Patents

Literature

421results about How to "Improve operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

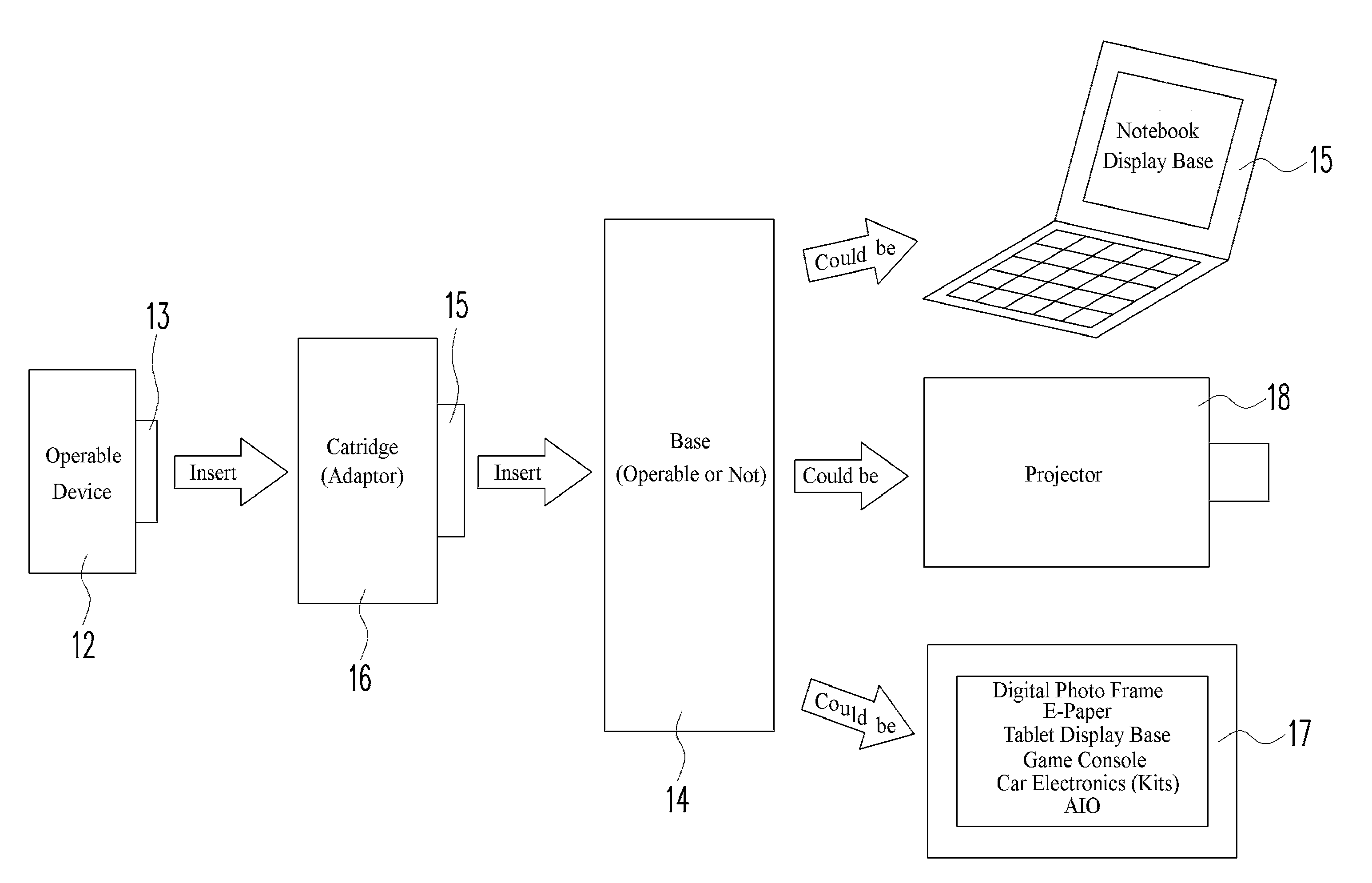

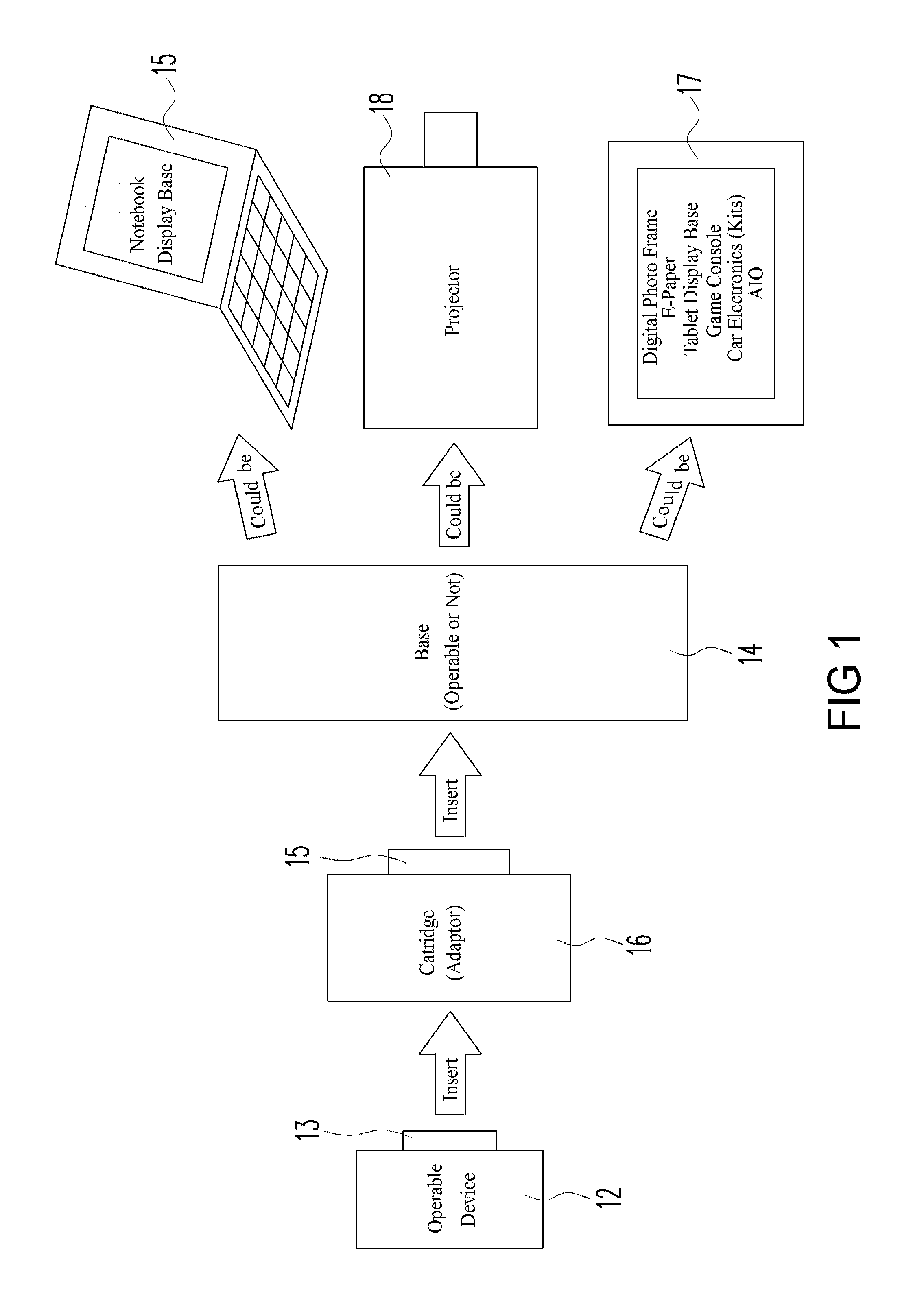

Modular system having expandable form factor

ActiveUS20120087078A1Reduce redundancyImprove operabilityBatteries circuit arrangementsPower supply for data processingModularityEmbedded system

A modular system of devices, in which a (master) device can be combined with one or more of other (slave) devices to transform to functional electronic devices having expanded functionalities and features in different form factors and / or platforms. The master device is docked to the slave device via a data / electrical interface, to transform the master device to the larger form factor of the slave device, with the master device maintaining control of the slave device, substantially based on the operating system installed in the master device, with access to the data, application programs, functionalities and features embodied in the master device. An intermediate removable physical interface adaptor (or docking adaptor) is provided to facilitate docking compatibility of the master device to the slave device. An enhanced charging and power management scheme is provided to optimize power management for the master device and the slave device.

Owner:COMPAL ELECTRONICS INC

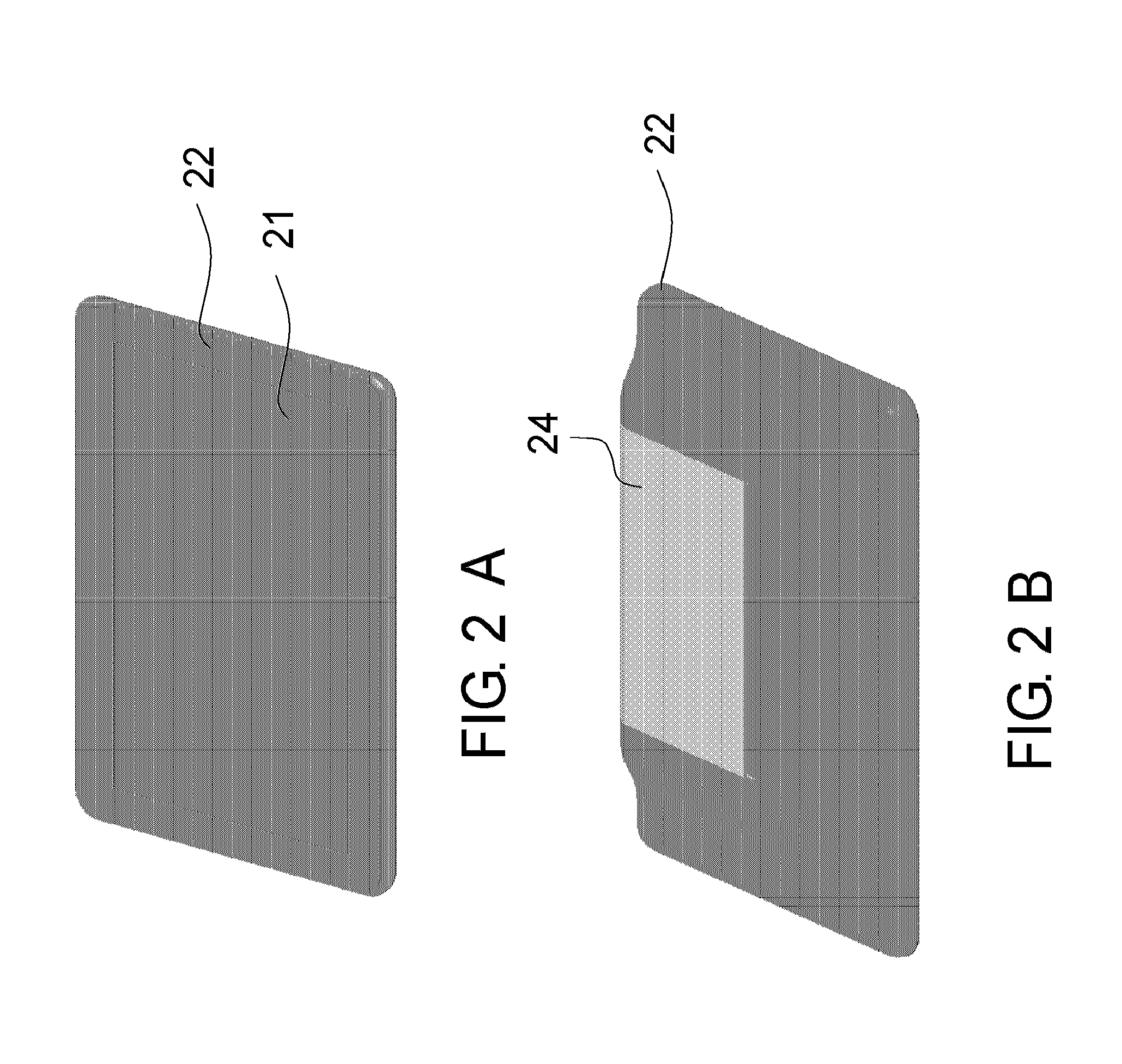

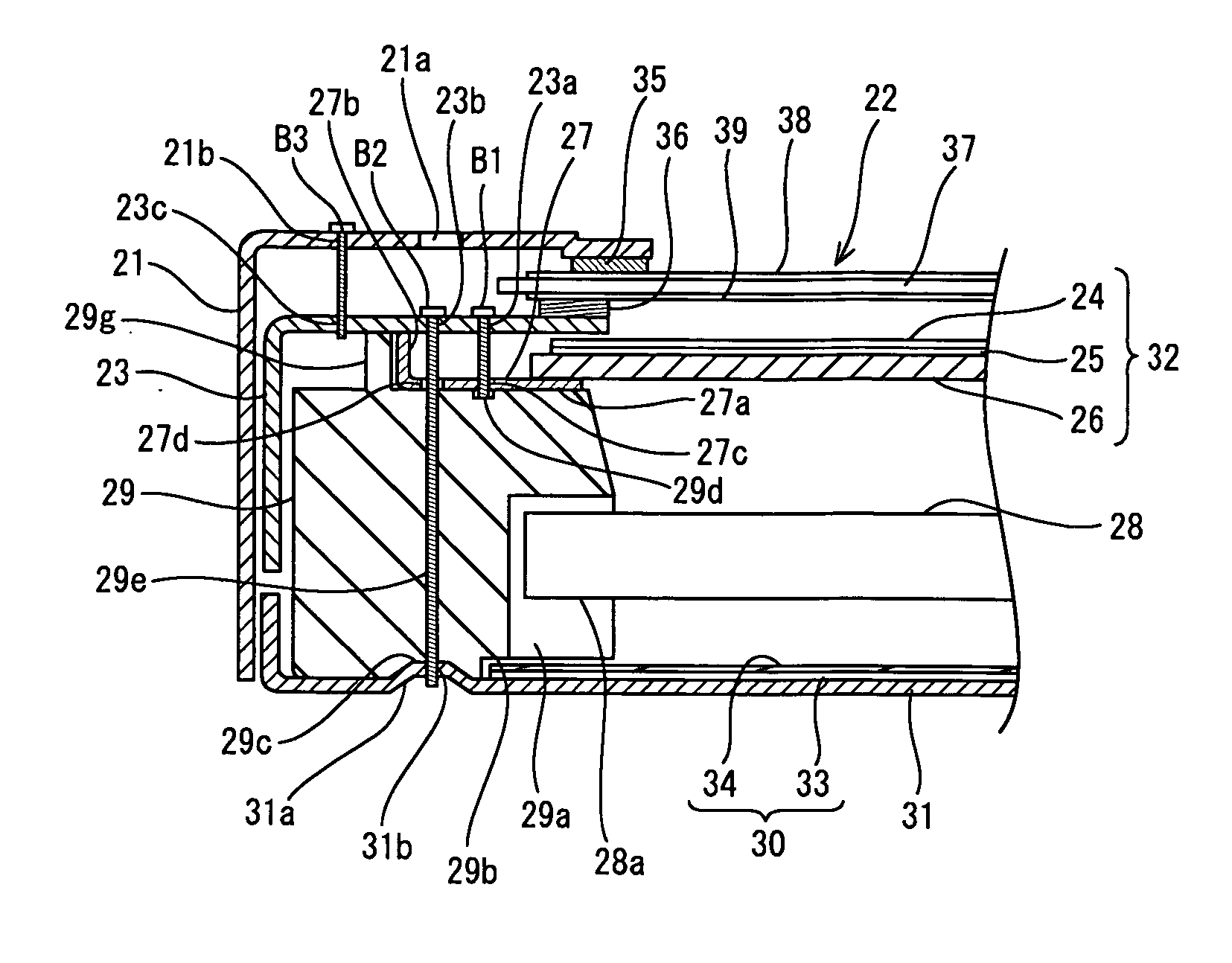

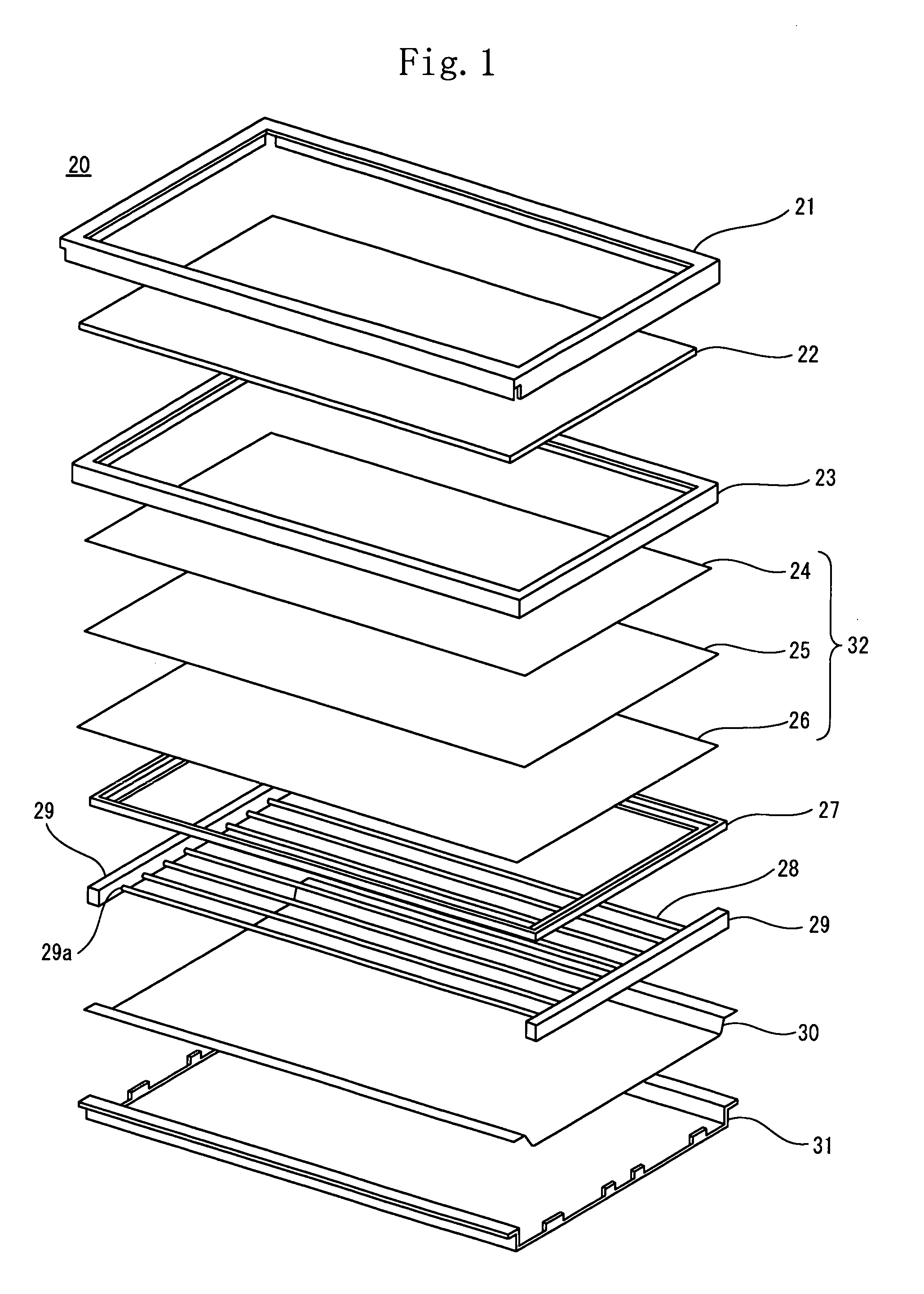

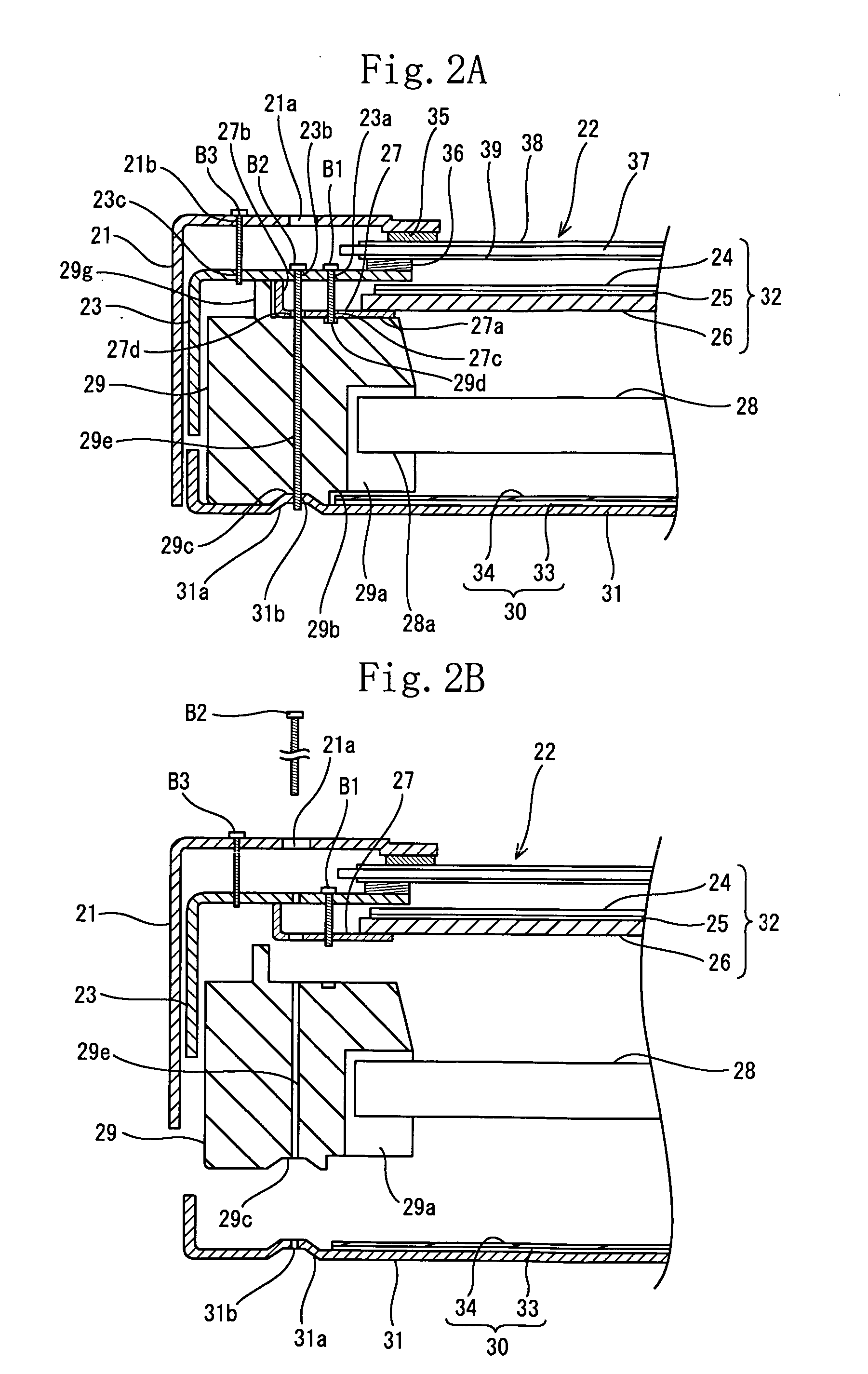

Liquid crystal display

InactiveUS20050151894A1Improve operabilityEasy to performMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLiquid crystal

A liquid crystal display comprises a liquid crystal panel (22), a group of optical sheets (32) disposed rearward from the liquid crystal panel (22), a light source (28) disposed rearward from the group of the optical sheets (32), a frame-shaped front frame (21, 23) disposed forward from at least the group of the optical sheets (32), a back chassis (31) disposed rearward from the light source (28) and fixedly connected to the front frame (21, 23) directly or indirectly, and a holding member (27) integrally holding the group of the optical sheets (32) to keep the group of the optical sheets (32) held in position integrally, when the back chassis (31) and the front frame (21, 23) are unfixed from each other.

Owner:SHARP KK

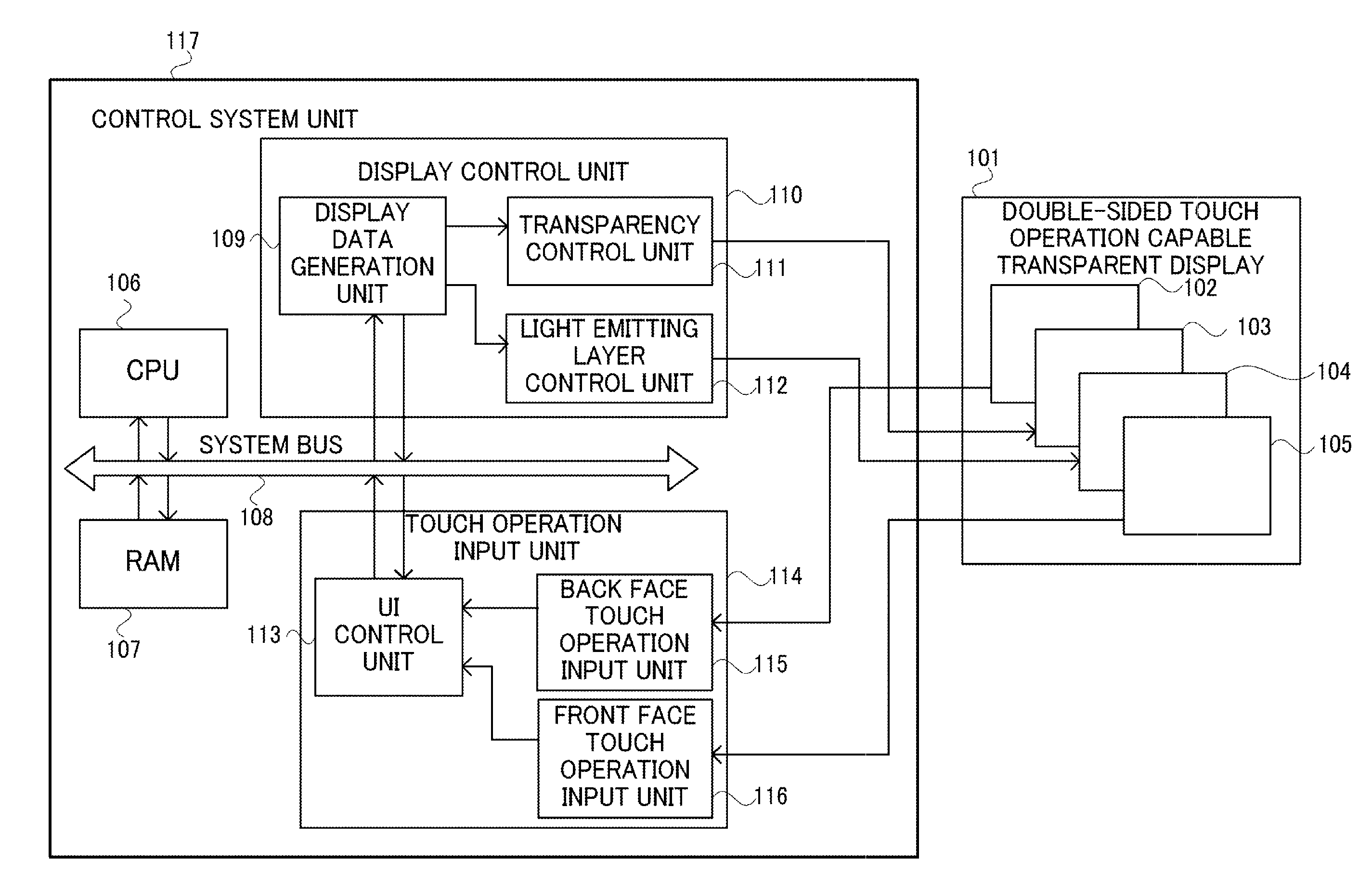

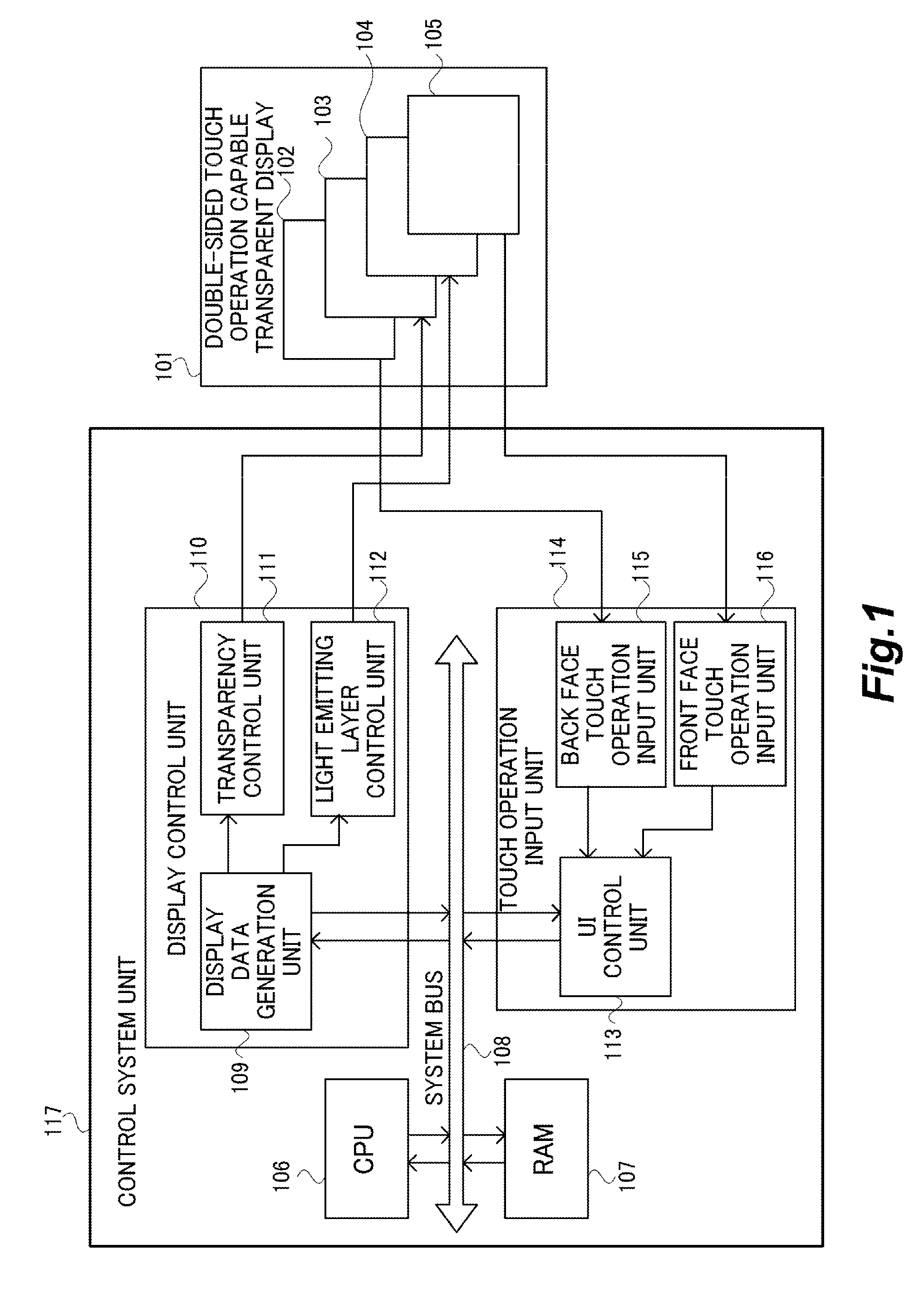

Display device and control method therefor

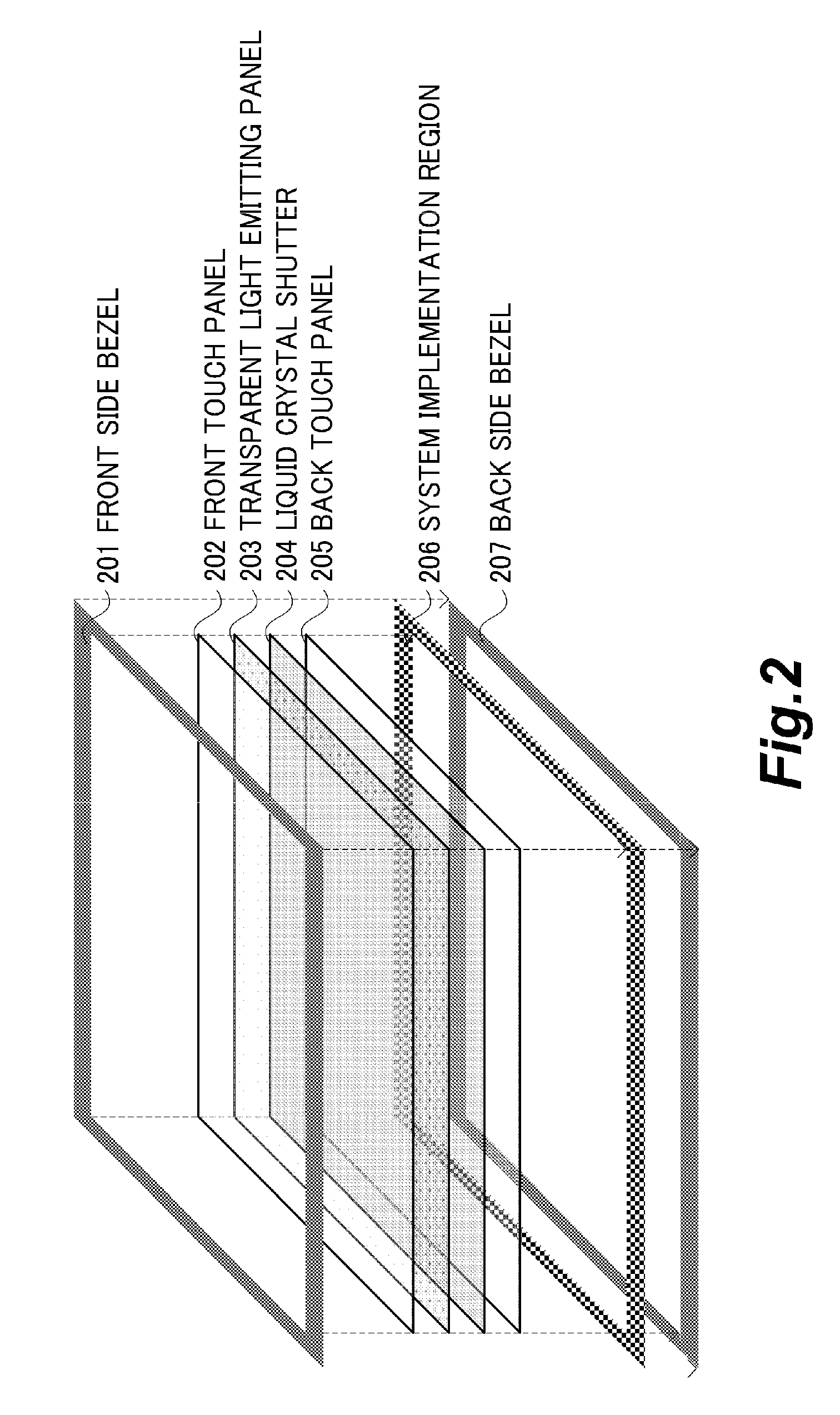

ActiveUS20140009415A1Improve operabilityEasy to operateInput/output processes for data processingDisplay deviceGraphics

In a display device which has a transparent display with touch operations being carried out from opposite sides thereof, i.e., a front face and aback face, operability of the touch operations can be improved. In display control of graphics data which is constructed to include a first component which assumes a touch operation from either one of the front face and the back face, and a second component which assumes a touch operation from a side opposite to the side from which the touch operation is assumed by the first component, only the first component is first displayed, and after a touch operation with respect to the first component is carried out, a content of the second component is decided according to an instruction inputted by the touch operation, so that the second component is then displayed.

Owner:CANON KK

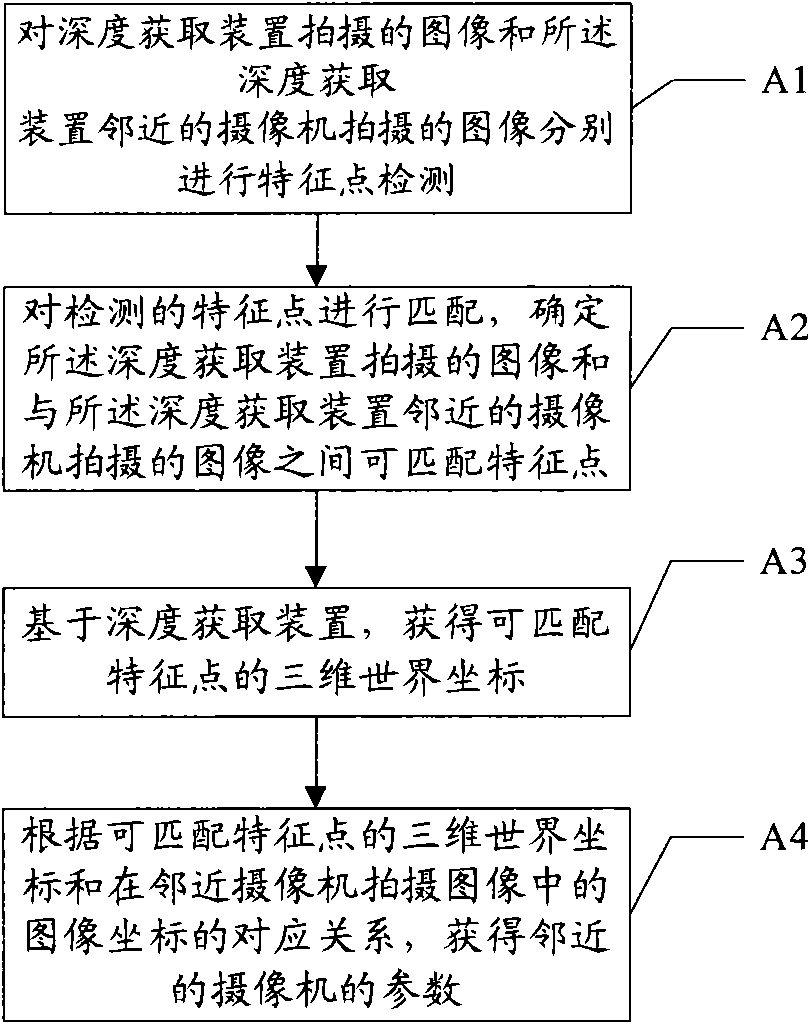

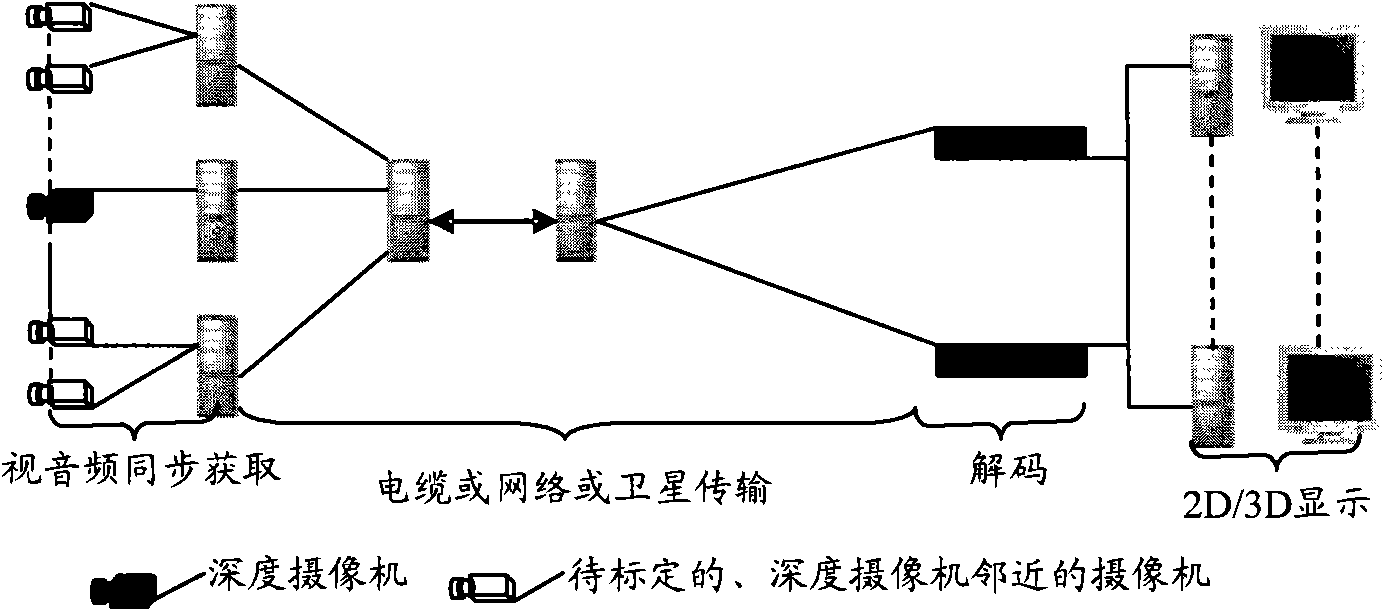

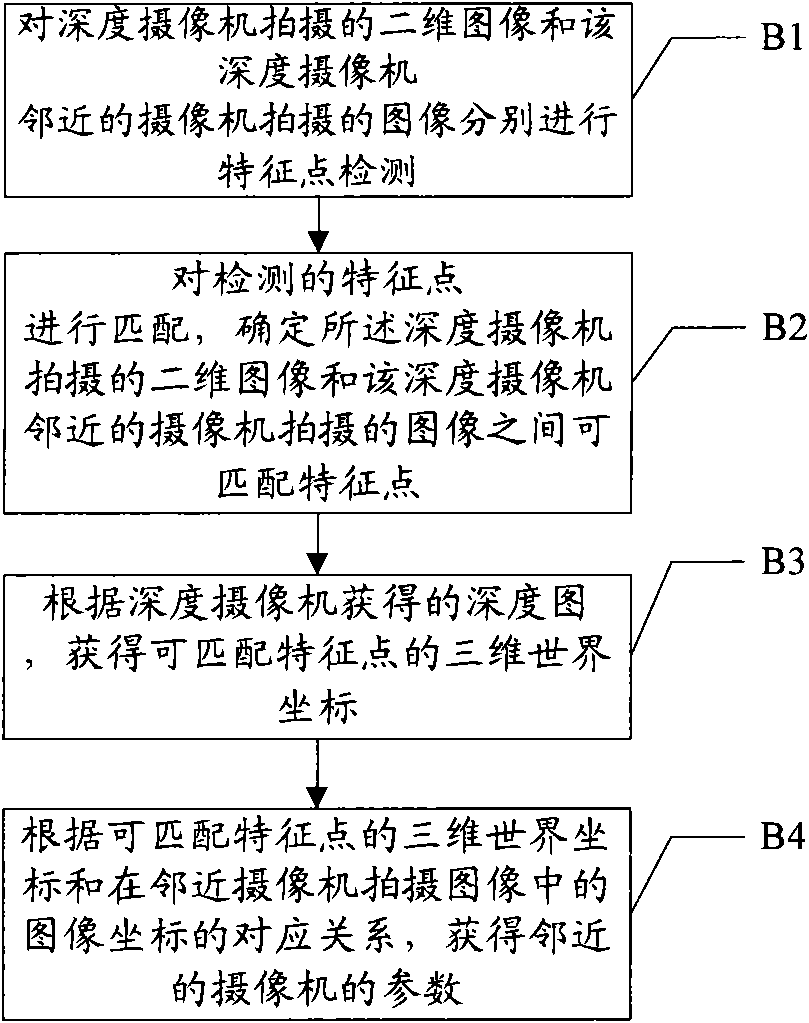

Camera calibration method and camera calibration device

ActiveCN101630406AParameter stabilityImprove operabilityImage analysisCharacteristic pointVideo camera

The invention provides a camera calibration method and a camera calibration device and is applied in the technical filed of images and video. The method and the device mainly acquire a three-dimensional world coordinate of a characteristic point through a depth acquiring device, and realize the calibration of the camera to be calibrated by using a correspondence of the three-dimensional world coordinate of the characteristic point and an image coordinate in an image taken by the camera to be calibrated. Compared with the scheme that a plurality of cameras are calibrated through a homographic matrix between images in the prior art, the method and the device can acquire stable and accurate parameters of the camera because of not needing to estimate the homographic matrix between a master camera and a slave camera. The method and the device can accurately acquire the three-dimensional world coordinate of the characteristic point. The movement of a calibration object can be in an unfixed direction when the camera is calibrated, which improves the operability of the camera calibration. Additionally, the camera calibration method can adopt the same calibration method to a plurality of adjacent cameras so as to simplify the camera calibration process.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

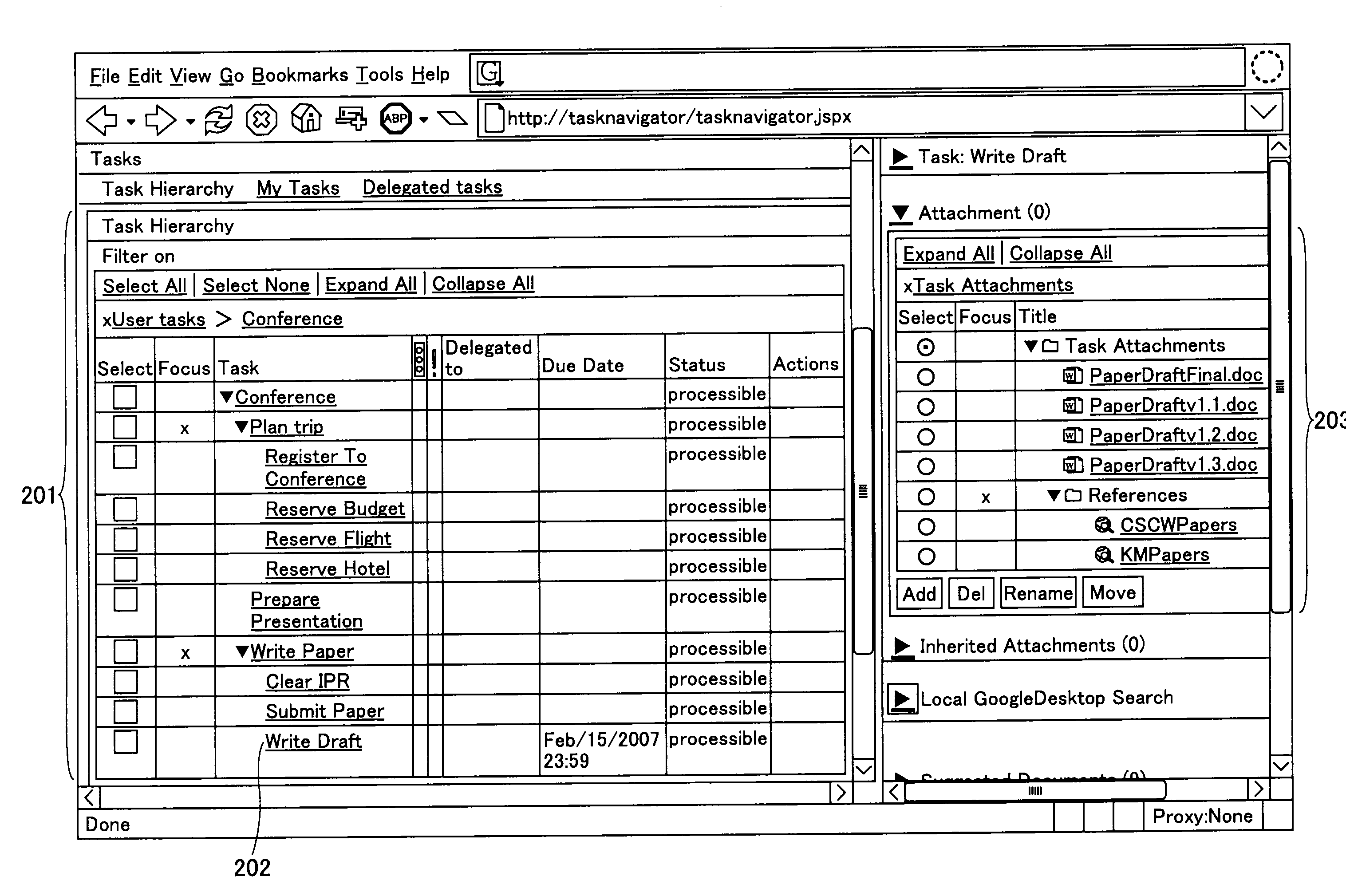

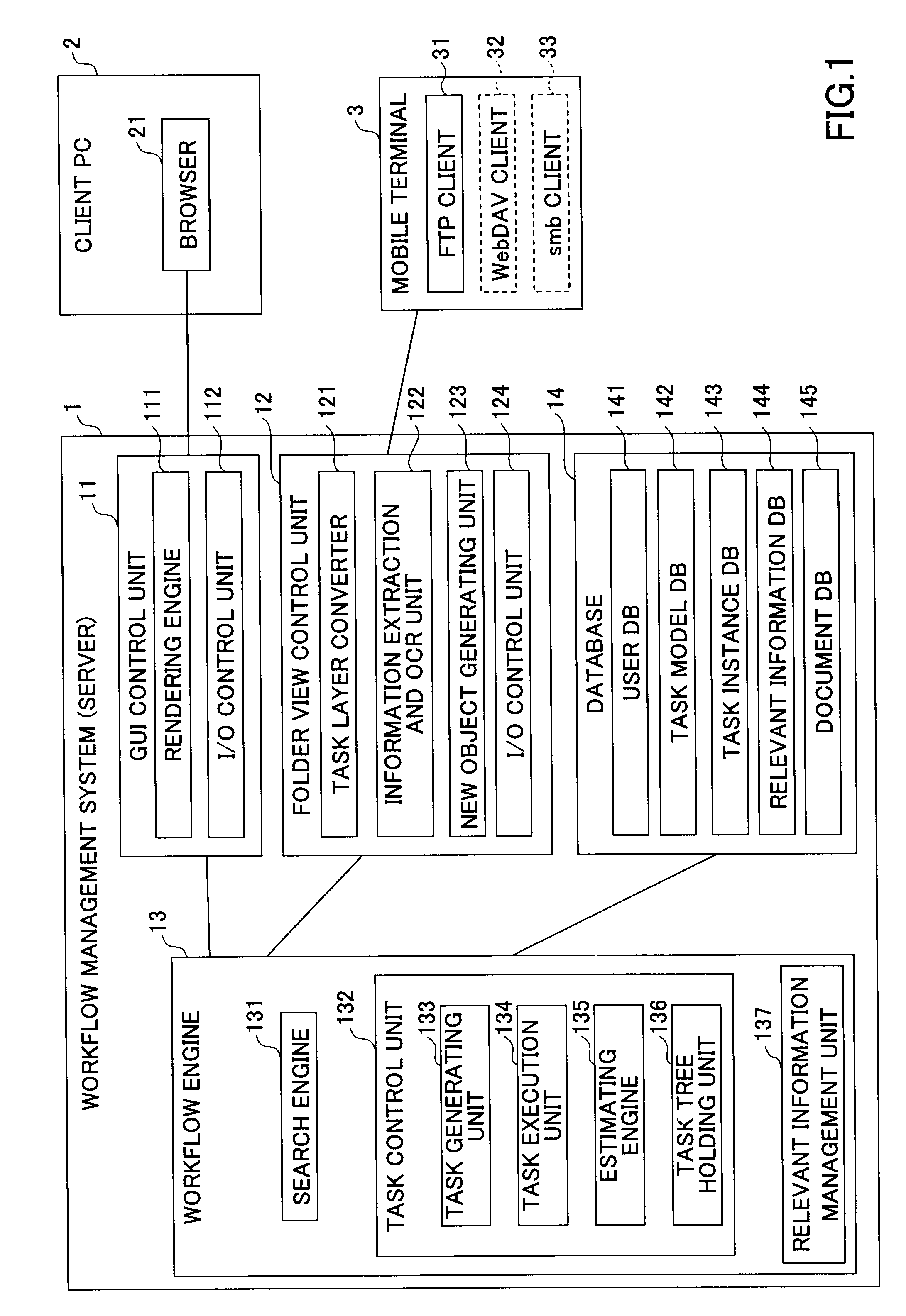

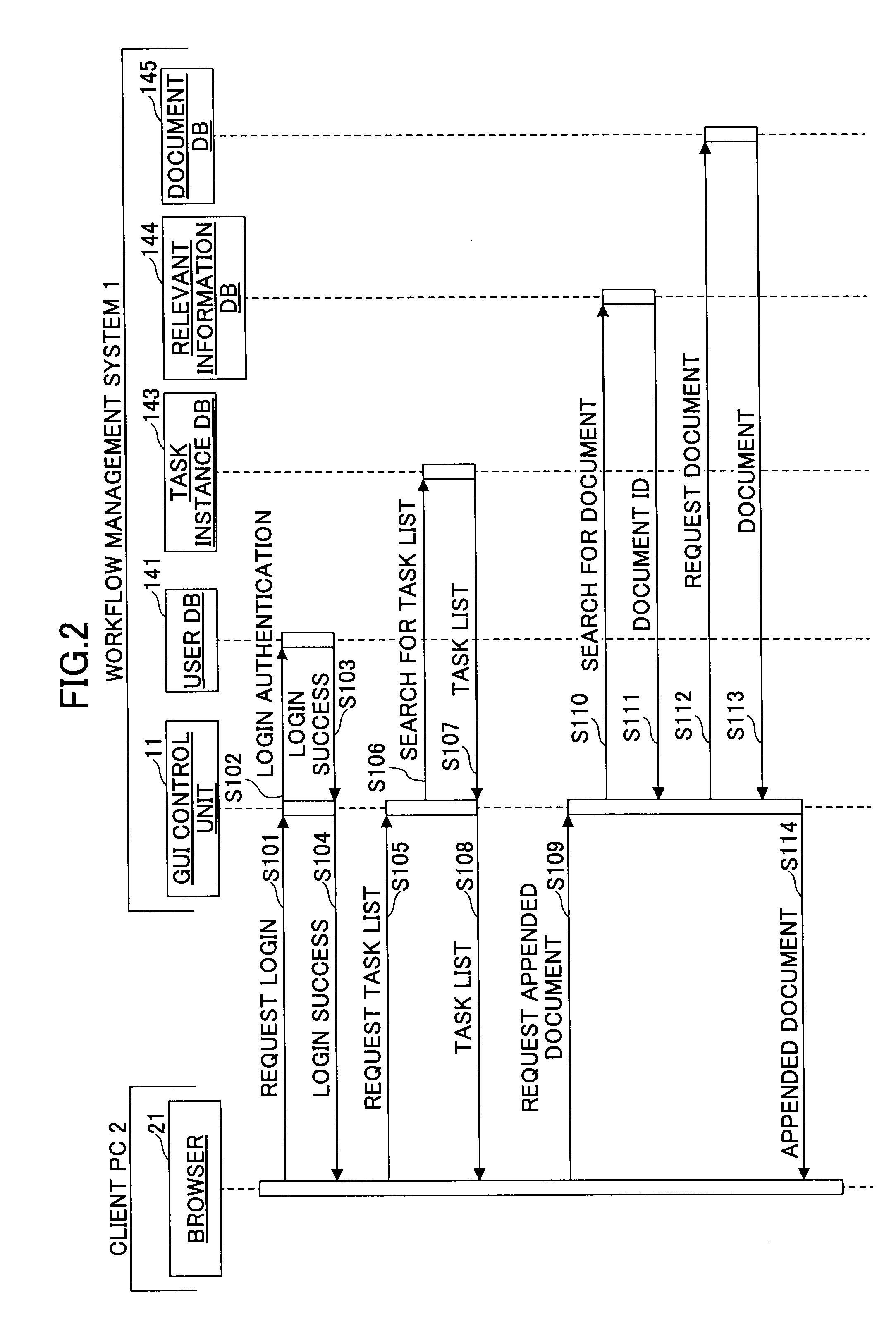

Workflow management system

InactiveUS20080229307A1Improve operabilityMultiprogramming arrangementsResourcesWorkflow processFile system

A workflow management system wherein a workflow model is dynamically constituted when a workflow is executed, its method, and its computer-executable program are disclosed. The workflow management system includesa receiving unit for receiving access from an external terminal based on a protocol that is capable accessing a file system;a providing unit for providing a folder list to the external terminal, wherein the folder list is acquired by converting a task layer of the workflow managed by the workflow management system into a folder layer of the file system; andan appending unit for appending a document as relevant information to a task of the workflow corresponding to a predetermined folder layer when the document is uploaded by the external terminal.

Owner:RICOH KK

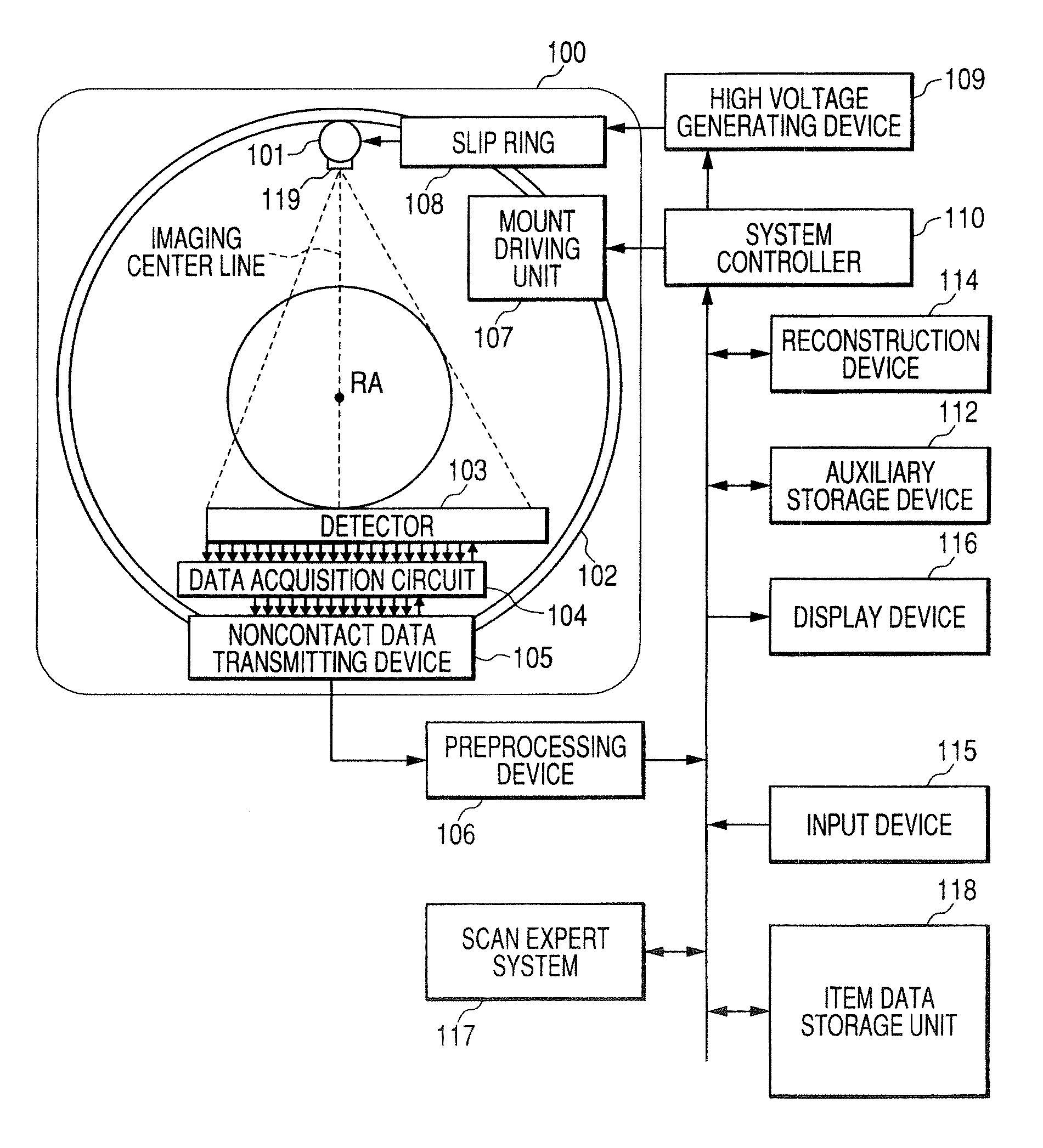

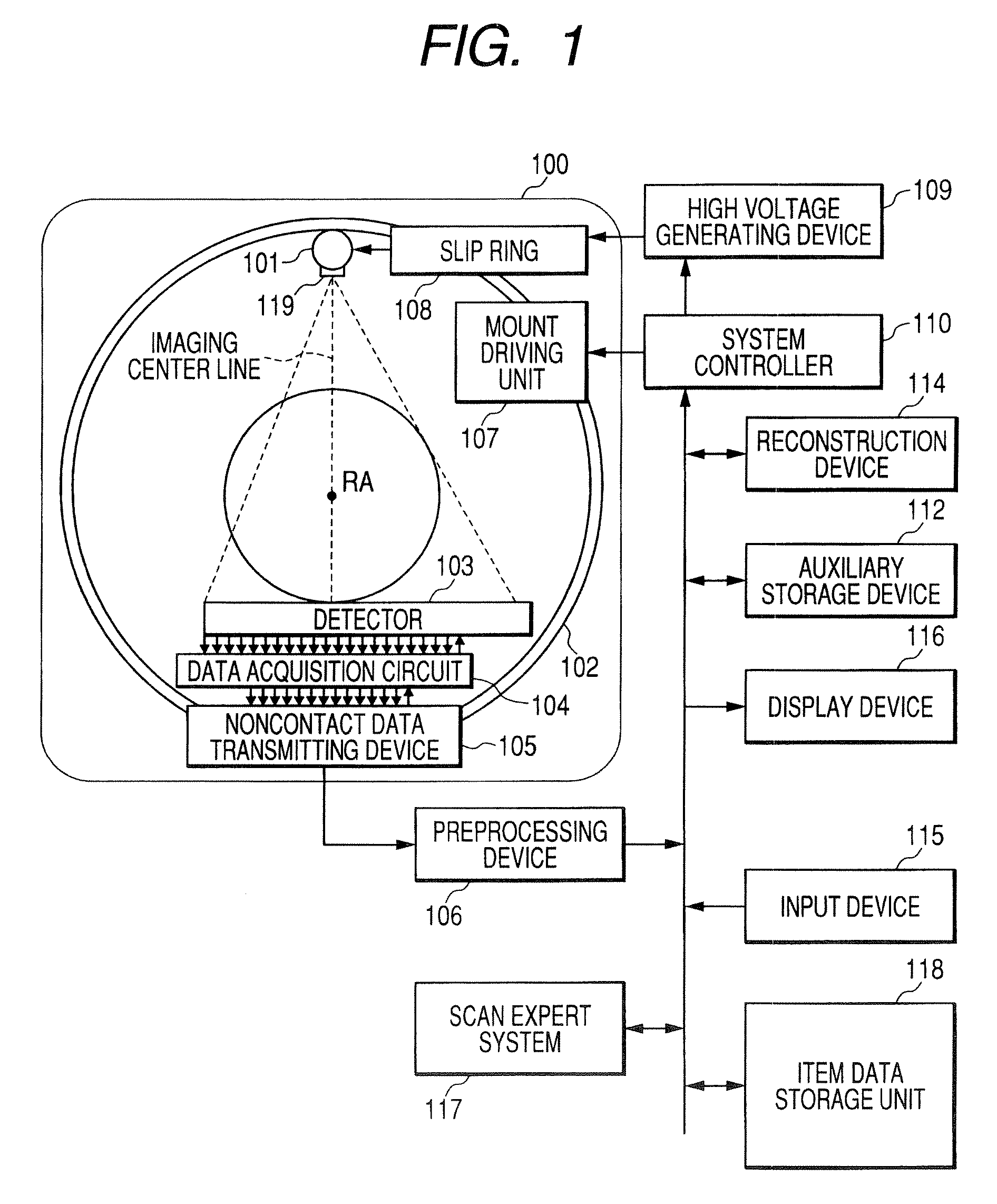

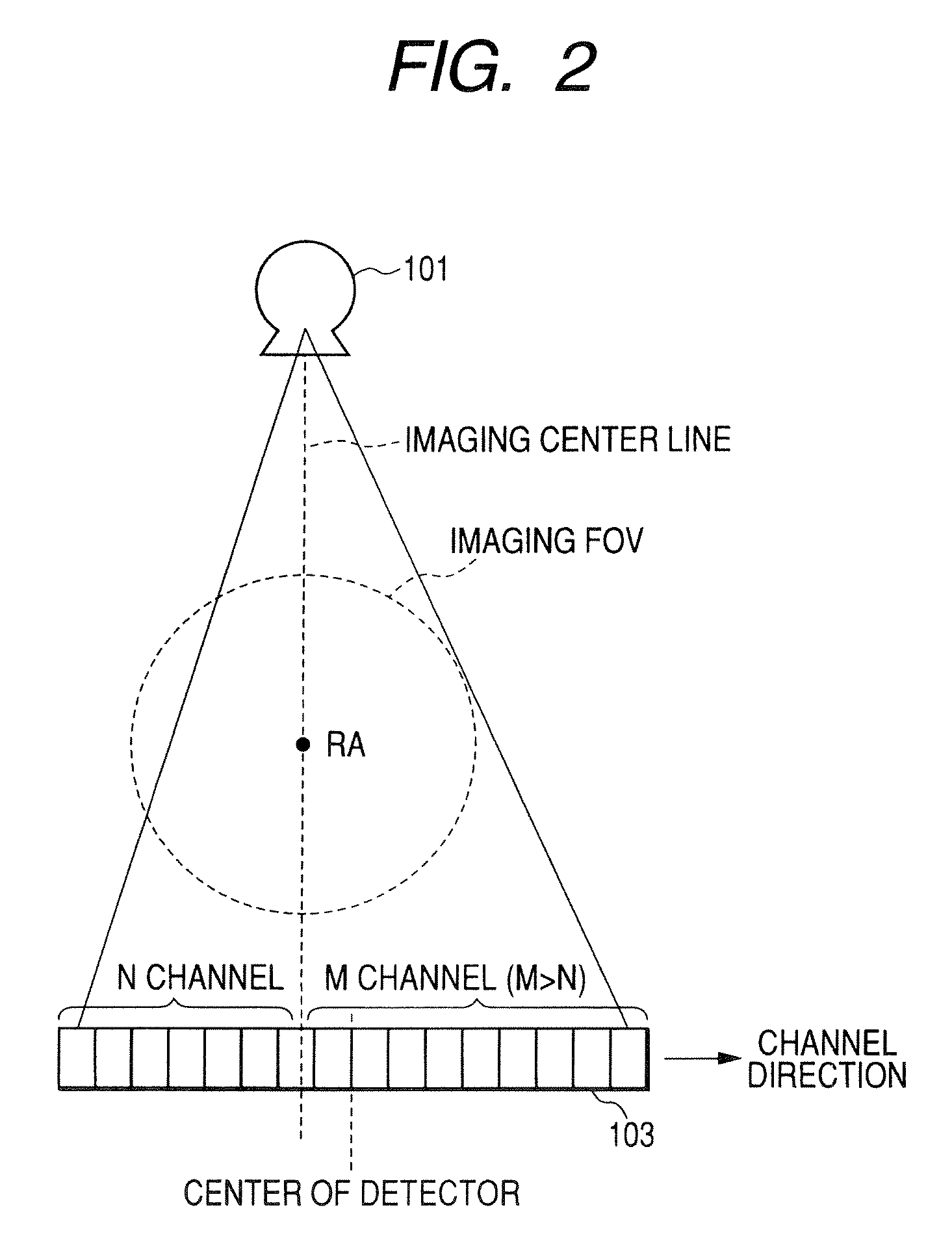

X-ray computed tomographic apparatus

InactiveUS20070081624A1Improve operabilityEasy to operateMaterial analysis using wave/particle radiationRadiation/particle handlingPhysicsRotational axis

An X-ray computed tomographic apparatus includes an X-ray tube that generates X-ray, an X-ray detector that detects an X-ray passing through an object, a supporting member that rotatably supports the X-ray tube and the X-ray detector around a rotational axis, a reconstructing unit that reconstructs an image on the basis of an output of the X-ray detector, an information creating unit that creates information concerning an arrangement of an asymmetrical field of view of the object when the field of view of the scanogram by the X-ray tube and the X-ray detector is asymmetric with respect to an imaging center line in a direction perpendicular to the rotational axis, and a display unit that displays information concerning the created arrangement.

Owner:TOSHIBA MEDICAL SYST CORP

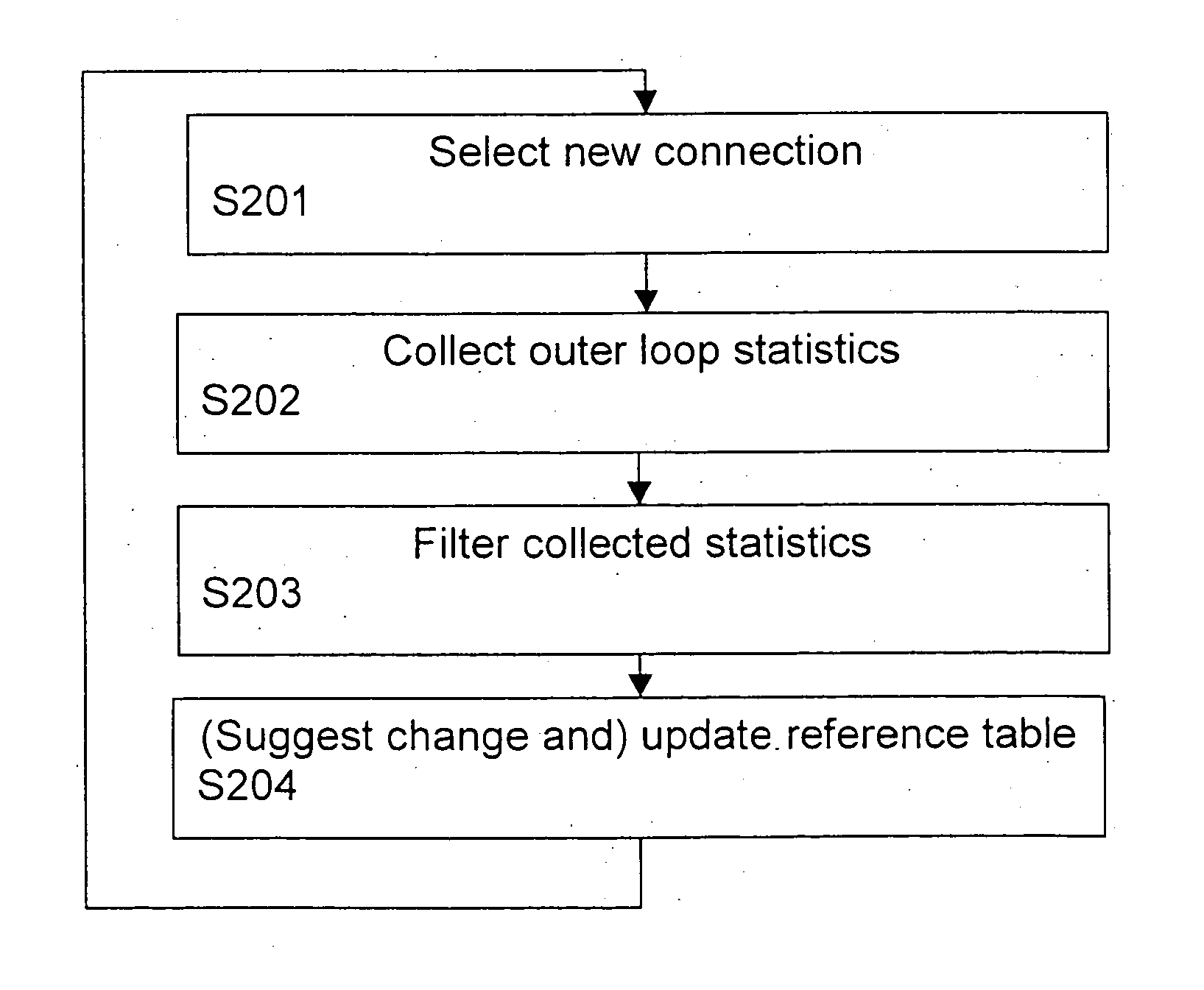

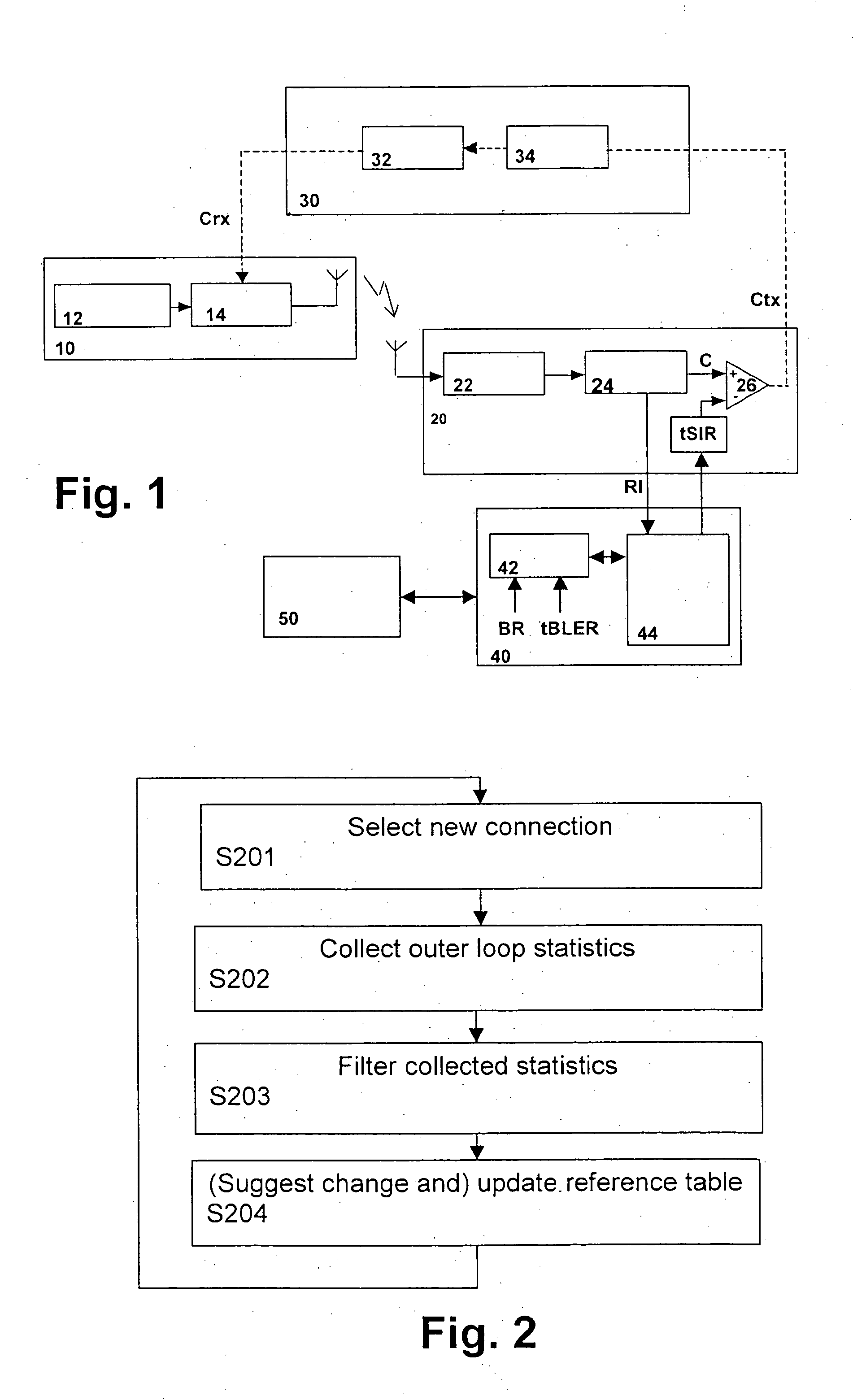

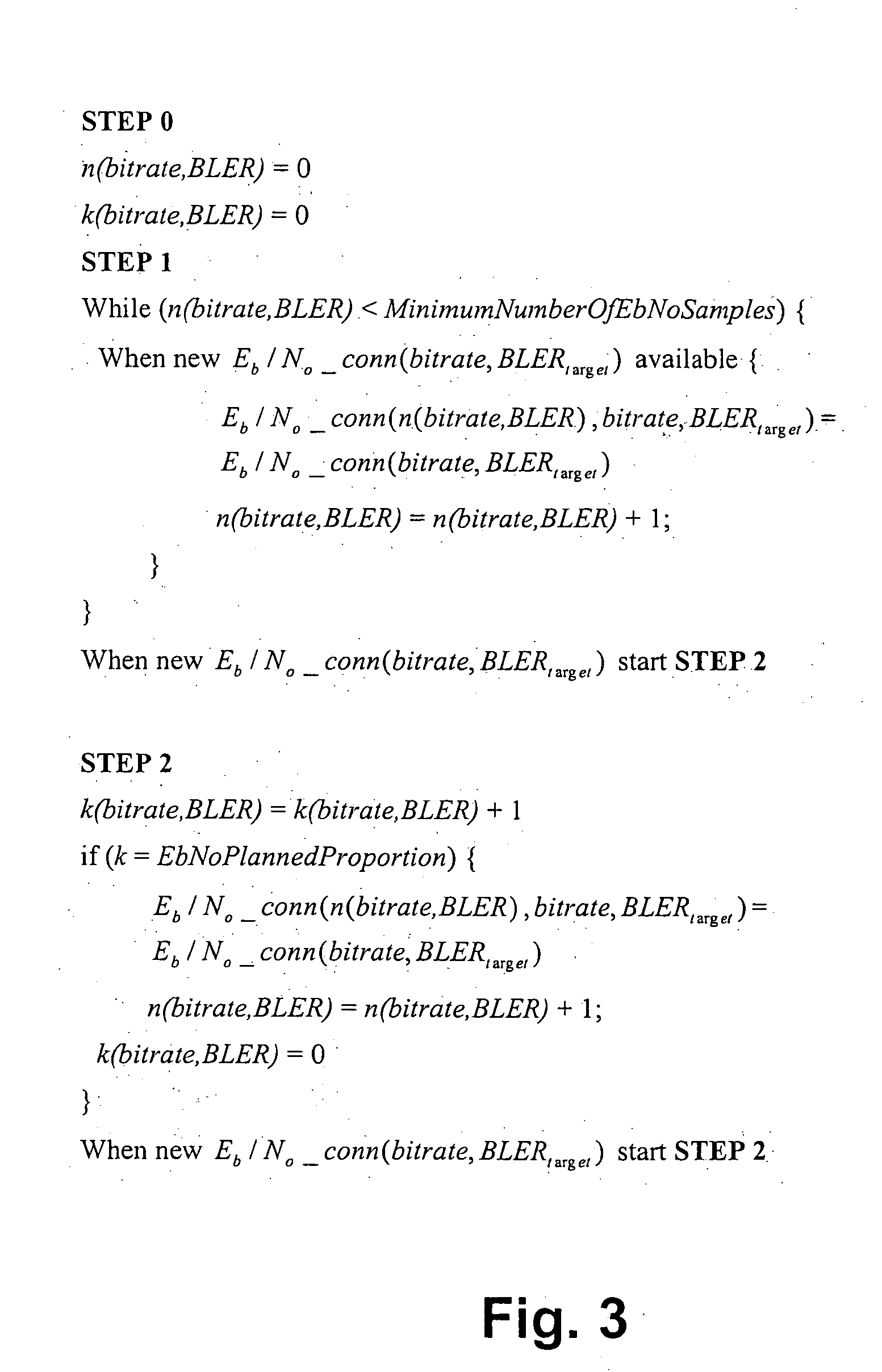

Method and network element for controlling power and/or load in a network

InactiveUS20050107106A1Increase operability and handlingImprove operabilityPower managementTransmission control/equalisingNetwork elementReference table

The present invention relates to a method and network element for controling power and / or load in a network, wherein a reference table is stored and used for deriving a reference control value from at least one connection-specific parameter. The power and / or load control is then performed based on the derived reference control value. The reference control values stored in the reference table are estimated based on a real measurement of at least one predetermined network parameter, and the reference table is updated using the estimated reference control values. Thereby, an autotuning mechanism is provided to adjust the reference control values based on real measurements, so that real location-dependent radio propagation conditions are taken into account.

Owner:NOKIA CORP

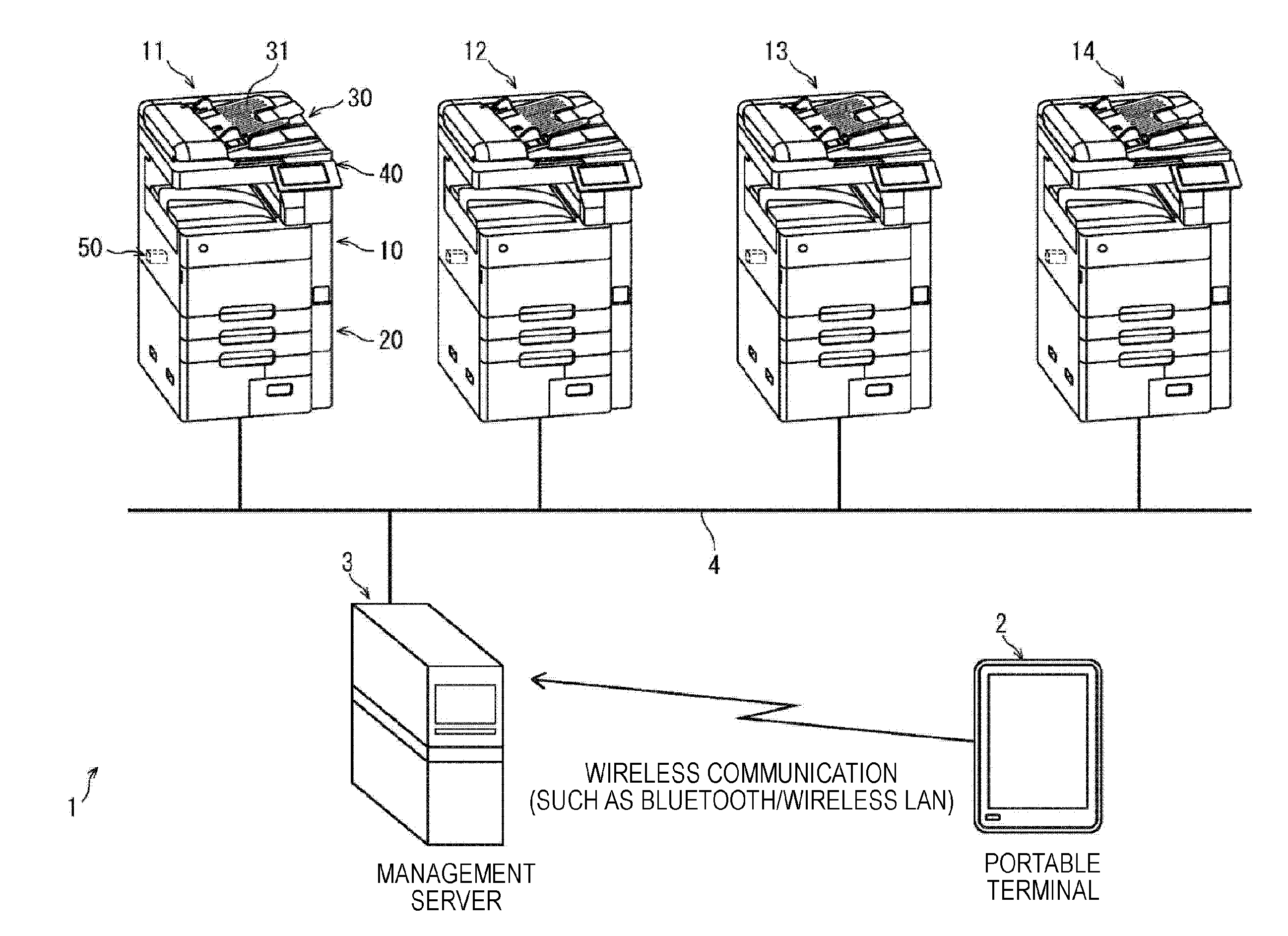

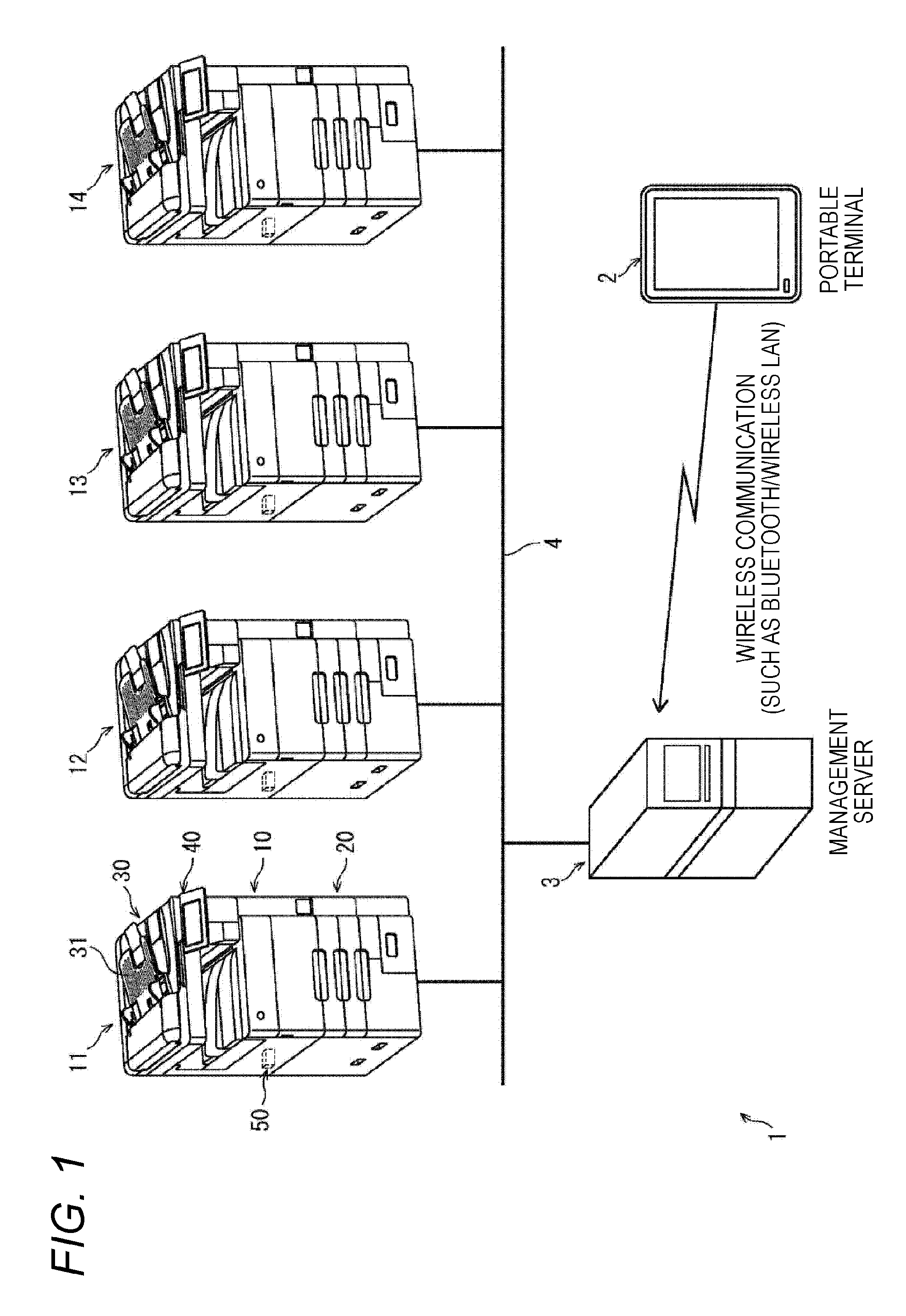

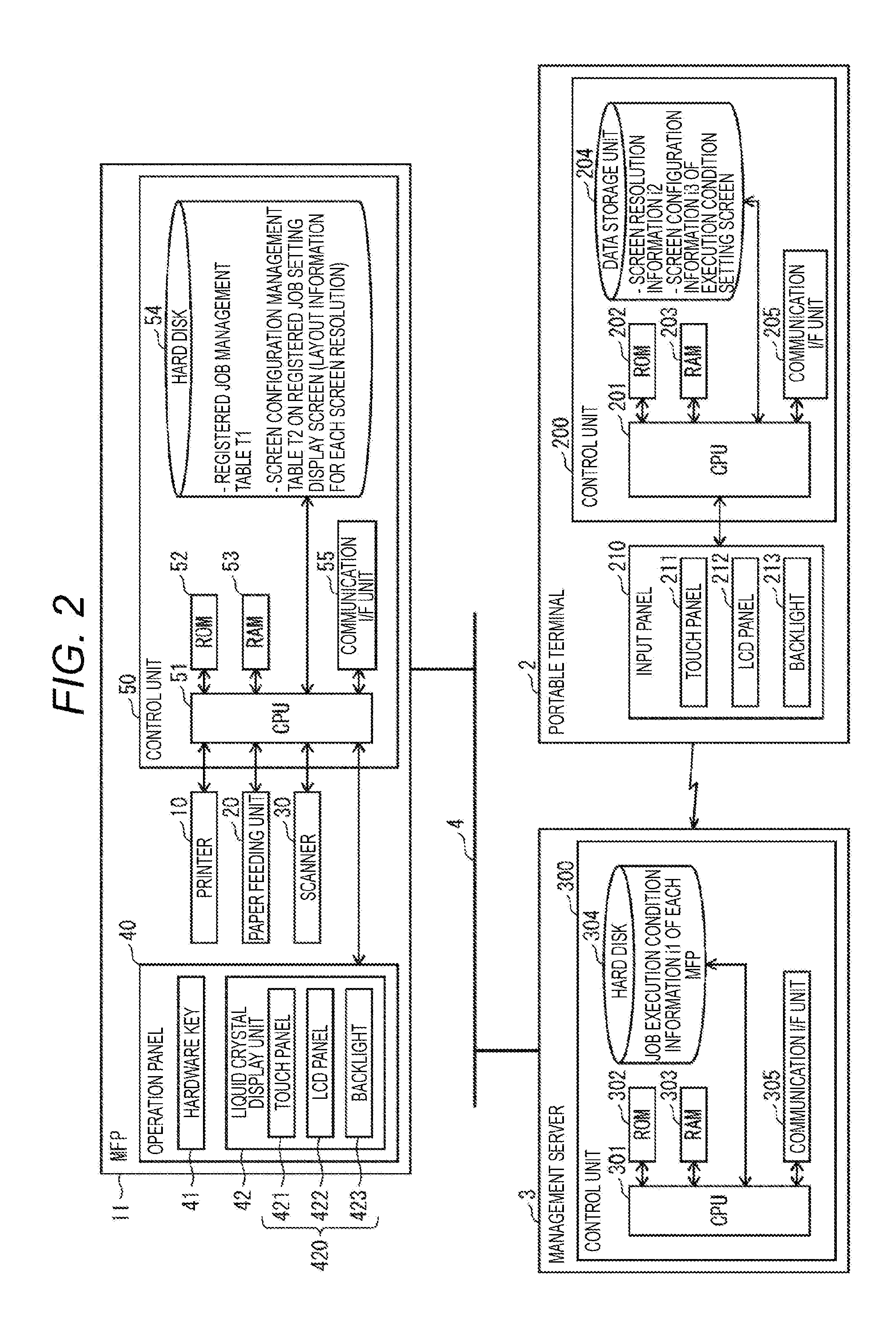

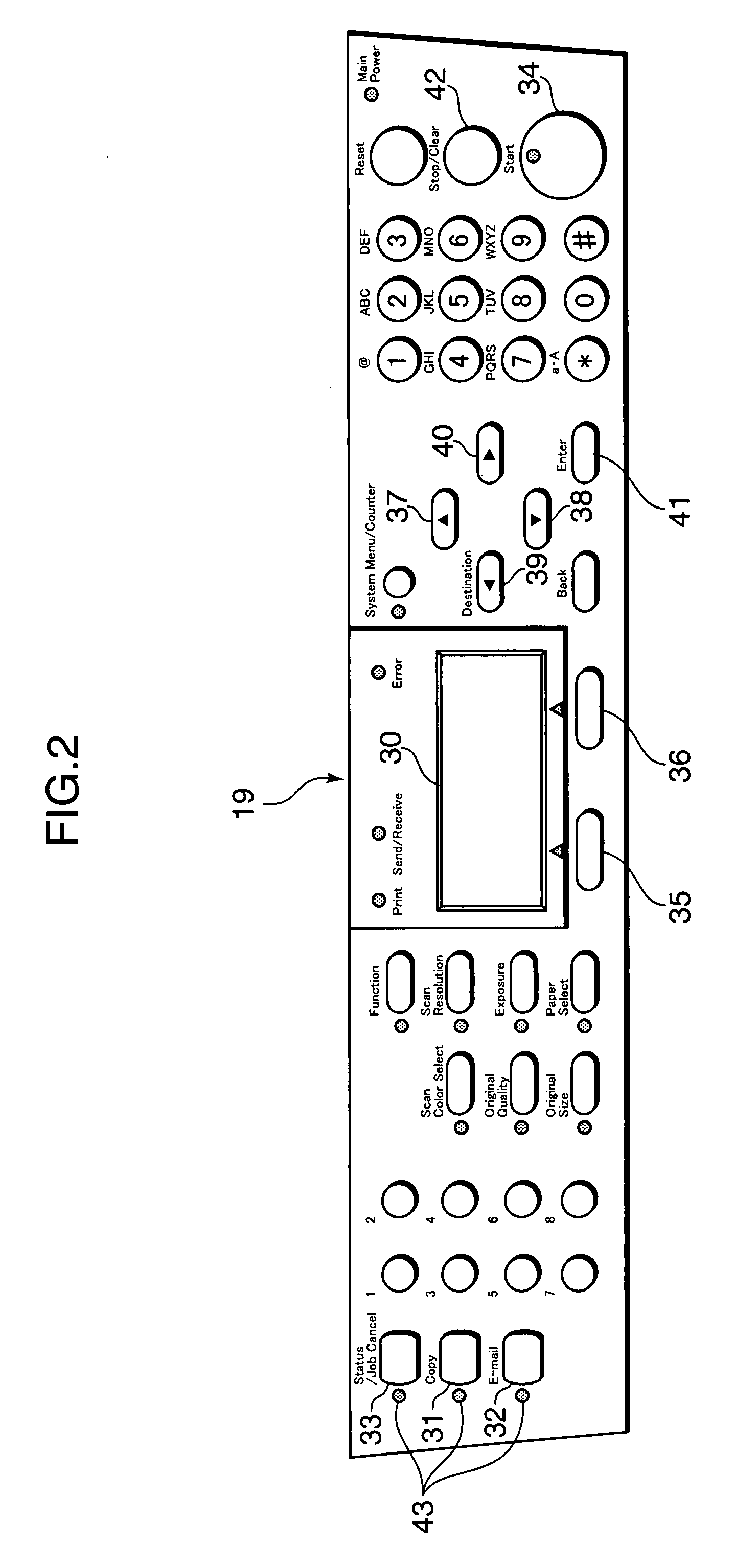

Image processing system, image processing apparatus, and portable information terminal

ActiveUS20150193674A1Improve operabilityEasy to operateVisual presentation using printersPictoral communicationComputer graphics (images)Control unit

An image processing system includes one or more image processing apparatuses connected to a network, and a portable information terminal having a function to preregister an image processing job to the image processing apparatus, wherein the portable information terminal includes a registration destination receiving unit configured to receive a selection of an image processing apparatus, a setting receiving unit configured to display a condition setting screen and receive setting input by a user, and a sending unit configured to send, to the image processing apparatus selected, first information on the execution condition of image processing and second information on a configuration of the condition setting screen, and each image processing apparatus includes a preregistration unit configured to preregister an image processing job, and a display control unit configured to generate a job setting display screen and display the job setting display screen on an operation panel.

Owner:KONICA MINOLTA INC

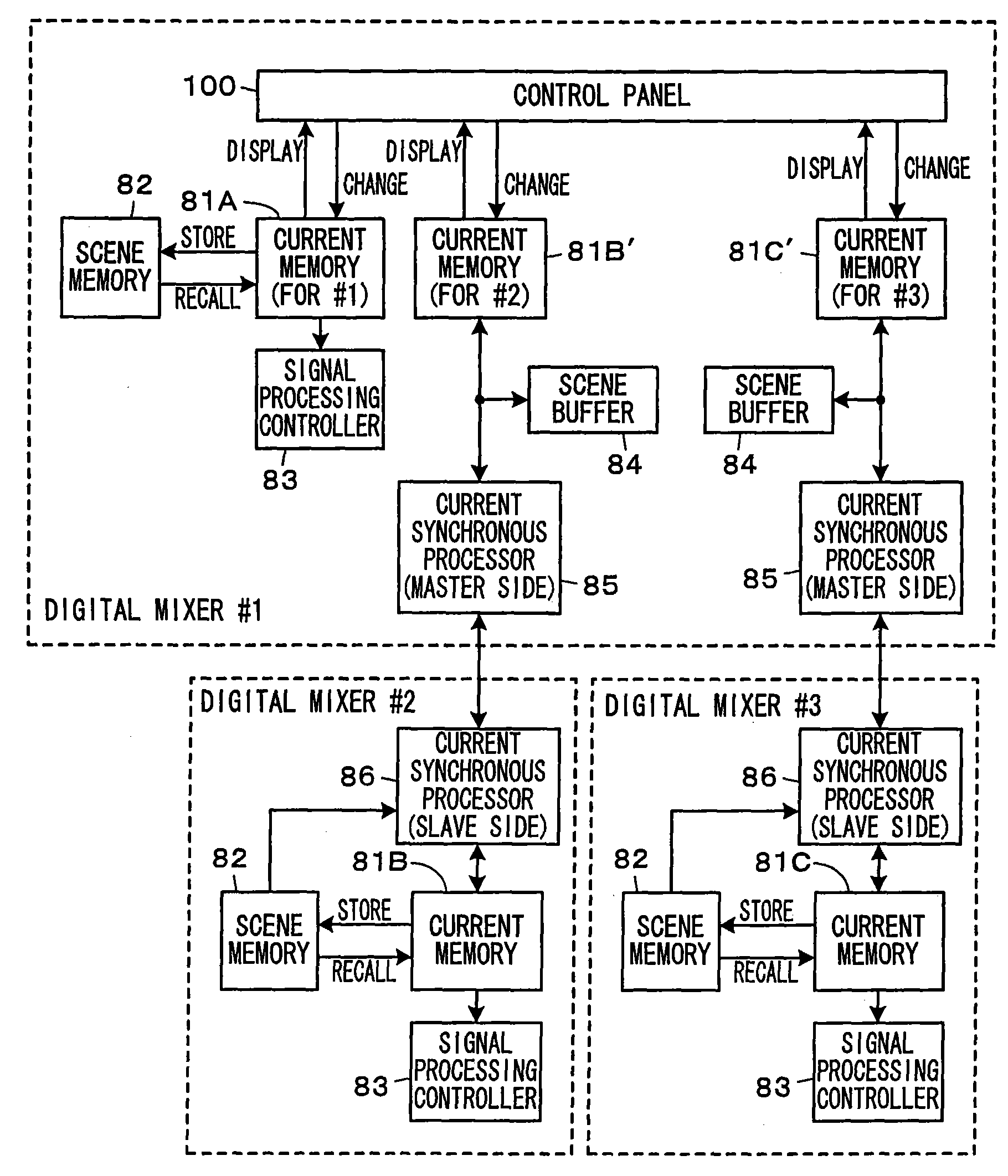

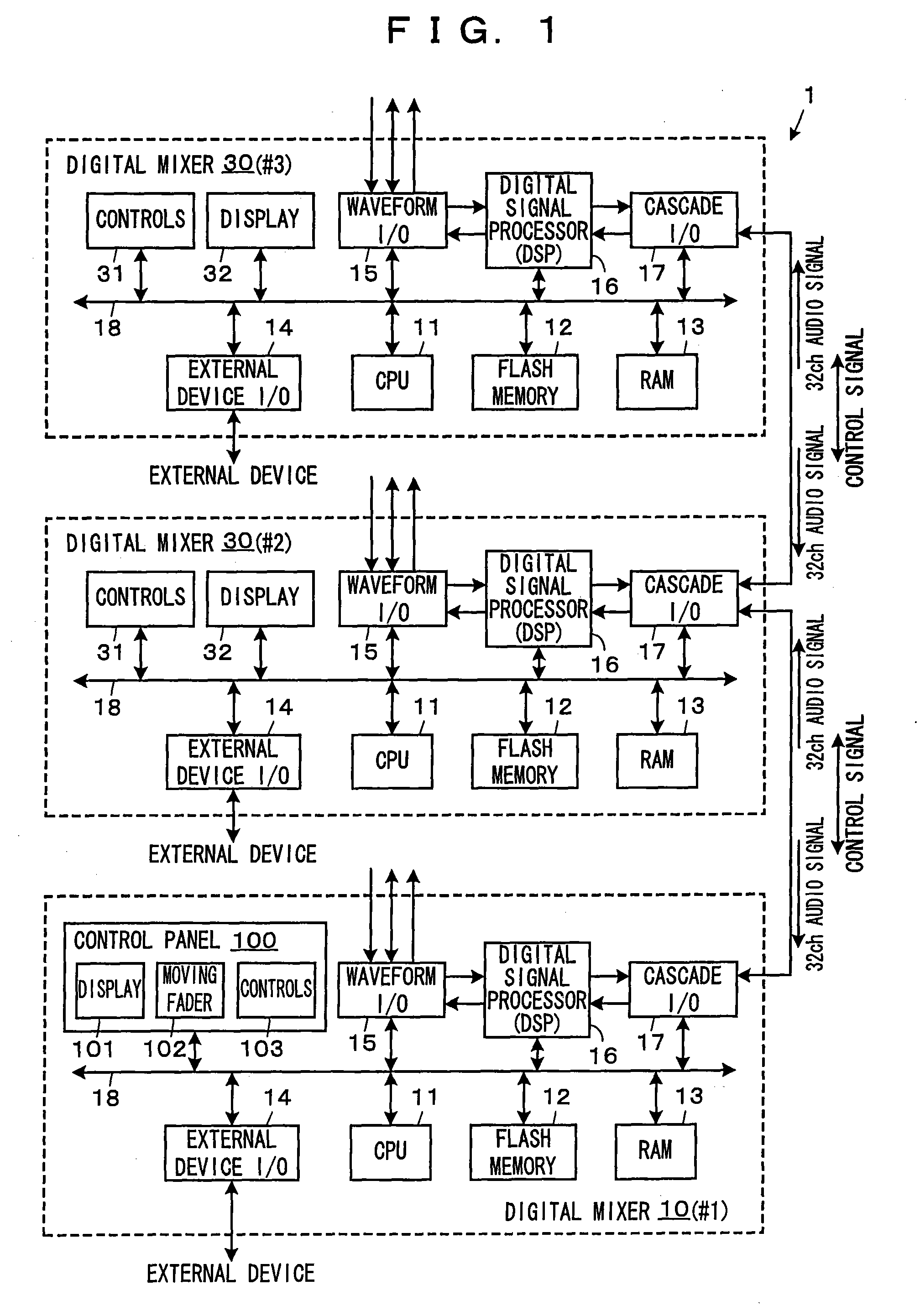

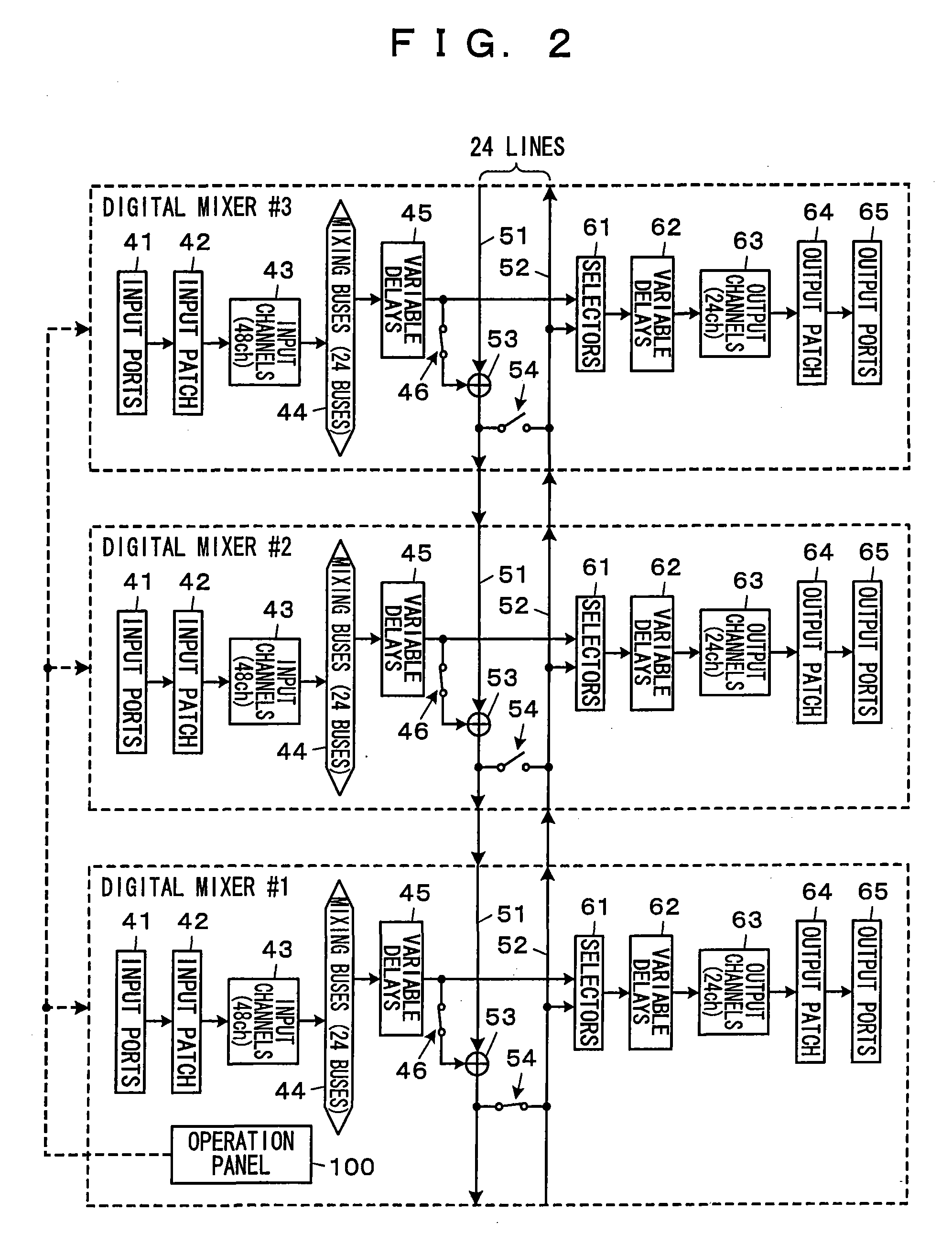

Digital mixer

InactiveUS20080219478A1Improve operabilityIncrease flexibilityTransmissionBroadcast information generationAudio signalDigital mixing console

Owner:YAMAHA CORP

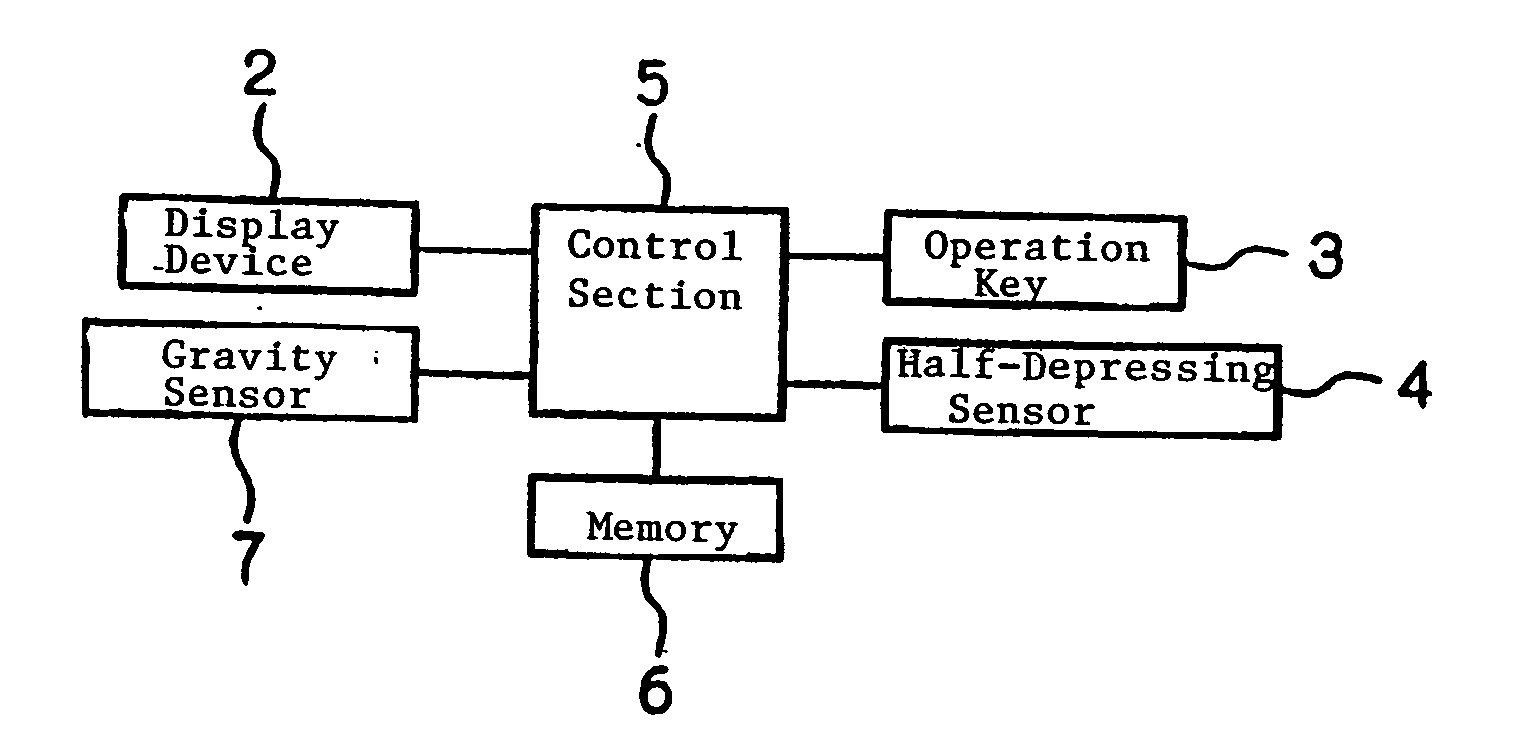

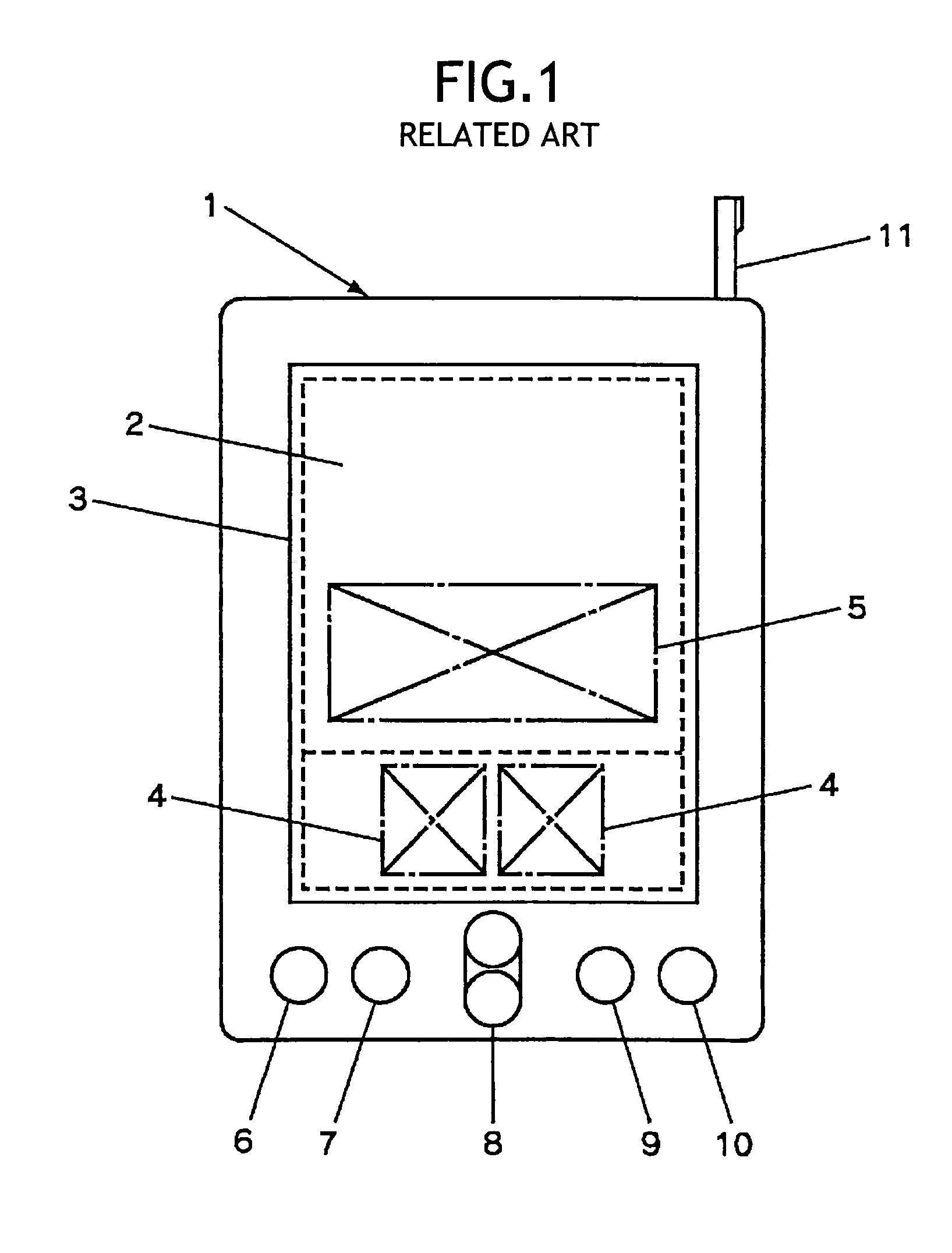

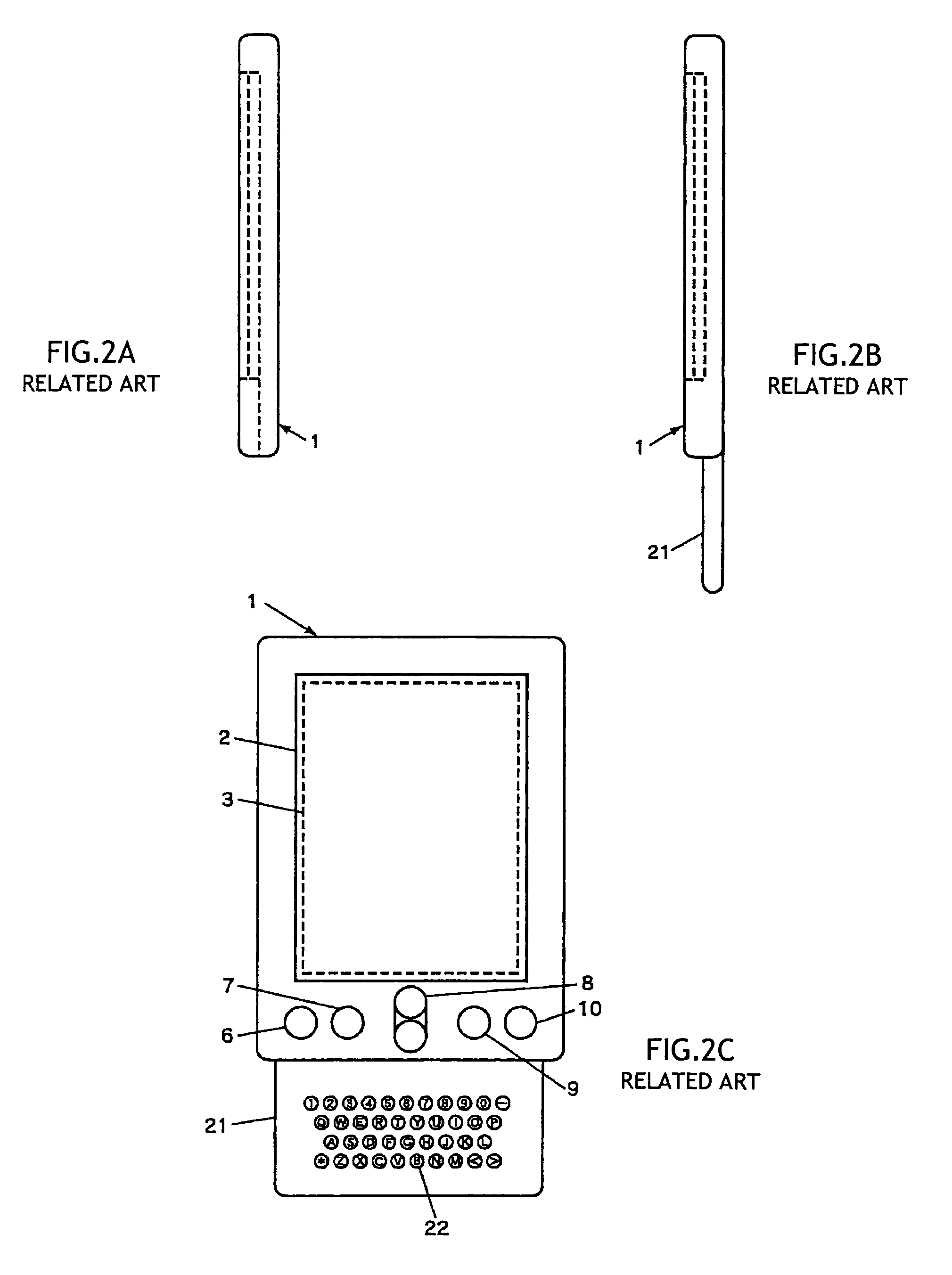

Mobile information terminal

ActiveUS20070063976A1Perform input operationImprove operabilityInput/output for user-computer interactionDigital data processing detailsEmbedded systemDisplay device

A mobile information terminal has a front surface on which a display surface of a display device is arranged and a rear surface on which a plurality of operation keys are arranged. The mobile information terminal further has a half-depressing sensor for detecting that each of the operation keys is half-depressed and / or a touch sensor for detecting that each of the operation keys is touched. A control section executes a processing operation to cause the display device to display an image showing the arrangement of said operation keys and to change an icon which corresponds to a key of operation keys when a control section determines, according to an input signal from the half-depressing sensor or the touch sensor, that the finger of the operator is placed on this key of operation keys.

Owner:LENOVO INNOVATIONS LTD HONG KONG

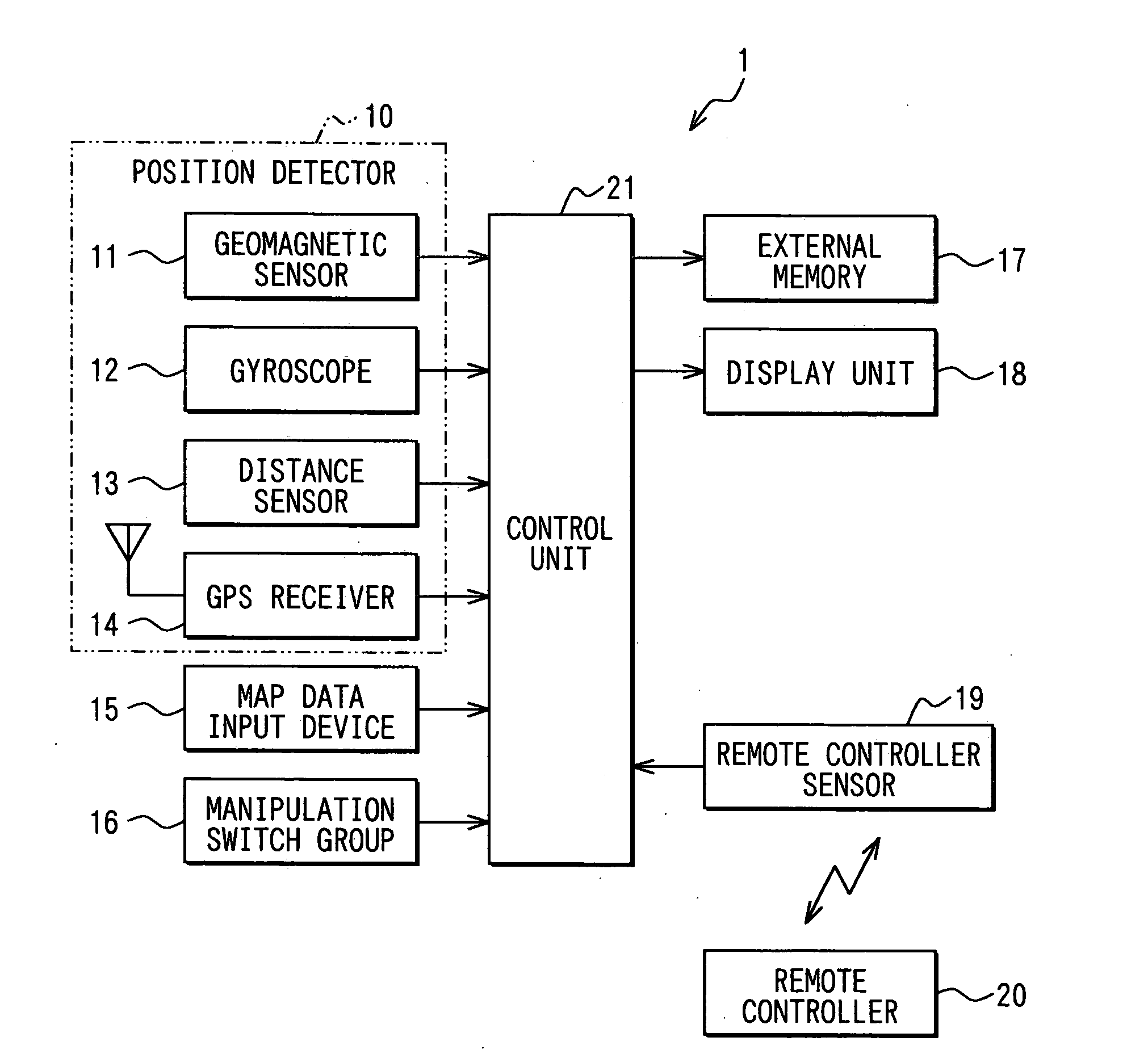

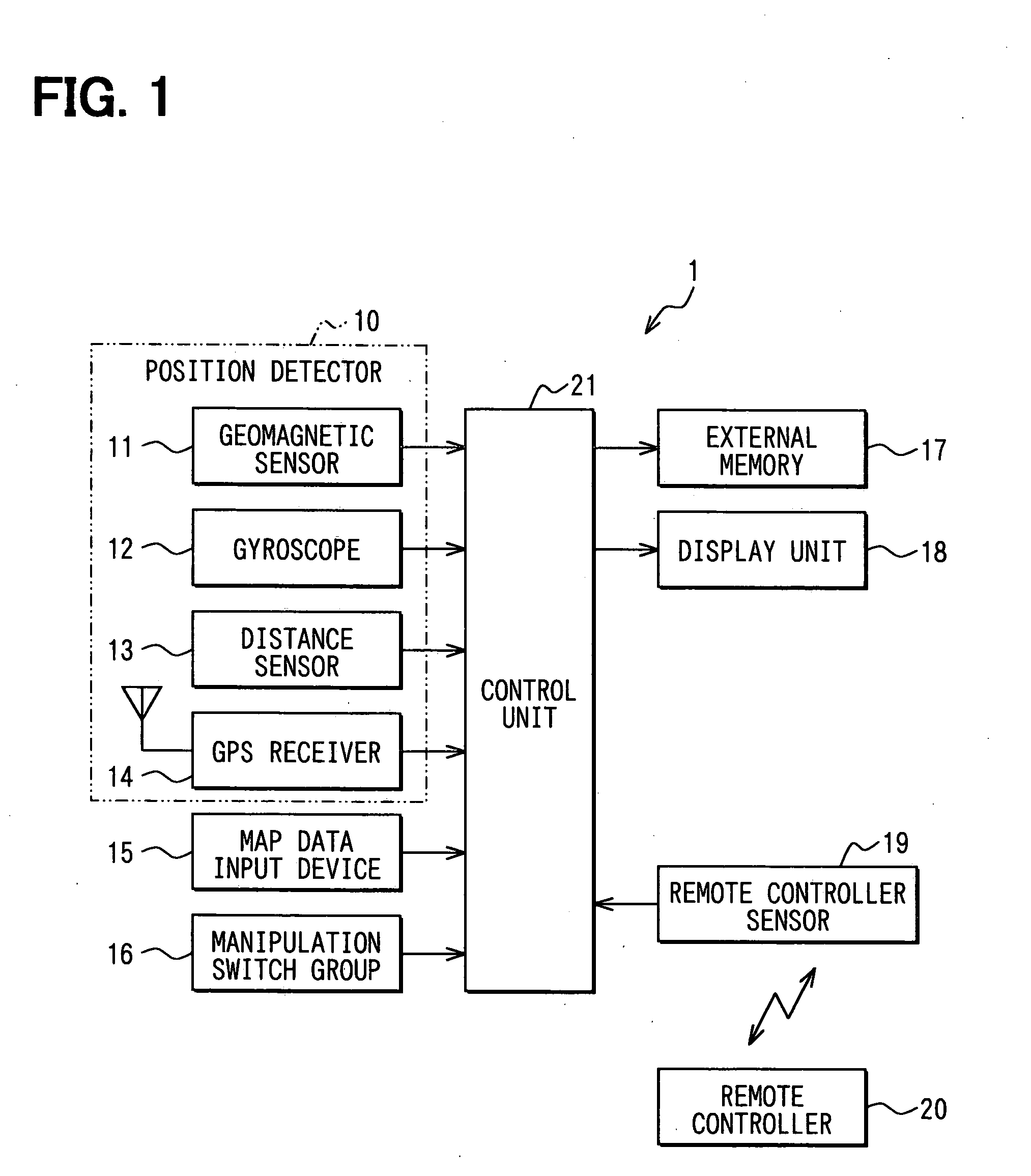

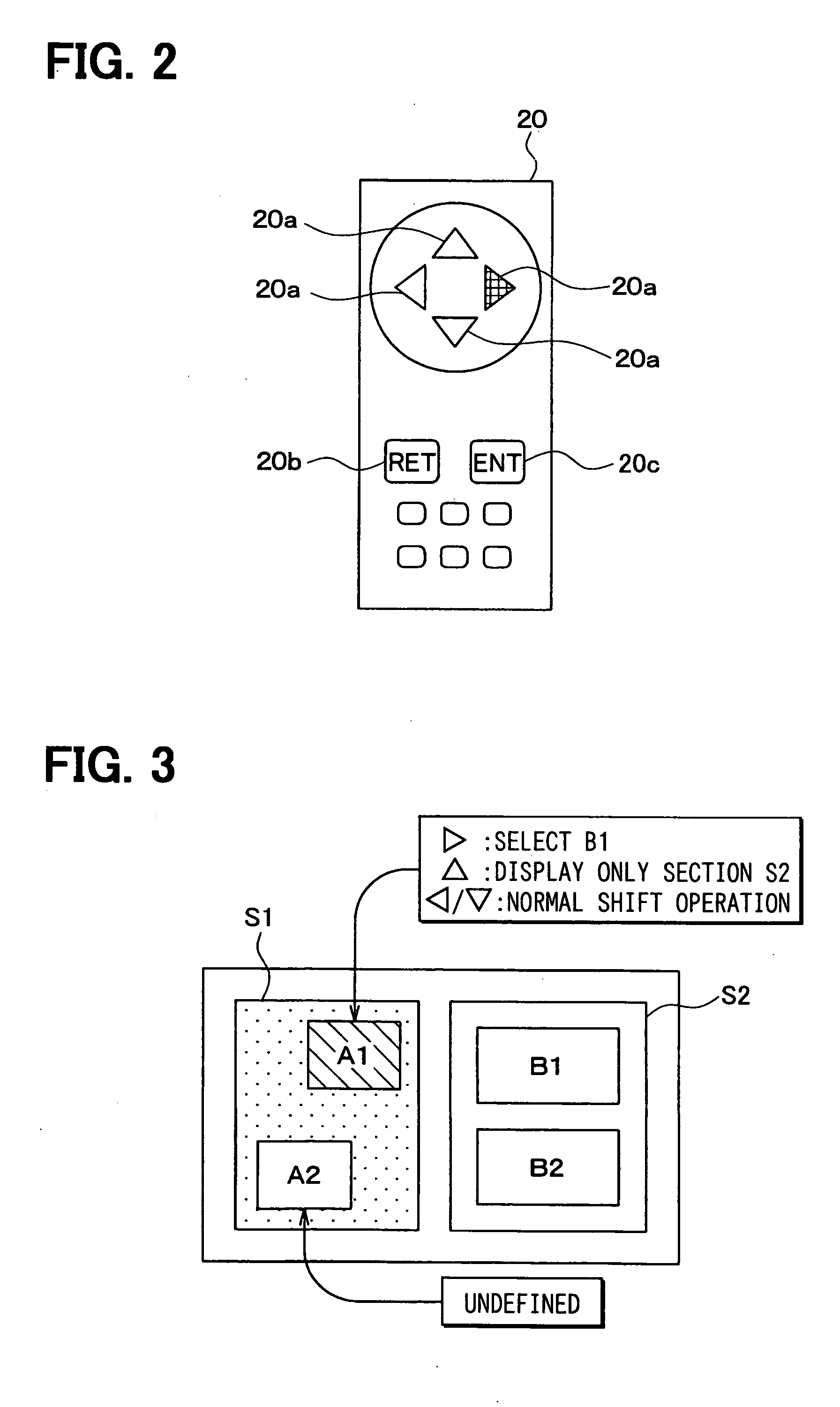

Image display system

InactiveUS20060097986A1Improve operabilityIncreased flexibility of arrangementCathode-ray tube indicatorsInput/output processes for data processingStorage cellControl unit

In an image display system, a manipulation signal obtaining unit obtains a manipulation signal in accordance with manipulation of manipulation switches. A display control unit controls to display a plurality of switch indicators, which are selectable based on the manipulation signal, on a display screen. A storing unit stores correspondences between the manipulation signal and a display content to be displayed next on the display screen, for the respective switch indicators. The display control unit determines the display content to be displayed next based on the manipulation signal obtained by the manipulation signal obtaining unit and the correspondence stored in the storing unit, and displays the determined display content on the display screen.

Owner:DENSO CORP

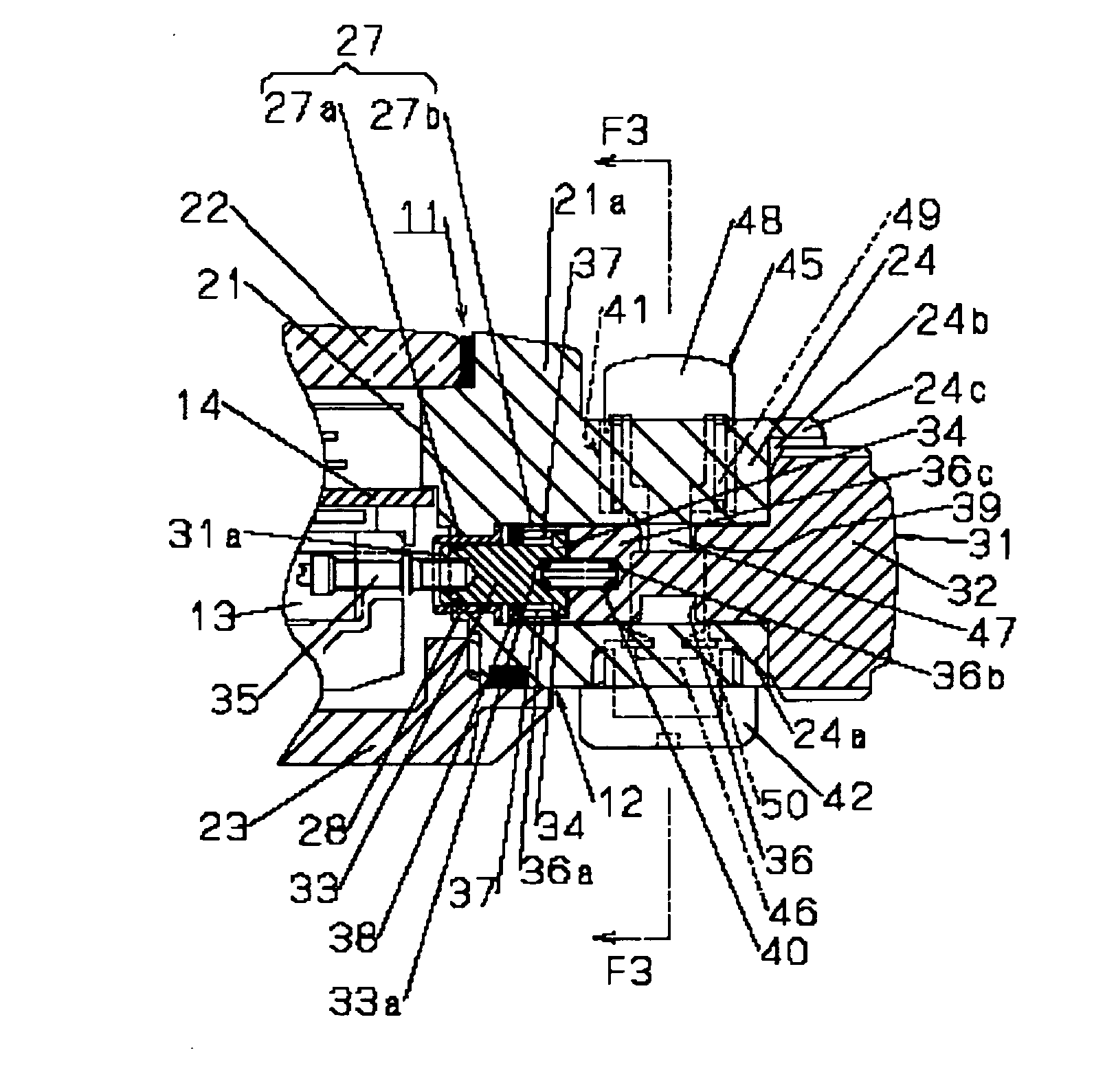

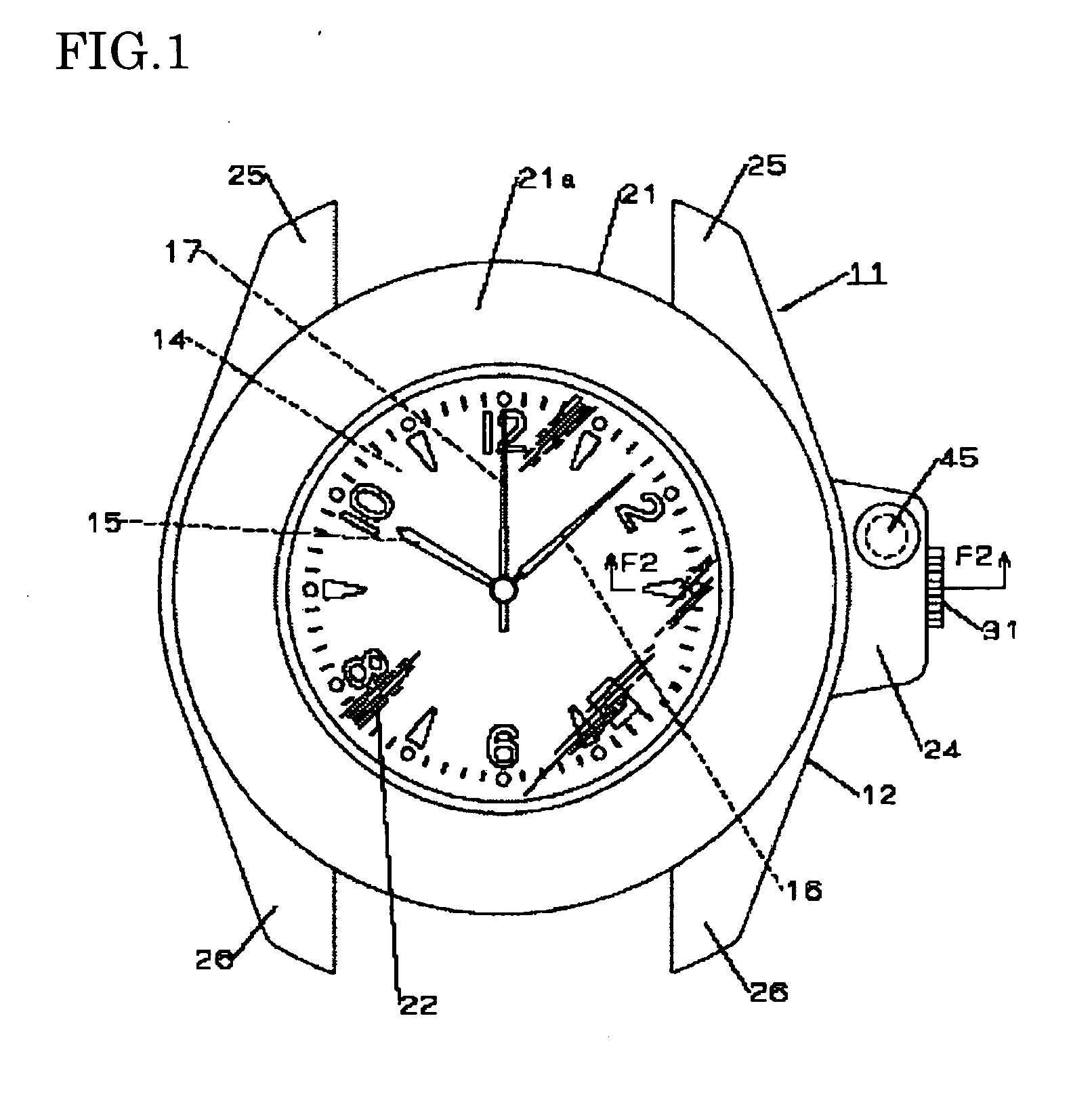

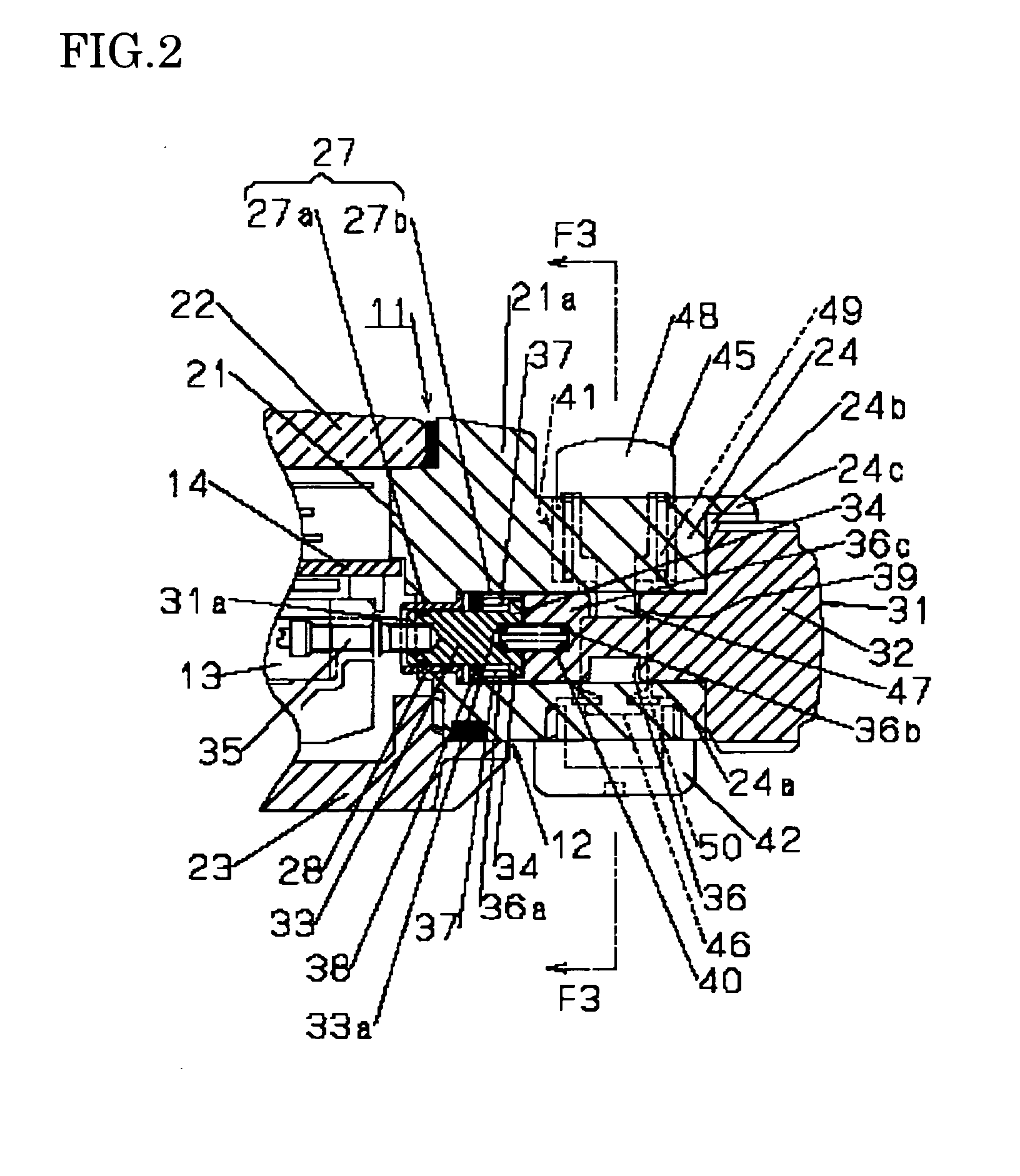

Portable watch

ActiveUS20100220562A1Improve operabilityEnable operationNormal windingClockwork casesEngineeringMechanical engineering

A portable watch is equipped with a watch exterior member, a crown, a crown lock button, and an urging member. In a case band with which the exterior member is equipped, there are formed a crown mounting hole and a member mounting portion communicating with this hole and vertically perpendicular thereto. The crown is arranged in the hole. The crown has a crown shaft portion passed through the hole and a crown head portion continuous therewith. The crown shaft is provided with a lock groove continuous in the peripheral direction. The lock button accommodated in the mounting portion has a button head portion (operation end portion) protruding from the mounting portion. The button is movable between a lock position where it is engaged with the groove to constrain the crown and a lock canceling position where it is detached from the groove to cancel the constraint of the crown, and is arranged at the lock canceling position through a one-touch operation of the button head portion. The watch is characterized in that the button is arranged at the lock position by an urging member accommodated in the mounting portion.

Owner:SEIKO INSTR INC

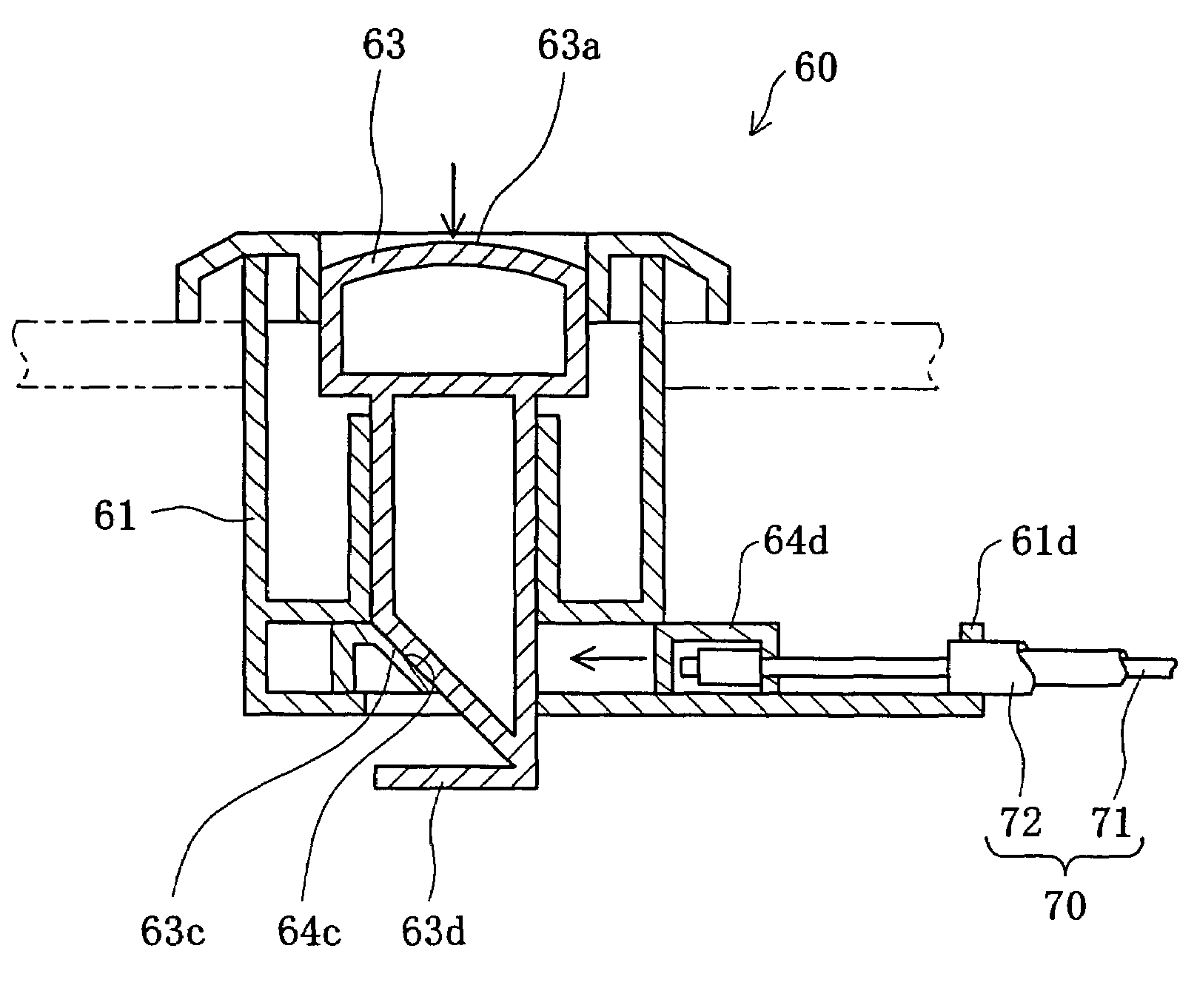

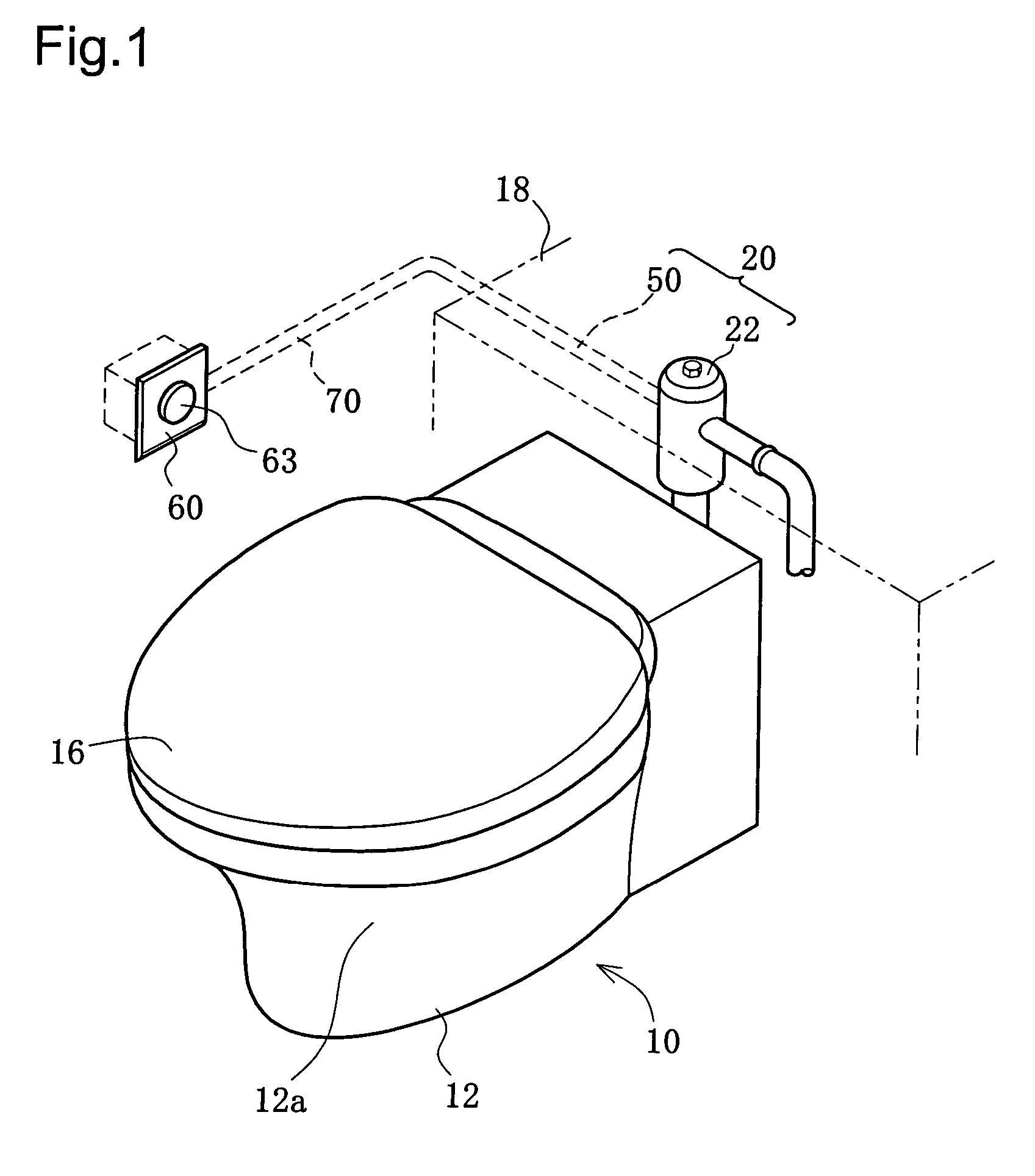

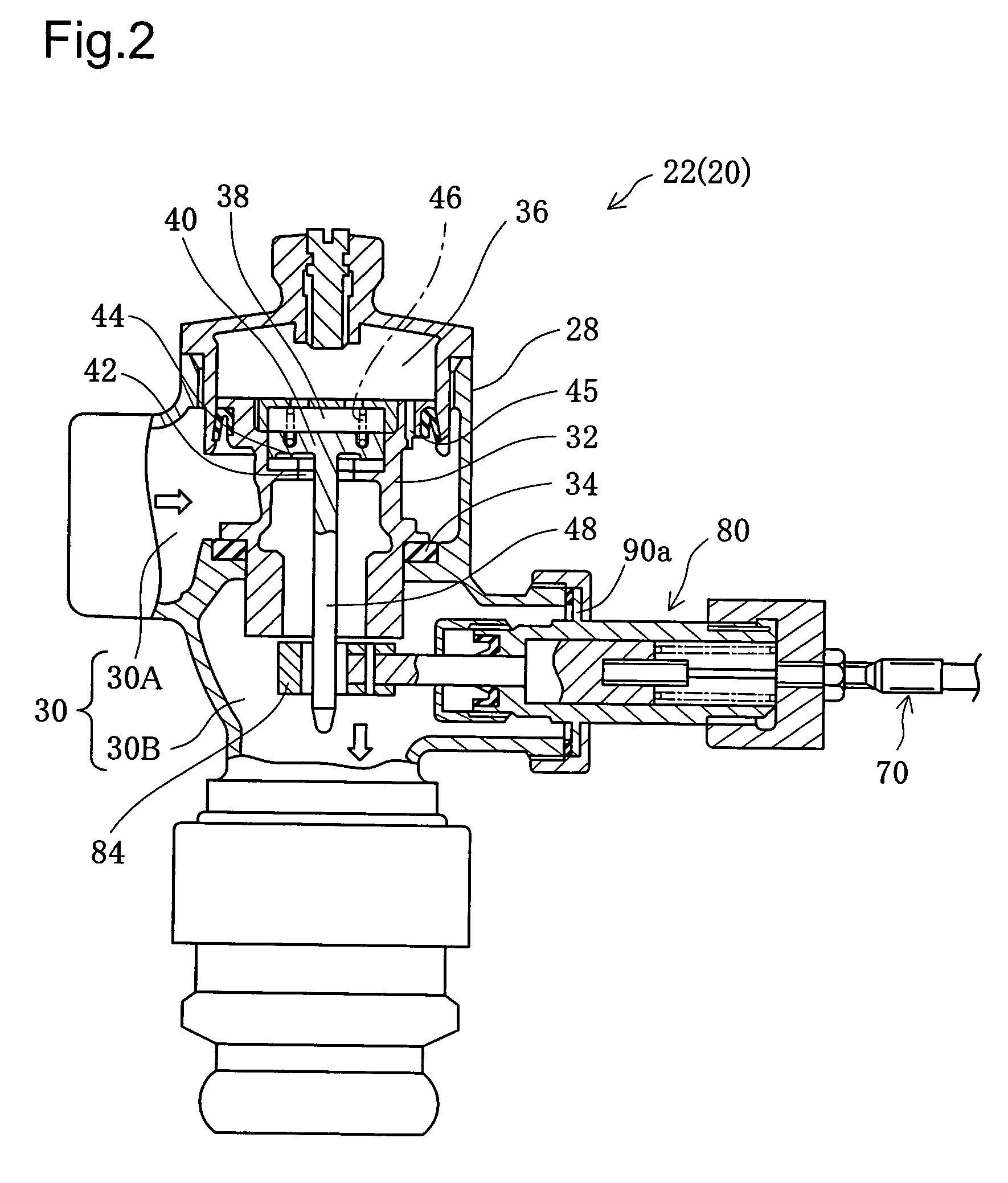

Flush valve device of flush toilet

InactiveUS6966536B2Increase degree of freedomImprove operabilityOperating means/releasing devices for valvesFlushing devicesEngineeringFlush toilet

A flush valve device 20 of a flush toilet includes a flush valve body 22 connected to a city water source and an operation unit 50. The operation unit 50 has an operation button 63 and a flexible inner cable 71, which is part of a cable mechanism 70. The inner cable 71 is extended from a rear side to a lateral side of a toilet body 12 and is linked with the operation button 63. In response to a press of the operation button 63, the flush valve body 22 opens to make a supply of washing water flown into the toilet body 12. This arrangement desirably increases the degree of freedom in positioning of the flush valve body and the operation unit, enhances the operability of the flush valve device 20, and effectively facilitates installation of the flush valve device 20.

Owner:TOTO LTD

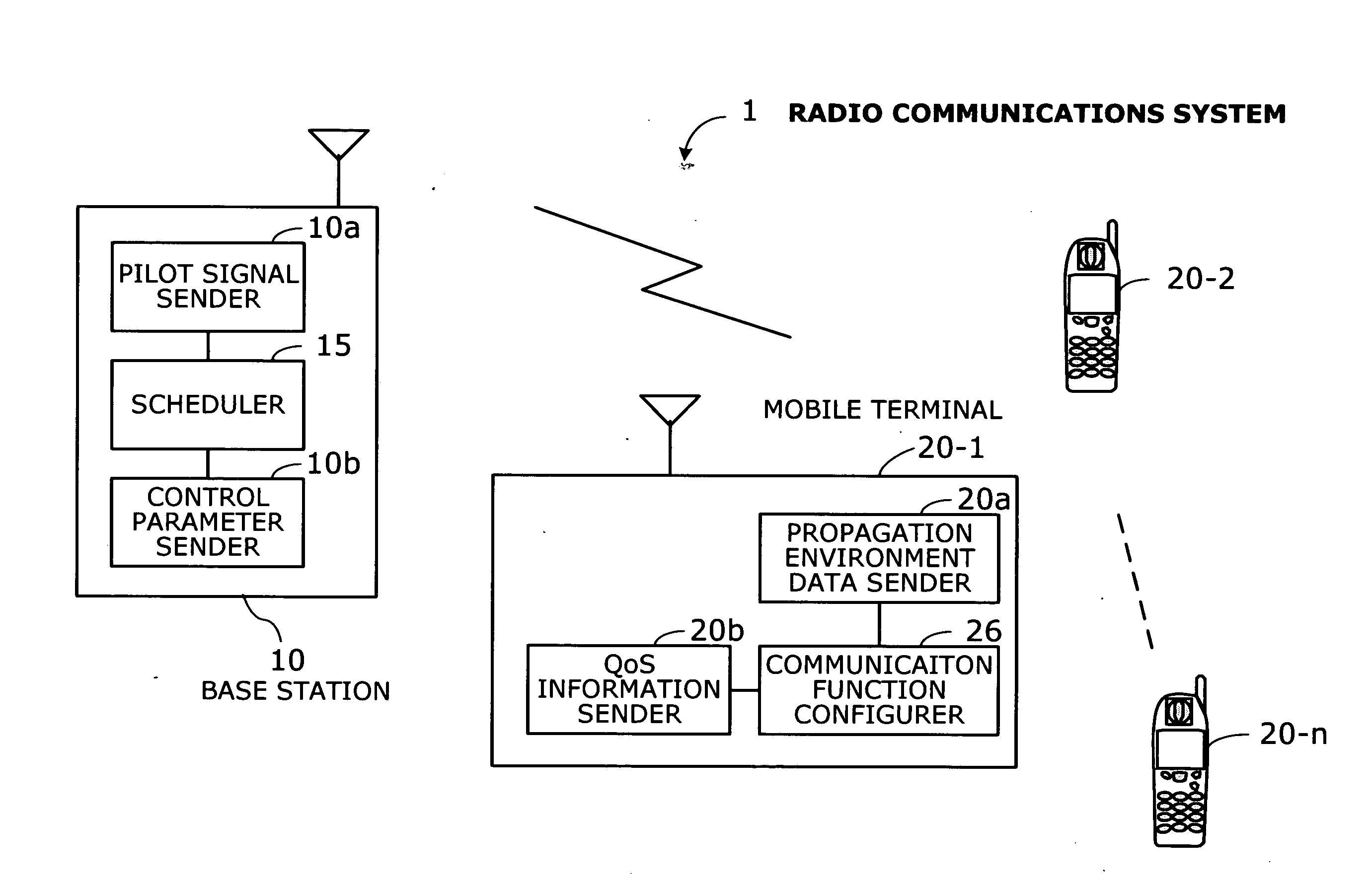

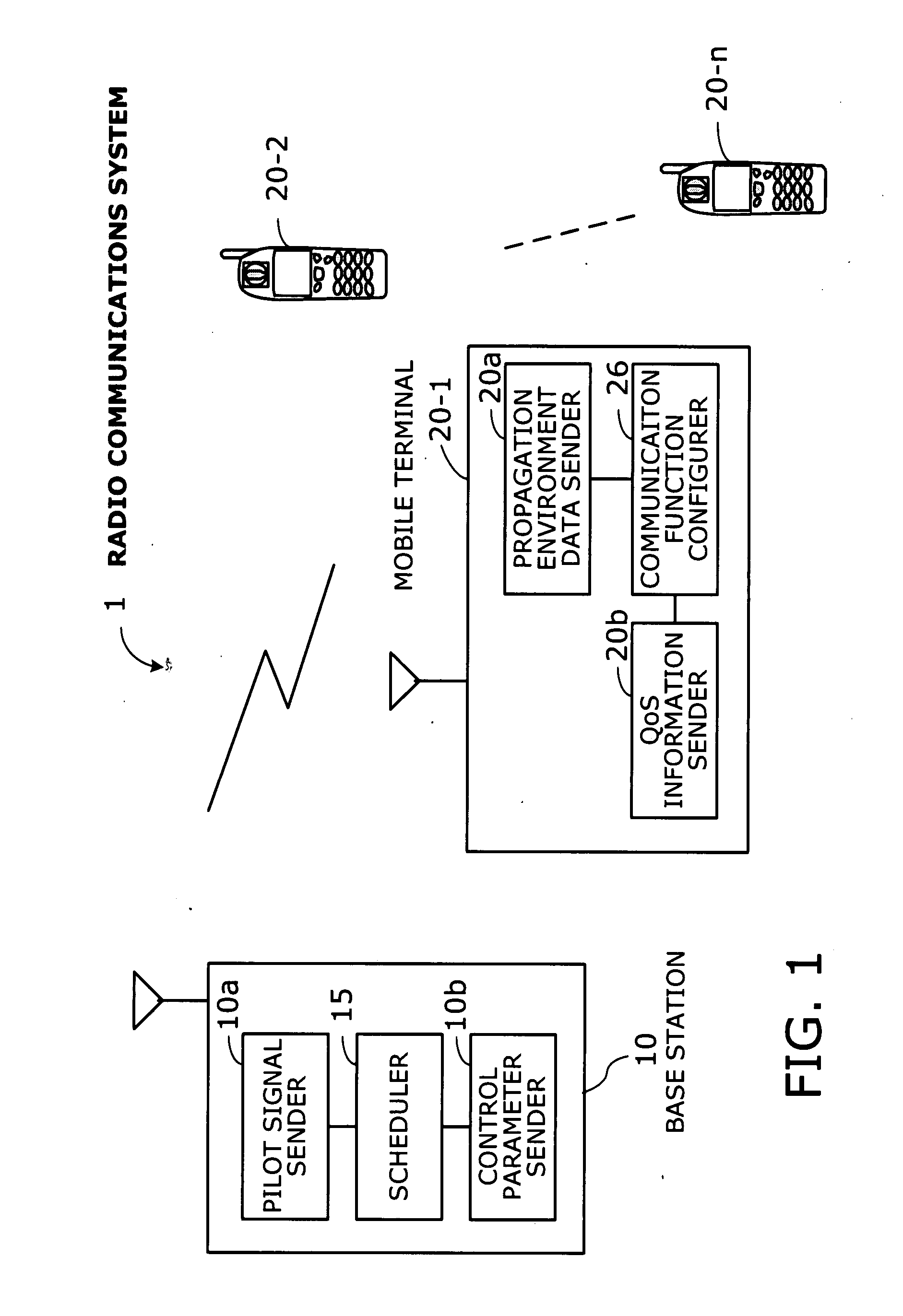

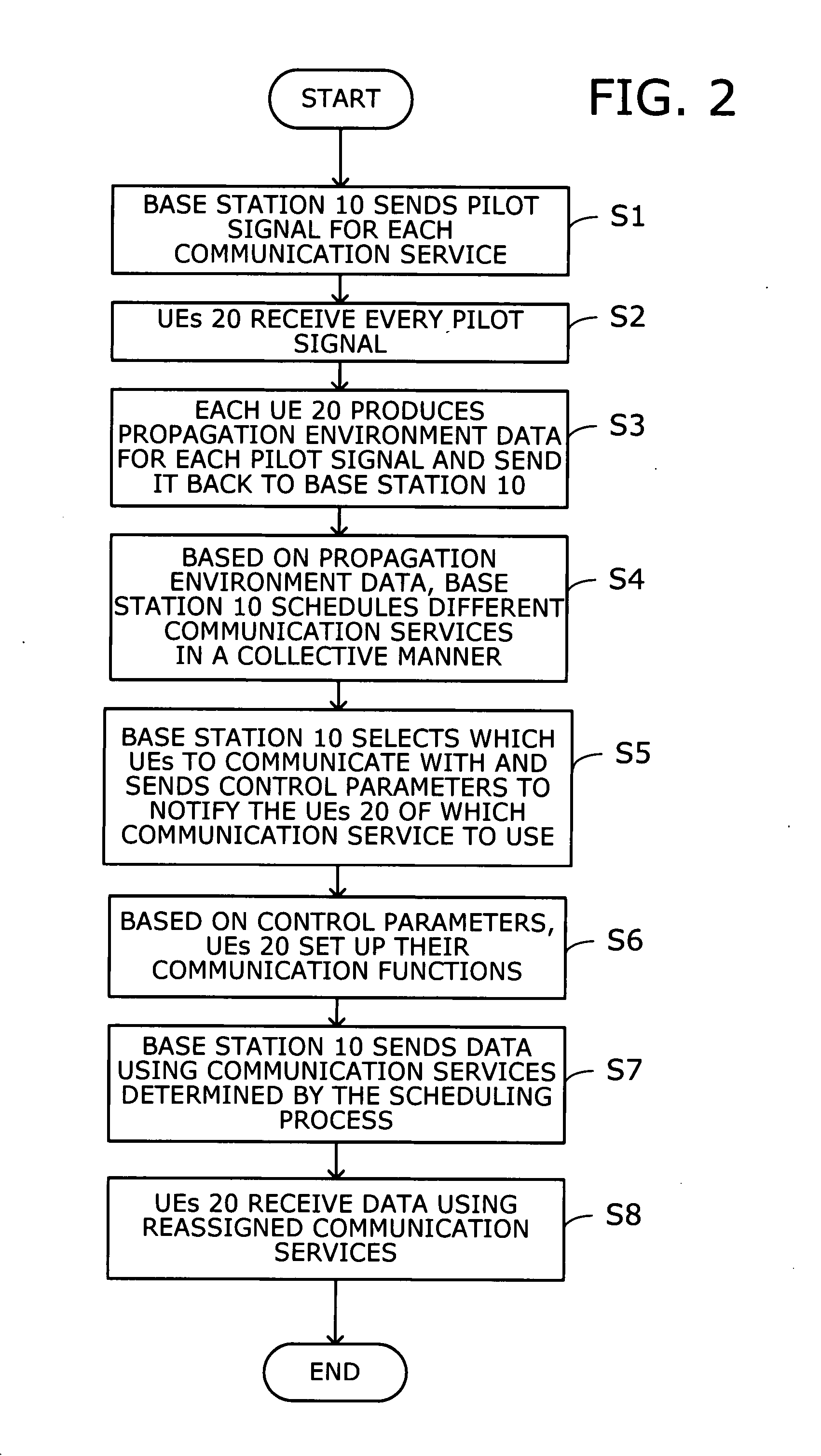

Radio communications system

ActiveUS20080020779A1Improve operabilityEasy to operateCriteria allocationSignal allocationPilot signalRadio communications

A scheduling process handles a plurality of communication services in a collective manner, thus making a radio communications system more operable. A pilot signal sender sends pilot signals with carrier frequencies each corresponding to an N (N≧1) different communication services. A scheduler collects N×n instances of propagation environment data from n (n≧1) terminal devices and selects terminal devices and communication services therefor by assigning terminal devices having a better propagation environment to the plurality of different communication services in a collective manner. The pilot signals are used by a propagation environment data sender to measure and report a propagation environment of each carrier frequency. A communication function configurer automatically sets up a communication function to adapt to the communication service that the base station has assigned.

Owner:FUJITSU LTD

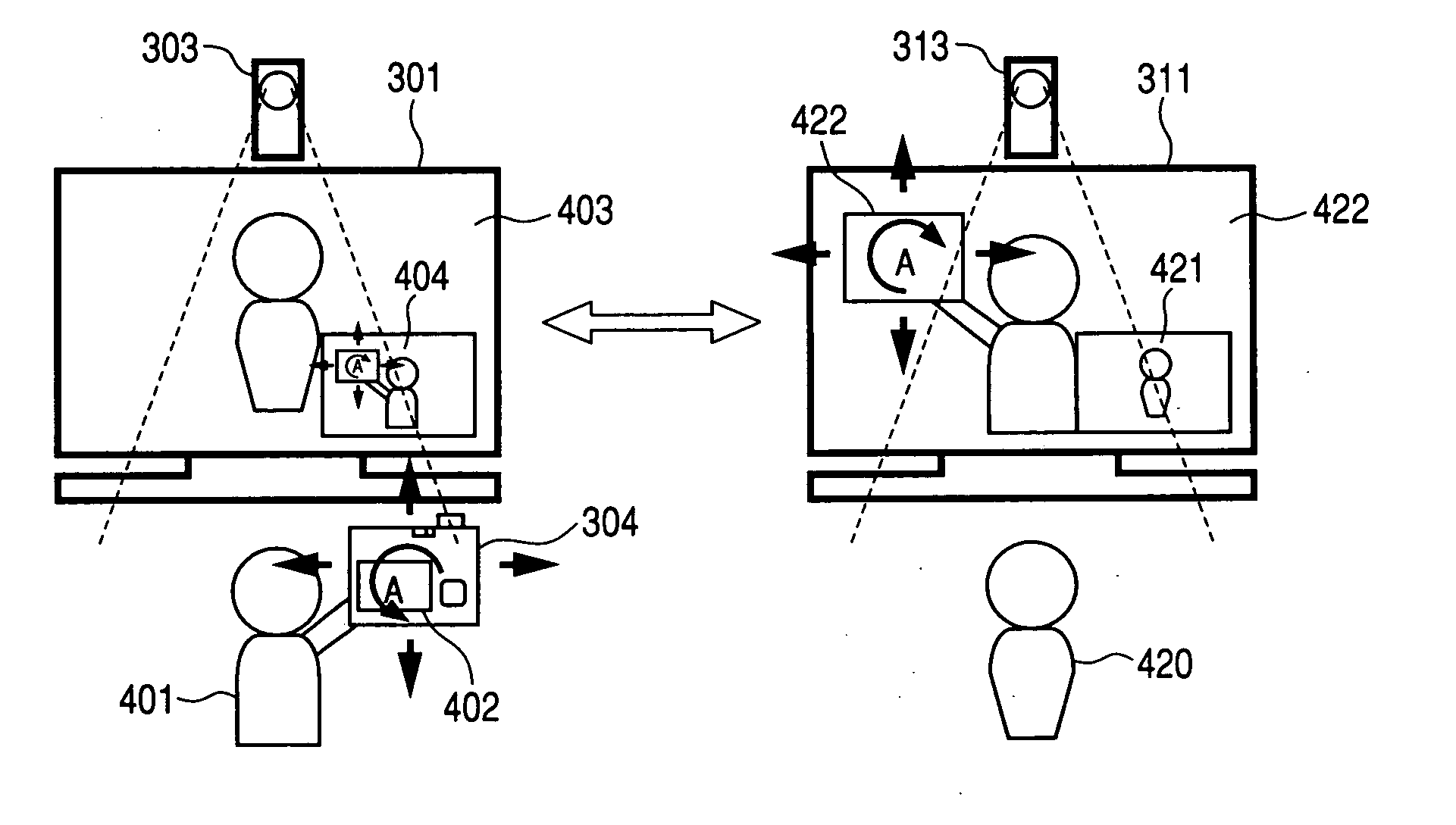

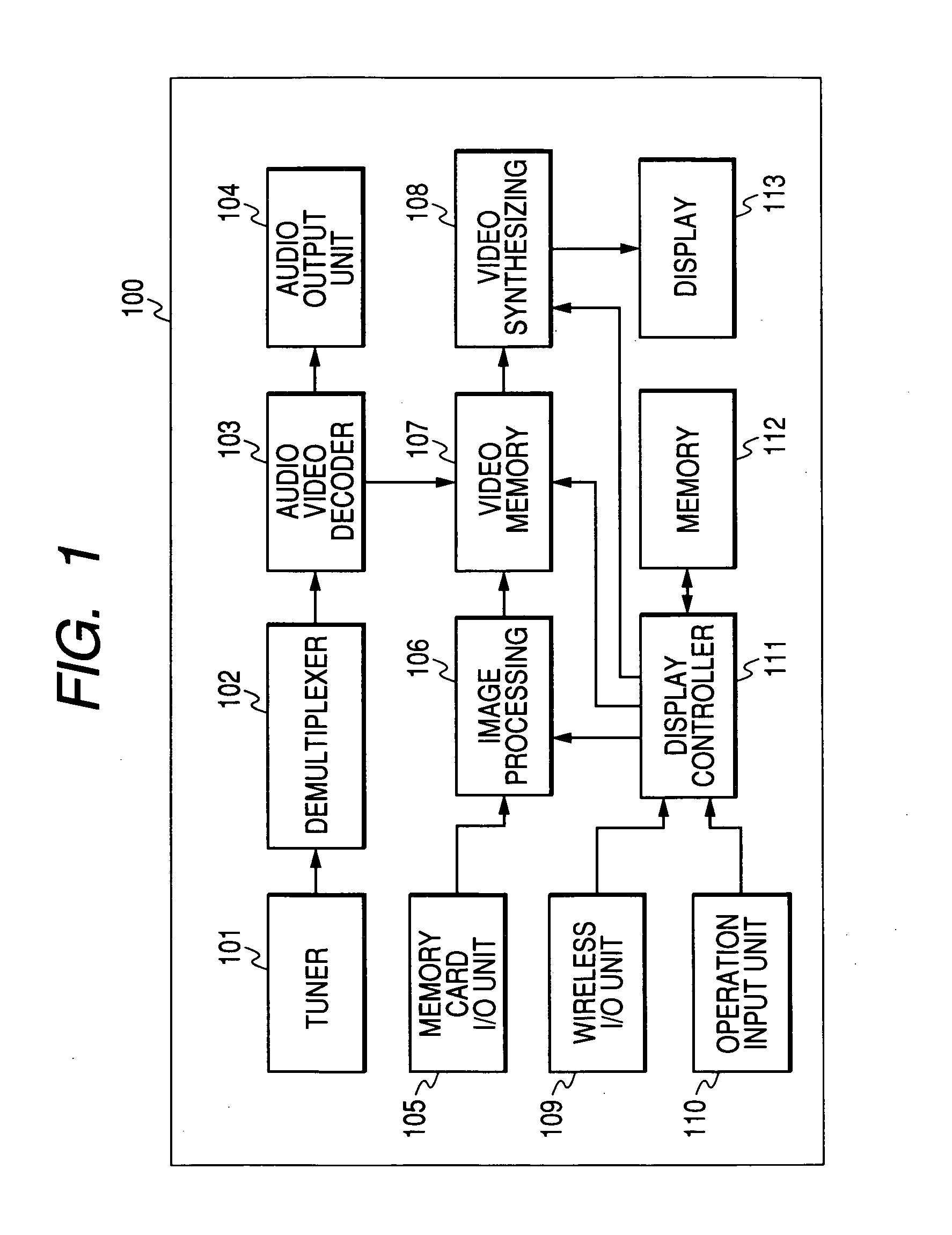

Image displaying method, image displaying program, and display

InactiveUS20050223333A1Improve operabilityEasy to operateTelevision system detailsColor television detailsImage storageComputer graphics (images)

Owner:CANON KK

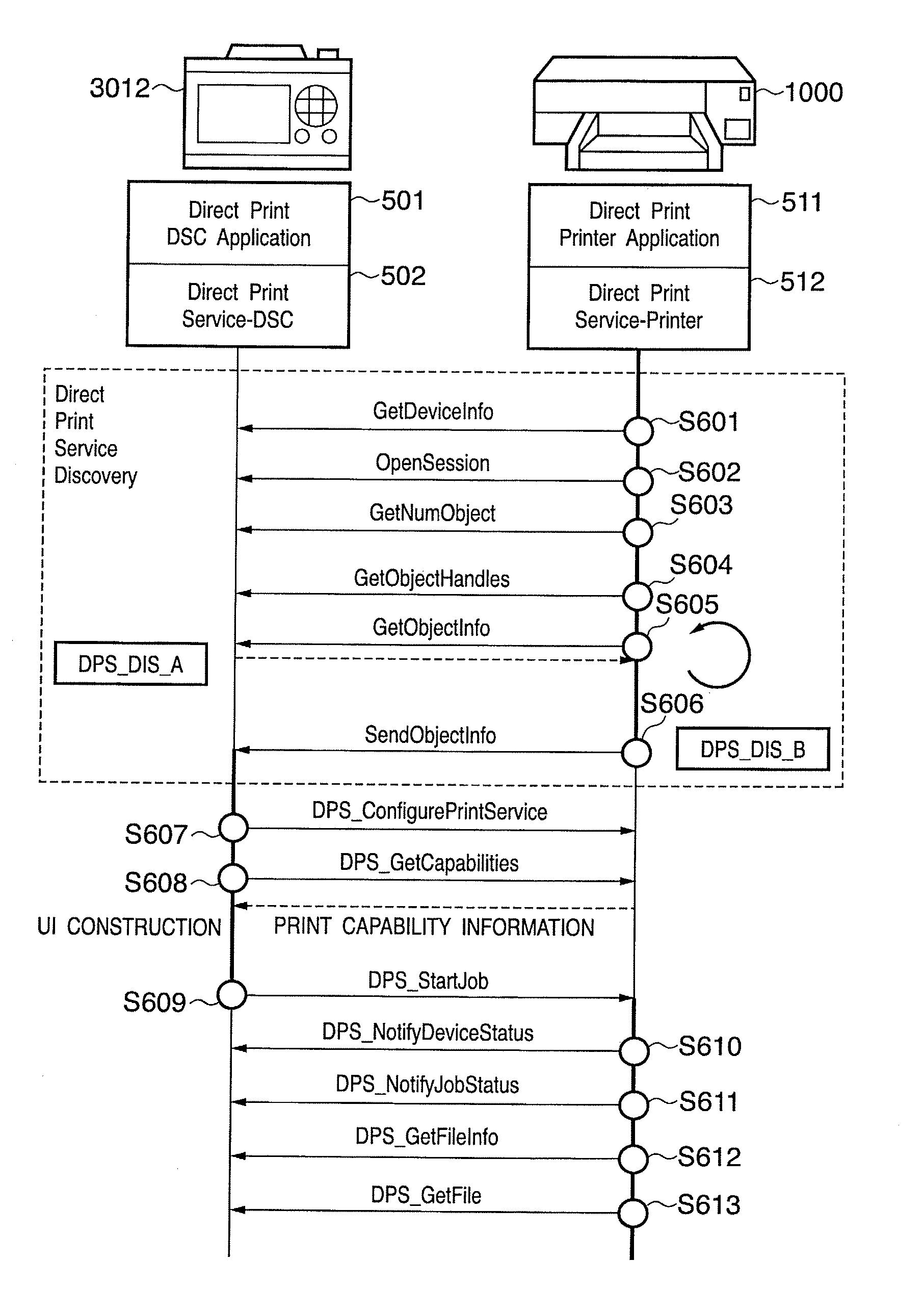

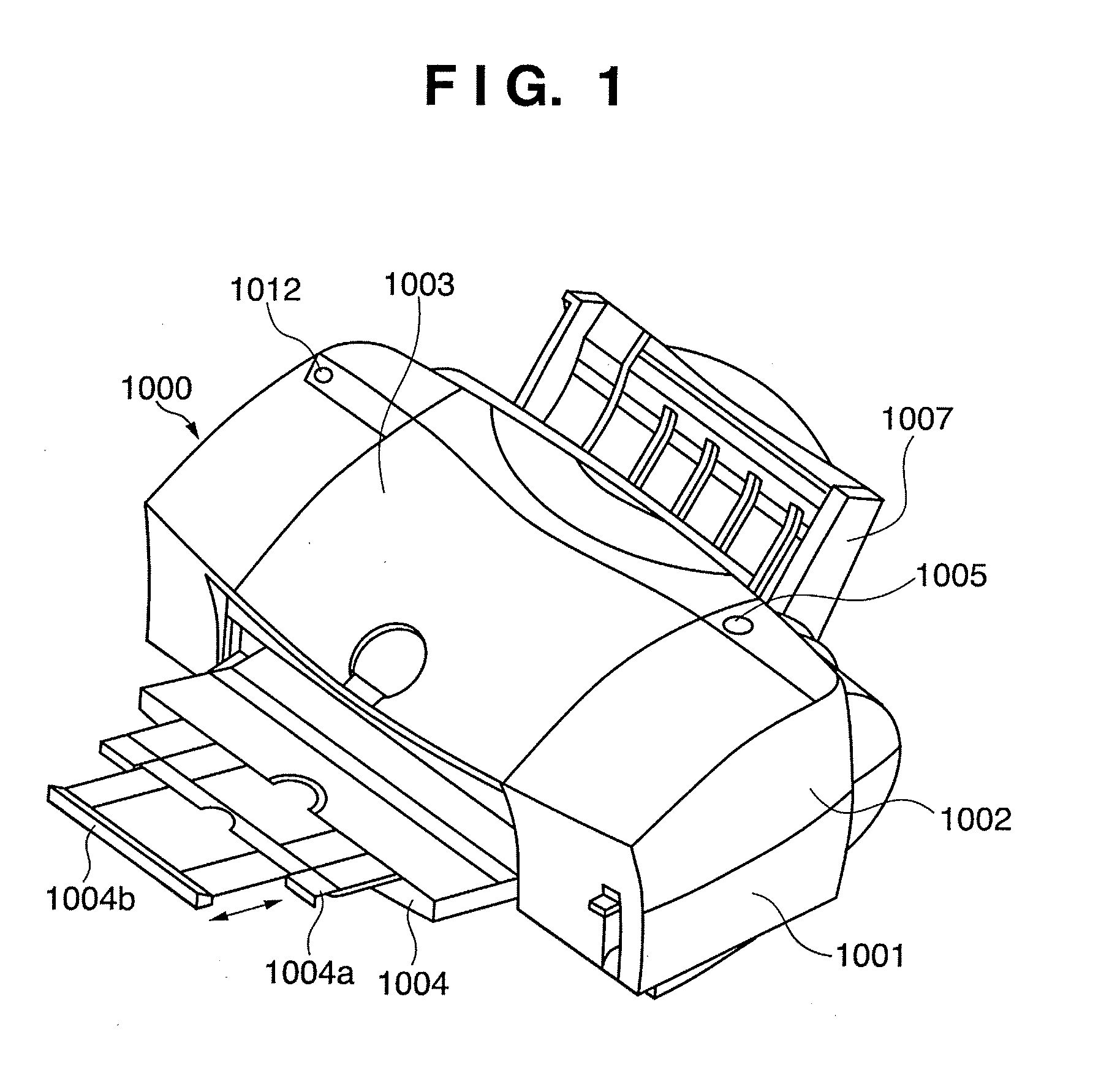

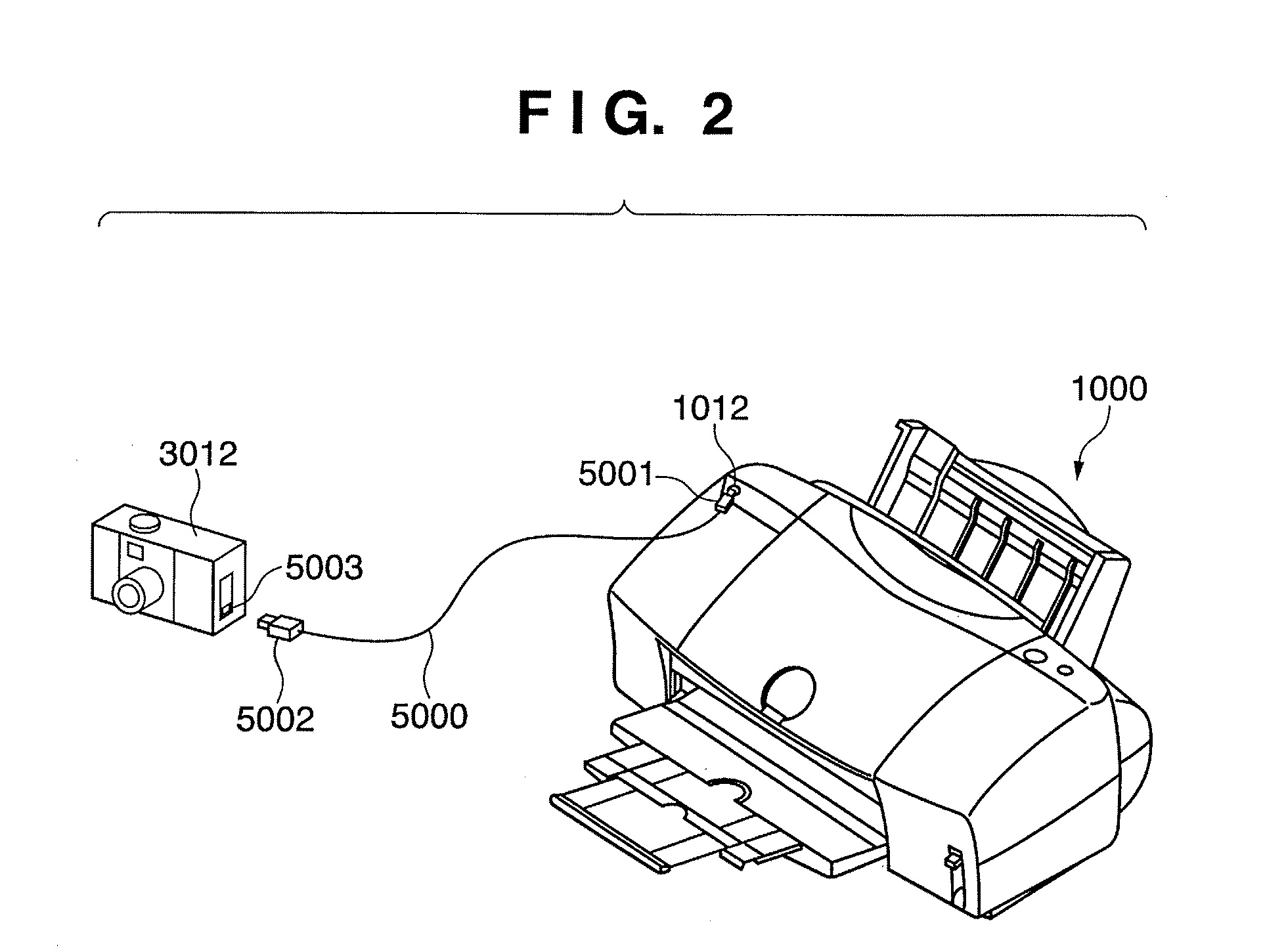

Image-providing apparatus, image-printing apparatus and image-printing system comprised thereof

InactiveUS20070195362A1Improve operabilityEasy to operateVisual presentationDigital output to print unitsService provisionEngineering

Owner:CANON KK

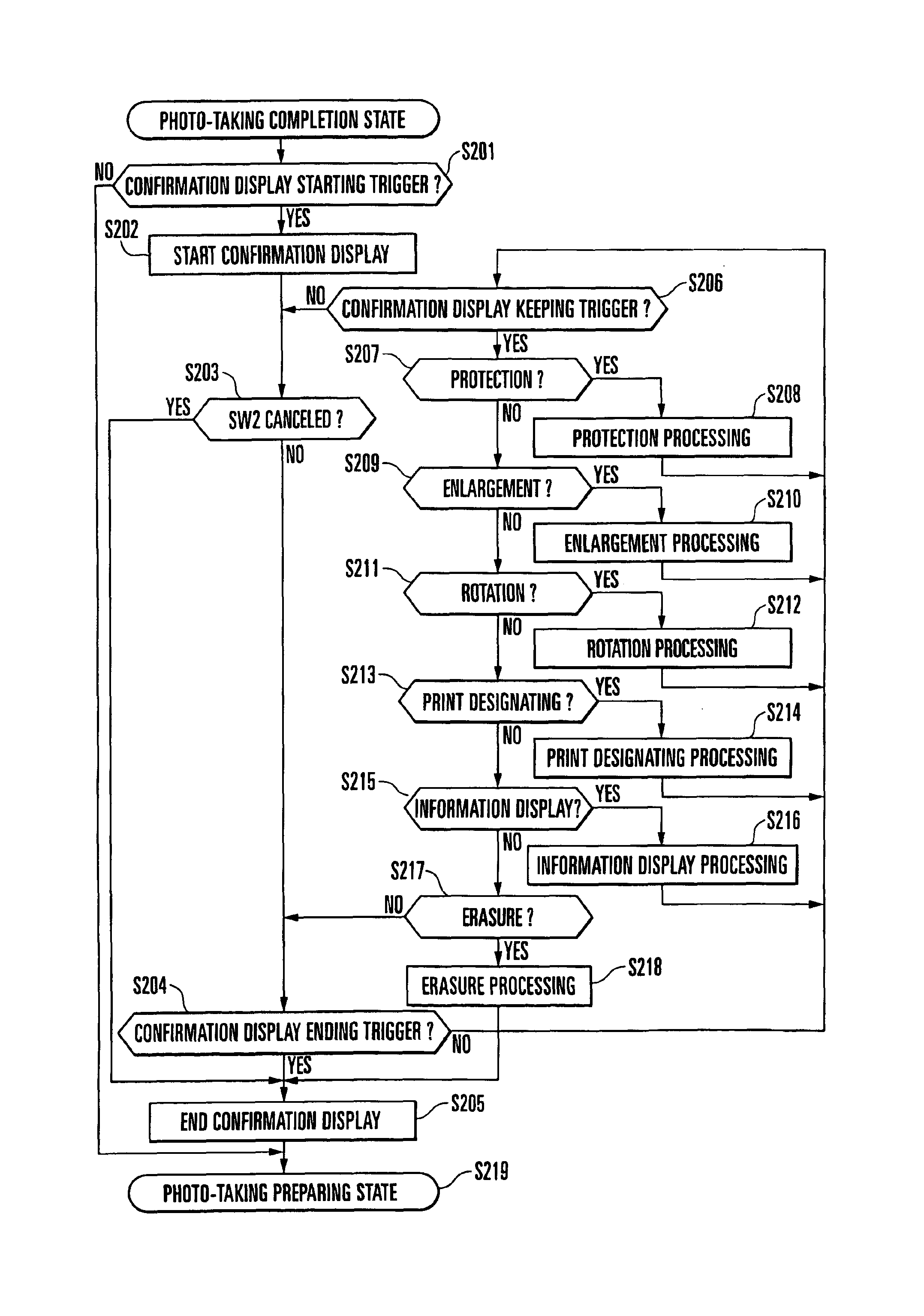

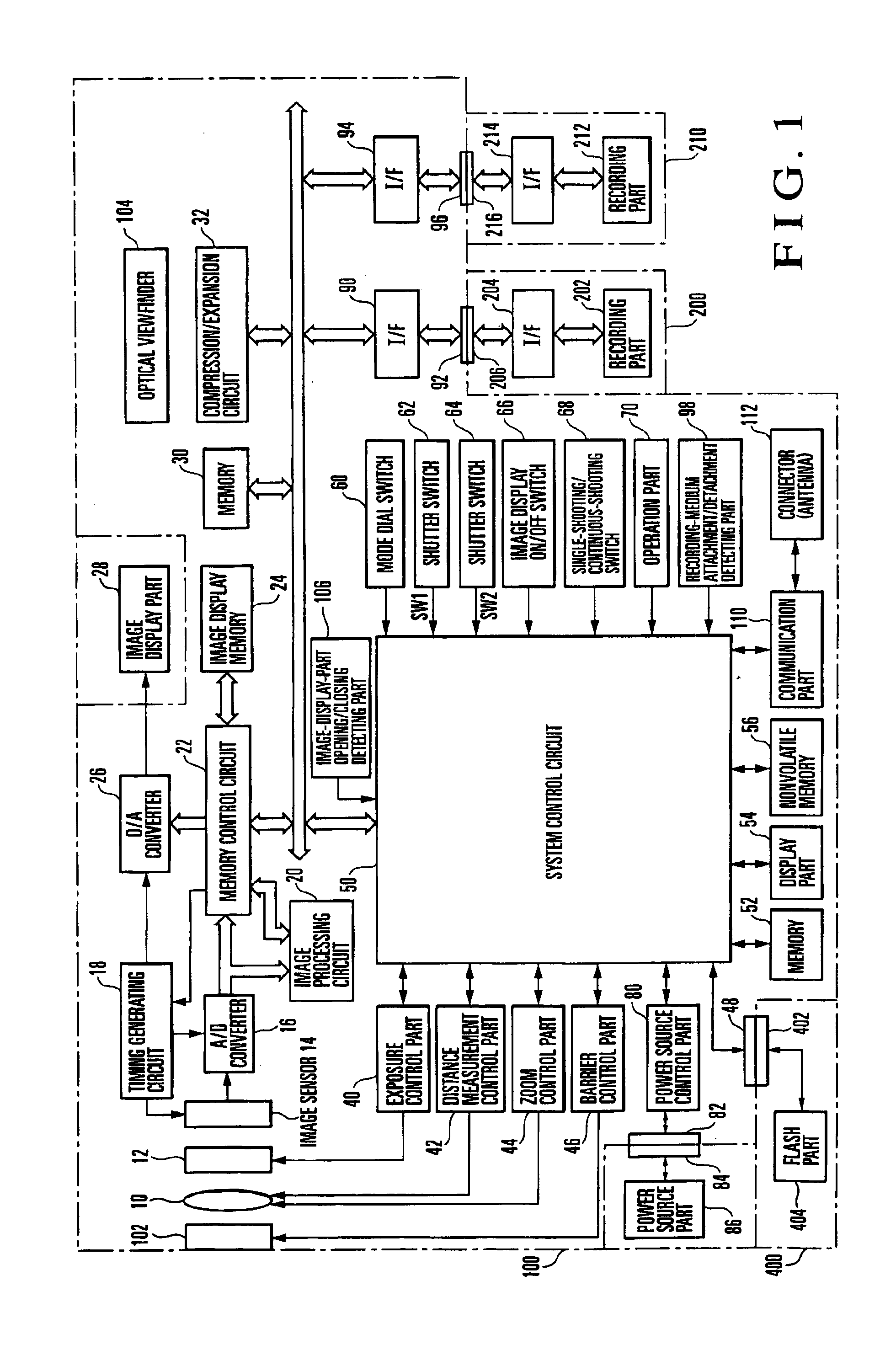

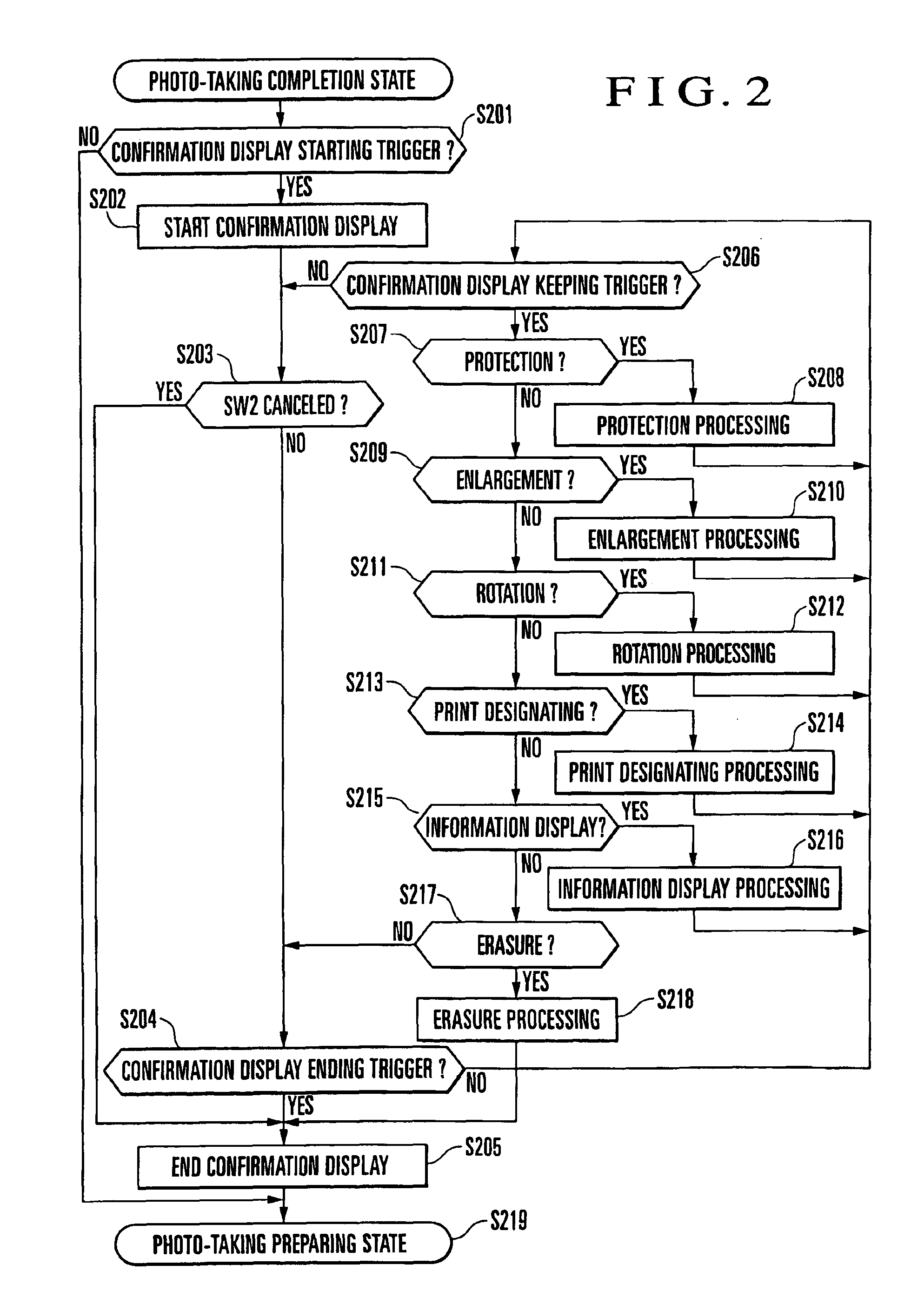

Image pickup apparatus, method and computer program procduct in which a decision to finish a displayed image is made and/or and a kept displayed image is processed

InactiveUS6937281B1Improve operabilityEasy to operateTelevision system detailsColor television detailsComputer graphics (images)Computer program

In an image pickup apparatus, a control method adapted for the image pickup apparatus, and a computer program product supplying a control program adapted for the image pickup apparatus, a photo-taken image obtained by a photo-taking operation is displayed in response to the photo-taking operation, and whether displaying of the photo-taken image displayed in response to the photo-taking operation is to be kept even after an operation of a photo-taking starting operation member for giving an instruction for starting photo-taking is canceled is decided.

Owner:CANON KK

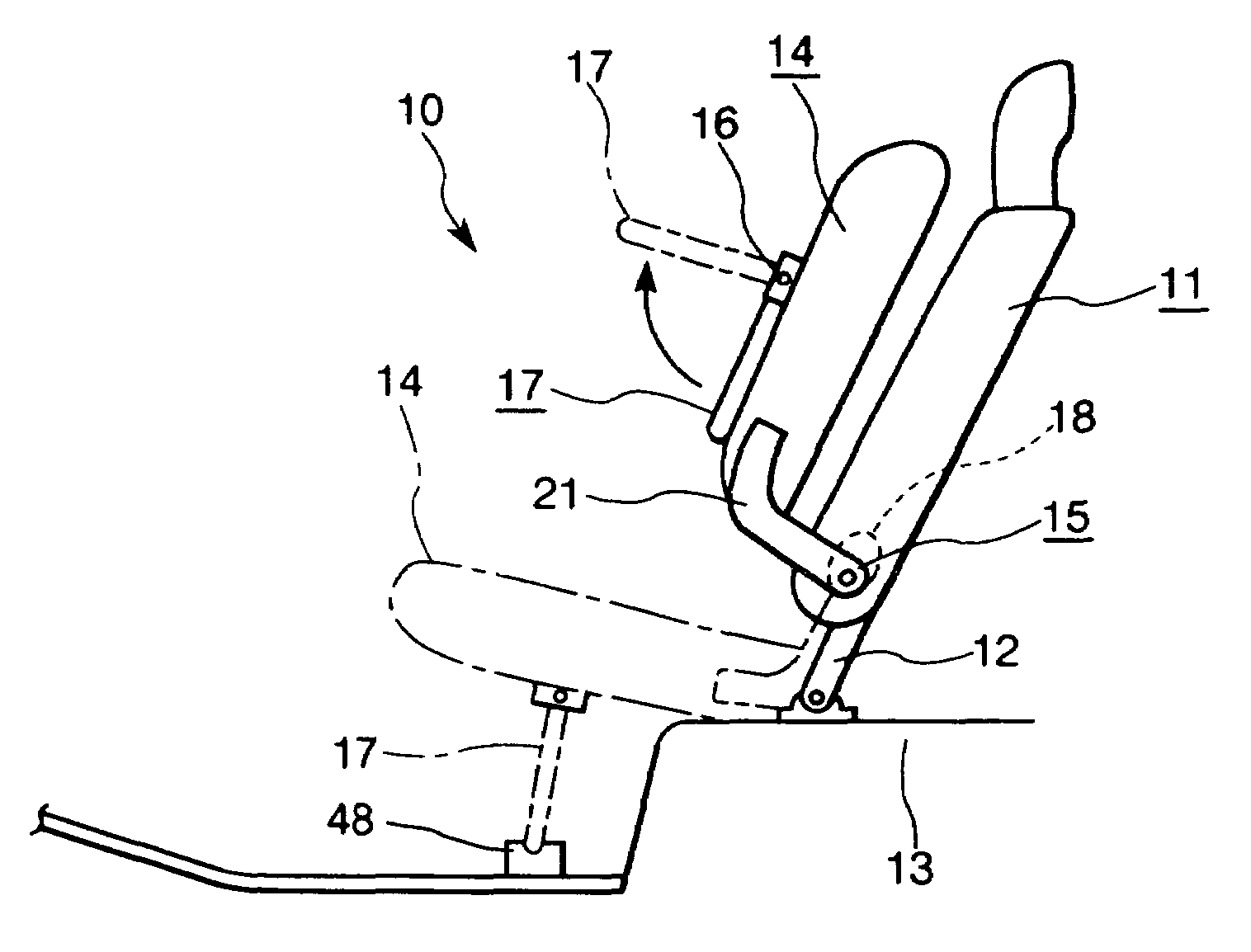

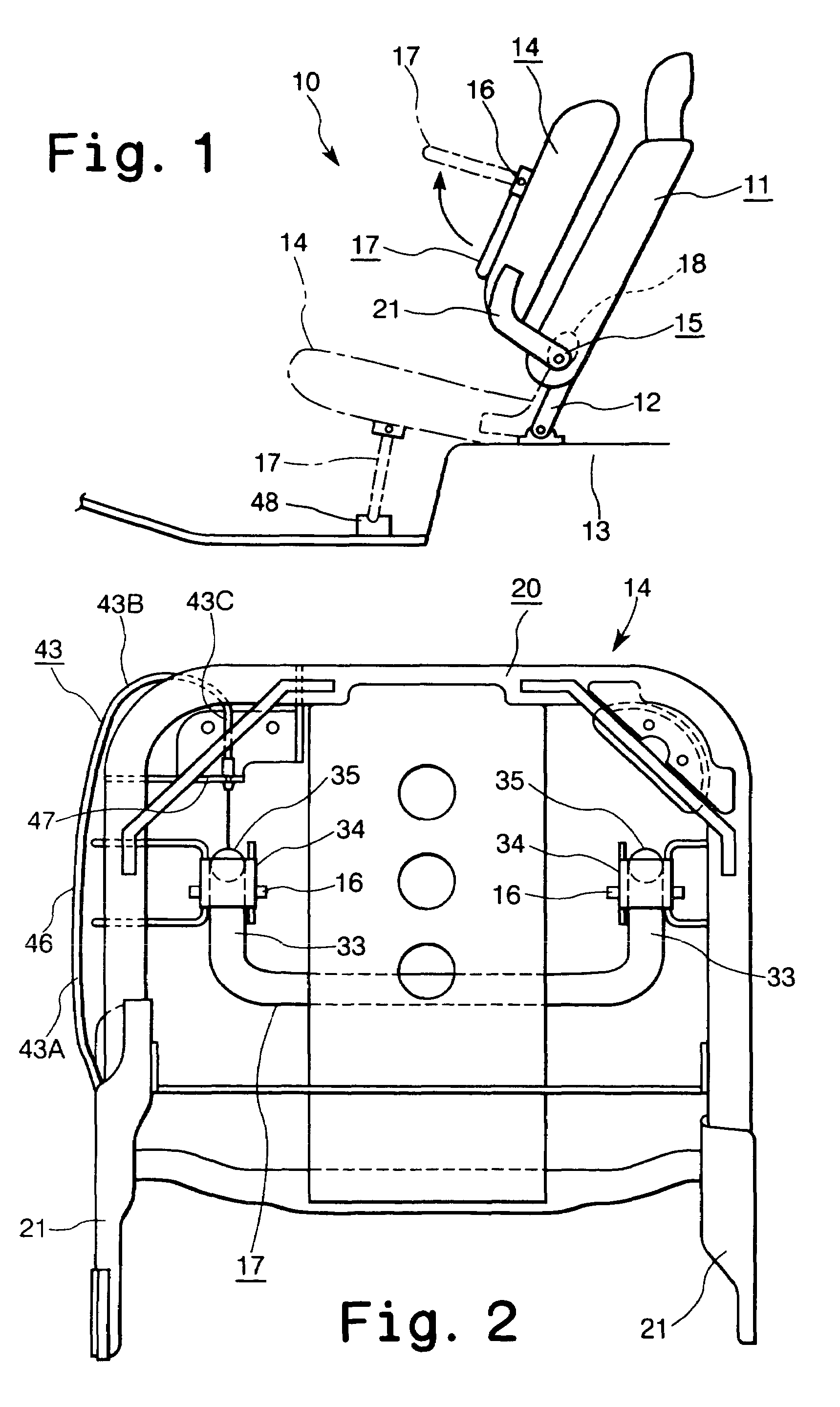

Tip-up vehicle seat

ActiveUS7040702B2Improve operabilityEasy to operateOperating chairsDental chairsEngineeringLocking mechanism

Owner:TS TECH CO LTD +1

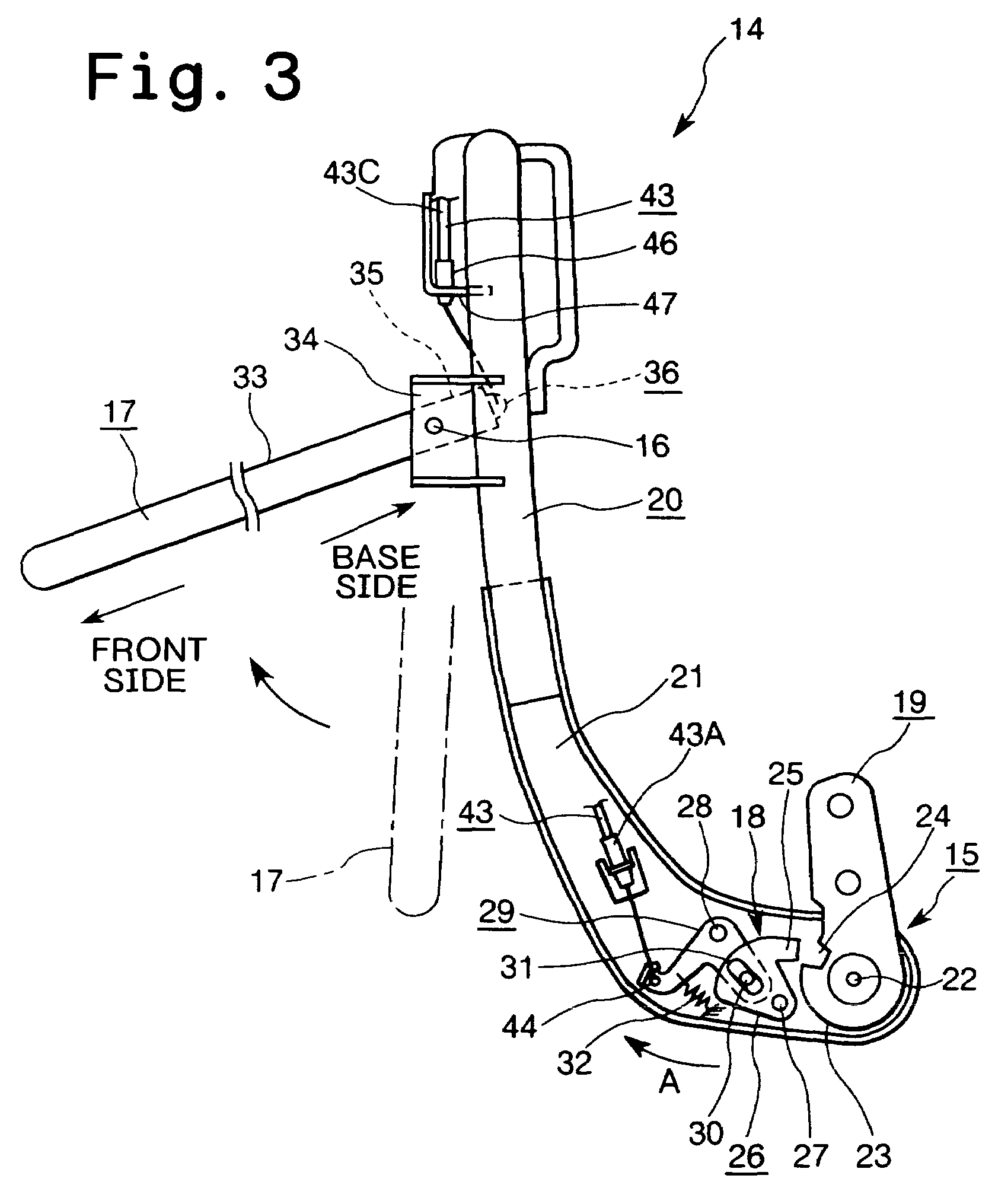

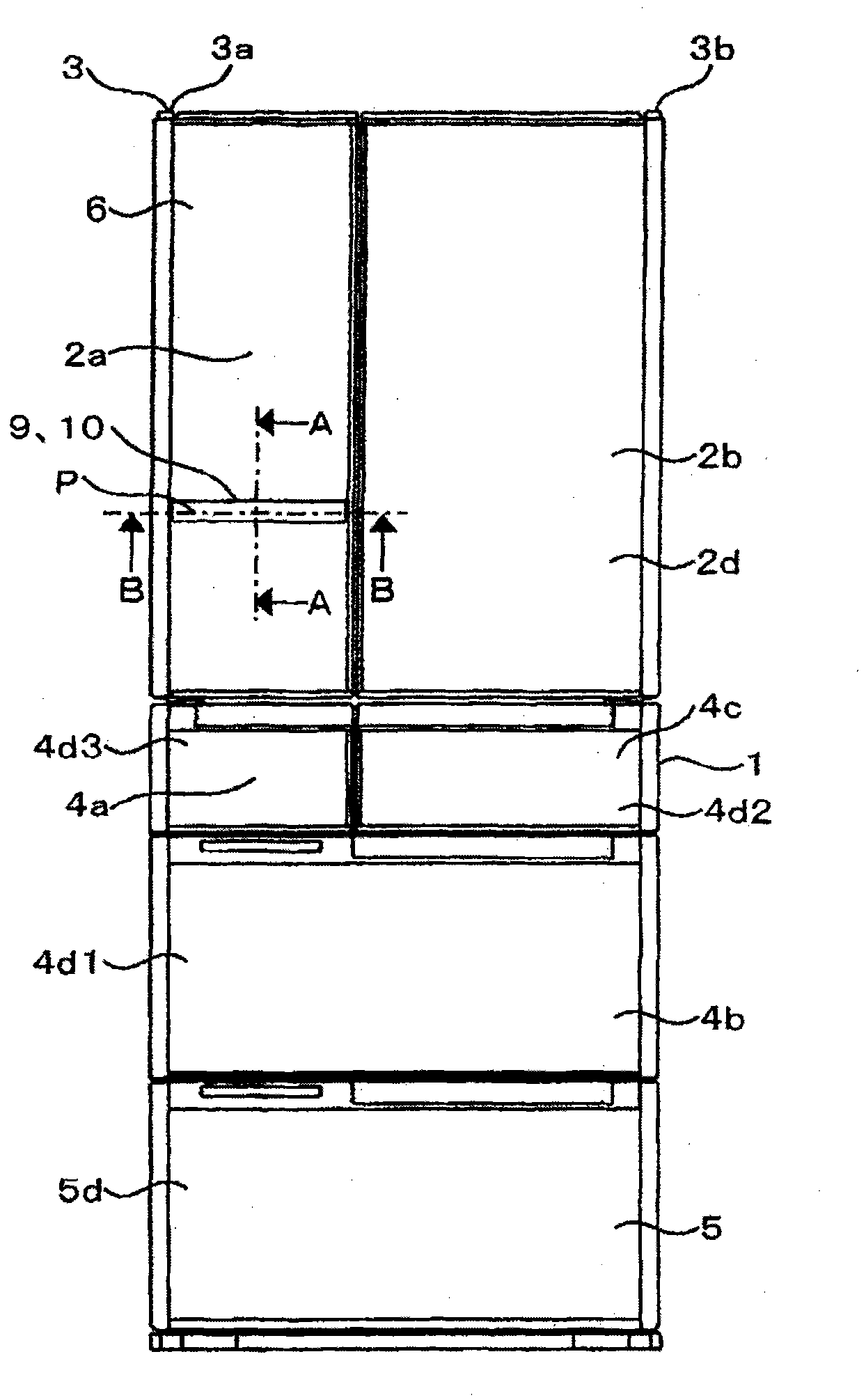

Refrigerator

ActiveCN101995140AImprove operabilityImprove cleanabilityWing accessoriesLighting arrangementEmbedded systemCapacitance

The object of the invention is to obtain a refrigerator having an operation part with improved operation performance and cleaning performance. The refrigerator is characterized by comprising: a storage space arranged in a main body of the refrigerator; a storage space door for opening / closing a front opening of the storage space; a door front panel with light permeability arranged on front face of the storage space door; an operation part arranged on front of the door front panel; a detection part contacted or close to the back side of the operation part and the door front panel to detect variation of electrostatic capacitance; a display part for displaying an operation result of the operation part; a lighting mechanism configured to light the display part from the back; a control part configured to control the lighting mechanism based on a detection value of the detection part; a circuit board equipped with the detection part and the lighting mechanism; and an insertion part arrangedon an edge of the storage space door to store the circuit board in the storage space door.

Owner:日立グローバルライフソリューションズ株式会社

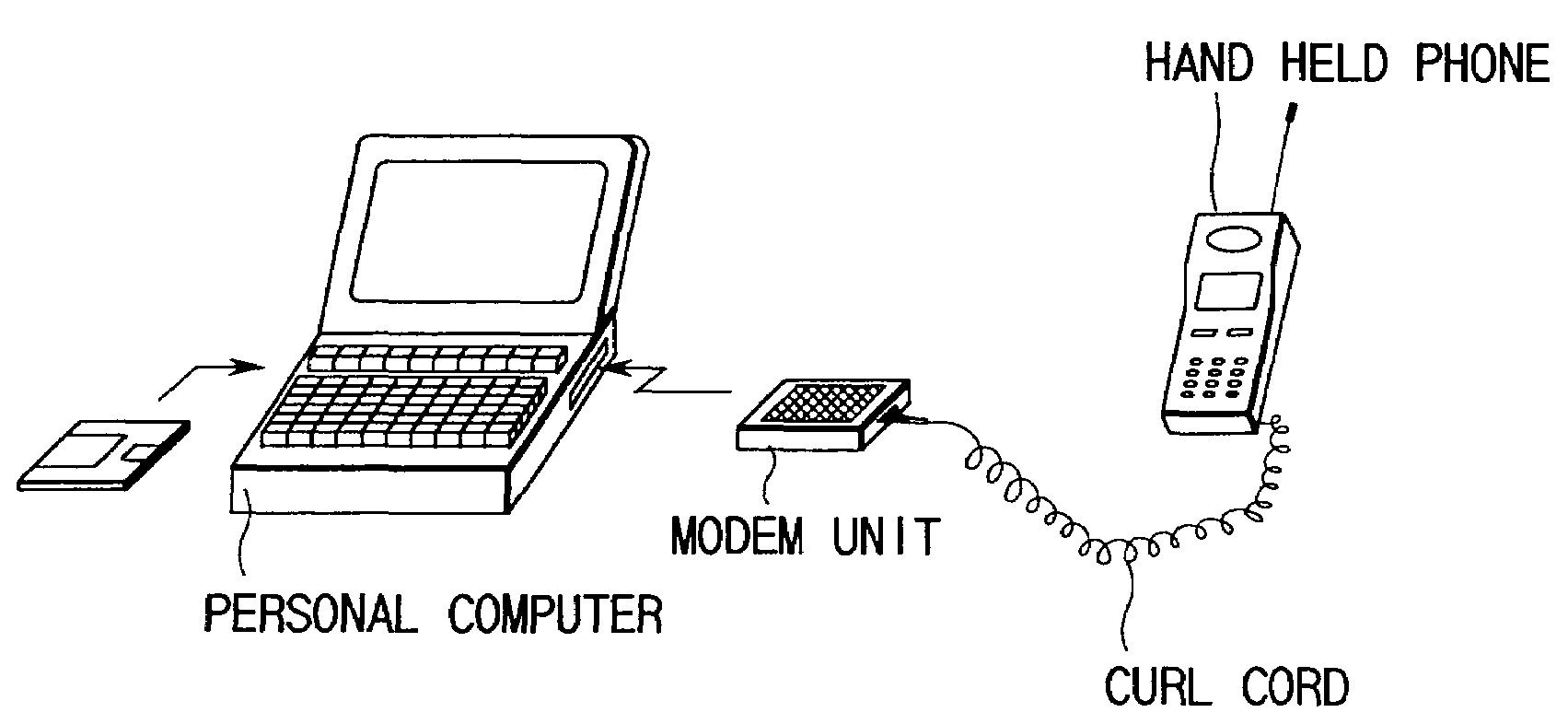

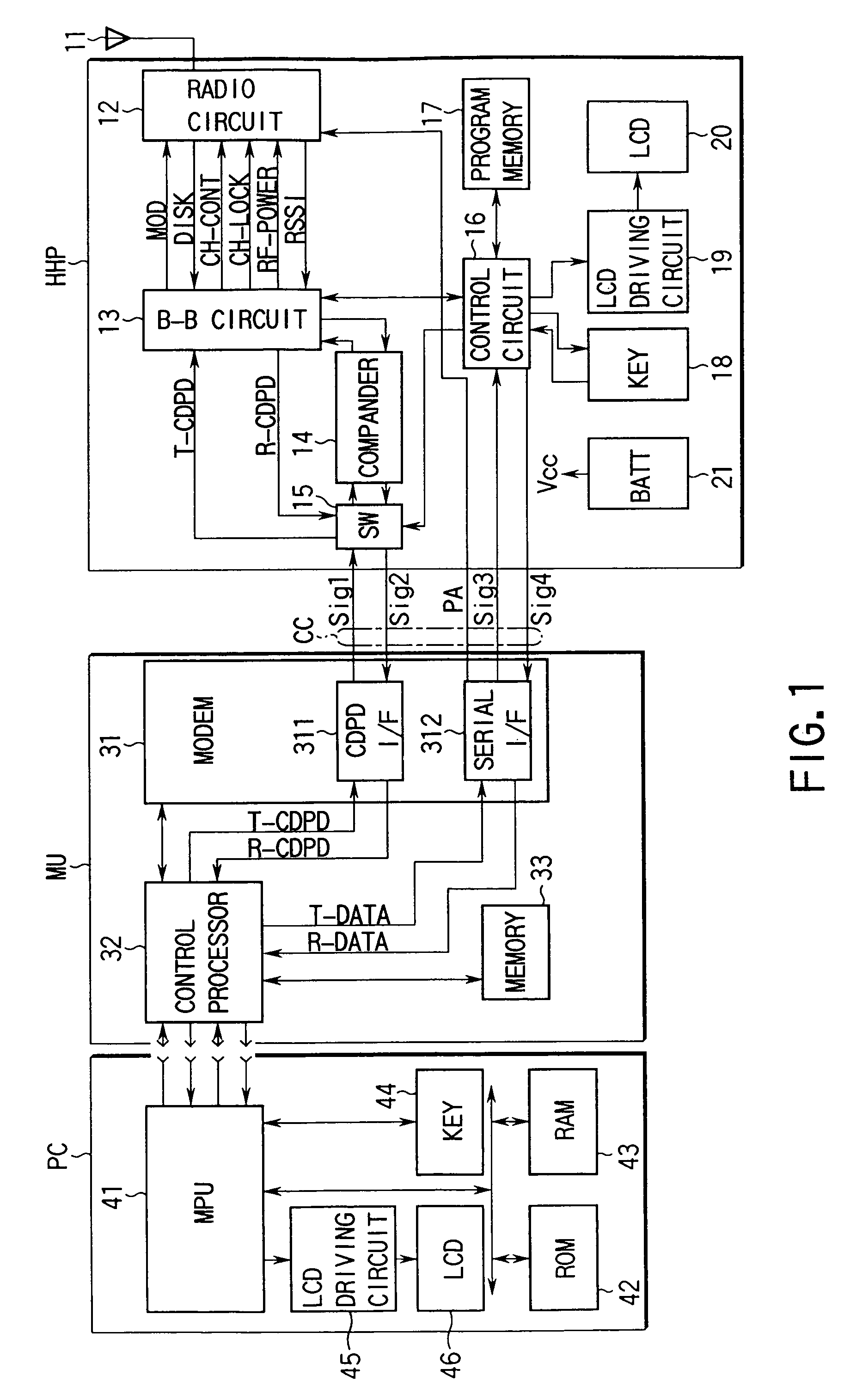

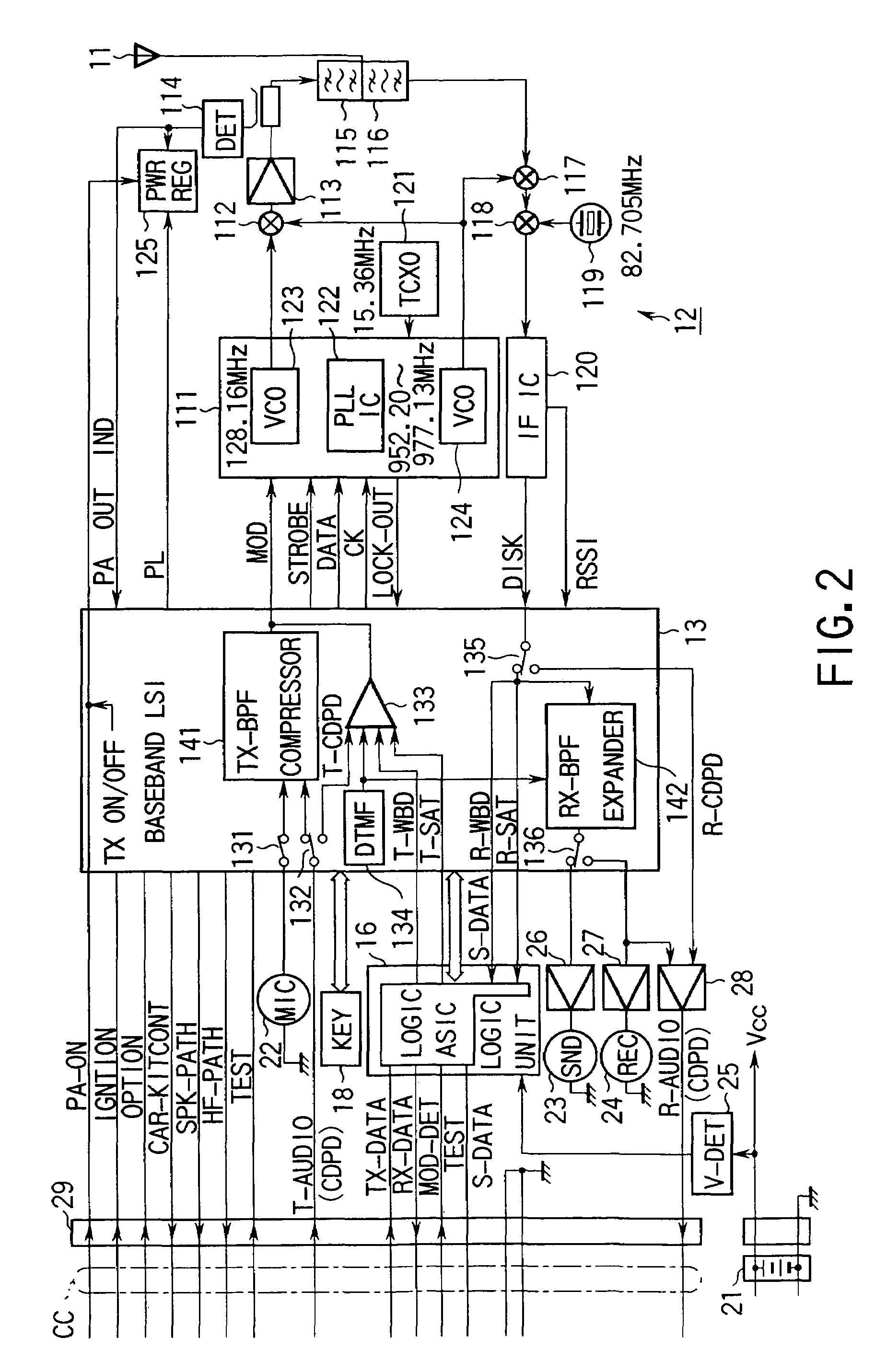

Mobile communication terminal apparatus with data communication function

InactiveUS6999791B1Improve operabilityEasy to operateNetwork traffic/resource managementInformation formatEngineeringPersonal computer

During the CDPD mode period, RSSI data and battery remaining capacity determination data measured by a hand held phone HHP are periodically transferred to a personal computer PC, and are displayed on an LCD display of the personal computer PC. During the CDPD mode period, status data representing the operation state of the personal computer PC is transferred to and displayed on the hand held phone HHP. Furthermore, during the CSCD mode period, status data representing the operation state of the hand held phone HHP is transferred to the personal computer PC, and is displayed on the LCD display of the personal computer PC.

Owner:KK TOSHIBA

Button processing method and data processing apparatus

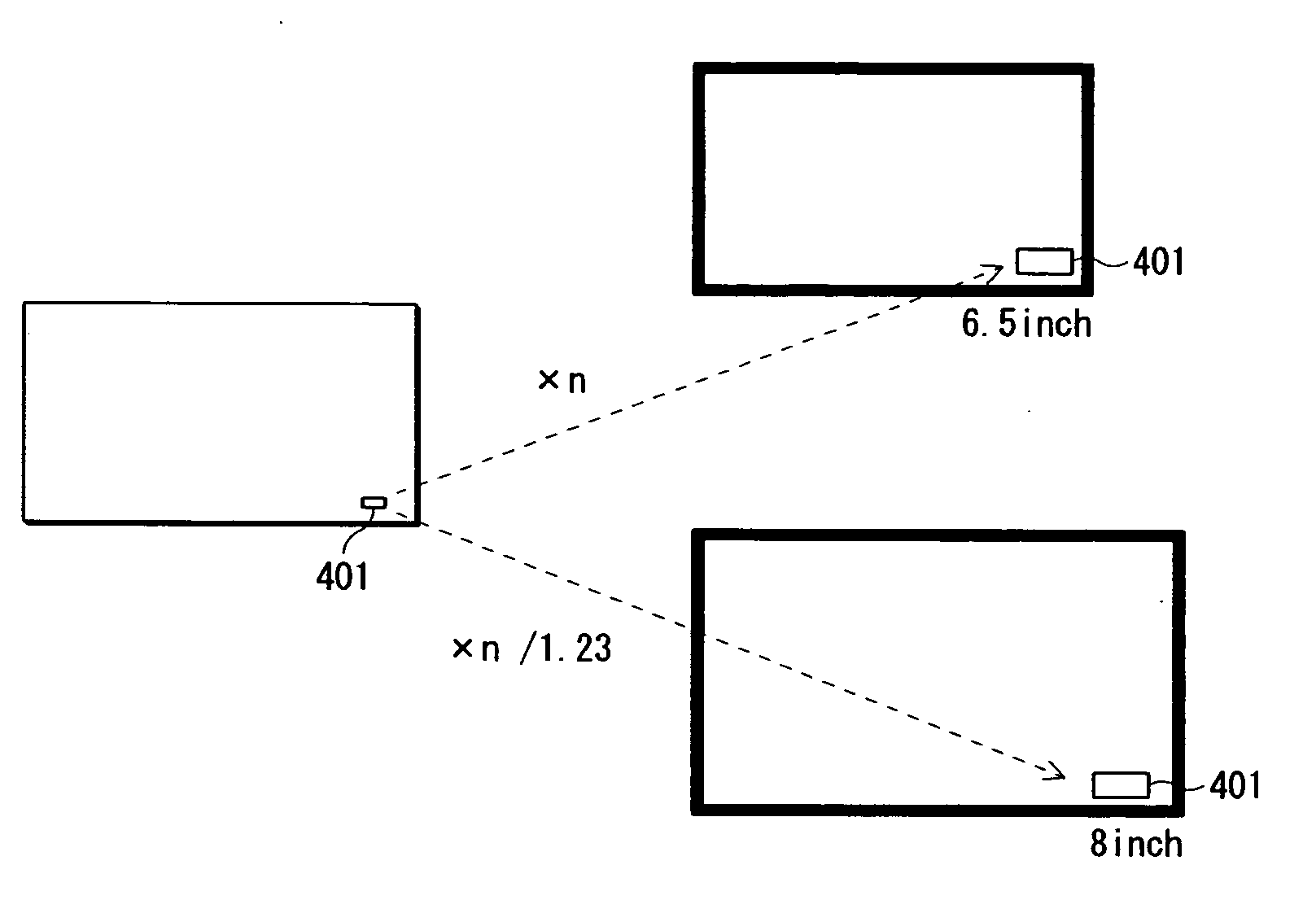

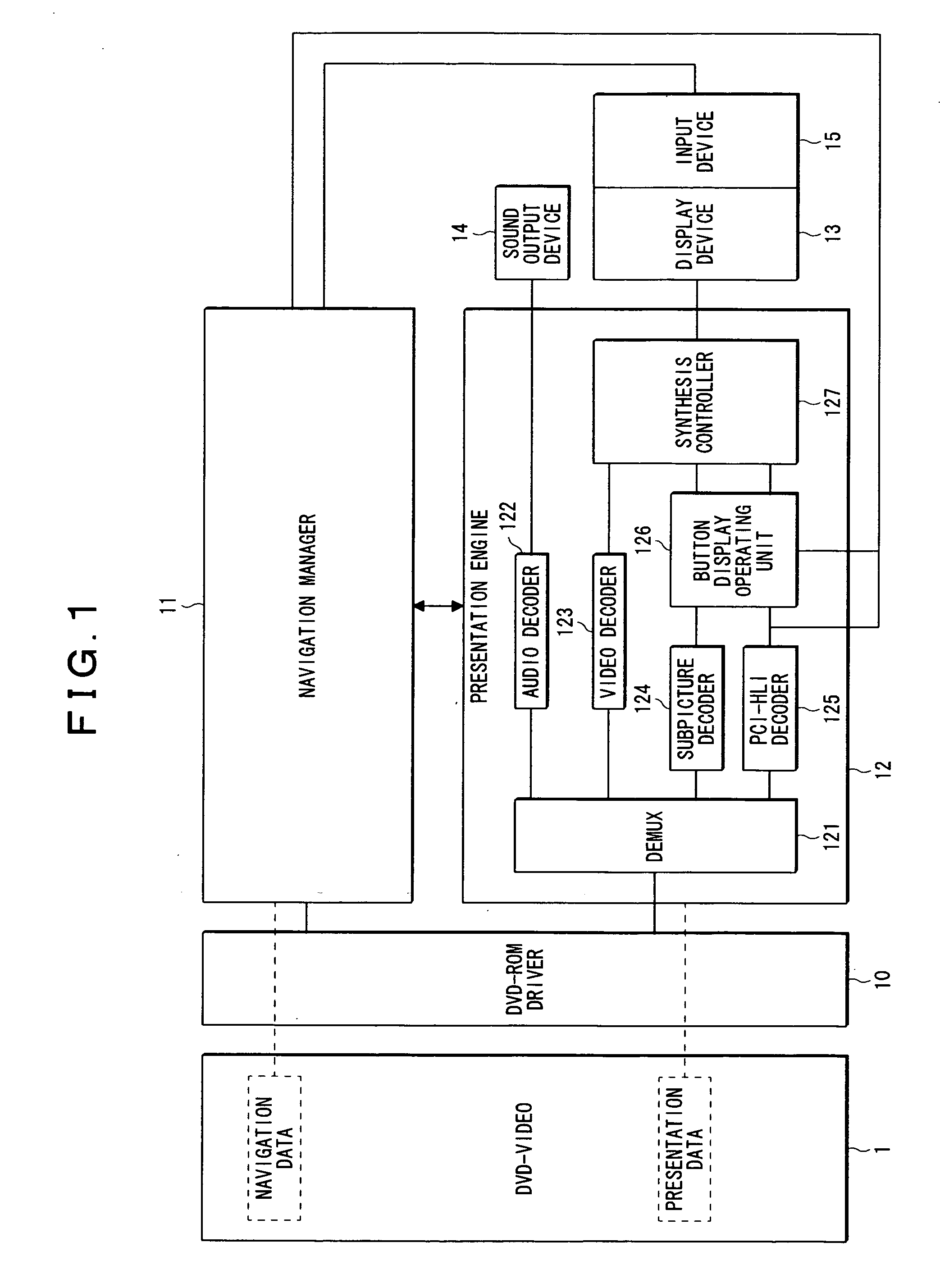

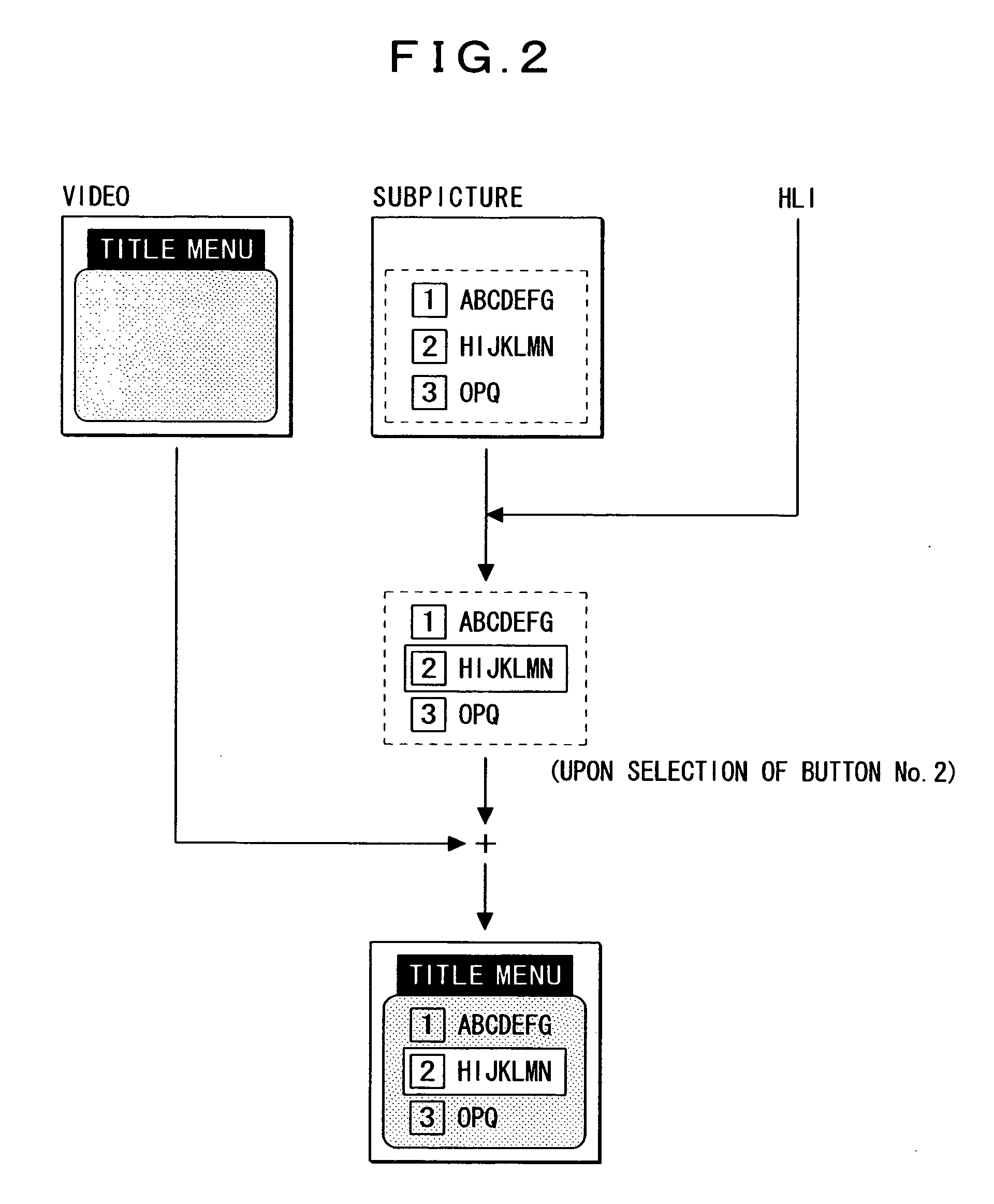

InactiveUS20050223335A1Improve operabilitySmall sizeTelevision system detailsColor television detailsSize determinationComputer graphics (images)

A button processing method and a data processing apparatus that improve the operability of buttons when a display device with a display screen of small size is employed. In cases where an output image includes a button, when a display image is displayed on a display device with a small display device size, e.g., 6.5 inches, the size of the button in an image space is enlarged n times at a button enlargement ratio determined in accordance with the display device size. In contrast, when a display image is displayed on the display device with a larger display device size, e.g., 8 inches, the size of the button in an image space is enlarged, e.g., n / 1.23 times at a button enlargement ratio determined in accordance with the display device size. That is, the smaller the size of the display screen of the display device, the larger the enlargement ratio of the size of the button in the image space, so that the button is displayed in predetermined size on the display device regardless of the display screen size of the display device.

Owner:ALPINE ELECTRONICS INC

Information processing apparatus

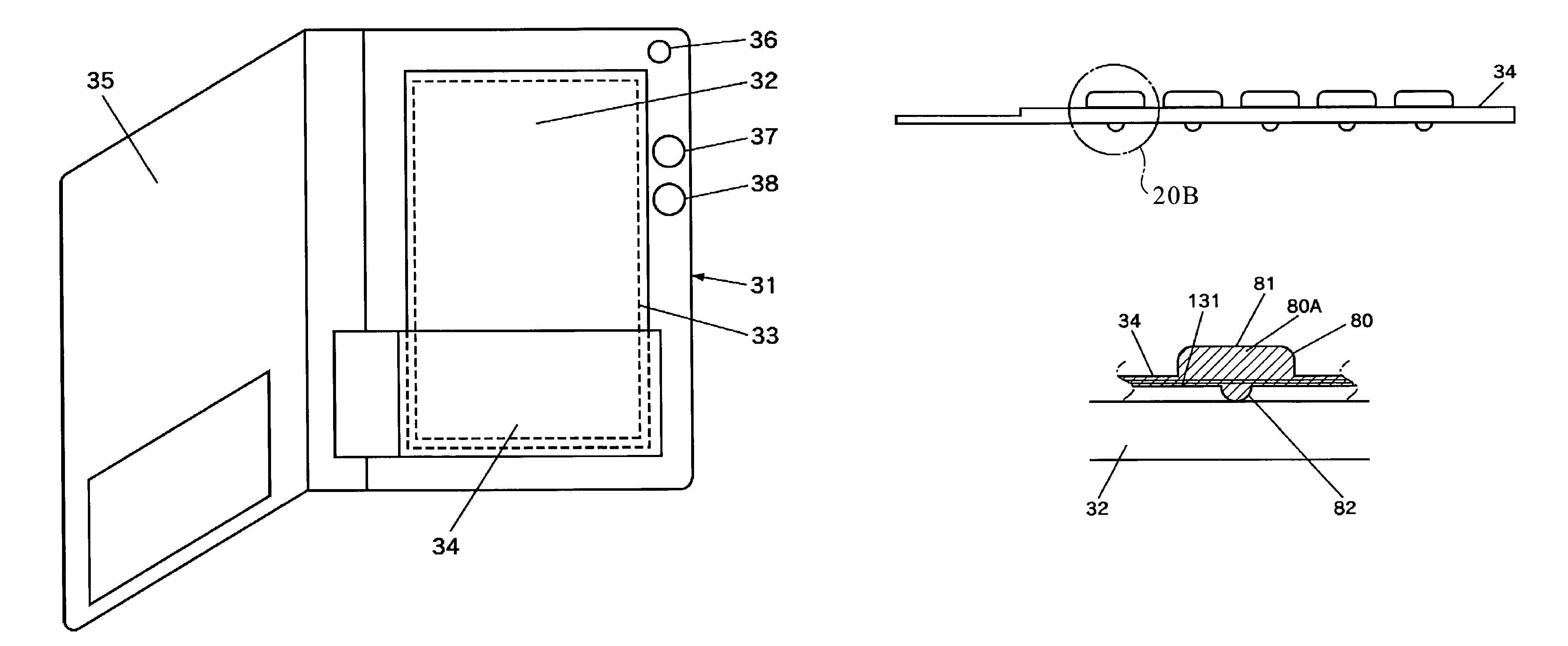

InactiveUS7277081B2Improve operabilityEasy to operateInput/output for user-computer interactionDigital computer detailsInput deviceIndividual data

In a personal data assistant, a main body includes an input sheet, which is turnable between a first position where at least a part of a display unit of the personal data assistant is covered and a second position where the display unit is not covered. The input sheet has various types of keys formed thereon. When any one of the keys is pressed on the input sheet, a pressure is applied to an input device formed on the display unit, and an input coordinate is detected by the change of, for example, the resistance value of the input device. Since the surface of the display unit is not entirely covered with the input sheet, the display in the range of the display unit which is not covered with the input sheet is not made dark. Further, since the input device is not directly touched with a finger, the input device is prevented from being made dirty, and the display of the display unit under the input device is prevented from being difficult to be seen. Accordingly, the operability of the personal data assistant can be improved while displaying information clearly.

Owner:SONY DISC TECHNOL KK

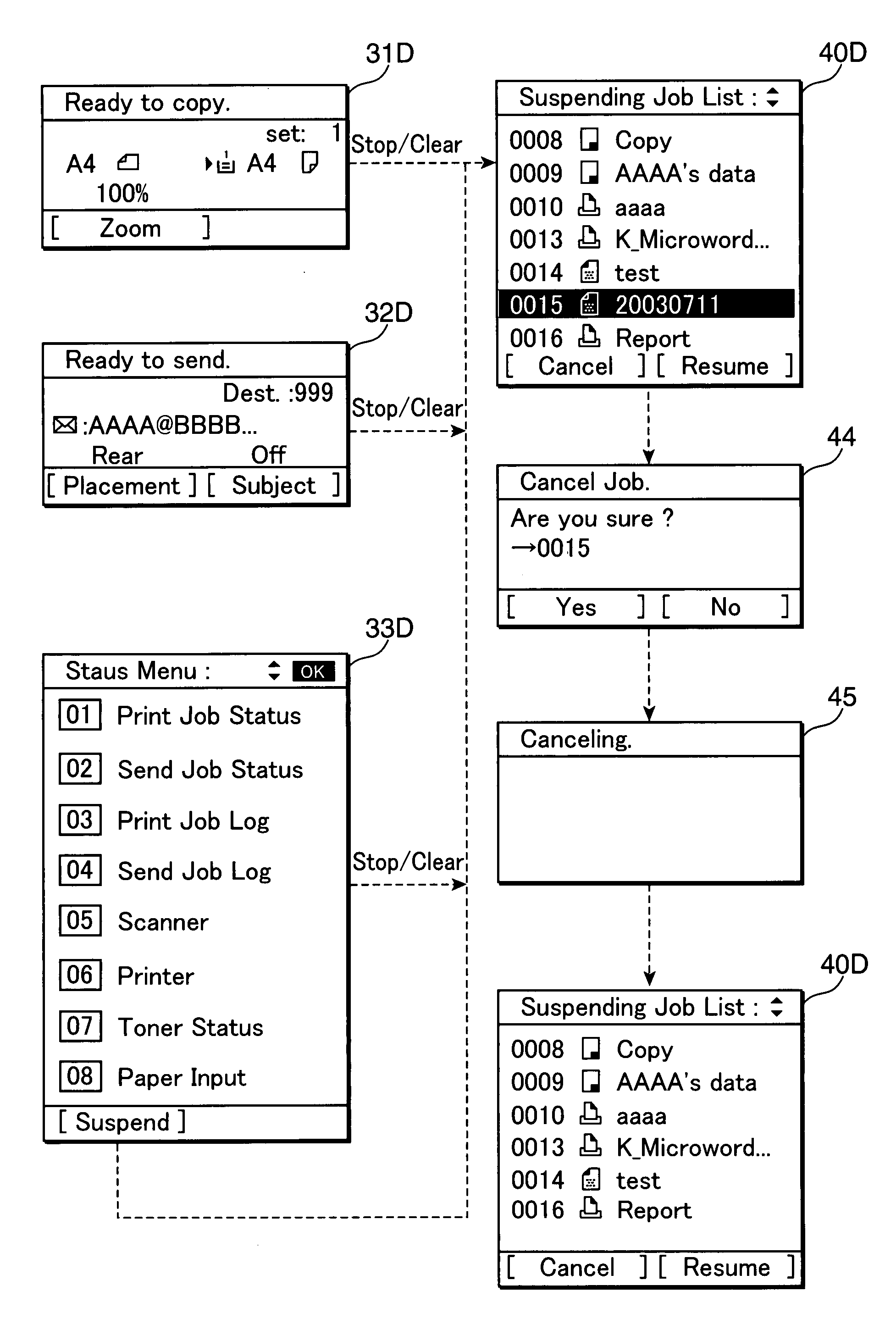

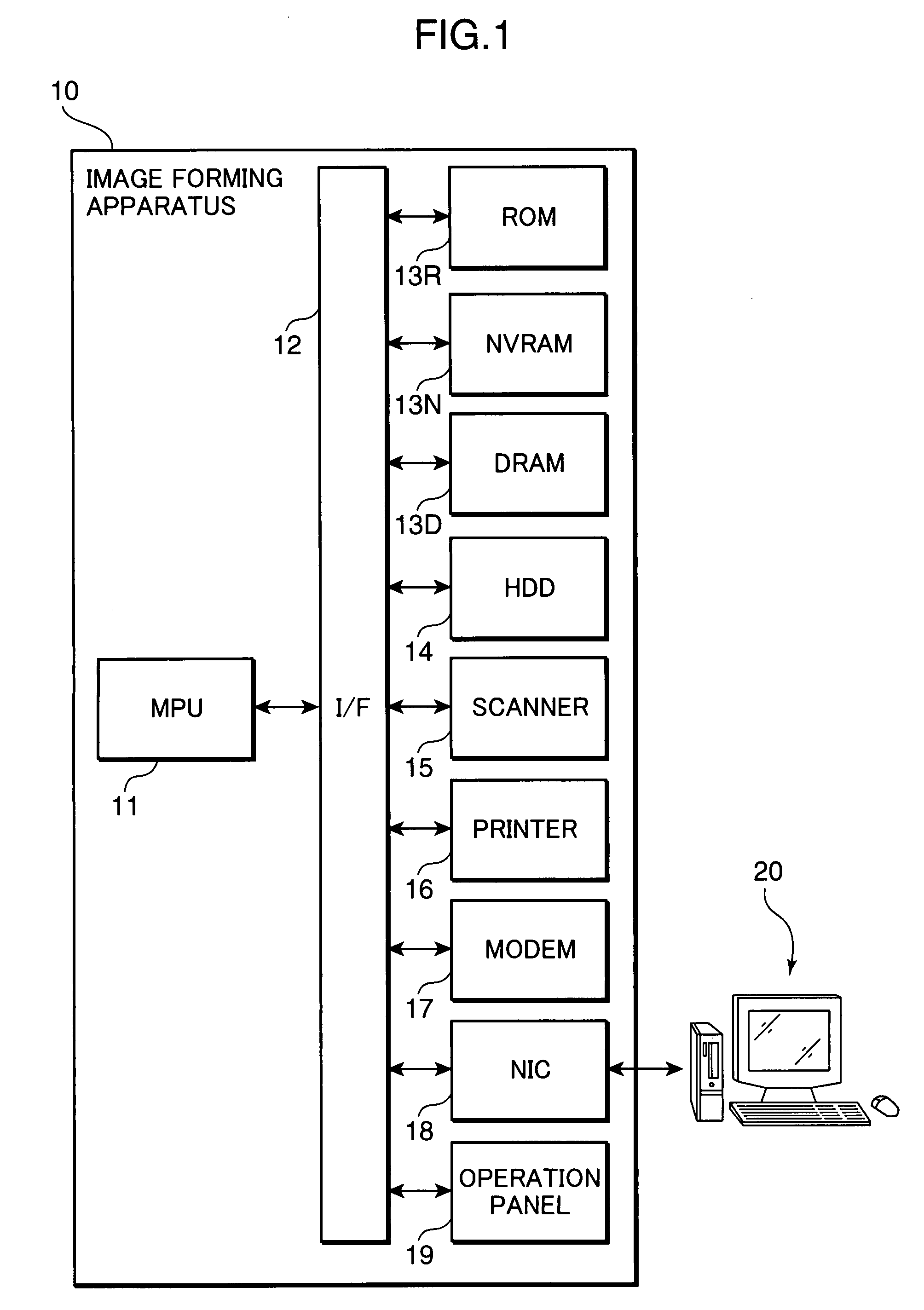

Image forming apparatus

ActiveUS20080013123A1Improve operabilityAllowed to operateElectrographic process apparatusVisual presentationCancelled operationFacsimile transmission

An image forming apparatus is operative to avoid user confusion during a job-cancelling operation. A job executing portion of the apparatus executes at least one of a copy job, a print job, a facsimile reception job, an e-mail reception job, a facsimile transmission job, and an e-mail transmission job. A suspending portion of the apparatus suspends a printing-out operation of a running job in response to pressing a stop / clear key. A job list screen display controller allows a display portion to display a suspending job list screen for showing a user a suspended job and a waiting job. A cancel job selection receiving portion receives a user selection of a job to be cancelled among the jobs displayed on the suspending job list screen. A job cancelling portion then cancels the job received by the cancel job selection receiving portion.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

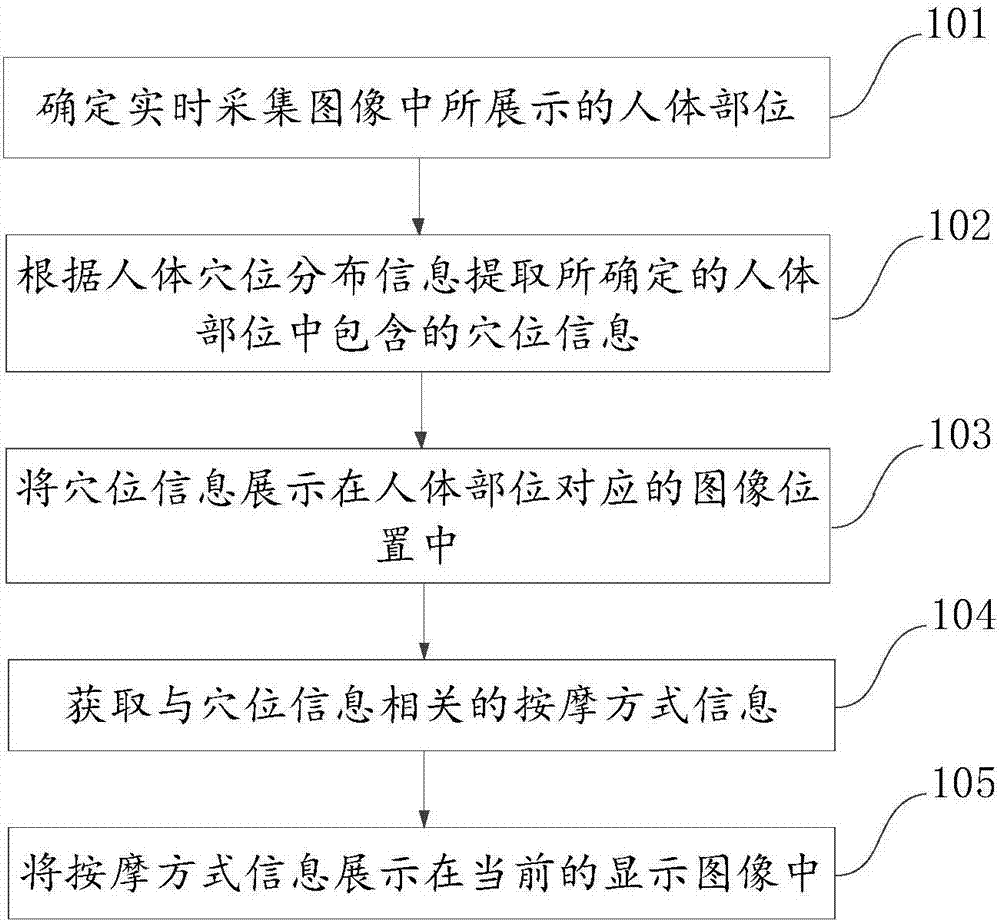

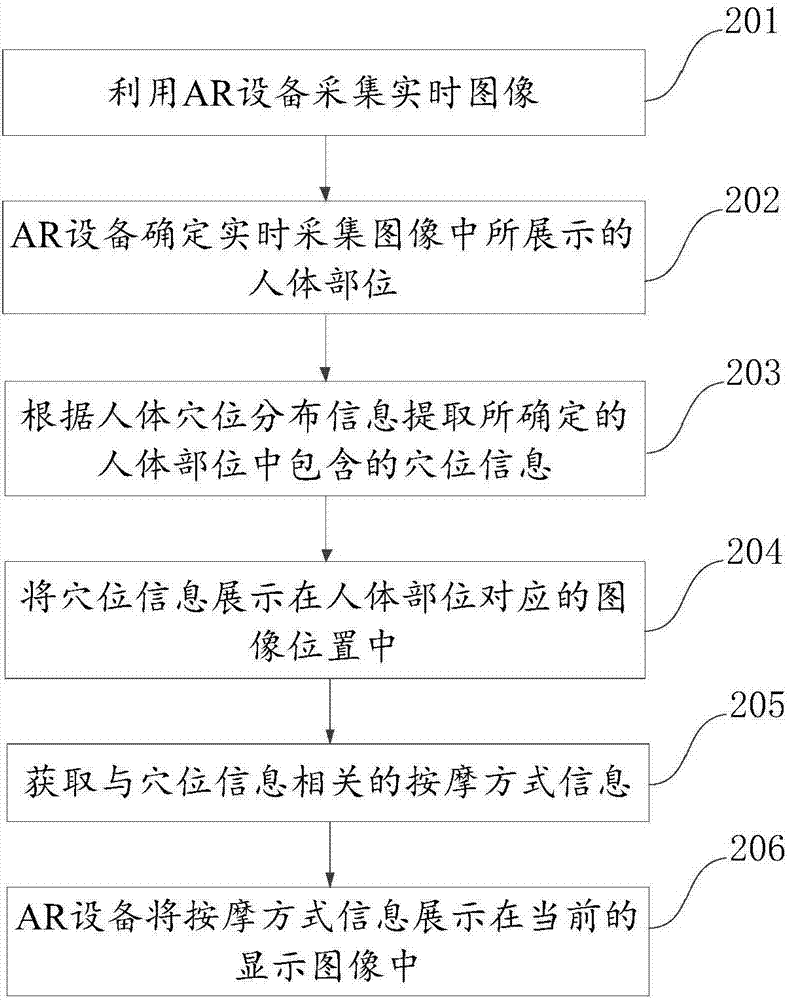

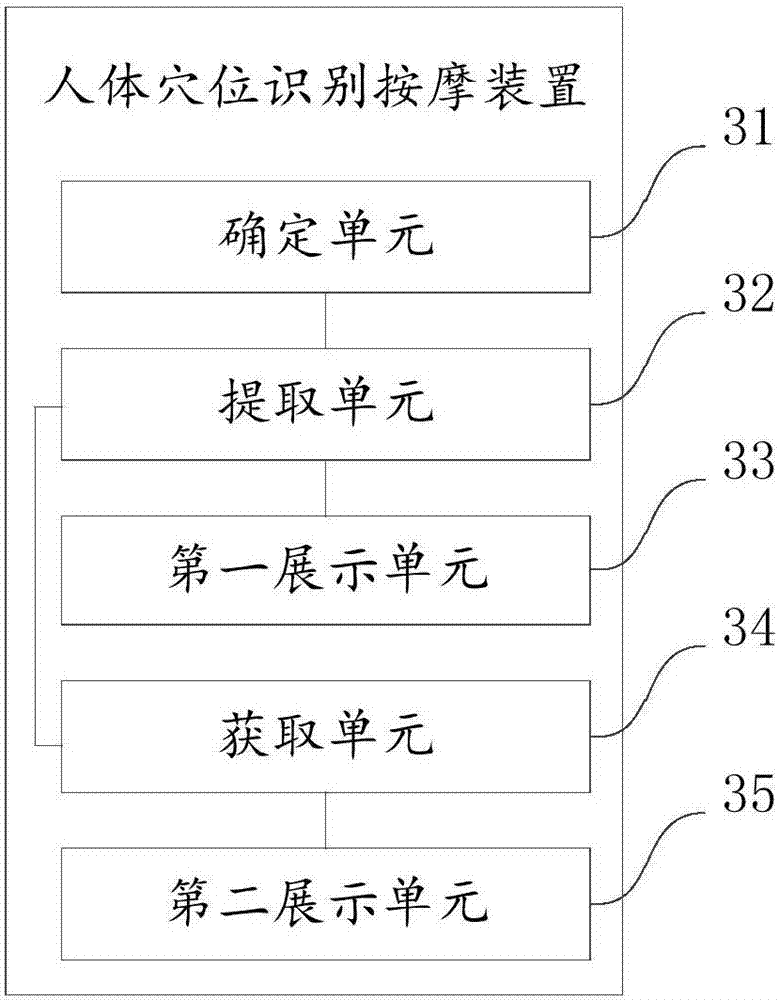

Human body acupuncture point recognizing and massaging method and device and AR equipment

ActiveCN106859956AReduce professionalismImprove operabilityDevices for locating reflex pointsAcupuncture pointHuman body

The invention discloses a human body acupuncture point recognizing and massaging method and device and AR equipment and relates to the technical field of computer application. A massaged human body part is determined by image matching, and corresponding acupuncture point positions and corresponding massage modes are displayed in an image, so that the professional property of acupuncture point massaging is reduced, and the operability of acupuncture point massaging is improved. According to the main technical scheme, the method comprises the following steps: determining a human body part exhibited in the real-time collected image, wherein the real-time collected image is a display image which is photographed by a photographing device in real time; extracting acupuncture point information contained in the human body part according to the human body acupuncture point distribution information; exhibiting the acupuncture point information in an image device corresponding to the human body part; acquiring massage mode information related to the acupuncture point information; and exhibiting the massage mode information in the current display image. The method and device disclosed by the invention are mainly used for automatically recognizing the acupuncture points and massaging the acupuncture points.

Owner:BEIJING ANYUNSHIJI TECH CO LTD

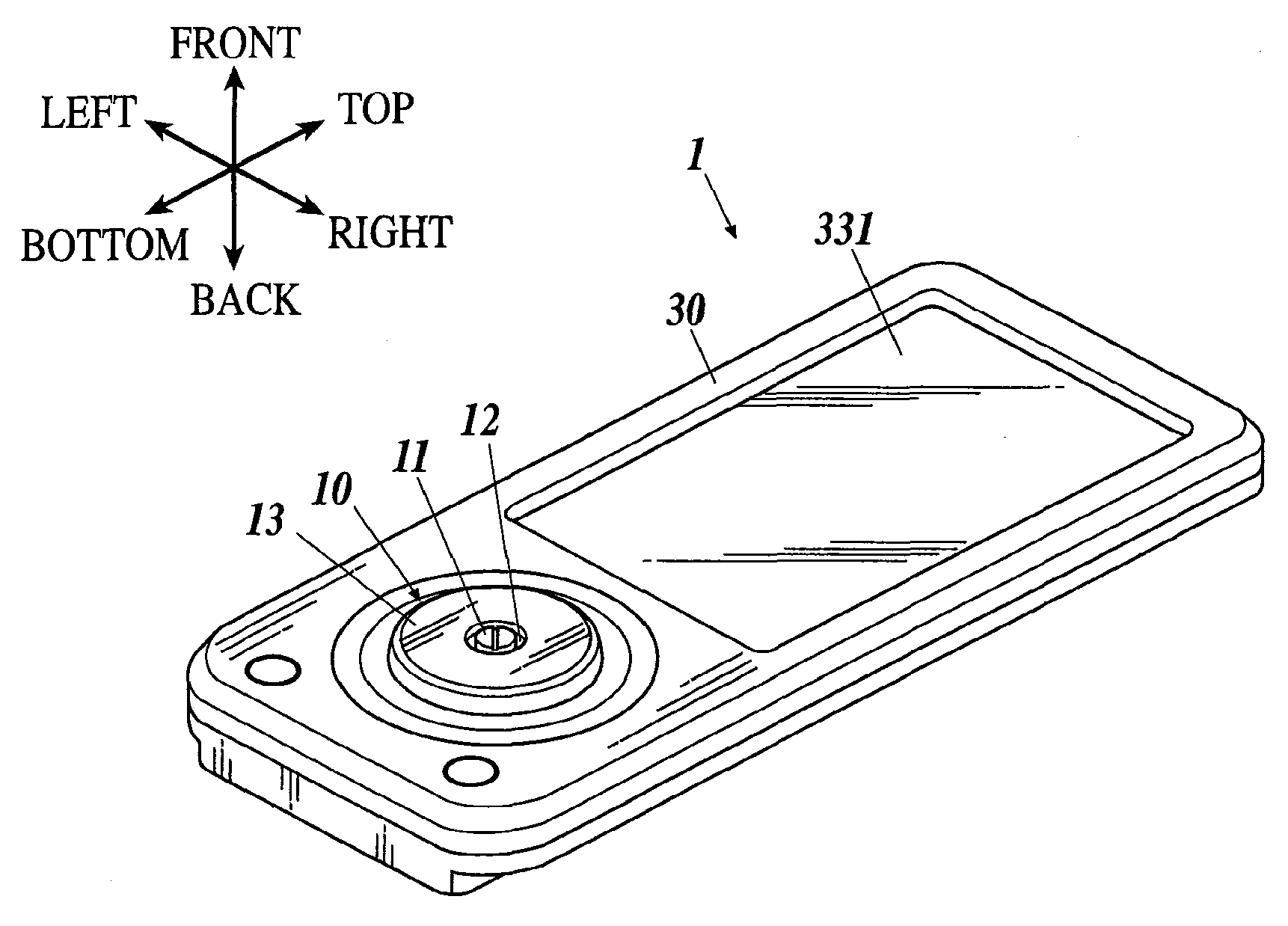

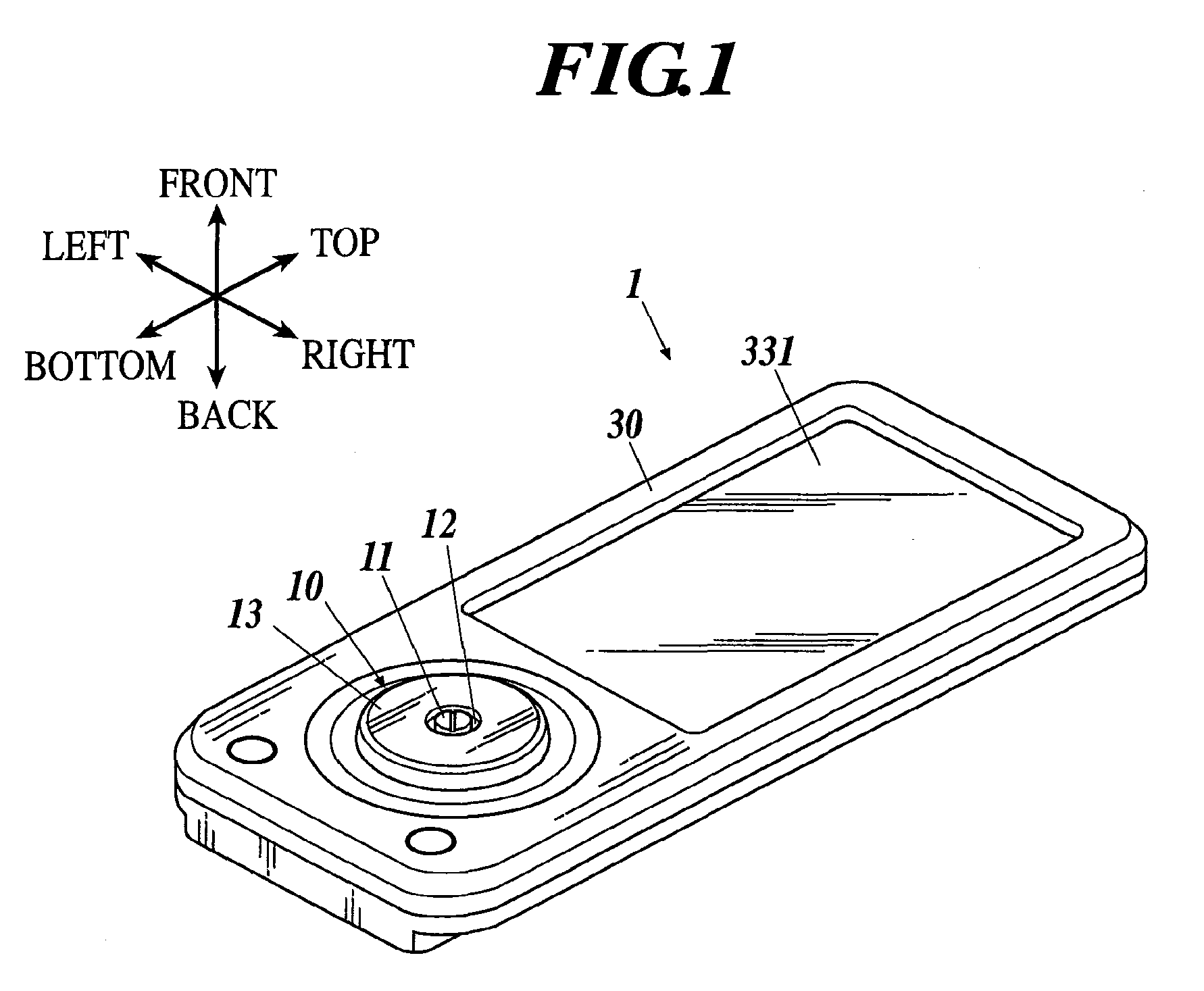

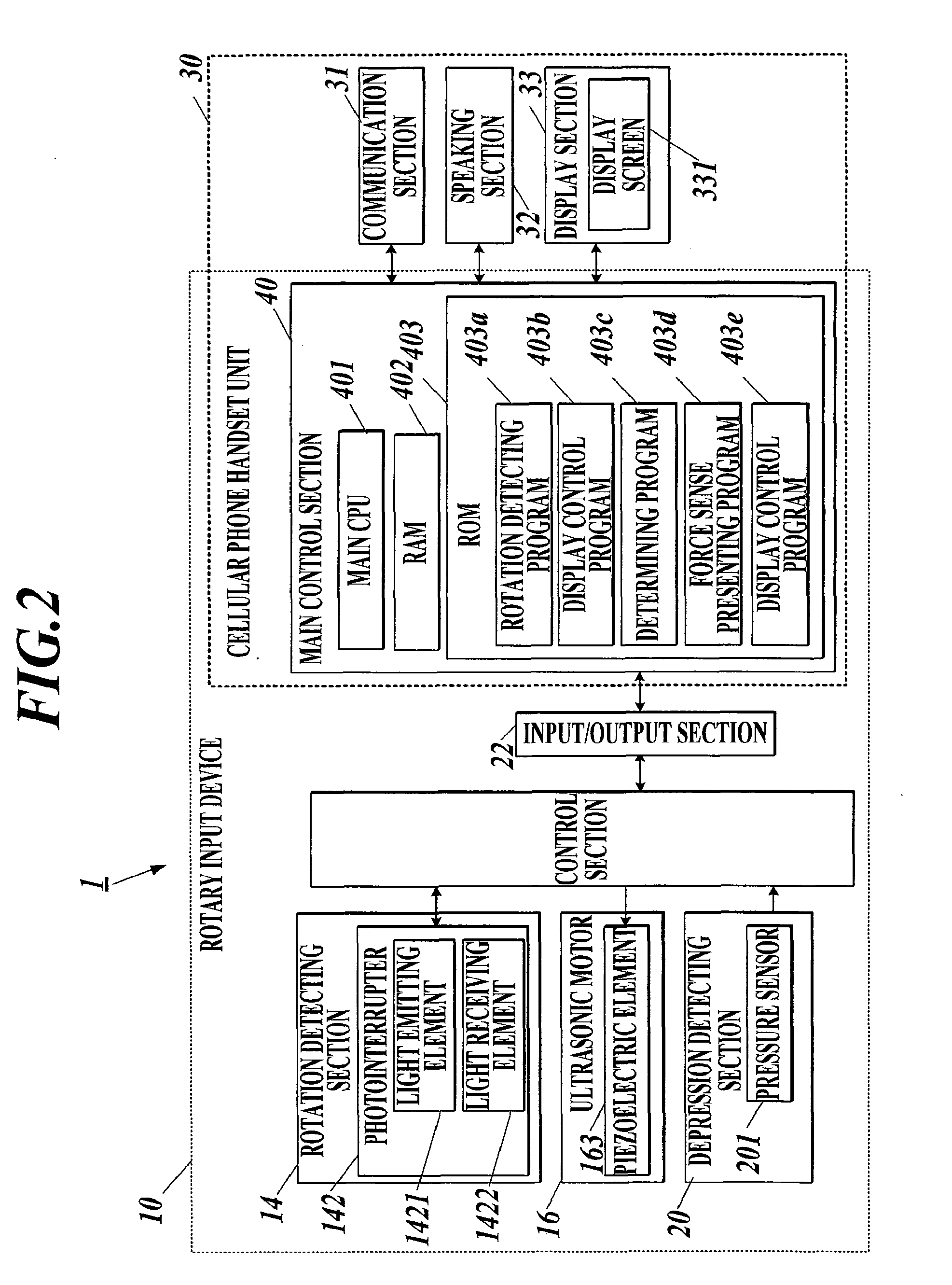

Rotary Input Device and Electronic Equipment

ActiveUS20100271342A1Improve operabilityEasy to operateCathode-ray tube indicatorsInput/output processes for data processingCounter rotationEngineering

Disclosed is a rotary input device, including: a rotary operation device; a rotation detecting section; a rotation driving section; a display control section to scroll an image under display by rotation of the rotary operation device; a judging section to judge whether the detected rotation angle reaches a critical angle corresponding to an end part of a range of the displayed image or not; and a rotation controlling section to reversely rotate the rotary operation device to an initial position or a reference position when it is judged that the rotation angle reaches the critical angle and the rotary operation is released, wherein the display control section displays the image displayed on the display section at a display position corresponding to the initial position or the reference position when the rotary operation device is reversely rotated to the initial position or the reference position.

Owner:FUKOKU CO LTD

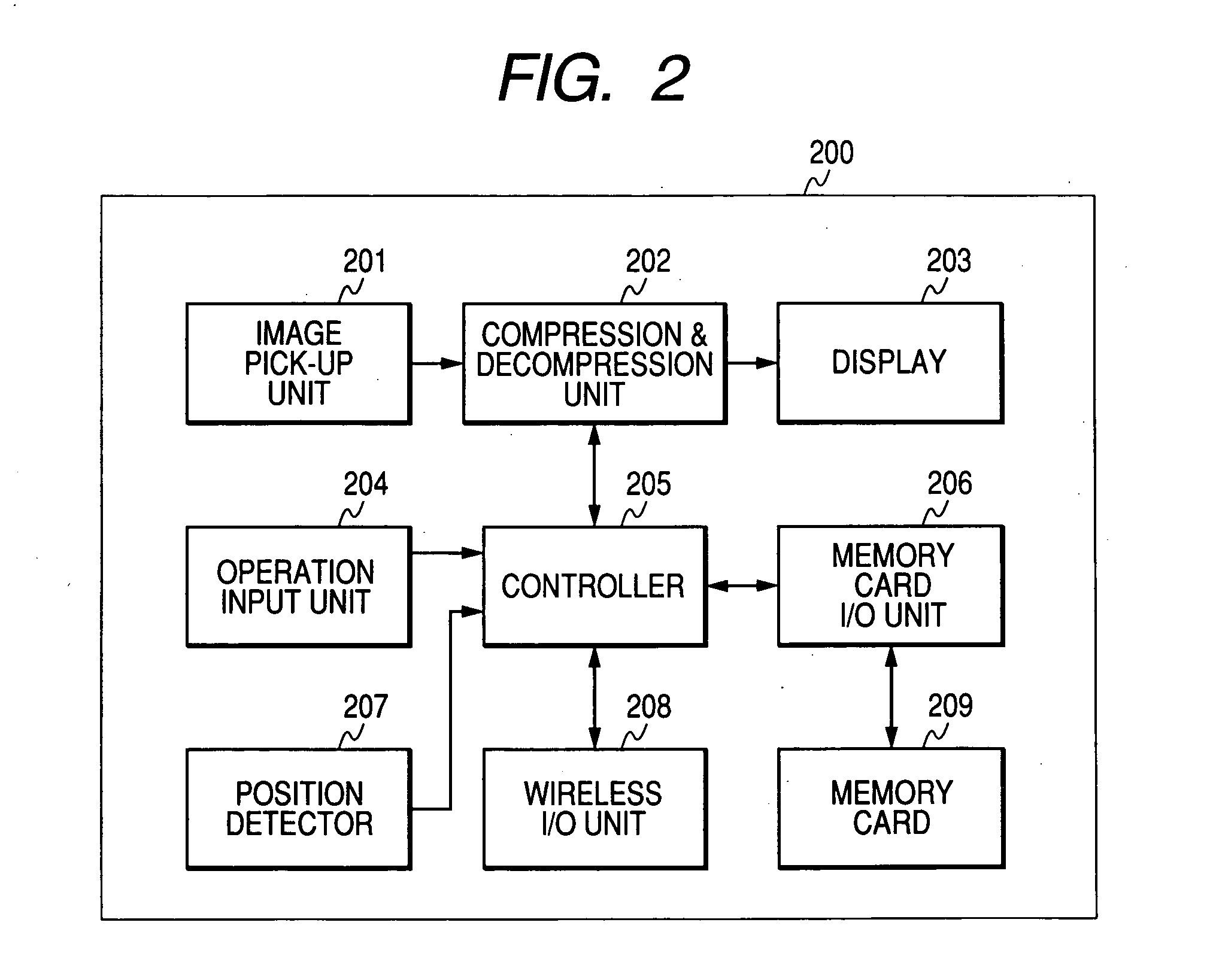

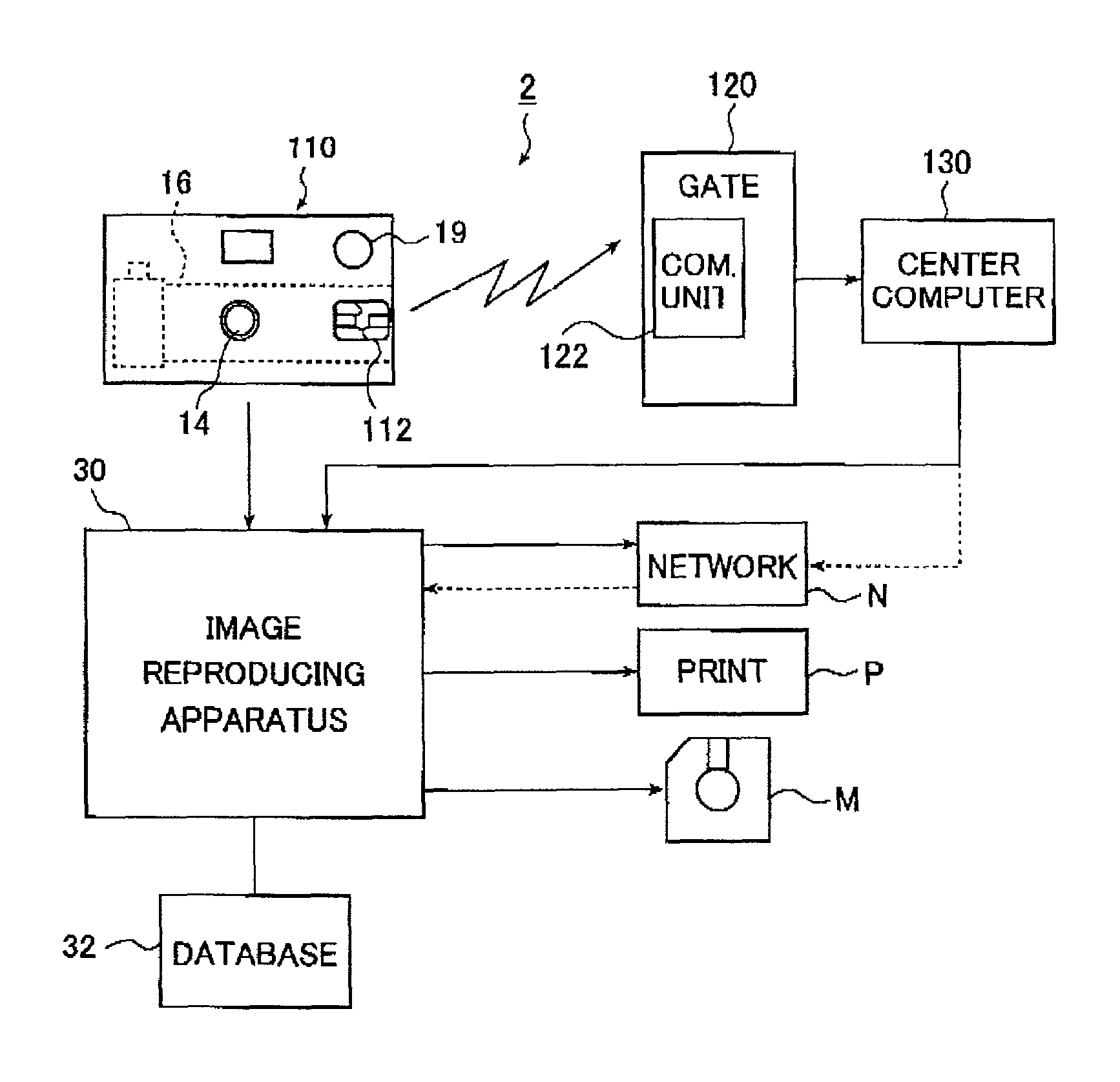

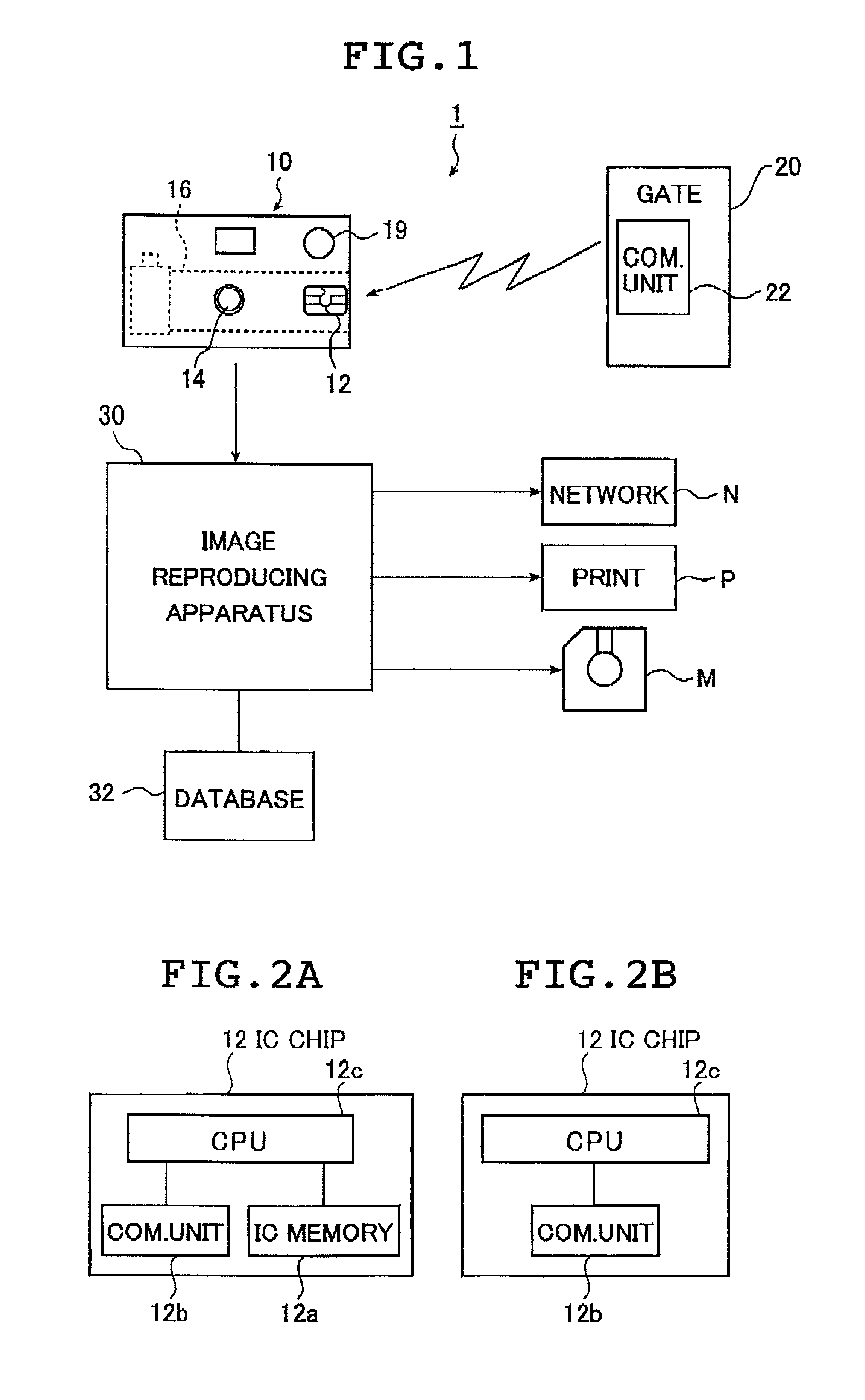

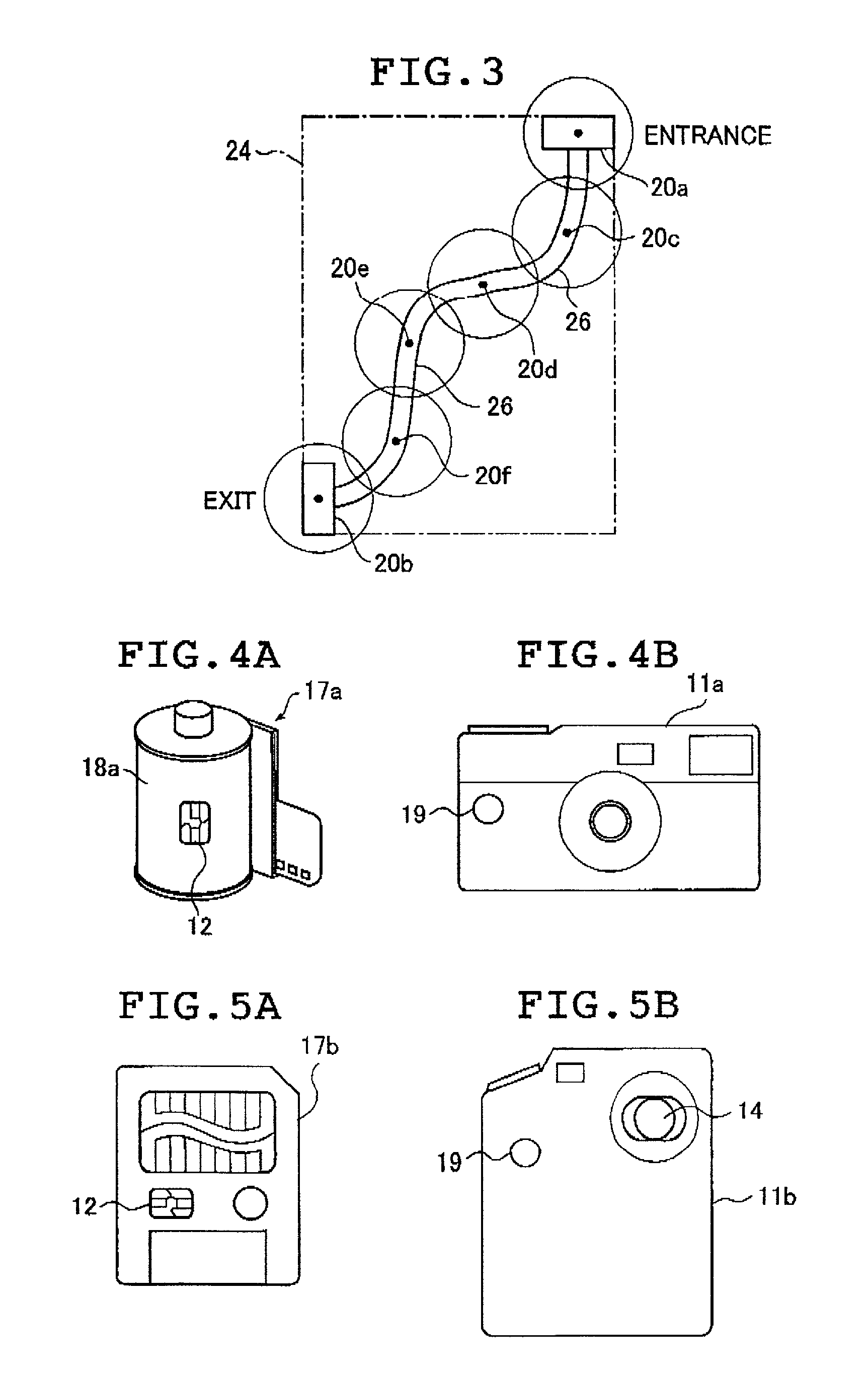

Image photographing/reproducing system and method, photographing apparatus and image reproducing apparatus used in the image photographing/reproducing system and method as well as image reproducing method

InactiveUS7075572B2Improve operabilityImprove imaging effectTelevision system detailsColor television detailsImage recordingTime information

The image photographing / reproducing system includes an photographing apparatus for photographing an image, first communication unit for transmitting and receiving information to and from second communication unit at a communication point installed in a predetermined region, information recording unit for recording at least one information of photographed frame information or photographed time information and first identification information of an image recording medium, and second identification information of the communication point, at least one information being transmitted and received between the first and second communication units and an image reproducing apparatus including photographed image acquiring unit, information acquiring unit for acquiring at least one information, data acquiring unit for determining a photographed place based on the second identification information and acquiring a predetermined image or document as composite data, image reproducing unit for reproducing the photographed image and data recording unit for recording the composite data in association with the reproduced image.

Owner:FUJIFILM HLDG CORP +1

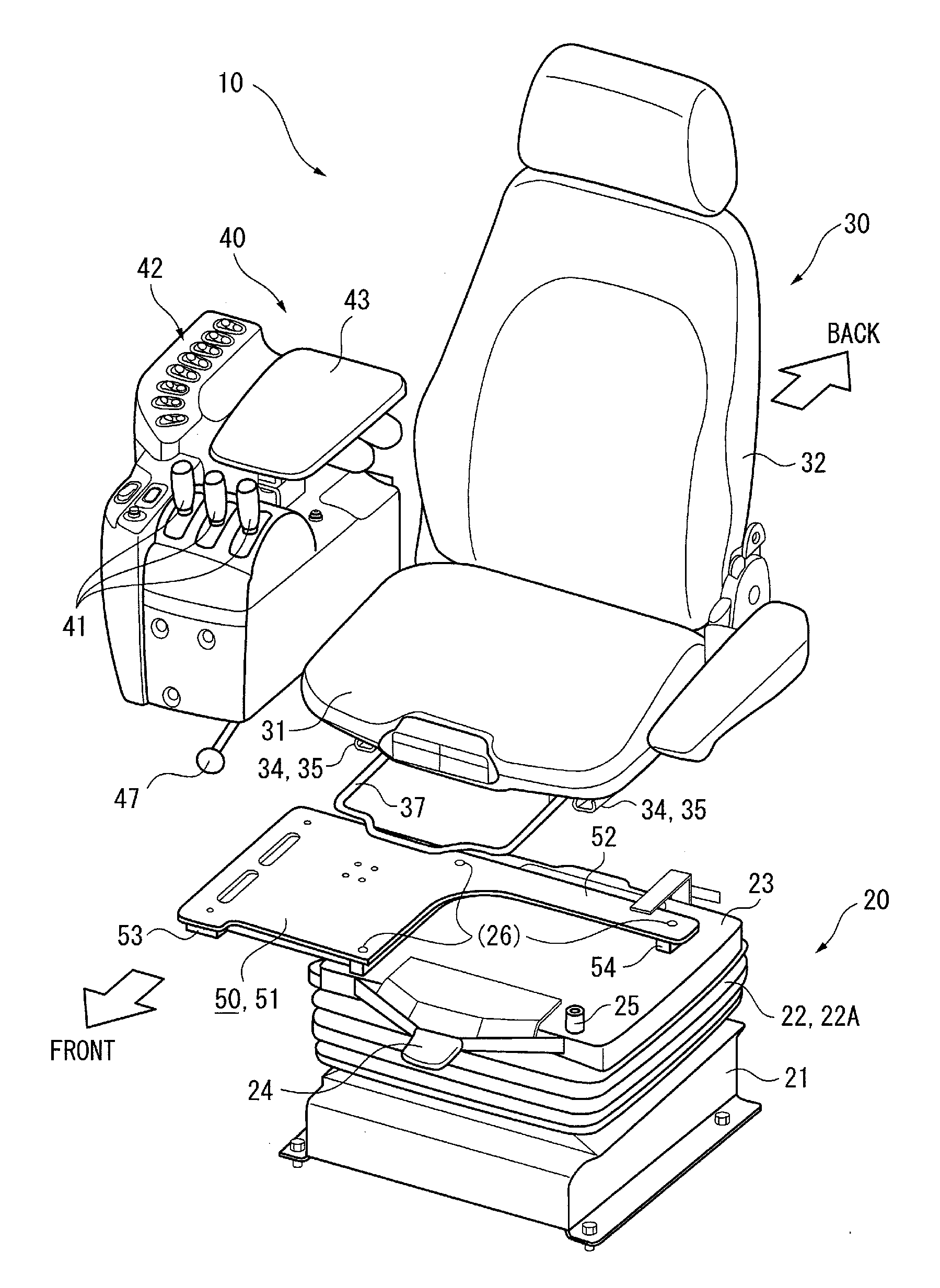

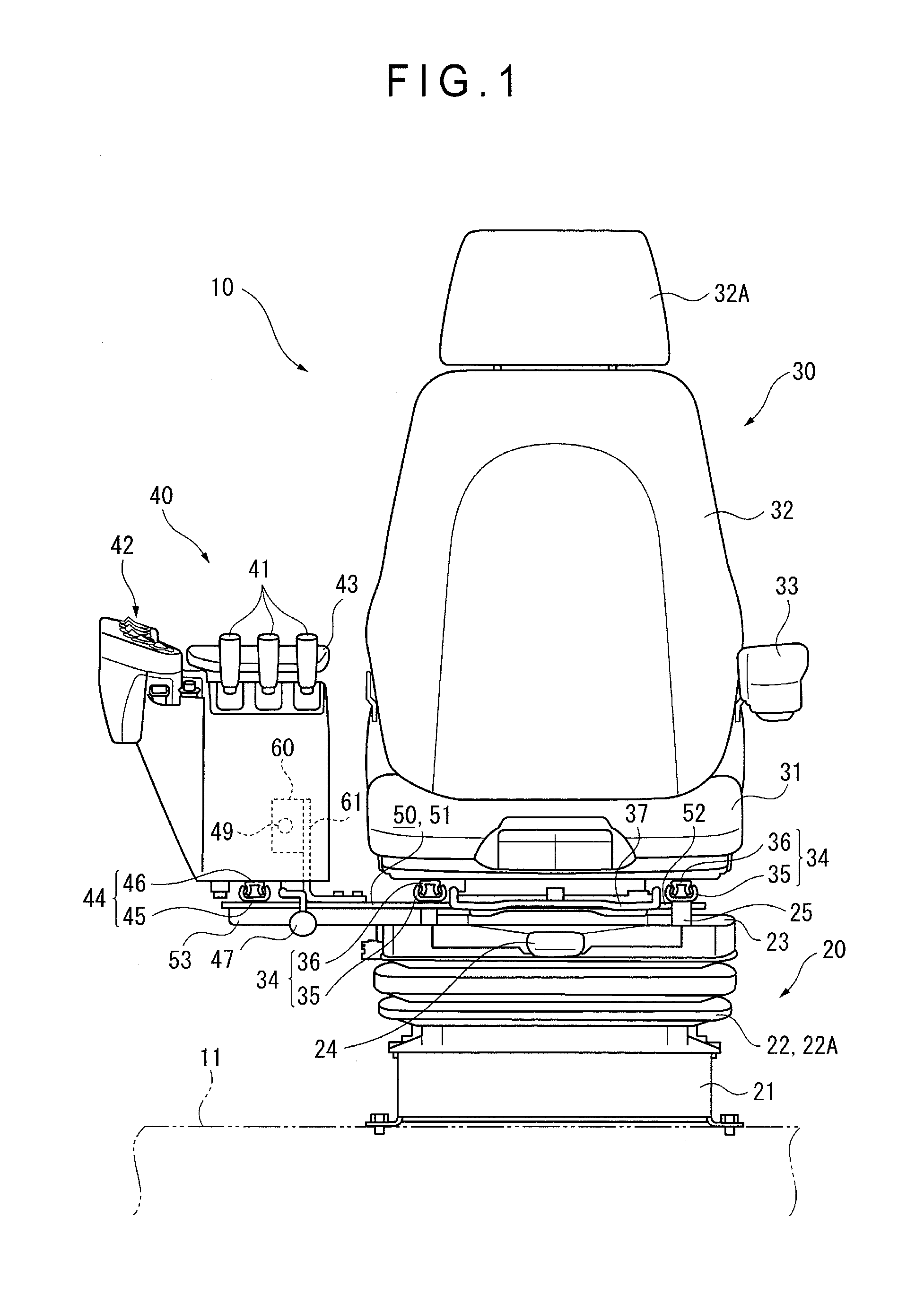

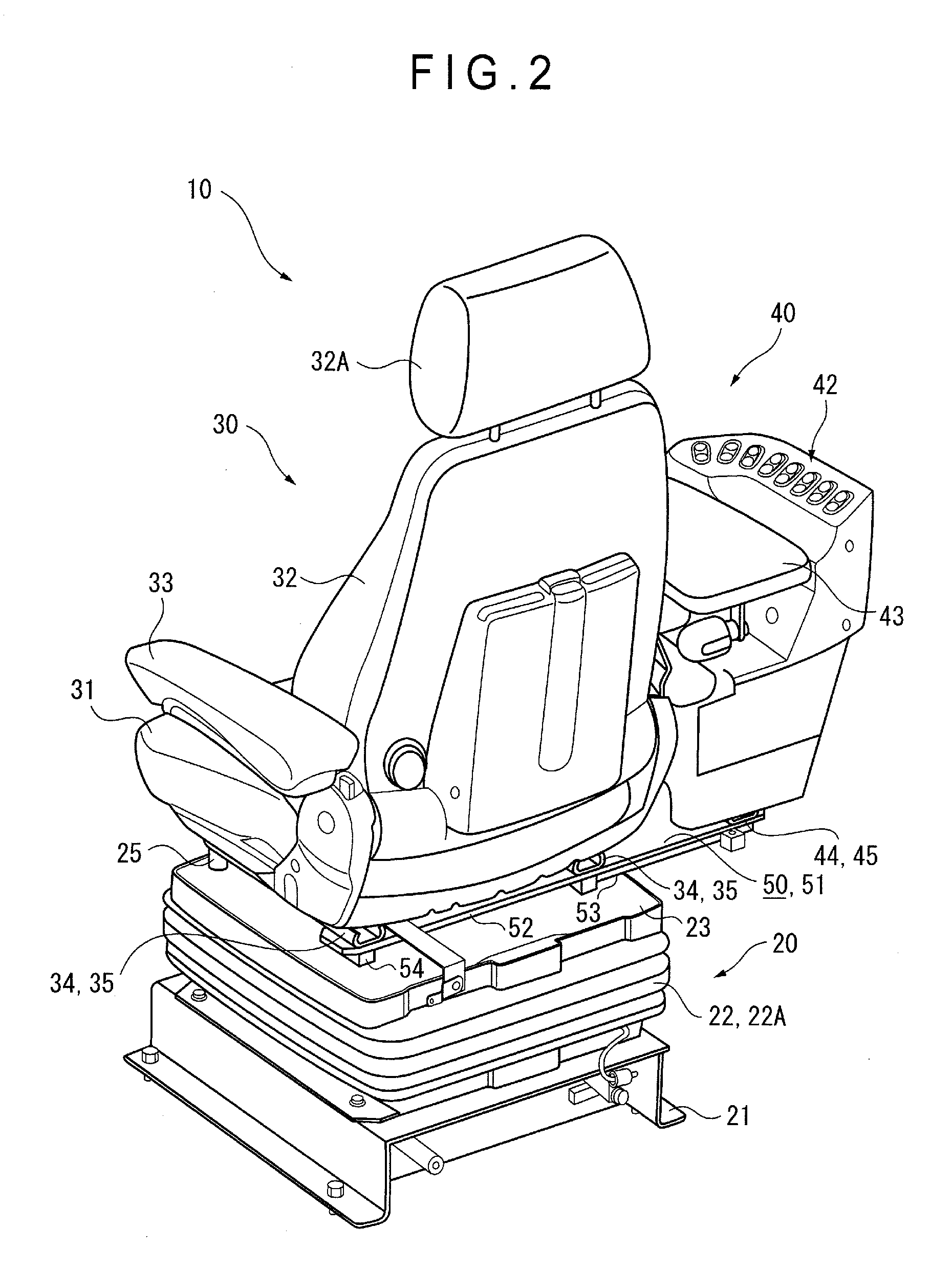

Operator Seat Structure of Construction Machine

ActiveUS20110127819A1Improve operabilityStably attachArm restsSoil-shifting machines/dredgersEngineeringMechanical engineering

A seat structure for an operator that is set in a cab of a construction machine such as a wheel loader includes: a suspension equipment fixed to a floor frame; a plate-shaped attachment bracket attached on the suspension equipment; a seat and a work equipment console juxtaposed to each other on the attachment bracket. The seat is attached to the attachment bracket via slide rails in a manner slidable back and forth. The work equipment console is also attached to the attachment bracket via a slide rail in a manner slidable back and forth.

Owner:KOMATSU LTD

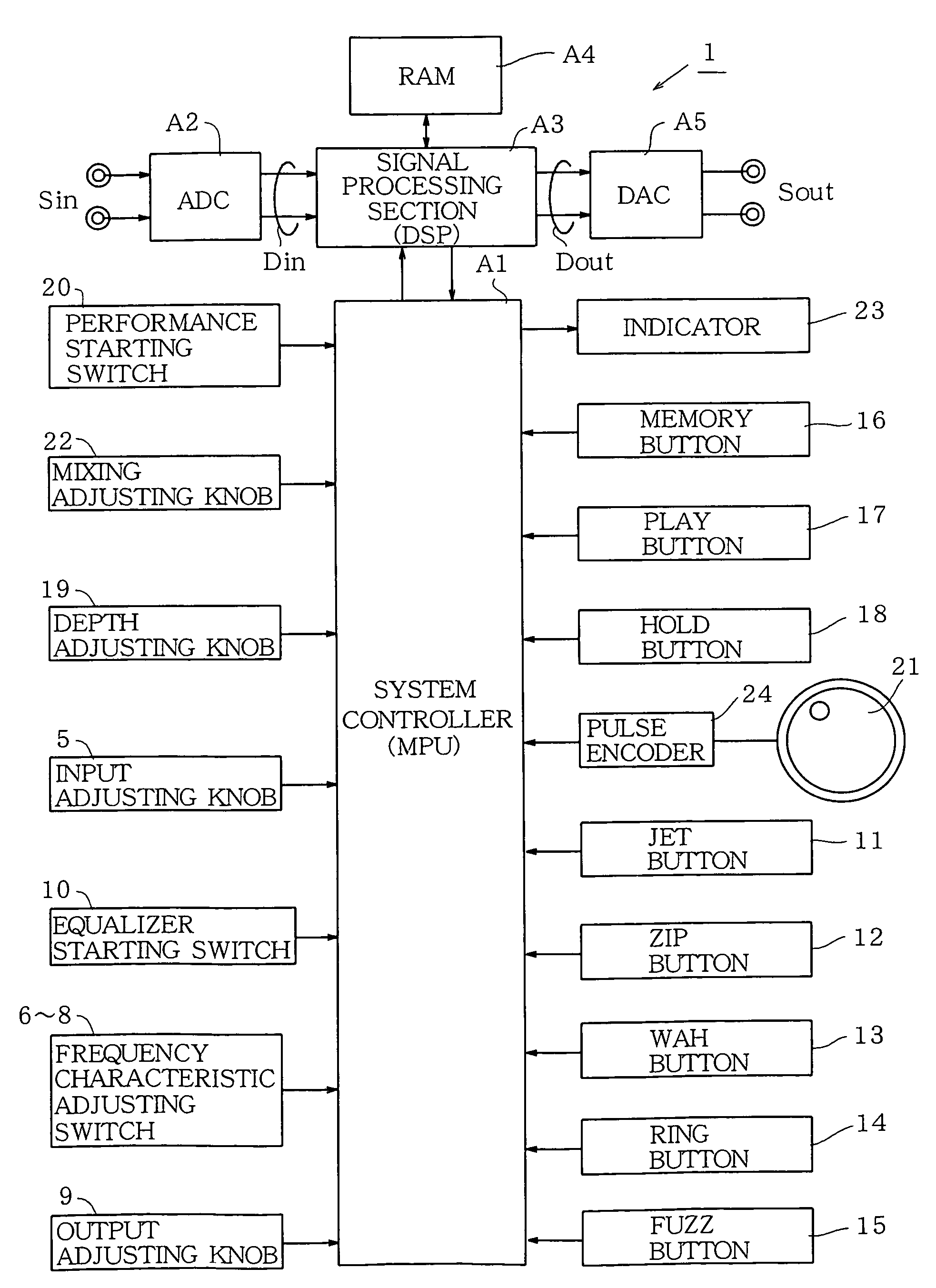

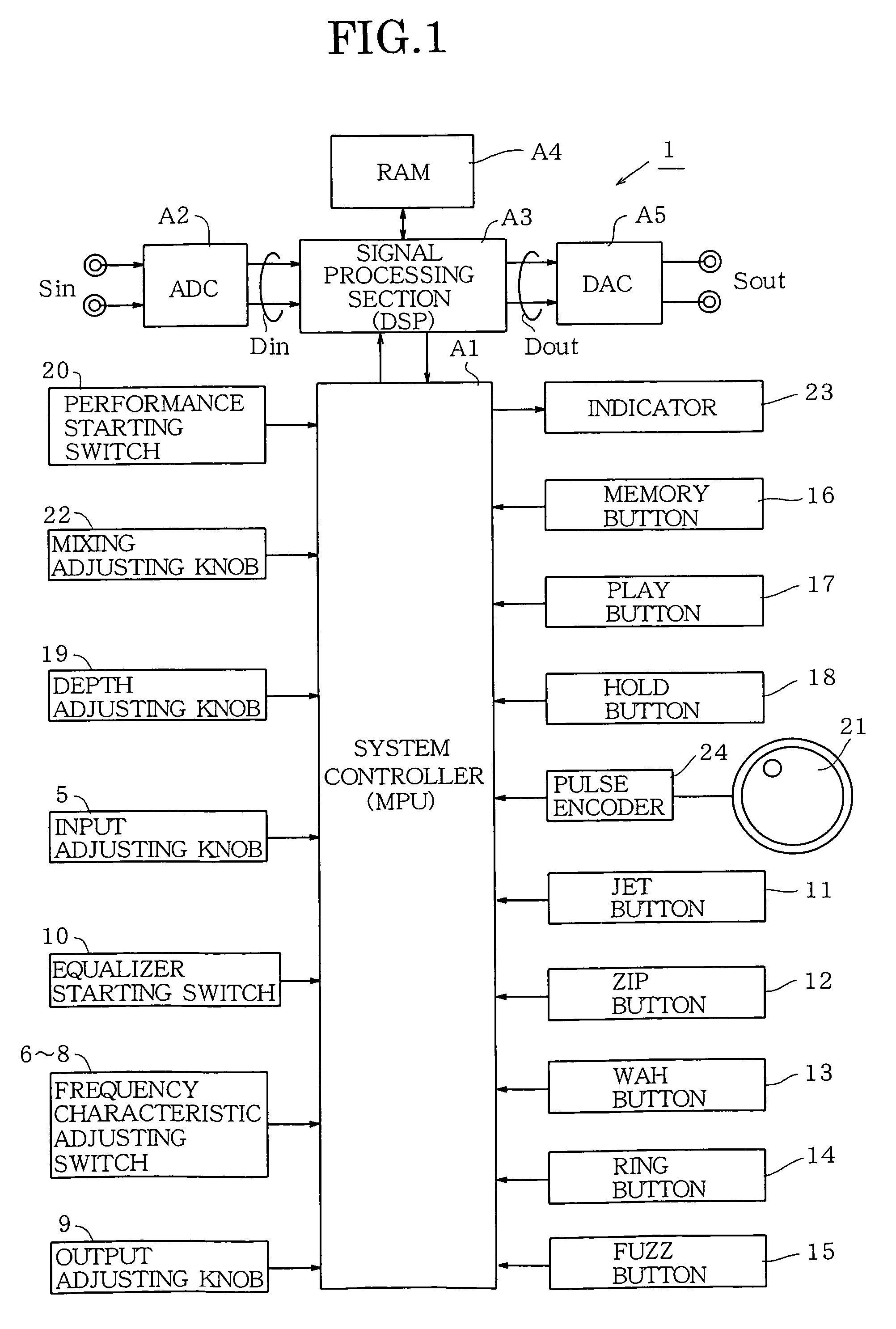

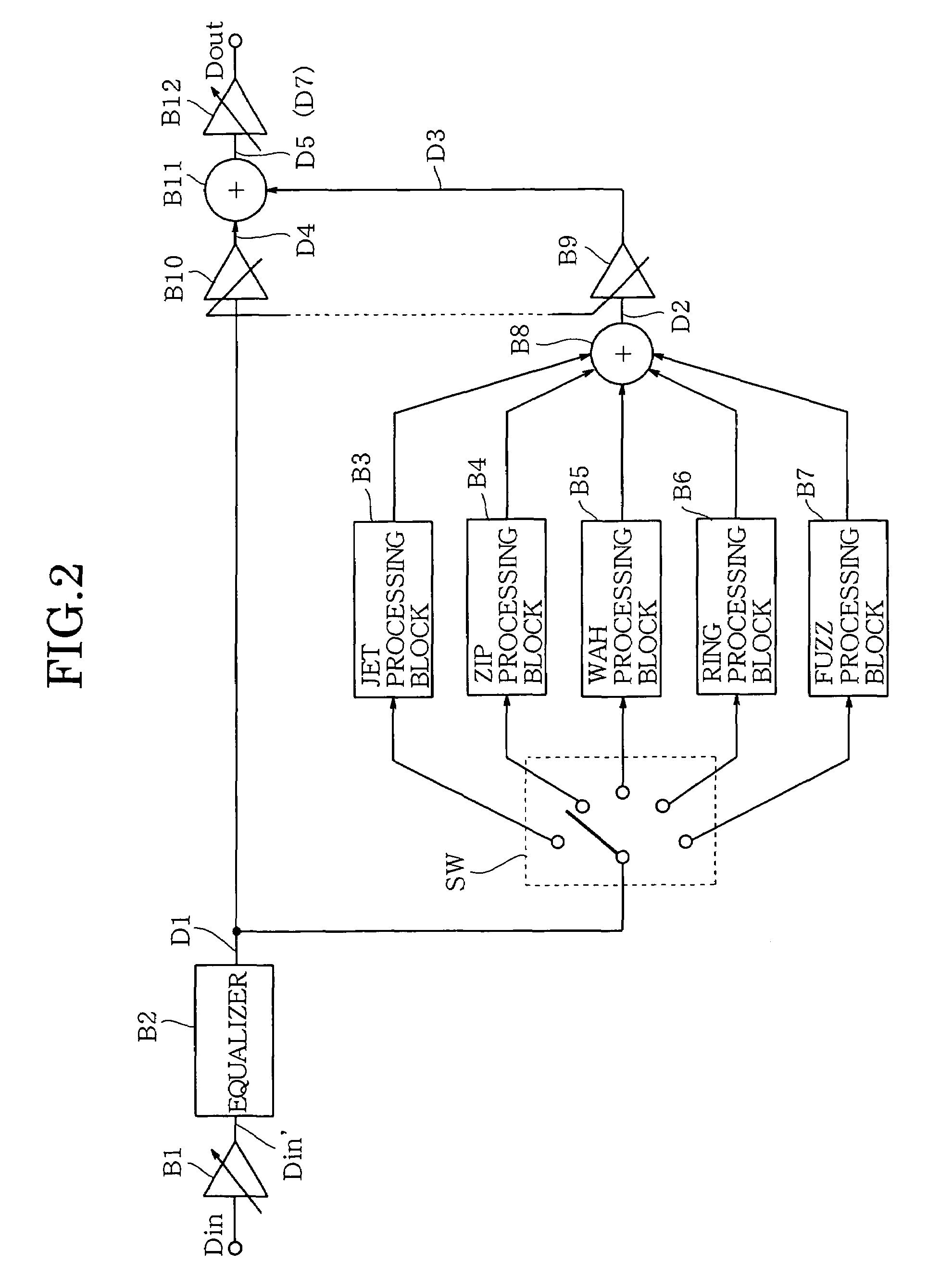

Audio signal processing apparatus

InactiveUS7227963B1Improve operabilityGood music effectElectrophonic musical instrumentsTransmissionPeripheralAudio signal

An audio signal processing apparatus comprises a signal processing section for processing audio signals fed from outside equipments, an operating section for producing commands in order for said signal processing section to process the audio signals, a storing memory for storing past operation data containing past operation information of the operating section, a controller for setting parameters in order for said signal processing section to process the audio signals in accordance with said past operation data stored in said storing memory.

Owner:ALPHATHETA CORP

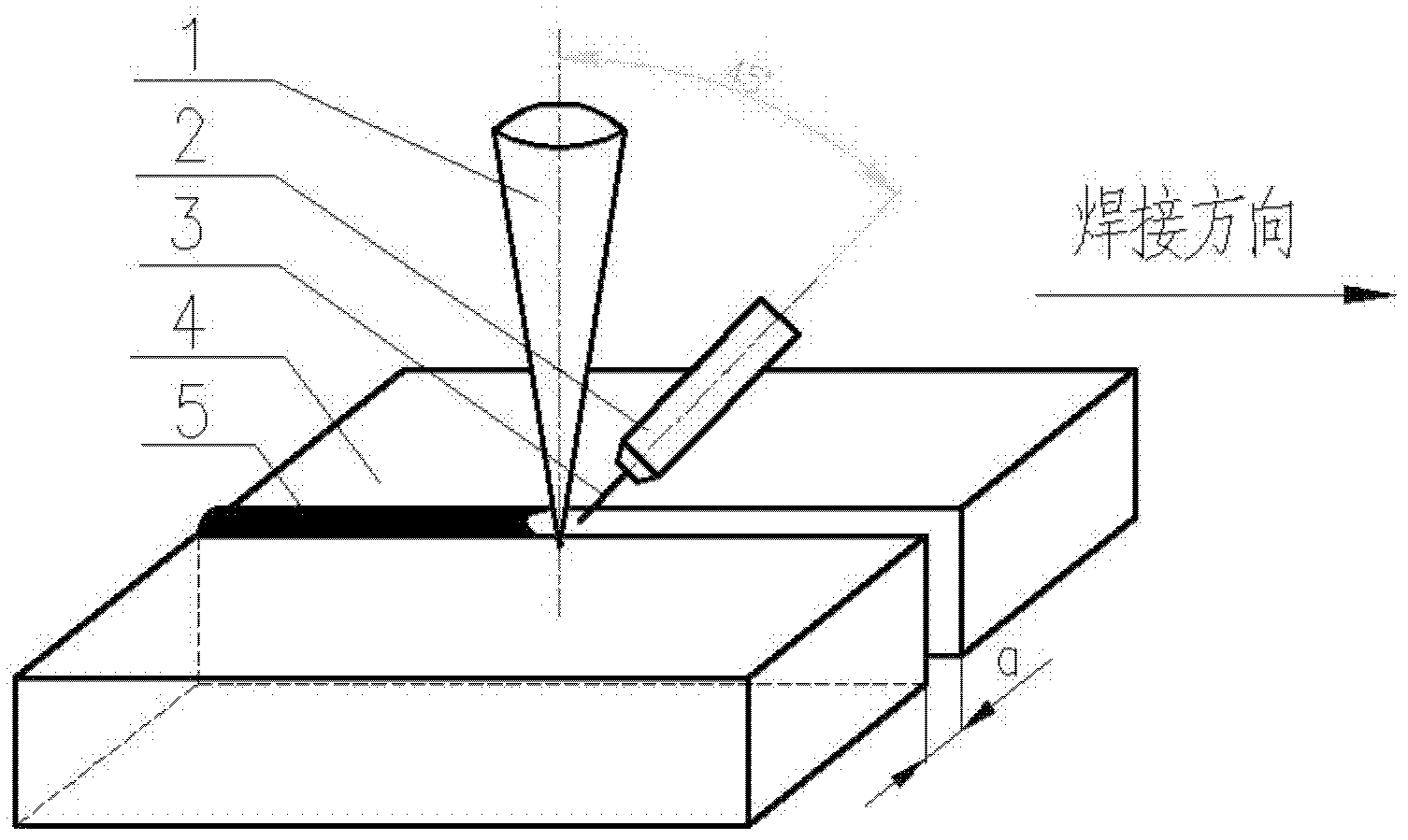

Laser-MAG (Metal-Active-Gas) compound welding method used for welding and splicing high-strength or ultrahigh-strength steel of thick plate

InactiveCN103252589AImprove welding efficiencyImprove operabilityWorkpiece edge portionsLaser beam welding apparatusSteel platesSheet steel

The invention discloses a laser-MAG (Metal-Active-Gas) compound welding method used for welding and splicing high-strength or ultrahigh-strength steel of a thick plate. The method aims at high-strength or ultrahigh-strength steel thick plates and utilizes a laser-MAG compound heat source to carry out single-side single-channel, single-layer and double-face molding welding; a welding part is an I-shaped groove; laser or oxyacetylene torch is adopted to pre-heat a work-piece before welding; and the temperature is kept for 20 min to 1 hour after the welding. The welding technical parameters are that the spot diameter of the laser is 0.3-1 mm, the laser power is 4-10 KW, the arc current is 200-300 A, and the arc voltage is 25.2-30 V. By improving the form of the groove of the work-piece and reserving an assembling distance and optimized welding parameters during the splicing, the splicing and welding of the ultrahigh-strength steel plate is realized; the welded joint performance is satisfied with and better than that of regular TIG (Tungsten-Inert-Gas) welding, the welding speed can be up to 60 m / h; and the welding efficiency is improved by 10 times than the regular TIG welding.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

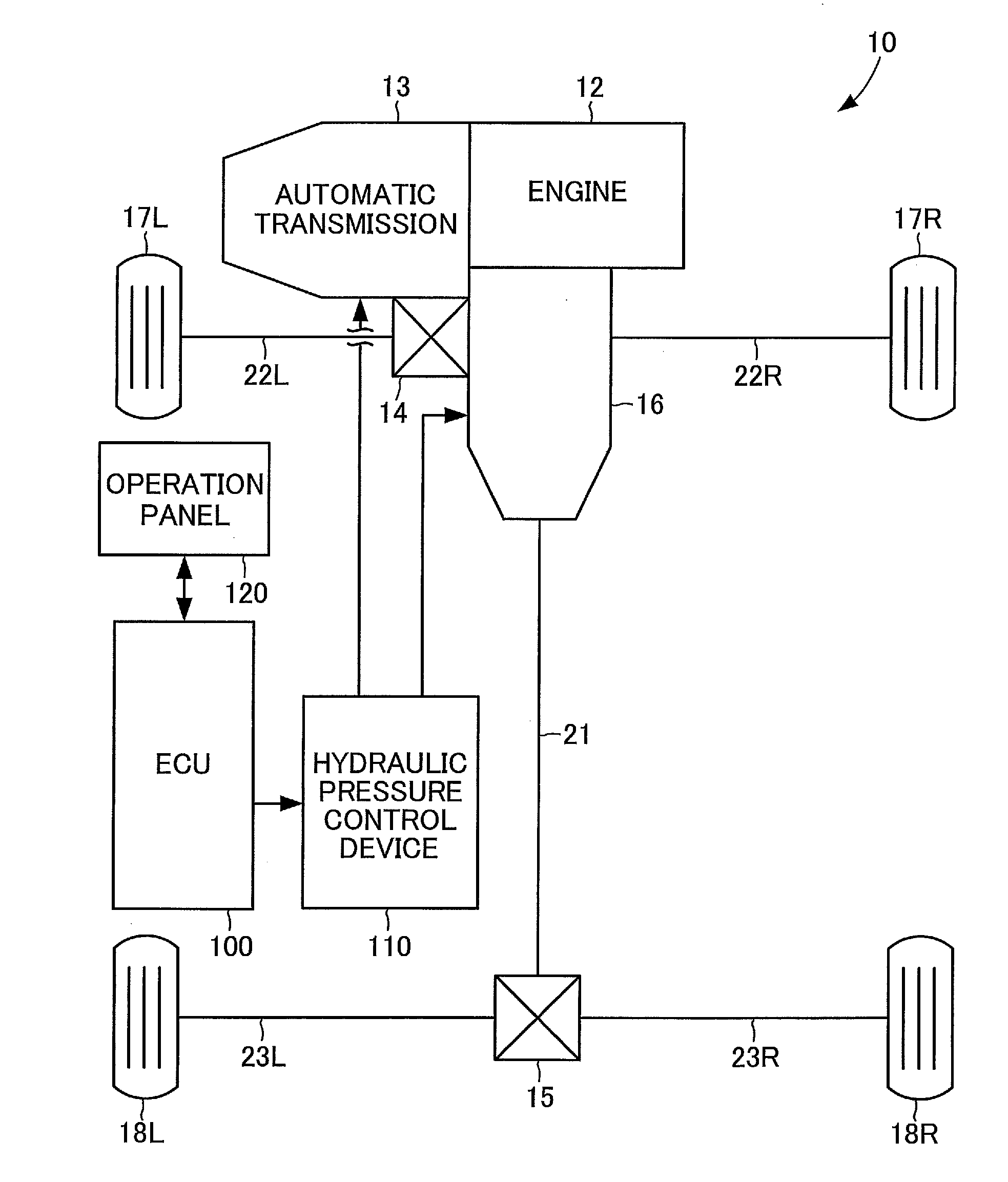

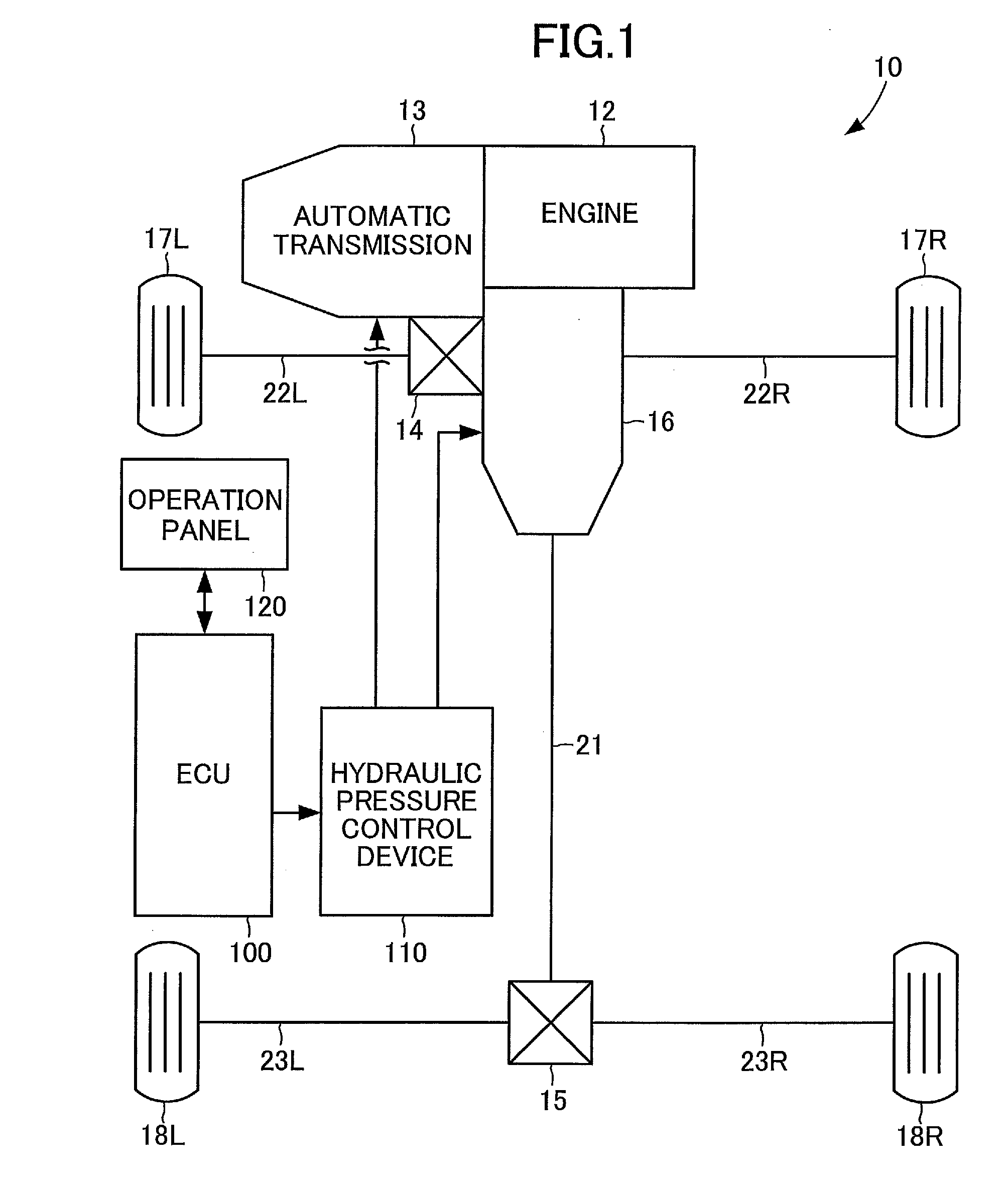

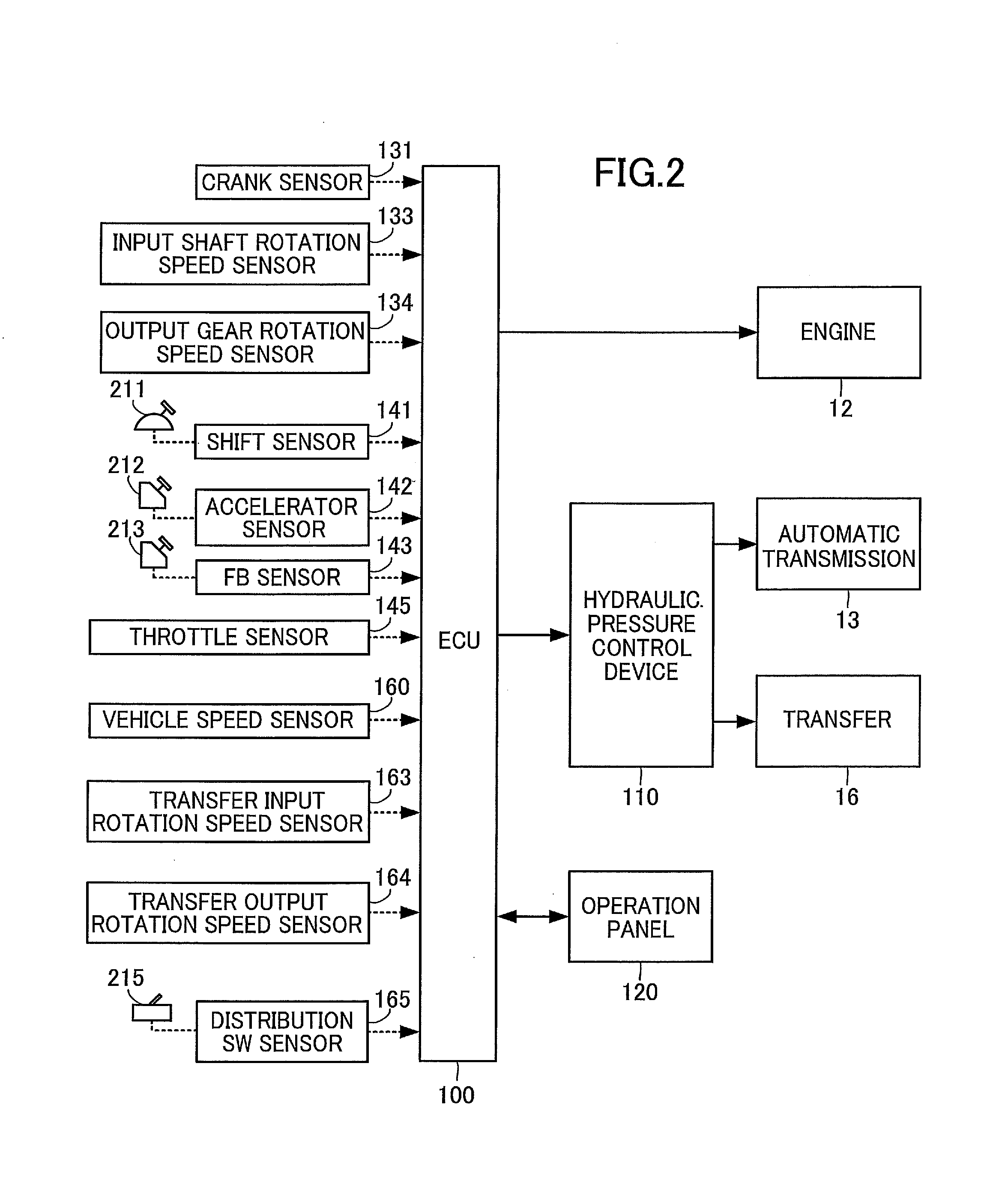

Vehicle control apparatus

InactiveUS20130030675A1Stop reduction controlImprove operabilityAnalogue computers for vehiclesProgramme-controlControl equipmentOperability

Provided is a vehicle control apparatus that can prevent the drivability from being deteriorated. The vehicle control apparatus has an ECU which determines, when the control permission condition is not established, not to execute the reduction control in the case that the accelerator opening degree is smaller than or equal to the accelerator threshold value or the vehicle speed is smaller than or equal to the vehicle speed threshold value, even if a depression of an accelerator pedal is detected and a depression of a foot brake pedal is detected. Therefore, the vehicle control apparatus can stop the torque reduction control to prevent the reduction of the engine output contrary to the intention of the driver in the case that an impact to the vehicle is small such that a load more than necessary is not applied to the vehicle even if the accelerator pedal and the brake pedal are both depressed by the driver. As a result, the vehicle control apparatus can improve the operability of the vehicle in the situations such as hill start and overcoming steps, thereby preventing the drivability from being deteriorated.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com