Application method for cutting hole in airtight chamber of upturned ship

A technology for airtight cabins and ships, which is applied to ship parts, ship construction, ships, etc., can solve the problems of low safety factor, long time, accelerated hull sinking, etc., and achieve the effects of saving rescue time, simple operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

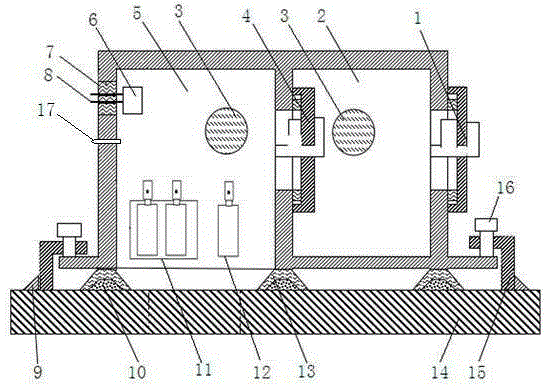

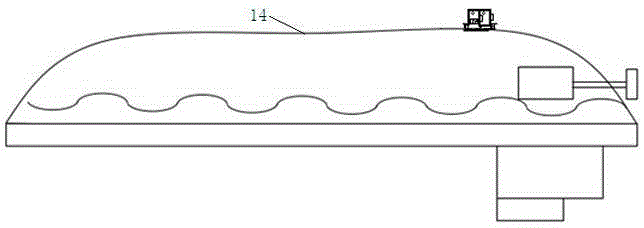

[0023] Such as figure 1 As shown, a perforated airtight cabin of an inverted ship includes a sealed cabin body and a sealed assembly. The sealed cabin body includes a transition cabin 2 and a working cabin 5. The transition cabin 2 is completely closed, and the bottom of the working cabin 5 is provided with openings for the rest are all closed, an outer airtight door 1 is provided between the transition cabin 2 and the outside world, an inner airtight door 4 is provided between the transition cabin 2 and the working cabin 5, communication equipment 6 and cutting equipment 11 are arranged in the working cabin 5, and the working cabin 5 An airtight nozzle 17 is arranged on the top, and the cable 8 of the communication device 6 is sealed to pass out of the sealed cabin body. During work, the sealing assembly seals and fixes the bottom surface of the sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com