Small sleeper stabilization integrating machine

An all-in-one machine and sleeper technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of limited train speed and impact on train operation, and achieve the effect of reliable installation and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

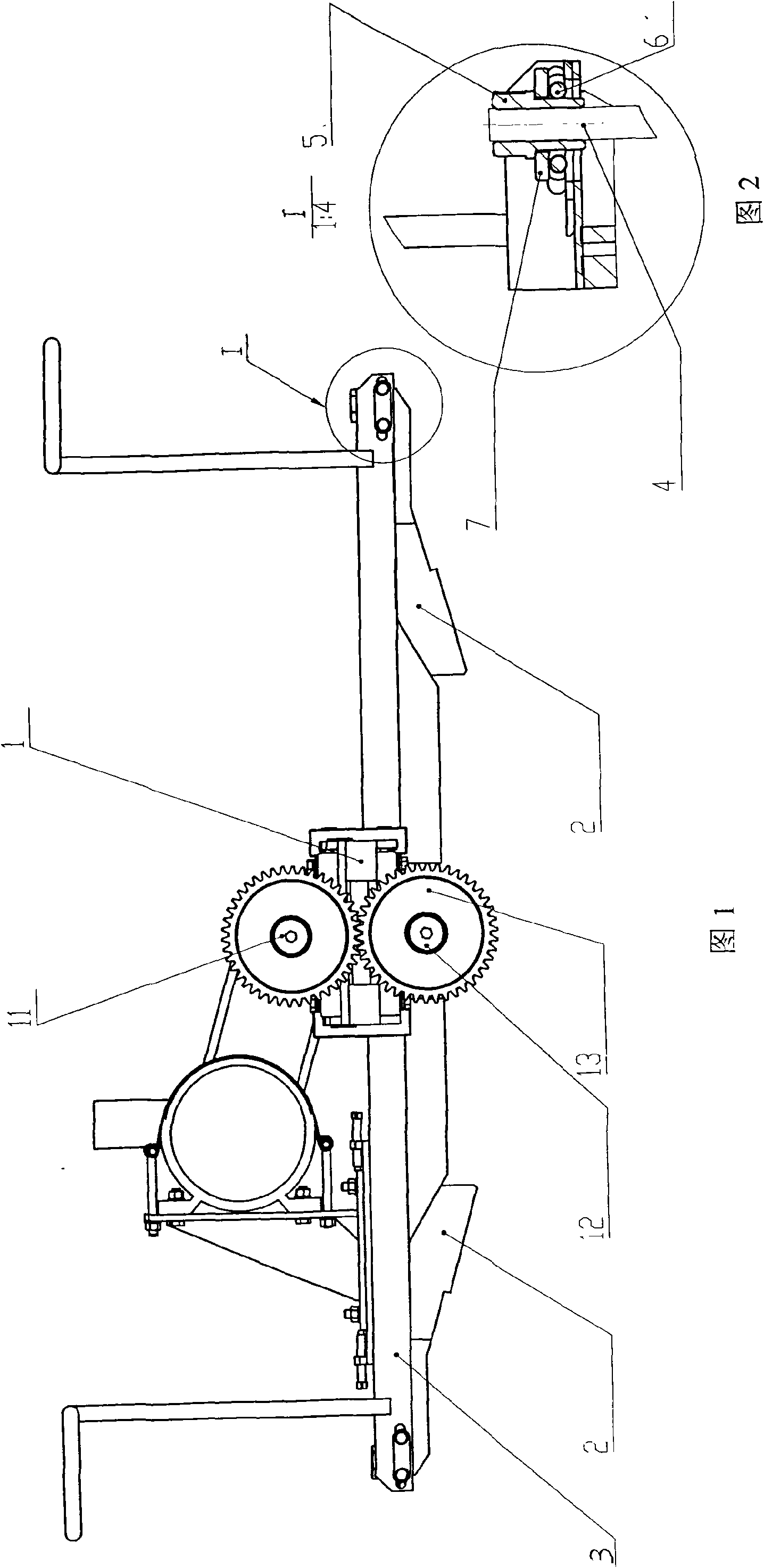

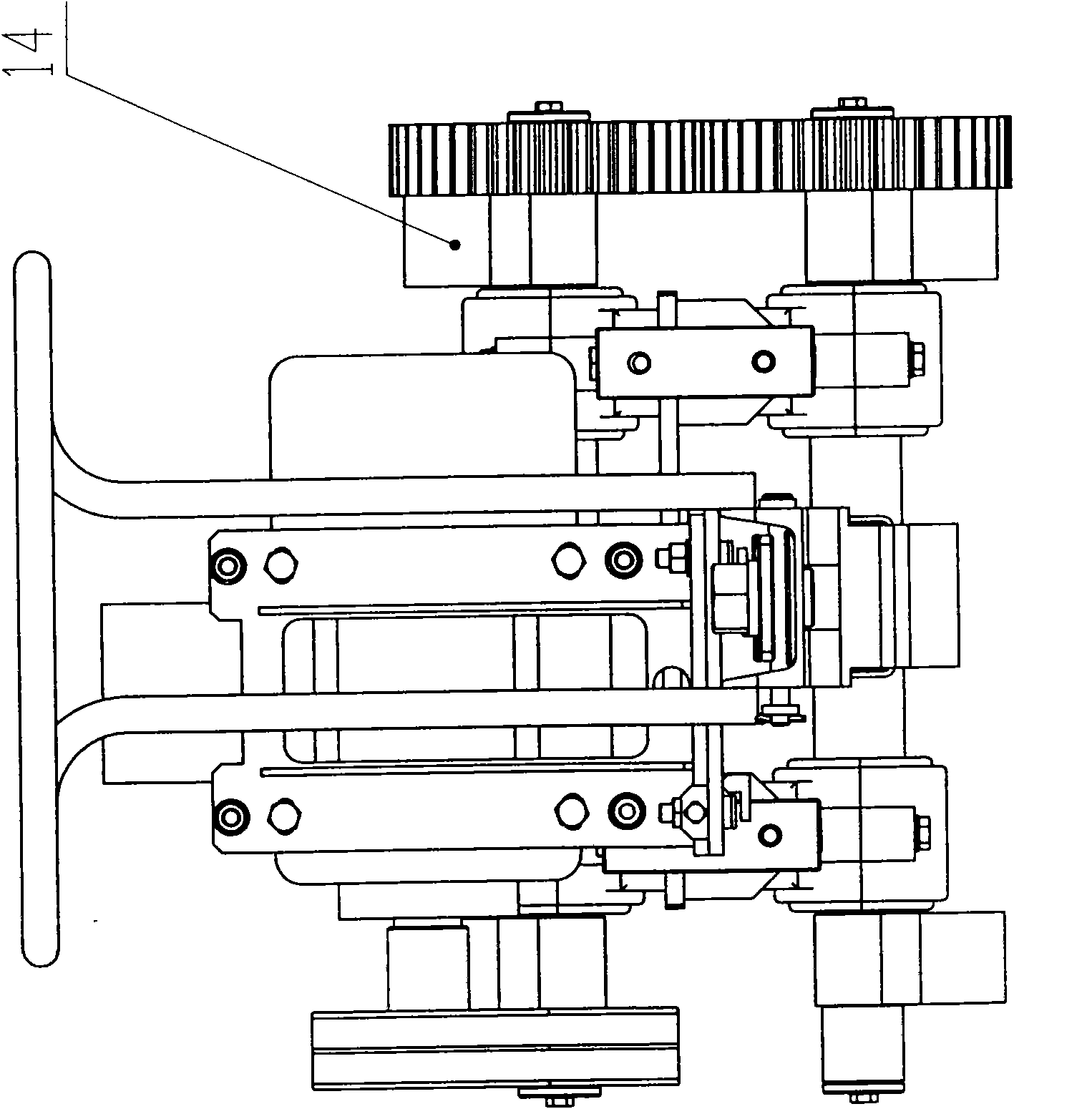

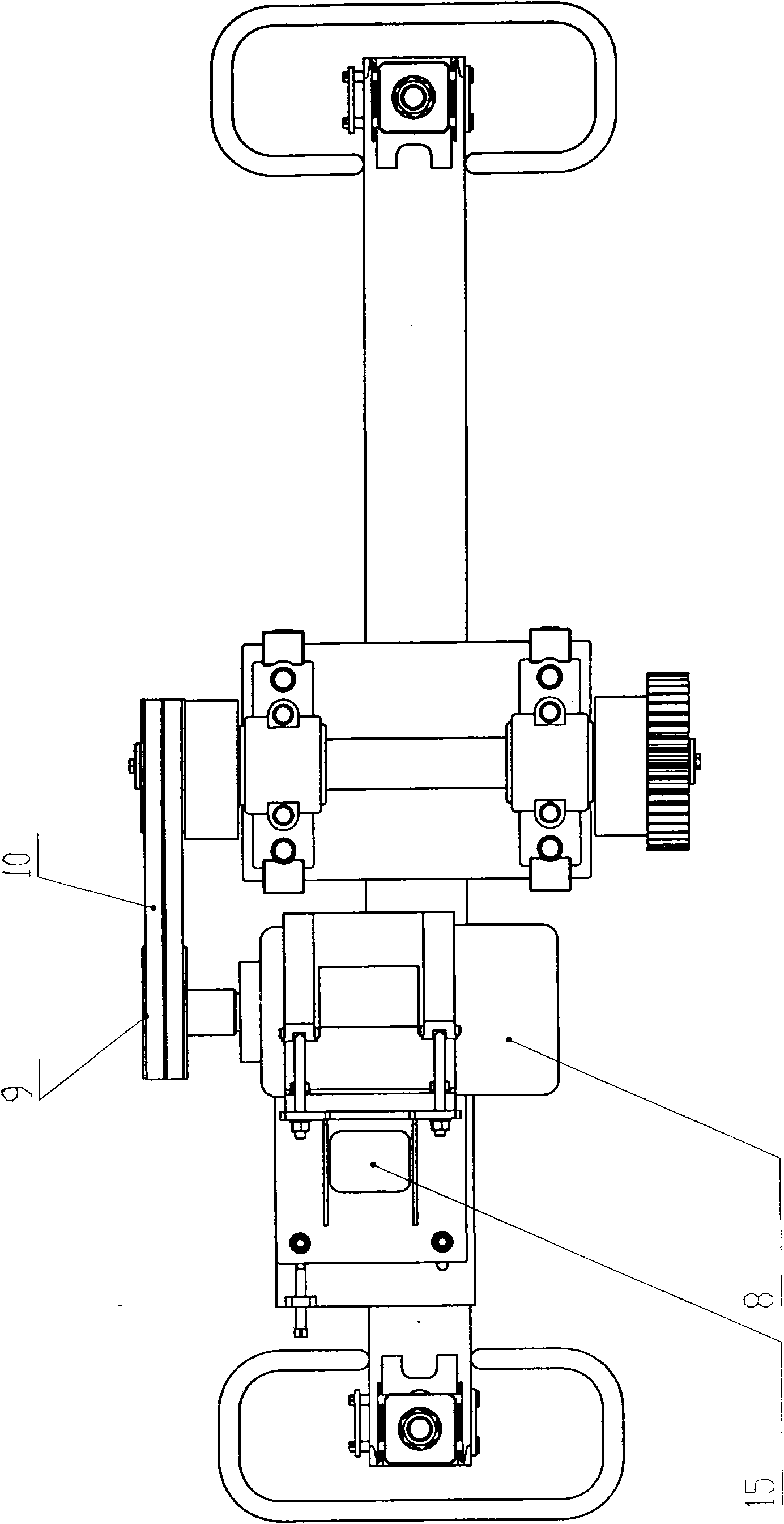

[0021] The structure of the sleeper machine is described in detail below in conjunction with the accompanying drawings:

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: this all-in-one machine for stabilizing sleepers has a frame 3 and a horizontal vibration generator 1 installed on the frame 3. Two ends of the frame 3 are provided with supporting feet 2 that cooperate with two symmetrical inclined surfaces of the sleeper 16, and the supporting feet 2 are piered on the inclined surface of the sleeper 16 through the inclined planes whose feet end are consistent with the inclined surfaces of the sleeper 16. The all-in-one stabilizing sleeper presses and fixes the all-in-one stabilizing sleeper on the sleeper 16 through the sleeper studs 4 and the sleeper stud nuts 5 at both ends of the frame 3, and rollers are arranged between the sleeper stud nuts 5 and the frame 3 6 and roller pressing plate 7. Vibration generator 1 is made up of motor 8, pulley 9, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com