Detachable triangular scaffold and steel truss assembly construction method

A triangular and steel truss technology, applied in the preparation of pillars and building components on site, construction, etc., can solve the problems of unstable support frames or scaffolding, poor construction safety, and large amount of engineering steel, so as to optimize the construction process, Structural safety and the effect of reducing the cost of construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

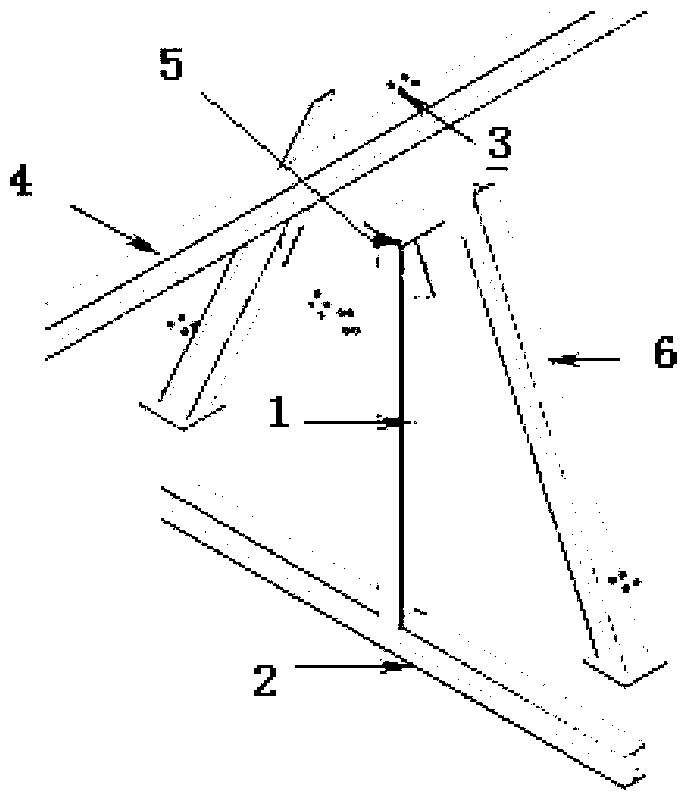

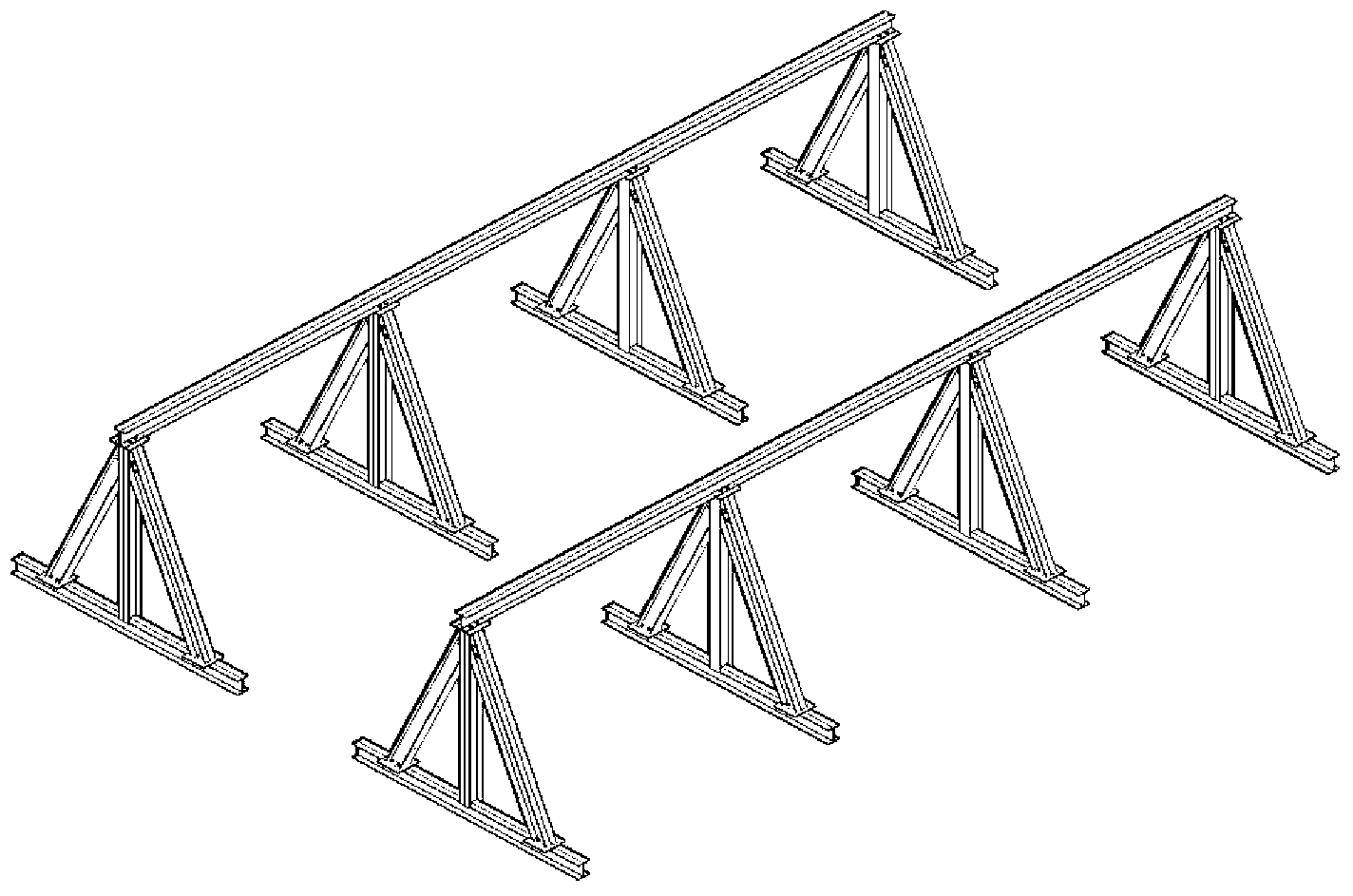

[0025] Such as figure 2 As shown, first make a triangular tire frame. The size of the triangular tire frame is 2.7m high, 4m wide, 12m long, and 6m apart; use theodolite and level to recheck its axis and elevation, and pre-assemble the main components in the assembly site. Put the projection line, and install the detachable triangular tire frame.

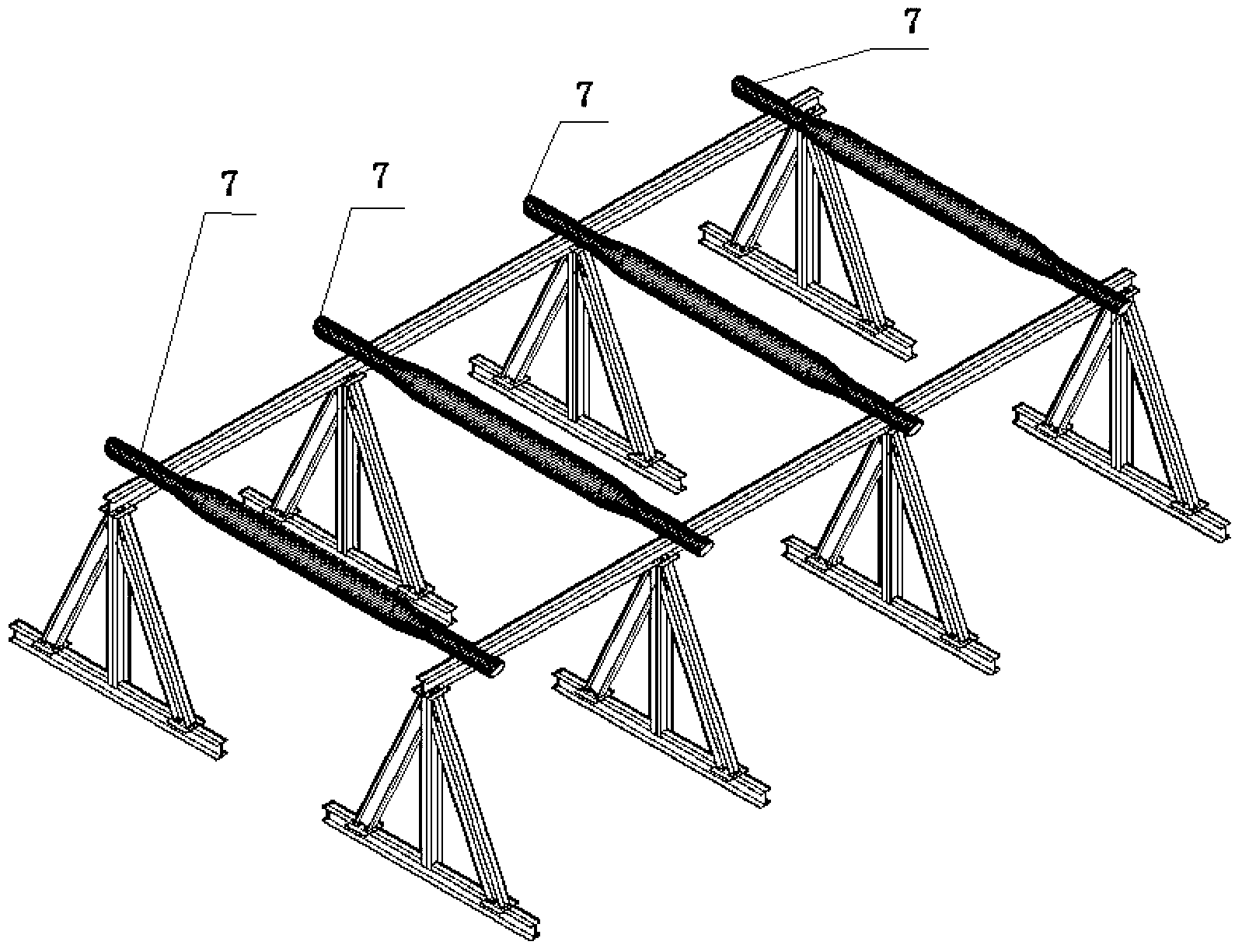

[0026] Such as image 3 As shown, four No. 1 main pipes 7 in the horizontal direction are first installed on the tire frame, and the four No. 1 main pipes 7 are all perpendicular to the steel beam 4, parallel to each other and arranged at equal intervals.

[0027] Such as Figure 4 As shown, the No. 1 main pipe 7 is welded to the No. 2 main pipe 13, and the No. 2 main pipe 13 is connected between every two adjacent parallel No. 1 main pipes 7 as the base surface.

[0028] Such as Figure 4 As shown, the No. 3 main pipe 8 and the No. 4 main pipe 9 are welded into a ladder shape through the connecting plate, and are temporarily f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com