Wetland paving method and recycling method

A technology for wetlands and metal pavements, applied in the field of pipeline engineering, can solve the problems of high production cost, long time and poor application effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

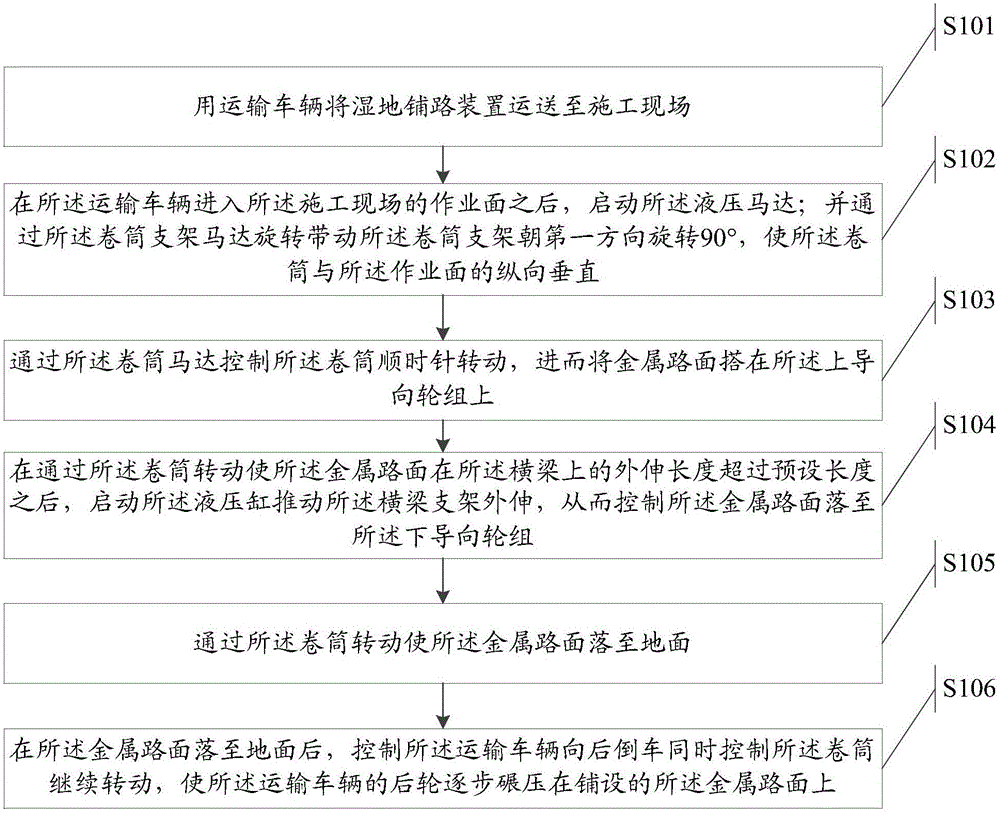

[0050] The invention provides a wetland road paving method and a recovery method, but there are technical problems of high cost or long time when laying a working belt.

[0051] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

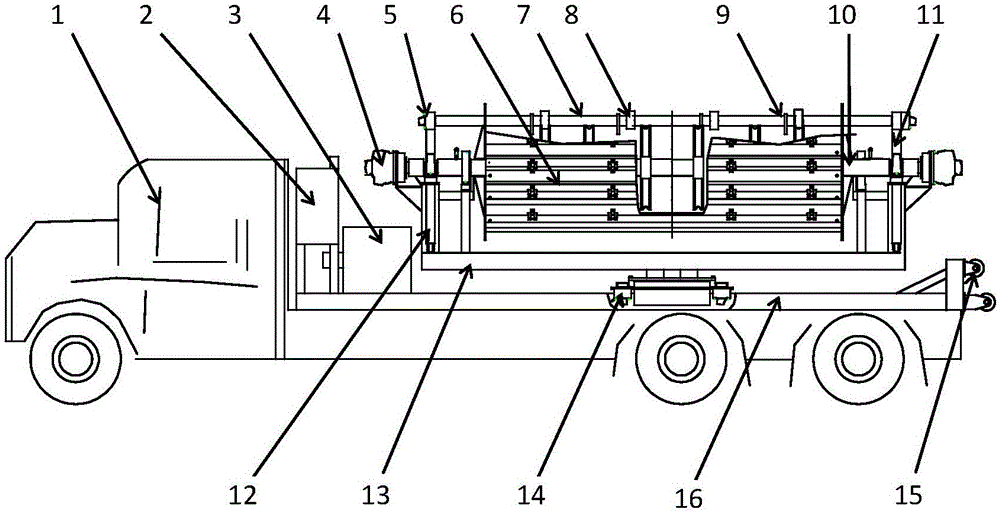

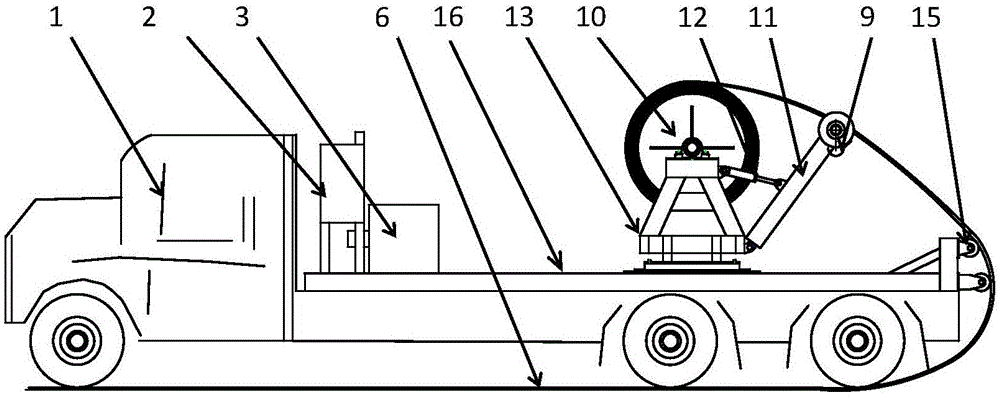

[0052] A wetland paving method is provided, using a transport vehicle to transport the wetland paving device to a construction site, the wetland paving device comprising: a base; a hydraulic motor arranged on the surface of the base; an electric control system arranged on the surface of the base and connected to the hydraulic motor; the reel support motor is set on the surface of the base; the reel support is set on the surface of the reel support motor; the hydraulic cylinder is set on the side of the reel support; the beam support is set on the The top of the hydraulic cylinder; the beam motor, arranged on the top of the beam bracket; the beam, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com