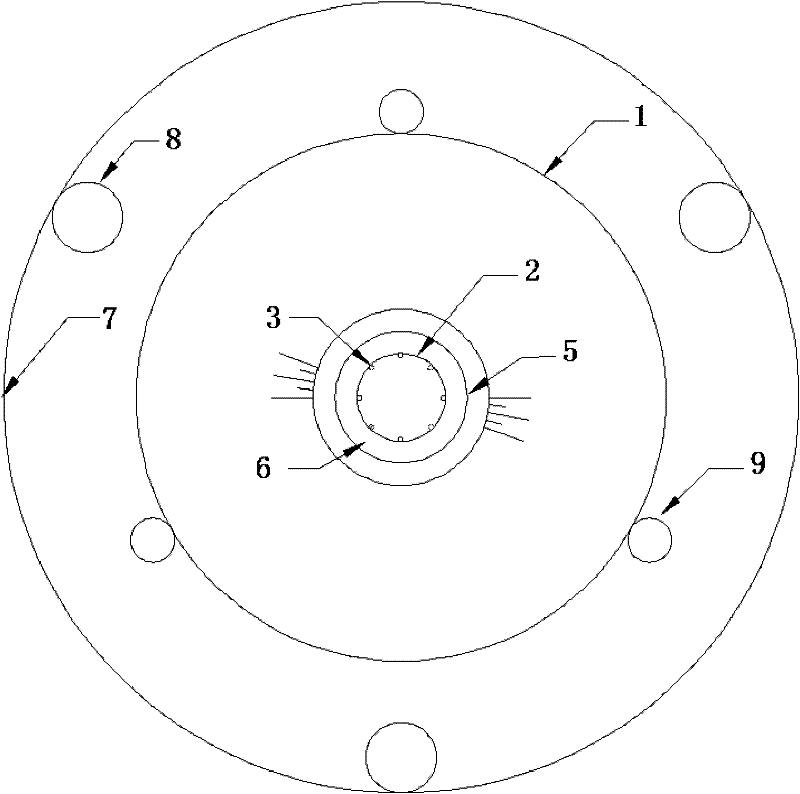

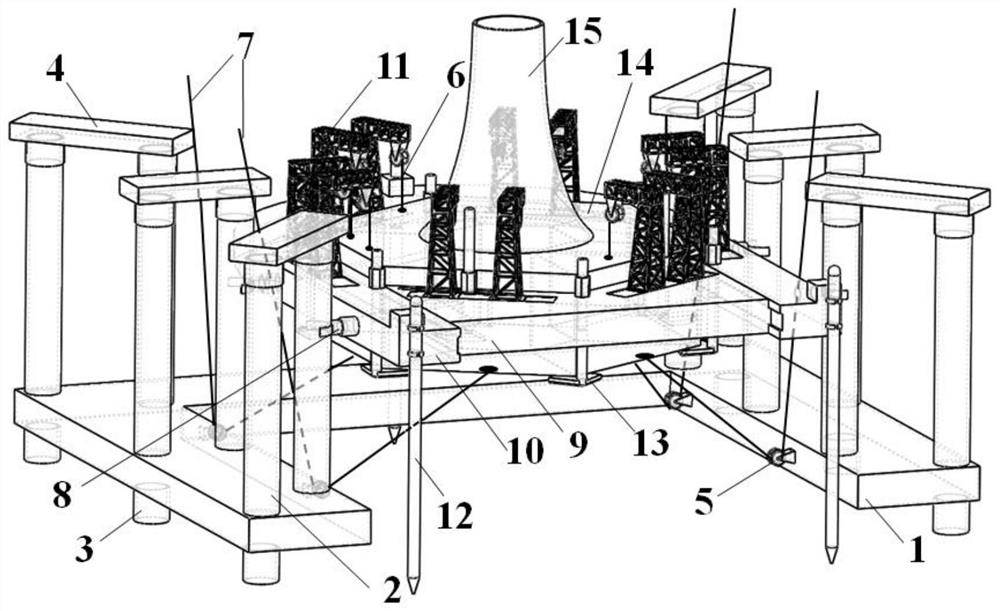

Deep water offshore wind power bucket foundation mounting device and method

PendingCN111910675AImprove installation efficiencyFree accessWind motor supports/mountsWind energy generationStructural engineeringStern

The invention provides a deep water offshore wind power bucket foundation mounting device and method. The device comprises a sinking pad, a floating transportation main body and a mooring rope assembly; fixed pulleys are arranged on the inner side wall of the sinking pad; the floating transportation main body comprises a K-shaped floating transportation ship and a U-shaped floating transportationship, wherein the K-shaped floating transportation ship is embedded into the inner contour of the U-shaped floating transportation ship, positioning piles are arranged on the bow and the stern of theU-shaped floating transportation ship, hoops are arranged on the outer wall of the U-shaped floating transportation ship, and hanging brackets are arranged on the K-shaped floating transportation shipand the U-shaped floating transportation ship; and the mooring rope assembly comprises upward pulling righting mooring ropes and downward pulling mooring ropes, one ends of the upward pulling righting mooring ropes are connected with the hanging brackets, the other ends of the upward pulling righting mooring ropes are connected with the top of a hexagonal bucket foundation, the downward pulling mooring ropes bypass the fixed pulleys, one ends of the downward pulling mooring ropes are connected with floating balls, and the other ends of the downward pulling mooring ropes are connected with thebottom of the hexagonal bucket foundation. According to the device and method, the safety and stability of the hexagonal bucket foundation in the sinking process are guaranteed.

Owner:TIANJIN UNIV

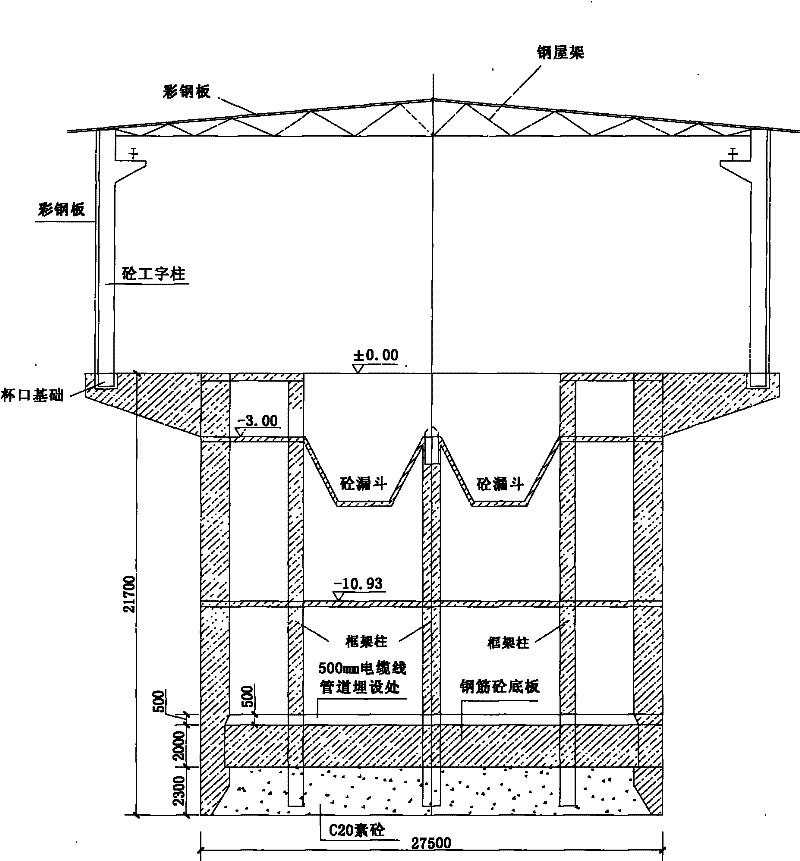

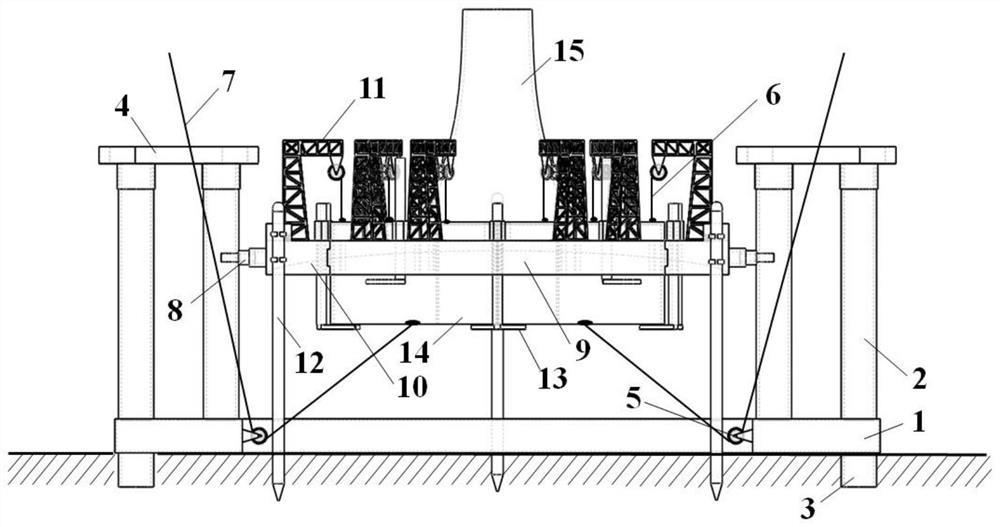

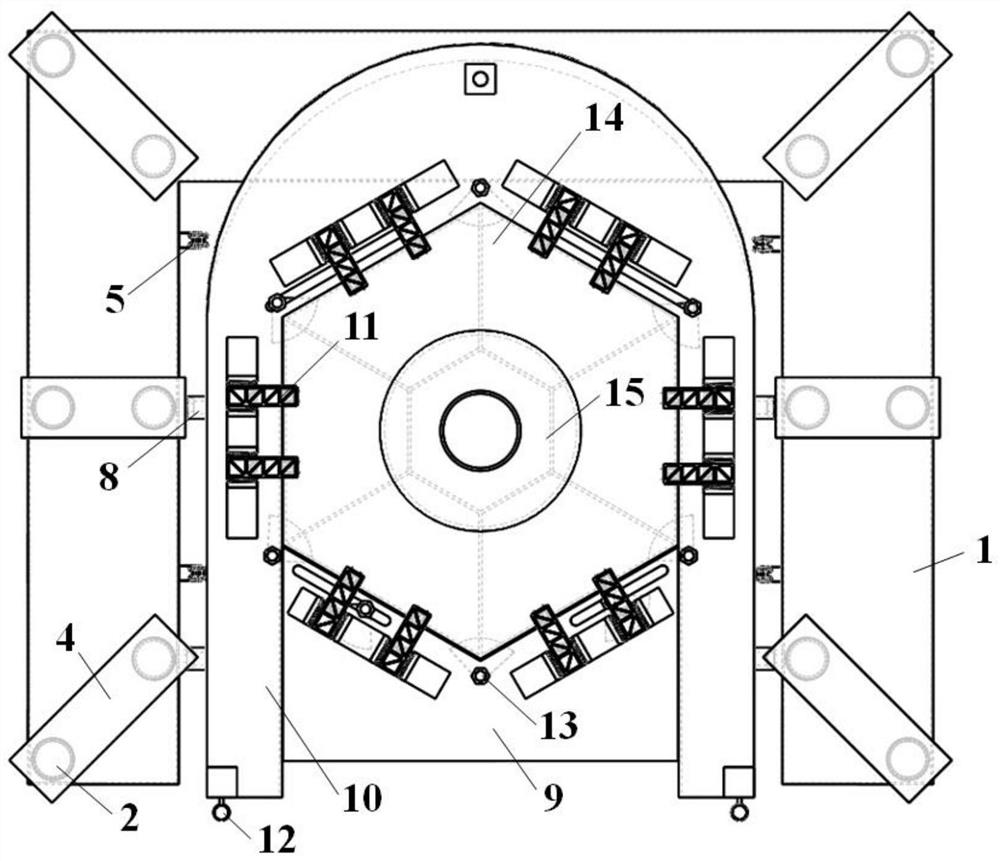

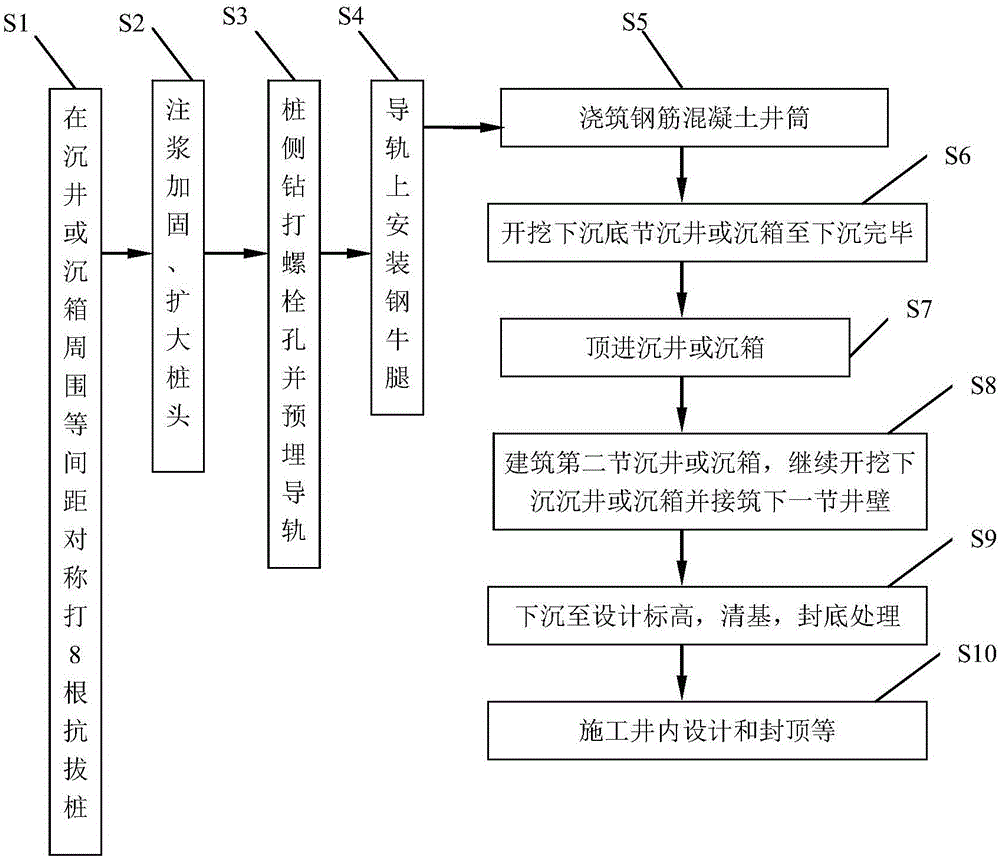

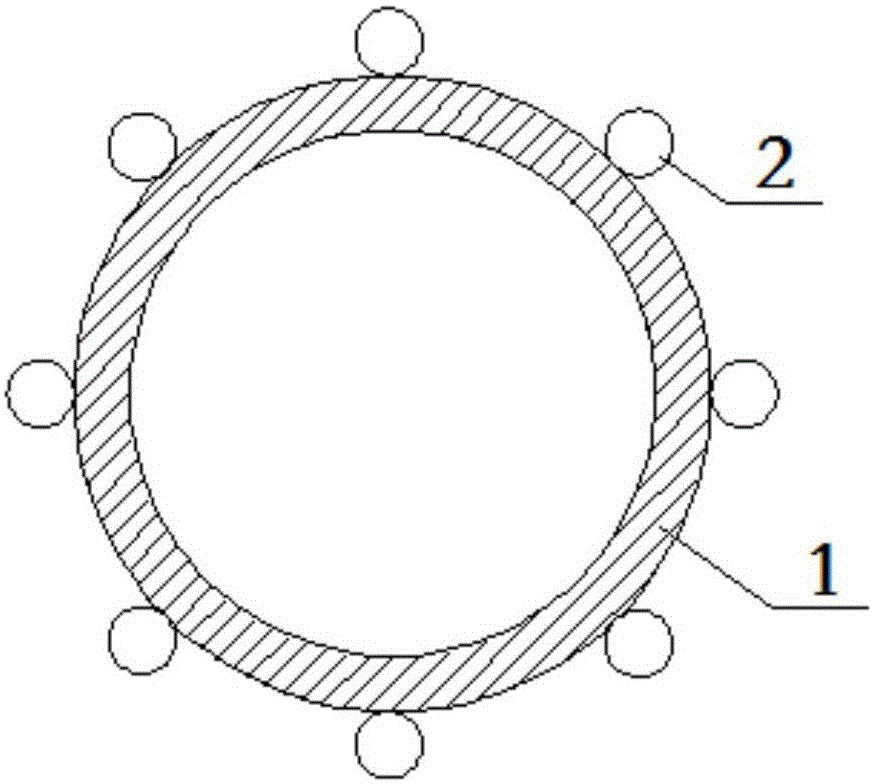

Construction method for shaft type underground garage

The invention relates to a construction method for a shaft type underground garage. The construction method comprises the following steps that firstly, uplift piles are driven around a drop shaft or a caisson; secondly, grouting is carried out after pile forming, the uplift piles are strengthened, and pile heads are expanded; thirdly, bolt holes are drilled in the pile sides of the uplift piles, and guide rails are embedded; fourthly, steel corbels are installed on the embedded guide rails and used for installing a weight balance system of a vehicle garage entering and exiting loading device; fifthly, a reinforced concrete shaft is poured on the ground; sixthly, a sinking bottom joint drop shaft or a bottom joint caisson is evenly dug till sinking is finished; seventhly, the caisson or the drop shaft is ejected; eighthly, a second joint drop shaft or a second joint caisson is built, the sinking drop shaft or the caisson continues to be dug, and a next joint shaft wall is built continuously; ninthly, after the designed elevation is achieved during sinking, foundation cleaning is carried out, and bottom sealing processing is carried out on the drop shaft or the caisson; and tenthly, designing and top sealing are carried out in a construction well. Compared with the prior art, the construction method has the beneficial effects that reliability is achieved, the construction period is short, and the shaft type underground garage digging construction is economical and reasonable.

Owner:TONGJI UNIV

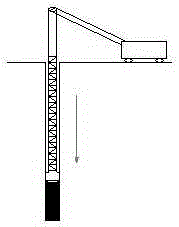

Improving method for open caisson sinking construction in geology of sludge layer

InactiveCN105256819APrevent slope collapsePrevent scurryingCaissonsBulkheads/pilesSludgeWell drilling

The invention relates to an improving method for open caisson sinking construction in geology of a sludge layer. Sinking stability piles are changed from cement powder spraying piles into after-drilling injection grouting pillars. Construction of the after-drilling injection grouting pillars comprises the steps that (1) site leveling is conducted, surveying and lining are conducted to determine the positions of the after-drilling injection grouting pillars, and a drill is put in a position; (2) holes are formed by drilling an open caisson with the adoption of a single spiral drill; and (3) after the holes are formed, grouting is conducted to hole bottoms, after the hole bottoms are solidified, grouting is conducted while a drill bit is lifted, the after-drilling injection grouting pillars are formed until the drill bit is retreated from the formed holes. The after-drilling injection grouting pillars are stable in structure and good in uniformity. No large chiseling height difference is generated when opposite-chiseling is conducted. The open caisson sinking process is more stable.

Owner:CHINA FIRST METALLURGICAL GROUP

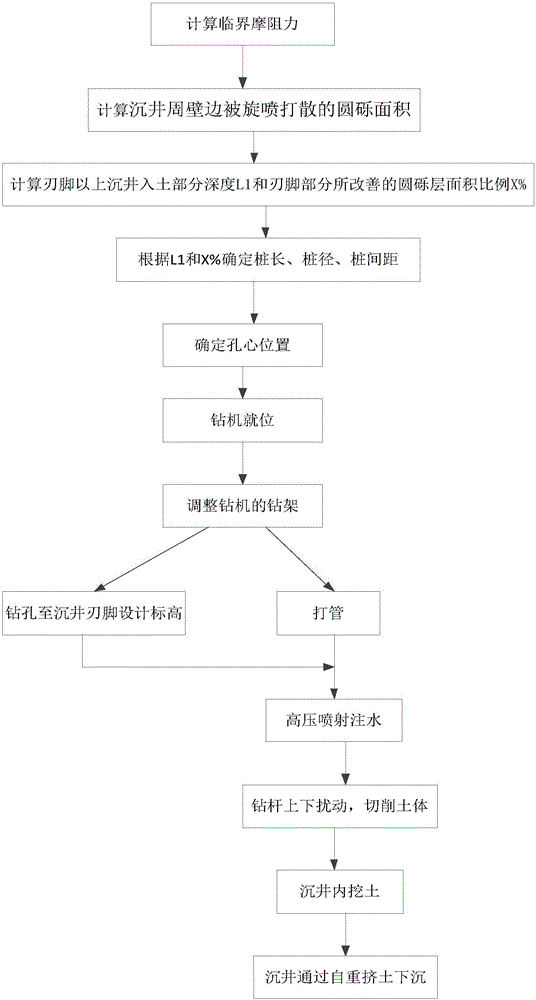

Aid-sedimentation construction method for open caisson engineering in dense round gravel layer or gravel layer

The invention discloses an aid-sedimentation construction method for open caisson engineering in a dense round gravel layer or a gravel layer, which is mainly used for solving the construction problem encountered very easily in the prior art that an open caisson sinks slowly and even does not sink in open caisson construction under the geological condition of the dense round gravel layer or the gravel layer. The aid-sedimentation construction method comprises the following steps: rotationally cutting soil masses in the range of cutting edges by rotary spraying of high-pressure rotary spraying water so as to reduce the percentage of the hard round gravel layer and the frictional resistance of the soil masses and cause the open caisson to sink by own gravity, determining the depth, radius and spacing which are needed by rotary spraying according to L1 and X% after sequentially calculating the critical frictional resistance, the area of round gravels scattered by the rotary spraying water on the peripheral wall sides of the open caisson, the depth L1 of the soil piercing part of the open caisson above the cutting edges and the area proportion X% of the round gravel layer improved at the cutting edges, then selecting an appropriate high-pressure jet grouting pile machine for scattering the soil masses, and cutting earth in the open caisson so as to cause the open caisson to sink by own gravity. By adopting the technical scheme, the aid-sedimentation construction method achieves the purpose of causing the open caisson to easily sink.

Owner:云南劲宏建设有限公司

Application method for cutting hole in airtight chamber of upturned ship

The invention relates to an application method for cutting a hole in an airtight chamber of an upturned ship. The method comprises the following steps of 1) sealing the bottom surface of a sealed chamber body through a sealing component and fixing the sealing chamber body at the bottom of the upturned ship; 2) exerting a cutting personnel to open an outer sealing door, enter a transitional chamber, close the outer sealing door, open an inner sealing door, enter a working chamber and close an inner sealing door; charging gas into the working chamber through an airtight mouth to supercharge the working chamber; performing leakage detection and leakage prevention on the working chamber after the working chamber is supercharged; and then cutting a hole in the bottom of the upturned ship through cutting equipment; and 3) after the hole is cut, exerting the cutting personnel to enter the transitional chamber, close the inner sealing door and walk out of the sealed chamber body; exerting divers carrying oxygen cylinders to enter the transitional chamber, close the outer sealing door, enter the working chamber, close the inner sealing door and enter the interior of the upturned ship from the hole so as to carry out rescue work. As rescuers carry out hole-cutting and rescue works under a sealed environment provided by the airtight chamber, the operation is safe, the efficiency is high and rescue time is saved.

Owner:WUHAN UNIV OF TECH

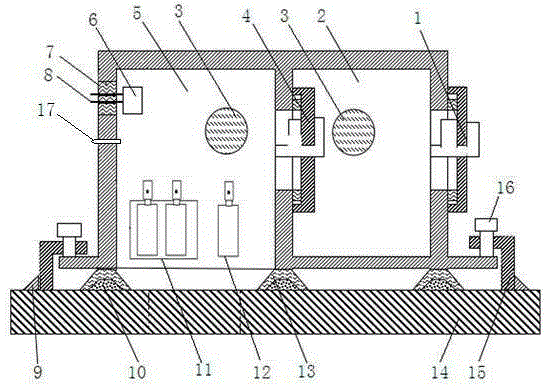

Construction method of rapid sinking of double-wall steel sleeve box cofferdam in sandy cobble stratum

The invention discloses a construction method of rapid sinking of a double-wall steel sleeve box cofferdam in a sandy cobble stratum. According to the method, the double-wall steel sleeve box cofferdam, a structural steel distribution beam, a jack, a pile foundation steel casing, a Larsen steel sheet pile, a steel ring beam, a guide device, a hydraulic pump station, a control computer and the sandy cobble stratum are included; according to the construction method, soil below the double-wall steel sleeve box cofferdam is closed, the cobble square mount in the cofferdam is fixed, the mud suction sinking time is effectively shortened, and the cofferdam sinking speed is obviously quickened. Stability of the double-wall steel sleeve box cofferdam can be improved, the effect of separating soil on the inner side and the outer side of the double-wall steel sleeve box cofferdam is achieved, a steel ring beam on the top of a Larsen steel sheet is arranged, and the aim of stabilizing a steel plate pile cofferdam hole opening is achieved; the Larsen steel sheet pile is arranged on the outer side of the double-wall steel sleeve box cofferdam, and is closed to a ring, the double-wall steel sleeve box cofferdam can smoothly sink in the closed space formed by the steel plate pile, and operation space can be provided for splicing of the next segment after the double-wall steel sleeve box cofferdam is implanted.

Owner:CCTEB INFRASTRUCTURE CONSTR CO LTD +2

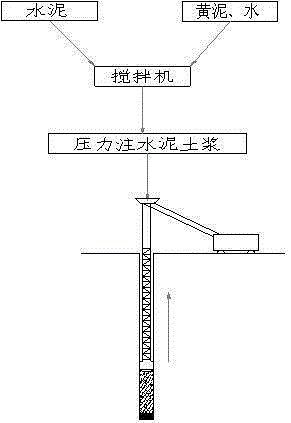

Construction technology and equipment for cement mixing pile

The invention discloses a construction technology and equipment for a cement mixing pile. The construction technology comprises the steps that when the hollow pile section is constructed, clear water is ejected from a grout ejecting opening, the clear water is also ejected by the grout ejecting opening in the first sinking process of the solid pile section, a mixing head is lifted and sunk for many times in the lifting process of the solid pile section, and cement grout is ejected from the grout ejecting opening. According to the construction technology for the cement mixing pile, the cement is distributed in the solid pile section uniformly, and the cement grout is combined with soil body in the solid pile section, so that the pile forming quality of the solid pile section is guaranteed, waste of the cement grout is avoided, and follow-up digging work of the hollow pile section is convenient.

Owner:中国能源建设集团广东电力工程局有限公司

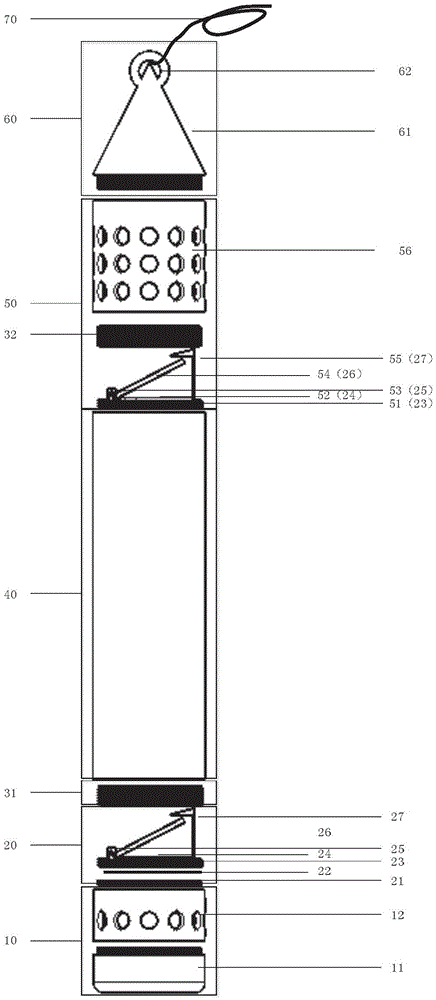

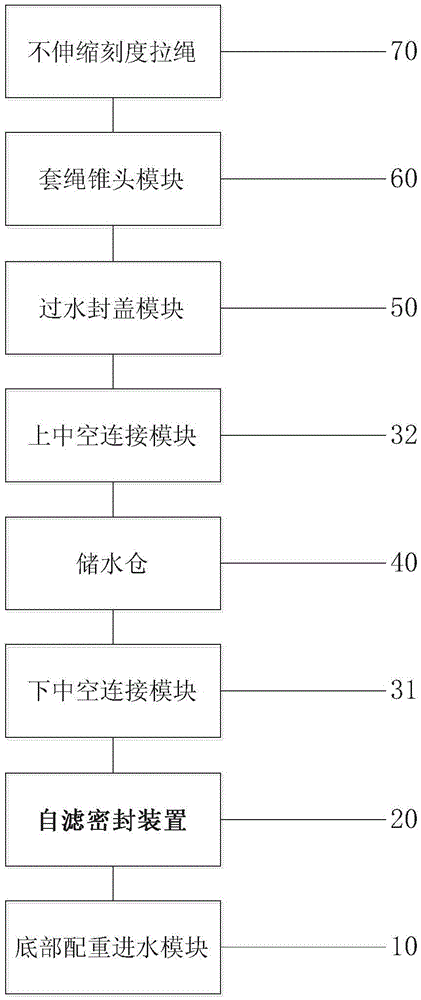

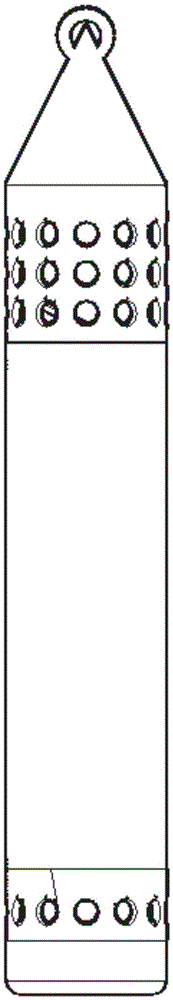

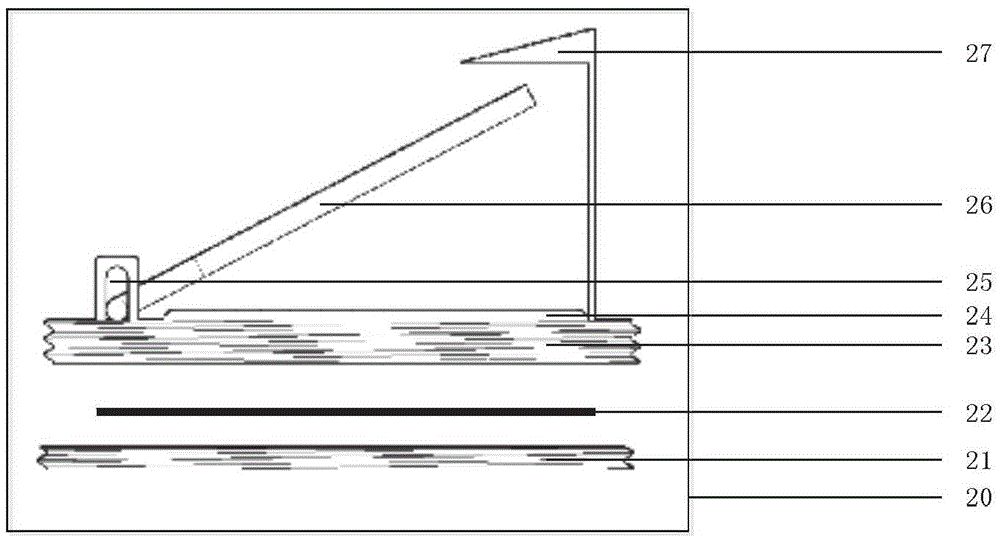

Device and method for collecting deep self-filtration sealing water sample

InactiveCN105571899AThe overall shape is smooth and beautifulEasy to assemble and disassemble on siteWithdrawing sample devicesPreparing sample for investigationWater storageFiltration

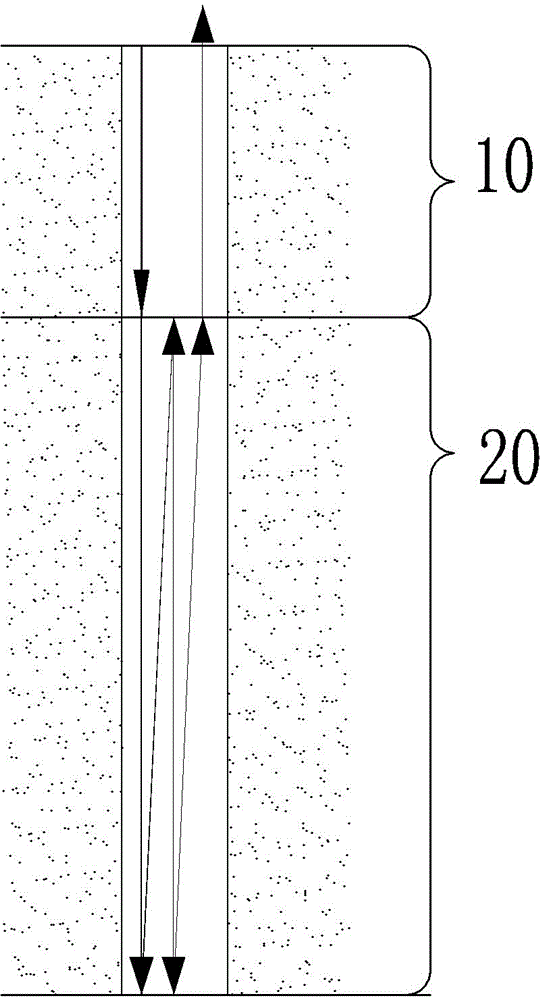

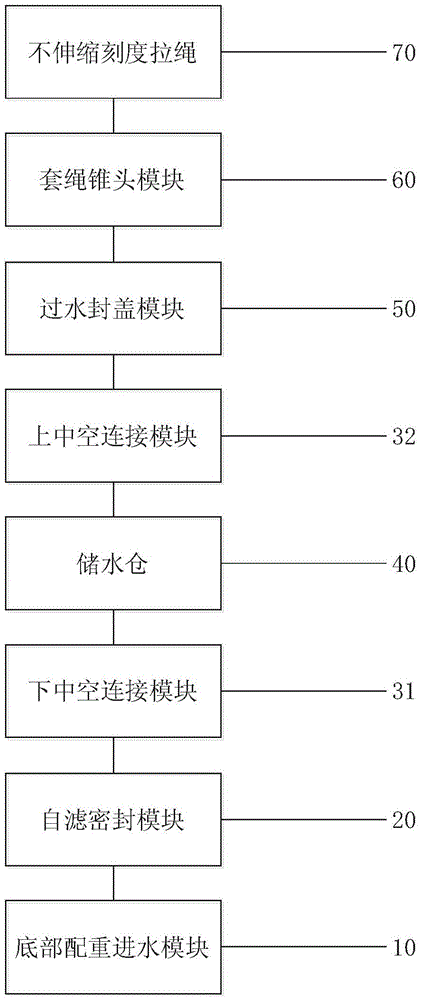

The invention discloses a device and a method for collecting a deep self-filtration sealing water sample, and relates to the technical field of environment protection and water resource monitoring. The device comprises a bottom counterweight water inlet module (10), a self-filtration sealing module (20), a lower hollow connecting module (31), a water storage cabin (40), an upper hollow connecting module (32), a water-passing sealing cover module (50), a prolonge conical head module (60) and an inflexible scale digging rope (70) which are sequentially connected from bottom to top. According to the device disclosed by the invention, a high-quality water sample which is subjected to preliminary filtration of impurities, is accurately located and is sealed without being mixed with the impurities is obtained; all components of the whole device can be independently disassembled, assembled and replaced, the structure is simple, the carrying is convenient, durability is realized, the economic benefit is obvious, and the popularization is easy.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

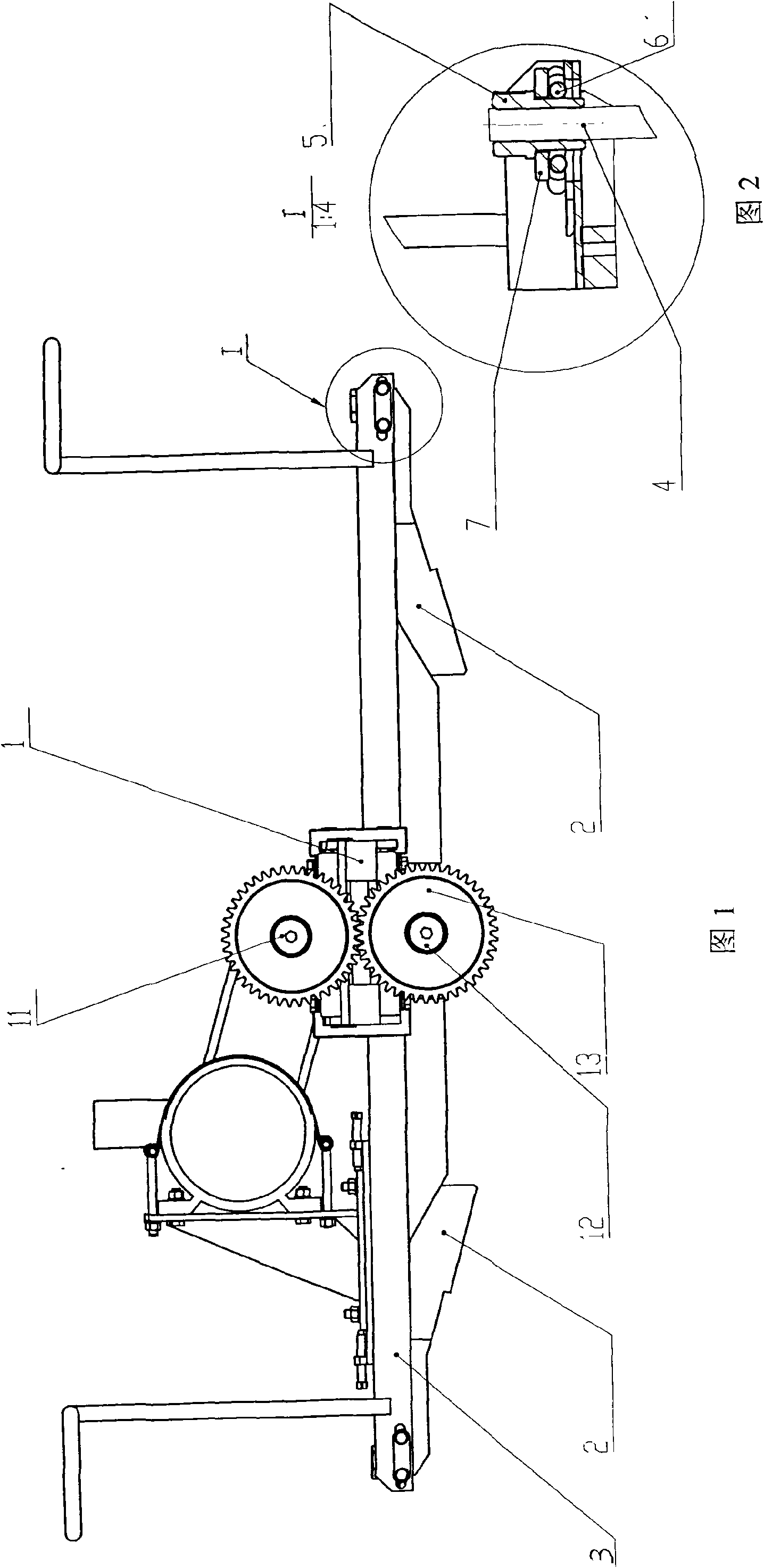

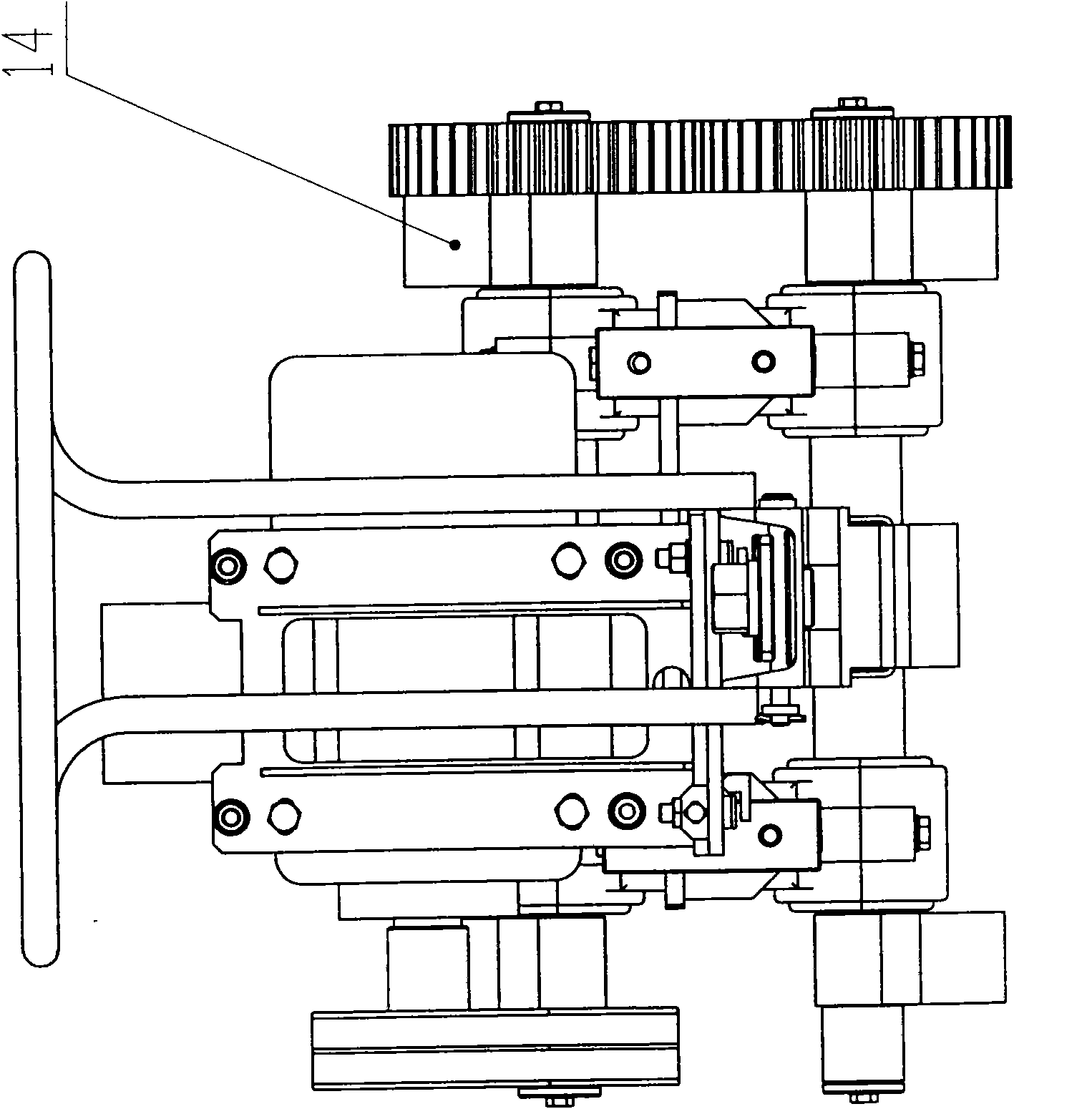

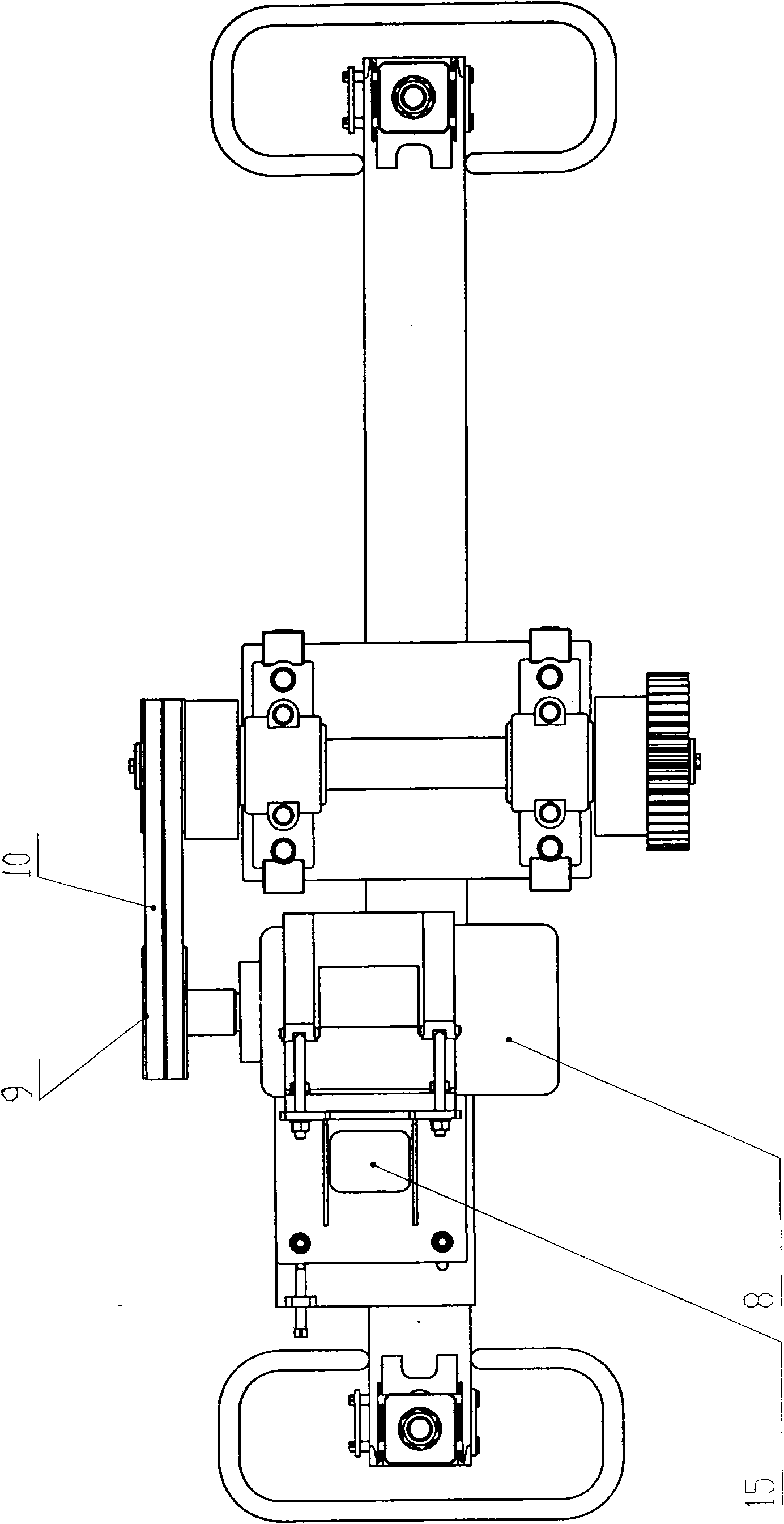

Small sleeper stabilization integrating machine

InactiveCN101603284AEasy to use and stableSinking smoothlyBallastwayEngineeringStructural engineering

The invention relates to a small sleeper stabilization integrating machine, which comprises a stander and a horizontal vibration generator arranged on the stander, wherein two ends of the stander are provided with supporting legs matched with two symmetrical bevels of a sleeper, and the stander compacts and fixes a stabilizer on the sleeper through sleeper studs and sleeper stud nuts at two ends of the stander; and a roller and a roller pressure plate for eliminating the influence of the horizontal lateral force of the sleeper stabilization integrating machine on the sleeper studs are arranged between the sleeper nuts and the stander. The pure horizontal reciprocating vibration force generated by the sleeper stabilization operating machine drives the sleeper to do reciprocating vibration, so that the ballast padded under the sleeper generates twisting and is quickly compacted, the sleeper sinks to a stabilization state with the ballast, and the train does not need decelerate when passing, so the small sleeper stabilization integrating machine greatly improves the operating capability after the railway is constructed.

Owner:重庆运达机电设备制造有限公司

Self-filtering sealing device of deep self-filtering sealing water collector

InactiveCN105547756AGuaranteed normal opening and closingAvoid situations where you cannot returnWithdrawing sample devicesPreparing sample for investigationEconomic benefitsWater resources

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Moxa cake and preparation process thereof

InactiveCN107280964AImprove AI utilizationWon't fallDevices for heating/cooling reflex pointsPharmaceutical product form changeFlueEngineering

The invention relates to a moxa cake and a preparation process thereof. The moxa cake is formed by pressing moxa, the whole moxa cake is cake-shaped, the maximum size of the bottom surface of the moxa cake is 1-5 times of the height of the moxa cake, the center of the upper surface of the moxa cake protrudes and is higher than the upper surface of the moxa cake, the bottom surrounding of the protrusion is downwards sunken and is lower than the upper surface of the moxa cake, a blind hole with a downward opening is formed in the moxa cake, and the hole bottom of the blind hole is located in the protrusion. The preparation process incudes a cold-press method or a hot-press method. A central hole of the moxa cake is the blind hole, the hole bottom of the blind hole is located in the protrusion of the moxa cake and is higher than the upper surface of the moxa cake, the blind hole is kept unchanged at a preliminary burning stage, moxa produced during moxa burning covers the hole bottom when the hole bottom of the blind hole is burned, so that the inside of the moxibustion smoke is always the blind hole, the upper end blocking a flue of the blind hole is opened, the moxa smoke only flows downward, and the moxibustion utilization rate is improved.

Owner:湖北蕲艾堂科技有限公司

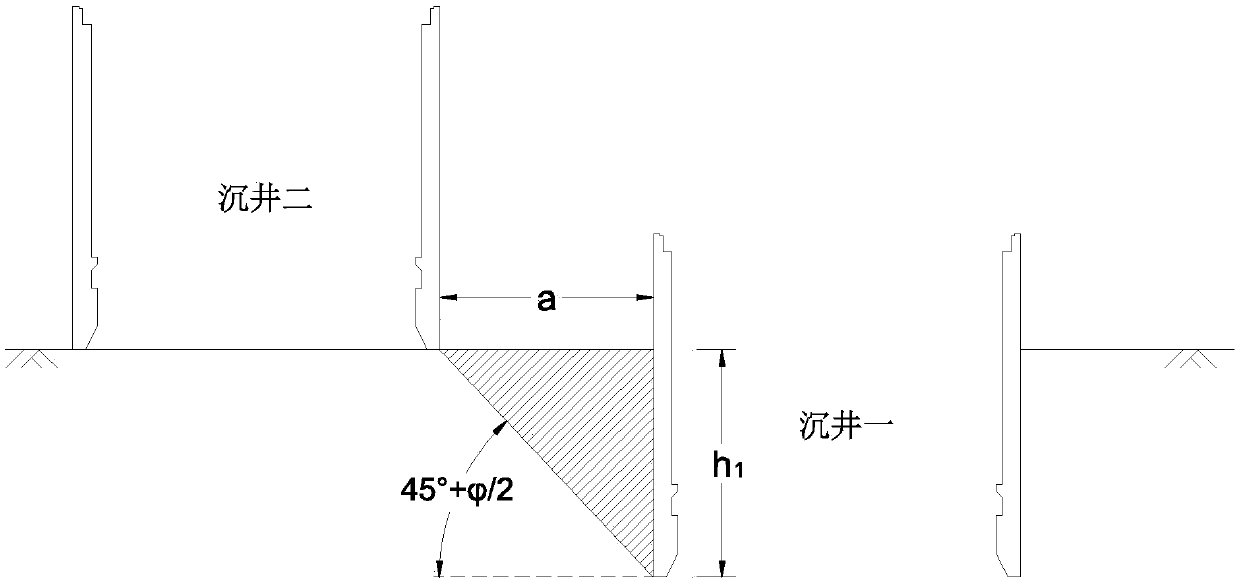

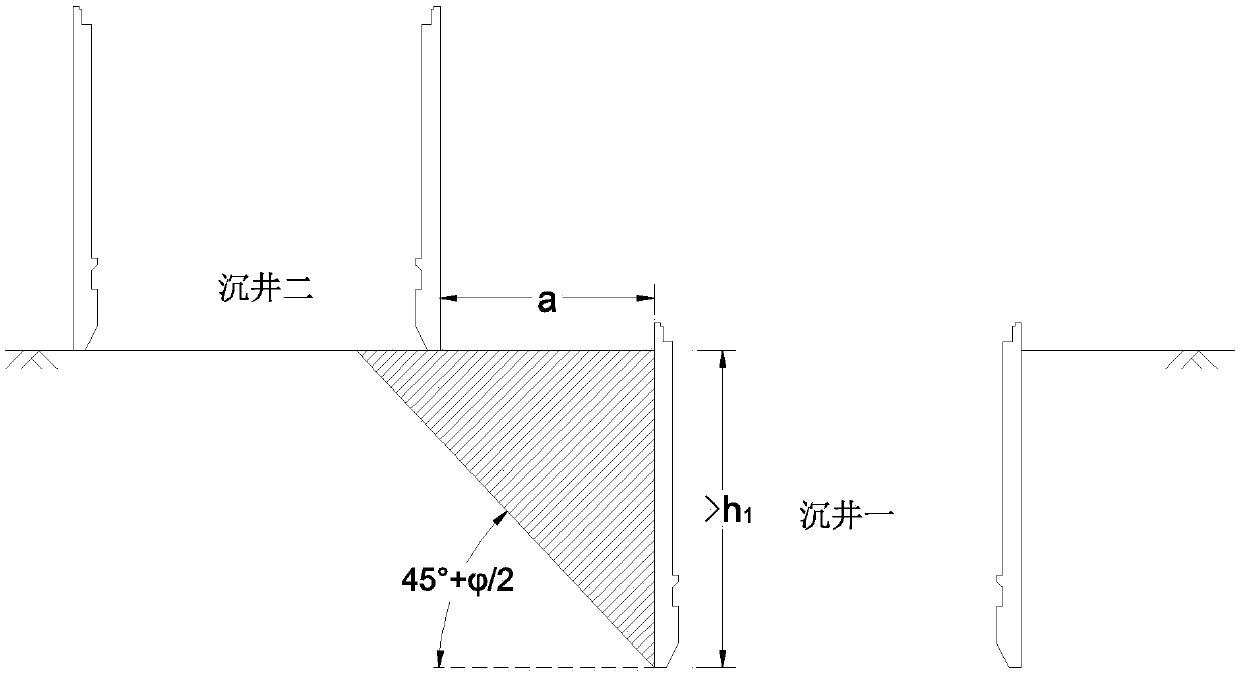

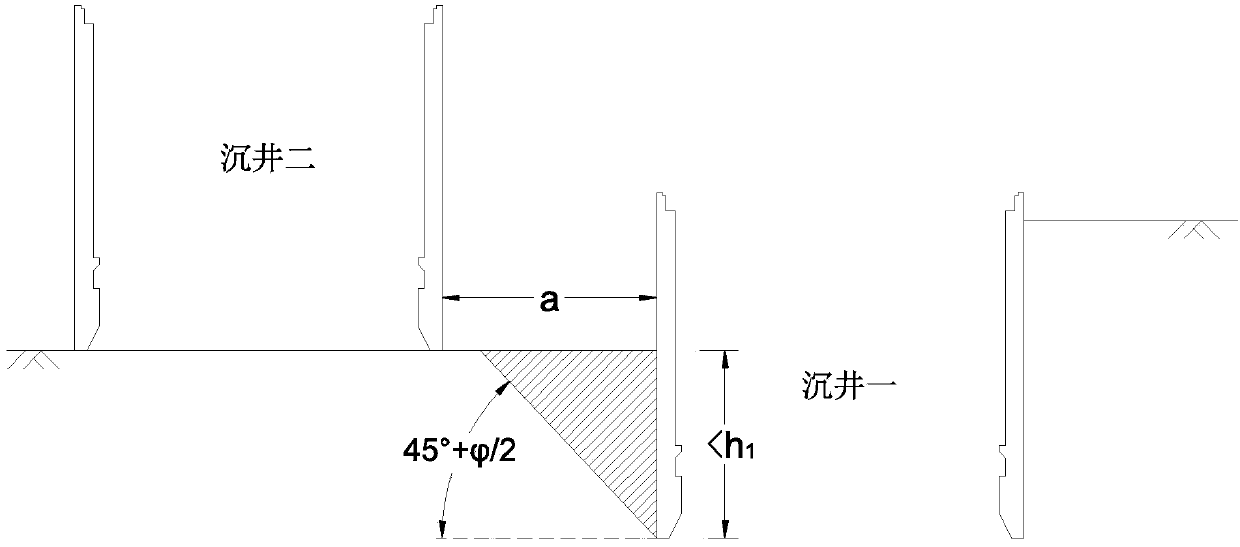

Close distance caisson group sinking construction method

ActiveCN108824505ASinking smoothlyReduce interactionFoundation testingCaissonsHeight differenceVertical load

The invention discloses a close distance caisson group sinking construction method. The close distance caisson group sinking construction method comprises the following steps that the minimum horizontal clear distance a between adjacent caissons in the caisson group is determined; according to the active earth pressure theory, the soil sliding surface vertical depth h<1>is calculated when the soilis in the state of ultimate pressure and the horizontal width of the soil sliding surface is a; vertical load of the caisson self-weight is regarded as local additional load, the vertical stress of the caisson self-weight diffuses downwards, and the vertical depth h<2> of the vertical stress diffusing downwards at the horizontal clear distance a is calculated; the cutting edge safe height difference H between adjacent caissons in caisson group construction is determined, wherein H<min{h<1>, h<2>}; and the adjacent caissons in the caisson group sink alternately to complete caisson sink construction and bottom sealing construction, and the cutting edge height difference of the adjacent caissons is always kept in the range of the safe height difference H. According to the construction method, through reasonable sinking sequence selection, the maximum sinkage in each stage of the caisson is controlled, mutual influence of the caissons is significantly reduced, and successful sink of the caissons in the caisson group is guaranteed.

Owner:SHANGHAI MUNICIPAL CONSTR

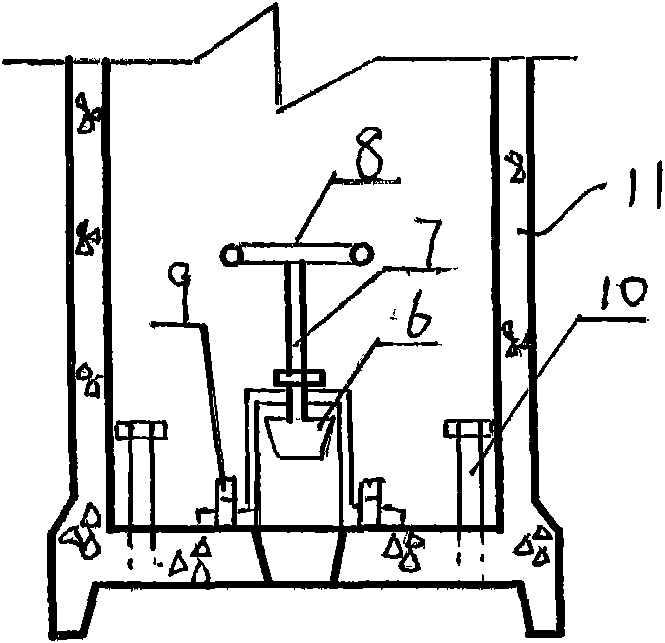

Mounting method of deep well high pressure aeration reactor steel drum

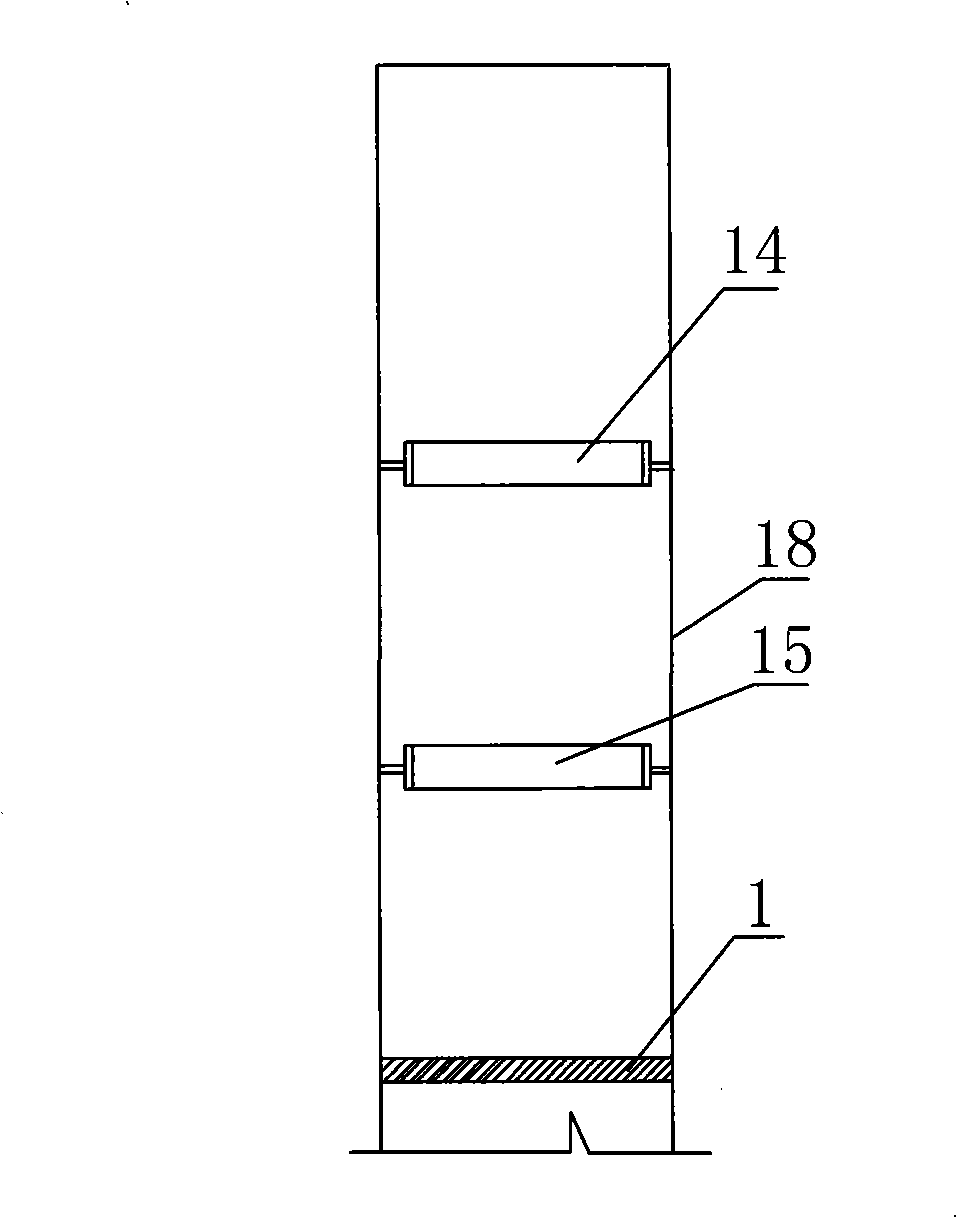

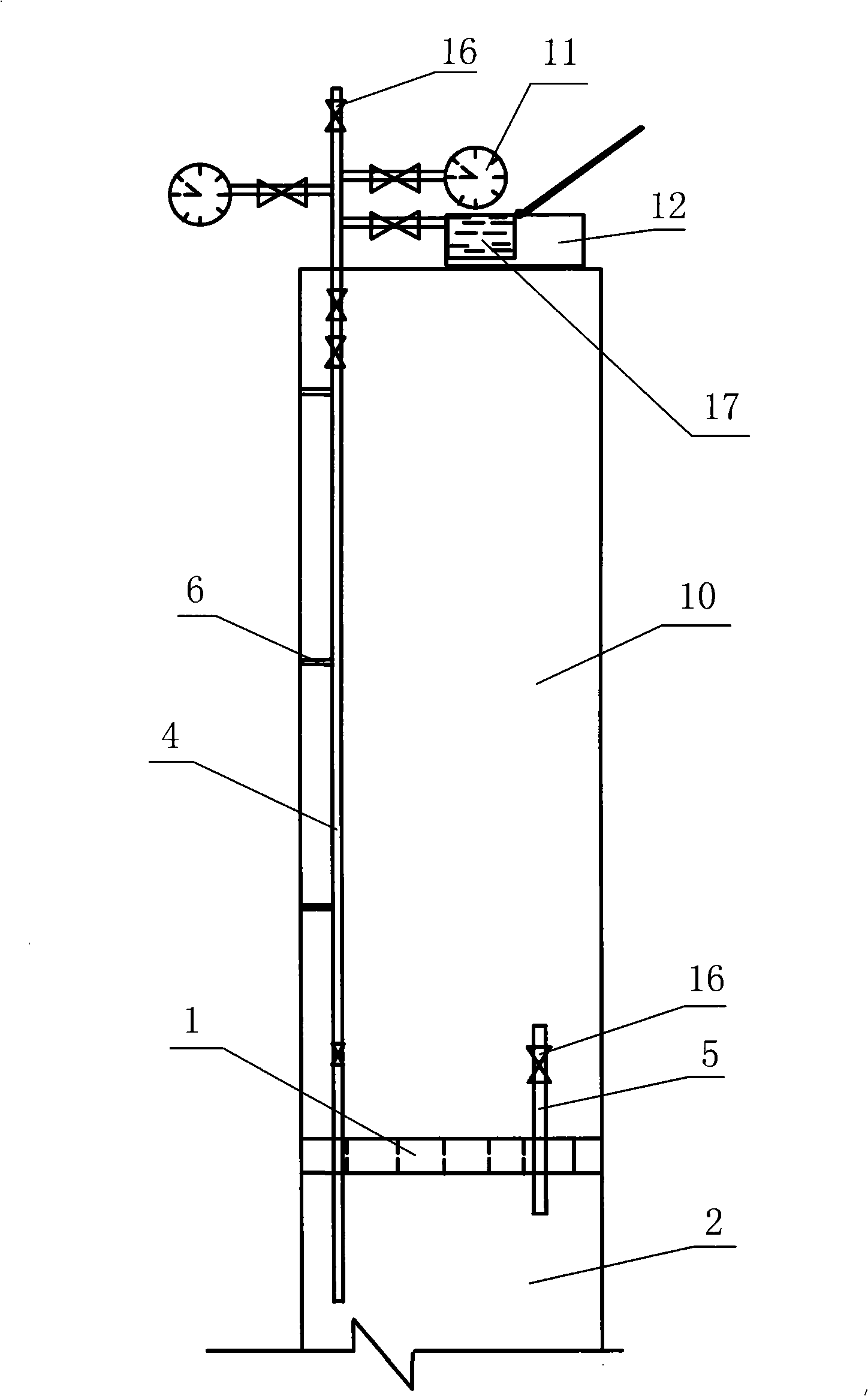

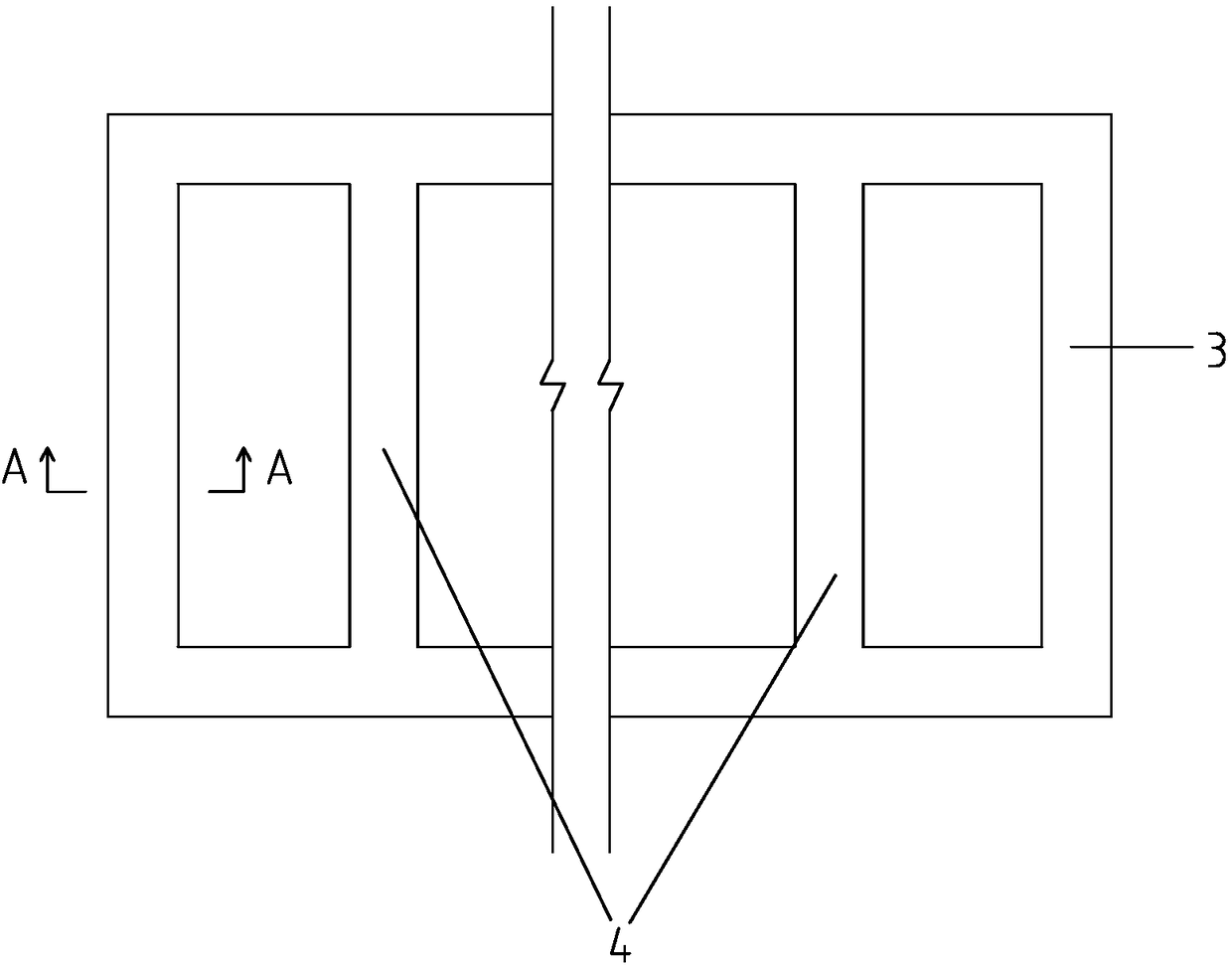

InactiveCN101344004AReduce lifting weightPrevent hole collapseFlow mixersMixing methodsInstabilityEngineering

The invention discloses an installation method for a steel cylinder of a high-pressure aeration reactor of a deep well, comprising the following steps of: processing and manufacturing an inner baffle; determining the installation position of the inner baffle: the steel cylinder consists of a plurality of groups of steel cylinder sections from bottom to top, the inner baffle is arranged on the steel cylinder section with the number of M and the length ratio of the upper part and the lower part of the inner baffle is 2.5 to 4.0 : 6.0 to 7.5; installing a plurality of groups of steel cylinder sections of the lower part of the inner baffle in sequence from bottom to top; installing the inner baffle; sinking and temporarily fixing the steel cylinder section with the number of M+1; sinking and installing the steel cylinder section with the number of M+2 after the pressure in the cylinder is transmitted up uniformly and installing a plurality of groups of steel cylinder sections of the upper part in sequence according to the installation method thereof; pouring concrete or mortar to the outside of the steel cylinder; releasing the pressure and carrying out cutting recovery of the inner baffle. The invention can solve the lifting problem of the steel cylinder and the instability and distortion problem of the steel cylinder under the effect of the side pressure of the slurry outside of the cylinder, can ensure that the steel cylinder sinks to the designed elevation safely and smoothly and can save the construction cost.

Owner:陈定平

Original-soil and in-situ slurrying-based underground wall construction method

ActiveCN108104112AEasy to construct and manufactureQuality is easy to controlBulkheads/pilesSlurryEngineering

The invention relates to the technical field of underground construction and discloses an original-soil and in-situ slurrying-based underground wall construction method. The original-soil and in-situslurrying-based underground wall construction method comprises the following steps of a, performing a grooving process, b, during the grooving process, injecting water into soil via a high-pressure pipe through a grooving machine, then performing stirring to form slurry, performing multi-spot sampling, detecting the density of slurry samples through a slurry densitometer, injecting water to adjustthe density of the slurry, performing sampling and detecting processes until the density of the slurry reaches a required density rho, and c, transversely and monolithically pouring a first wall piece on a support plate, after the first wall piece is formwork-removed, sinking the top surface of the first wall piece through a hoist till being level to the ground, and transversely and monolithically pouring a second wall piece on the first wall piece, wherein the second wall piece and the first wall piece are longitudinally overlapped, and sequentially transversely and monolithically pouring and sinking a plurality of wall pieces and son on in the identical manner until underground wall construction is completed. An underground wall constructed according to the original-soil and in-situ slurrying-based underground wall construction method is high in quality, free from leakage and secondary construction and capable of greatly reducing the construction cost and shortening the constructionperiod.

Owner:章胜南 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com