Reinforced concrete winding stairs die type formwork and its construction method

A reinforced concrete and mold technology, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of large consumption of construction wood, difficult reinforcement, and high construction cost, and achieve savings. Cost of construction measures, improvement of construction quality and progress, and effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

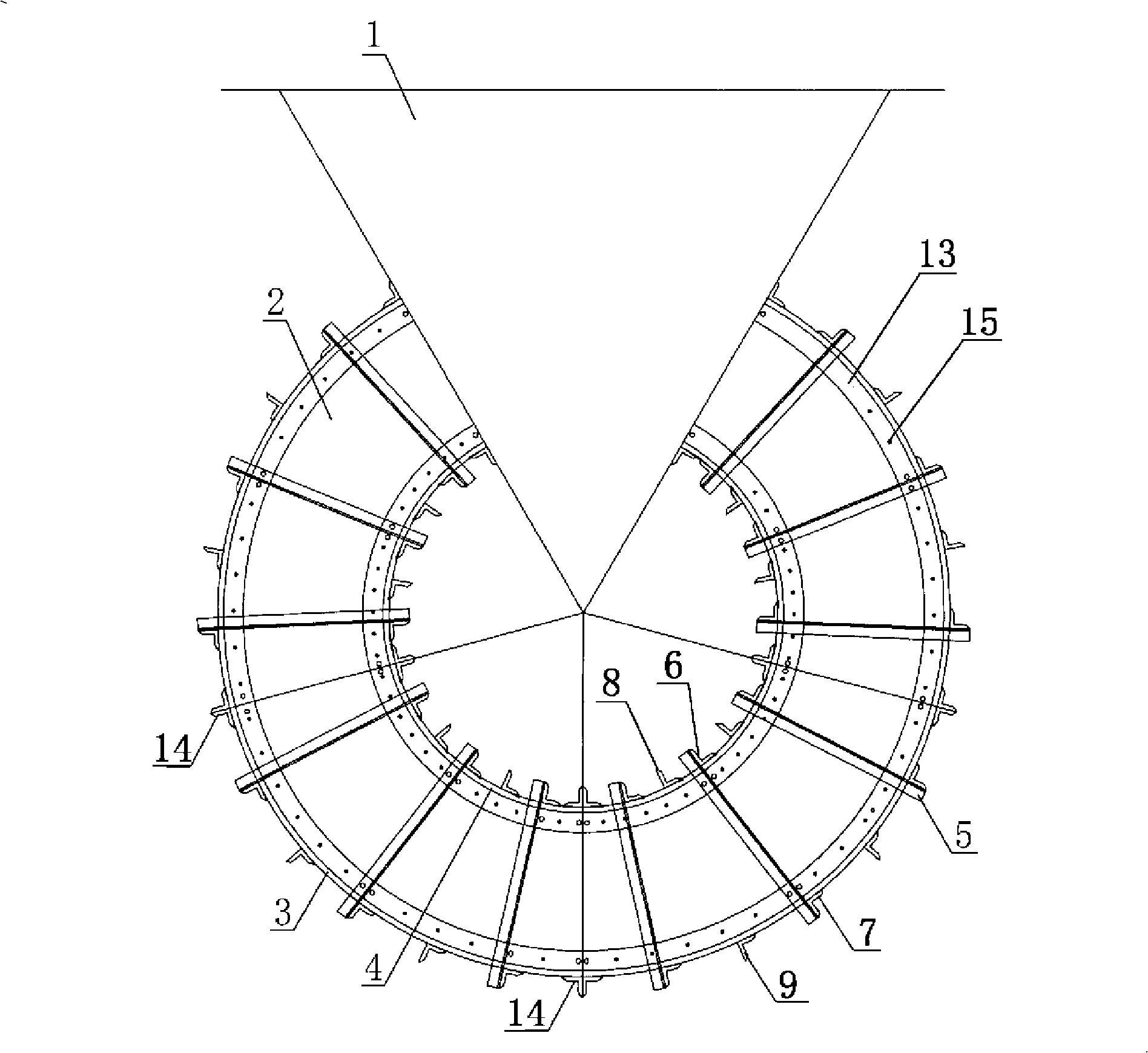

[0030] For an example of a silo spiral ladder see figure 1 As shown, this reinforced concrete spiral staircase mold formwork includes a bracket located at the position of the spiral staircase between the upper and lower floors of the building 1, the inner panel 4, the outer panel 3, the front side panel 16, and the enclosed area of the inner panel 4 and the outer panel 3 Inner bottom plate 2. The formwork is divided into at least two sections along the spiral direction, and each section is connected end-to-end by bolts and section end angle steels to form a spiral detachable mold-type shaped steel formwork.

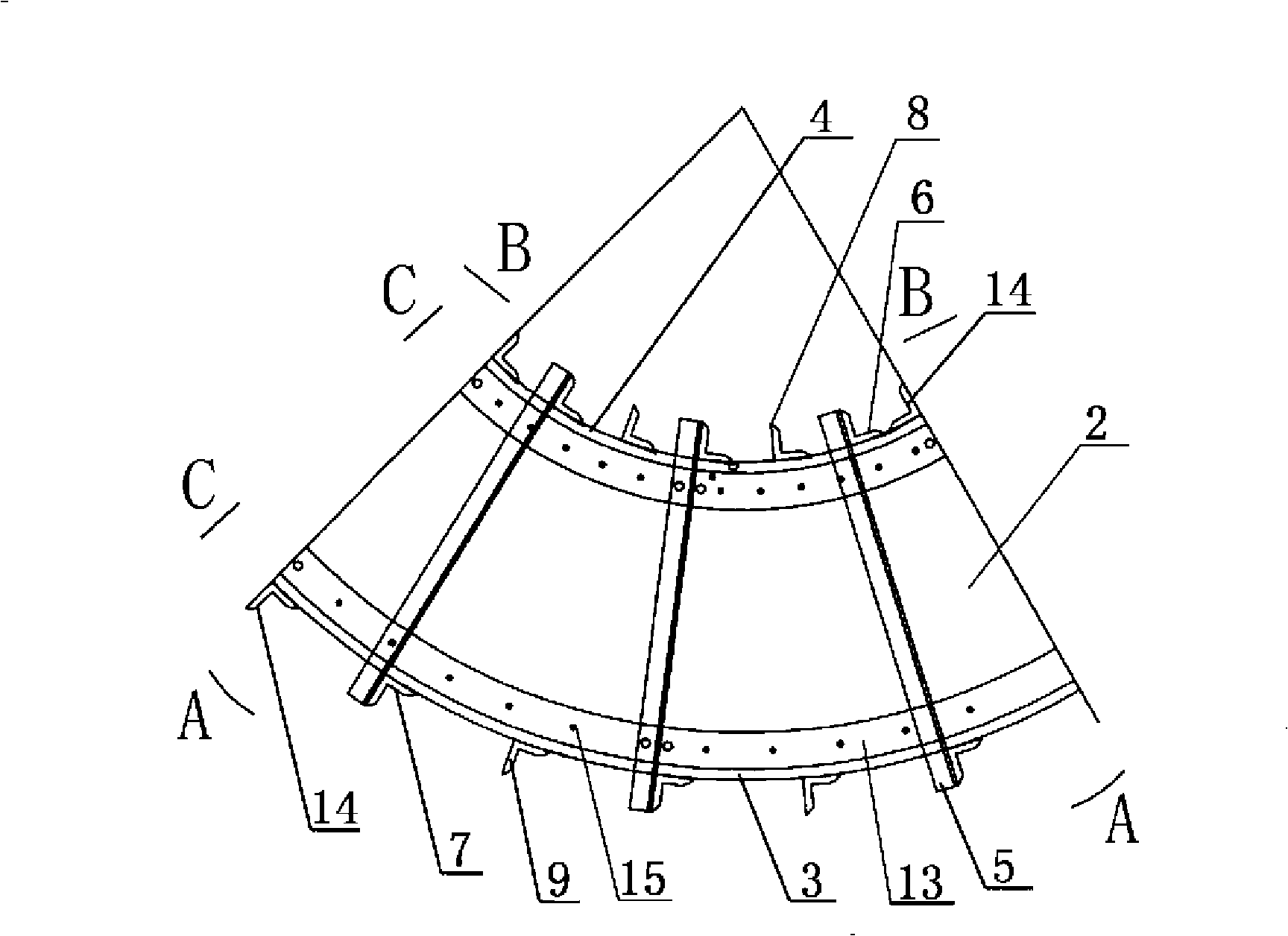

[0031] see figure 2 , the upper and lower longitudinal sides of each section are fixedly connected to the section end angle steel 14, and the bolts and the section end angle steel are used to assemble each section end to end into a spiral mold type shaped steel template.

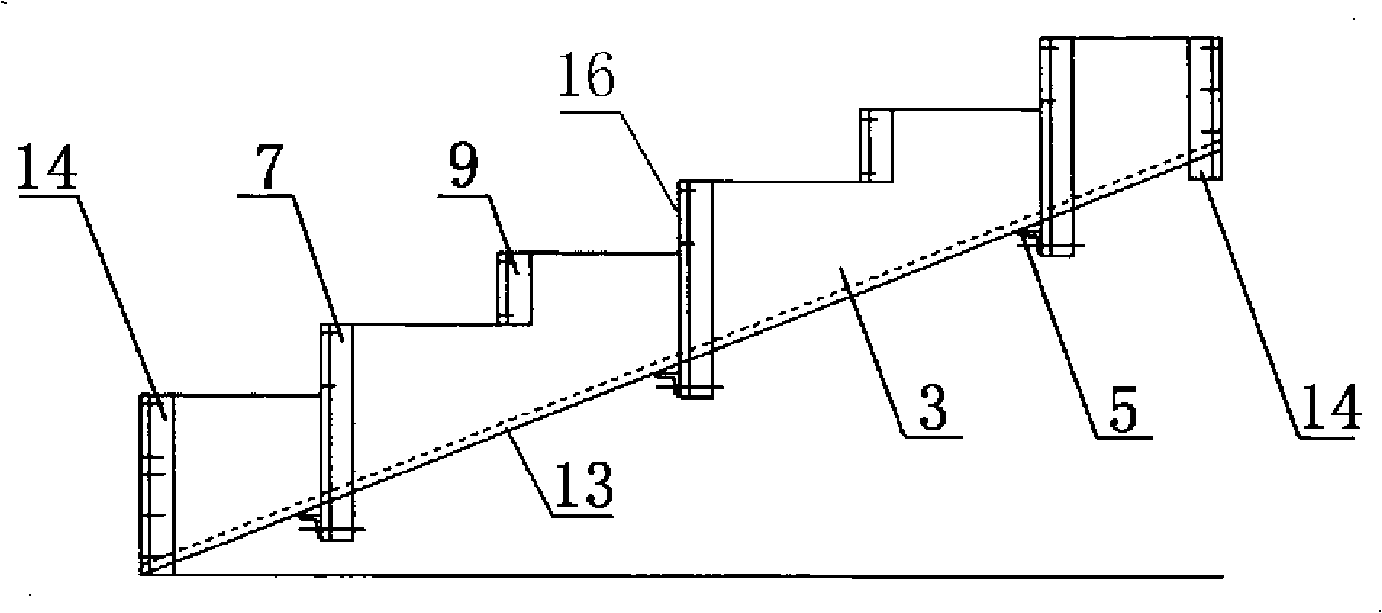

[0032] see image 3 , Fig. 4, inner plate 4 and outer plate 3 are made of 3mm thick steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com