Laser-MAG (Metal-Active-Gas) compound welding method used for welding and splicing high-strength or ultrahigh-strength steel of thick plate

An ultra-high-strength steel, composite welding technology, applied in laser welding equipment, welding equipment, workpiece edge parts, etc., can solve the problems of low tolerance of welding assembly, slow welding speed, inhibiting the efficiency of tailor welding of thick plates, etc. Improved operability and welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

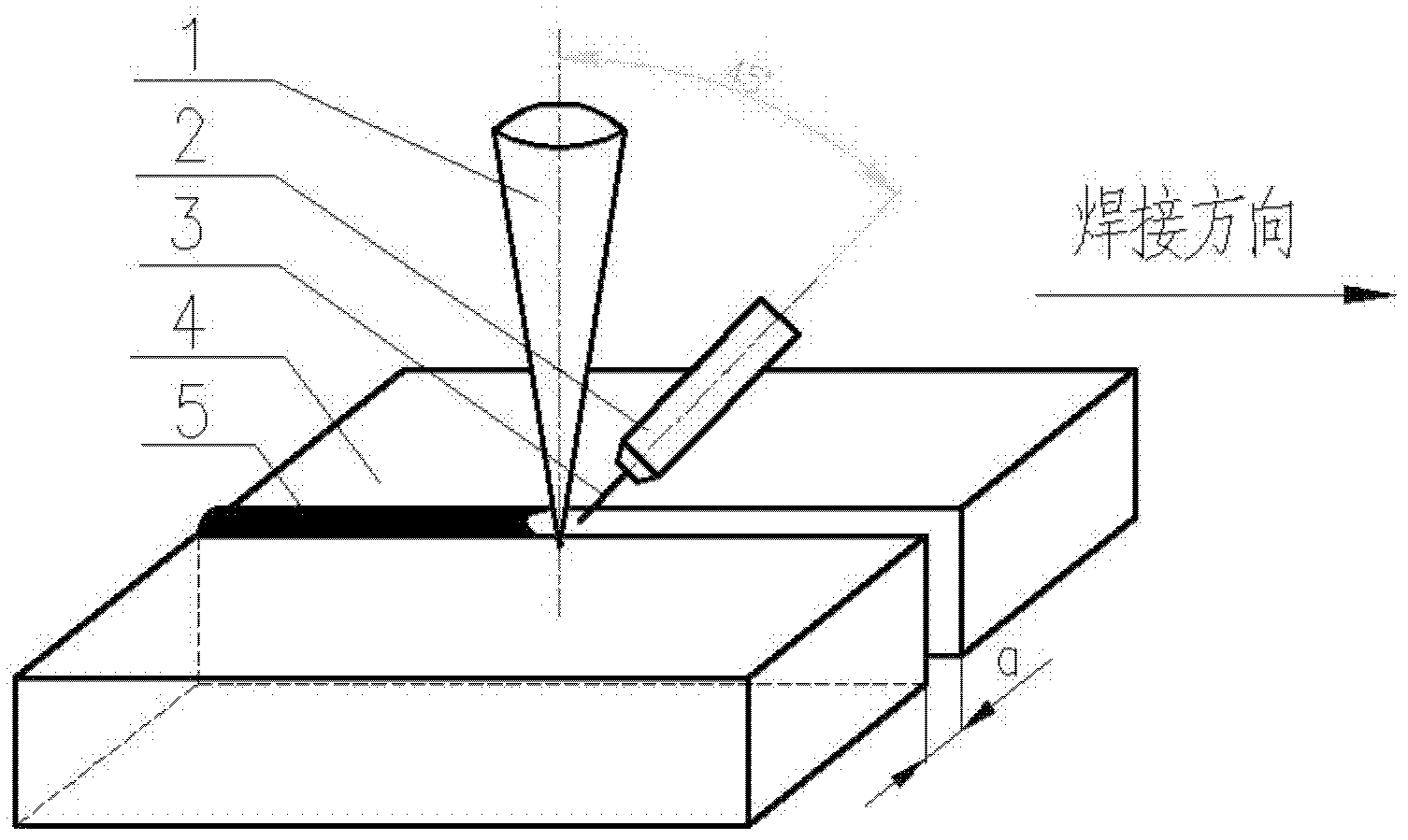

[0022] like figure 1 As shown, in this embodiment, the welding base material is 31Si2MnCrMoVE ultra-high-strength steel plate 4 with a thickness of 10 mm and a tensile strength of 1600 MPa, and the welding wire 3 is H10SiMnCrNiMoV with a diameter of 1.2 mm. First, polish off the rusty part of the tailor welding and clean it with acetone. Then proceed as follows:

[0023] (1) Clamping tailor-welded blanks: open an I-shaped bevel on the part to be welded, and the splicing distance is 1 to 2 mm;

[0024] (2) Use oxyacetylene flame to preheat, and control the preheating temperature within the range of 150°C to 250°C;

[0025] (3) Laser-MAG composite welding: After reaching the preheating temperature, the welding is performed in a composite form in which the arc is in front and the laser 3 is in the back; welding process parameters: laser spot diameter 0.3 ~ 1mm, laser power 4.2KW, arc The current is 280A, the arc voltage is 28.2V; the welding speed is 1m / min, the shielding gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dry elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com