Concrete filled steel tube lattice type wind power tower based on corrugated steel web box girder

A technology of corrugated steel webs and concrete-filled steel tubes, which is applied in wind power generation, wind engines, installation/supporting configurations of wind engines, etc., can solve problems such as easy resonance, difficult transportation, economical decline, etc., to reduce wind loads, The effect of reducing the workload and reducing the amount of materials used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

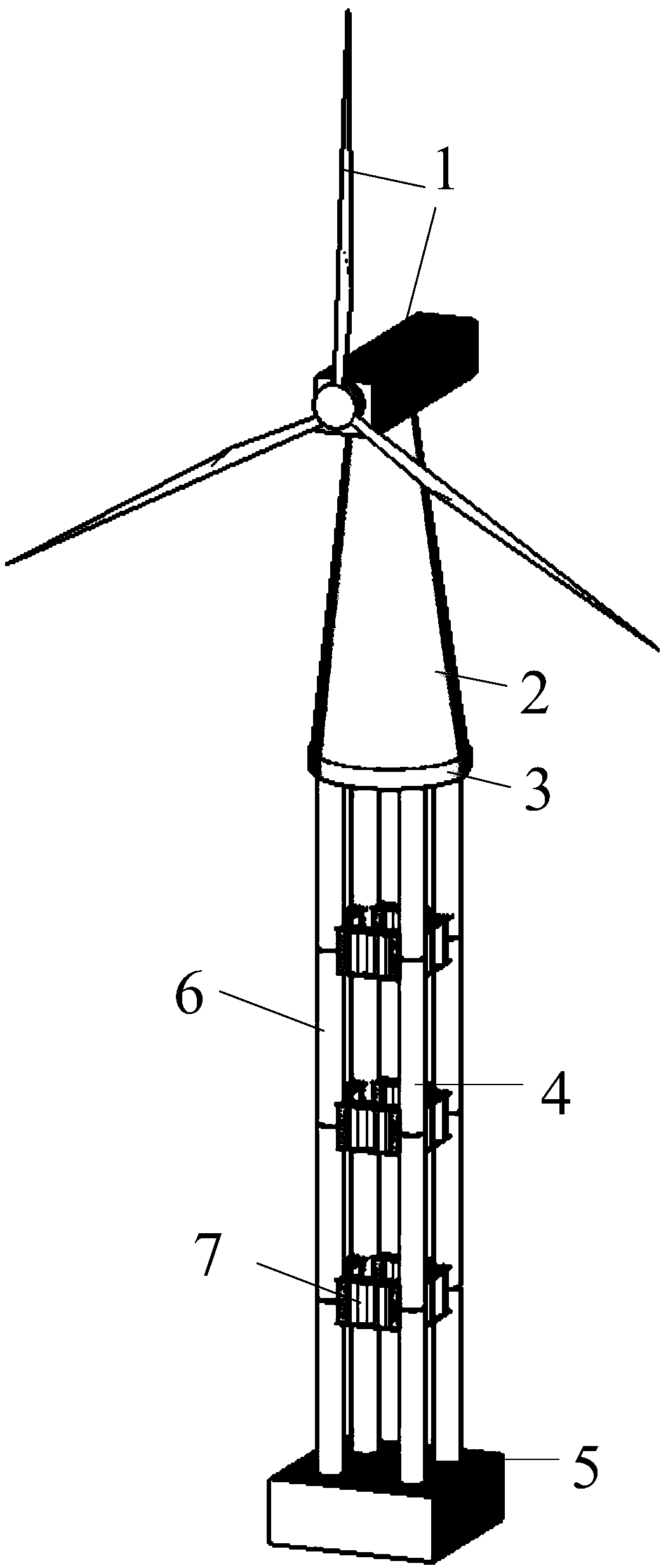

[0023] Such as figure 1 As shown, a steel pipe concrete lattice wind power tower based on a corrugated steel web box girder relates to the technical field of onshore wind power generation. The system includes a fan (1), an upper steel tower (2), a ring-shaped steel-concrete composite box girder (3), a lattice tower (4), and a foundation (5). The lower parts of the limbs (6) of the lattice tower (4) are directly anchored into the foundation (5), and are connected with the upper steel tower tube (2) through a ring-shaped steel-concrete composite box girder (3); The piece (6) can be segmented according to its length, and each segment is connected into a whole (9) through prestressing, and a shear steel pipe (15) is arranged at the splicing position; the structure is arranged on the upper steel tower (2) a fan.

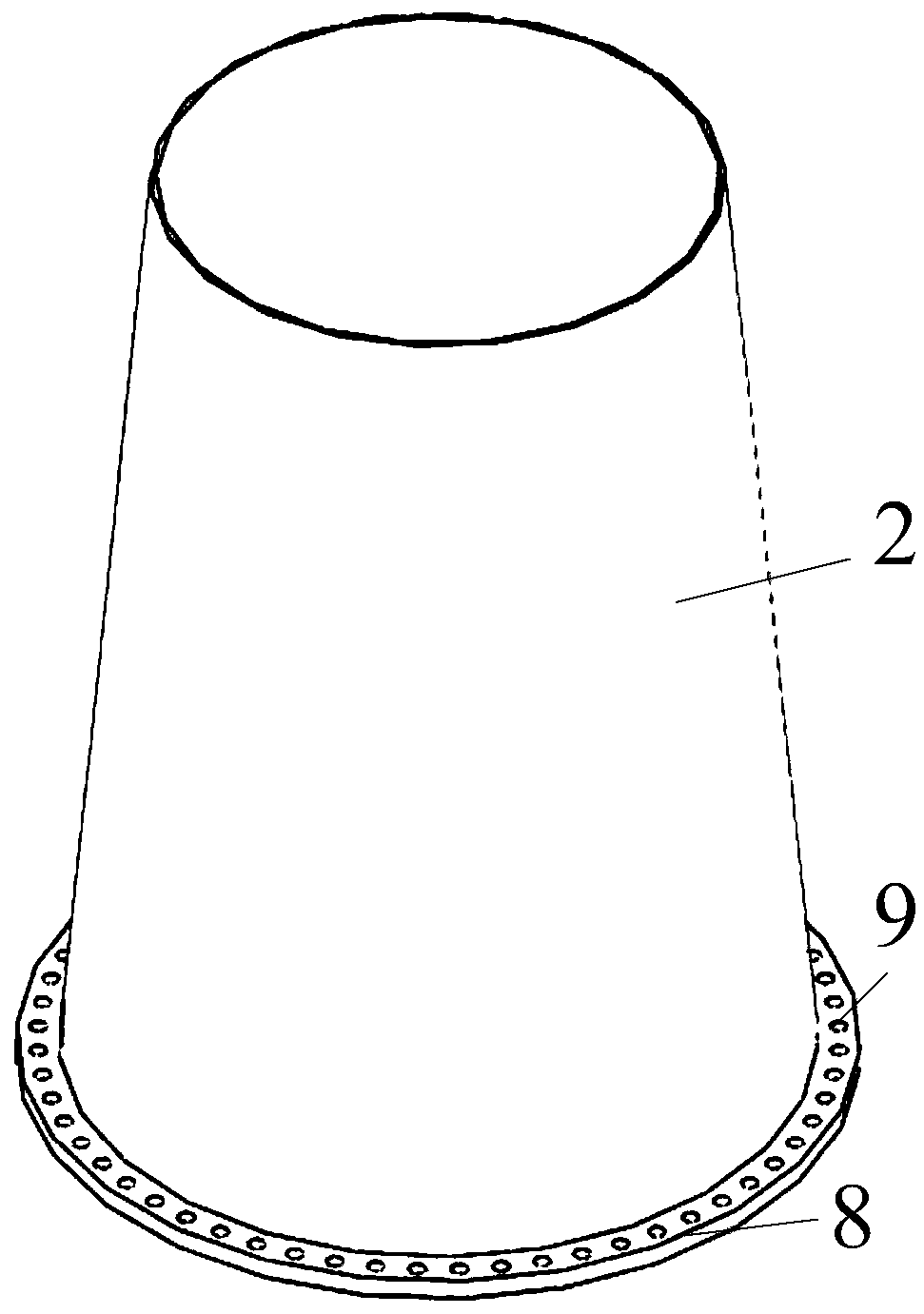

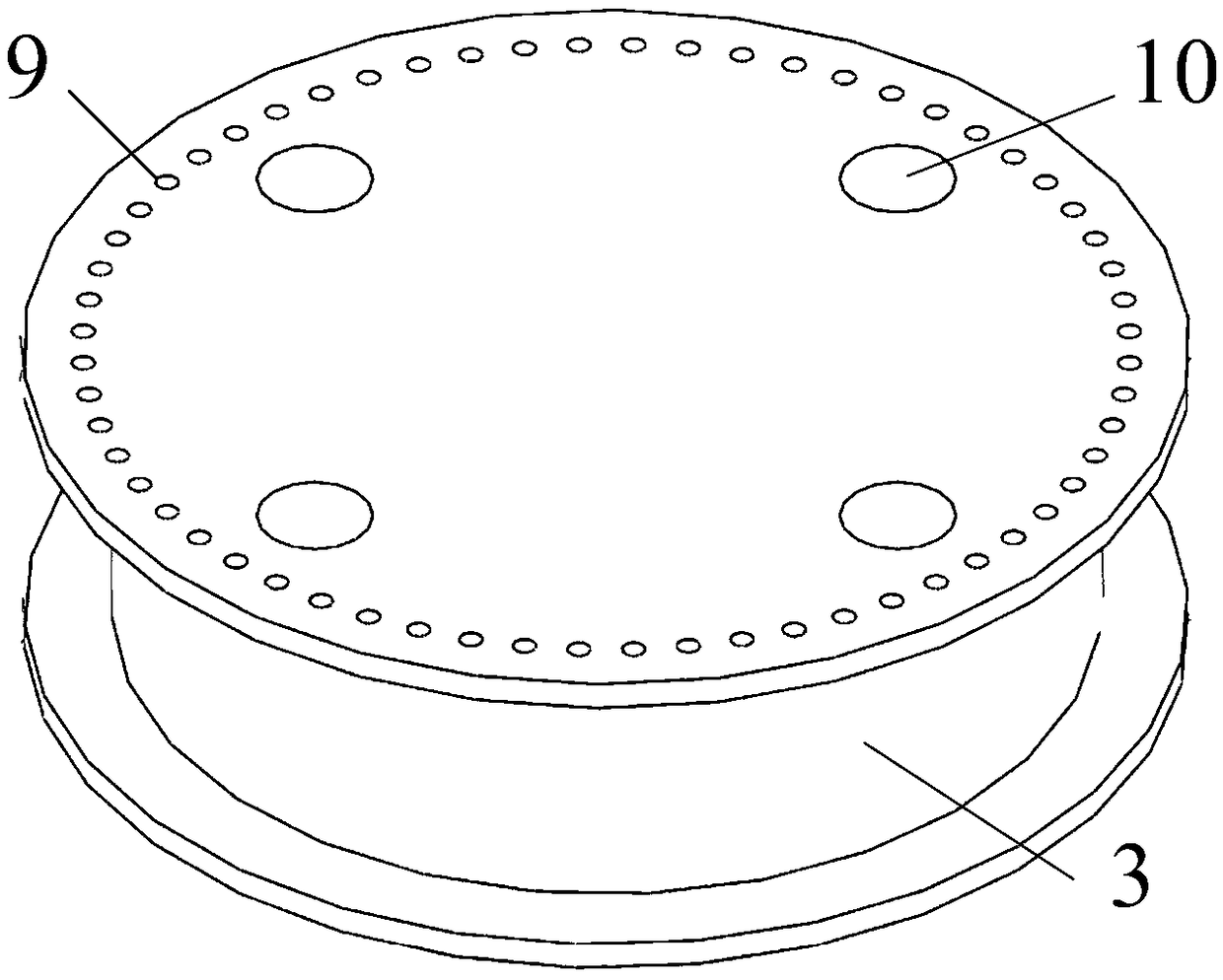

[0024] Such as figure 2 , image 3 , Figure 4 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com