Pi-shaped cross section prefabricated capping beam adopting internal prestressed steel bar and prefabricated method thereof

A technology of pre-stressed tendons and pre-stressed steel bars, applied in bridges, manufacturing tools, ceramic molding machines, etc., can solve the problems of large processing workload of internal molds, non-reusable internal molds, and heavy structural weight, and save construction measures. cost, reduce the difficulty of design and construction, and improve the efficiency of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

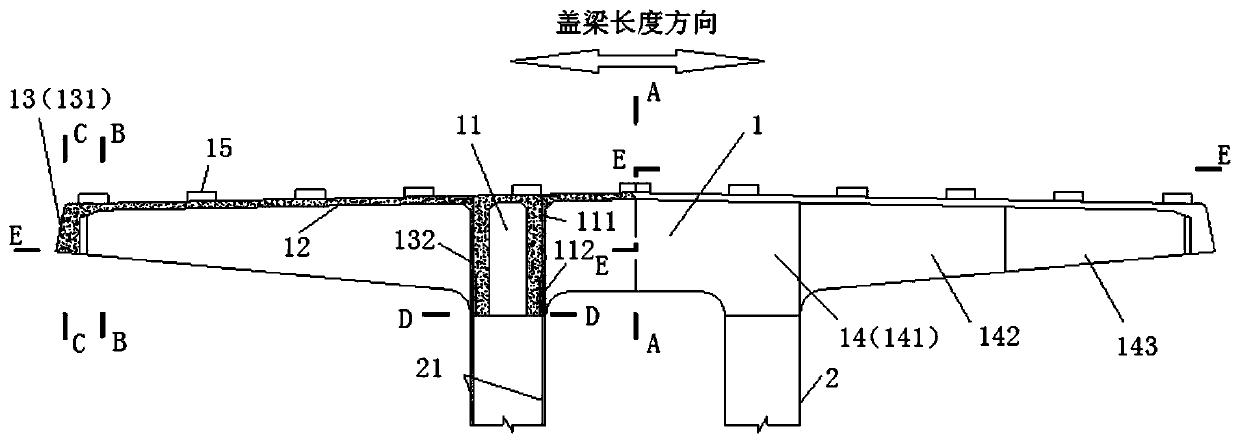

[0051] Such as Figure 1 to Figure 10 As shown, the π-shaped cross-section prefabricated cover beam with prestressed tendons in the body is used. The cover beam 1 is made of UHPC material.

[0052] The cover beam structure is a large cantilever prestressed concrete cover beam with an upper span of 30 meters to 35 meters and a bridge width of 23 meters to 26 meters with a double column pier structure.

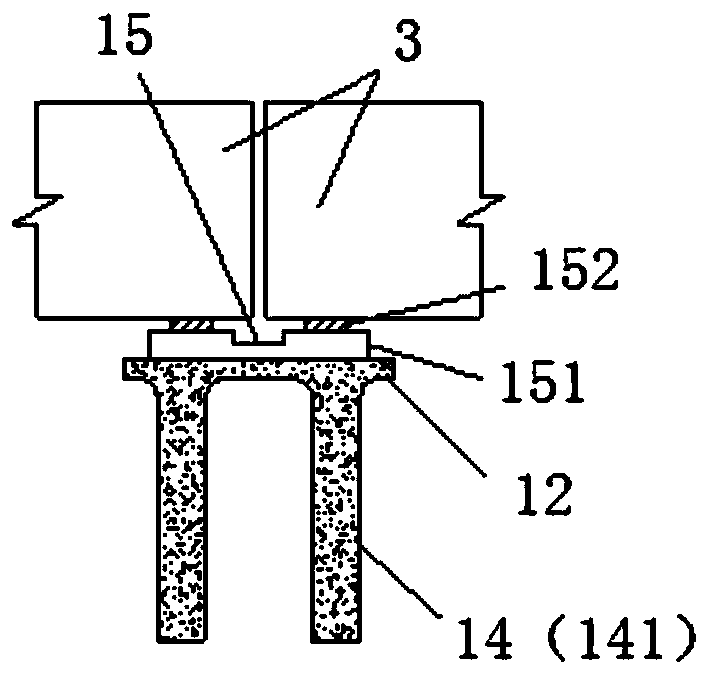

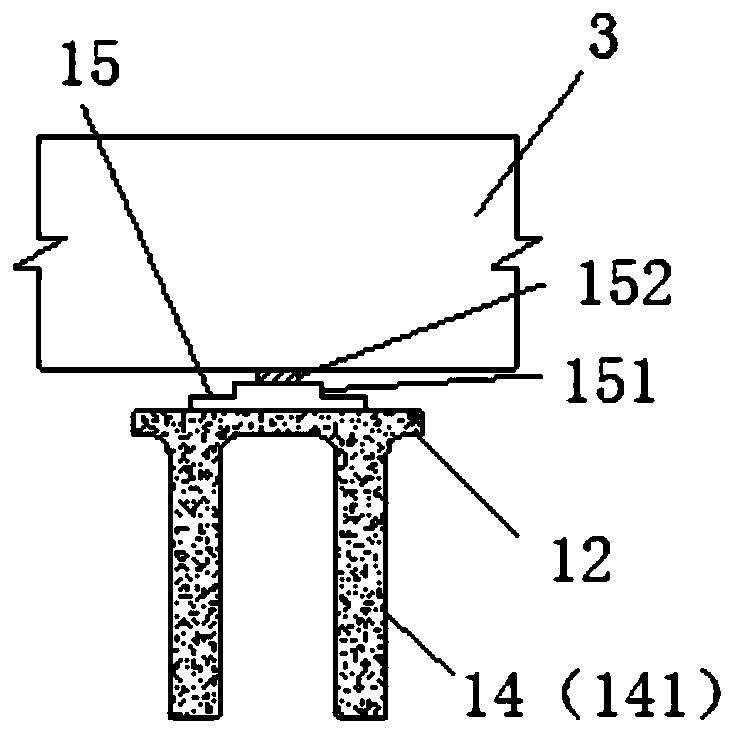

[0053] Wherein, the cover beam 1 includes a top plate 12 arranged horizontally, and two webs 14 vertically arranged under the top plate 12 and parallel to each other;

[0054]Both sides of the top plate 12 extend outward along the horizontal direction, so that the top plate 12 and the two webs 14 form a π-shaped cross-sectional structure with an opening below;

[0055] The total height of the cross section of the cover beam 1 is 1.0m to 2.3m; the total width of the roof 12 is 2.0m to 2.2m, and the thickness is 0.15m to 0.2m; the thickness of the web 12 is 0.2m to 0.35m, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com