Patents

Literature

84results about How to "Reduce the cost of construction measures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

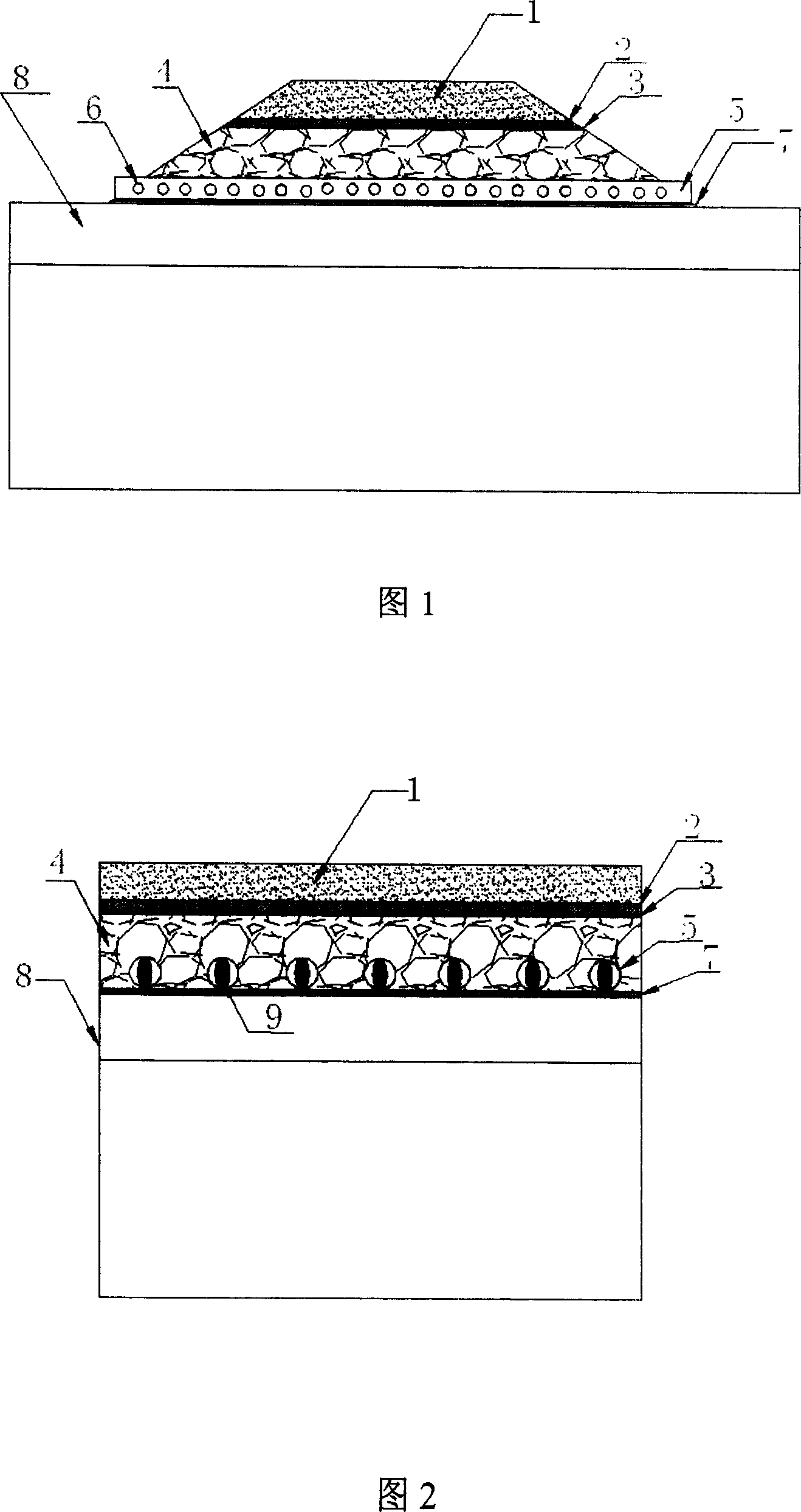

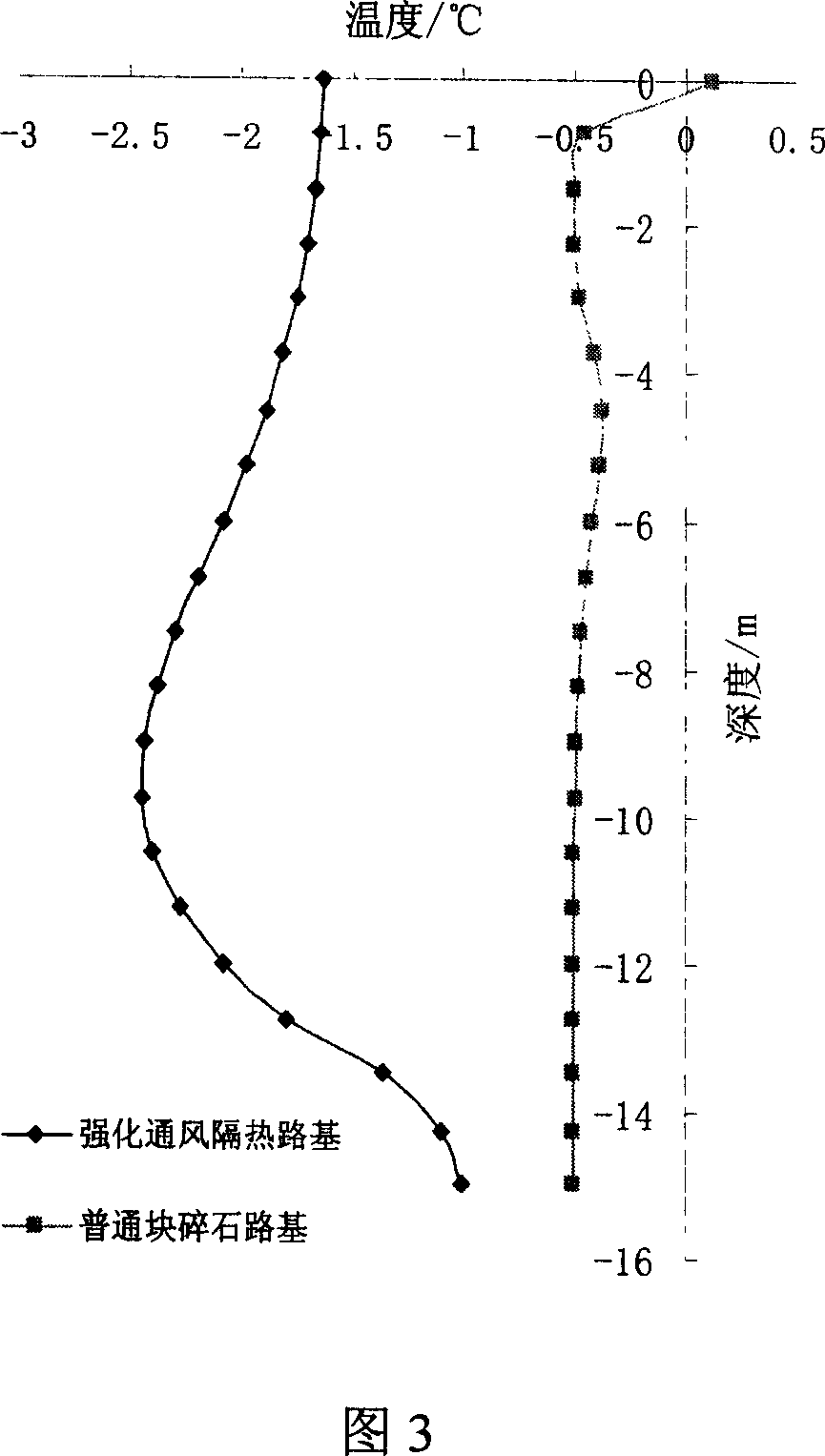

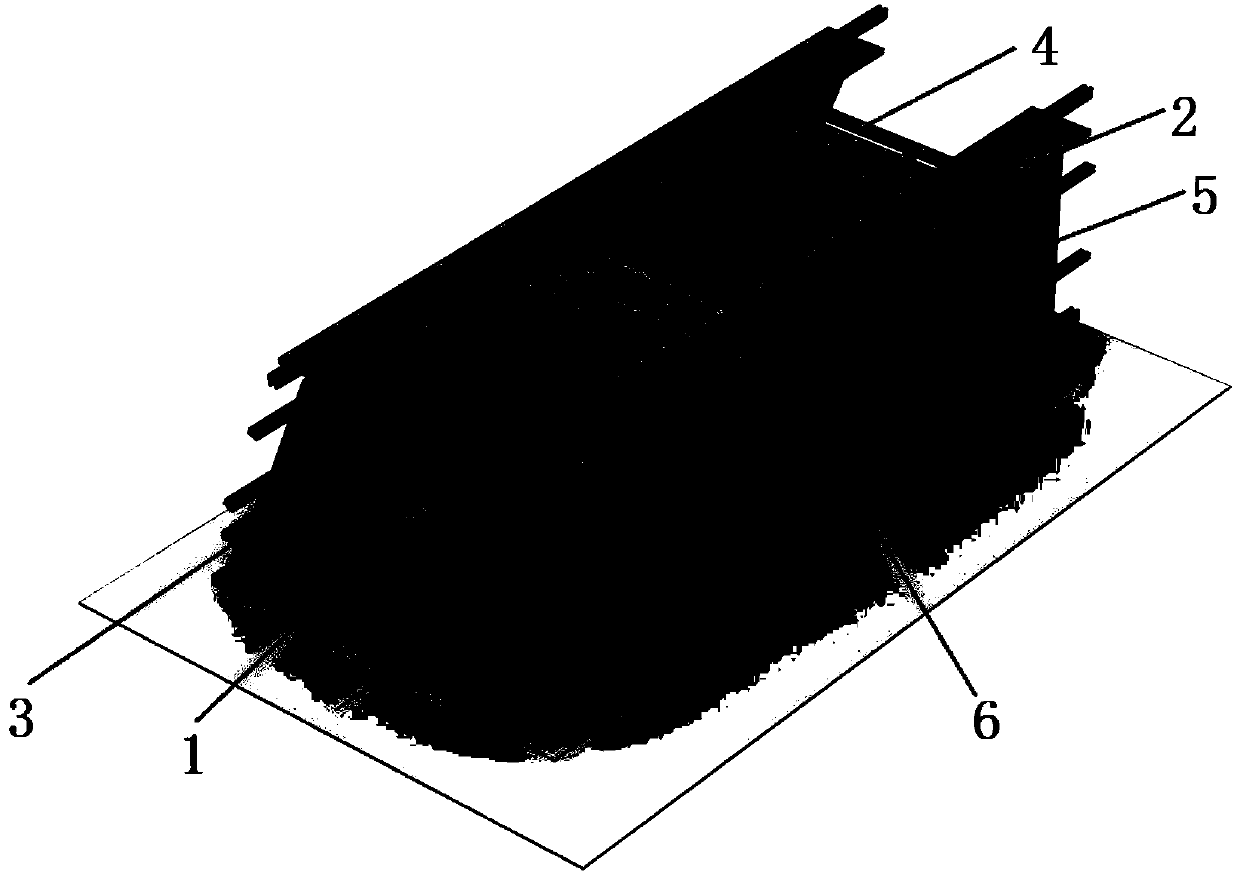

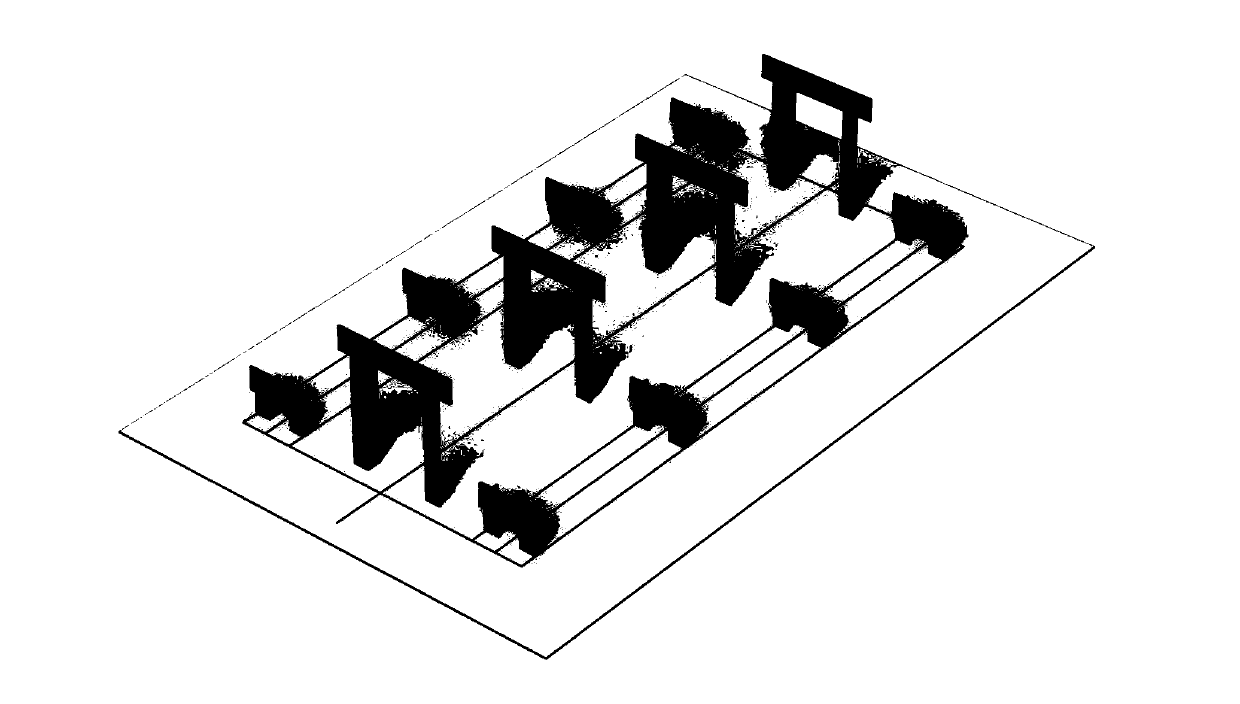

Reinforced ventilating heat-proof foundation

InactiveCN101012632AEnhance ventilation and convection cooling effectStrong ventilation and convection cooling effectRoadwaysCooling effectCrushed stone

The invention discloses a strengthening ventilation heat-insulation roadbed, characterized in that compacting sand-gravel-soil cushion is set on the compacting native surface; transverse concrete air ducts through wall with automatic air door controlled by temperature are set on the sand-gravel-soil cushion in a certain distance; crushed stone layer is set between air ducts through wall and above them; earthwork cloth is put on the horizontal crushed stone layer; heat insulation material is set on the earthwork cloth; and compacting embankment fill is filled on the heat insulation material. In the invention air ducts through wall are set in the crushed stone layer. In winter, by using lower temperature in frozen earth area and bigger wind speed through permeable hole of air duct the effect of convective cooling of air in the crushed stone layer is strengthened and there is strong ventilation cooling effect in air duct through wall itself. Two are combined with each other and are used by each other to decrease the temperature of frozen soil under the roadbed. In summer, the heat insulation material, the crushed stone layer and air duct through wall with air door controlled by temperature can play a role of thermal screen effect so as to prevent heat energy entering into embankment. At last storing cooling energy to the utmost is achieved; the temperature of frozen soil is decreased, the melting of frozen soil is avoided and the stability of embankment of frozen soil is ensured.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

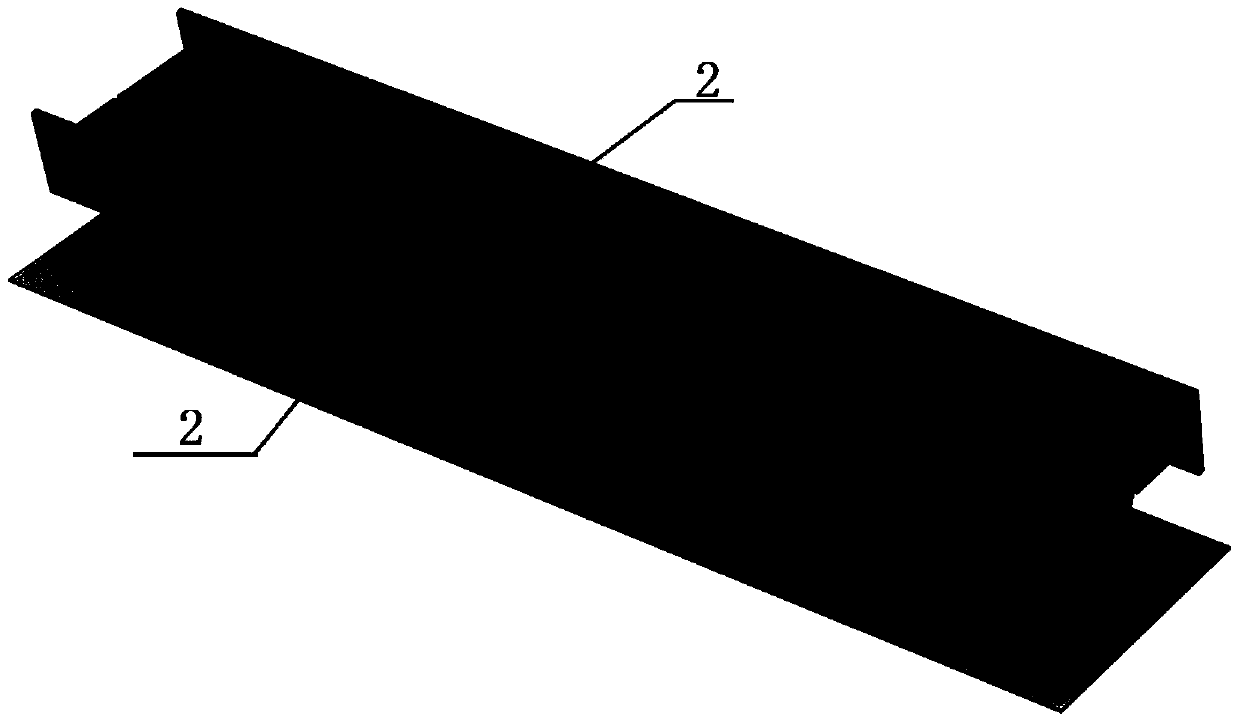

Ultra-large type combined H-section steel column and manufacturing method thereof

ActiveCN104196166AGuaranteed bearing capacityNovel structural designStrutsPillarsManufactured materialStructural engineering

The invention discloses an ultra-large type combined H-section steel column. The ultra-large type combined H-section steel column comprises two I-section steels and a connecting web; the two I-section steels are respectively arranged at two sides of the connecting web, and the section is of an H shape after installation; the upper end face of the connecting web and the I-section steels at two sides form a concave structure, a stiffening plate is arranged along the concave structure, and a reinforcing rod is arranged on the stiffening plate. Meanwhile, the invention further provides a manufacturing method of the steel column. According to the steel column and the manufacturing method thereof disclosed by the invention, when the bearing capacity of the post is ensured, the structure of the column is maximally simplified, raw materials are saved, the cost is saved, the manufacturing process is simple, the installation precision can be ensured, the effective usable area of a building is increased, the gravity of the structure is reduced, and the seismic response of the structure is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

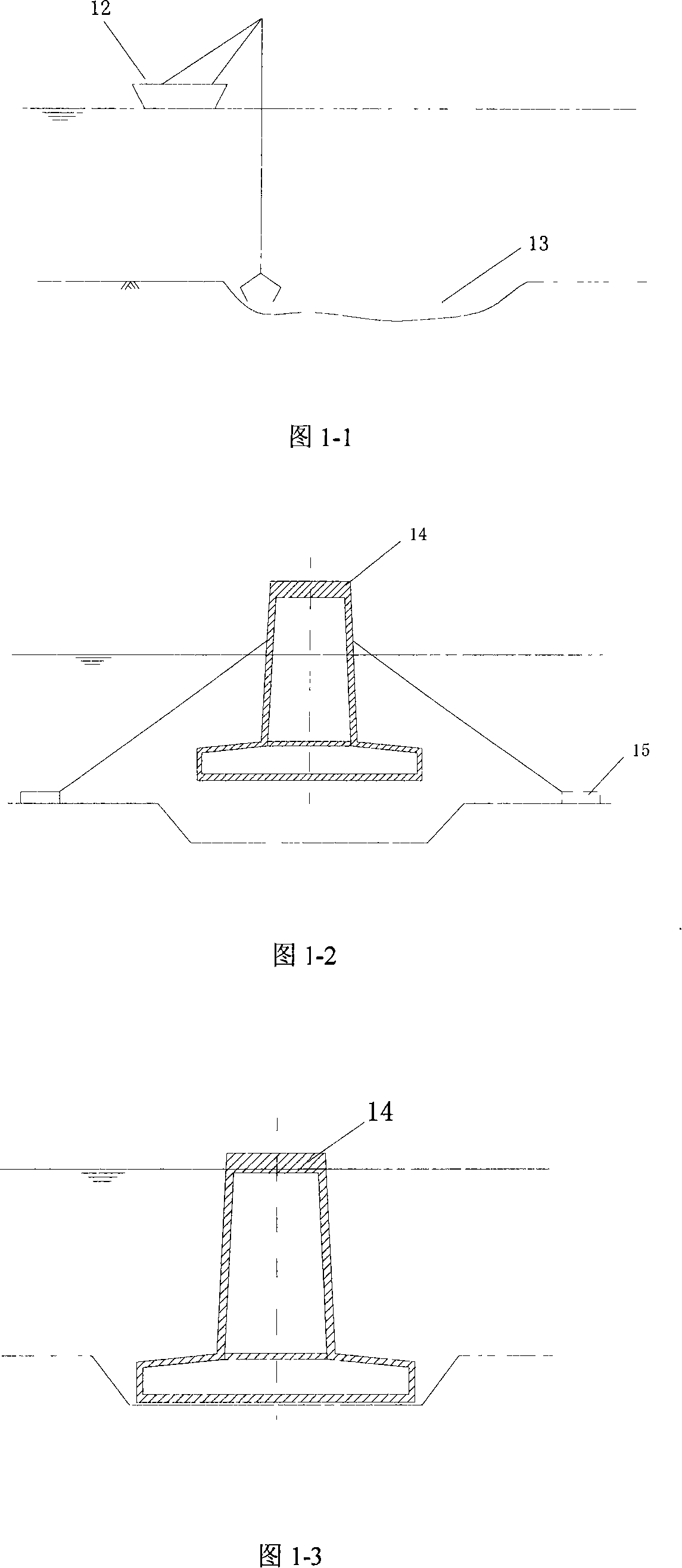

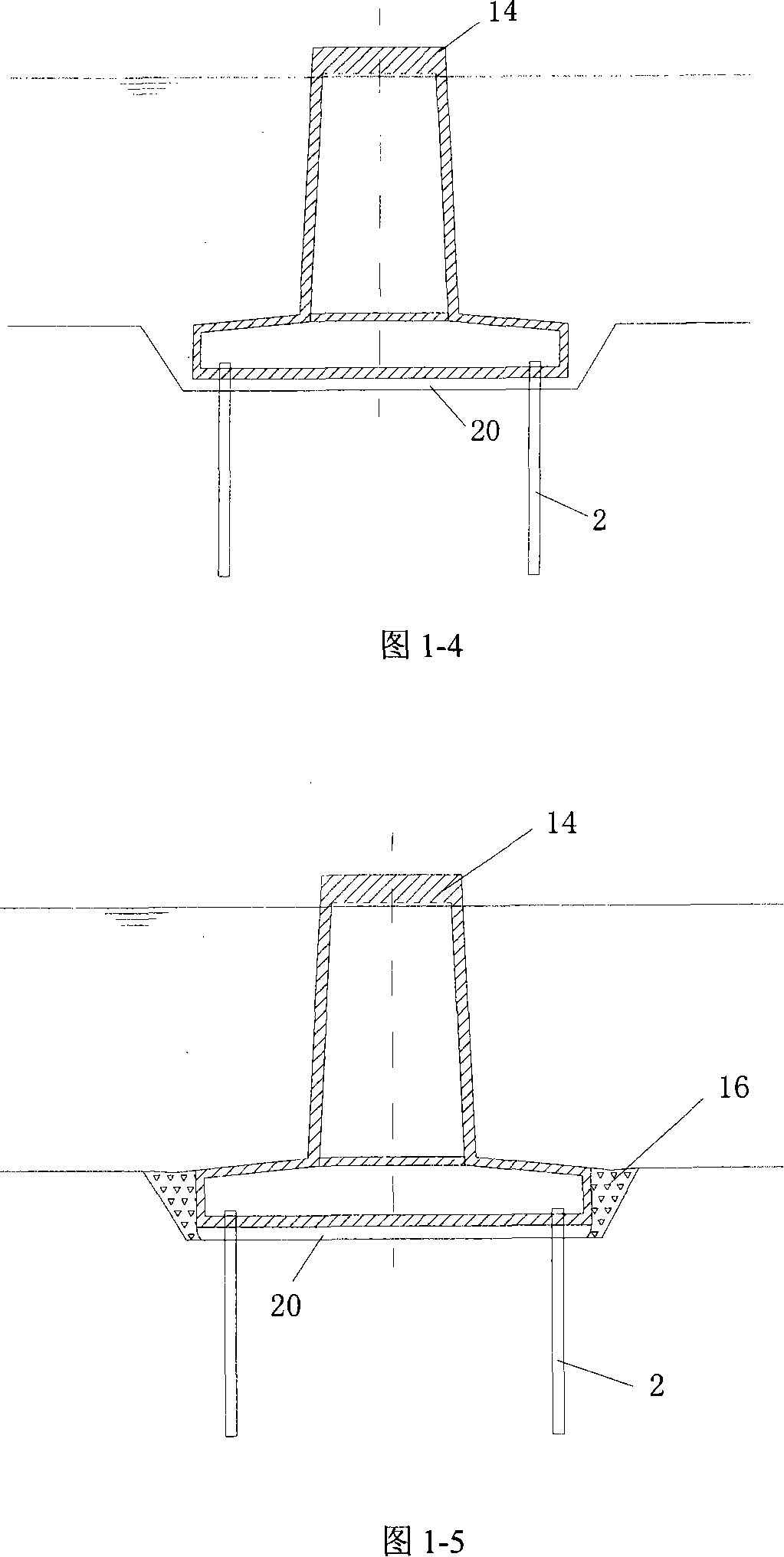

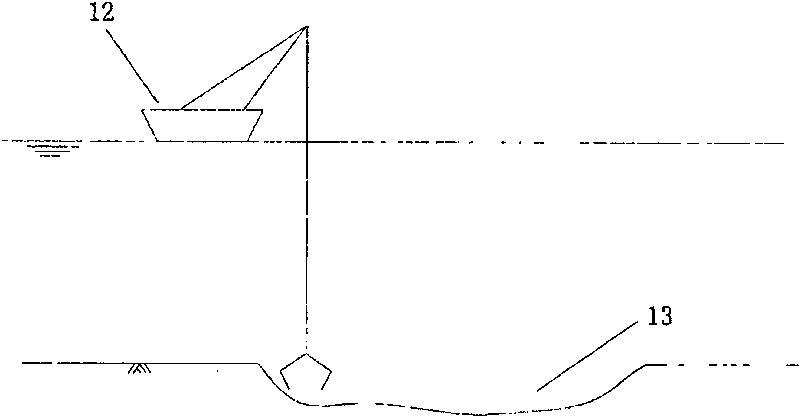

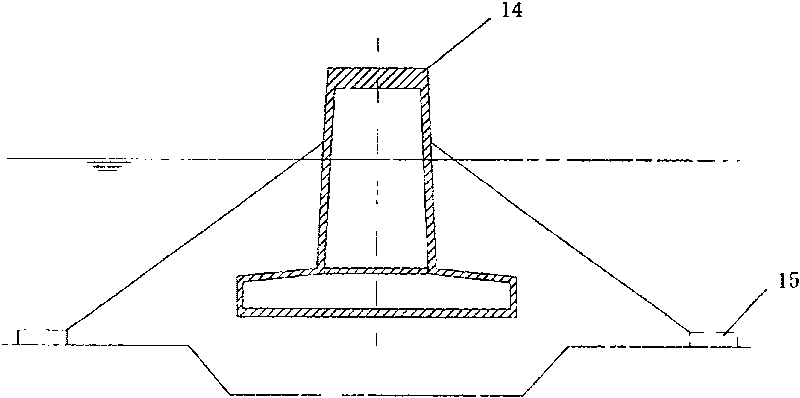

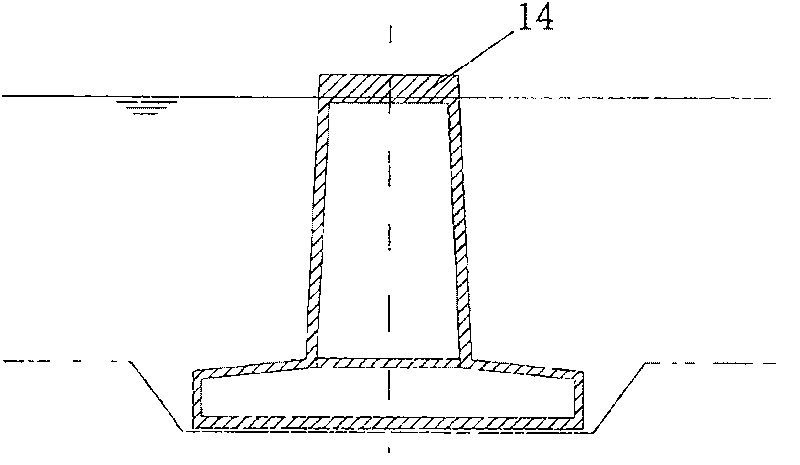

Bridge caisson composite pile foundation and reverse construction method thereof

The present invention discloses one kind of composite bridge caisson pile foundation and its reverse construction process. After the bridge caisson is sunk to site, piling construction is performed inside the caisson to form pile with upper part connected to the caisson integrally and to constitute composite caisson pile foundation. The construction process includes the steps of prefabricating caisson in land, floating the caisson and setting the caisson in dredged sea bed, driving steel pipe pile through the pre-formed hole in the bottom of the caisson through operation inside the caisson, performing the upper structure construction simultaneously, pouring concrete to connect the bottom plate of the caisson with the steel pipe pile. The present invention has the load borne commonly by the caisson and the pile, and is suitable for bridge construction in deep sea and soft soil foundation.

Owner:CCCC HIGHWAY CONSULTANTS +1

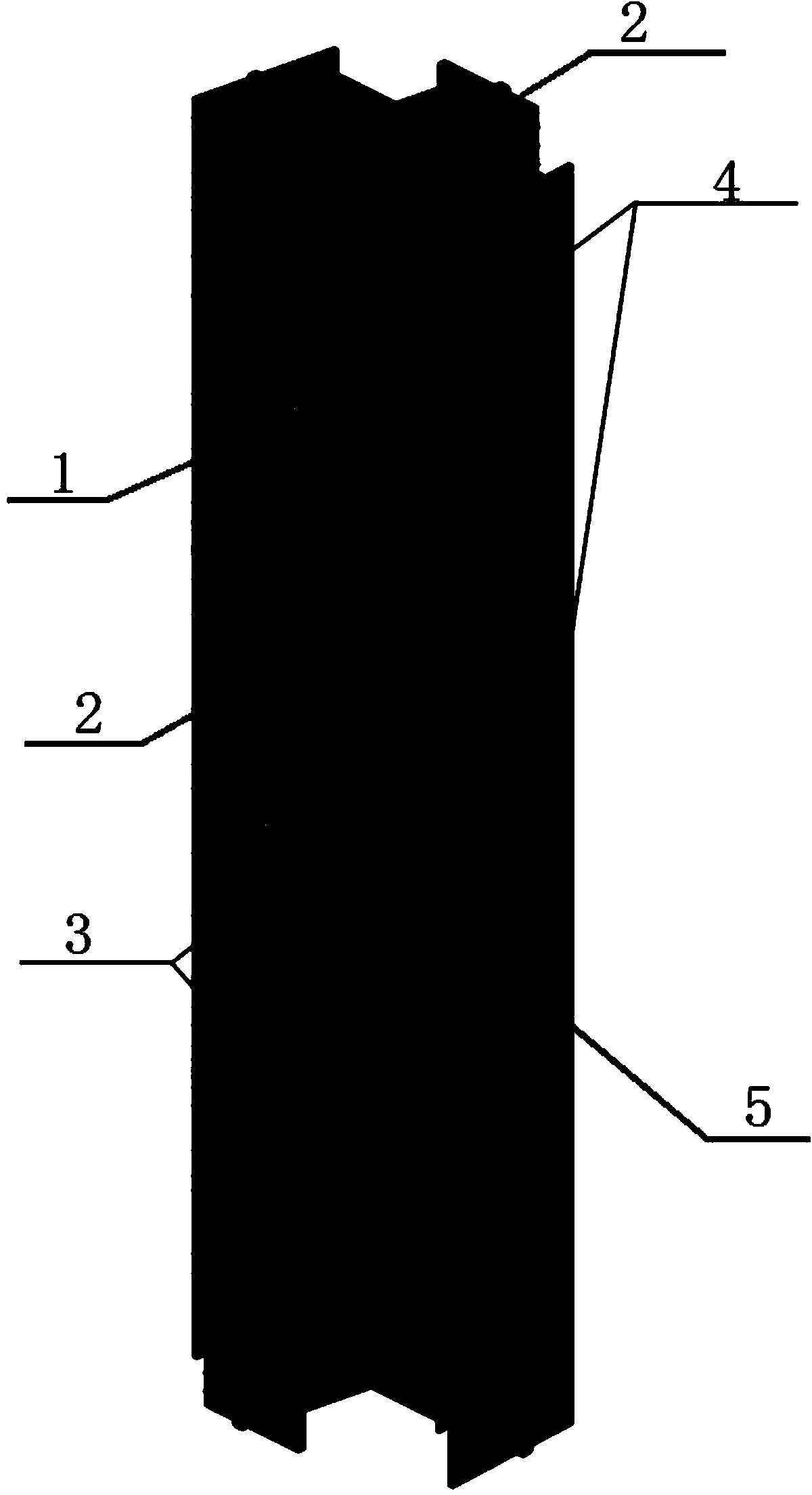

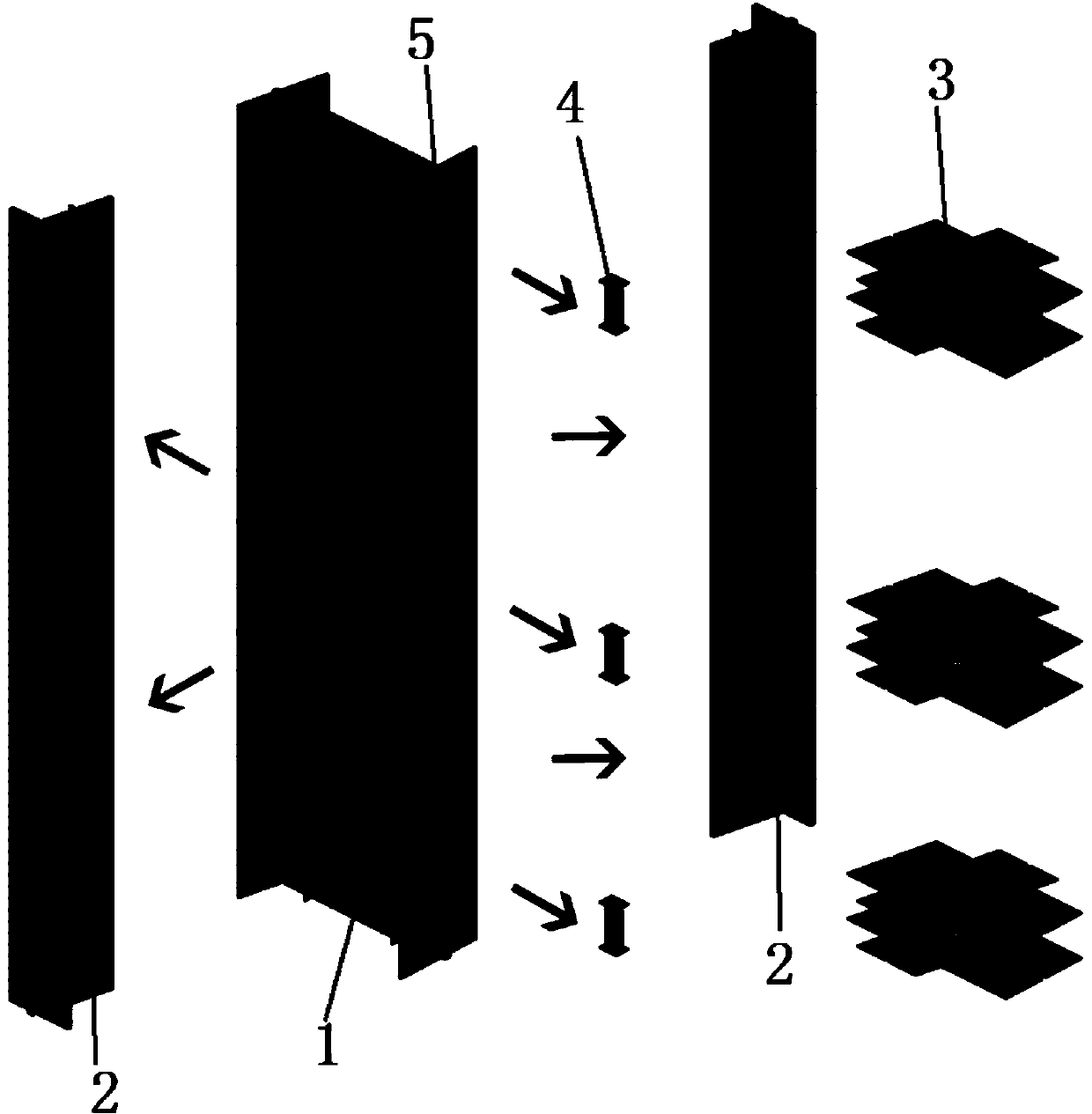

Giant cruciform combination column and manufacturing method thereof

ActiveCN104196164AGuaranteed bearing capacityNovel structural designStrutsMilling equipment detailsCruciformMechanical engineering

The invention discloses a giant cruciform combination column which comprises two pieces of T-shaped steel and a pieces of I-shaped steel, wherein the T-shaped steel is mounted at two sides of the I-shaped steel so as to form a cruciform column body structure with side plates; the upper part, the middle and the lower part of the column body structure are respectively provided with two layers of stiffening plates; studs are arranged on the side plates of the column body structure; corbels are arranged at the parts, connected with the stiffening plates, of the I-shaped steel. The invention further discloses a manufacturing method of the giant cruciform combination column. Based on the giant cruciform combination column and the manufacturing method thereof, the structure of the column is simplified to a maximum extent while the load-bearing capacity of the column is ensured, the raw materials and the cost are saved, and the effective usable area of a building is increased; the self-weight of the structure is reduced, and thus the structural seismic response is reduced.

Owner:JIANGSU HUNING STEEL MECHANISM

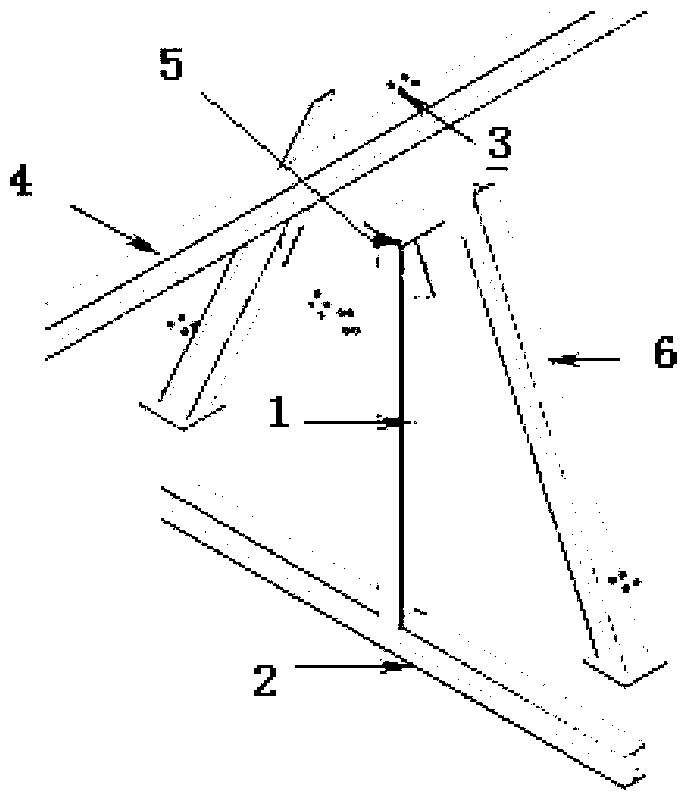

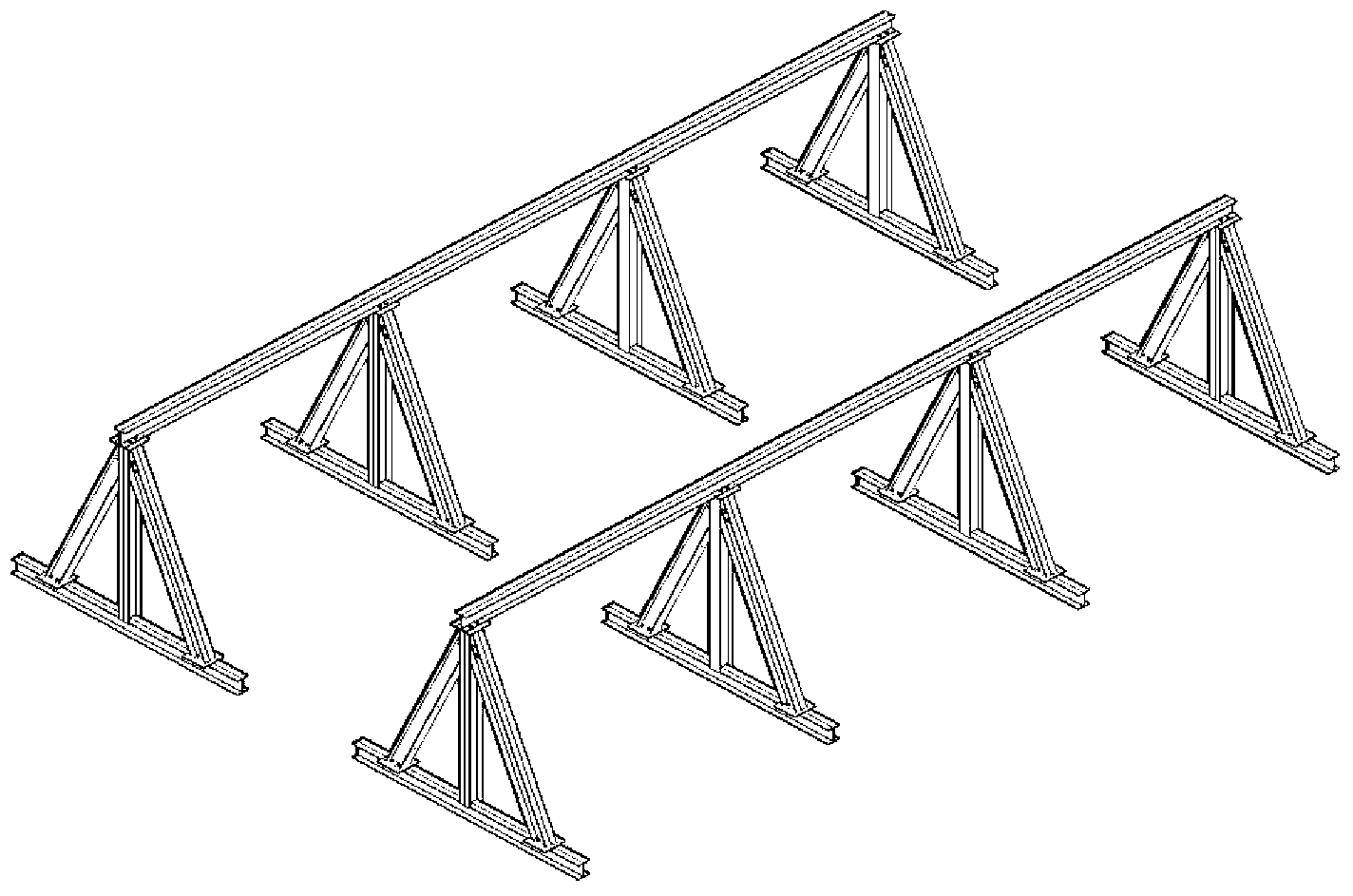

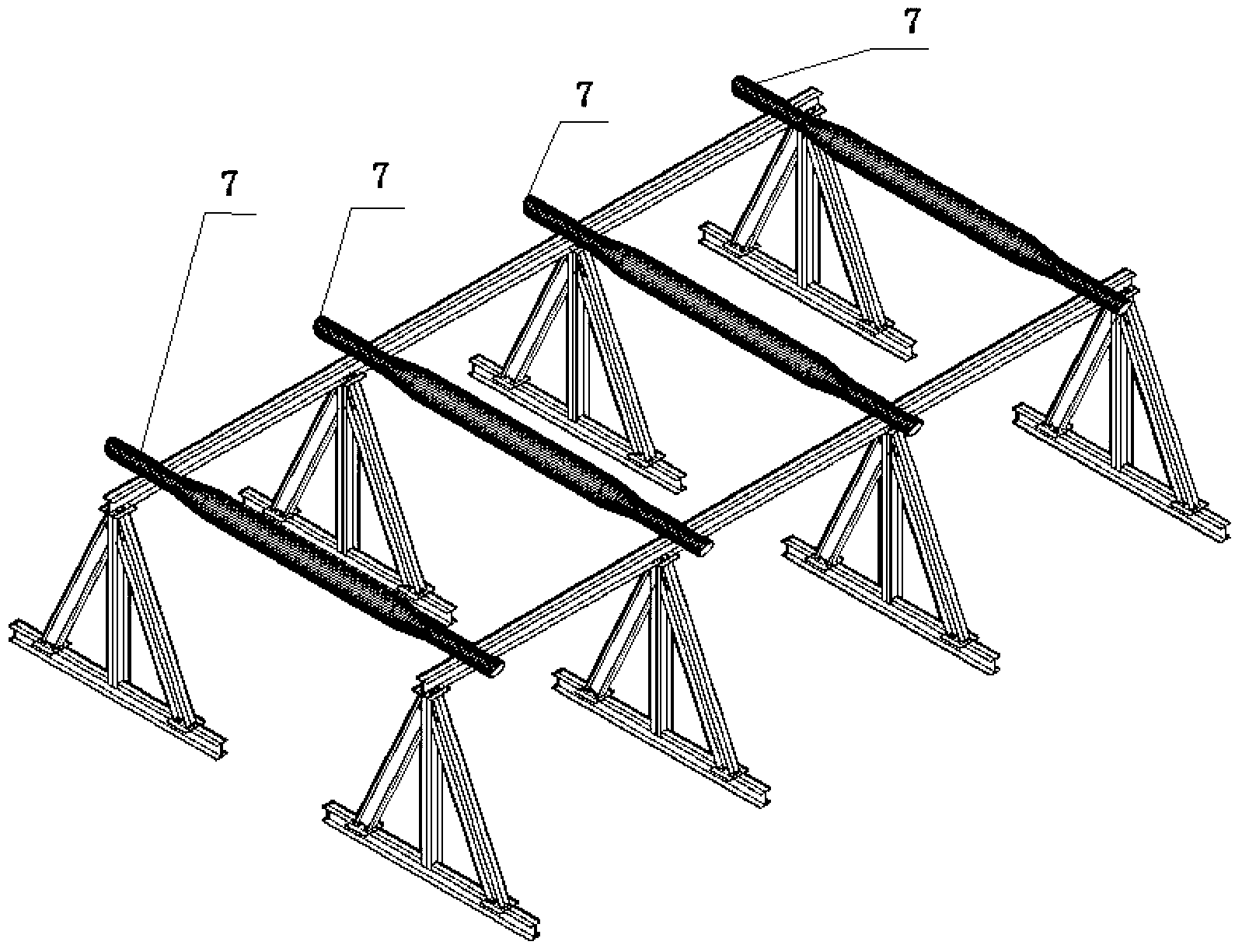

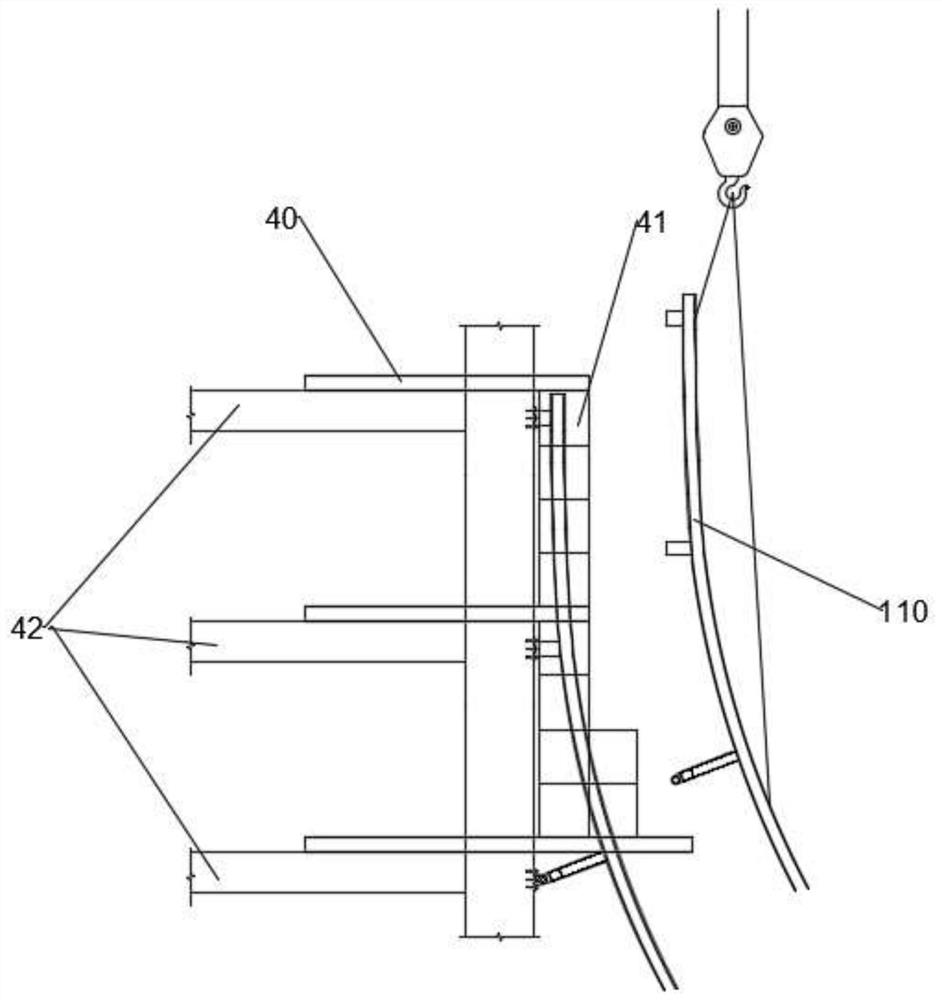

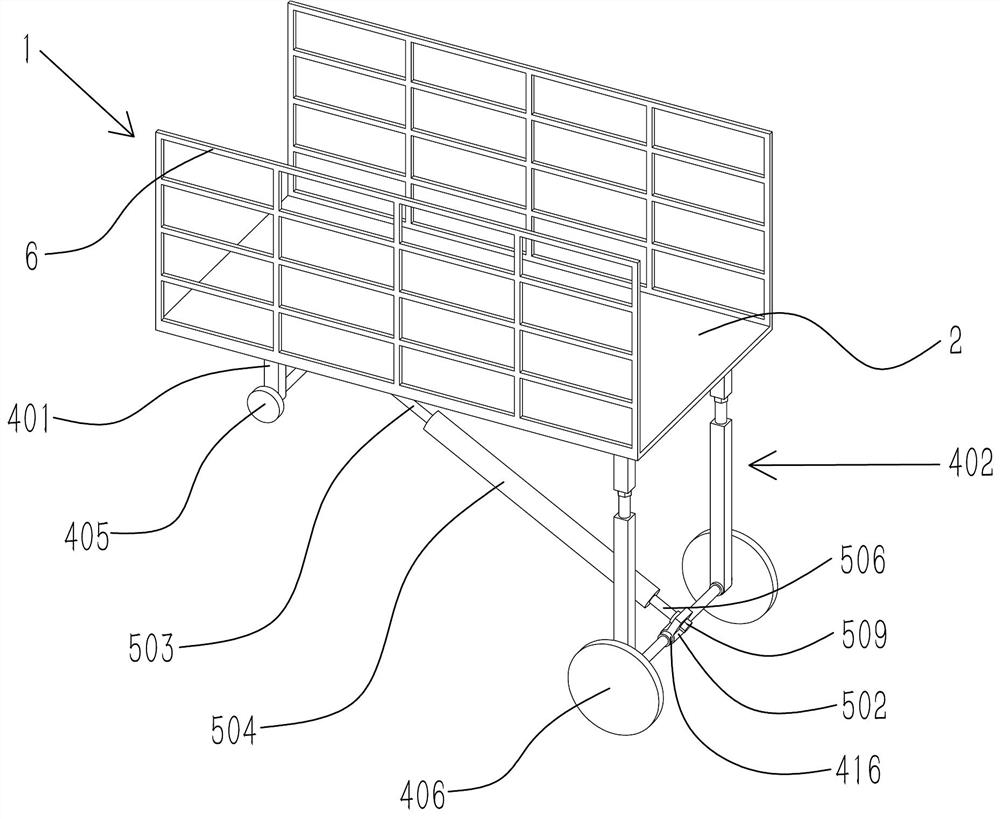

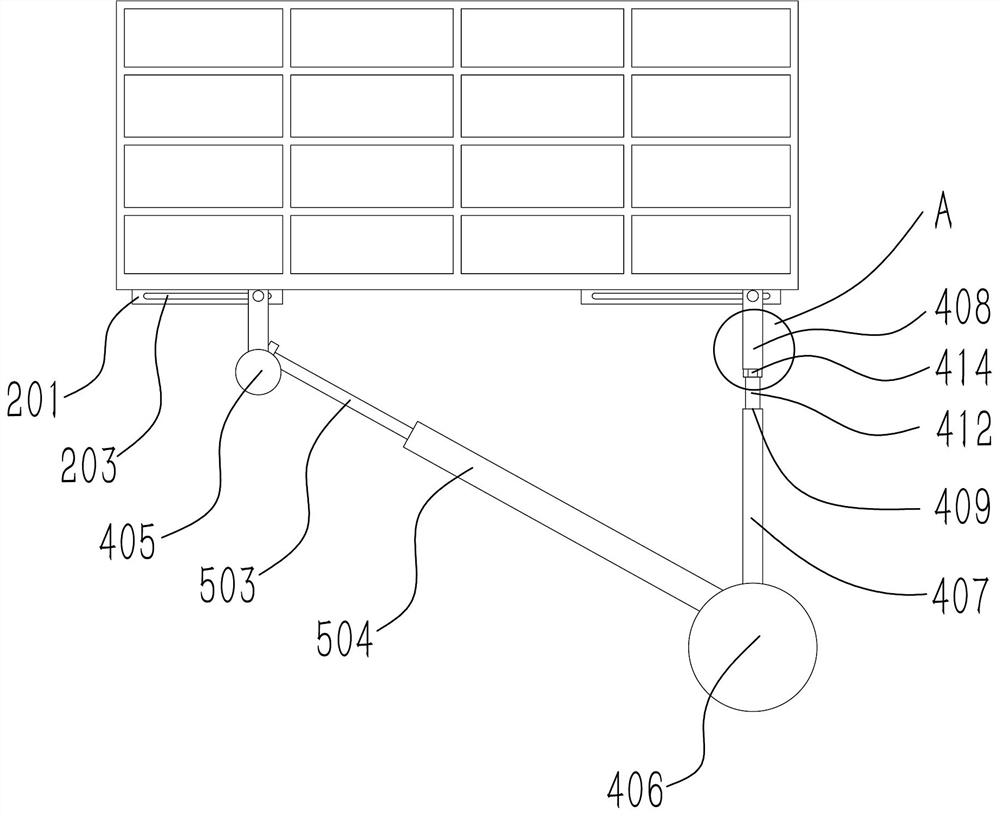

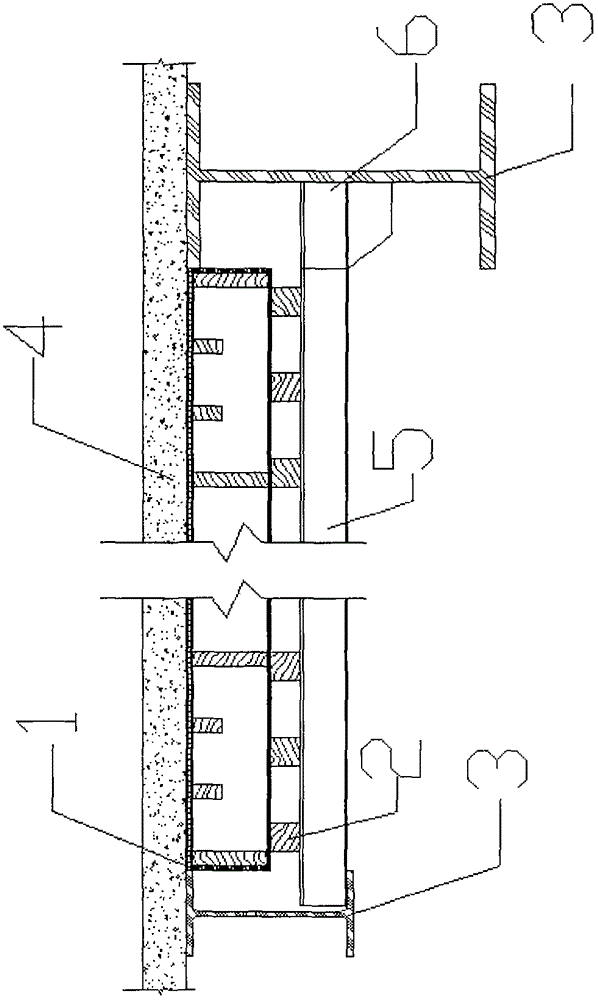

Detachable triangular scaffold and steel truss assembly construction method

InactiveCN103266778AMaintain stabilityEnsure stabilityBuilding material handlingShoresClassical mechanicsAssembly (construction)

The invention provides a detachable triangular scaffold and a steel truss assembly construction method. The scaffold is of a triangular connected structure, and comprises main vertical rods, bottom cross rods, top steel beams, connecting plates, diagonal rods, bolts and the like. The rods are connected by the bolts in a positioning manner, and positioning holes are reserved at the top of each steel beam and used for controlling the axis position of a steel truss. The detachable triangular scaffold is capable of achieving on-site repeated assembling of ultrahigh ultra-wide steel members, and can be widely applied to the field of steel structure assembly construction.

Owner:北京城建精工钢结构工程有限公司

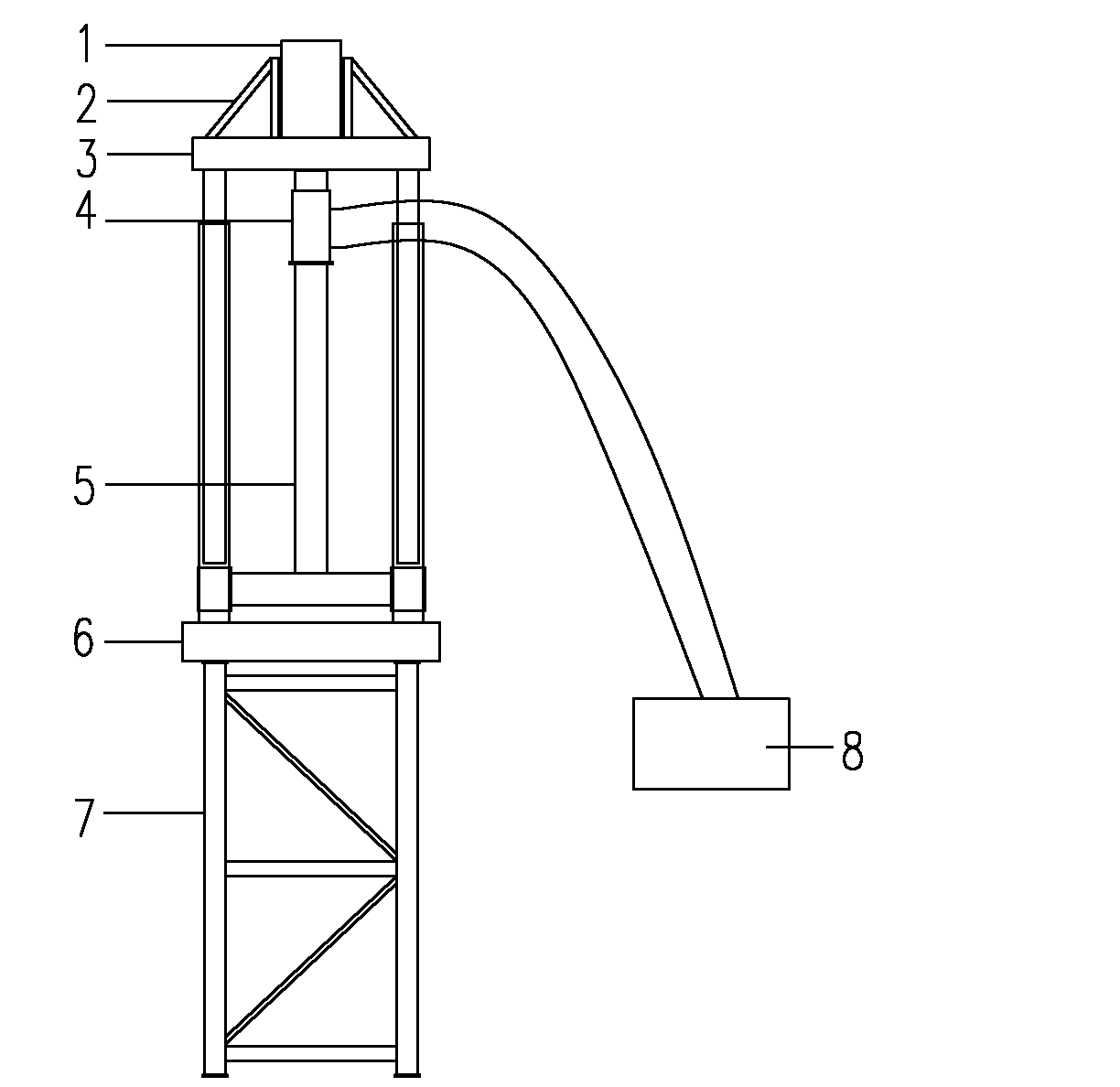

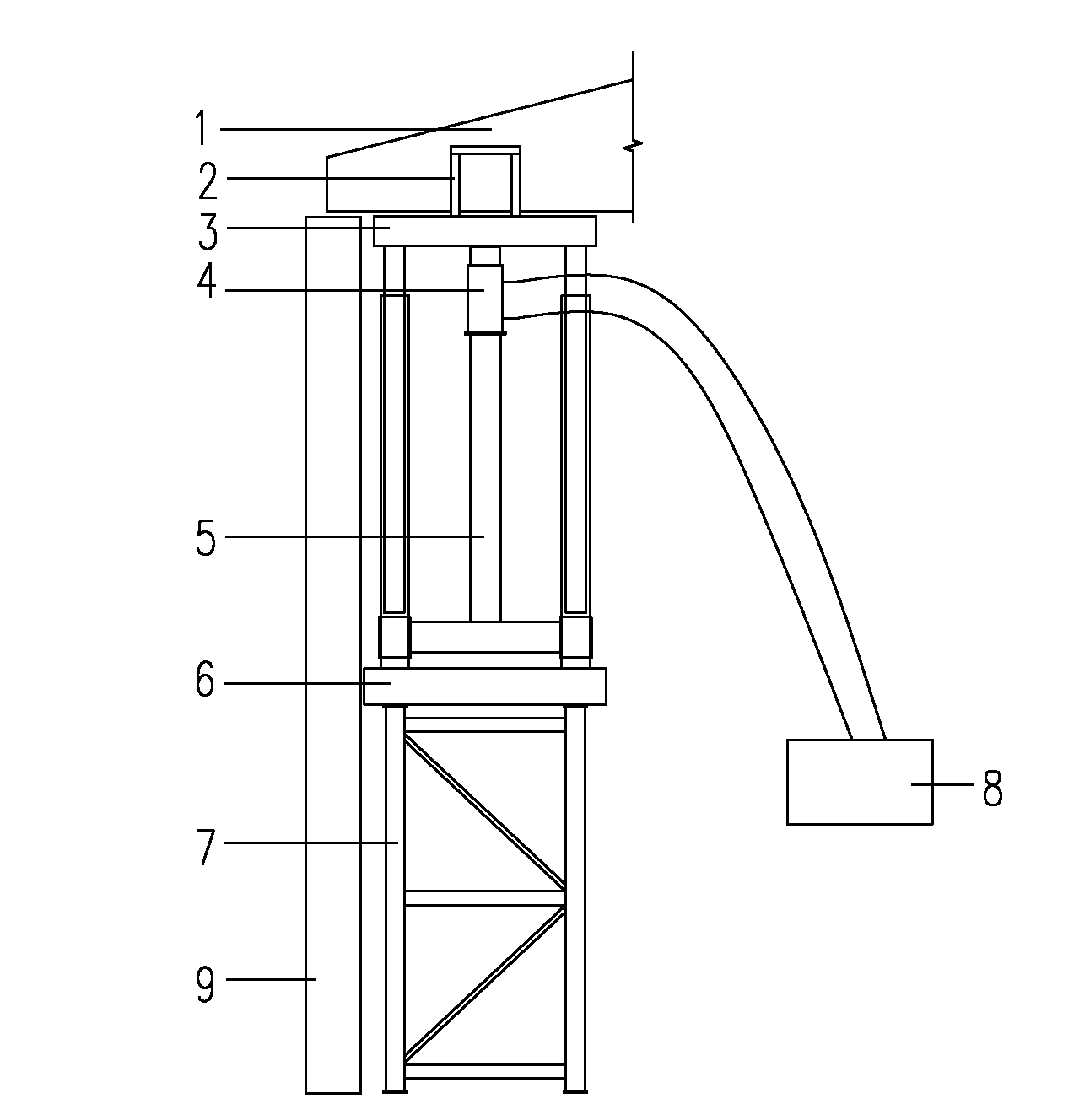

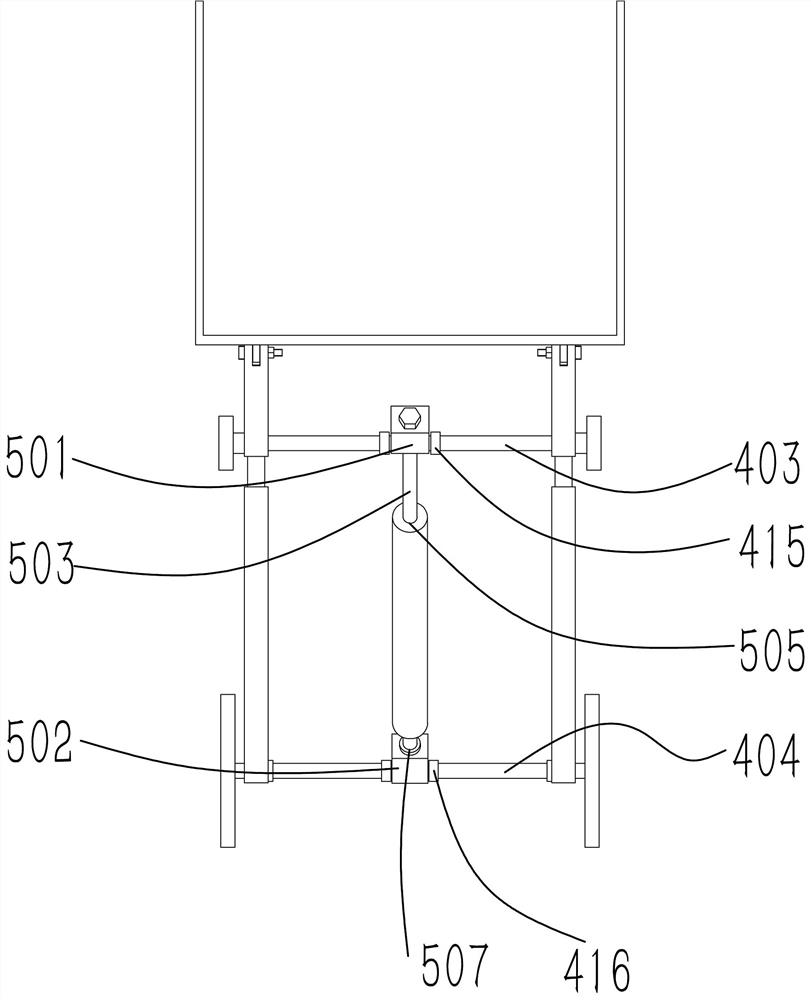

Device and construction method for overall lifting of single-story industrial factory roof

The invention relates to a device for integrally jacking a roof of a single-layer industrial factory building. The device is characterized by comprising three parts, namely a jacking device, a vertical force transfer device and a synchronous control device, wherein the vertical force transfer device is arranged on the ground of the factory building; and the jacking device is fixed above the vertical force transfer device and is connected with the synchronous control system. The construction method comprises the following steps of: enabling an upper section of an adjustable steel support column to be positioned in a freely-retractable state; fixing an inverted T-shaped counterforce cross beam, starting the synchronous control system and jacking a conventional shot-travel hydraulic jack to one travel height; fixing the upper section of the adjustable steel support column to enable the inverted T-shaped counterforce cross beam to be positioned in a freely-retractable state, starting the synchronous control system, retracting the jack and upwards hoisting the inverted T-shaped counterforce cross beam to be a travel height; and repeating the step (1) and the step (2) until an original roof frame beam is jacked to the designed elevation and realizing integral jacking of the roof of the single-layer industrial factory building. In the jacking process, an inserting pin of the adjustable steel column and an inserting pin at the end part of the counterforce cross beam are extracted out or inserted into conveniently and quickly by just arranging constructors according to the sequenceof jacking cycle.

Owner:HOHAI UNIV +1

Steel-structure-polyurethane-material underground pipe gallery or working well

ActiveCN105239599ALow costRealize factory productionArtificial islandsUnderwater structuresUltimate tensile strengthWall plate

The invention discloses a steel-structure-polyurethane-material underground pipe gallery or working well. The steel-structure-polyurethane-material underground pipe gallery or working well comprises pipe gallery units. Each pipe gallery unit is defined by steel-structure polyurethane wall plates. Each steel-structure polyurethane wall plate comprises two wall plate bodies arranged in parallel, wherein a steel structure is located between the two wall plate bodies, and the portion, on the periphery of the steel structure, between the two wall plate bodies is poured with polyurethane concrete. Two end openings of the one or more pipe gallery units are plugged to form the steel-structure-polyurethane-material underground working well. The multiple pipe gallery units are connected end to end to form the steel-structure-polyurethane-material underground pipe gallery. Intensity is higher, installing and construction are more convenient and rapider, the water resistance is better, the service life is longer, and the multiple purposes are achieved.

Owner:陈培军

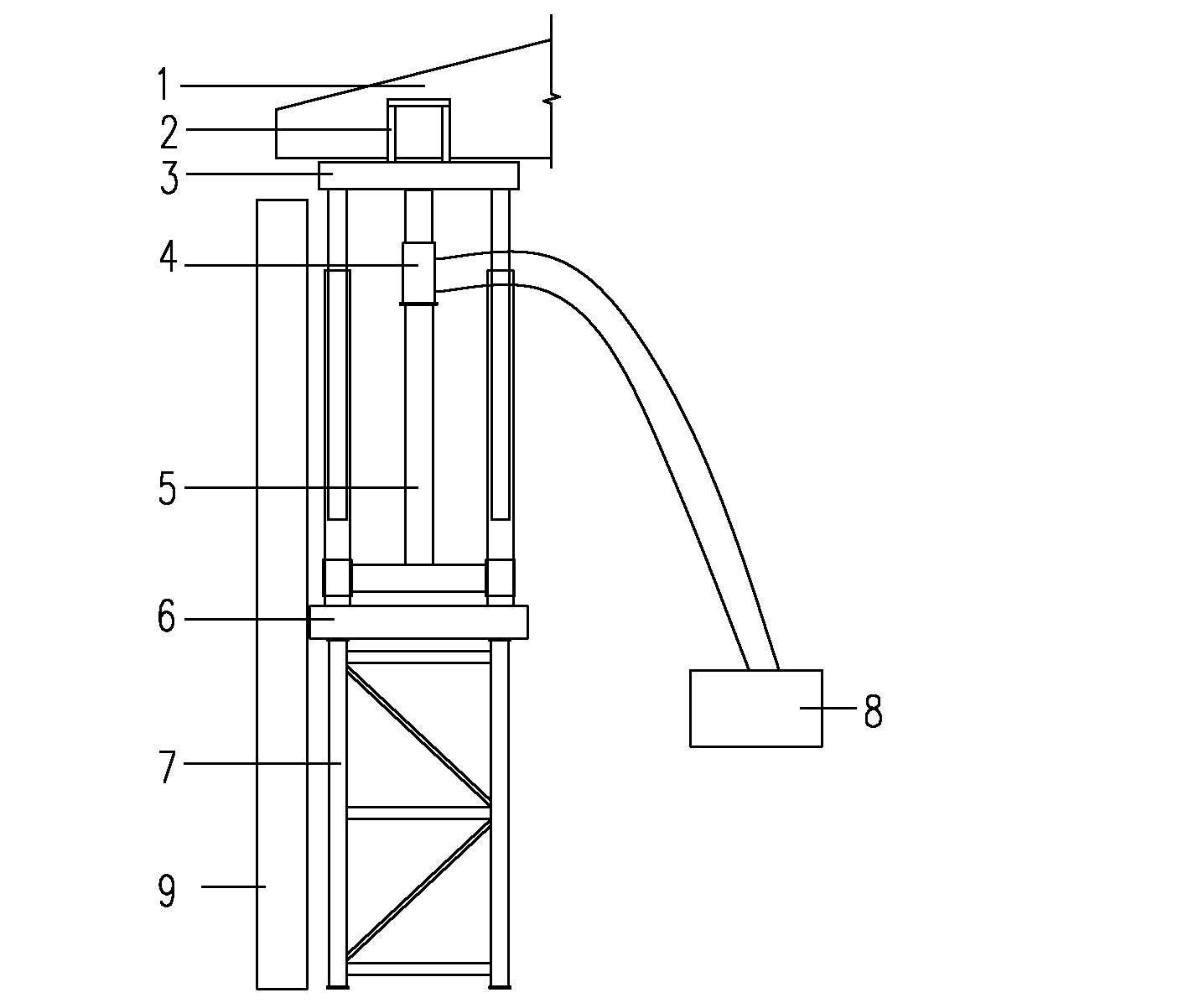

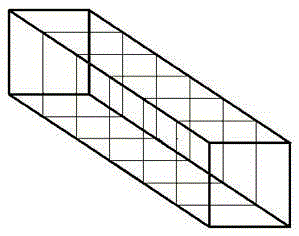

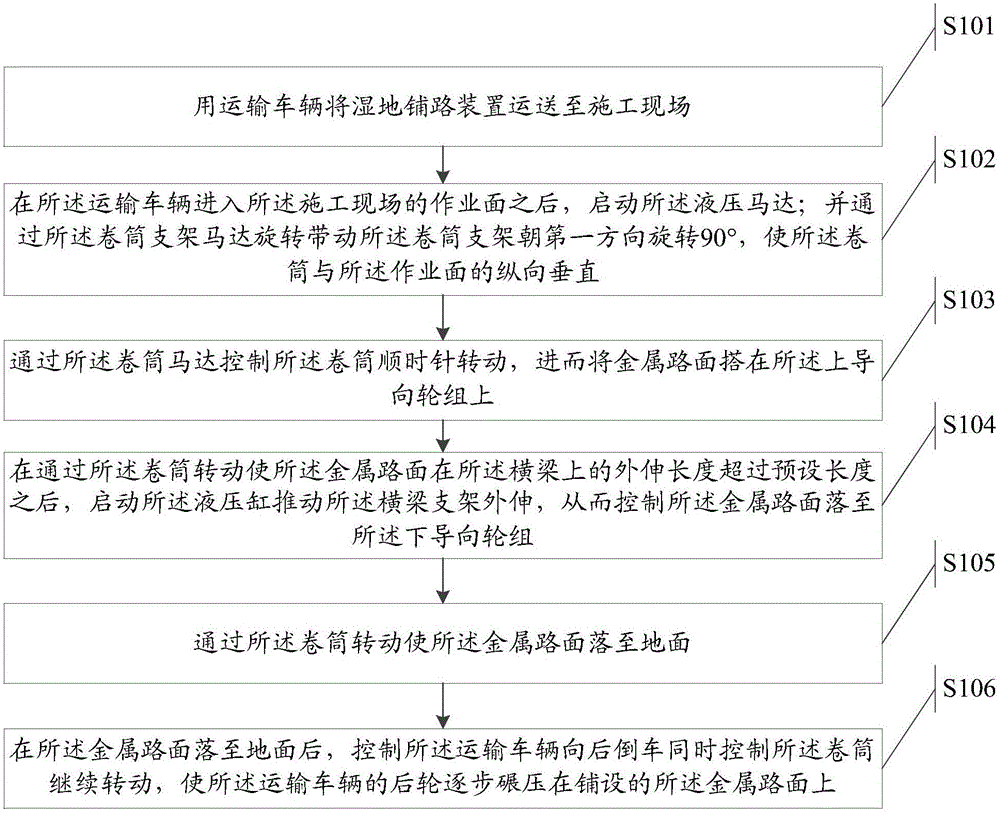

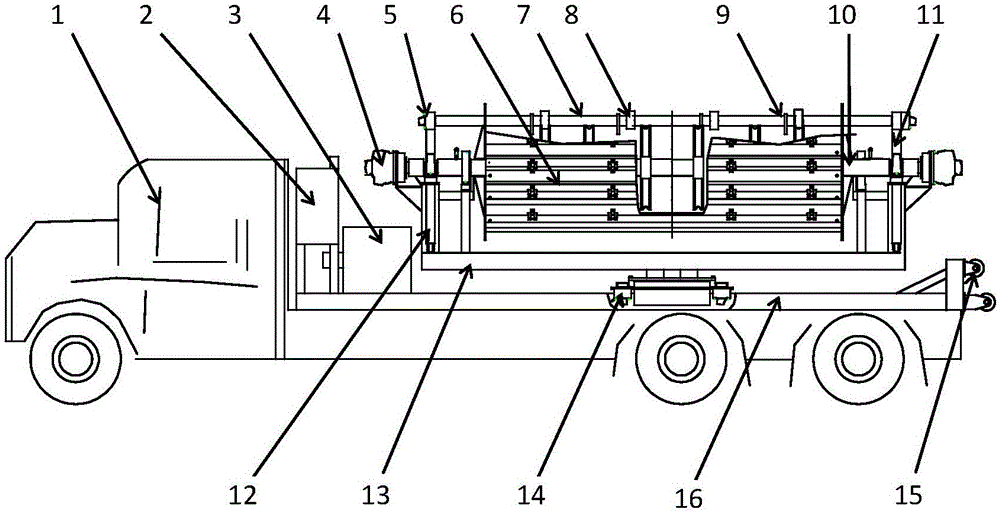

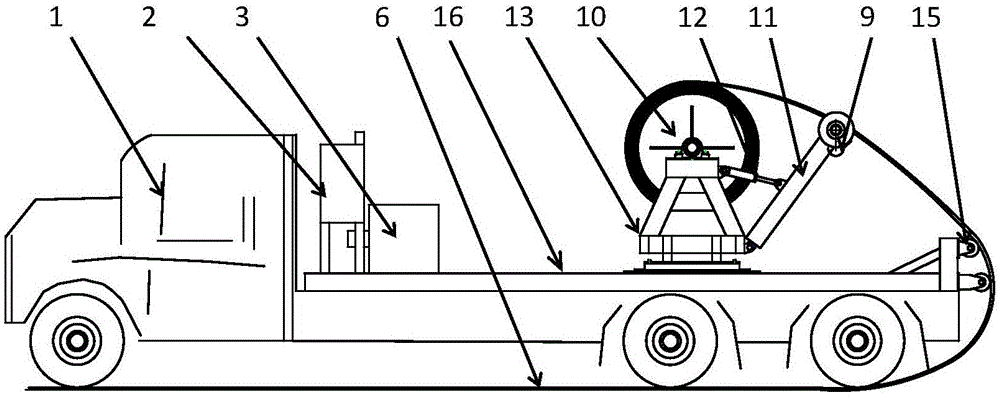

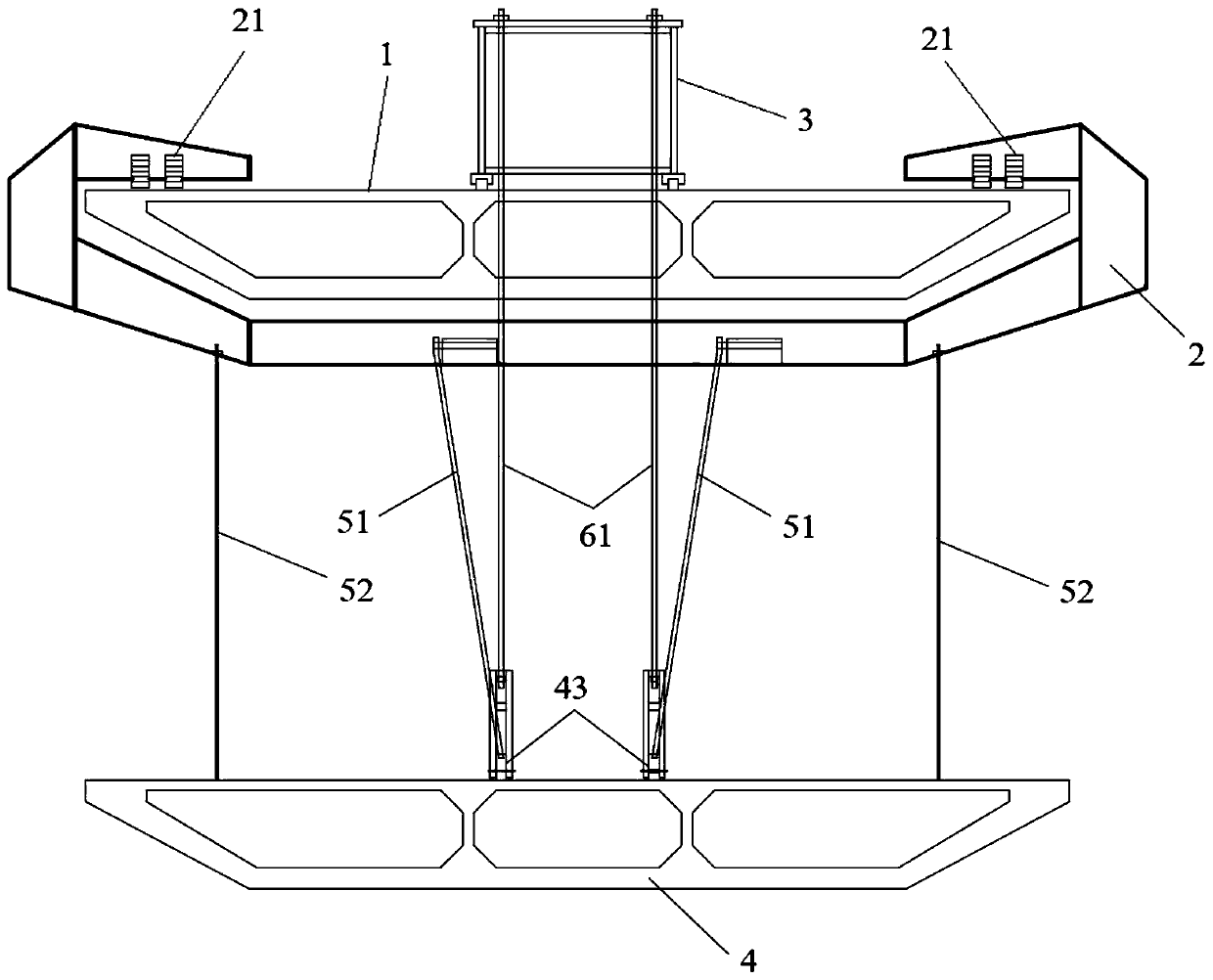

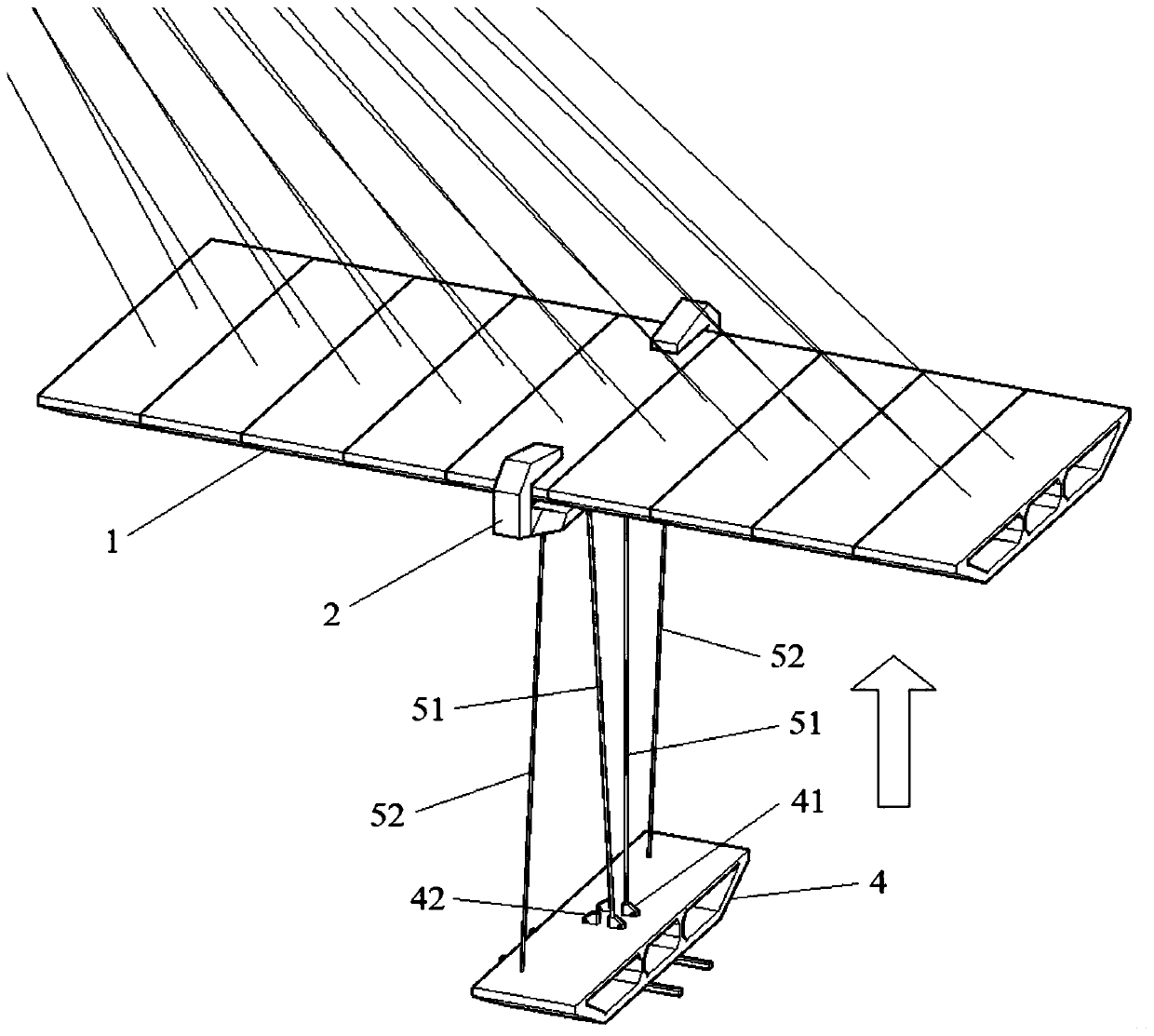

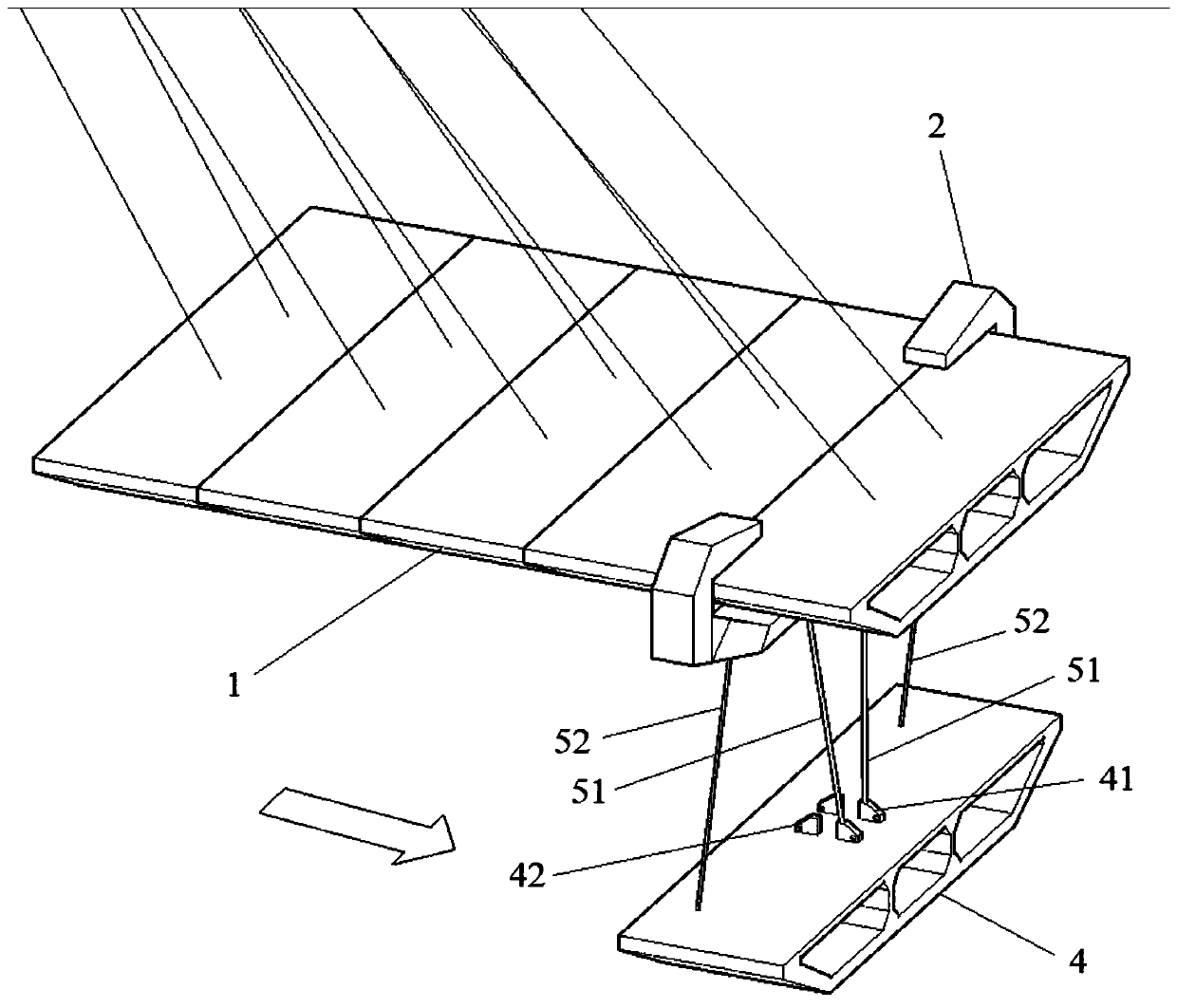

Wetland paving method and recycling method

The invention relates to the field of oil and gas pipelines, discloses a wetland paving method and a recycling method and solves the technical problem of either high cost or long time during paving of a construction operation zone in the prior art. The method comprises the steps of transporting a wetland paving device to the construction site through a transport vehicle; starting a hydraulic motor after the transport vehicle enters the operation plane of the construction site; rotating a barrel support motor to drive a barrel support to rotate by 90 degrees towards the first direction; arranging a metal road surface on an upper guide wheel set through a barrel; starting the hydraulic cylinder to push a beam support to extend outwards after the extended length of the metal road surface on a beam exceeds the preset length through rotating the barrel, to control the metal road surface to fall onto a lower guide wheel set; rotating the barrel to cause the metal road surface to fall to the ground; and after the metal road surface falls to the ground, and controlling the transport vehicle to back off and controlling the barrel to go on rotating. By applying the wetland paving method and the recycling method, the technical effects of both decreasing the time and lowering the cost during paving of the construction operation zone are achieved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Beam section transportation method for bridge girder cantilever assembly

InactiveCN111172882ANot affected by layoutReduce extra workBridge erection/assemblyArchitectural engineeringCofferdam

The invention discloses a beam section transportation method for bridge girder cantilever assembly. A beam transporting vehicle is connected to the lower portion of an installed beam section, a to-be-mounted beam section can be lifted at a fixed lifting point close to a pier and the like, a construction shortcut or a cofferdam platform of a pier can be directly utilized to reduce additional work amounts, reduce construction measure expenses and avoid the influence of bridge floor arrangement; when the to-be-mounted beam section is transported to a preset position, the lifting part II of the beam erecting machine is anchored on the to-be-mounted beam section and is moved to a design position, then the lifting part I is loosened, the lifting part I is lifted to a preset position for furtherinstallation, the beam section transportation method is convenient for construction operation, high in the mechanization level, safe and reliable and high in construction efficiency, a large amount ofadditional engineering cost is effectively avoided, the beam section transportation method is widely suitable for hoisting and transporting cable-stayed bridges or continuous rigid frame bridges limited by terrain features, and the construction speed and the construction quality are guaranteed.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

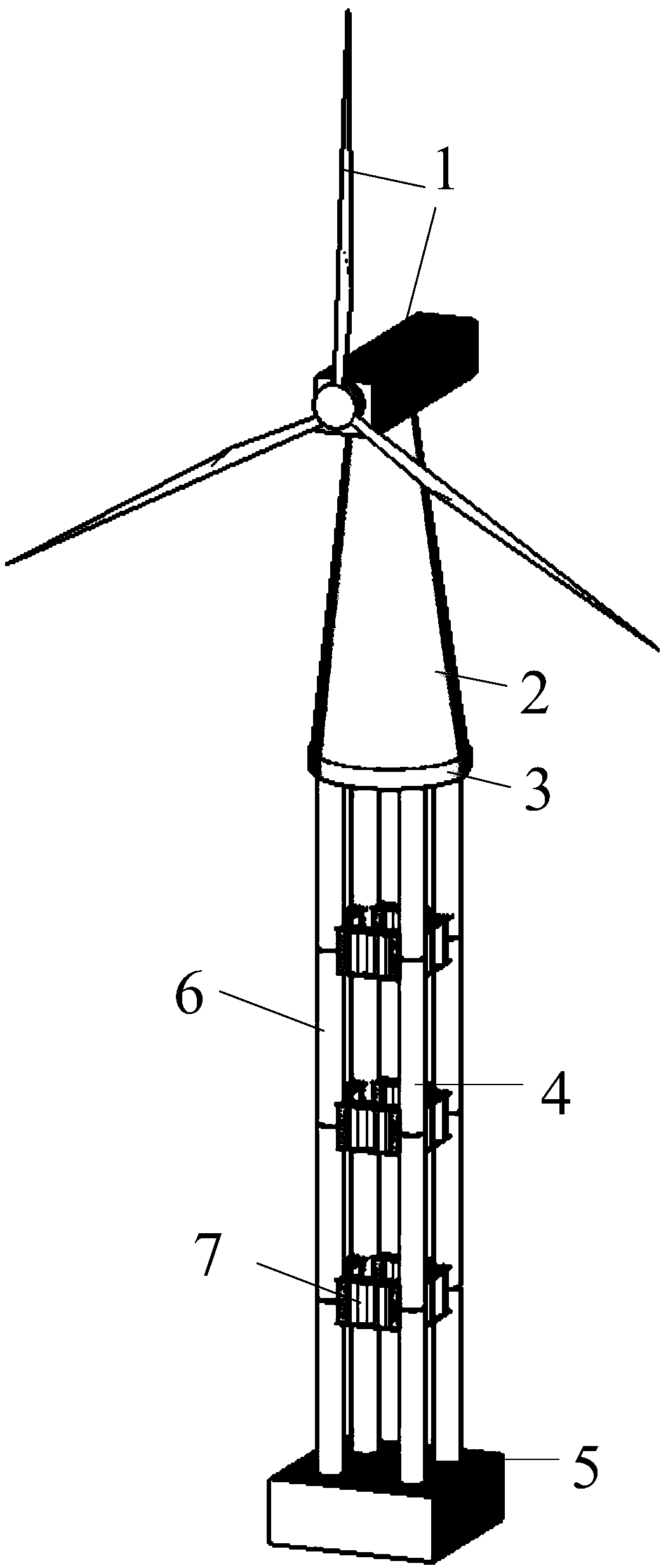

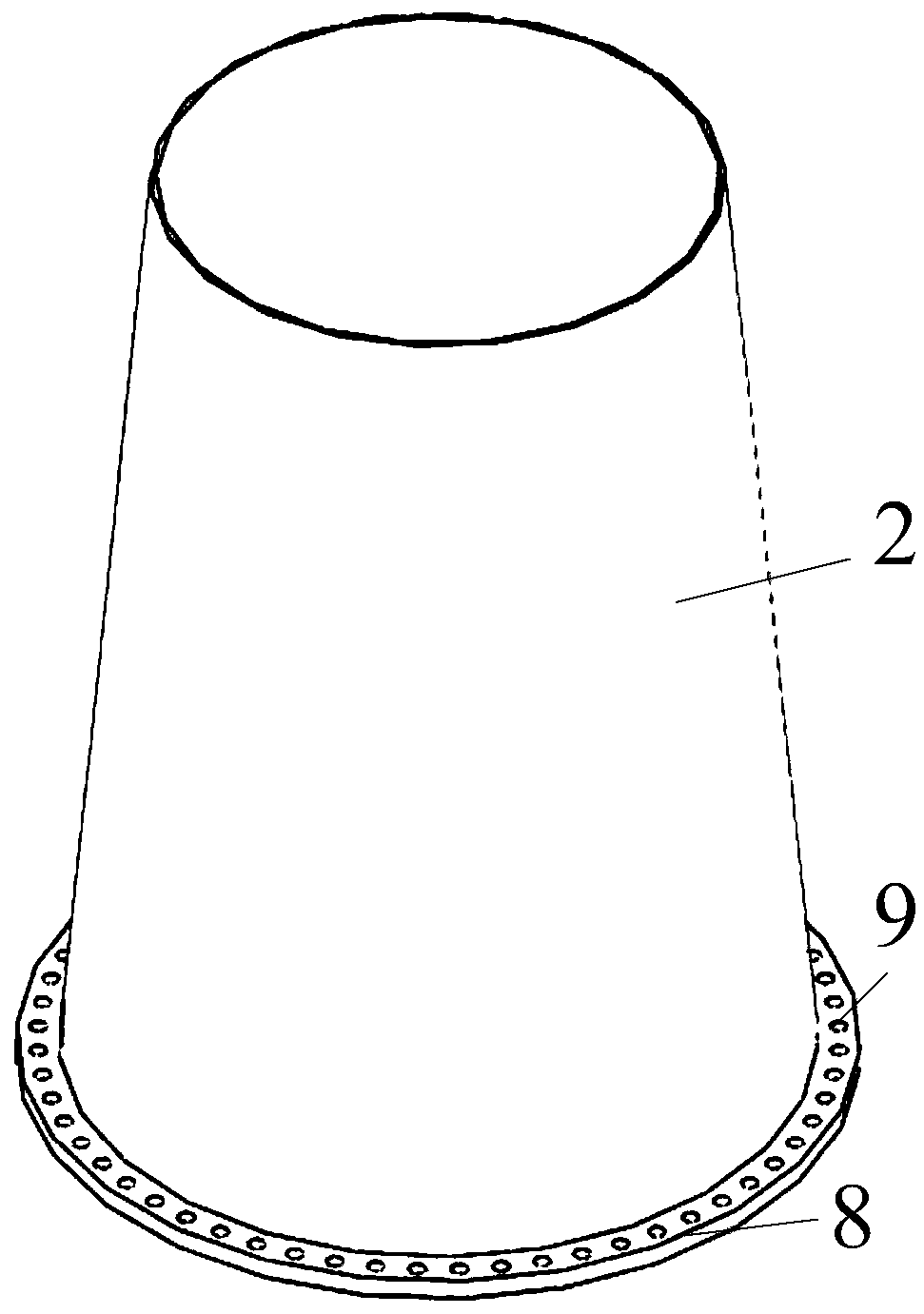

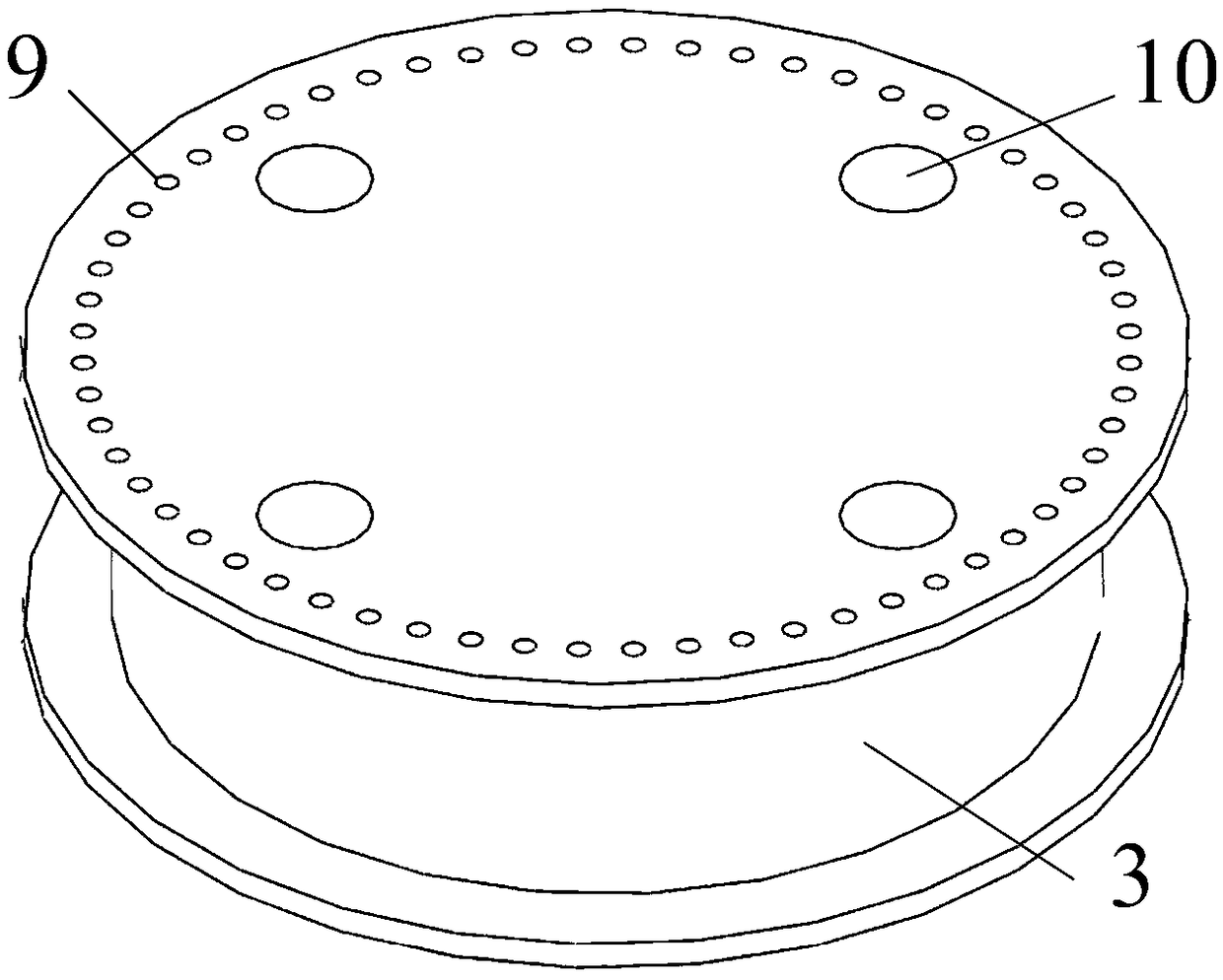

Concrete filled steel tube lattice type wind power tower based on corrugated steel web box girder

PendingCN109322792AIncrease stiffnessImprove carrying capacityWind motor supports/mountsMachines/enginesElectricityPre stress

The invention discloses a concrete filled steel tube lattice type wind power tower based on a corrugated steel web box girder, and relates to the technical field of land wind power generation. The system comprises a fan, an upper steel tower cylinder, an annular steel-concrete combined box girder, a lattice type tower and a foundation. The lower portion of each limb piece of the lattice type toweris directly anchored in the foundation, and the uppermost portion of the lattice type tower is connected with the upper steel tower cylinder through the annular steel-concrete combined box girder. Each limb piece of the tower is a prestress steel tube constraint concrete column, and a post-tensioning method is adopted to ensure that each limb piece only bears pressure, so that the compression resistance of concrete and the tensile property of steel are fully utilized; the limb pieces can be segmented according to length of the limb pieces, and each segmented splicing part is provided with ananti-shearing short steel tube; each gusset piece is the corrugated steel web box girder, whether the concrete is poured is selected according to the stress demand, the gusset pieces are connected with the limb pieces through bolts, the structural system adopts wholly an assembly consturction mode, the construction efficiency can be remarkably improved, the construction quality is guaranteed, andthe construction measure cost is reduced.

Owner:CHONGQING UNIV

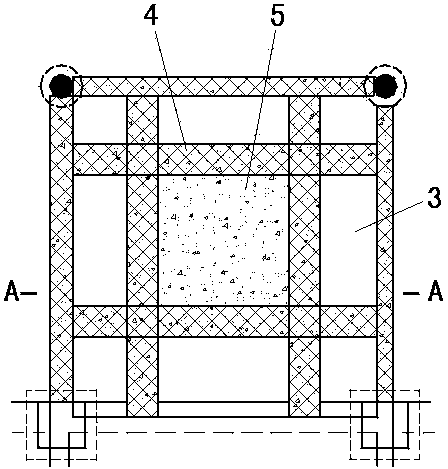

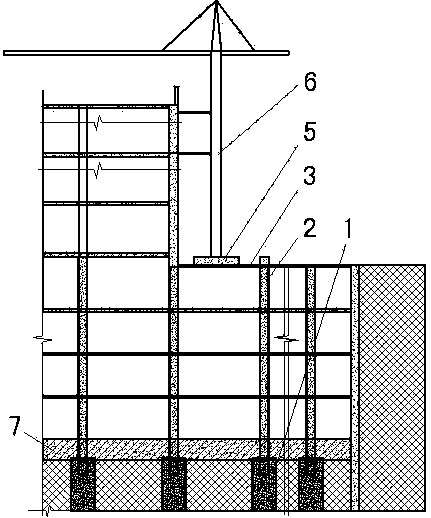

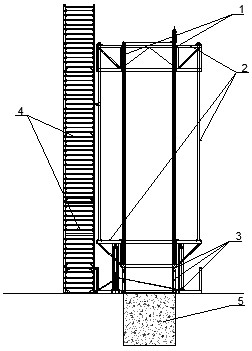

Basement tower crane foundation construction method and structure adopting reverse construction method

InactiveCN104141317AEasy to useReduce secondary constructionArtificial islandsUnderwater structuresArchitectural engineeringTower crane

The invention discloses a basement tower crane foundation construction method and structure adopting a reverse construction method. The method comprises the steps as follows: a tower crane is directly mounted on a basement roof by means of a permanent basement structure; the basement roof is reinforced by a cross beam; and a tower crane foundation is constructed on the cross beam, and the tower crane foundation, the cross beam and the basement roof are connected into a whole through steel bars. At the early stage of design, permanent basement structure pile foundations, steel pipe columns and the basement roof are utilized, and through reexamination and checking calculation of an original design institute, a tower crane model meeting selection requirements is directly mounted on the basement roof for mounting construction. The basement tower crane foundation construction method and structure adopting the reverse construction method have the advantages as follows: the permanent basement structure is utilized, a tower crane foundation pile and a built-up steel column are omitted, reserved holes in the basement structure are reduced, secondary construction of the basement structure is reduced, the construction period is shortened, the potential safety hazard is reduced, the construction measurement expense is saved, and meanwhile, normal use of the tower crane and safety of the permanent basement structure are guaranteed.

Owner:CHINA CONSTR FOURTH ENG DIV

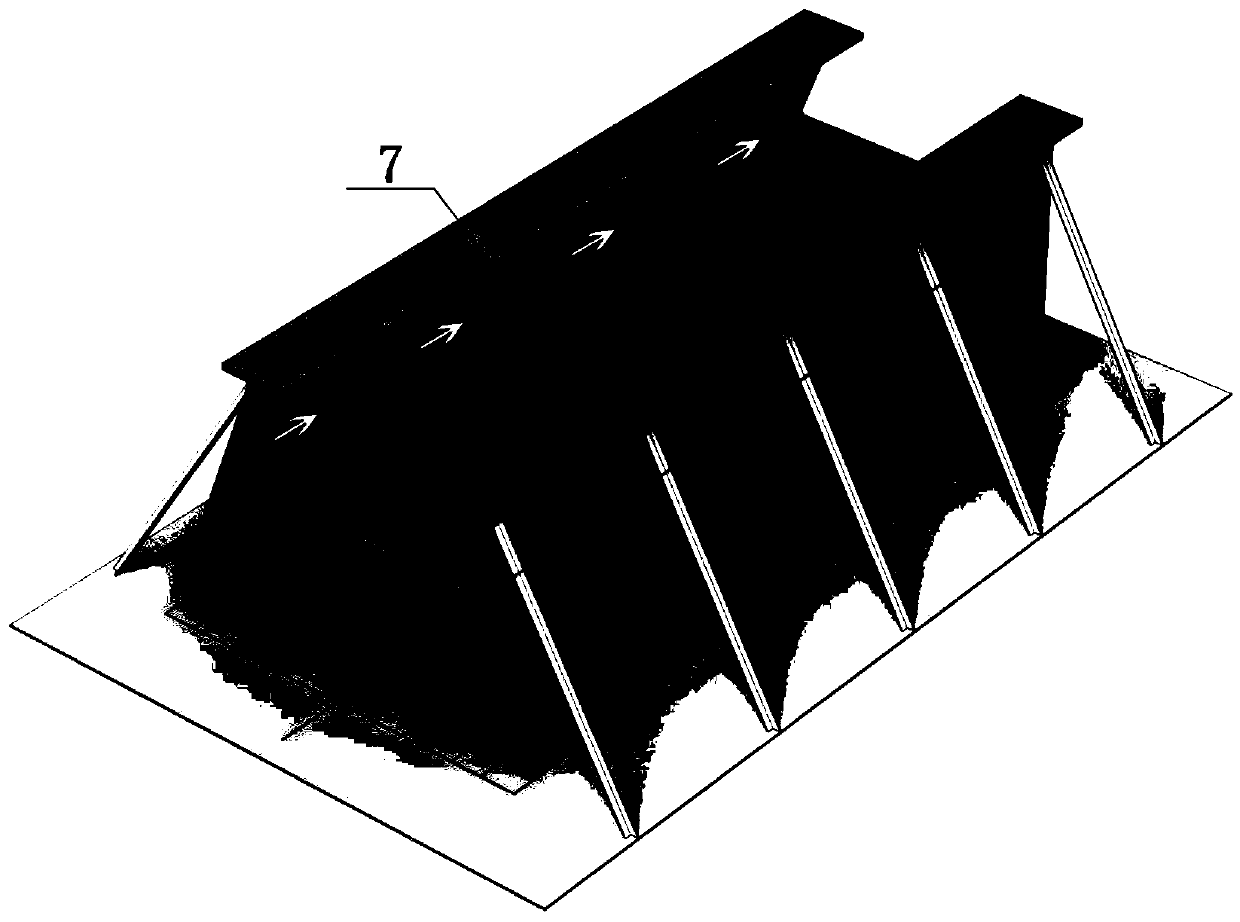

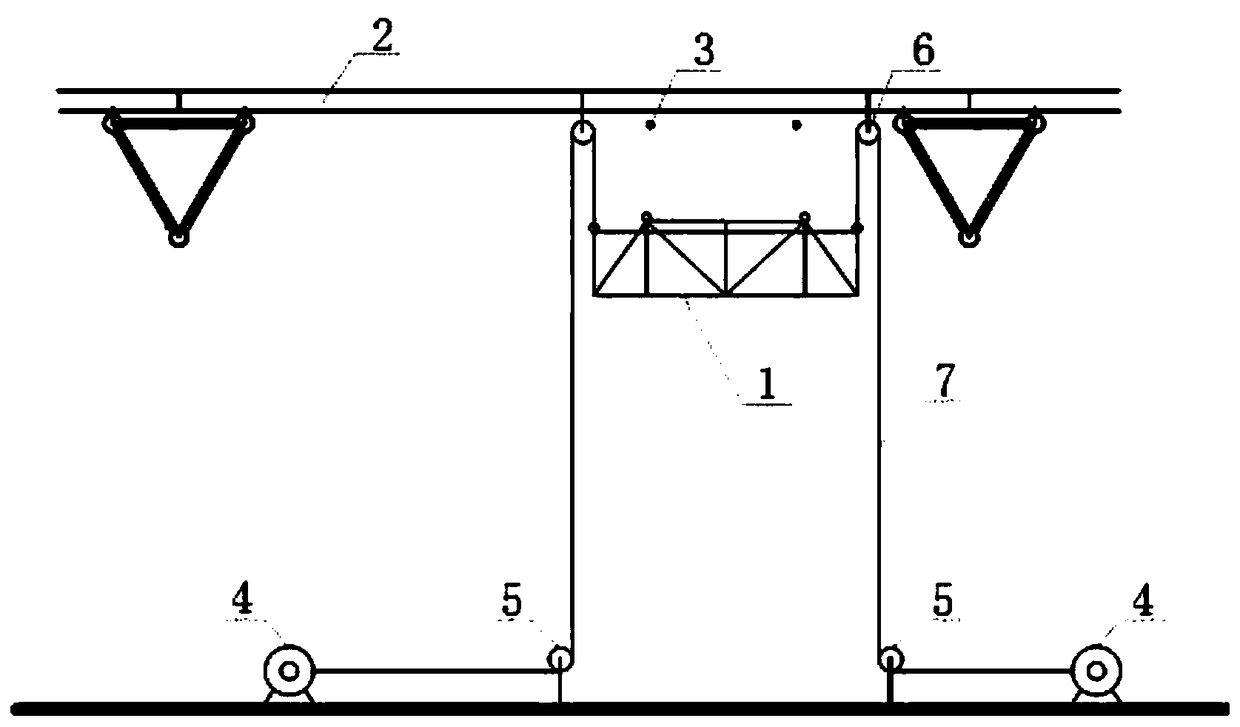

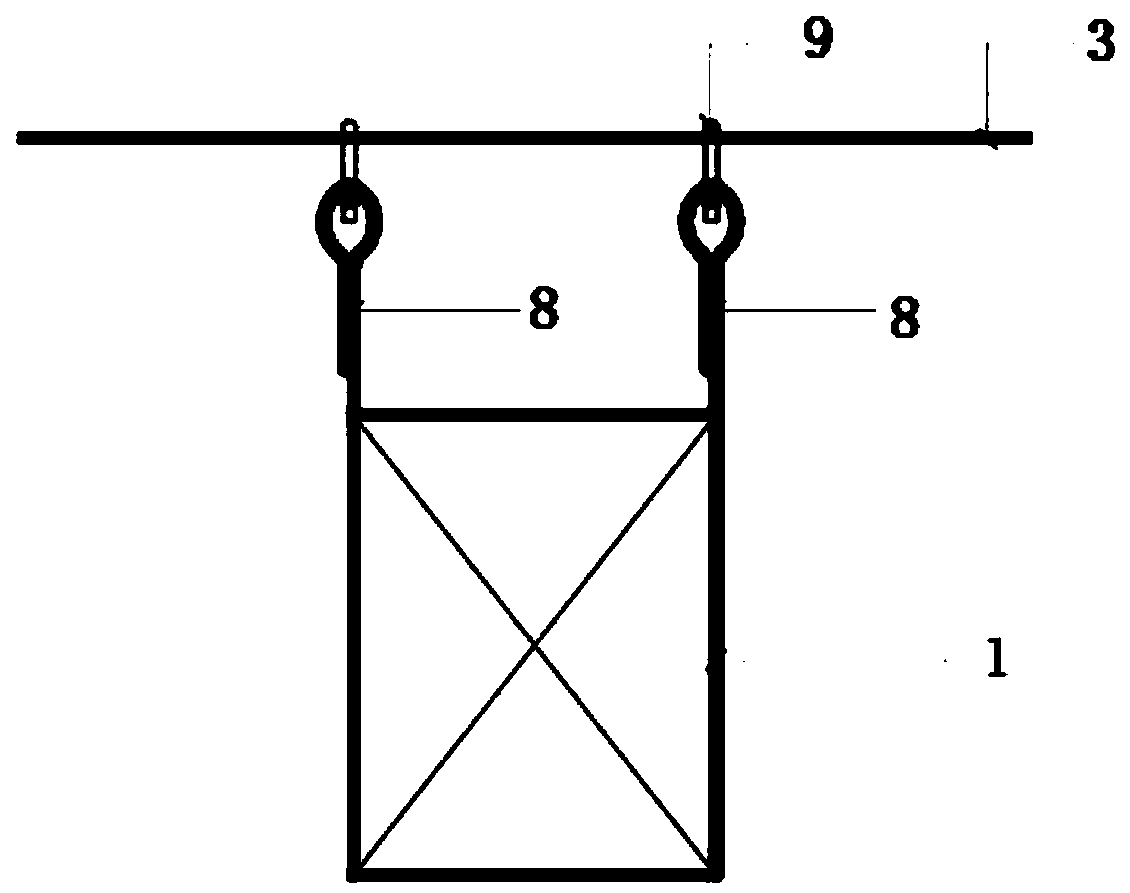

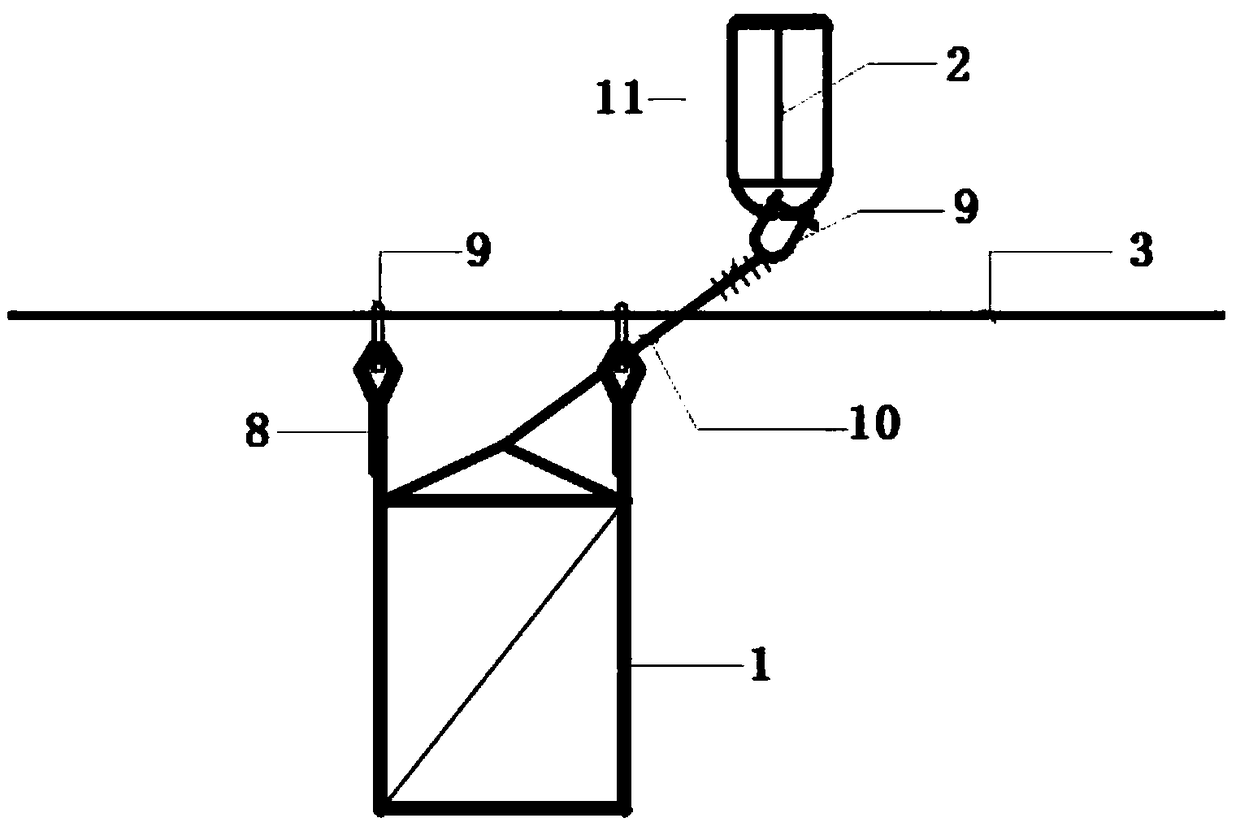

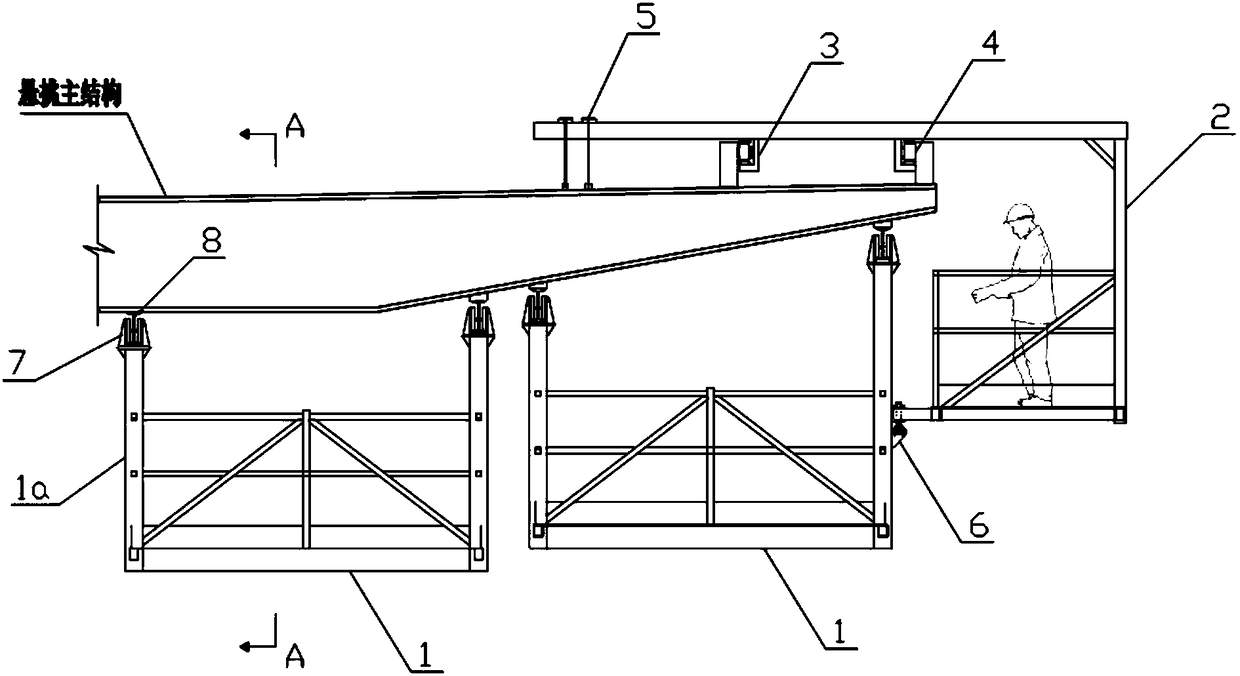

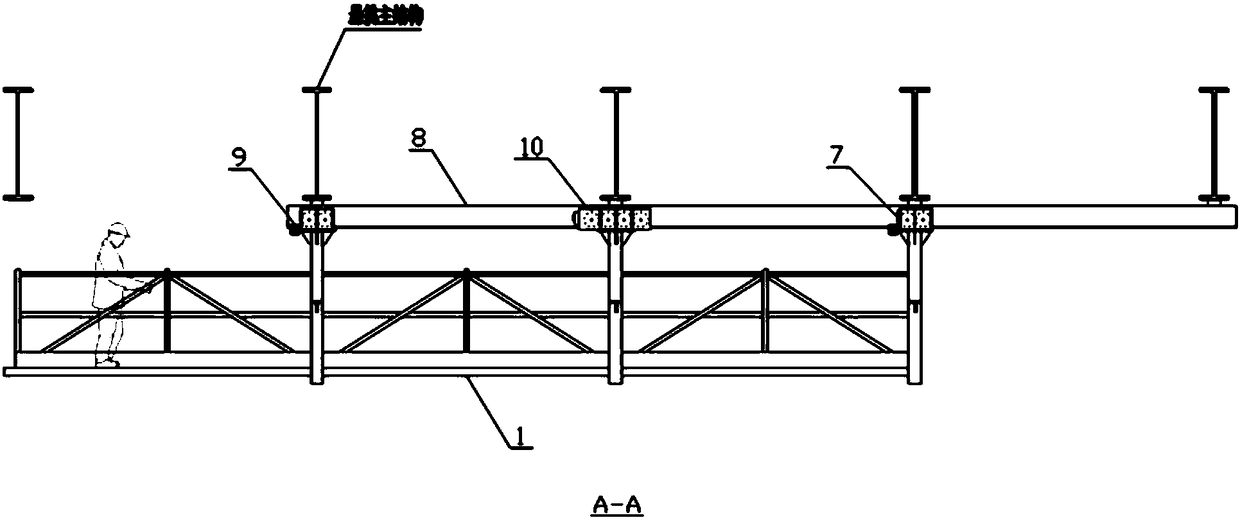

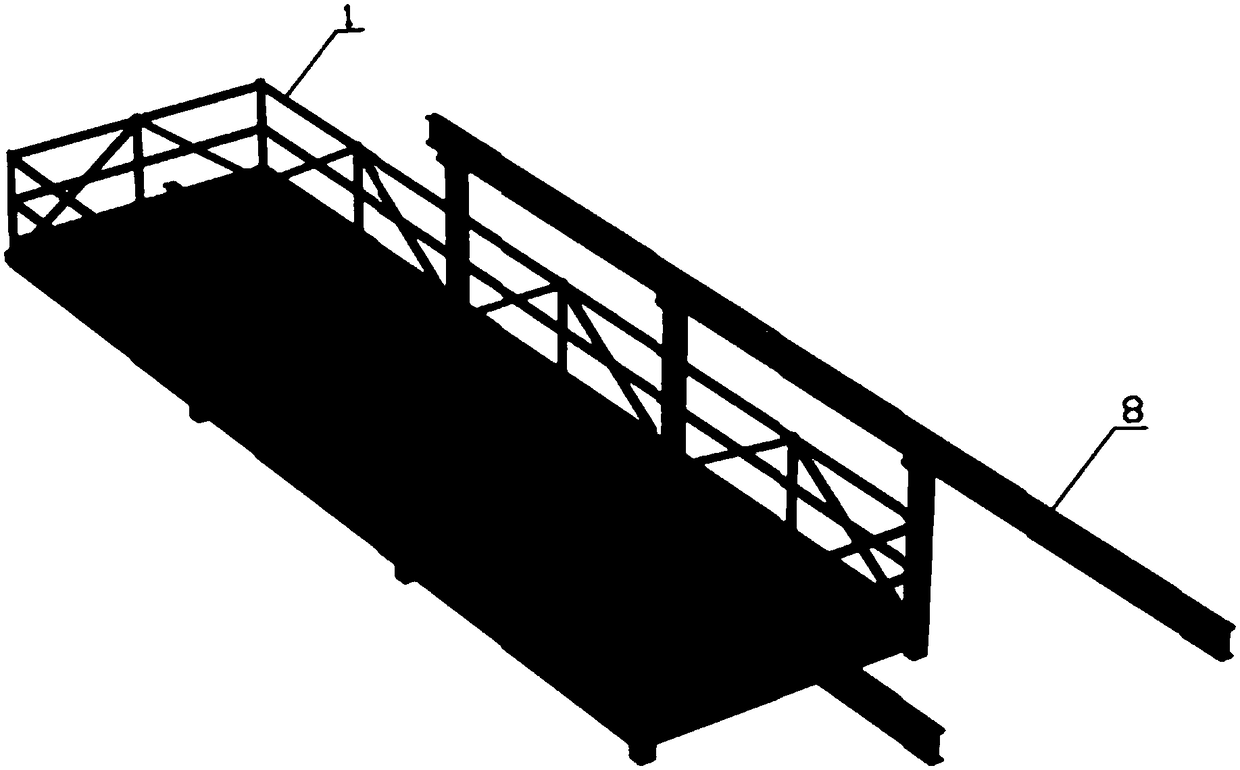

Suspended platform system for steel structure metal roof base plate installation

InactiveCN109372243AImprove construction efficiencyThe operating platform is stableBuilding support scaffoldsEngineeringWinch

The invention relates to a suspended platform system for steel structure metal roof base plate installation. The suspended platform system comprises a suspended platform lifting unit and a suspended platform hanging and sliding unit. A suspended platform is arranged in a roof base plate installation area. The suspended platform lifting unit is formed by winches, a lifting steel wire rope, bottom fixed pulleys and top fixed pulleys. The suspended platform hanging and sliding unit is formed by two main steel wire ropes, a first end joint connecting assembly, a second end joint connecting assembly and a plurality of fixed point connecting assemblies. A stable operating platform is provided for roof base plate construction, synchronous cross operation of a roof system and an external wall canbe further realized on the basis, and thus the overall construction efficiency of a project is improved, the suspended platform system is convenient to transport and arrange, the mobility is high, andthe suspended platform system is convenient to operate, safe and reliable.

Owner:CHINA THIRD METALLURGICAL GRP

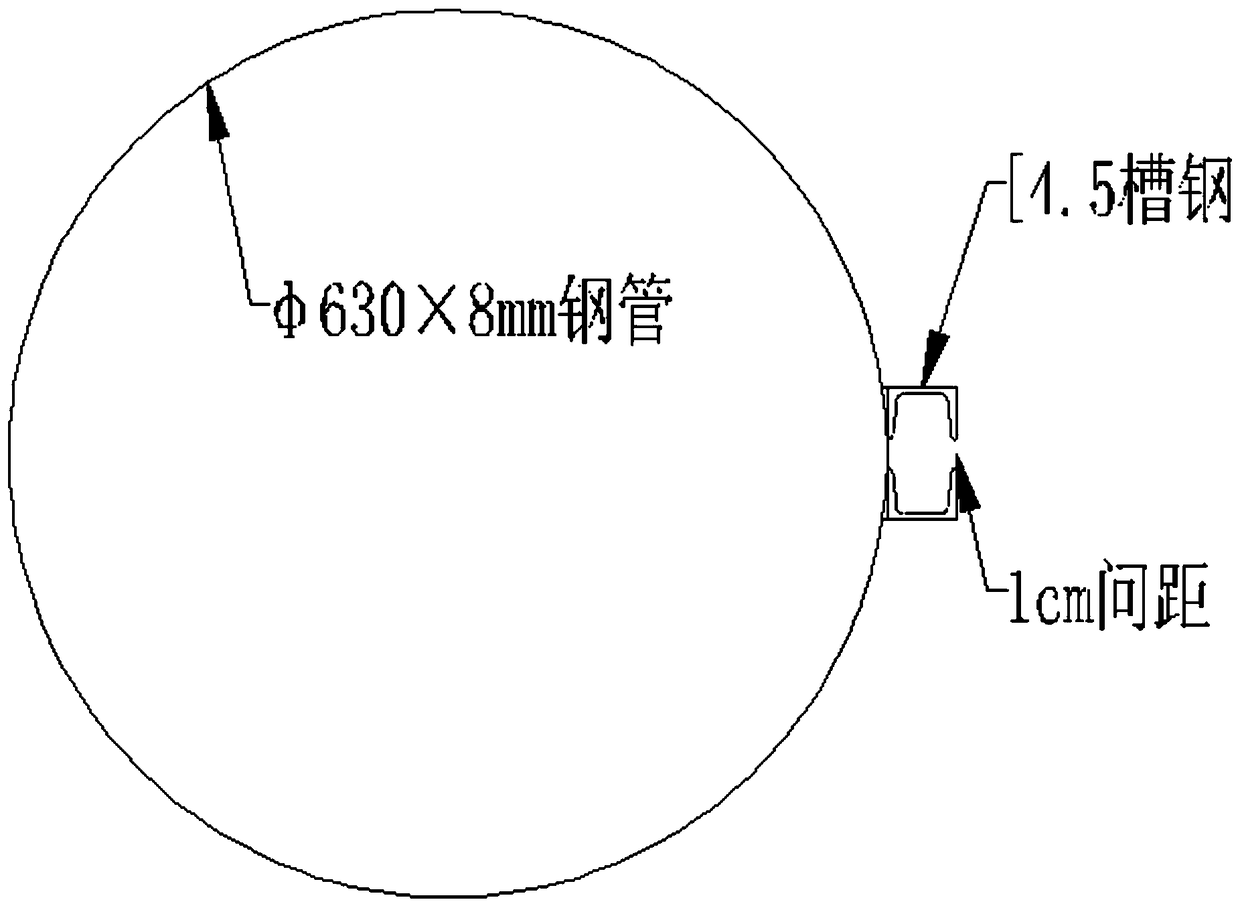

Supporting method for super-large deep foundation pit construction in soft soil area

InactiveCN108360528AReduce construction costsShorten the timeExcavationsBulkheads/pilesPollutionSteel tube

The invention discloses a supporting method for super-large deep foundation pit construction in a soft soil area. The supporting method is characterized in that the supporting method mainly includes anovel buckle steel pipe and Larsen steel plate combined system and is suitable for supporting measures of super-large super-scale deep foundation pit foundation construction of the soft soil area. Conventional super-large super-scale foundation pit excavation supporting measures in the soft soil area are combined, the measures utilize buckle steel pipe piles and Larsen steel plate piles, the problem that during construction of deep foundation pits in the soft soil area and near the edges of important buildings, the cost of the conventional construction technological measures is high is mainlysolved, the cost of the construction measures of the supporting method is low, the period is short, and pollution to the surrounding environment is avoided.

Owner:四川路桥华东建设有限责任公司

Bridge caisson composite pile foundation and reverse construction method thereof

ActiveCN101148890BControllable working timeReduce the cost of construction measuresCaissonsBulkheads/pilesSeabedDeep water

The present invention discloses one kind of composite bridge caisson pile foundation and its reverse construction process. After the bridge caisson is sunk to site, piling construction is performed inside the caisson to form pile with upper part connected to the caisson integrally and to constitute composite caisson pile foundation. The construction process includes the steps of prefabricating caisson in land, floating the caisson and setting the caisson in dredged sea bed, driving steel pipe pile through the pre-formed hole in the bottom of the caisson through operation inside the caisson, performing the upper structure construction simultaneously, pouring concrete to connect the bottom plate of the caisson with the steel pipe pile. The present invention has the load borne commonly by thecaisson and the pile, and is suitable for bridge construction in deep sea and soft soil foundation.

Owner:CCCC HIGHWAY CONSULTANTS +1

Horizontal-moving type operating platform device applied to construction of creasing curtain wall

PendingCN108277971AMeet construction requirementsConstruction safety and controllableBuilding support scaffoldsHanging basketEngineering

The invention provides a horizontal-moving type operating platform device applied to construction of a creasing curtain wall. The horizontal-moving type operating platform device comprises a modular lower-hanging type platform system and an upper-hanging type overhung platform system, the modular lower-hanging type platform system comprises an operating platform and a hanging system, and the hanging system is composed of a hanging column, a guide rail, a guiding module, a braking device and a power sliding vehicle; the operating platform is assembled through the hanging column and the guidingmodule and is hung on the guide rail, and the operating platform takes the power sliding vehicle as a power source and moves front and back in the direction of the guide rail; and the upper-hanging type overhung platform system comprises an overhung platform body, a guiding module, a guide rail, a rebar hanging ring and a fixing connecting piece, the overhung platform body and the guiding module are assembled into a whole and are buckled on the two sides of an inner edge of the guide rail, the tail end of the overhung platform body is fixed to an overhung main structure by adopting the rebar hanging ring, and the bottom end of the overhung platform body is fixed to a hanging column connecting joint of a lower-hanging type platform by adopting fixing connecting pieces. The horizontal-movingtype operating platform device makes up defects of conventional hanging basket and scaffold construction, and it is ensured that construction is safe and controllable, and the quality and the precision meet design requirements.

Owner:SHANGHAI MECHANIZED CONSTR GRP

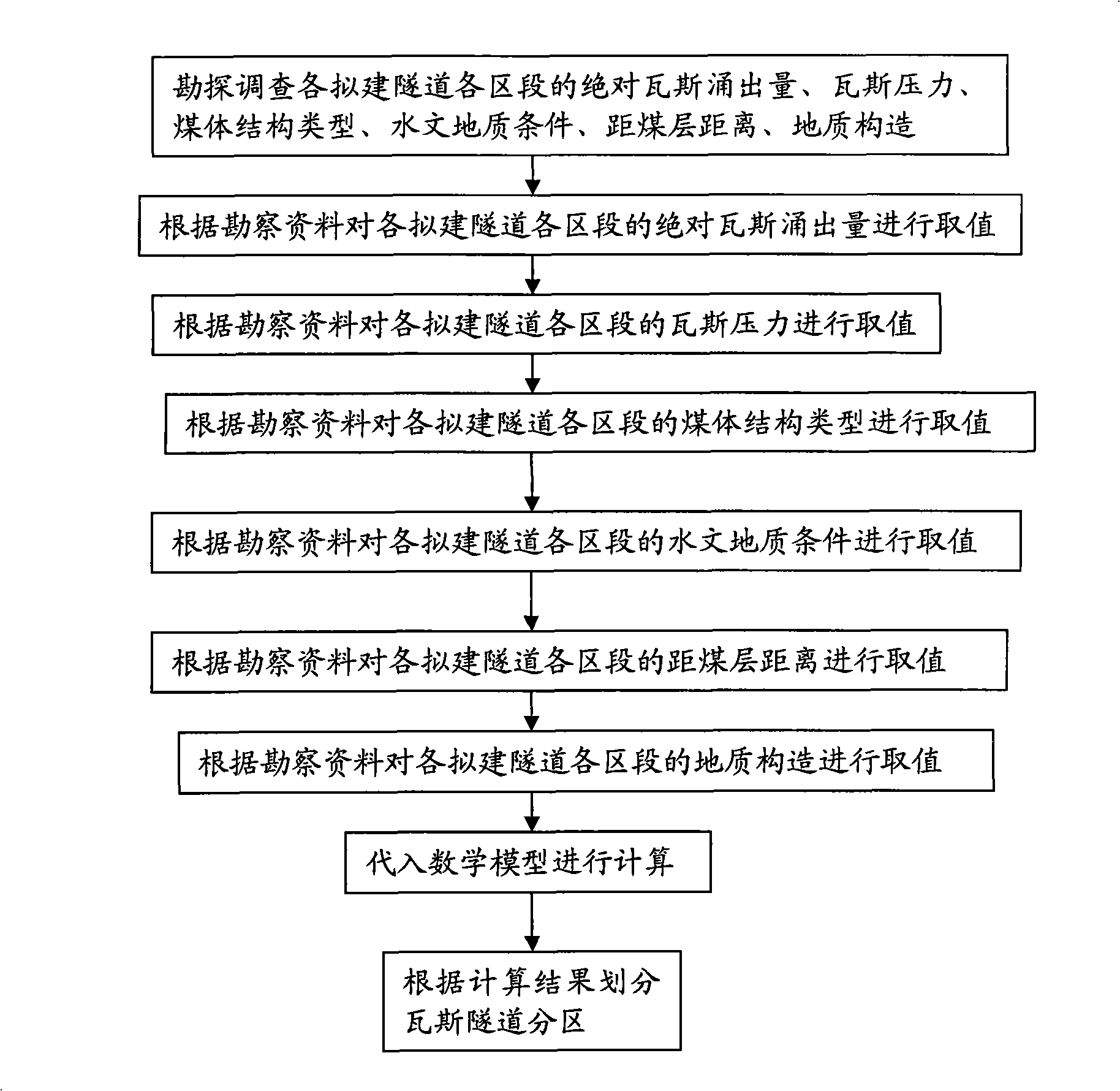

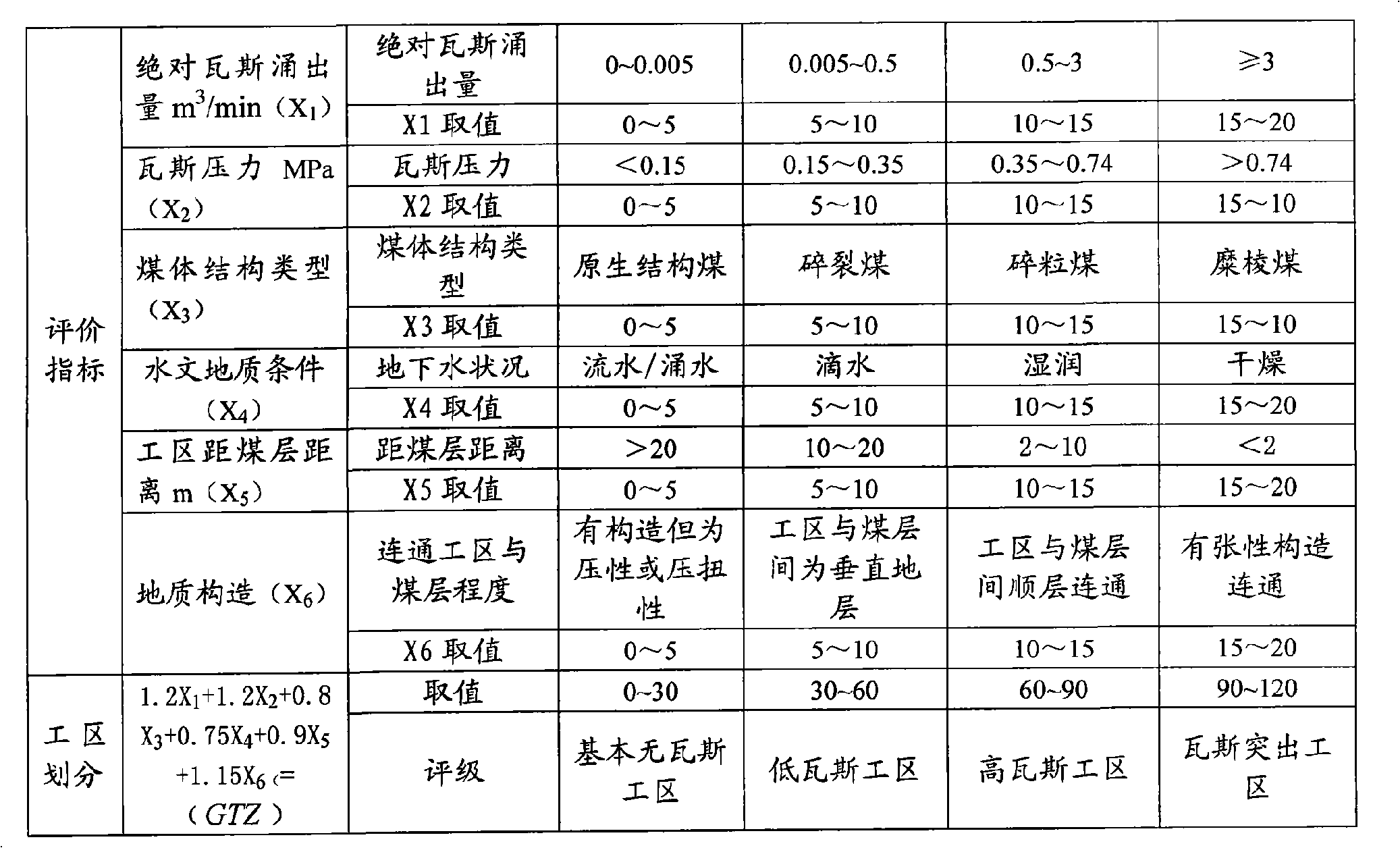

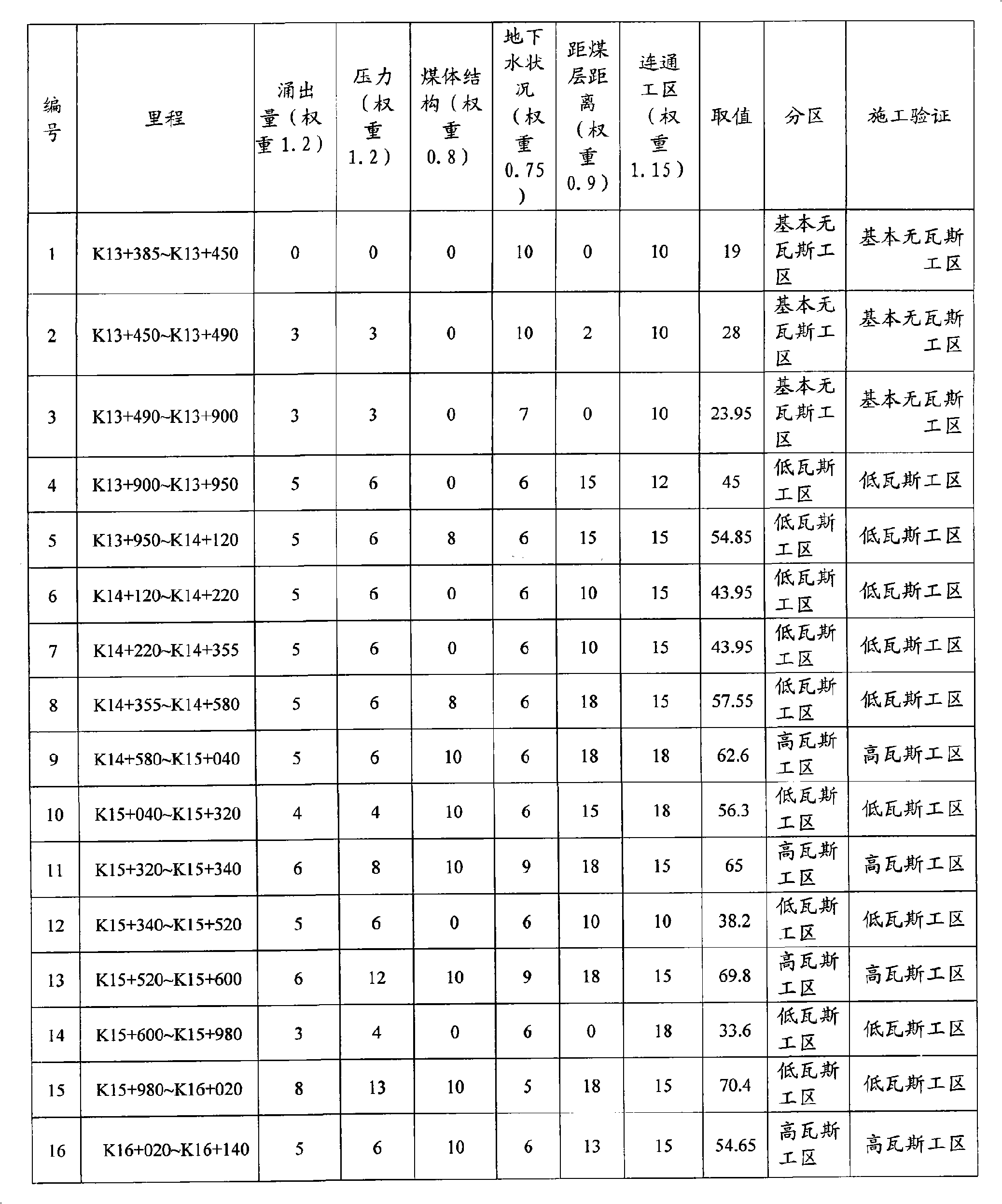

Method for partitioning gas tunnels

The invention discloses a method for partitioning gas tunnels. The method is characterized in that based on the exploration of geological conditions of tunnel gas, the six main factors, i.e. absolute gas emission rate, gas pressure, coal structure type, geohydrologic conditions, distance to coal layers and geological structure, are taken into consideration comprehensively, the index of each main factor is quantified, and proposed gas tunnels are partitioned by mathematical models of gas tunnel partition presented by the invention; the method provides a systematic and reliable solution for partitioning the public road and railroad gas tunnels which penetrate through coal measure strata, so that with regards to different work areas with gas, corresponding construction measures can be adopted during the construction of the gas tunnels, thereby effectively preventing gas accidents from happening and ensuring the safety of constructors; and besides, the method saves the cost of construction measures, shortens the construction period and is of great importance to the implementation of engineering.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

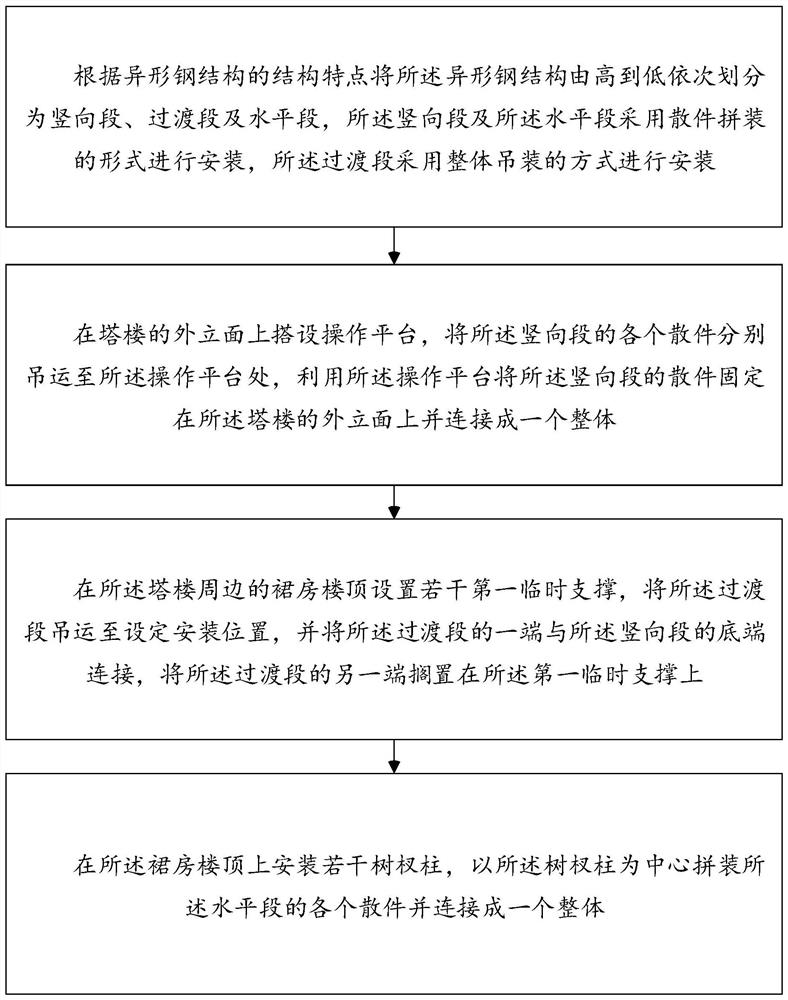

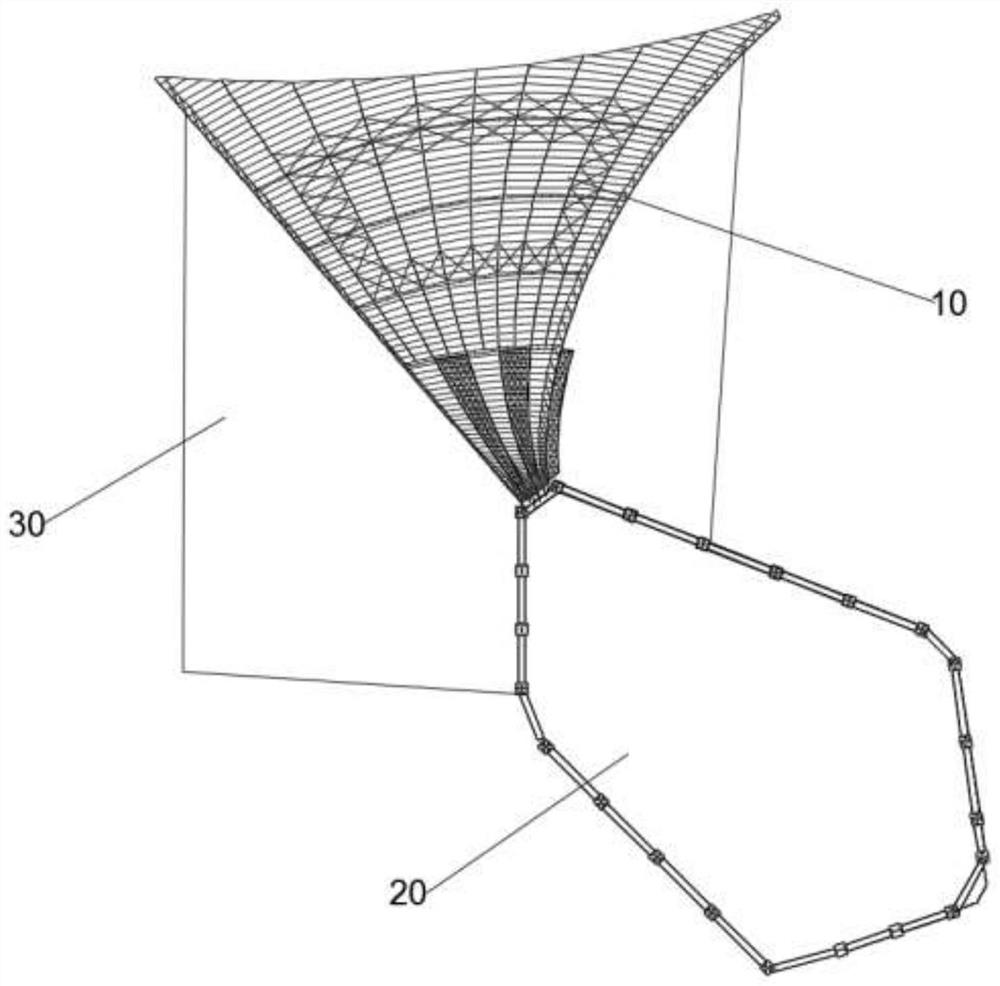

Mounting method of special-shaped steel structure and mounting method of steel grid structure

ActiveCN111997191AReasonable controlMeet construction requirementsBuilding material handlingArchitectural engineeringTower

The invention provides a mounting method of a special-shaped steel structure and a mounting method of a steel grid structure. The mounting method of the special-shaped steel structure comprises the following steps that the special-shaped steel structure is sequentially divided into a vertical section, a transition section and a horizontal section from high to low according to the structural characteristics of the special-shaped steel structure; an operation platform is erected on the external wall of a tower building, and the operation platform is used to fix scattered pieces in the vertical section and connect the scattered pieces integrally; a plurality of first temporary supports are arranged on the roof of a skirt building at the periphery of the tower building, and the transition section is hoisted to a set mounting position; and a plurality of branch columns are mounted on the roof of the skirt building, and the branch columns are used as the centers to assemble all the scatteredpieces of the horizontal section and connect the scattered pieces into a whole. According to the mounting method of the special-shaped steel structure and the mounting method of the steel grid structure, by using a top-down reverse construction method, the vertical section, the transition section and the horizontal section are sequentially mounted, the tower building is used as the center, mounting is carried out from inside to outside, the site utilization rate can be increased greatly, and meanwhile the control over the structural stability is more reasonable.

Owner:SHANGHAI MECHANIZED CONSTR GRP

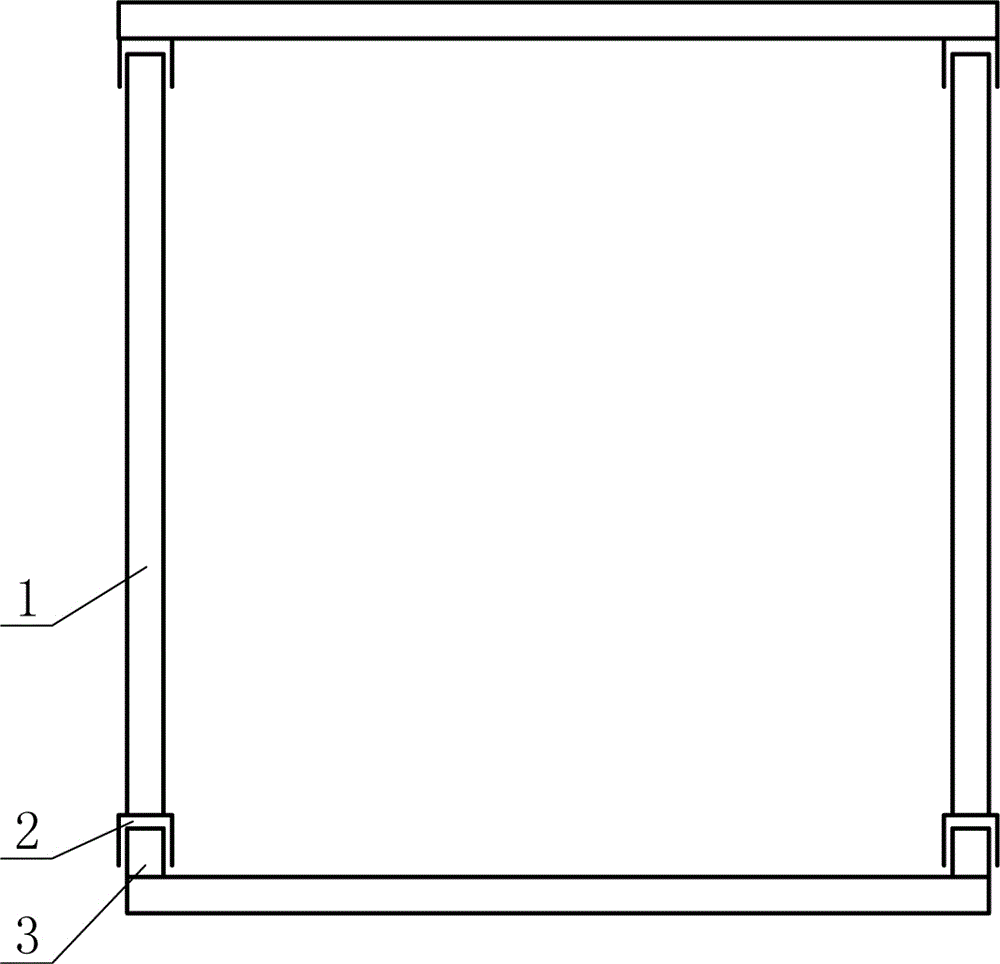

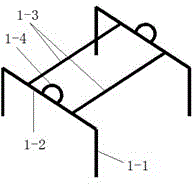

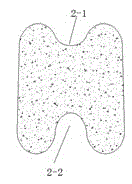

Recoverable and reusable combined floor reinforcing bar iron support

InactiveCN103982007AReduce the cost of construction measuresControl thicknessBuilding reinforcementsRebarFloor slab

The invention discloses a recoverable and reusable combined floor reinforcing bar iron support, comprising a reinforcing bar iron support body, reinforcing bars used as floor surface bars and a mortar cushion block used for supporting the floor surface bars, wherein the reinforcing bar iron support body comprises reinforcing bar supporting legs, reinforcing bar supporting beams, spacing reinforcing bars and reinforcing bar pulling rings, every two reinforcing bar supporting legs and one reinforcing bar supporting beam are an integral body formed by bending a reinforcing bar, the spacing reinforcing bars and the reinforcing bar pulling rings are fixed on the reinforcing bar supporting beams through welding, the reinforcing bars are arranged below the spacing reinforcing bars and connected with the spacing reinforcing bars through colligation, the top and the bottom of the mortar cushion block are respectively provided with a groove, and the mortar cushion block is arranged near the reinforcing bar iron support body. The recoverable and reusable combined floor reinforcing bar iron support provided by the invention can replace traditional split head reinforcing bars in supporting structural floor surface bars, controlling floor thickness, protecting reinforcing bars and the like, and the purposes of green construction and conservation of project construction cost are achieved through recovery and reuse of the tool type reinforcing bar iron support.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

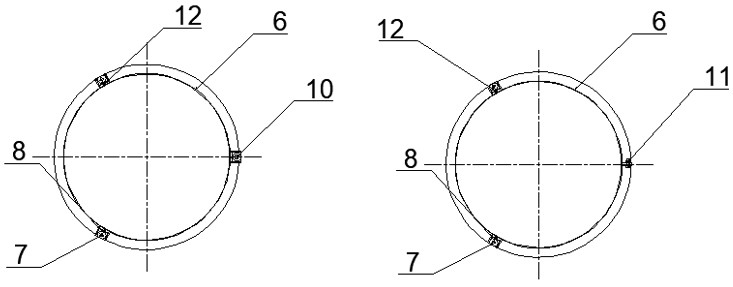

High-upright formwork integrated construction technology

ActiveCN105951599AEnsure construction safetyReduce the cost of construction measuresBridge erection/assemblyFalseworkArchitectural engineering

The invention discloses a high-upright formwork integrated construction technology suitable for construction of an upright with the height over 3 m. A hoop and an operation platform which are assembled are integrally lifted and arranged on the upright from the top in a sleeving manner to the corresponding elevation so as to be fixedly installed; a lower-section formwork is then installed; an operator stands on the lower-section formwork, so that an upper-section formwork and the operation platform are integrally lifted; then a maintenance net and a vase-section formwork are integrally lifted and installed in sequence, and the operator gets on and off the operation platform through an elevator cage; then reinforcing steel bars are bound upwards from the bottoms in the formworks, and concrete is poured after binding is conducted; and finally, the vase-section formwork, the upper-section formwork, the lower-section formwork and the operation platform are detached. Compared with erection of a conventional scaffold, the formwork integrated construction technology can be used for reducing the measure cost by over 90%, and the construction safety and the construction quality can be guaranteed.

Owner:CCCC FIRST HARBOR ENG +1

Reinforced concrete winding stairs die type formwork and its construction method

The invention relates to a reinforced concrete caracol mould type moulding board and a construction method thereof. The moulding board is divided into at least two sections along the spiral direction; various sections are connected with each other end to end by bolts and section end angle irons and are assembled into a spiral line detachable mould type forming steel mouldng board; an inner side plate, an outer side plate, a front side plate and a bottom plate of each section of the detachable mould type forming steel moulding board are all thin steel plates; both the insides on the lower edges of the inner side plate and the outer side plate are connected with bottom corner angles; the bottom corner angles on both sides are connected with the bottom plate through bolts; the bottom plate is connected with the front side plate through bolts; the inner side plate and the outer side plate take the shape of ladders; the upper vertical edges and the lower vertical edges of the inner side plate and the outer side plate are respectively and fixedly connected with the section end angle irons; both an inner vertical edge and an outer vertical edge of each step are fixed with an inner facade long angle iron and an outer facade long angle iron; and a horizontal bottom-holder angle iron is connected between the lower end of the inner facade long angle iron and the lower end of the outer facade long angle iron through bolts and is positioned under the bottom plate. The reinforced concrete caracol mould type moulding board solves the technical problems of large construction wood consumption, large consolidation difficulty and high construction cost of a reinforced concrete independent caracol moulding mould.

Owner:MCC TIANGONG GROUP

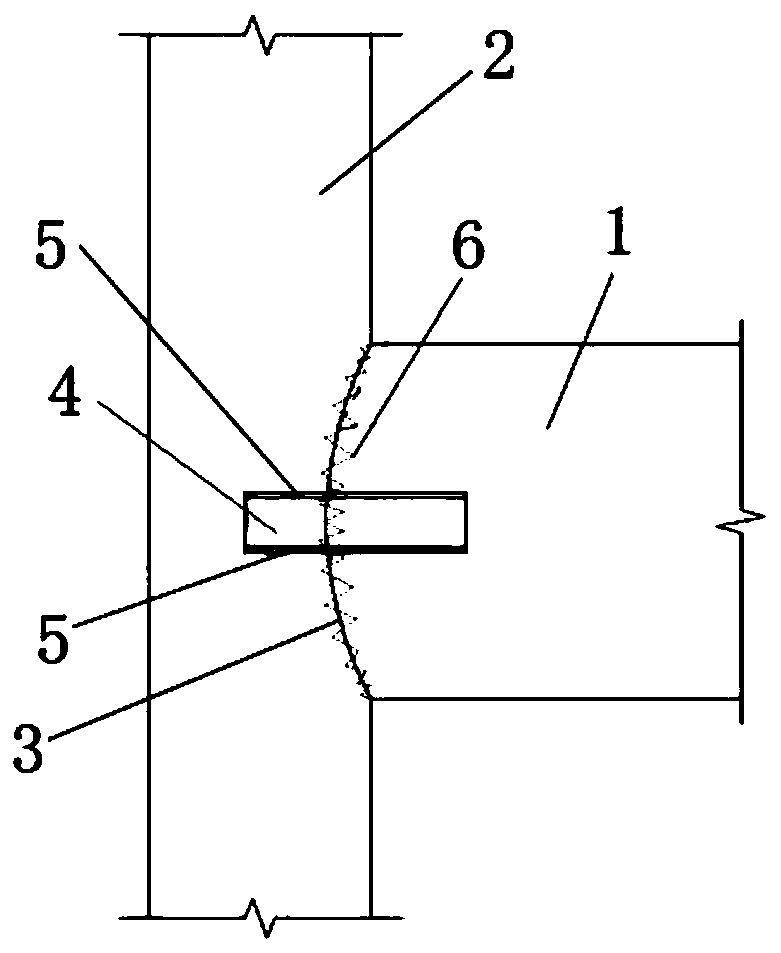

Concrete beam end and curved surface shear wall construction joint disposal device and method

PendingCN110528700ASolve the problem of retentionImprove adhesionBuilding insulationsAdhesion forceConcrete beams

The invention relates to a concrete beam end and curved surface shear wall construction joint disposal device. The concrete beam end and curved surface shear wall construction joint disposal device comprises a concrete beam and a concrete shear wall. A construction joint is formed in the junction of the end of concrete beam and the concrete shear wall. A section steel shear resisting key is pre-embedded in the construction joint and penetrates through the construction joint, one part of the section steel shear resisting key is located in the concrete shear wall, and the other part of the section steel shear resisting key is located in the concrete beam. The invention further relates to a concrete beam end and curved surface shear wall construction joint disposal method. According to the concrete beam end and curved surface shear wall construction joint disposal device and method, due to the fact that the section steel shear resisting key is embedded, the high shear resistance of the section steel shear resisting key and the feature that anchor bars are welded on the section steel shear resisting key are utilized to solve the problem of force transmission between beam-shear wall joints; and due to the fact that a dense-hole steel wire mesh serves as a formwork of pouring of the construction joint, the penetration of rebars of the concrete beam and the section steel shear resisting key is facilitated, the adhesion force of the construction joint is increased, the construction measure cost is saved, the construction period is shortened, and the concrete beam end and curved surface shear wall construction joint disposal device and method have certain engineering application value for spatial abnormally-shaped concrete beam construction.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

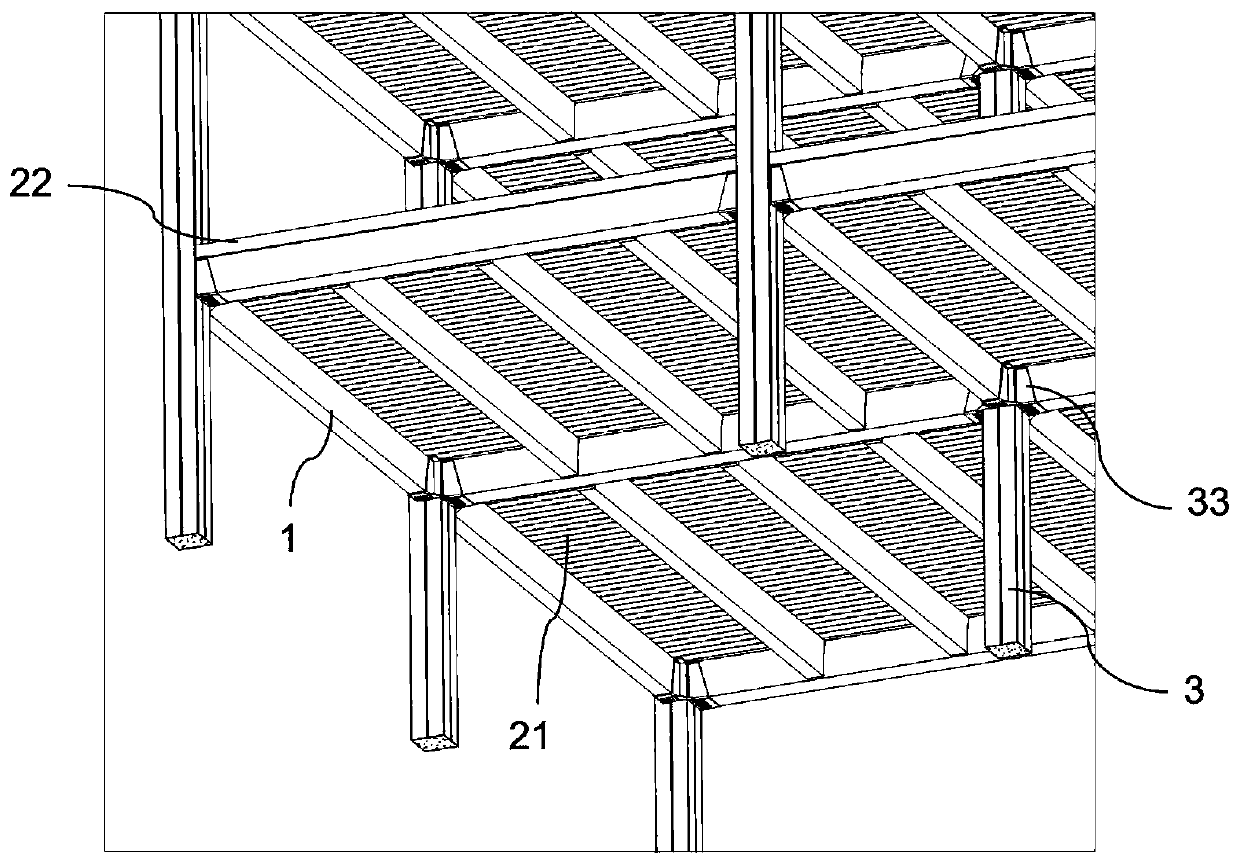

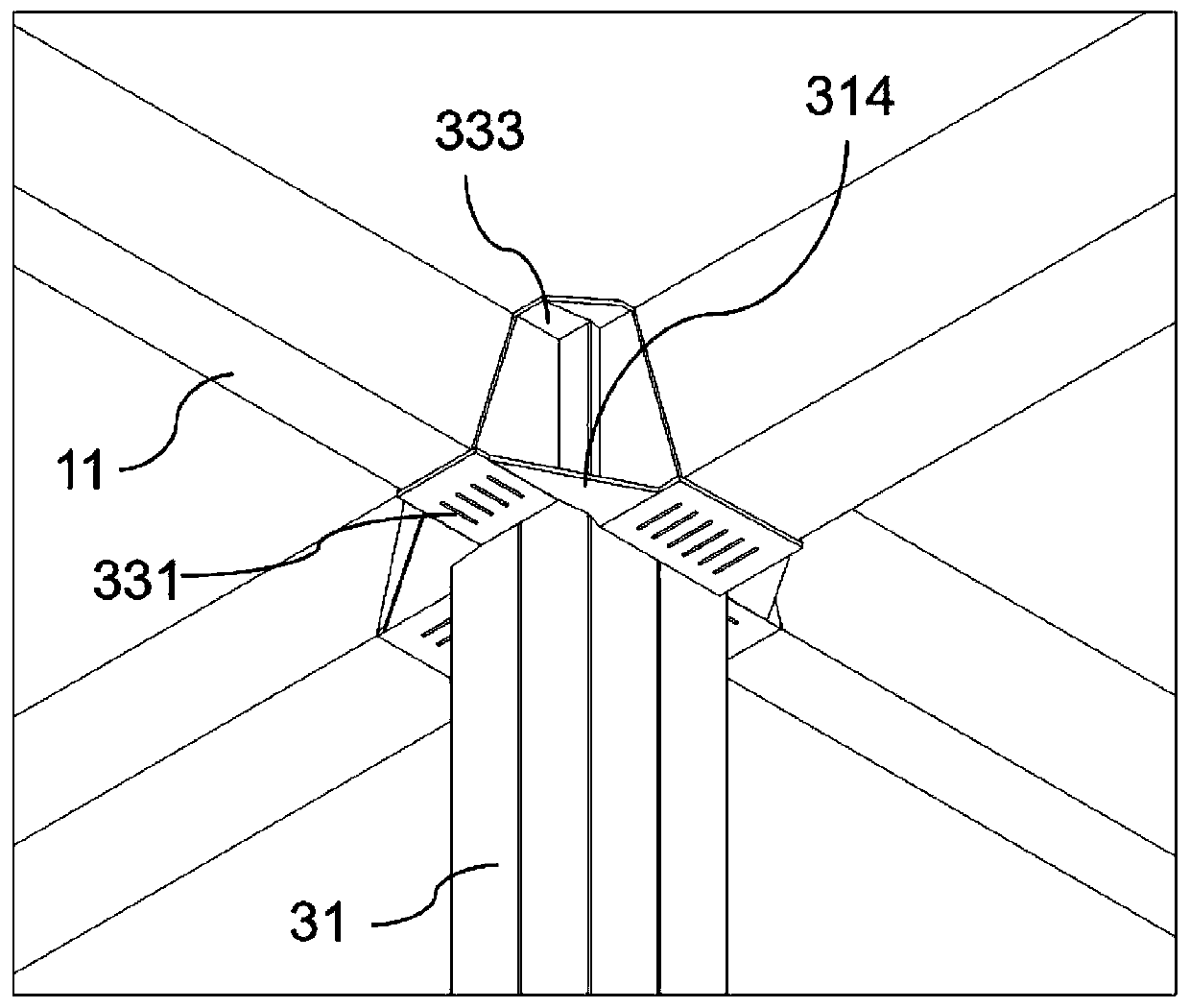

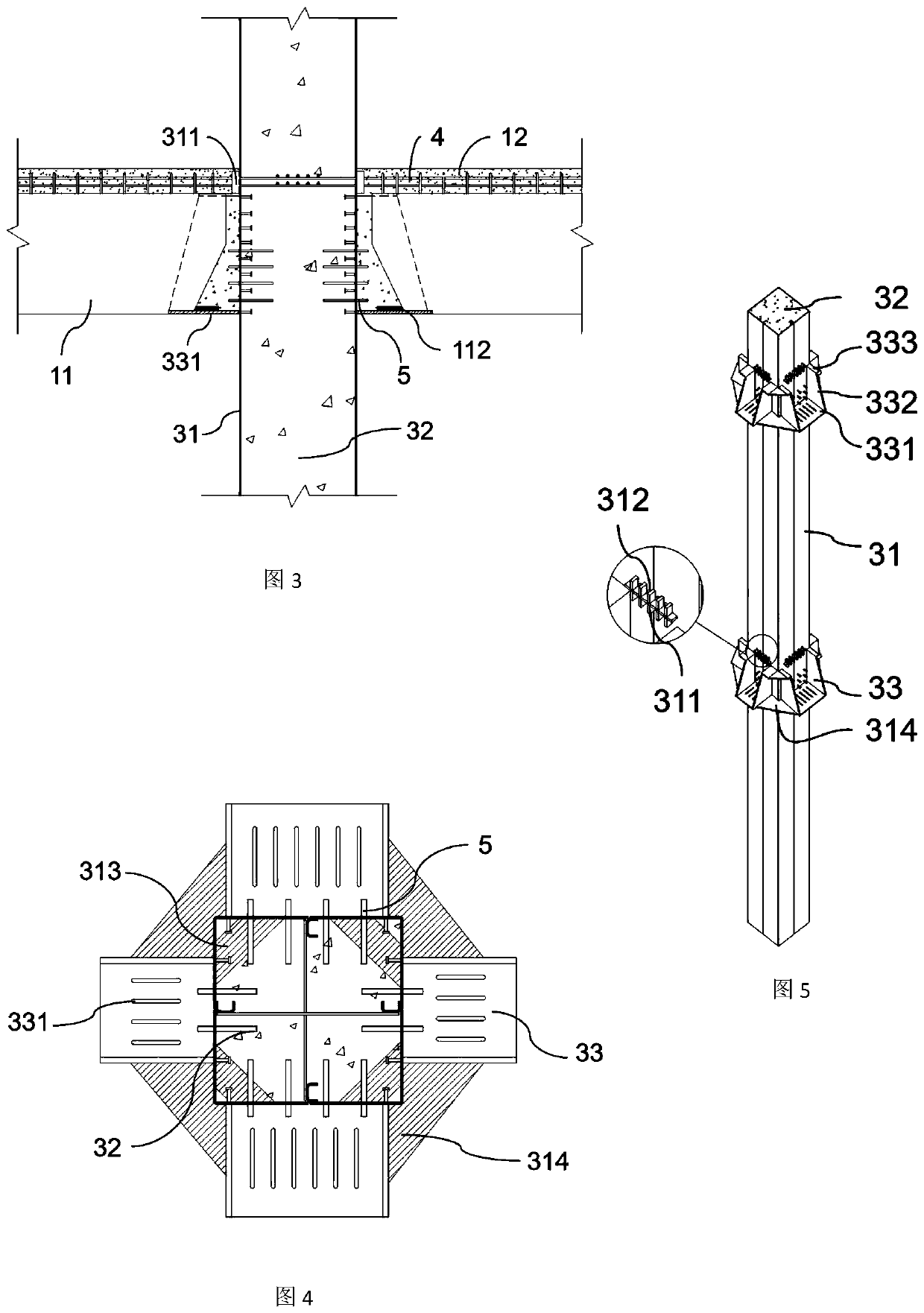

Construction method of novel assembled mixed frame structure system

InactiveCN111561058AImprove construction progressImprove carrying capacityFloorsFloor slabArchitectural engineering

The invention relates to a construction method of a novel assembled mixed frame structure system. The construction method comprises a foundation, a prefabricated concrete superposed beam, a steel deckcombined floorslab and a thin-walled steel pipe concrete combination column. The thin-walled steel pipe concrete combination column comprises a U-shaped steel bracket of a joint, a thin-walled steelpipe and steel pipe inner concrete. The prefabricated concrete superposed beam comprises a prefabricated beam and a cast-in-place part. The method can be used for hoisting the prefabricated beams of the multilayered frame structure system simultaneously by adopting a stepped construction method, so that the construction progress is accelerated and the cost is lowered.

Owner:宁波优造建筑科技有限公司

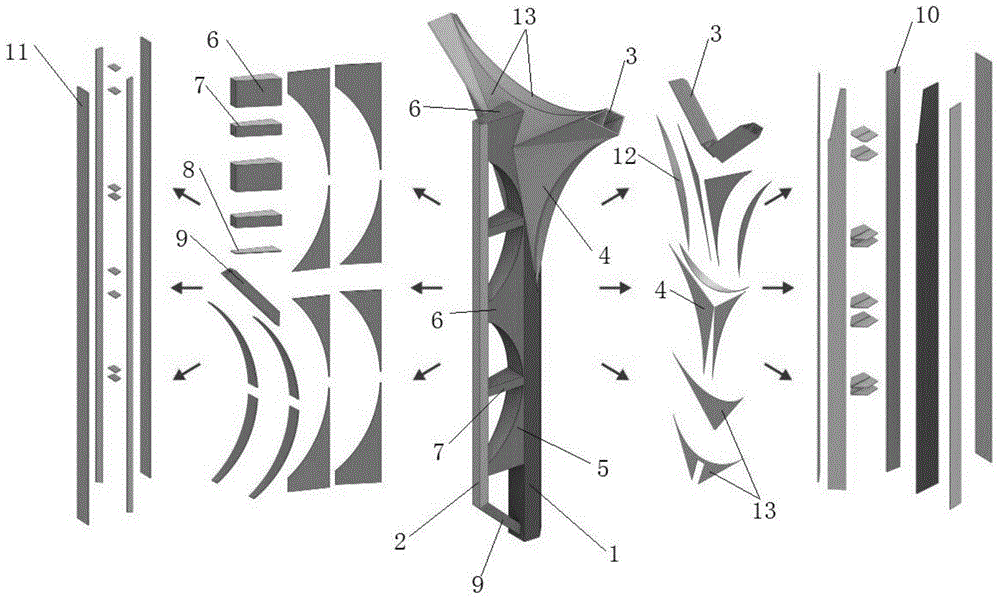

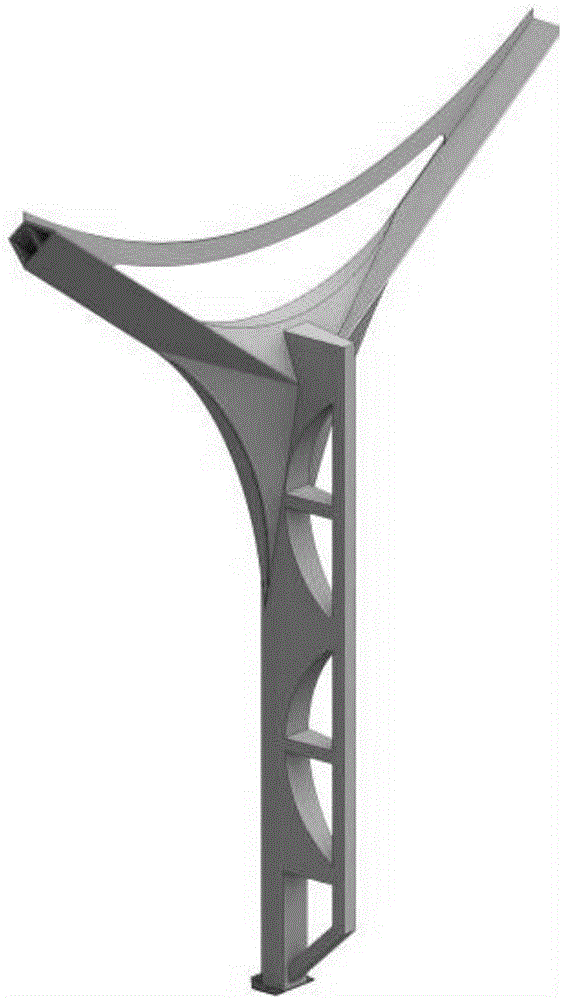

Y-shaped steel column and manufacturing method thereof

ActiveCN104389379AGuaranteed shape accuracySimplify the difficulty of subsequent constructionStrutsPillarsChinese charactersManufactured material

The invention discloses a Y-shaped steel column and a manufacturing method thereof. The Y-shaped steel column comprises a Y-shaped trunk and a front end part which is connected with the Y-shaped trunk, wherein the Y-shaped trunk comprises a box-shaped column of which the cross section takes the shape of a Chinese character ri, and inverted splayed steel plates mounted on the box-shaped column which takes the shape of the Chinese character ri; the front end part comprises a box-shaped column of which the cross section is square-shaped, and front-end steel plates which are connected with the square-shaped box-type column horizontally; the front part forms a shape consisting of two letters B which are arranged up and down after being connected; the inverted splayed steel plates and the front-end steel plates consist of specially-shaped components of different shapes; inclined support components connected with the box-shaped column which takes the shape of the Chinese character ri are further arranged at the bottom of the square-shaped box-type column. The Y-shaped steel column reflects perfect combination of art and construction engineering, by reasonably disassembling the Y-shaped steel column and due to detailed design of constitutional units, the later construction difficulty is relieved, the structure of the column is simplified to the maximum extent while the bearing property of the column is ensured, the raw materials are saved, and the effective building use area is increased.

Owner:JIANGSU HUNING STEEL MECHANISM

Side slope anchor rod construction device and rapid construction method

ActiveCN112302534AAvoid settingReduce the cost of construction measuresClimate change adaptationDirectional drillingArchitectural engineeringRock bolt

The invention provides a side slope anchor rod construction device and a rapid construction method. The side slope anchor rod construction device comprises a movable bearing trolley, the movable bearing trolley is provided with an operation table and a moving device connected with the operation table, the moving device comprises a supporting mechanism, the supporting mechanism is located below theoperation table, and an adjusting mechanism is arranged below the supporting mechanism. The side slope anchor rod construction device and the rapid construction method are economical, efficient and safe, and the problems that an auxiliary support is needed during side slope anchor rod construction, fixing is troublesome, the device is affected by the side slope terrain, a drilling machine is prone to moving during work, the drilling quality is unstable, and the construction safety is low are well solved.

Owner:中交昆明建设有限公司

Combination frame structure system with rigid-connection joints

PendingCN111576644AImprove construction progressImprove carrying capacityFloorsReinforced concreteFloor slab

The invention discloses a combination frame structure system with rigid-connection joints. The combination frame structure system comprises a prefabricated concrete superposed beam, a steel bearing plate composite floor and a thin-walled concrete-filled steel pipe composite column, the prefabricated concrete superposed beam comprises a prefabricated beam and a cast-in-place part, the cast-in-placepart is internally provided with a beam hogging moment rebar, and the prefabricated beam comprises a main bar and a beam end bottom steel plate; and the steel bearing plate composite floor comprisesa steel bearing plate and reinforced concrete poured on the steel bearing plate, the thin-walled concrete-filled steel pipe composite column comprises a thin-walled steel pipe, steel pipe inner concrete and a joint U-shaped steel corbel, the thin-walled steel pipe is provided with a through hole for reinforcing the steel plate and penetrating the hogging moment rebar at the joint, and a groove-shaped through hole is formed in the bottom of the joint U-shaped steel corbel. The composite column has large bearing capacity, the prefabricated beam can be hoisted at the same time in multiple layers,the beam hogging moment rebar directly penetrates through the joint in the joint area, the lower beam end steel plate is connected by overhead welding after the floor constructed is completed, the construction is convenient, the beam end lower rebar has direct and reliable force transfer, the structure is simple, and the comprehensive cost is low.

Owner:宁波优造建筑科技有限公司

Flat-opening temporary rotating guardrail at elevator shaft entrance of civil building

InactiveCN106592992AReduce the cost of construction measuresReduce sizeBuilding material handlingMeasurement costMechanical engineering

The invention discloses a flat-opening temporary rotating guardrail at an elevator shaft entrance of a civil building. The flat-opening temporary rotating guardrail comprises two guardrails, wherein one end of the two guardrails is respectively arranged at each of the two sides of the elevator shaft entrance through a rotating support base and is in rotatable connection with the elevator shaft entrance; the other ends of the two guardrails are interlocked with each other through a locking device; a fixing hole is formed on the rotating support base; the rotating support base is fixed on the outer side of the elevator shaft entrance in the manner of penetrating a bolt into the fixing hole. The flat-opening temporary rotating guardrail disclosed by the invention is designed as being made of section steel; the dedicated rotating support base can be reused; the construction measurement cost is lowered; the width of the two guardrails can be uniformly confirmed according to the width of each elevator shaft entrance and the size of the guardrails at the elevator shaft entrance can be reduced; the guardrail can be horizontally and outward rotated and opened in the process of temporary construction in the elevator shaft, so that the constructors can conveniently enter into the elevator shaft; the flat-opening temporary rotating guardrail can meet the neat, beautiful and safe standard of the guardrail of comprehensive floor; the civilized construction image can be promoted; higher social benefit can be acquired; the popularization and application values are higher.

Owner:CHINA MCC5 GROUP CORP

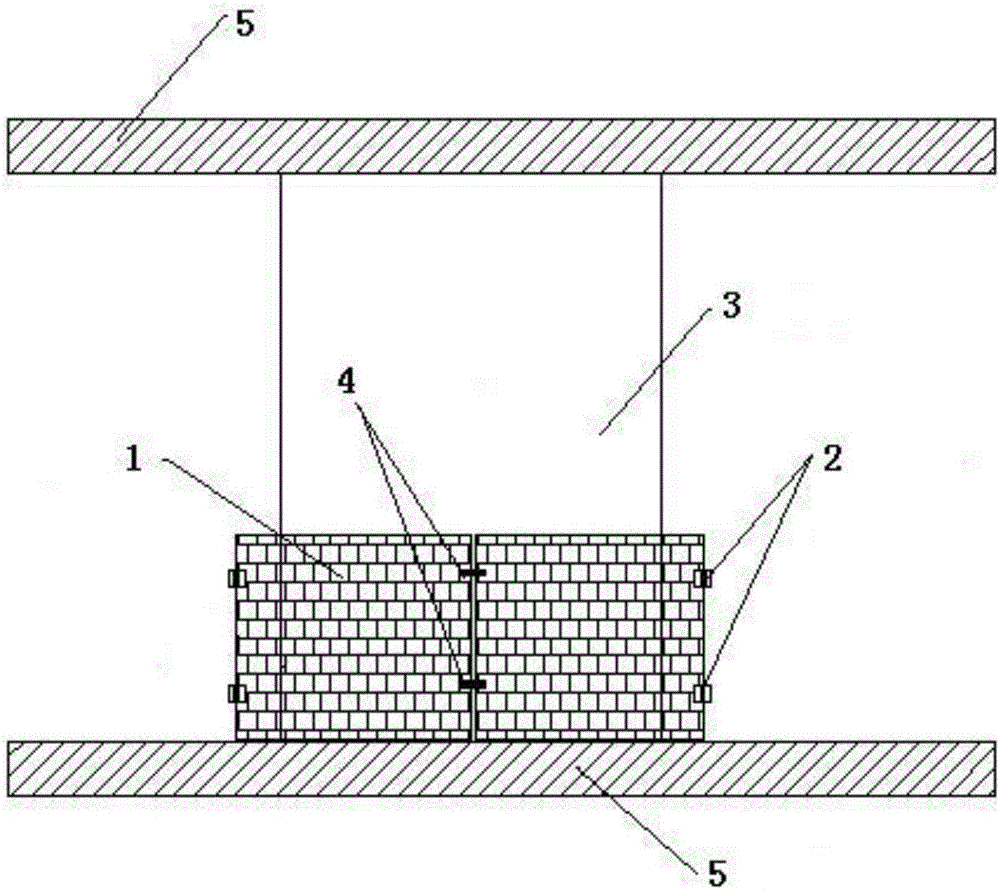

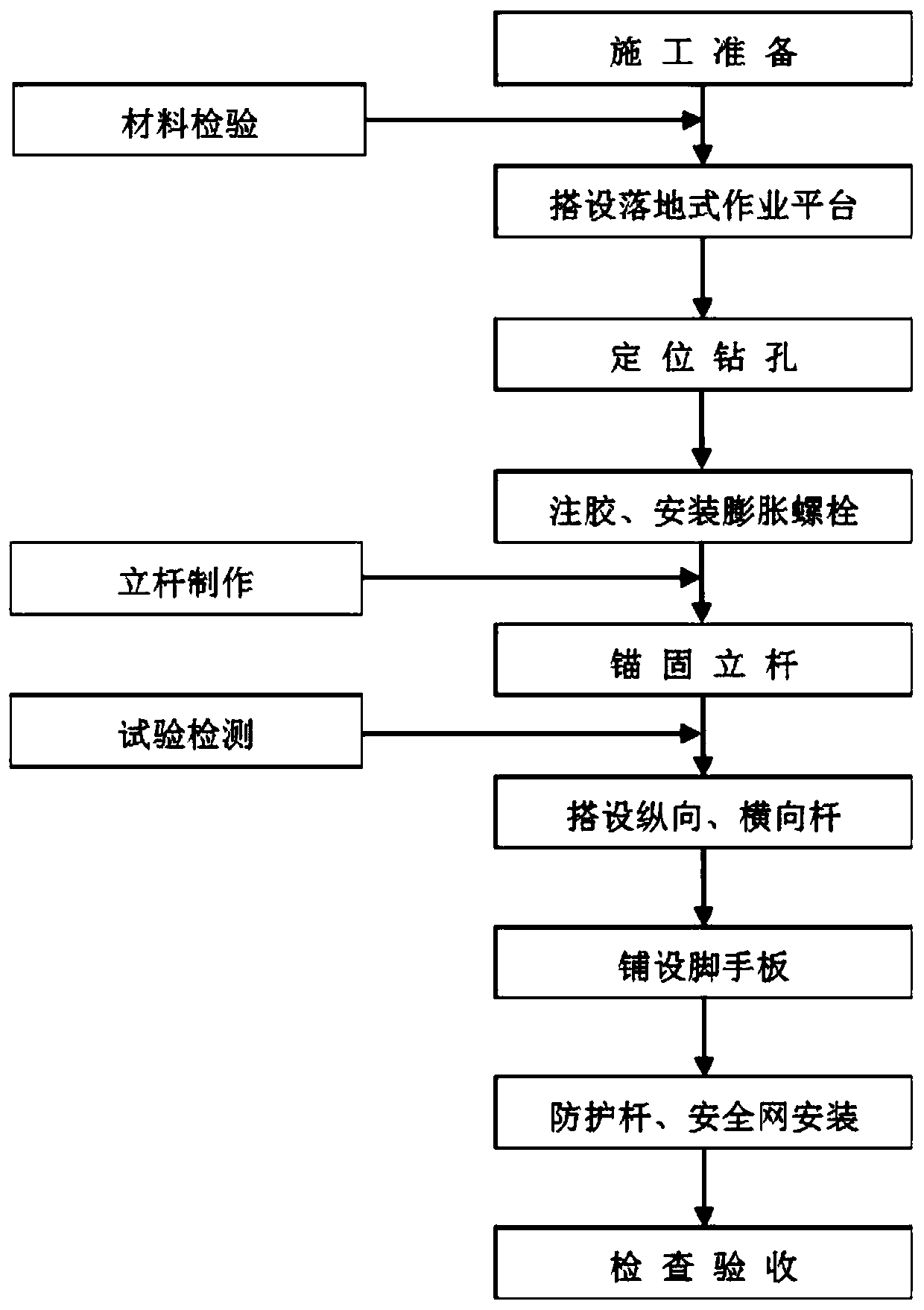

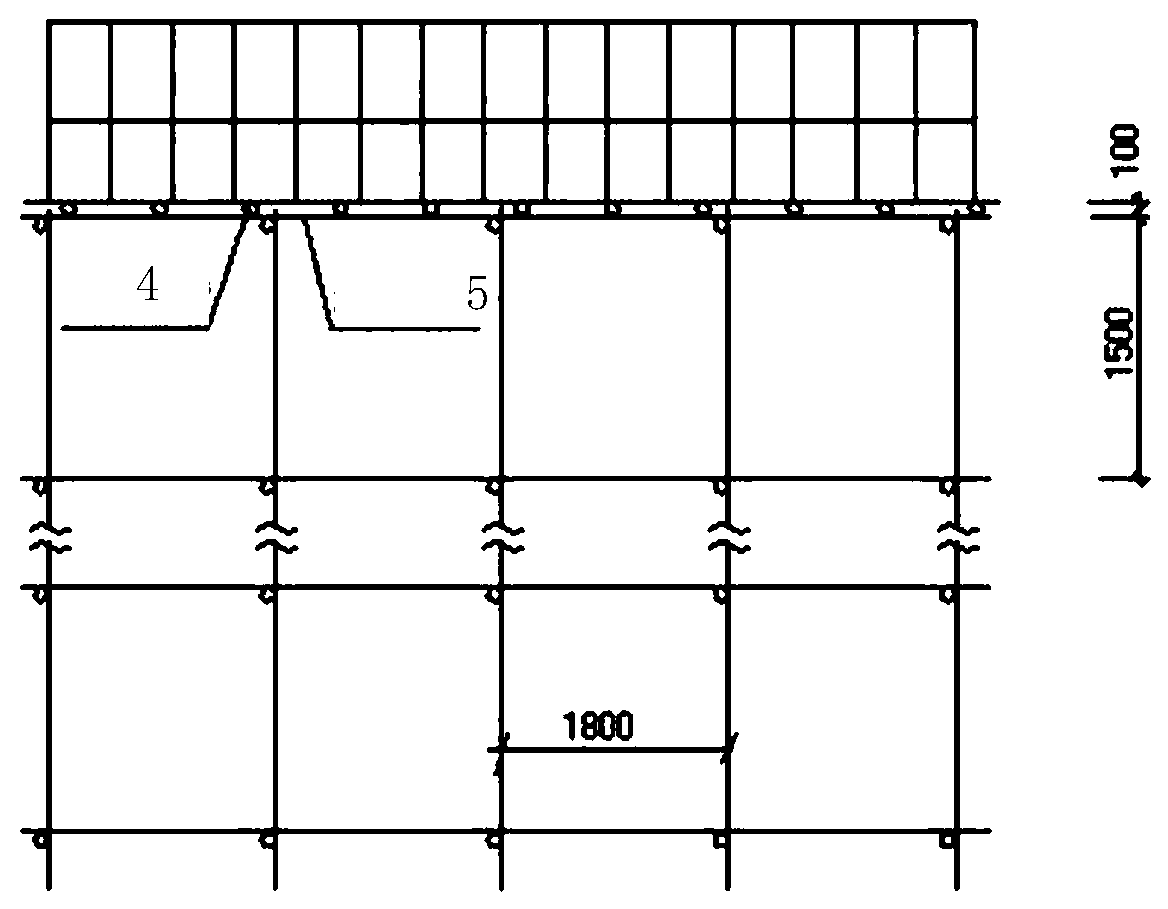

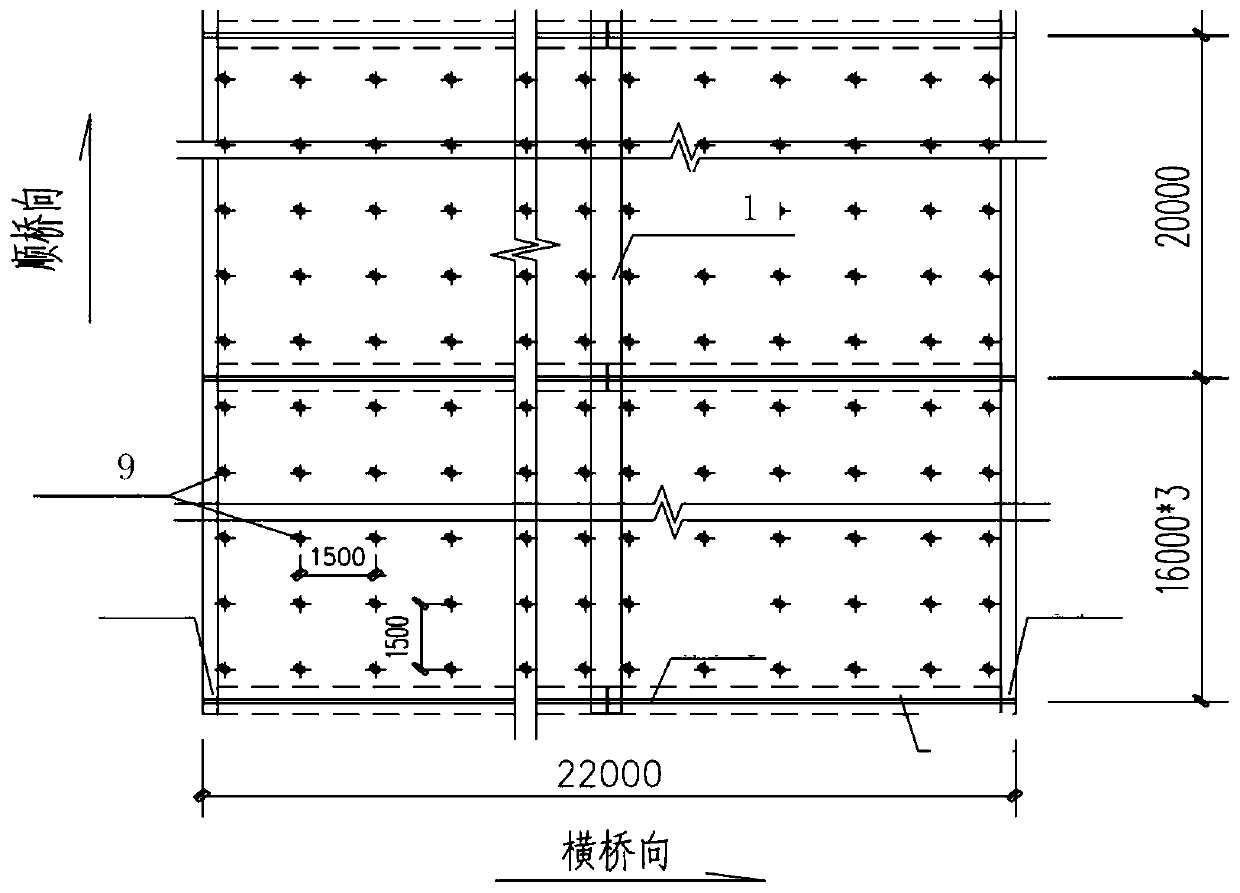

Reinforced concrete bridge suspension anchor type operation platform and construction method thereof

ActiveCN110485315ASave materialEffective combinationBridge erection/assemblyBridge strengtheningSafety netReinforced concrete

The invention discloses a reinforced concrete bridge suspension anchor type operation platform and a construction method thereof. The operation process mainly comprises the steps of performing construction preparation; erecting a floor type operation platform; carrying out positioning and drilling; performing glue injection, and installing expansion bolts; anchoring vertical rods; erecting longitudinal rods and transverse rods; laying scaffold boards; installing a protective fence and a safety net; and carrying out inspection and acceptance. The suspension anchor type operating platform builtby the construction method comprises bolts, hanging rods, hanging ring locking pieces, longitudinal rods, transverse rods, fasteners and scaffolds. By means of the design, the influence of on-site geography and hydrology is effectively overcome, the construction period is shortened, the construction measure cost is saved, and the platform is firm in structure and high in safety and stability through mutual fixation of the expansion bolts, the hanging rods, the fasteners, the hanging ring locking pieces and the scaffolds.

Owner:广西建工集团控股有限公司

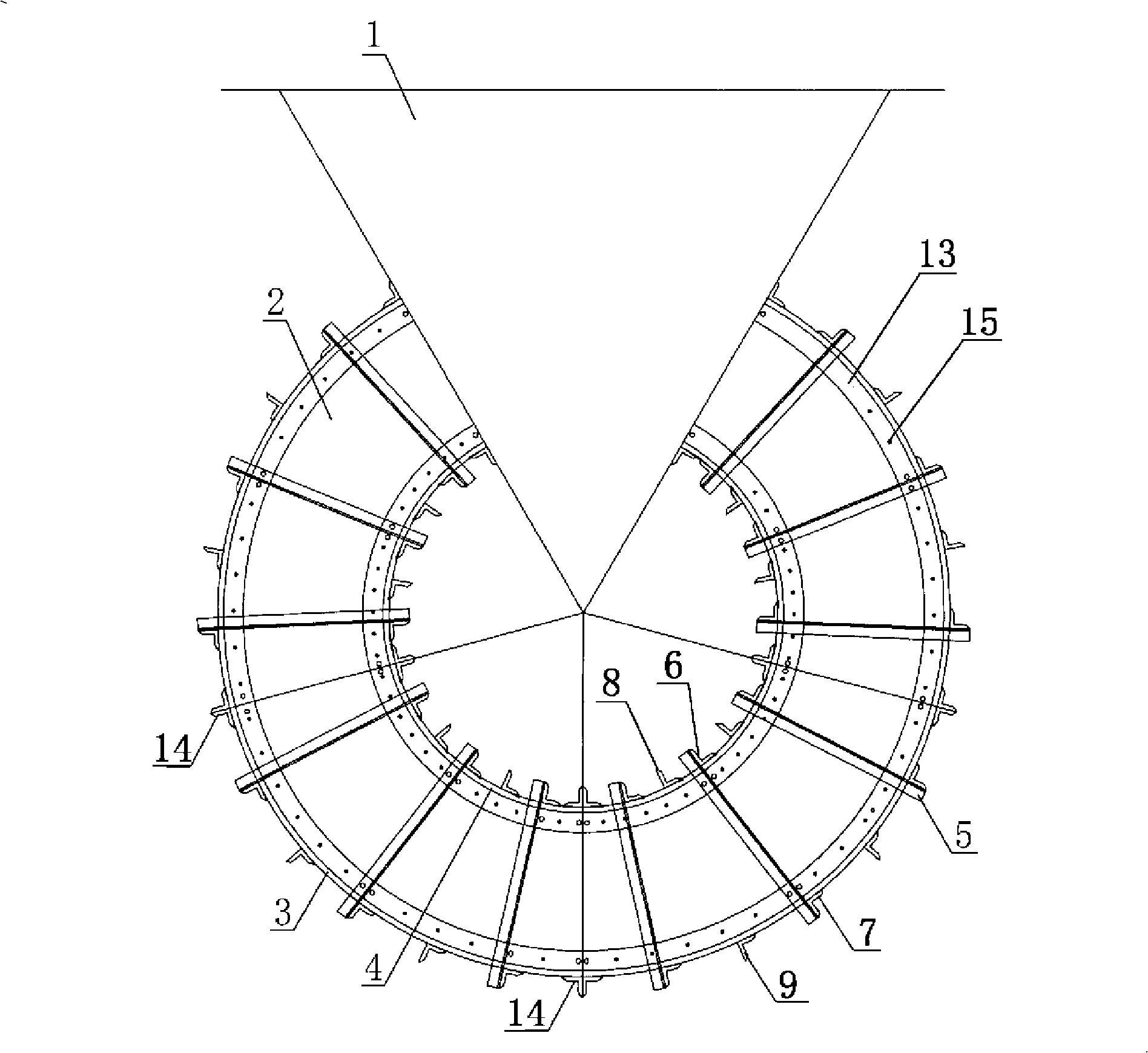

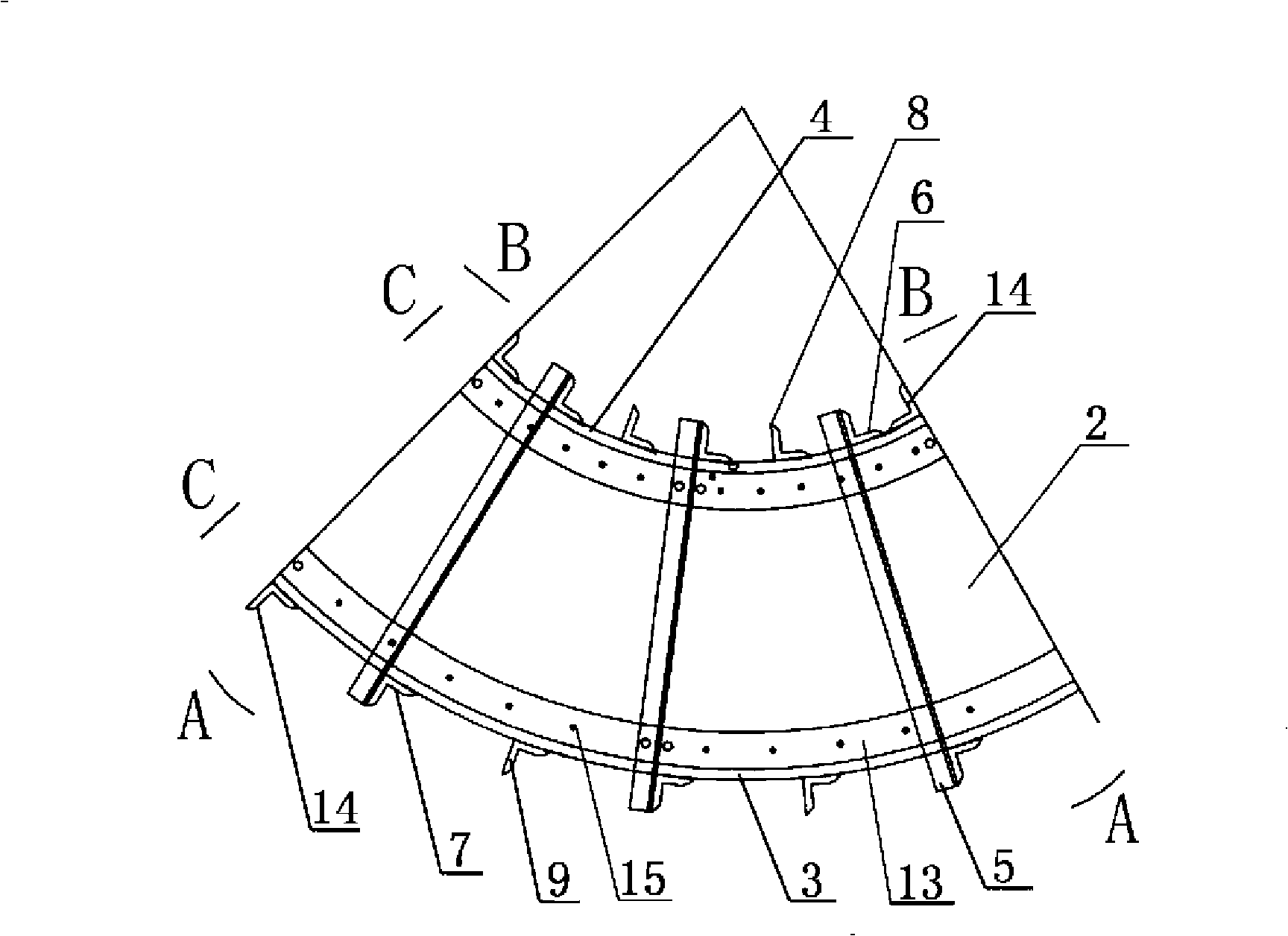

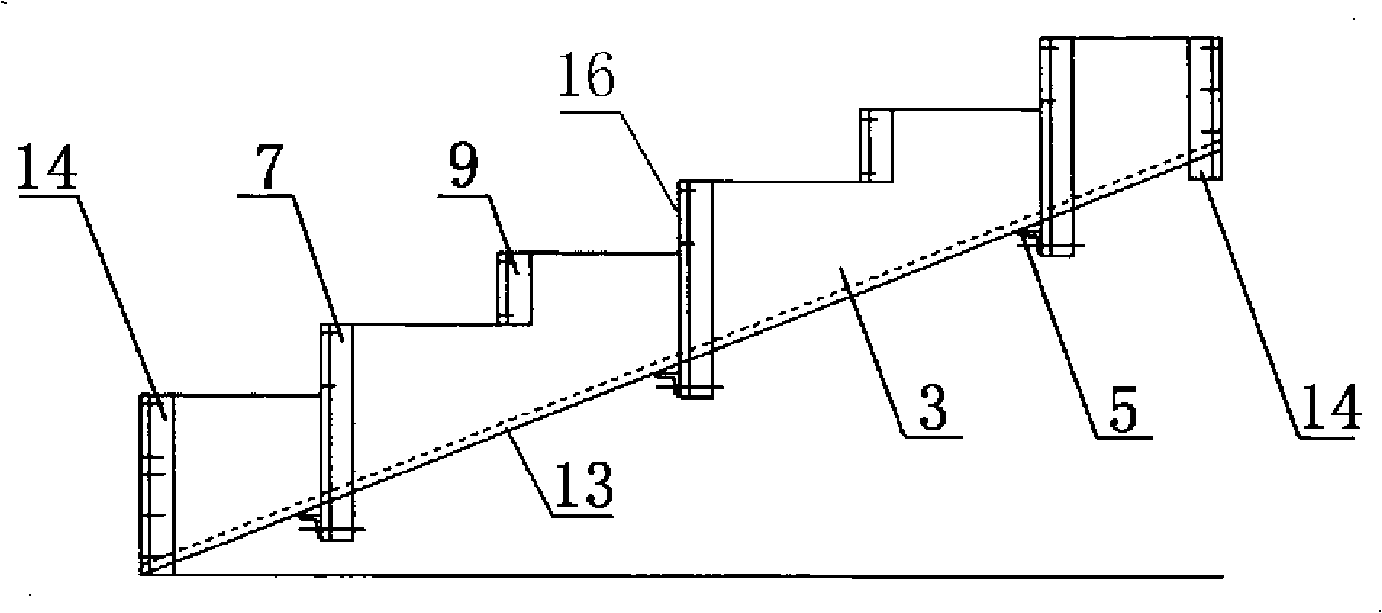

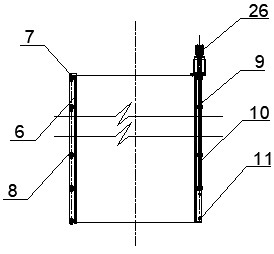

Three-blade pin hinge type bridge cylindrical pier column creeping formwork device

ActiveCN113403946ASolve the self-climbing (descending) functionSave the cost of cooperating with Taiwan shiftsBridge structural detailsForms/shuttering/falseworksArchitectural engineeringBoard structure

The invention discloses a three-blade pin hinge type bridge cylindrical pier column creeping formwork device and a construction method, and is applied to construction of a bridge cylindrical pier. The three-blade pin hinge type bridge cylindrical pier column creeping formwork device is divided into a formwork system, a platform system, a hydraulic jacking and fulcrum conversion system and a crawling ladder channel system. According to the structural system of the device, the creeping formwork concept, the mechanical principle that a pin hinge type formwork structure increases the degree of freedom of plates, the characteristic that hoops are combined with circular wedge-shaped supports and have the self-locking function are adopted, and the innovative thinking that through long pin shafts are combined, crawling ladder channels are synchronously lifted, and the bottom is lengthened and connected with standard sections is adopted; the problems that a two-blade bolting type formwork structure used for several decades is difficult to technically improve, the entity project amount is small, the measure cost input cost is high, the safety controllability of a large amount of aloft work is poor, and the work labor intensity is large are solved. Popularization and application of the three-blade pin hinge type formwork structure have revolutionary influence on the construction technology of the cylindrical pier, and the construction of the cylindrical pier enters the era of the three-blade pin hinge type formwork structure.

Owner:杨铖章 +1

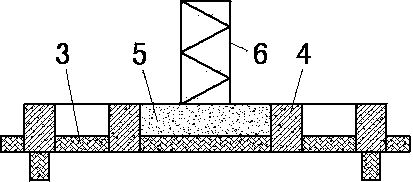

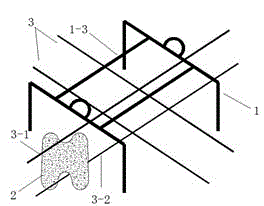

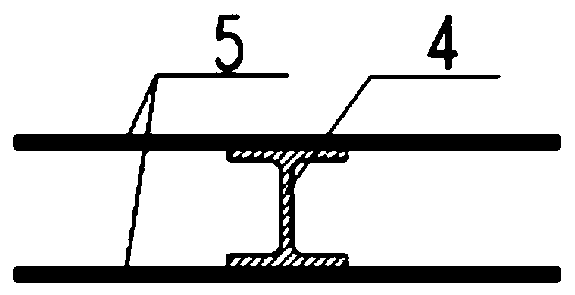

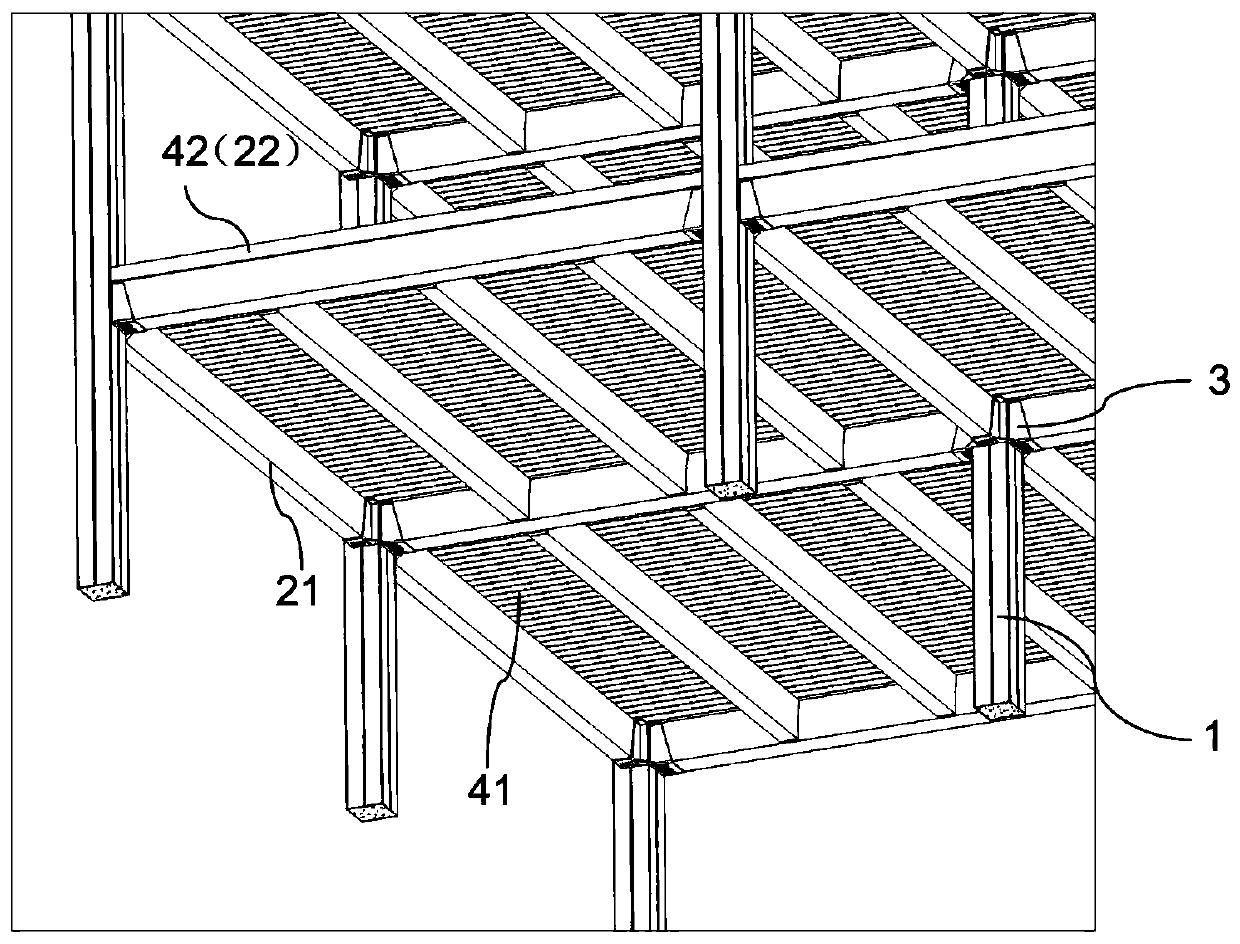

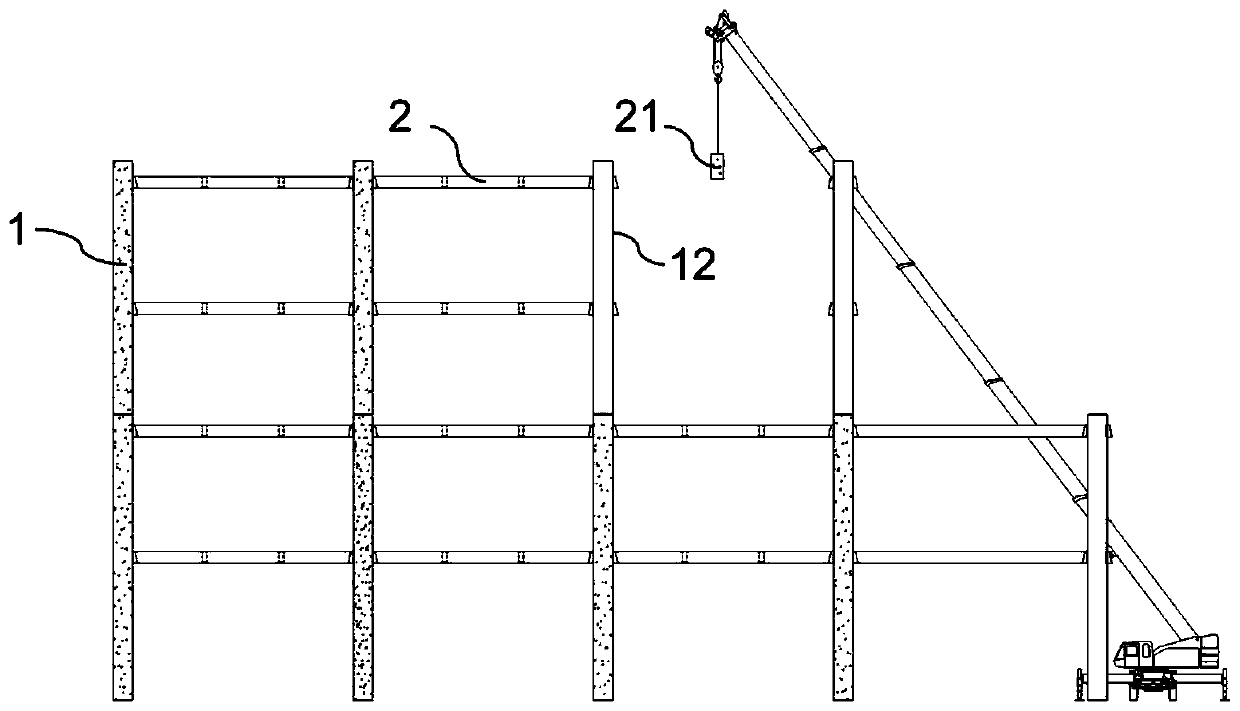

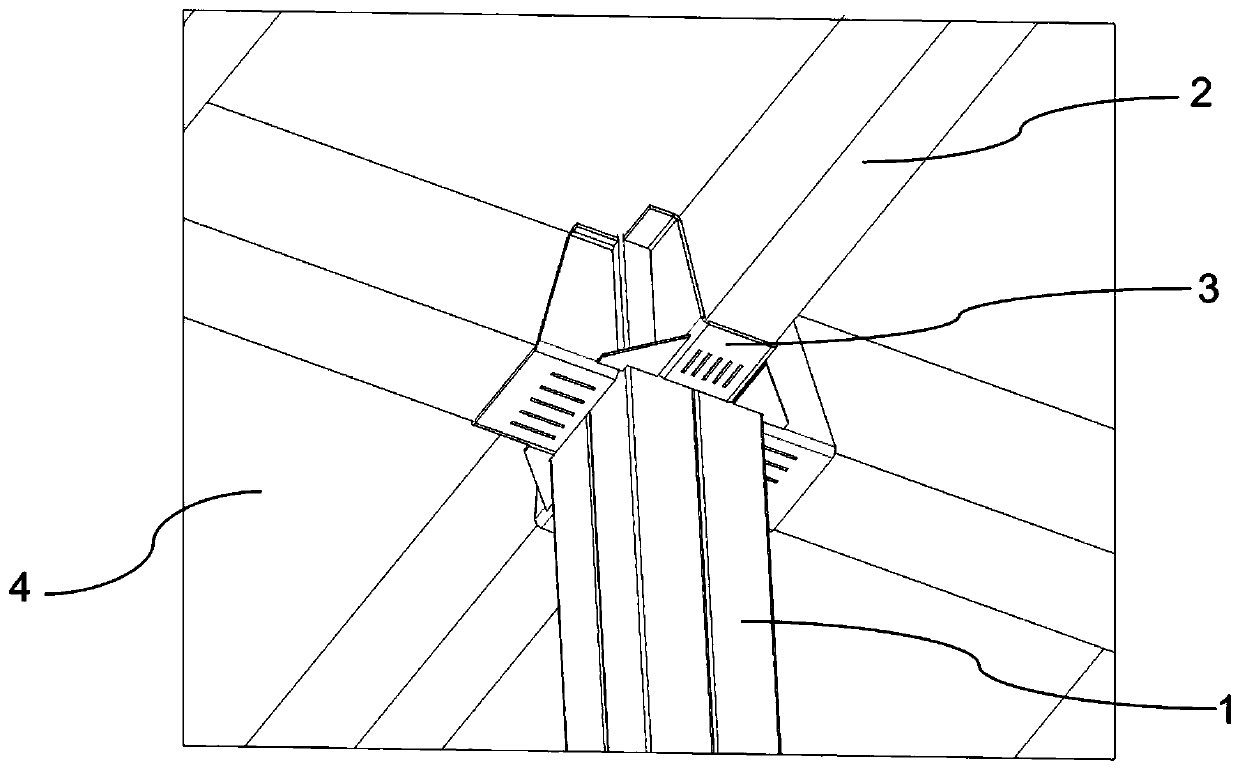

Novel steel truss concrete slab form support system

InactiveCN102720355AEasy to operateAvoid influenceForms/shuttering/falseworksSupporting systemSheet steel

The invention discloses a novel steel truss concrete slab form support system which comprises steel truss shaped steel beams (3), an I-shaped steel keel (5), a forming template box (1), a square wooden column (2), steel plate welding corbel-pieces (6) and a to-be-poured concrete floor (4), wherein the I-shaped steel keel (5) is arranged between the steel truss shaped steel beams (3) and serves as a template supporting main keel; the square wooden column (2) is distributed in vertical to the I-shaped steel keel (5), and the forming template box (1) is arranged at the upper part of the square wooden column (2); the forming template box (1) serves as a concrete slab bottom form; and the steel plate welding corbel-pieces (6) are welded on the steel truss shaped steel beams (3). The novel steel truss concrete slab form support system provided by the invention has the advantages that the support system is simple to operate, the investment is reduced, and influence, which is caused by reinforcing a lower part floor, on others procedures of construction in the lower part floor can be avoided.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

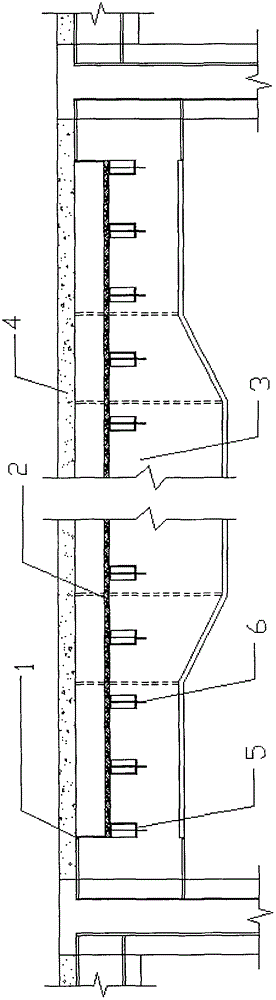

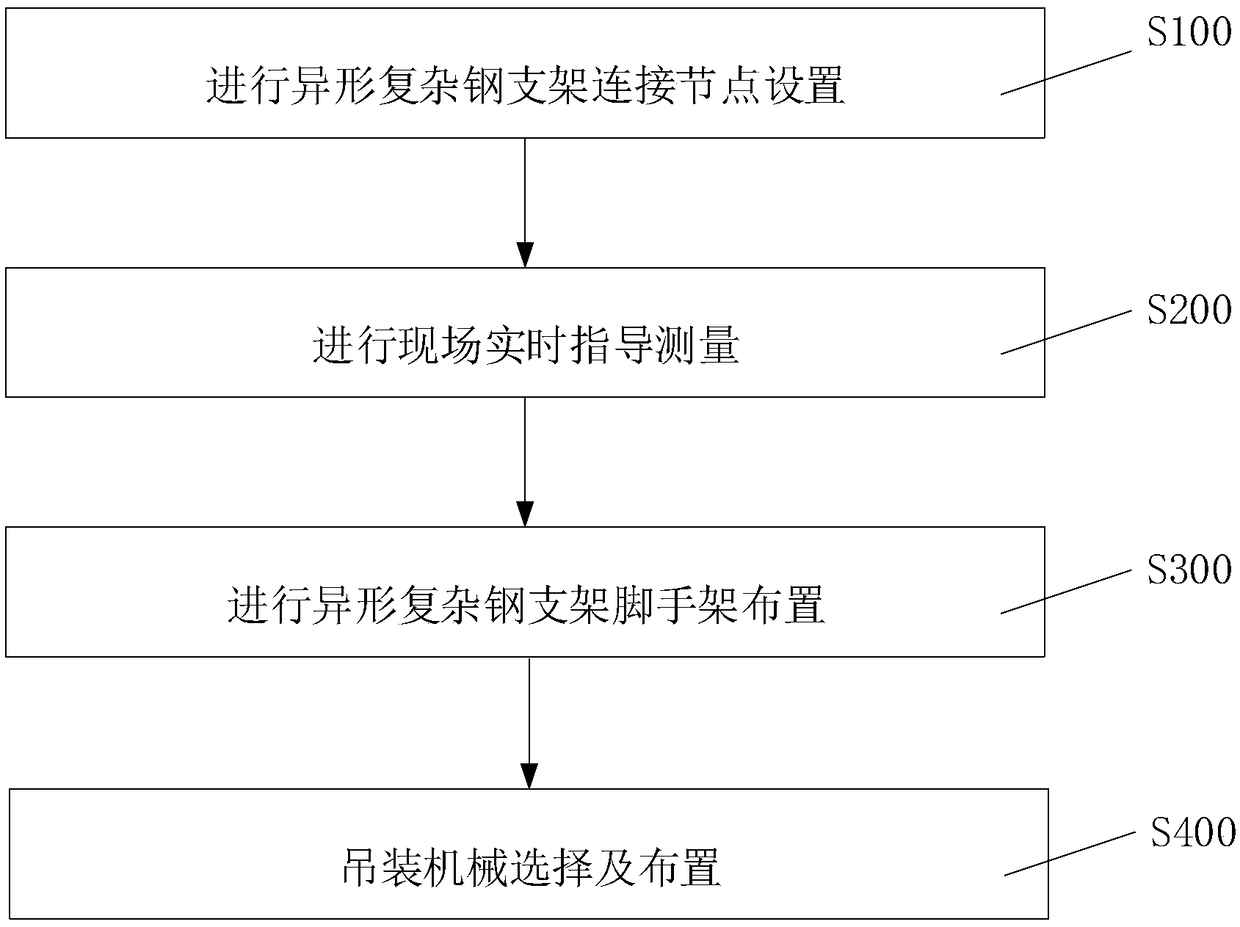

Construction method of plastic stone rockery special-shaped complex steel support structure

InactiveCN109113346AHigh strengthImprove operabilityBuilding material handlingReinforced concreteOperability

The invention provides a construction method of a plastic rockery stone special-shaped complex steel support structure. The construction method of the plastic rockery stone special-shaped complex steel support structure comprises the following steps that connection joints of a special-shaped complex steel support are arranged, the connection problem of main and secondary limbs of a steel support and a base and steel support structure is solved, and a reasonable connection mode between members is provided; field real-time guide measurement is carried out, and according to the difference of thefield measurement requirements, a theoretical value corresponding to an actual point position is provided in real time to ensure the operability and precision control requirements of field measurement; the layout of a special-shaped complex steel support scaffold is carried out, so that the problem of a construction operation channel and an operation platform is solved to ensure the safety and operation convenience of personnel; and hoisting machinery is selected and arranged, so that the problem of the steel support hoisting machinery is solved to ensure the construction quality and construction efficiency. According to the construction method of the plastic rockery stone special-shaped complex steel support structure, it is ensured that the construction quality and precision of the steelsupport structure meet the requirements of glass fiber reinforced concrete (GRC) precast members, and meanwhile, the construction efficiency is improved, and the construction cost is reduced.

Owner:SHANGHAI MECHANIZED CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com