Bridge caisson composite pile foundation and reverse construction method thereof

A construction method and technology of composite piles, applied in caissons, foundation structure engineering, construction, etc., can solve problems such as difficult adaptation, high foundation engineering costs, high cost, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is used to explain the technical solution of the present invention, and the protection scope of the present invention is not limited to the construction steps and corresponding structures described in the following examples.

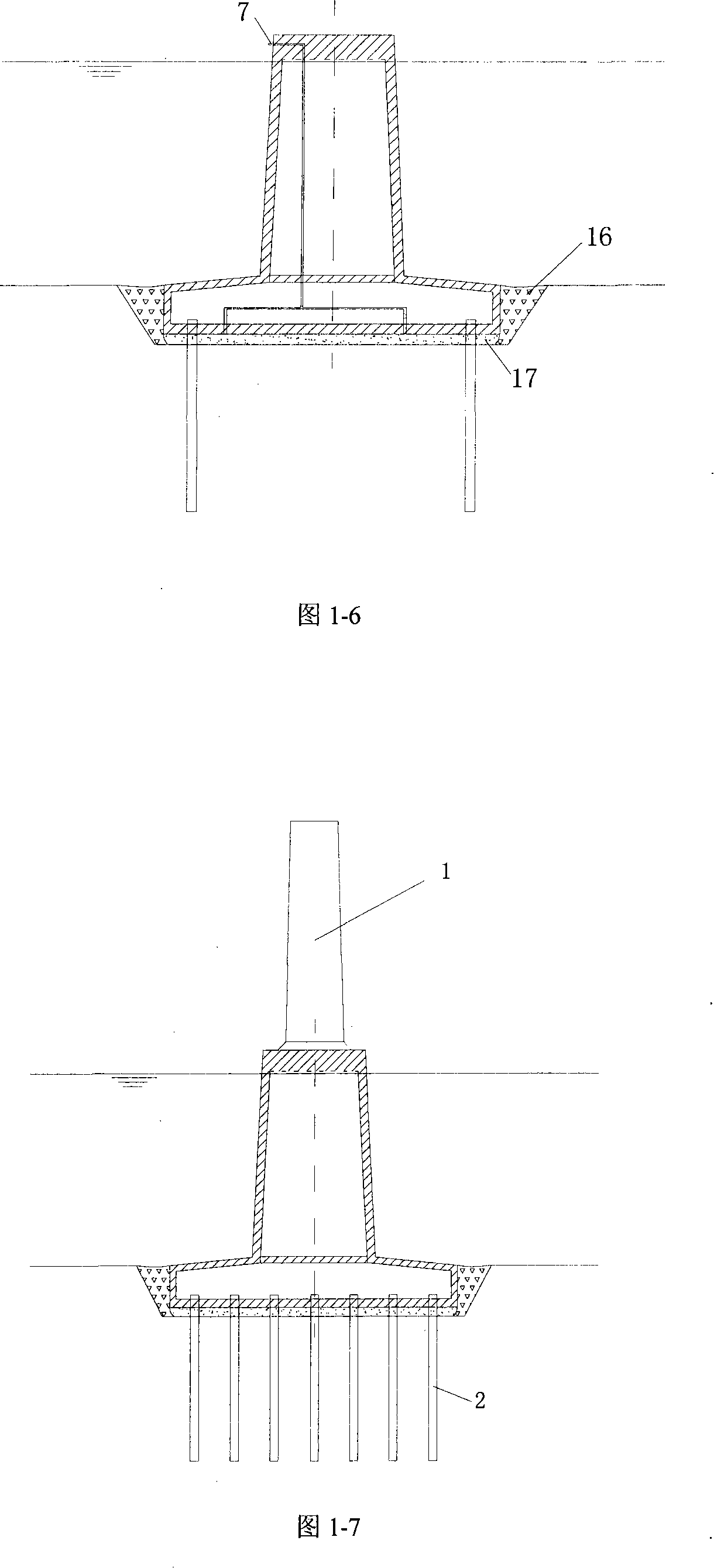

[0025] Inverse construction of bridge caisson composite pile foundation:

[0026] Basic dredging:

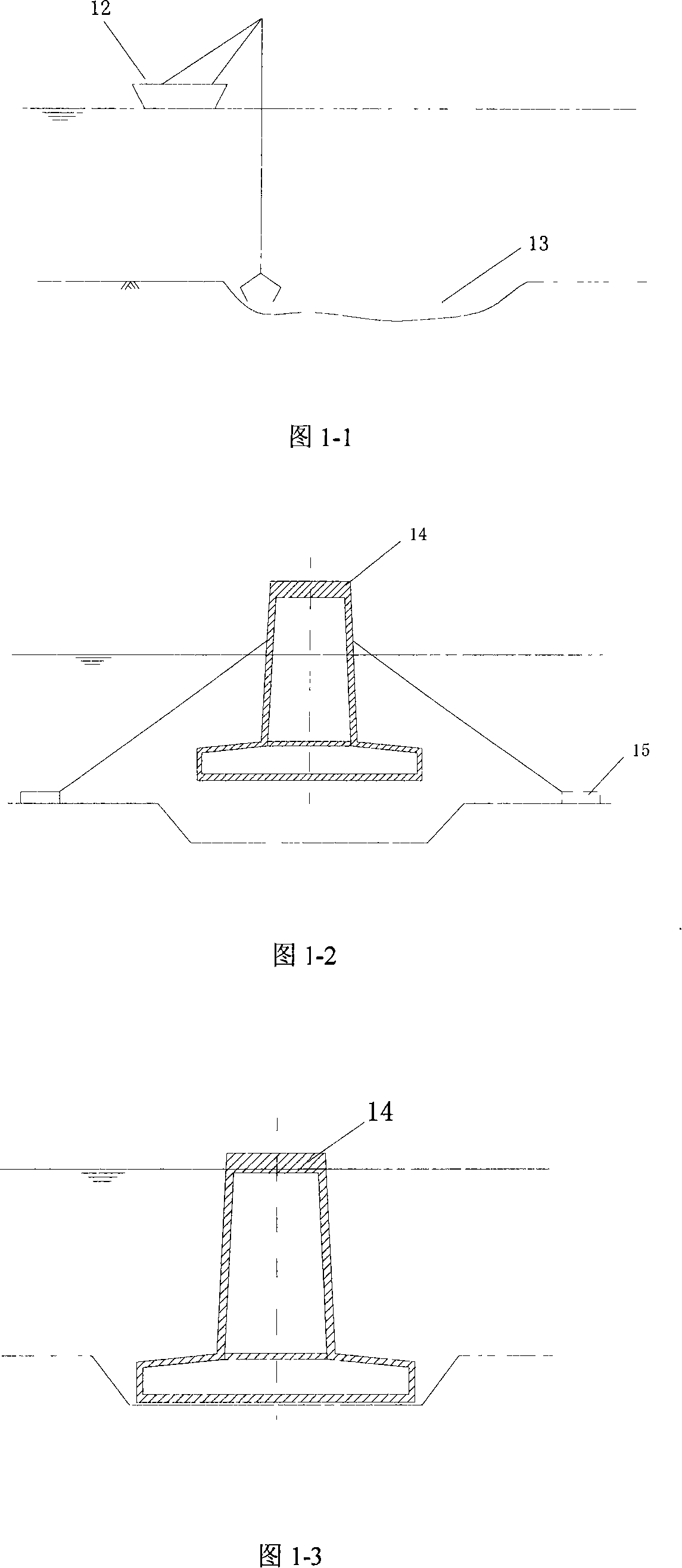

[0027] The dredger 12 carries out foundation dredging and excavation, excavates the foundation trench 13 where the caisson is placed, and the bed surface is basically flat (height difference within 2 meters is acceptable) (accompanying drawing 1-1);

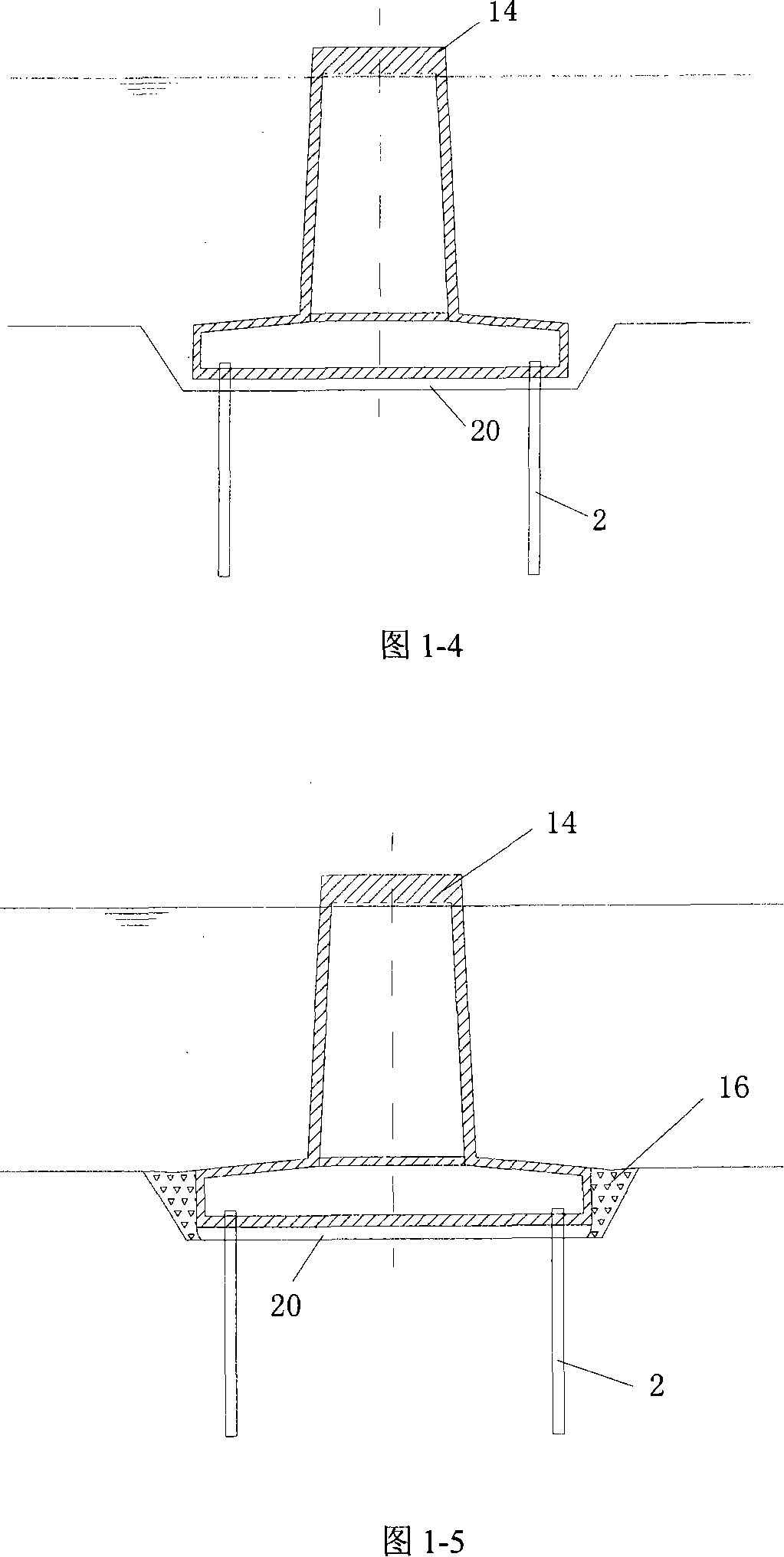

[0029] The caisson 14 is prefabricated as a whole on land and entered into the water, floated to the site, and the anchorage system 15 is used to locate the anchorage of the caisson. The internal clearance height of the caisson is not less than 5 meters. The compartments with separate internal structures, the compartment bulkheads 4 are provided with conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com