Mounting method of deep well high pressure aeration reactor steel drum

An installation method and reactor technology, applied to chemical instruments and methods, water aeration, mixing methods, etc., can solve problems such as instability and deformation, and achieve the effects of preventing hole collapse and reducing hoisting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

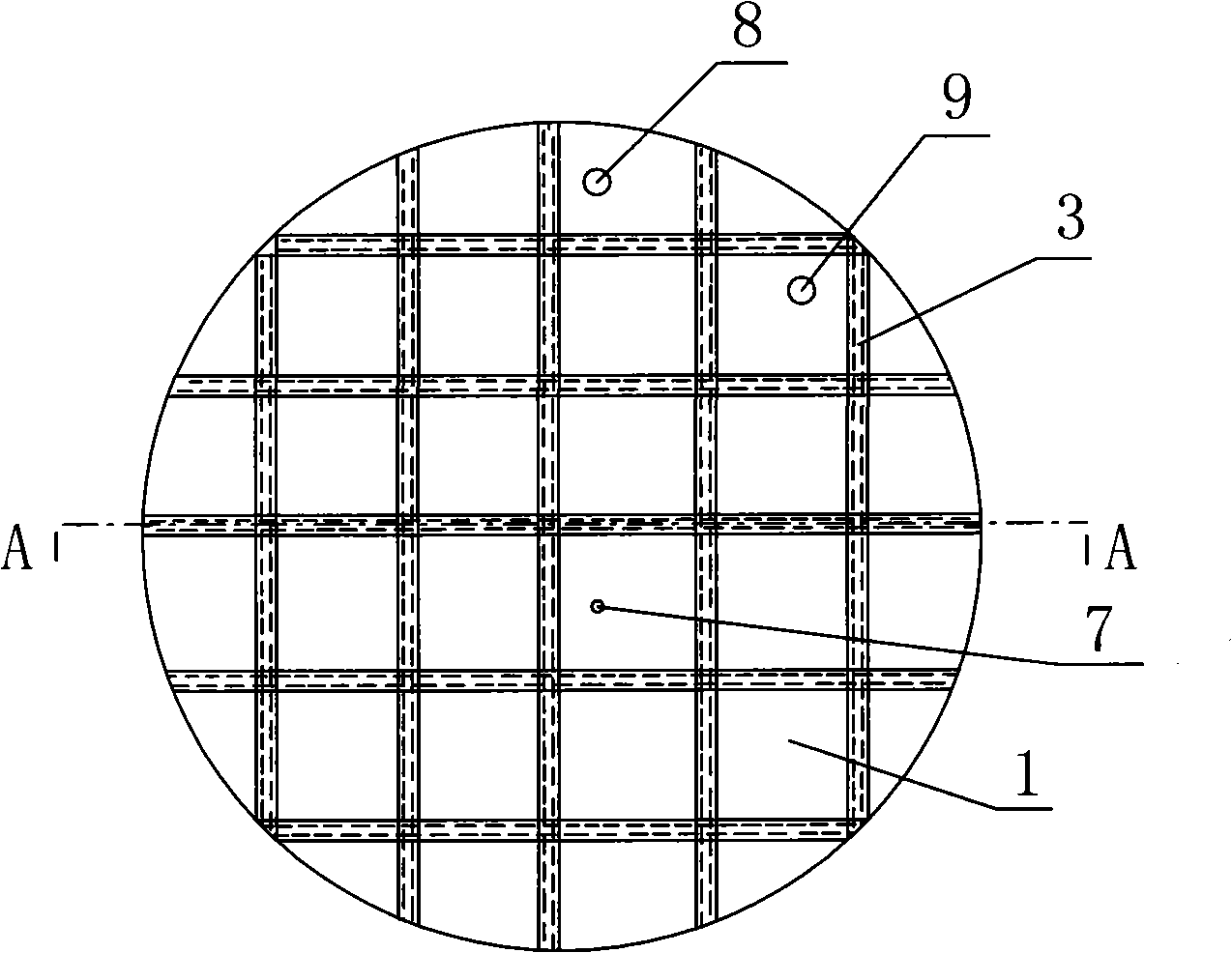

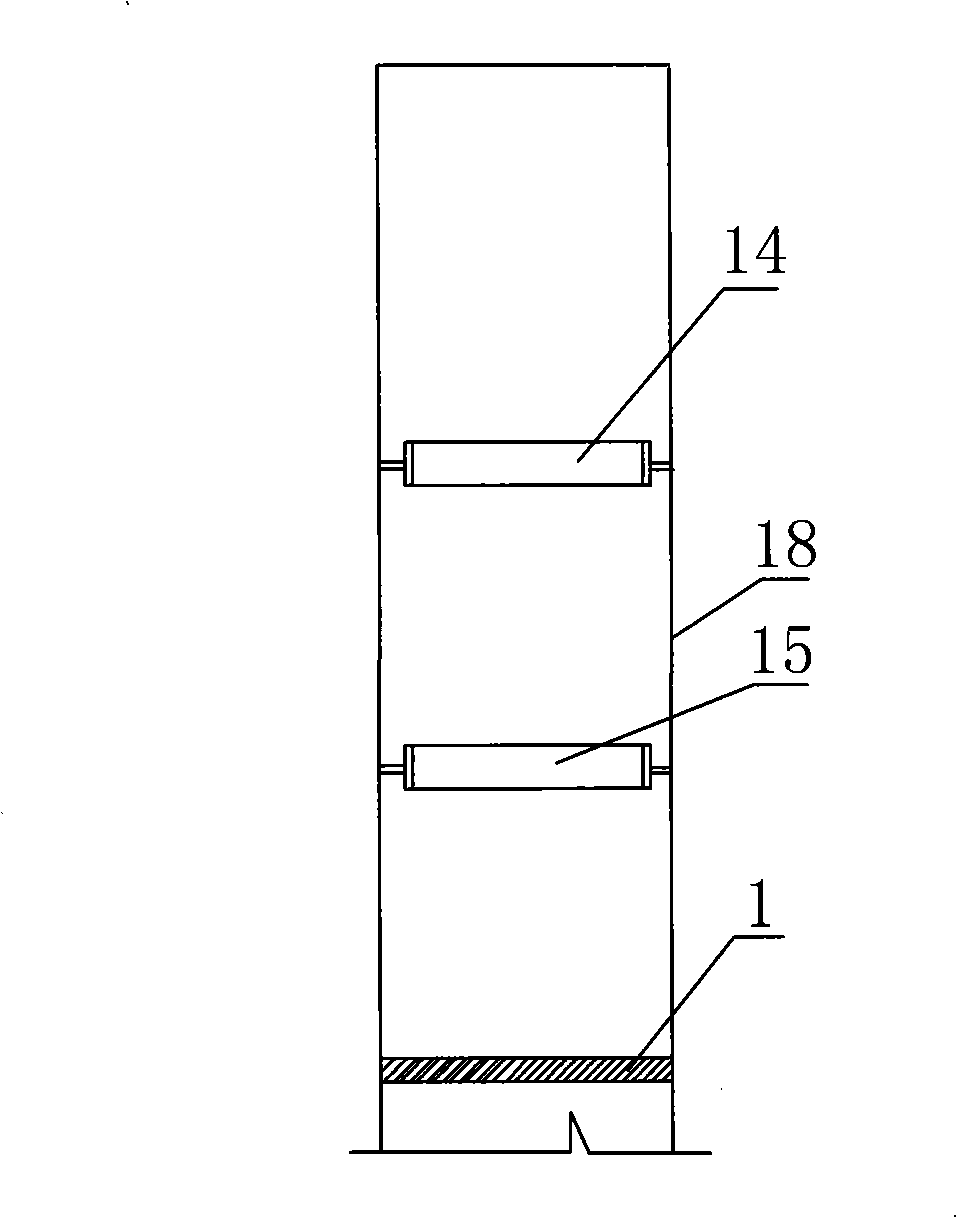

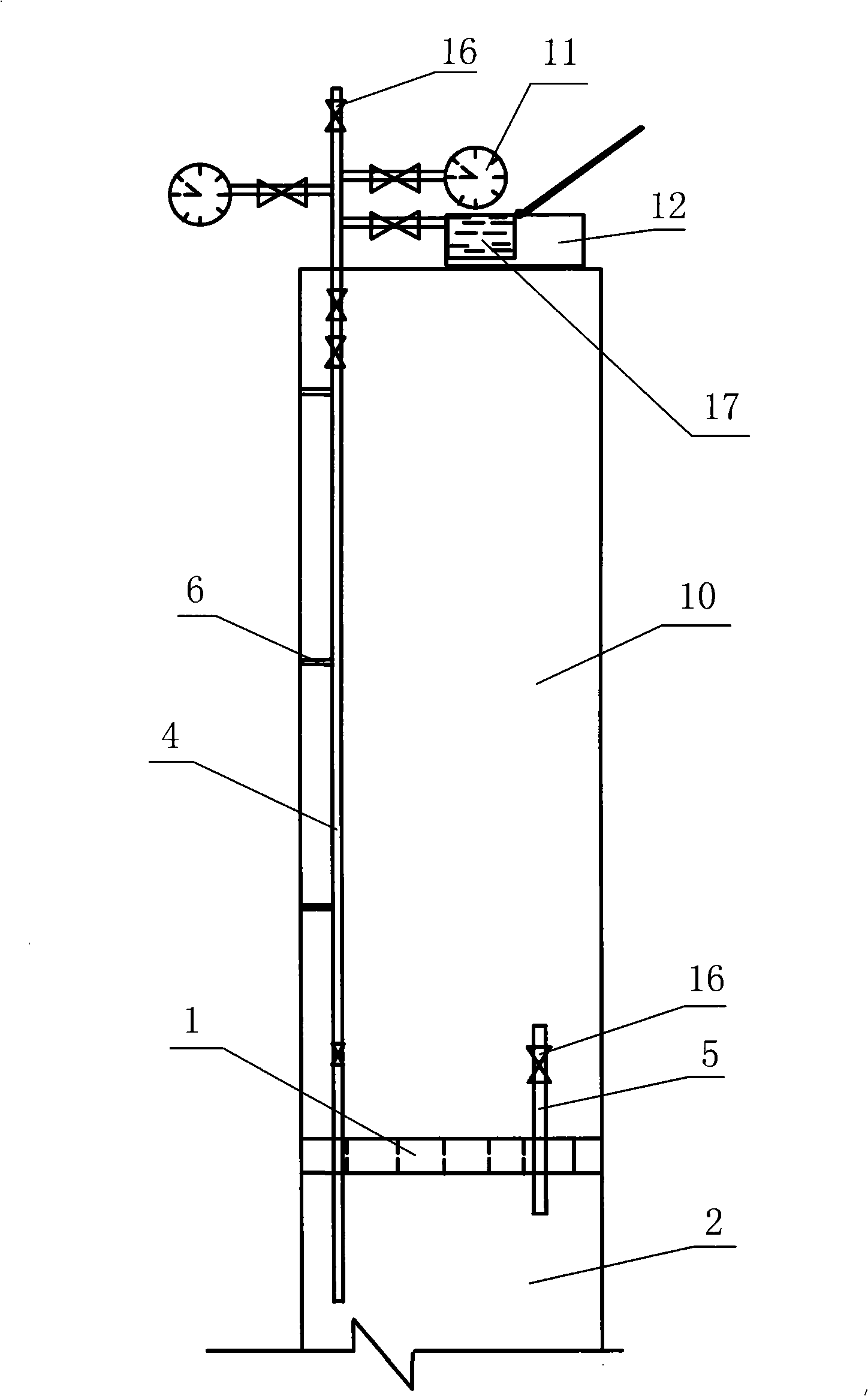

[0050] combine figure 1 , figure 2 , image 3 and Figure 4 , the installation method of a deep well high pressure aeration reactor steel drum of the present invention comprises the following steps:

[0051] The first step, processing and manufacturing the inner partition 1: according to the internal structure and size of the steel drum 18, determine the structure and size of the inner partition 1 installed inside it; Hole 8, exhaust hole 9 and water filling hole 7. In this specific embodiment, the diameter of the steel drum 18 is 3200 mm, the wall thickness is 20 mm, and the depth is 92 m, which is composed of 13 groups of steel drum segments numbered 1-13. The inner partition 1 selected and installed is Q235B steel plate with a thickness of 20mm and a diameter of 3180mm; the diameter of the pressure hole 8 and the exhaust hole 9 set on the inner partition 1 is 20-25mm, and the water supply hole The diameter of 7 is 9-11cm. The surroundings of the inner partition 1 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com