Patents

Literature

516results about How to "Guaranteed bearing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curing agent and construction method of weak soil

InactiveCN101684038AReduce adverse effectsReduce manufacturing costSolid waste managementSlagCarrageenan

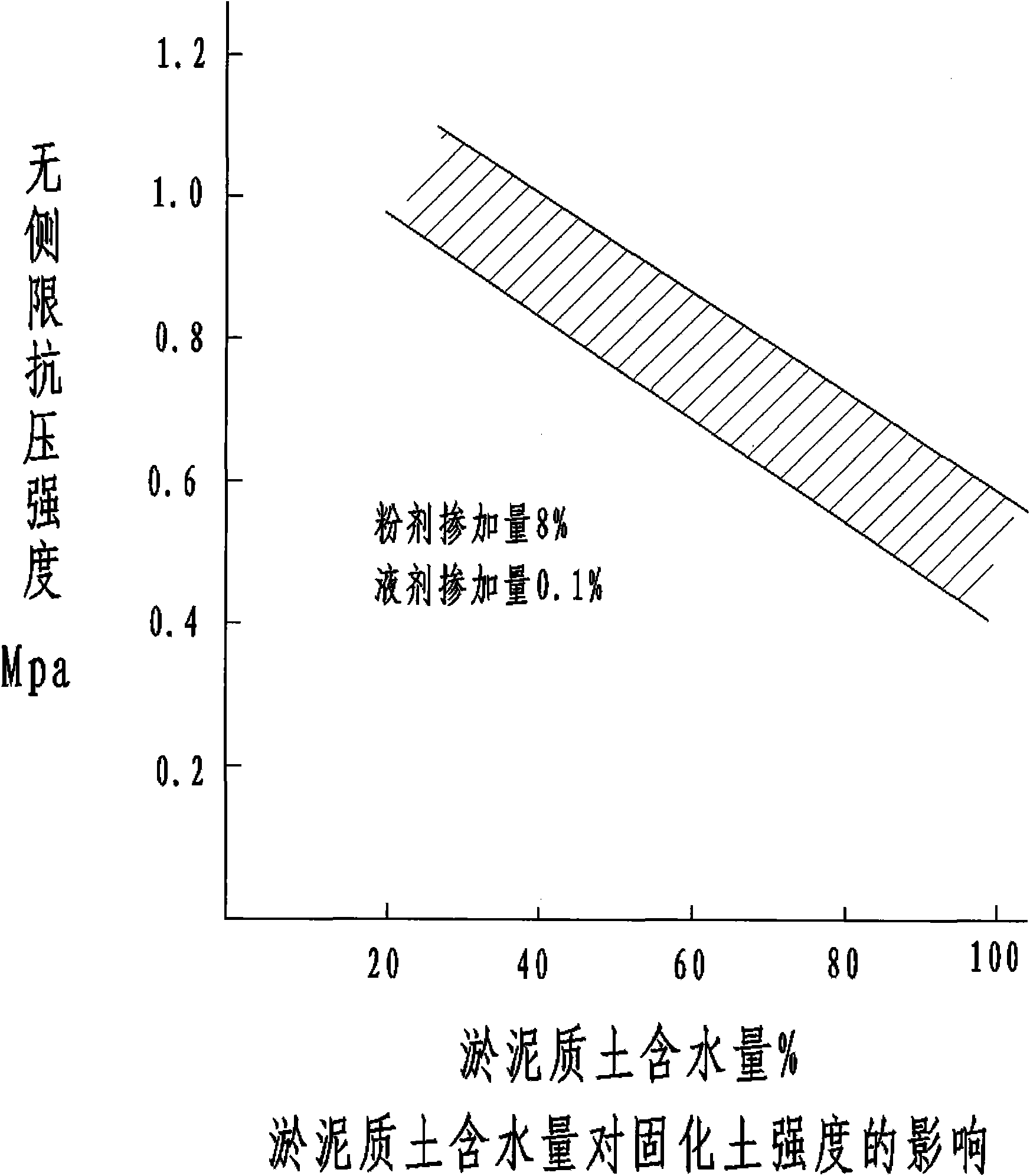

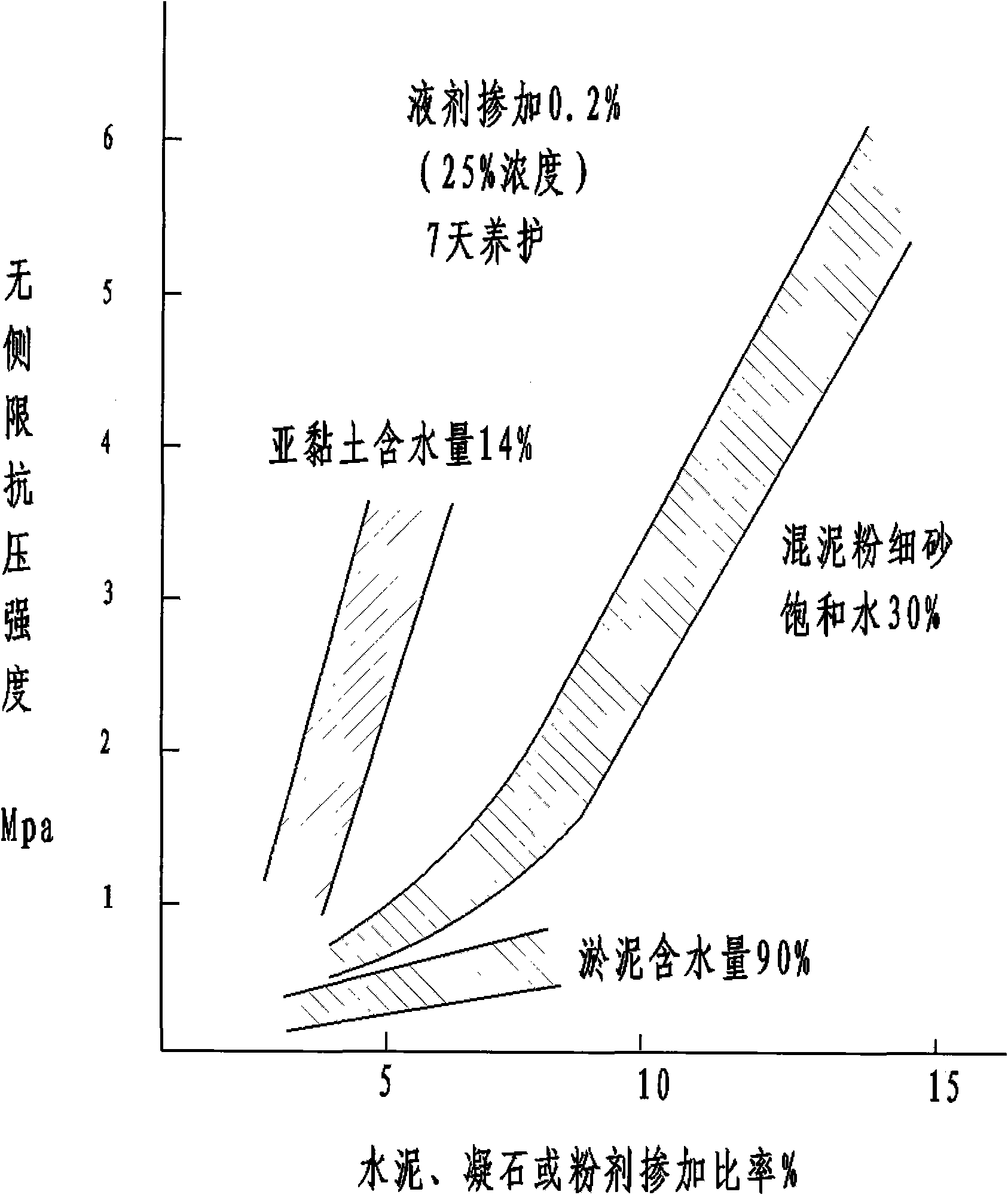

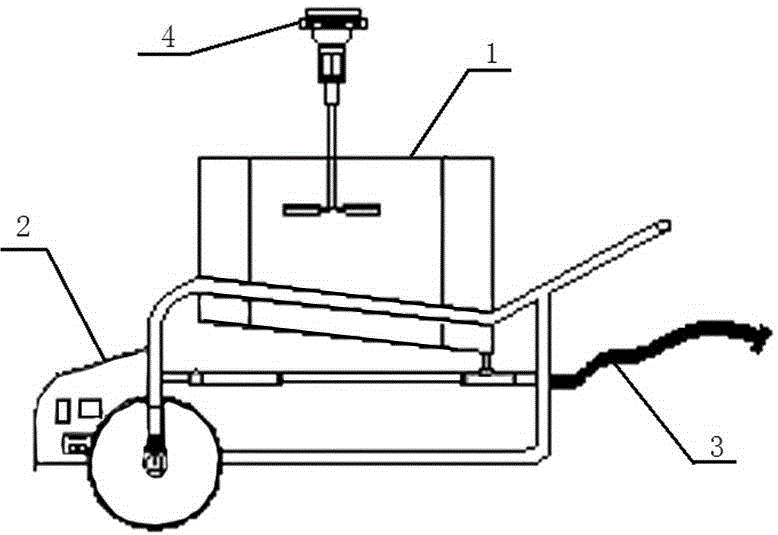

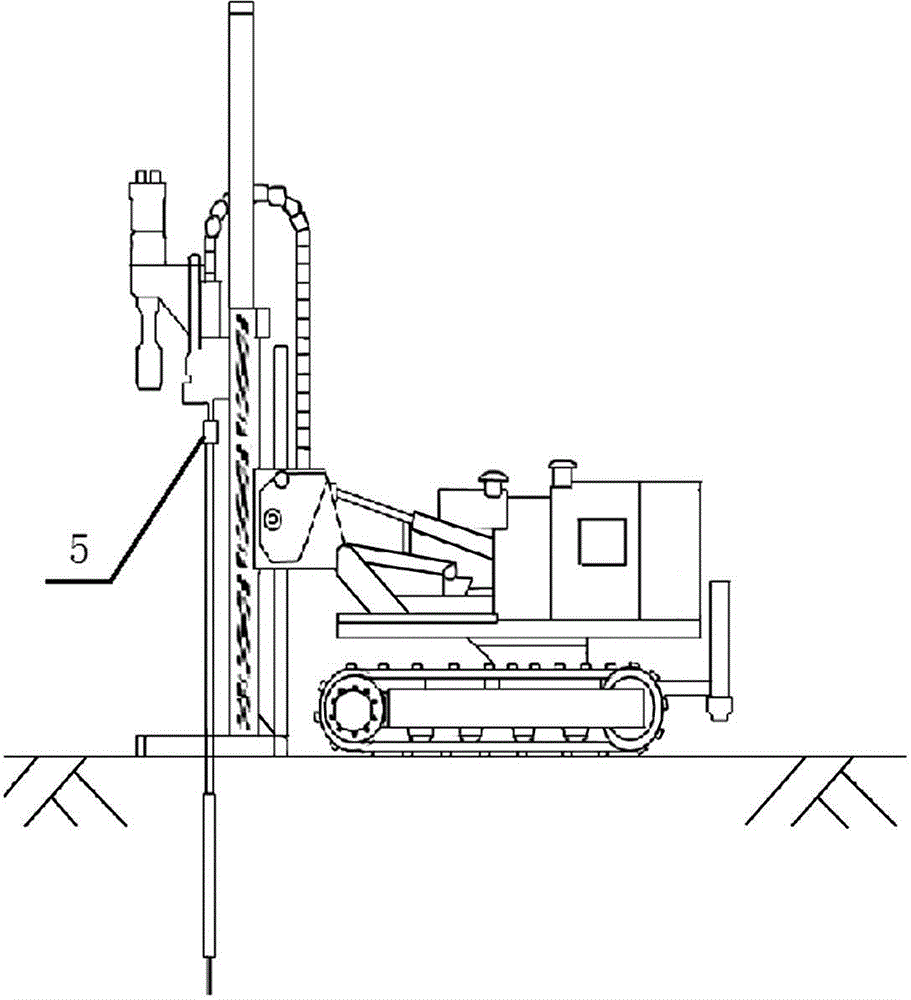

The invention relates to a curing agent and a construction method of weak soil. The curing agent of the weak soil is characterized by comprising powder and liquid, wherein the powder comprises cementand congealing stones or the following materials in parts by weight: 0-20 parts of cement clinker, 60-95 parts of grain slag or slag, 1-5 parts of lime, 1-5 parts of plaster, 1-5 parts of anhydrous sodium sulphate, 0-10 parts of caustic soda, 0-10 parts of water glass and 0.1-3 parts of sodium fluosilicate; the liquid comprises the following components in parts by weight: 1-15 parts of polyacrylamide, 20-60 parts of pulp waste liquid, 10-40 parts of cement retarder, 0.5-1.5 parts of OP emulsifier, 0.3-1.0 part of carrageenan, 0.3-1.0 part of xanthan gum and 0.5-1.5 parts of alpha-olefin sulfonate. The curing agent is previously prepared into seriflux before being used, and the weak soil and the curing agent seriflux are uniformly stirred by mechanical stirring equipment and then are spreador compacted. The addition quantity of the powder is greatly reduced because a small quantity of the liquid is added; in addition, materials can be easily obtained, and the performance of consolidated soil is superior, thus the curing agent of the weak soil, i.e. sludge and the like, has high efficiency and environmental protection.

Owner:要明伦

Chromium contamination in-situ remediation method

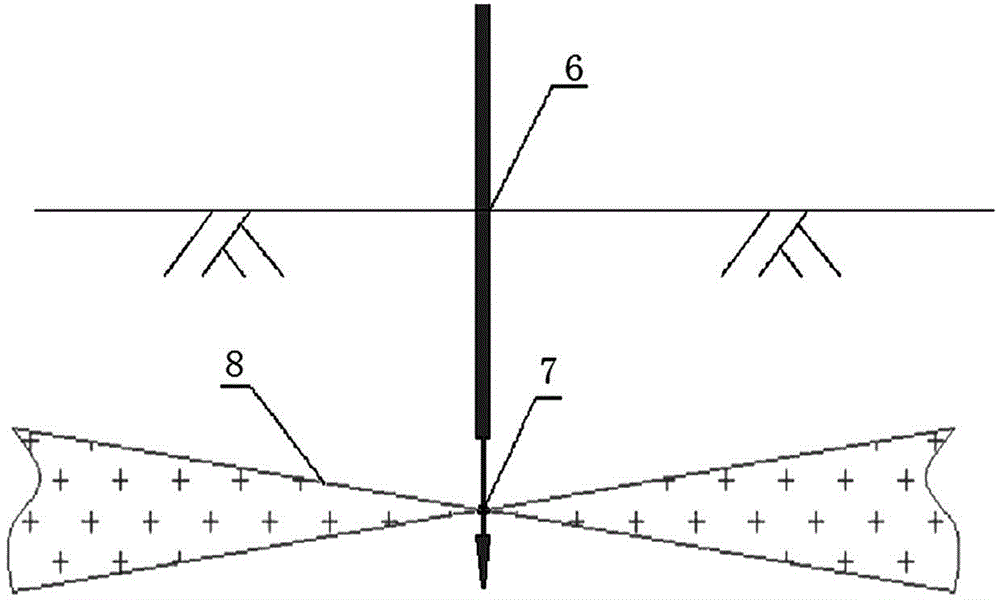

InactiveCN104815844ASmall direct disturbanceMaintain foundation bearing capacityContaminated soil reclamationWater/sewage treatmentDrilling systemChromium contamination

The present invention discloses a chromium contamination in-situ remediation method, which comprises: 1) injection points are arranged and the dosage of a repair agent is determined, wherein it is ensured that the repair agent covers all the place to be repaired; 2) the repair agent is prepared; 3) a drilling system is provided with depth fixation equipment for positioning the injection points; and 4) the repair agent is subjected to high pressure injection. The in-situ remediation system suitable for the remediation method comprises the drilling system for supporting the operation and the agent mixing and injection system. According to the present invention, the large-scale infrastructure investment and building is not required, the stratum structure is not basically destroyed, the stratum condition does not affect the high pressure injection, the repair agent is uniformly distributed in the formed fracture cracks and provides advantages of targeting property, good repair effect, complete repair, and no bounce for the chromium contamination, the starting and the stopping can be performed at any time, the continuous large-scale construction can be achieved, and the engineering applications can be achieved.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

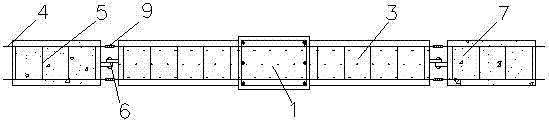

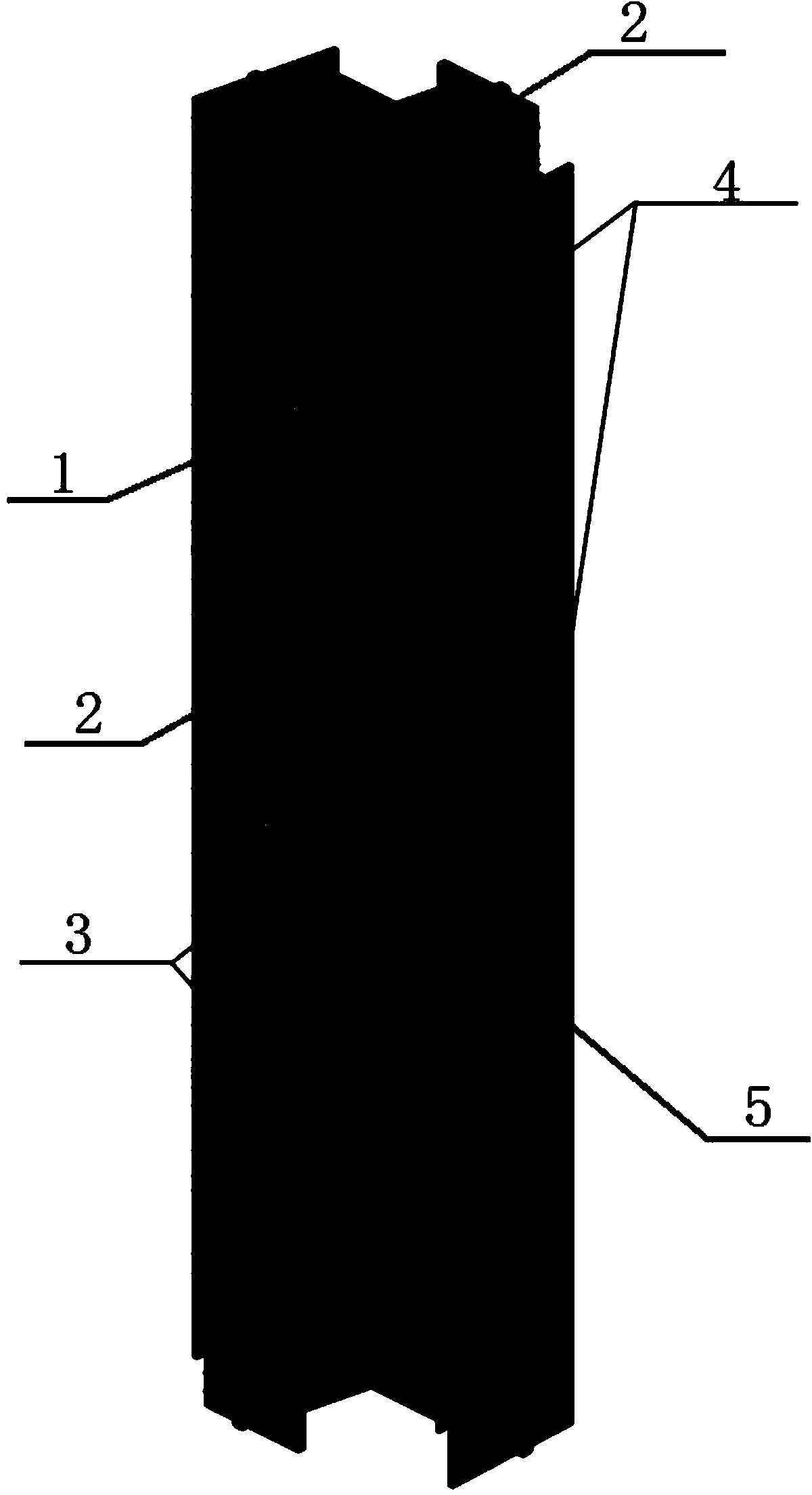

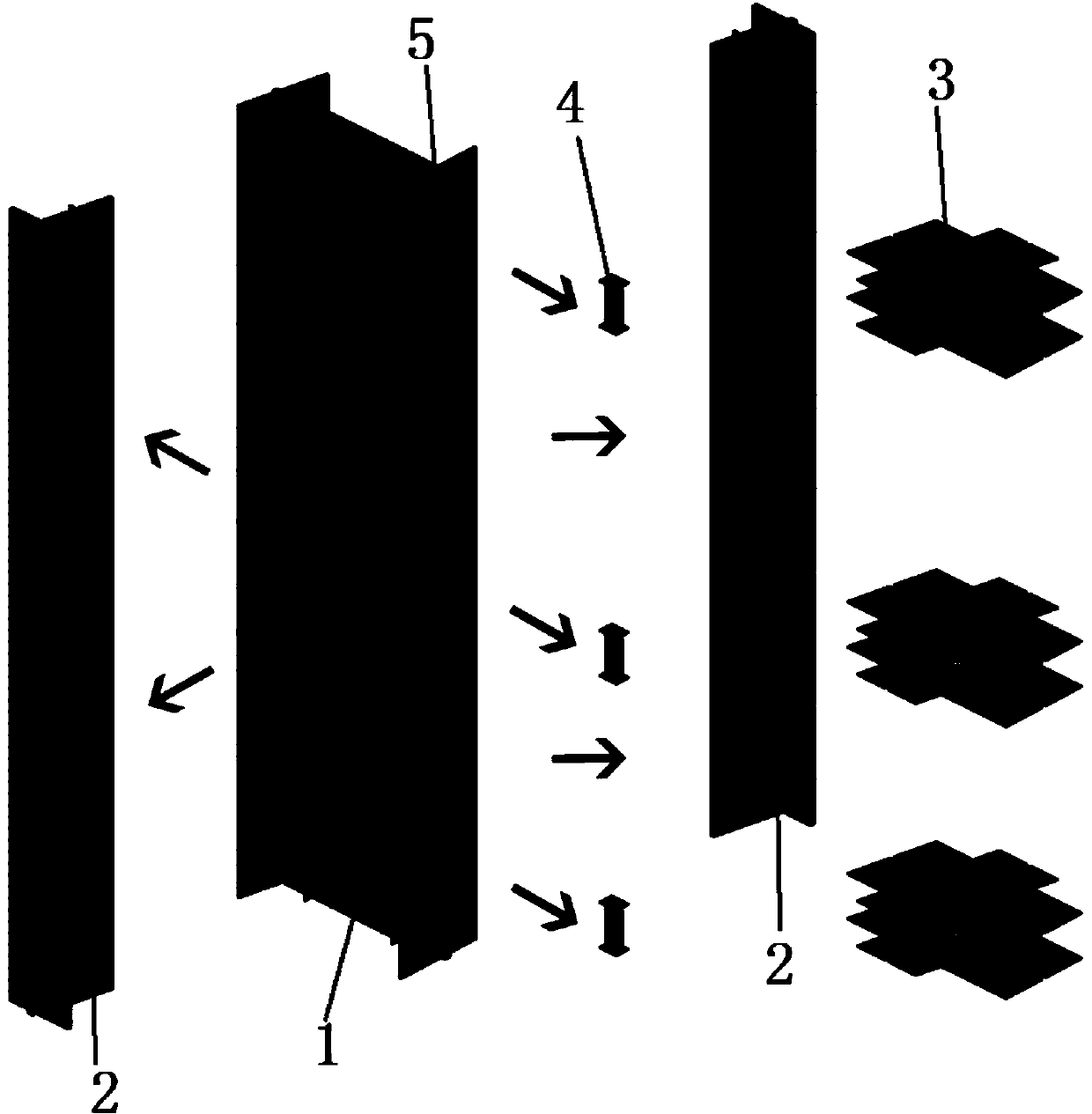

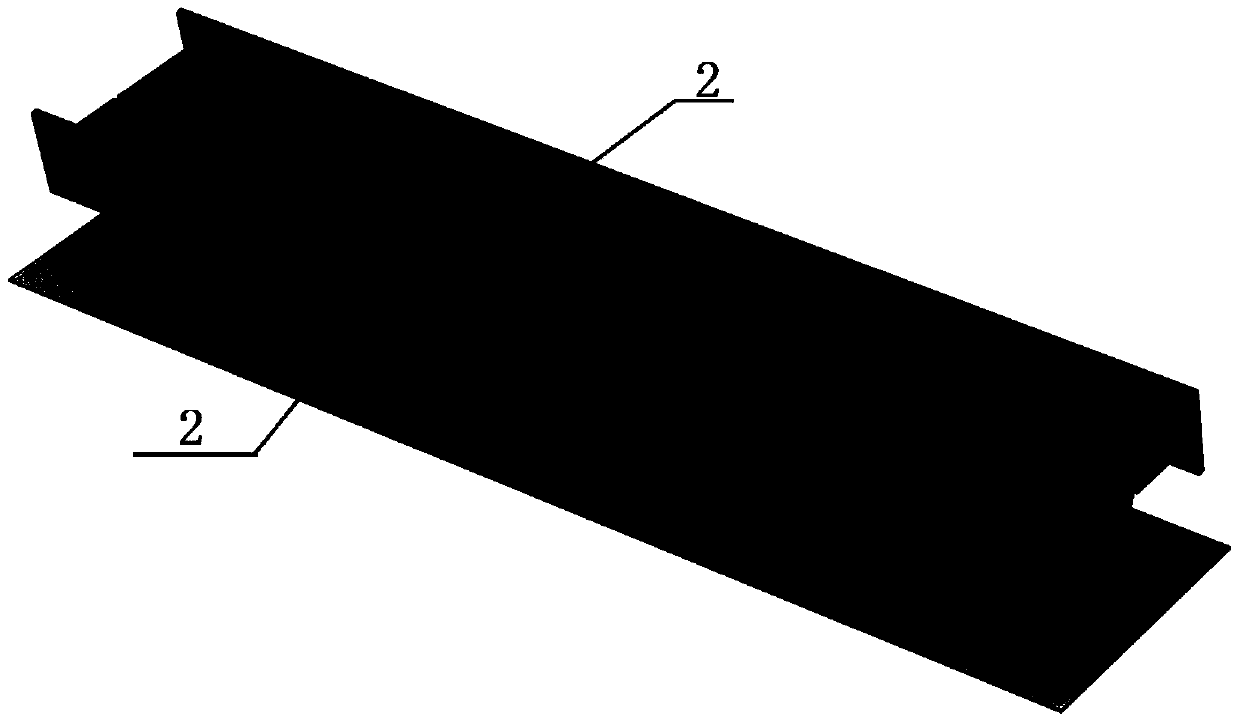

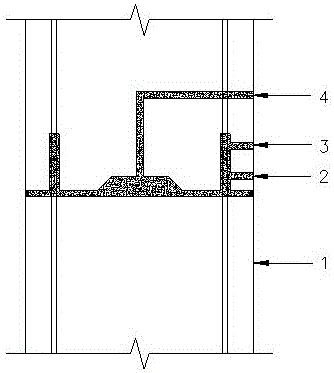

Ultra-large type combined H-section steel column and manufacturing method thereof

ActiveCN104196166AGuaranteed bearing capacityNovel structural designStrutsPillarsManufactured materialStructural engineering

The invention discloses an ultra-large type combined H-section steel column. The ultra-large type combined H-section steel column comprises two I-section steels and a connecting web; the two I-section steels are respectively arranged at two sides of the connecting web, and the section is of an H shape after installation; the upper end face of the connecting web and the I-section steels at two sides form a concave structure, a stiffening plate is arranged along the concave structure, and a reinforcing rod is arranged on the stiffening plate. Meanwhile, the invention further provides a manufacturing method of the steel column. According to the steel column and the manufacturing method thereof disclosed by the invention, when the bearing capacity of the post is ensured, the structure of the column is maximally simplified, raw materials are saved, the cost is saved, the manufacturing process is simple, the installation precision can be ensured, the effective usable area of a building is increased, the gravity of the structure is reduced, and the seismic response of the structure is decreased.

Owner:JIANGSU HUNING STEEL MECHANISM

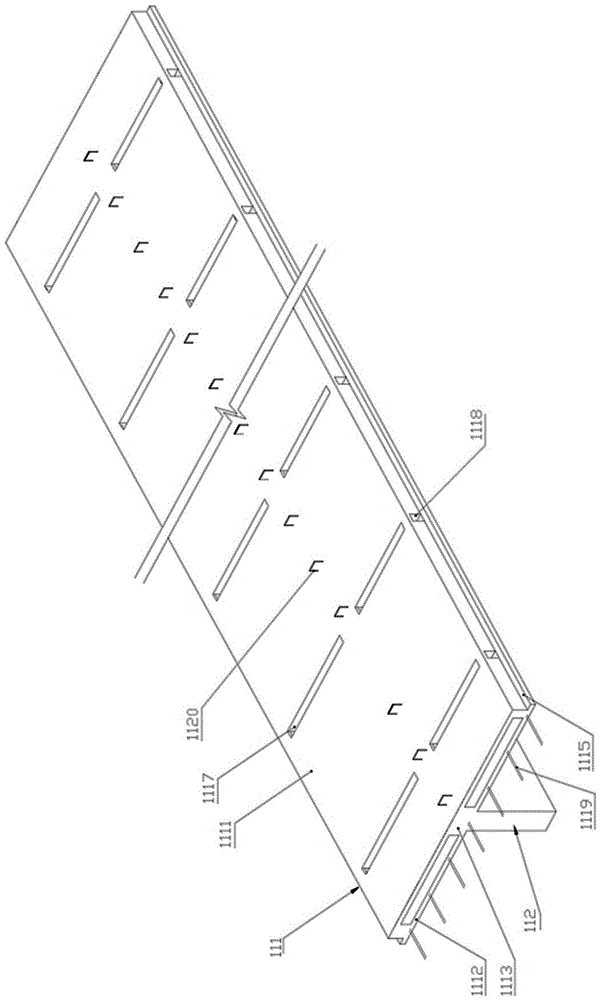

Fully prefabricated reinforced concrete bridge assembly structure and connecting method for same

ActiveCN103741604AImprove assembly rateReduce construction costsBridge erection/assemblyReinforced concreteBridge deck

The invention discloses a fully prefabricated reinforced concrete bridge assembly structure and a connecting method for the same. The fully prefabricated reinforced concrete bridge assembly structure is characterized by comprising prefabricated piles, prefabricated floor collar beams, prefabricated pier studs, prefabricated capping beams, prefabricated longitudinal beams, prefabricated composite bottom plates and prefabricated anti-collision barriers. The connecting method includes connecting the tops of the prefabricated piles with the bottoms of the prefabricated floor collar beams; upwardly connecting the prefabricated floor collar beams with the prefabricated pier studs; upwardly connecting the prefabricated pier studs with the prefabricated capping beams; erecting the prefabricated longitudinal beams on the prefabricated capping beams via bridge supports or fixing ends; supporting the prefabricated composite bottom plates on the prefabricated longitudinal beams, tying reinforcing steel bars of a bridge deck on the prefabricated composite bottom plates and integrally casting concrete on a site to form the bridge deck; mounting the prefabricated anti-collision barriers on the bridge deck. The fully prefabricated reinforced concrete bridge assembly structure and the connecting method have the advantages that components, except for the bridge deck, of the fully prefabricated reinforced concrete bridge assembly structure are of prefabricated structures, so that the bridge prefabricated rate can be greatly increased; common construction labor consumption can be reduced to the greatest extent, and the labor productivity can be improved; the construction period of the fully prefabricated structure can be greatly shortened, the bridge building cost can be reduced, and the bridge construction quality can be improved.

Owner:张利铨

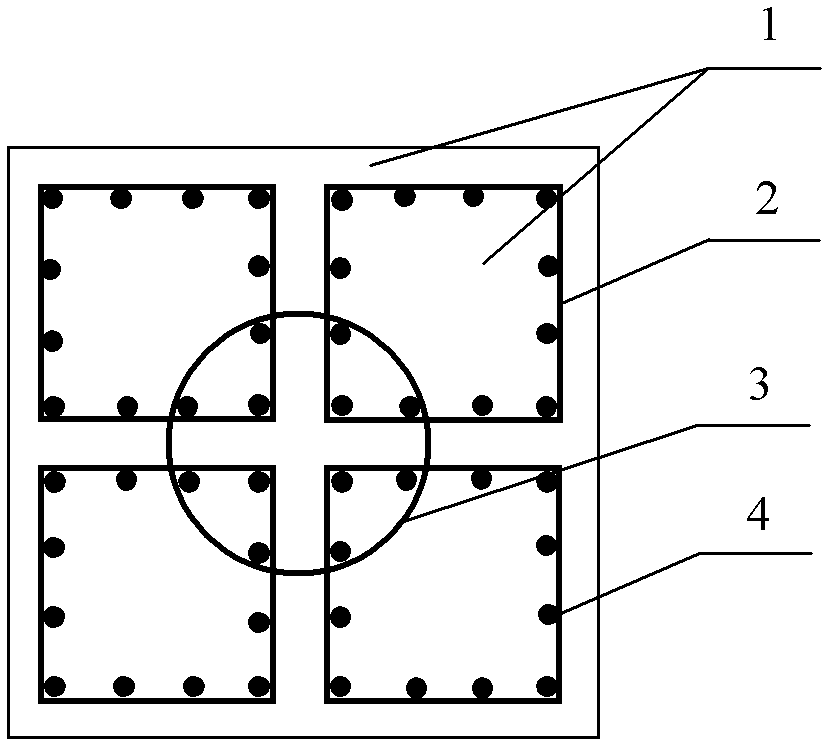

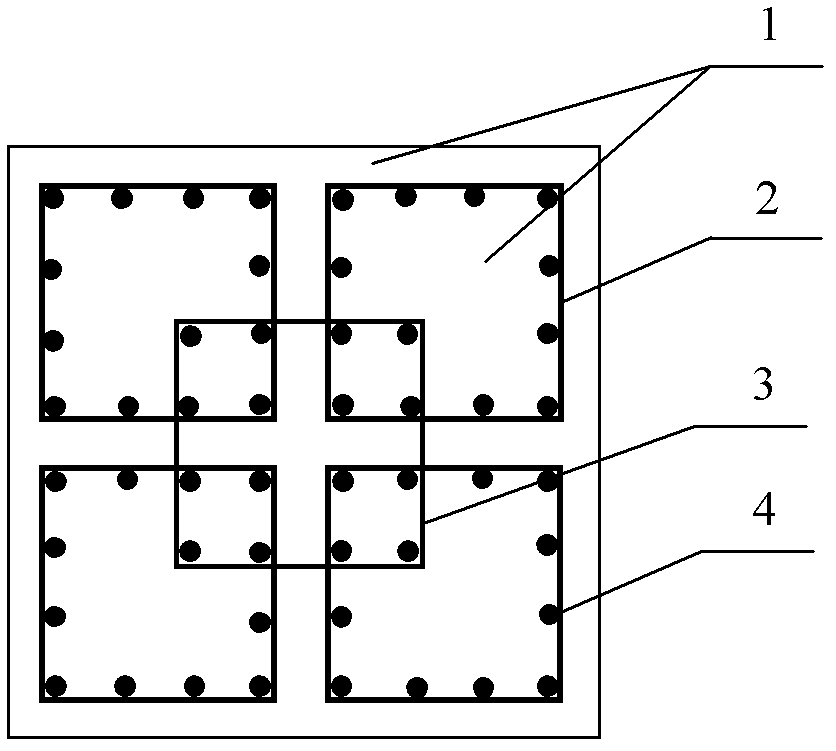

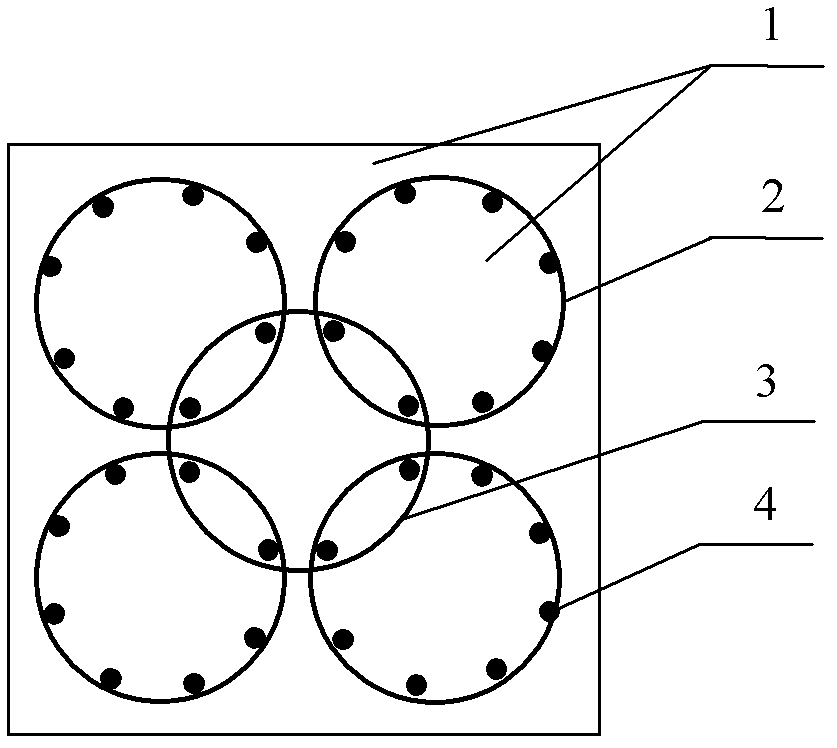

High-seismic-resistance light high-intensity reinforced column

InactiveCN102561595AImprove column deformabilityReduce the weight of the structureStrutsPillarsRebarEngineering

The invention relates to a high-seismic-resistance light high-intensity reinforced column and is characterized in that the high-seismic-resistance light high-intensity reinforced column is formed by depositing concrete after a reinforcement cage is assembled, wherein the reinforcement cage comprises four fission stirrups with equal sections, a center positioning stirrup, and longitudinal bards, the space between the external limbs of the two adjacent fission stirrups ranges from 25 mm to 200 mm; the center positioning stirrup is partially overlapped with the stirrup part of each limb of the four fission stirrups with equal sections, a plurality of longitudinal ribs are arranged on the inner sides of the fission stirrups and the positioning stirrup; at least one longitudinal rib is arranged in the overlapping part between the fission stirrup and the positioning stirrup, and the fission stirrup and the positioning stirrup are fixed into a whole; and the weights of the raw materials in the concrete are as follows: 130 kg / m3 to 180 kg / m of water, 160 kg / m3 to 500 kg / ms of cement, 50 kg / m3 to 250 kg / m of mineral admixtures, 100 kg / m3 to 400 kg / m of light aggregates, 300 kg / m3 to 900 kg / m of broken stones, 650 kg / m3 to 850 kg / m of sand, and 4 kg / m3 to 15 kg / m3 of water reducers. The high-seismic-resistance light high-intensity reinforced column has the advantages of high seismic performance, deformability, strong bearing capacity, and lightness.

Owner:WUHAN UNIV OF TECH

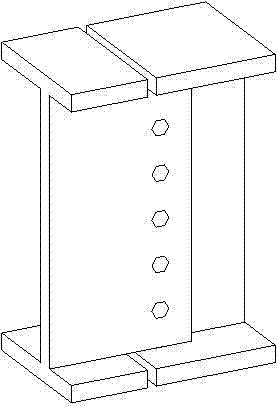

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

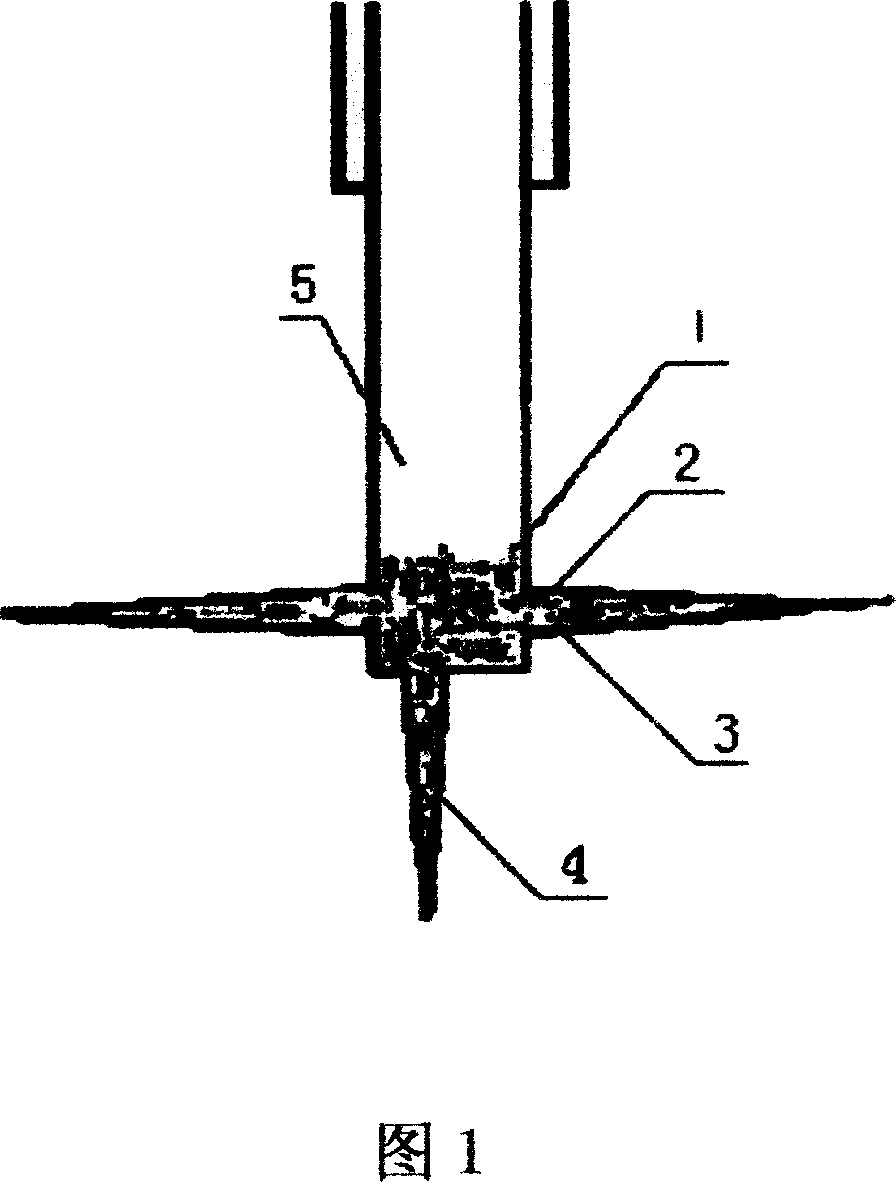

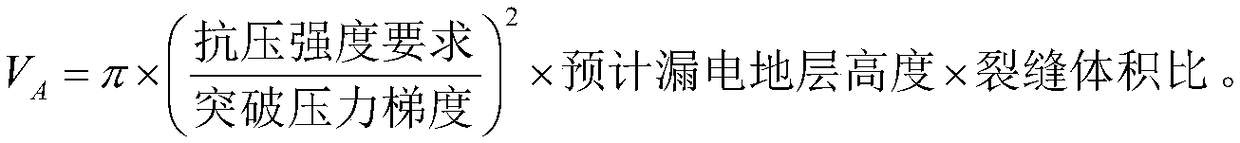

Filling and leakage blocking process for cracking leak gravel

InactiveCN1928319AThe betting process is simpleGuaranteed StrengthFluid removalSealing/packingCement pasteDrill bit

The invention relates to a plugging technology, especially plugging technology with gravel for cracking leakage. First 2-5t gravel with the uneven grain size is poured and entered gravel with different grade blocks relative crack. Then one drill extends to pull gravel out so that gravel enters into relative crack at the greatest level. Naked drill-stem extends to the position in 20-60m to the top layer of leakage layer and cement is injected. Because gravel is resorted in crack and cement paste flowing further is hindered cement plug is formed. The technology is used to solve extra crack leakage in Luohe formation of Longdong area, especially extra malignancy leakage with leakage amount more than 130 stere per hour, still fluid face less than 150m and bridge plug leakage stoppage so on.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

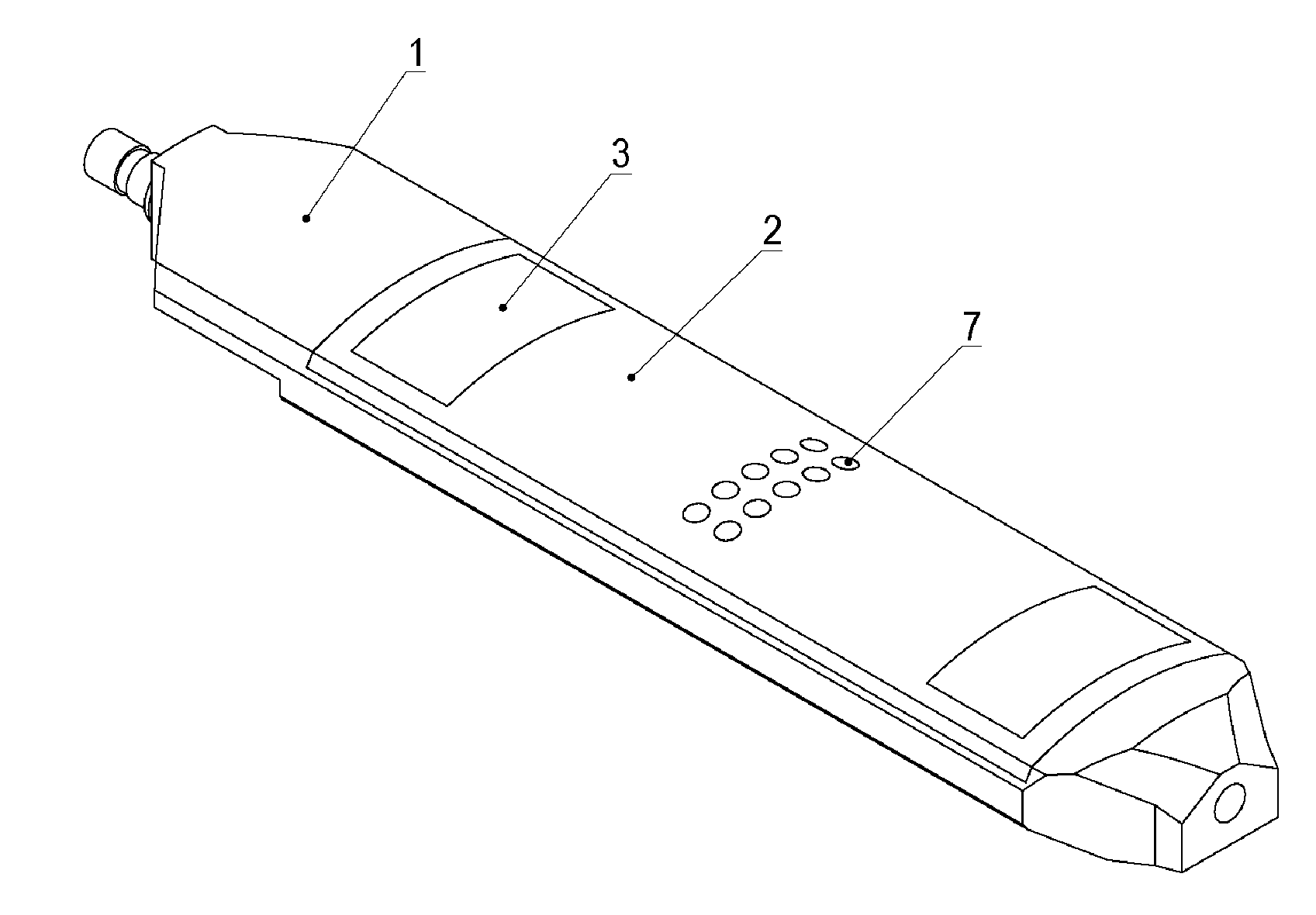

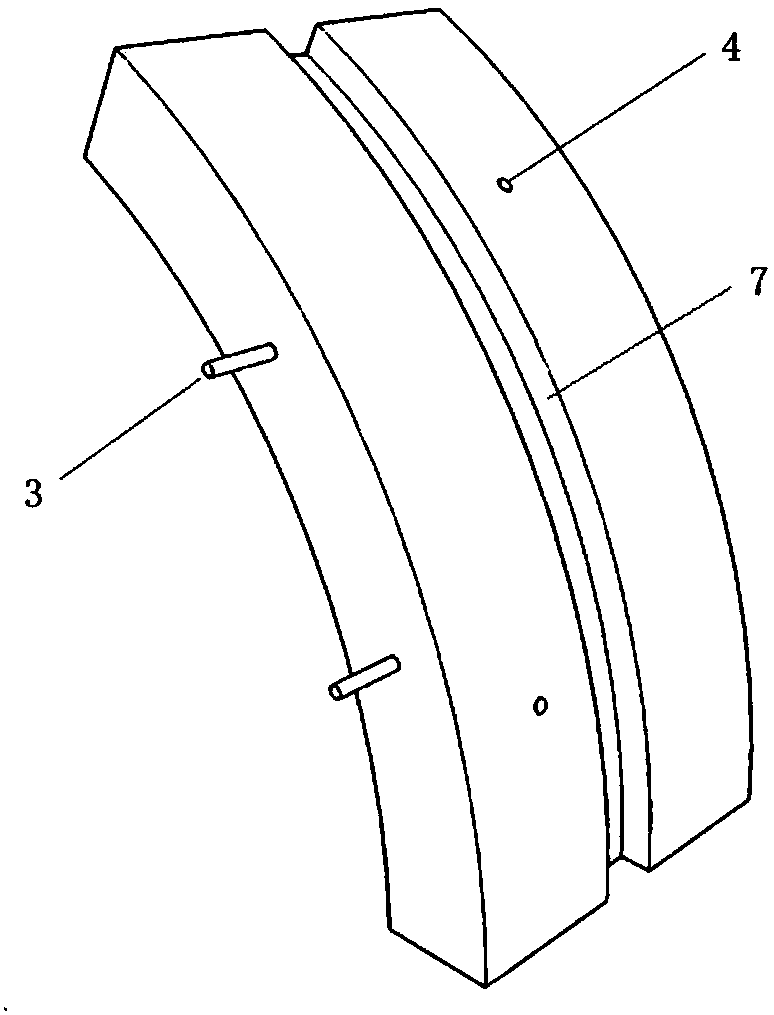

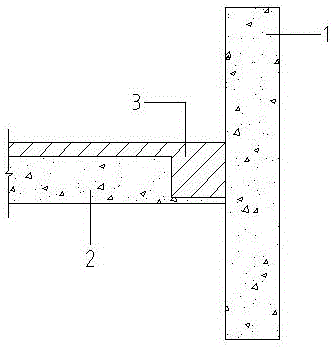

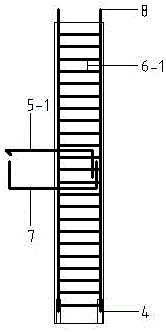

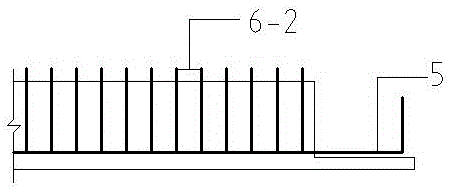

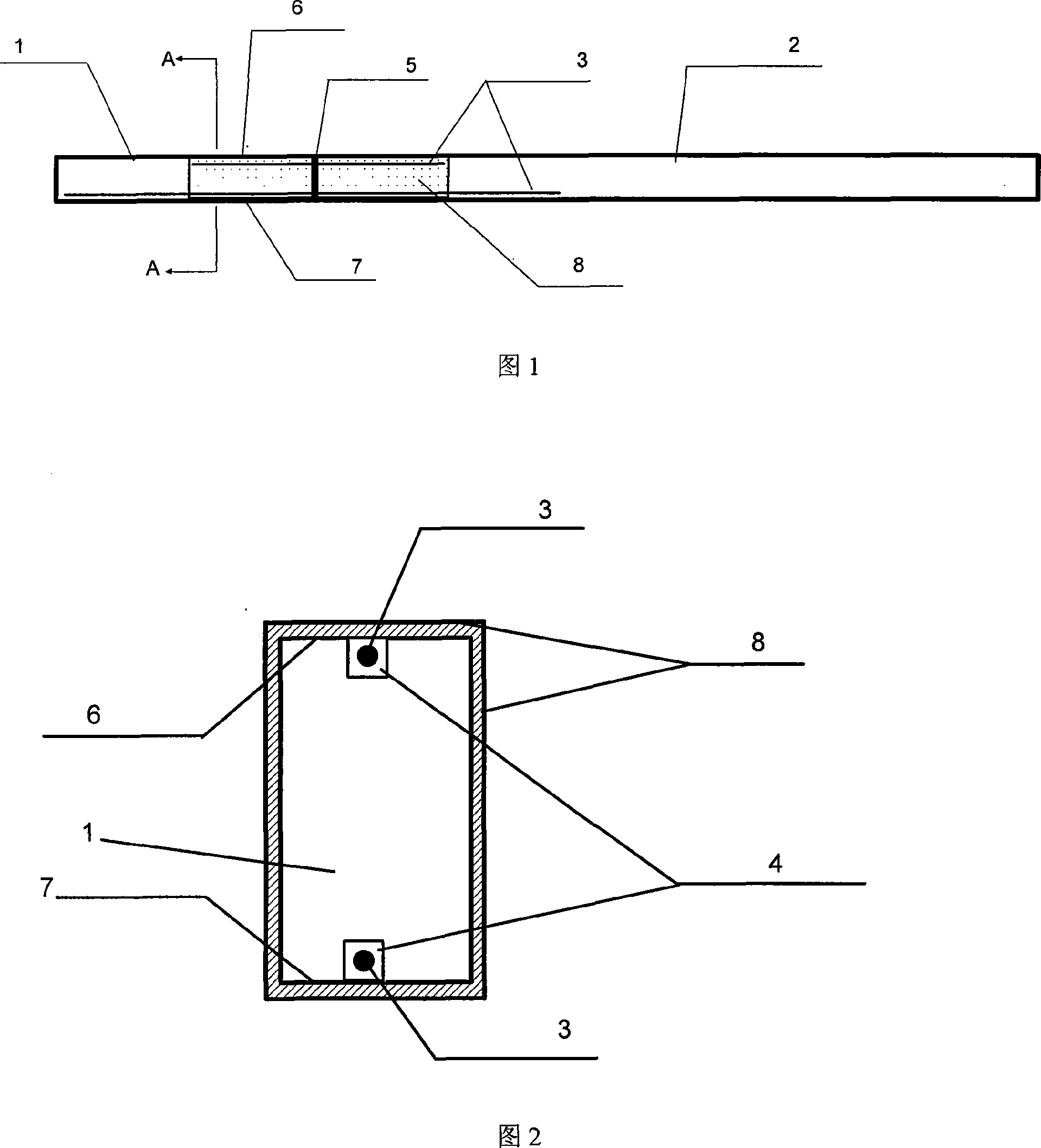

Pole plate electrode system for logging instrument

ActiveCN103726831AIncrease the areaGuaranteed insulation performanceConstructionsBorehole/well accessoriesEngineeringInstrumentation

The invention relates to a pole plate electrode system for a logging instrument. The pole plate electrode system for the logging instrument comprises an insulating plate (2), a pair of emission electrode plates (3) and electric buttons (7), wherein a pair of grooves is formed in the two ends of the insulating plate (2), the emission electrode plates (3) are transversely embedded into the grooves of the insulating plate (2), the electric buttons (7) are embedded into the middle of the insulating plate (2), and the emission electrode plates (3) are symmetrically arranged relative to the electric buttons (7).

Owner:CNPC GREATWALL DRILLING ENG

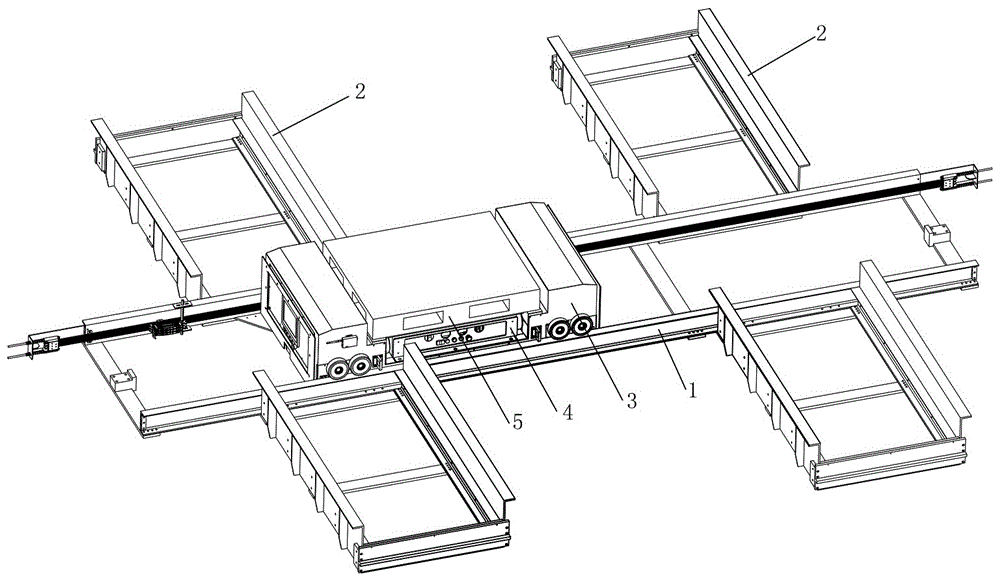

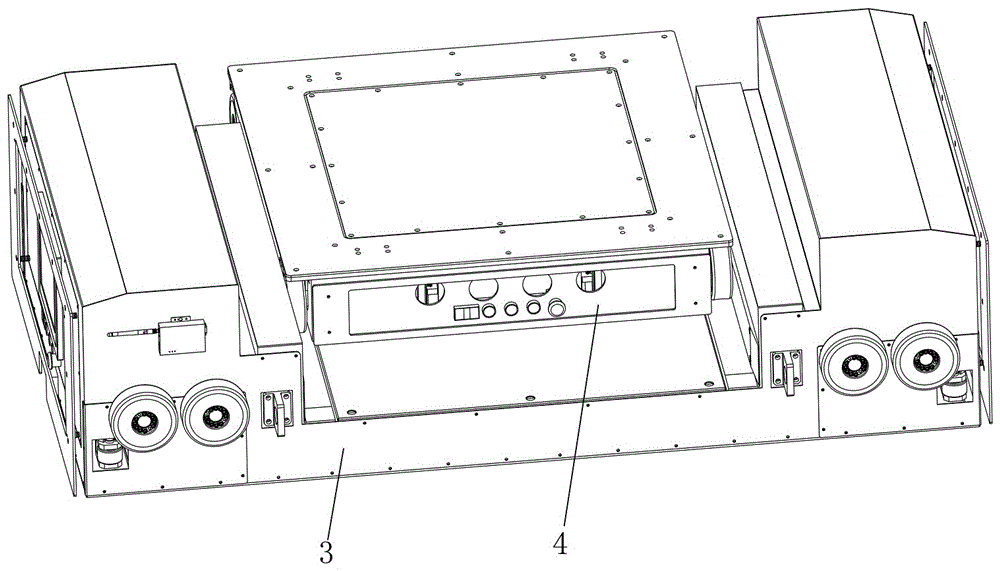

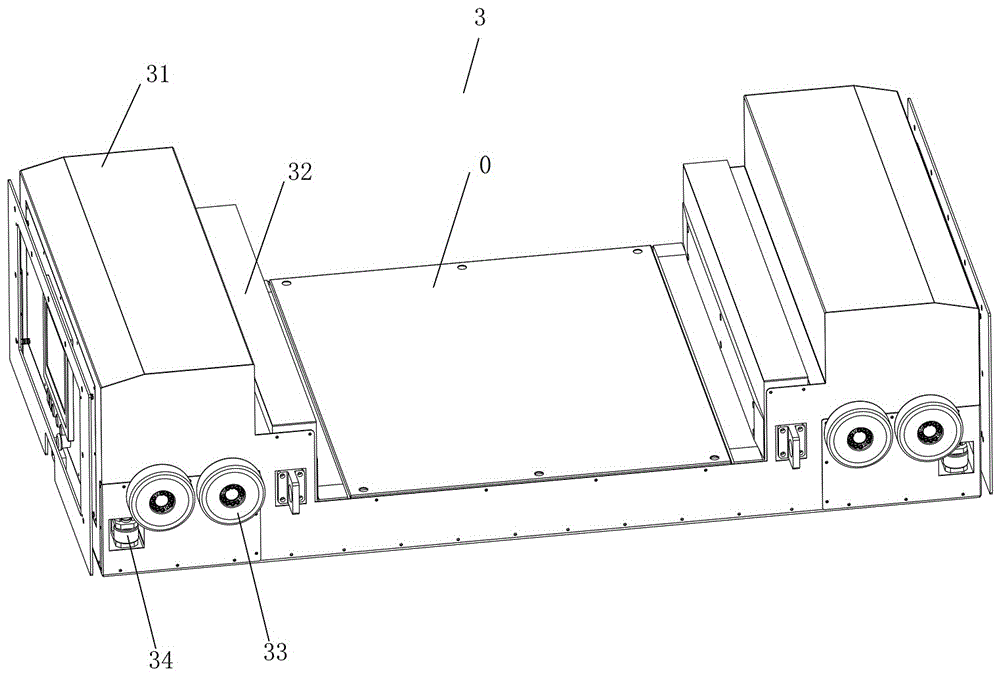

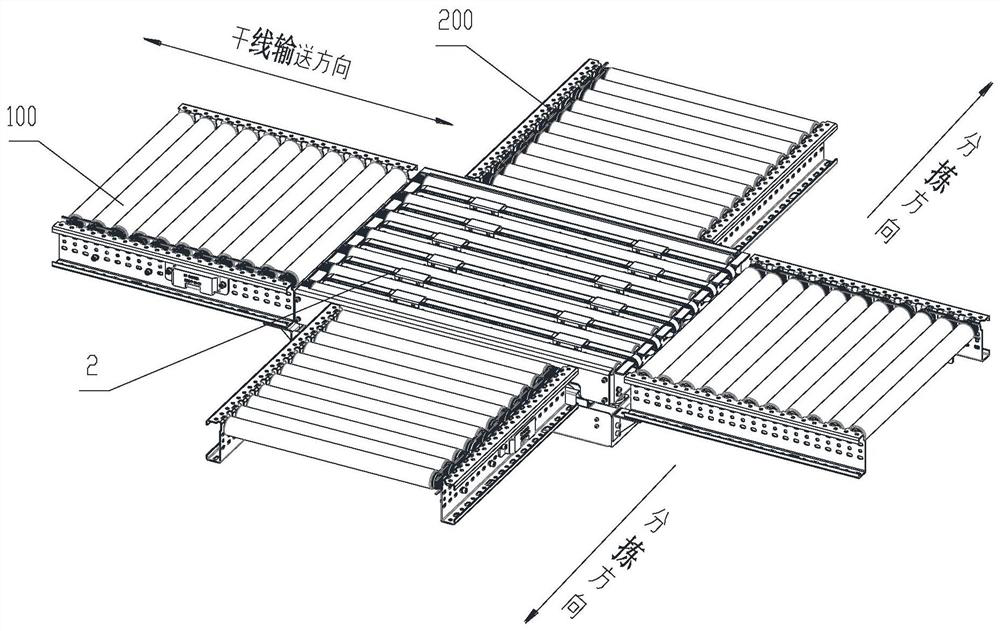

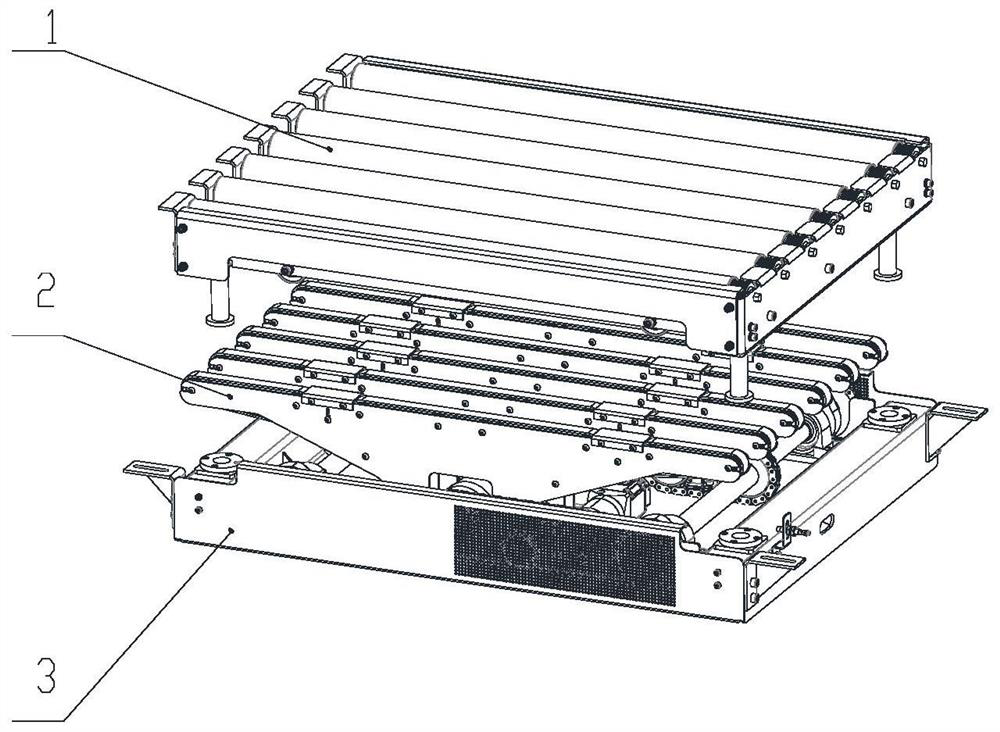

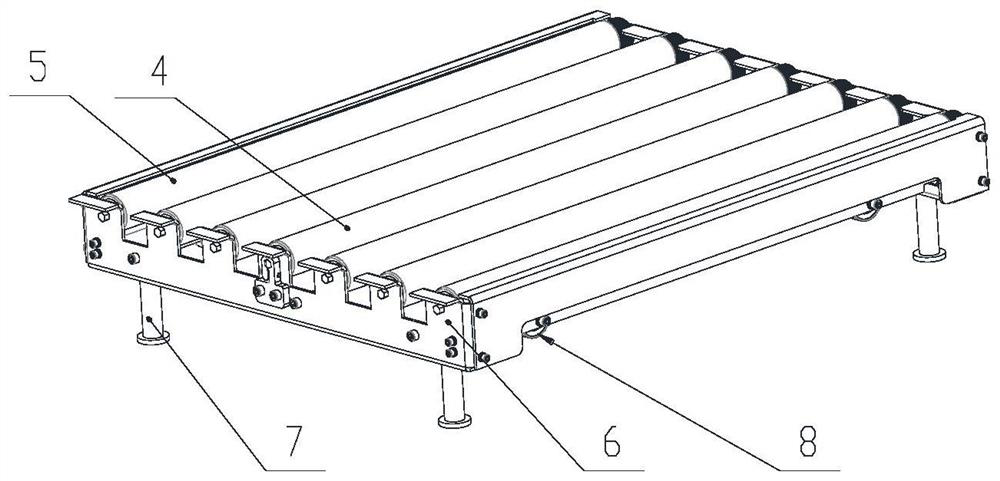

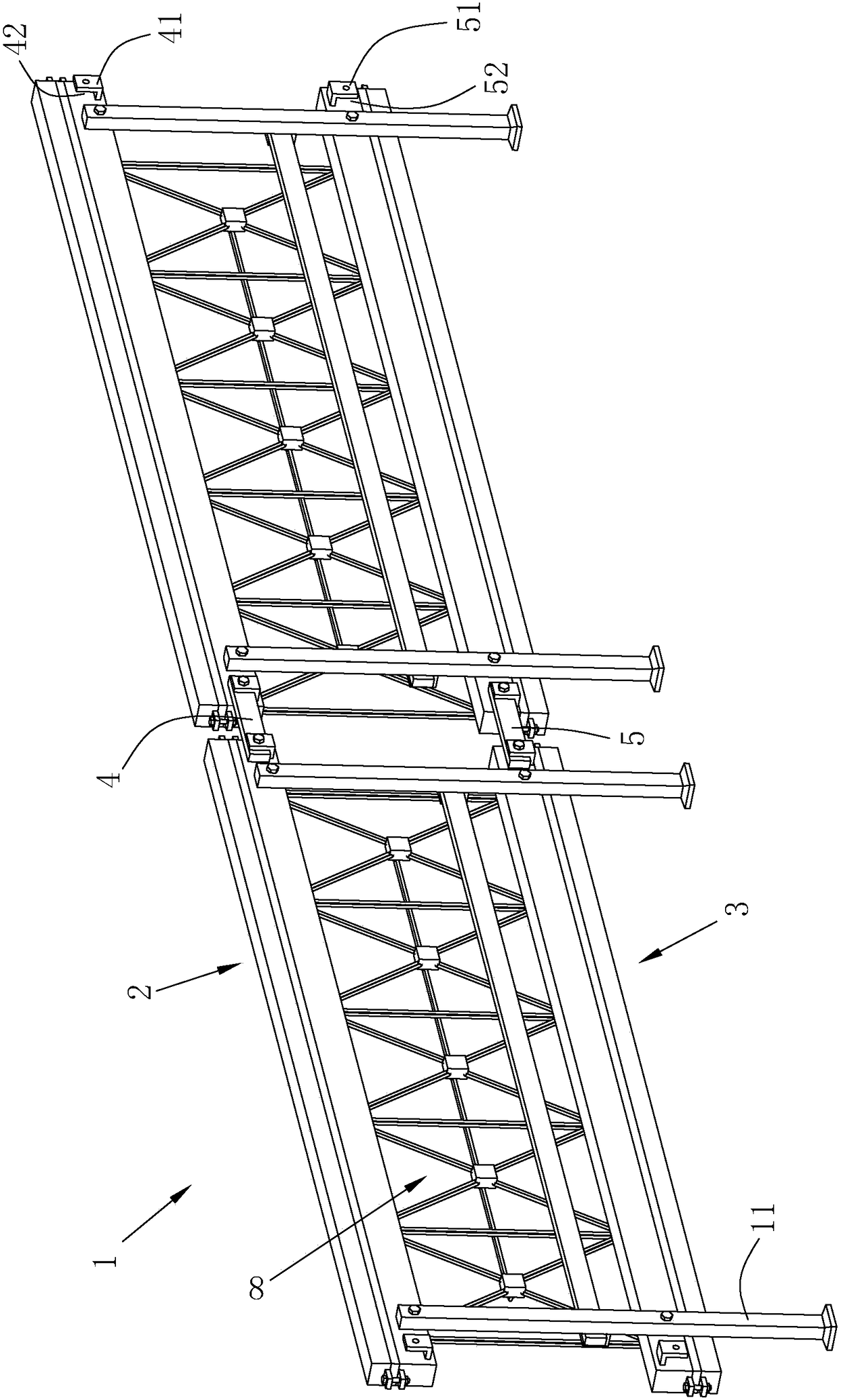

Shuttle child-mother vehicle for automatically carrying materials in and out from warehouse

InactiveCN106429156AImprove carrying capacityGuaranteed stabilityStorage devicesAutomotive engineering

The invention discloses a shuttle child-mother vehicle for automatically carrying materials in and out from a warehouse. The shuttle child-mother vehicle comprises at least two lanes spaced in parallel, and rails vertically connected to two sides of the lanes; and the lanes and the rails form material transportation rails. The shuttle child-mother vehicle further comprises a mother vehicle, and a child vehicle slidingly arranged on the mother vehicle; the mother vehicle is arranged on the lanes, and linearly slides along the lanes in a reciprocating manner; a child vehicle groove inwards recessed is formed in the middle part of the mother vehicle; slide ways are respectively formed in two sides of the child vehicle groove; the child vehicle is arranged in the child vehicle groove; child wheels on two sides of the child vehicle are put on the slide ways for supporting the child vehicle; a walking module and an ejecting module are arranged in the child vehicle, and adopt independent driving mechanisms; the walking module drives the child vehicle to linearly slide on the slide ways or the rails; and the ejecting module drives an object carrying plate to lift in the vertical direction. The shuttle child-mother vehicle matches the mother vehicle with the child vehicle to realize full-automatic material carrying, effectively promotes the carrying efficiency, and reduces the carrying cost.

Owner:SHENZHEN XING GRAIN AUTOMATION CO LTD

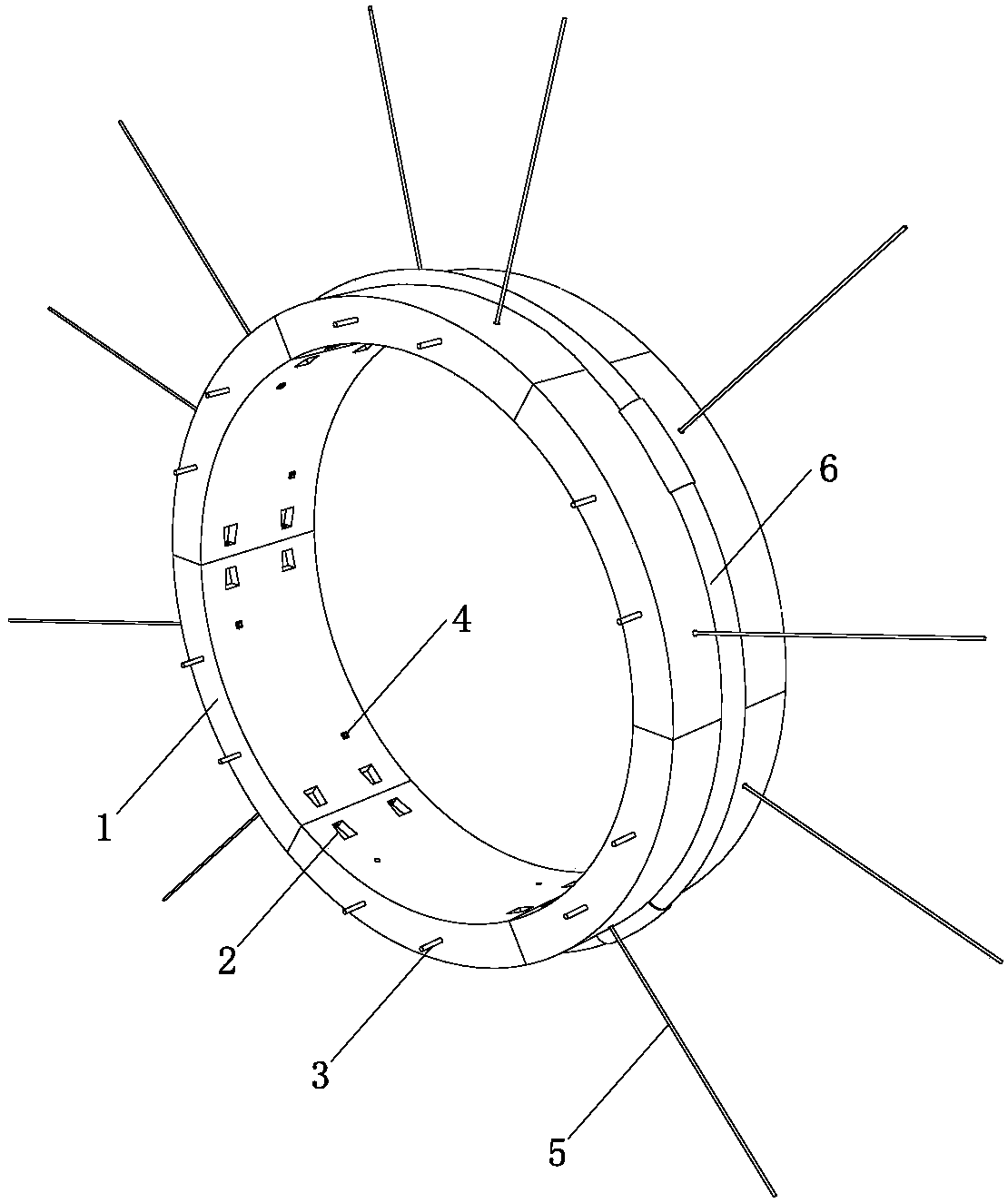

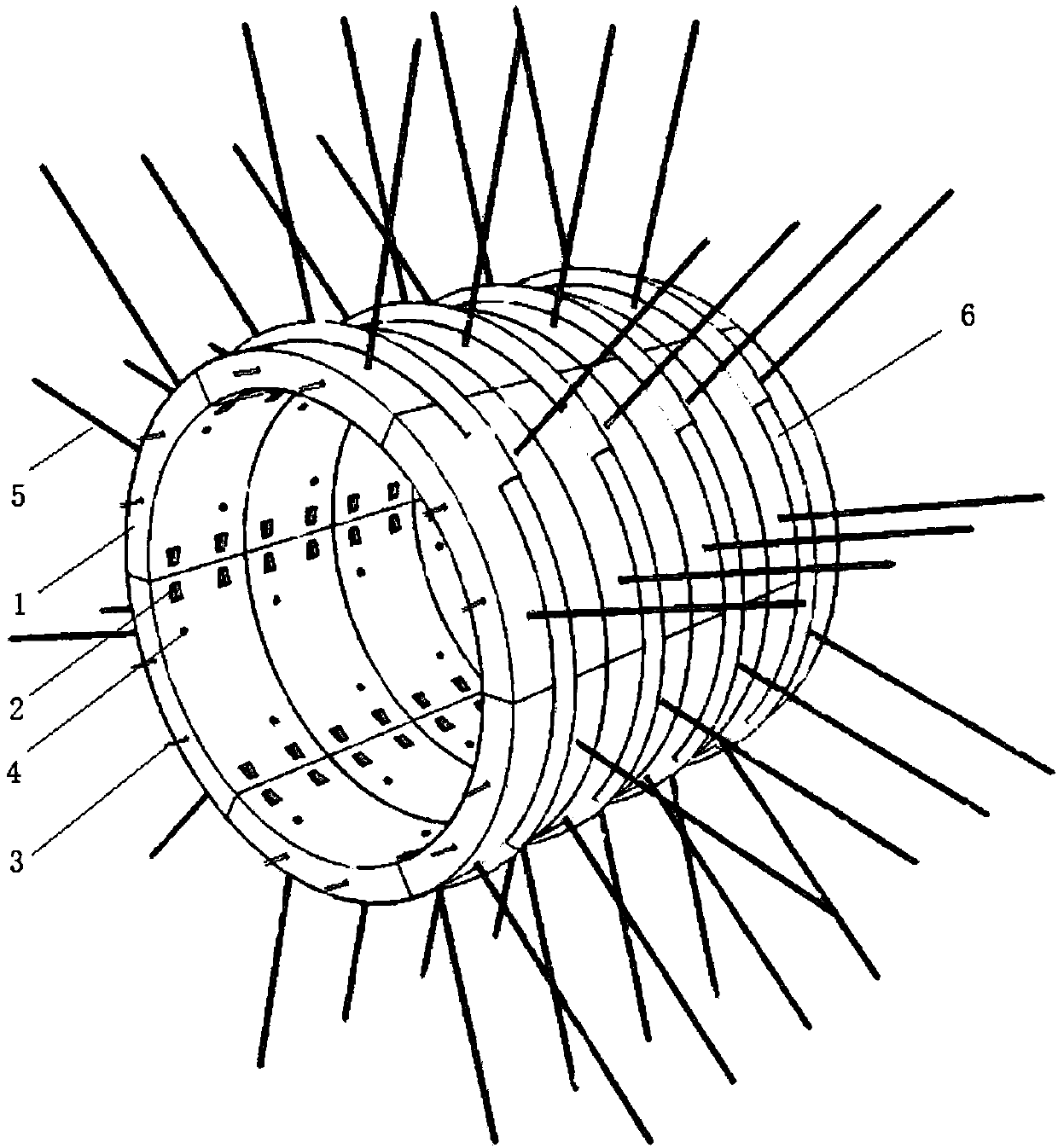

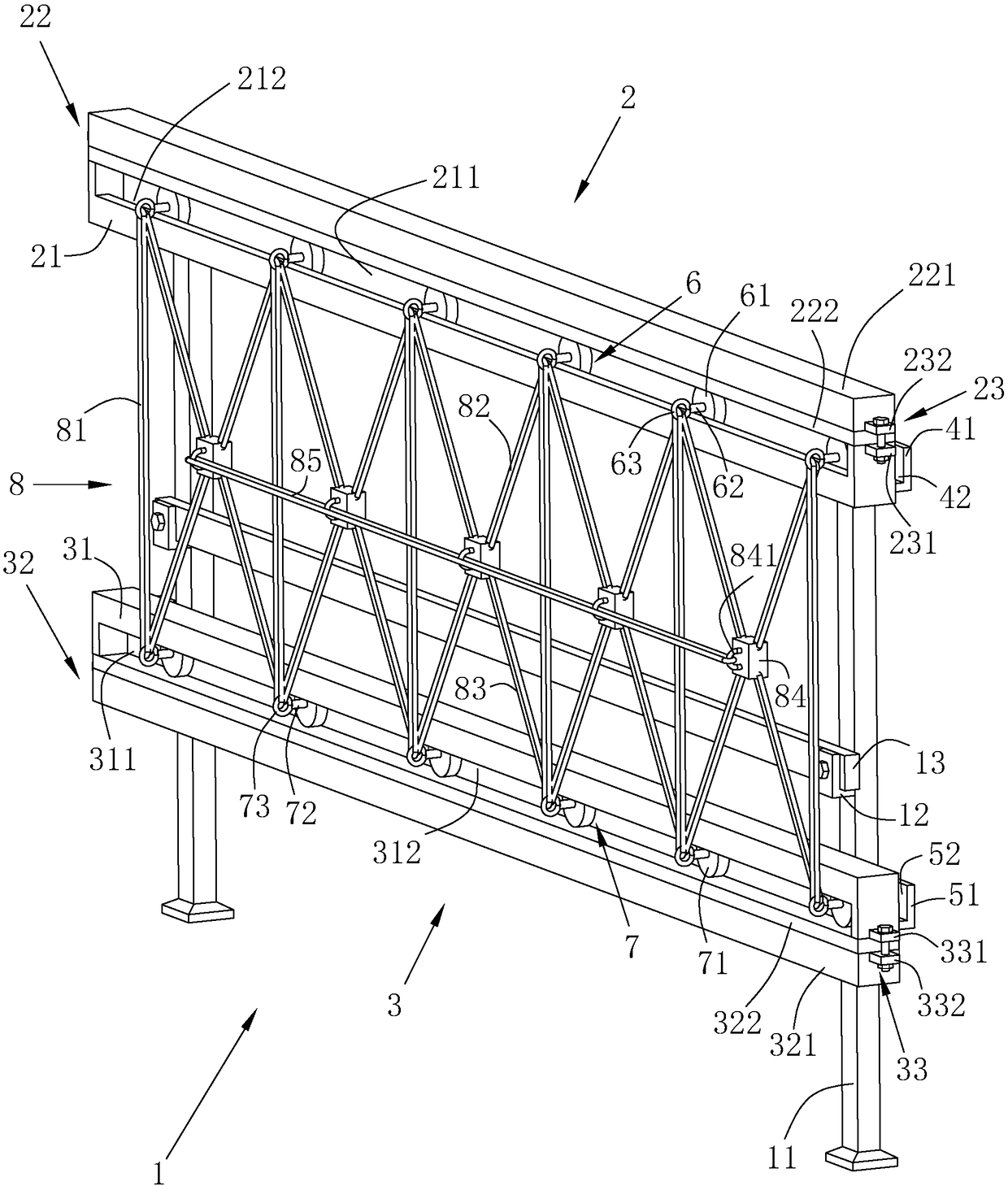

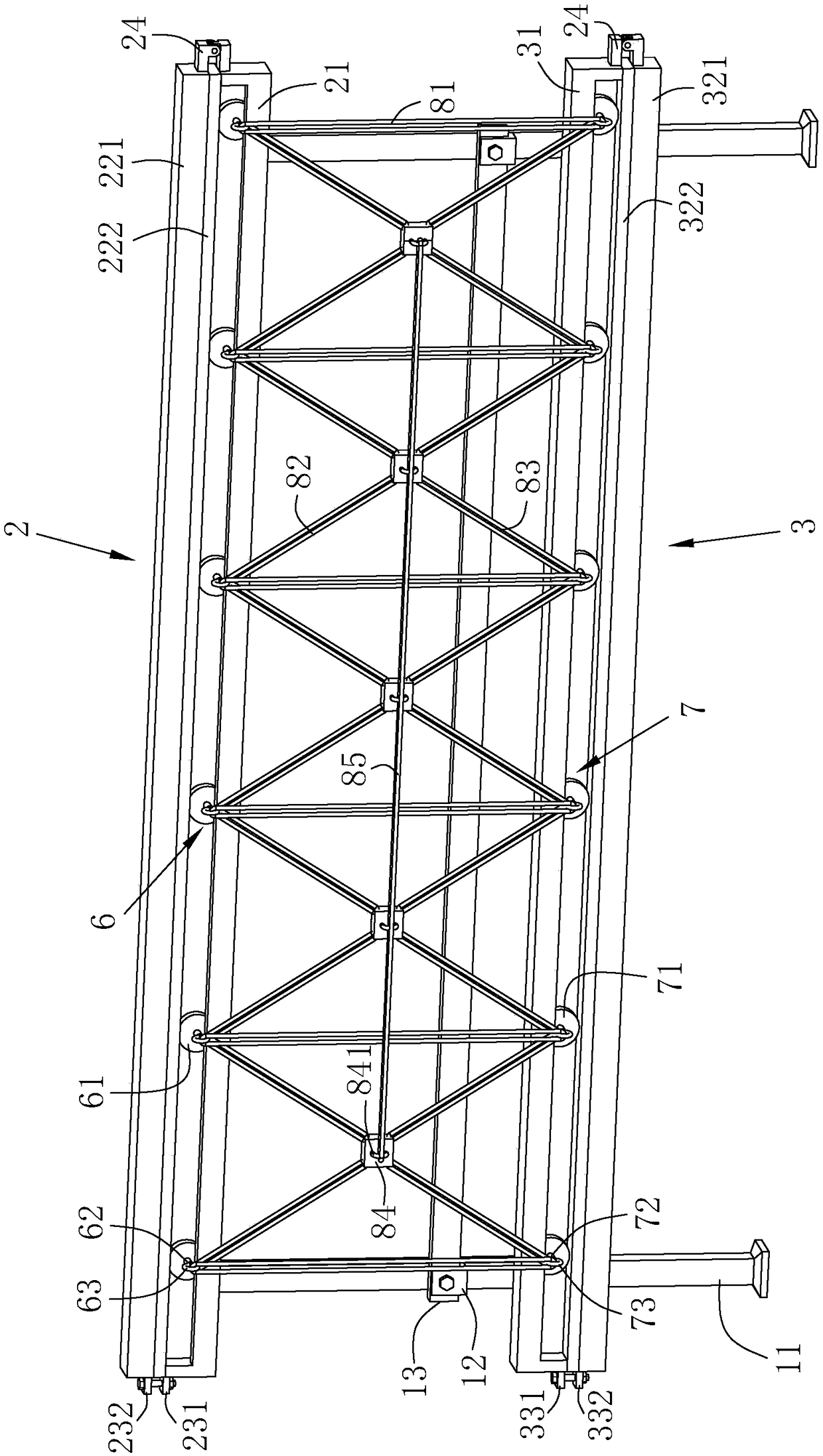

Assembled type support and protection structure based on outer steel arch and inner concrete plate and construction method of assembled type support and protection structure

The invention relates to an assembled type support and protection structure based on an outer steel arch and an inner concrete plate. The assembled type support and protection structure comprises a steel arch and a concrete support, wherein the concrete support is of a multi-piece arced plate assembling structure; the steel arch is arranged on the outer side of the concrete support; the concrete support and the steel arch are fixed on surrounding rock of a roadway / tunnel through anchor rods. By adopting the composite support and protection structure provided by the invention, the reinforced steel concrete casting and maintenance time is saved on the basis that a relatively large bearing force is ensured, and the support and protection construction speed is greatly increased. By adopting the assembled type support and protection structure, a novel technical way is provided for support and protection of deep well roadways and soft rock roadways, and a novel support and protection methodis provided for the field of roadway / tunnel support and protection.

Owner:SHANDONG JIANZHU UNIV

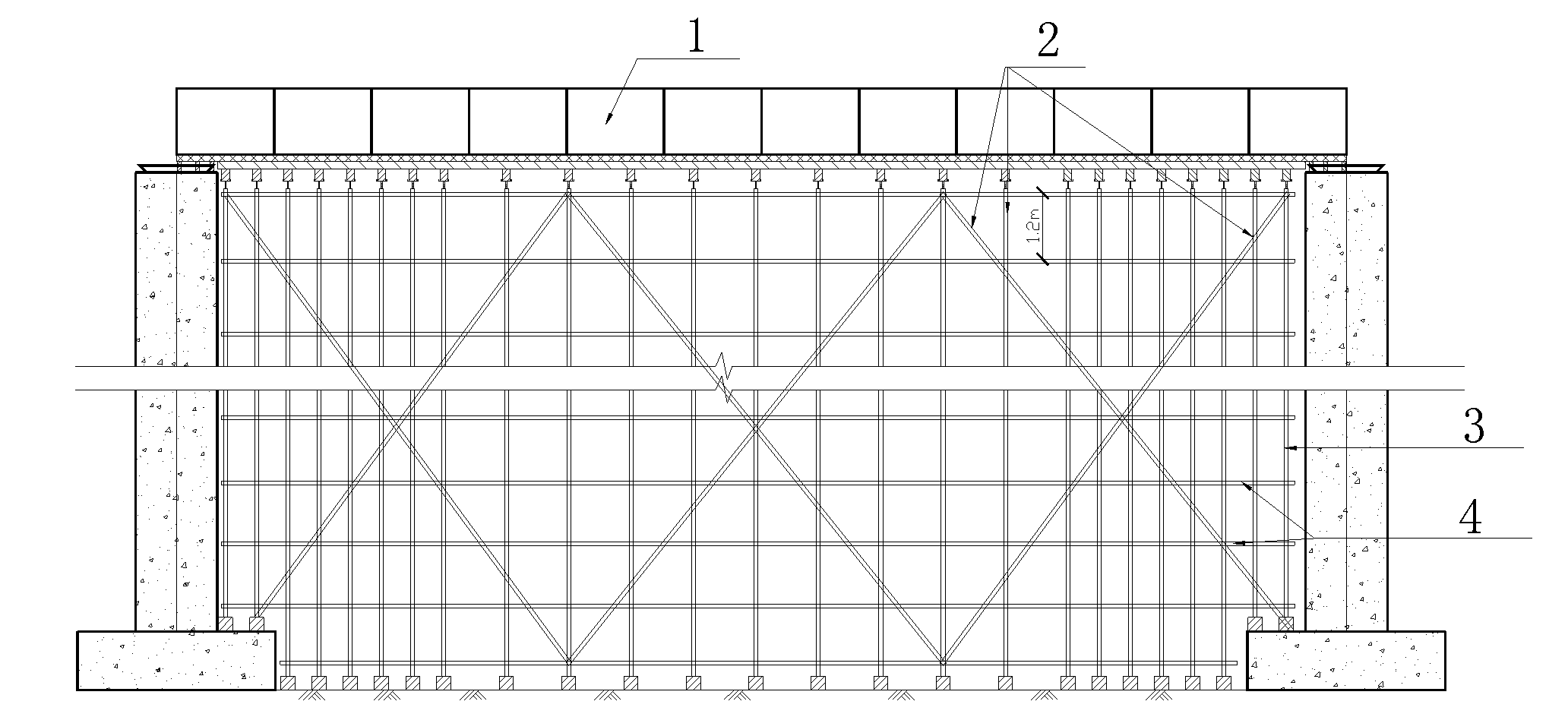

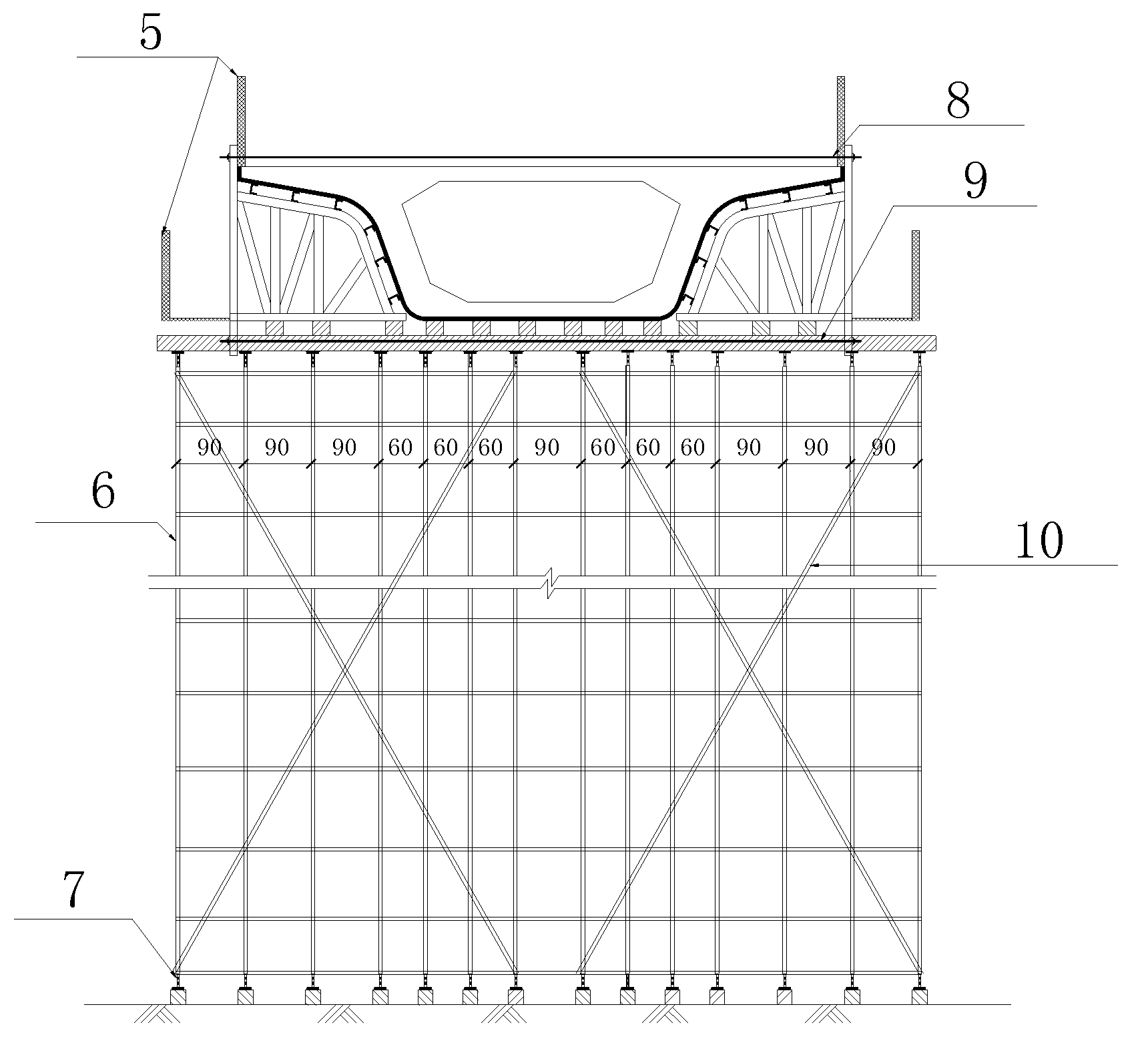

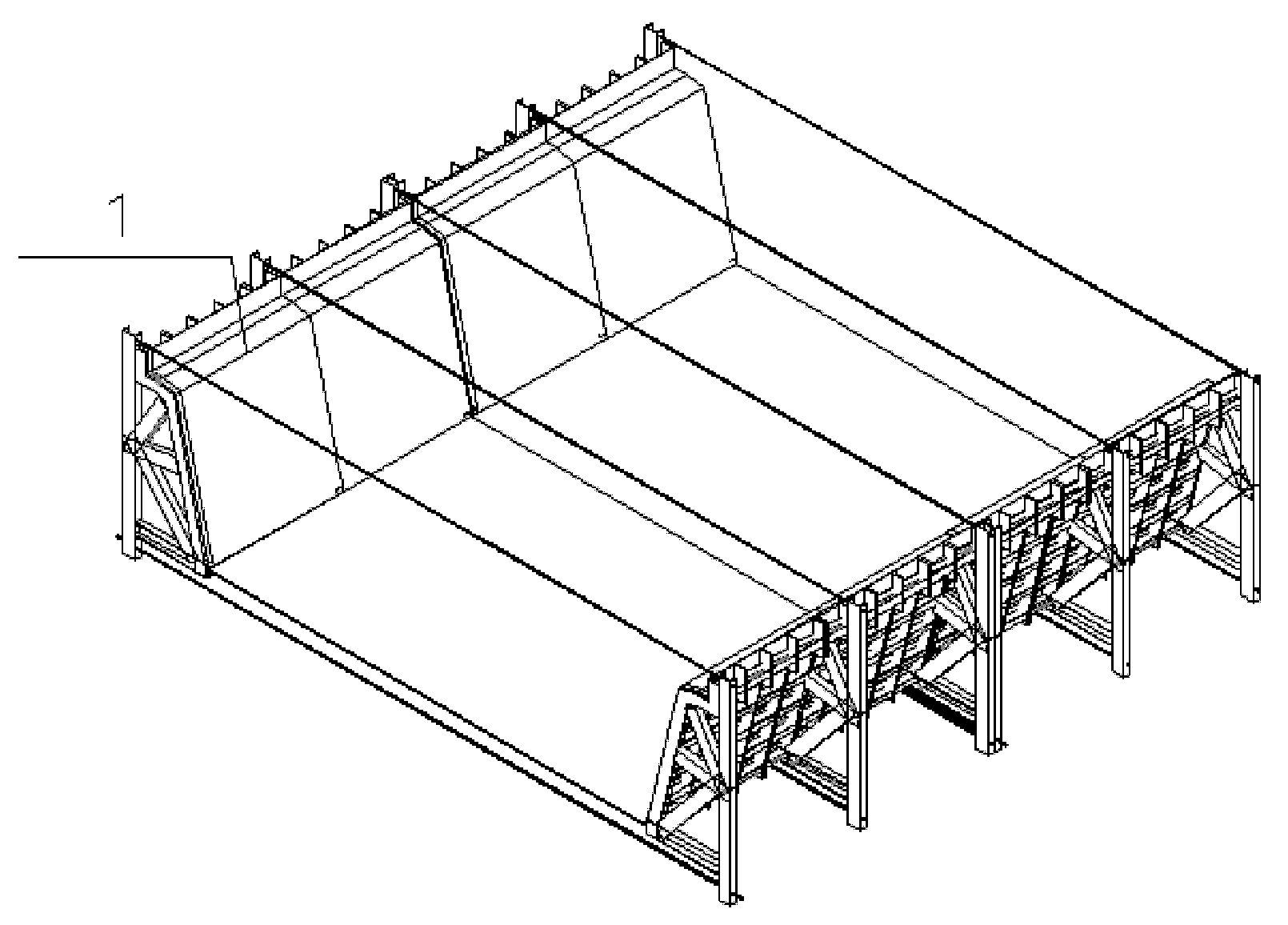

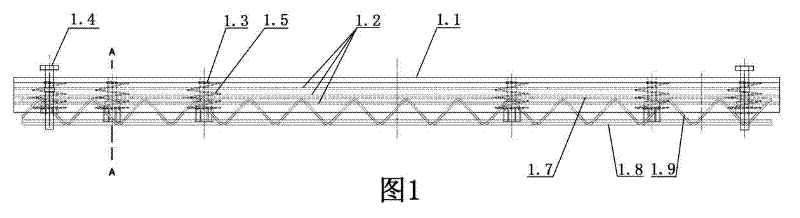

Construction method of bridge cast-in-place box beam

InactiveCN102121233AGuaranteed bearing capacityReduce in quantityBridge erection/assemblyManufacturing technologyHeat transmission

The invention relates to a construction method of a bridge cast-in-place box beam, belonging to the technical field of bridge construction. The construction method of a bridge cast-in-place box beam is characterized in that components are isolated from a furnace heating element by using a metal material when the components are heated in a furnace mainly based on radiation heat transmission so that the components are subjected to thermal treatment under a uniform heating condition. The construction method is simple, easy to realize, scientific and reasonable in design, convenient in operation, practical and economic; the components are uniformly heated during thermal treatment; and the construction method has the advantages of excellent quality and wide application range, and can be used for effectively improving the performance of metal materials.

Owner:天津第三市政公路工程有限公司 +1

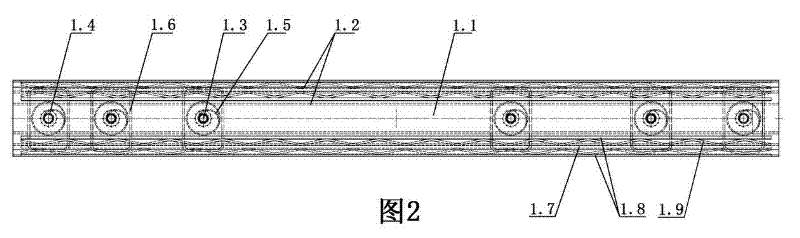

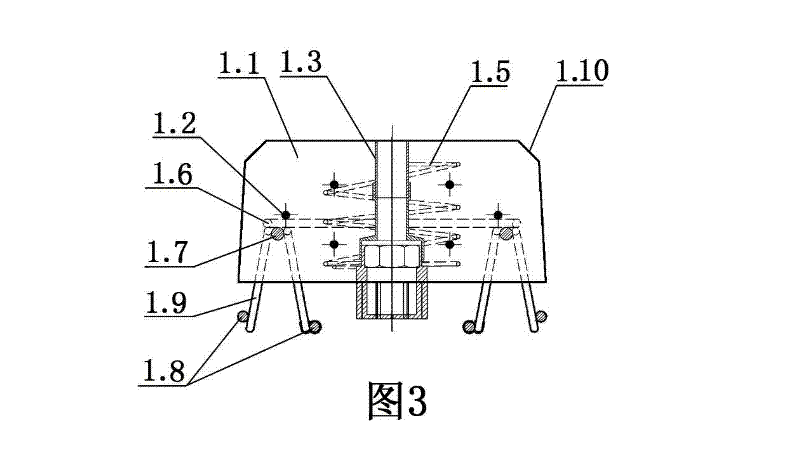

High-speed turnout switch tie for speed of 350km per hour and manufacturing method thereof

ActiveCN102162209AImprove bearing capacityHigh strengthRail switchesCeramic shaping apparatusAutomatic controlUltimate tensile strength

The invention discloses a high-speed turnout switch tie for speed of 350km per hour and a manufacturing method thereof. The method comprises the following steps of: 1, installing a template; 2, laying steel wires; 3, laying end plates; 4, installing sleeves and laying separators; 5, laying fittings; 6, starting a computer to automatically control the tensioned steel wires; 7, performing final tension; 8, fastening the separators, and binding the fittings; 9, putting an ash bucket and concrete into a die; 10, vibrating; 11, detaching the separators and partition plates; 12, clearing the production line; 13, curing; 14, performing concrete stripping; 15, tensioning; 16, breaking the wires, and stripping; 17, spraying, treating the sleeves, and cutting the exposed ribs; 18, clearing the die and the parting agent; and 19, warehousing. Accurate control of distribution quantity, uniform distribution and high speed are realized, stirring uniformity and concrete compactness are realized in automatic distribution, and the strength of the switch die is ensured.

Owner:中铁十四局集团房桥有限公司

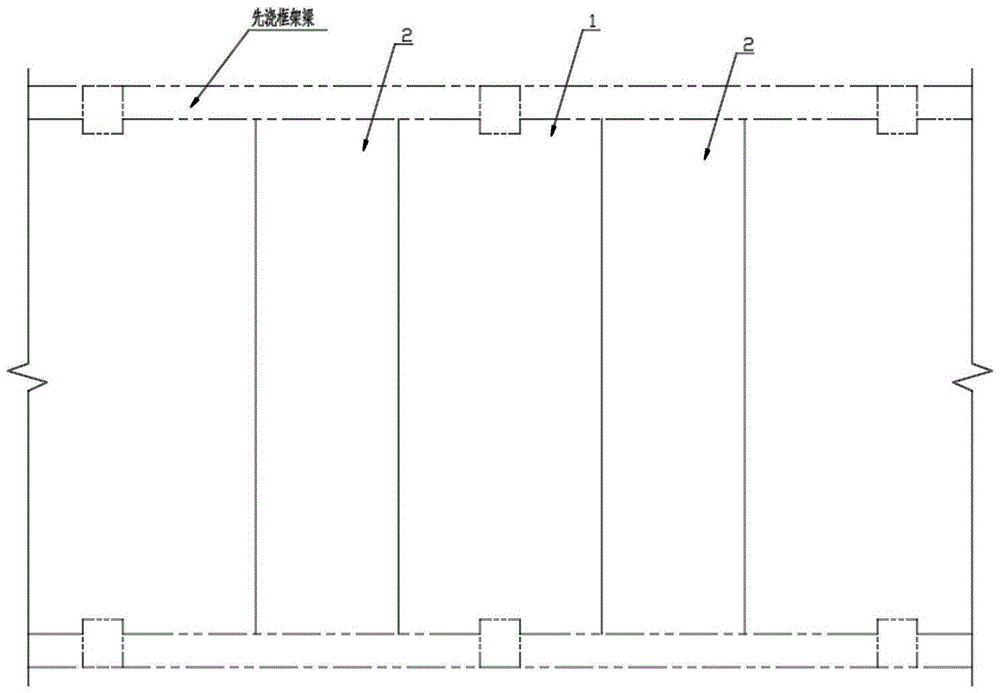

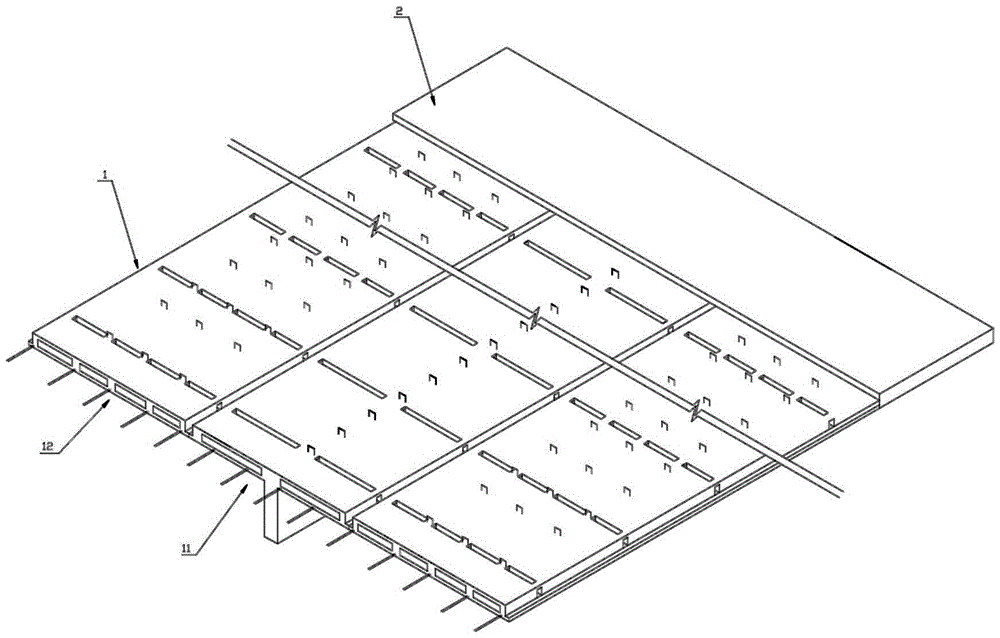

Overlapped floor

The invention discloses an overlapped floor which comprises a plurality of prefabricated reinforced concrete panels and T beam plates. At least one panel is spliced between every two adjacent T beam plates, and the prefabricated reinforced concrete panels and the T beam plates form the integral overlapped floor through post-poured reinforced concrete overlapped layers. According to the overlapped floor, due to the prestress technology and a bidirectional dense rib sandwiching structure form, the use amount of concrete is reduced, dead load is reduced, cost is reduced, and the rigidity and the bearing force of the overlapped floor are improved. Longitudinal rib belts and transverse rib belts are poured through lightweight aggregate structure heat insulation concrete so that the thermal bridge influences on the longitudinal rib belts and the transverse rib belts can be reduced, and meanwhile light filling blocks are matched for improving the heat insulation capability of the overlapped floor. When the overlapped floor is used, the T beam plates and the panels are arranged on a pre-pouring frame beam, and then the integral overlapped floor is formed after post-pouring of the reinforced concrete overlapped layers. The dead load is not increased, the bearing force is ensured, the shearing resisting capability of connecting points is ensured, and meanwhile heat preservation and heat insulation can be achieved; under the premise that the integrity and safety of the overlapped floor are ensured, the construction cost is reduced, and construction is simplified.

Owner:HUNAN DONGFANGHONG CONSTR GRP

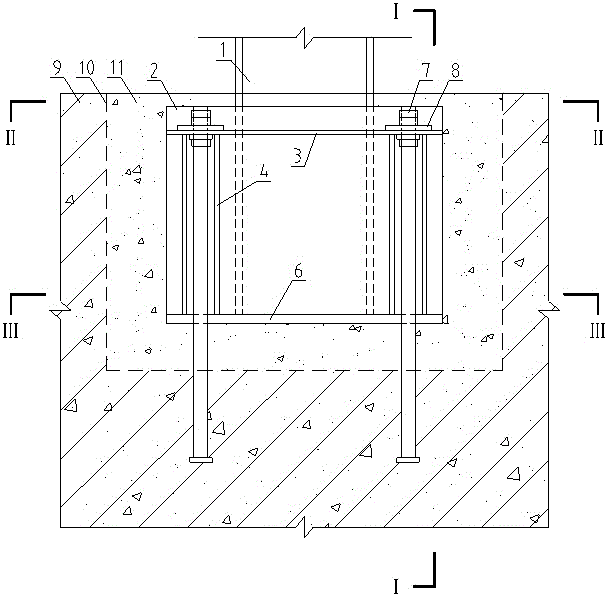

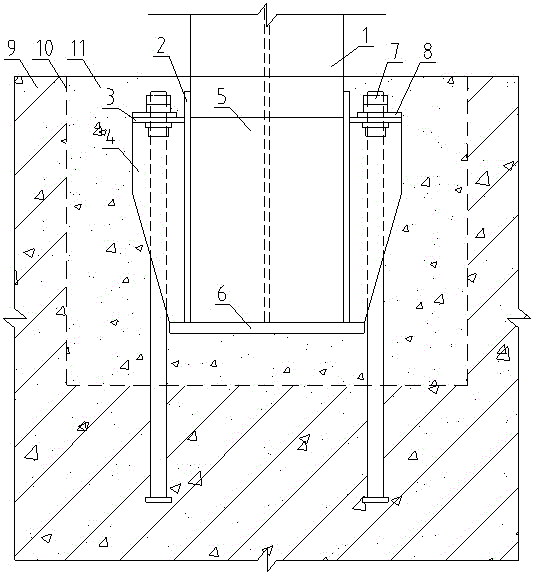

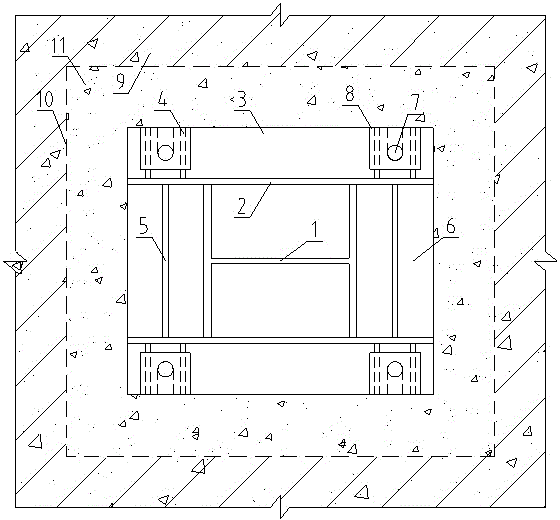

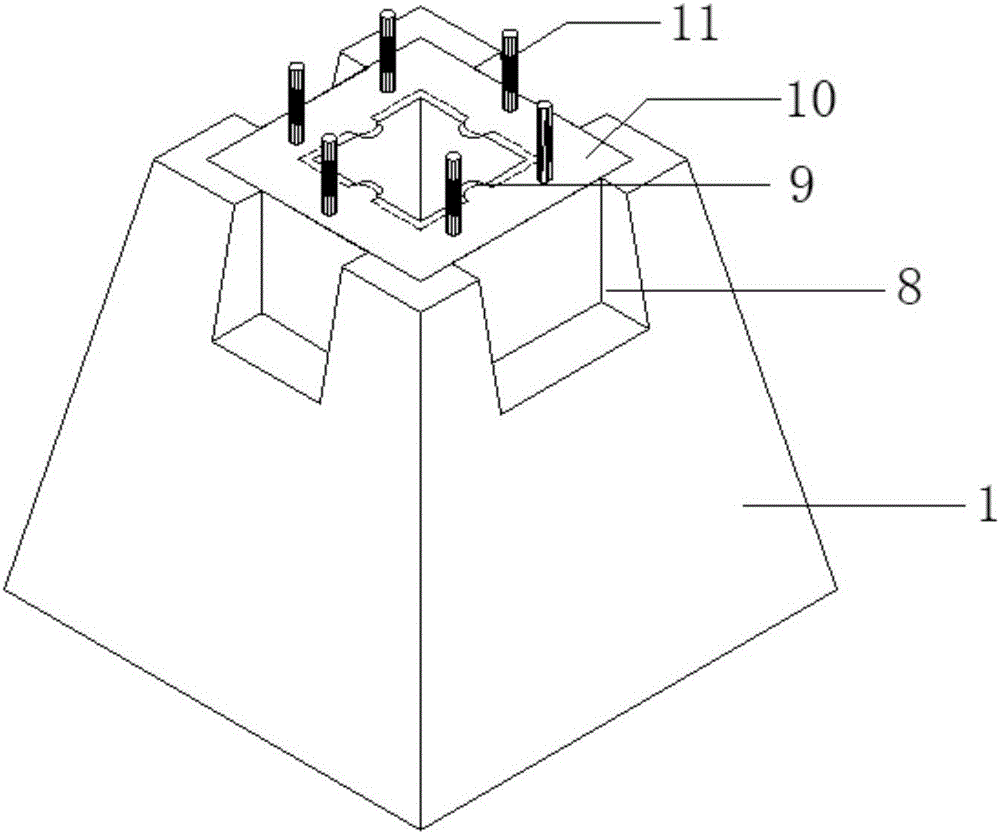

Whole body embedded type rigid pedestal and construction method thereof

ActiveCN104963354AGuaranteed stiffnessGuaranteed bearing capacityFoundation engineeringReinforced concreteWhole body

The invention relates to a whole body embedded type rigid pedestal and a construction method thereof. The whole body embedded type rigid pedestal comprises a steel column, boot-beam plates, cross plates, rib plates, partition plates, a pedestal base plate and anchor bolts, wherein the steel column is embedded in a reinforced concrete foundation, the base plate is arranged on the bottom of the pedestal, the boot-beam plates are welded to a steel column flange and the pedestal base plate, the cross plates are horizontally welded to the outer sides of the boot-beam plates, the rib plates are welded to the boot-beam plates, the cross plates and the pedestal base plate, the partition plates are welded to the boot-beam plates and the pedestal base plate, and the anchor bolts are symmetrically arranged on the outer sides of the two boot-beam plates within the range of the cross plates. According to the whole body embedded type rigid pedestal, the integral rigid pedestal is embedded in the reinforced concrete foundation, and the effective bearing area of the embedded portion of the pedestal is increased by arranging the boot-beam plates; the tensile effect of the anchor bolts is effectively utilized, transmission of bending moment and shearing force borne by pedestal joints is facilitated, pedestal embedding depth can be reduced on the premise that the overall rigidity, bearing force and anti-seismic property of the pedestal are guaranteed, and economical effectiveness is high in engineering practice.

Owner:黄冀卓 +1

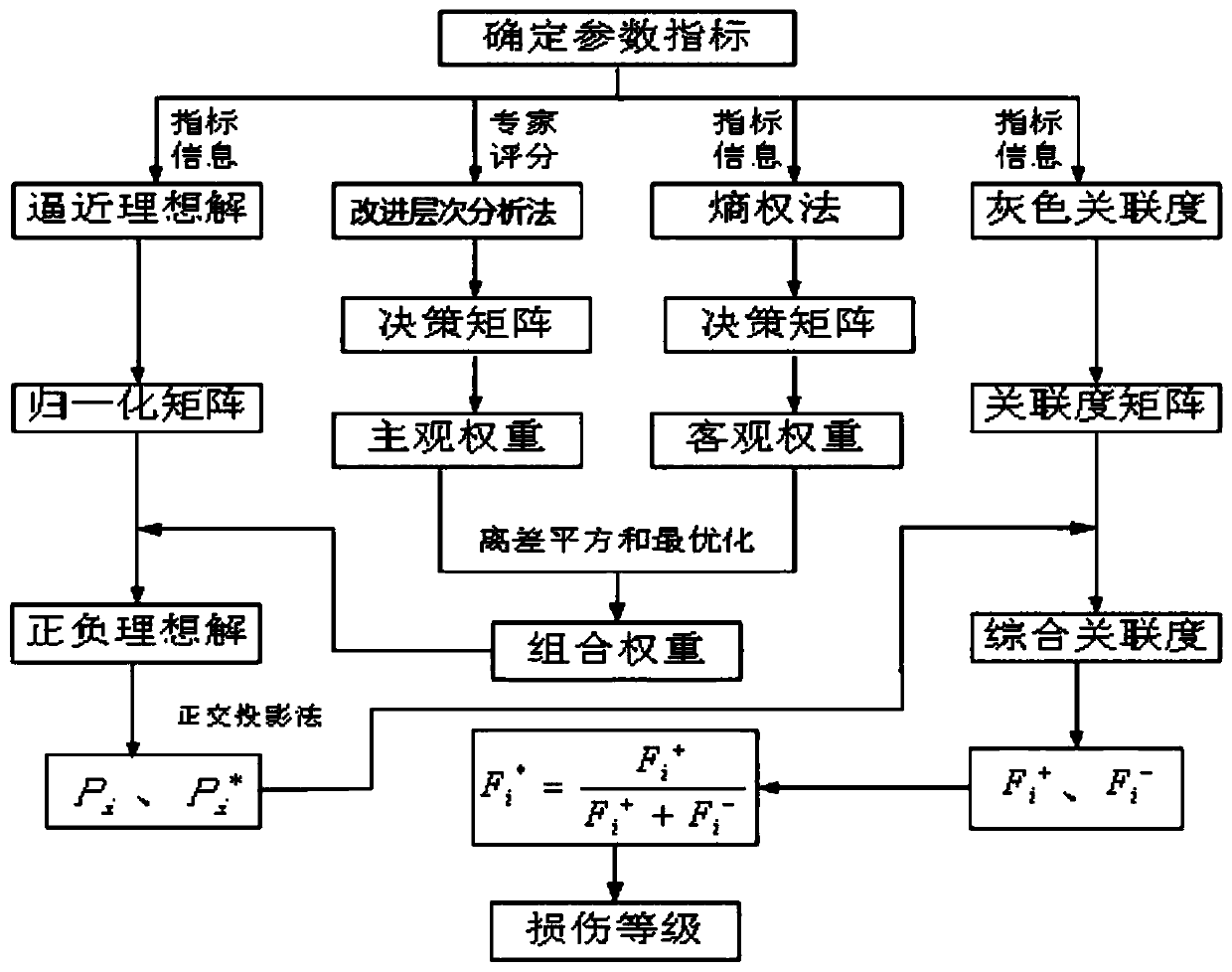

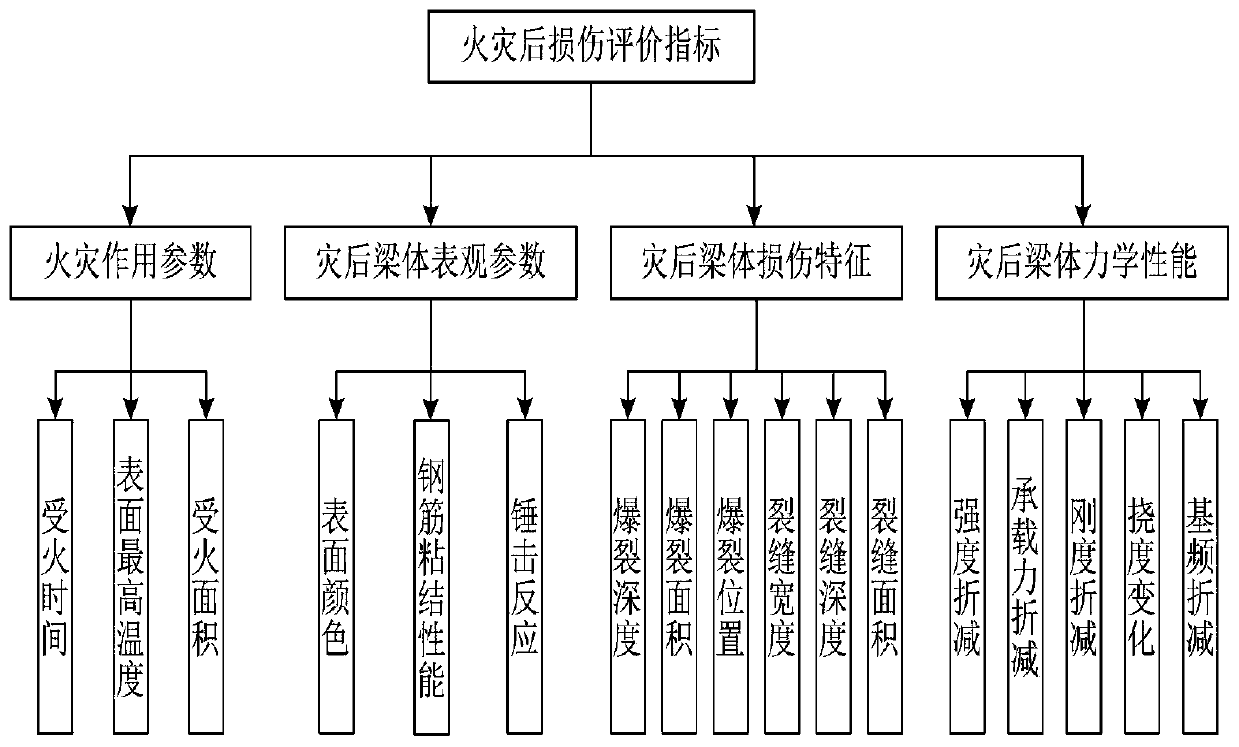

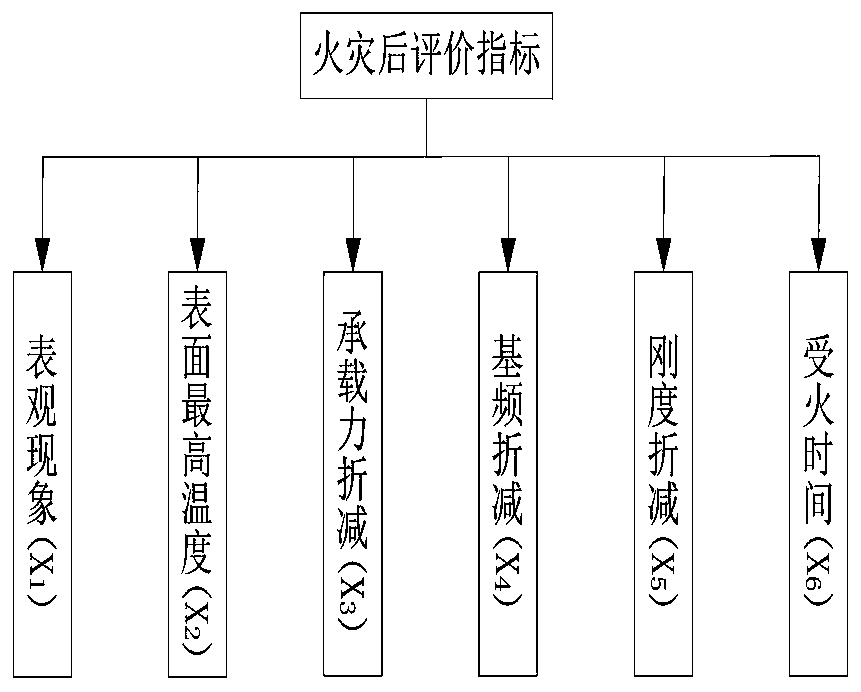

Concrete T-shaped beam post-fire damage evaluation method

ActiveCN111598448AAvoid damageGuaranteed bearing capacityResourcesComplex mathematical operationsEvaluation resultShaped beam

The invention discloses a concrete T-shaped beam post-fire damage evaluation method, and relates to the technical field of post-fire building damage grade evaluation methods, and the concrete T-shapedbeam post-fire damage evaluation method comprises the following steps: 1, determining parameter indexes; 2, according to the determined parameter indexes, obtaining the comprehensive closeness of each evaluation object by utilizing a plurality of evaluation methods, wherein the multiple evaluation methods comprise an improved analytic hierarchy process, an entropy weight method, an approximate ideal solution, a deviation quadratic sum optimization method, a grey relational degree method and an orthogonal projection method; and 3, finally determining the damage grade of the building accordingto the comprehensive relative closeness of each evaluation object. According to the concrete T-shaped beam post-fire damage evaluation method, a set of comprehensive evaluation system of a grey relational degree correction improved approximate ideal solution (MTOPSIS-GRA) method based on the optimal combination weight is established, so that the evaluation result is more objective, and the technical defects of the evaluation method in the prior art are avoided, and the concrete T-shaped beam post-fire damage evaluation method is suitable for engineering application and popularization.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

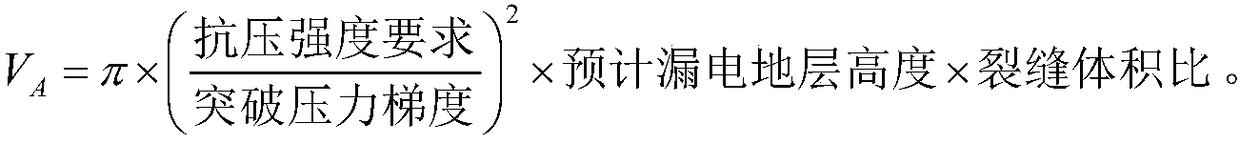

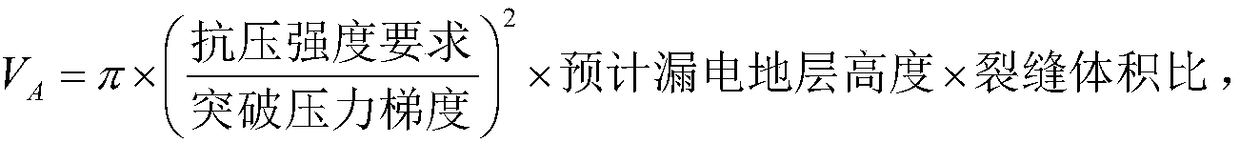

Treatment method for casing channeling and casing leakage of oil and gas production well

PendingCN108756806AGood sealingConducive to anti-channelingDrilling compositionSealing/packingOil wellWellbore

The invention discloses a treatment method for casing channeling and casing leakage of an oil and gas production well. The treatment method comprises the following steps that S1, a first plugging agent, a second plugging agent and a third plugging agent are configured correspondingly; S2, clear water is injected into a casing to measure the water absorbing index, and the using quantity of the plugging agents is predicted preliminarily according to the water absorbing capacity of a stratum; S3, a casing gate is closed, an oil well pipe string or a polished wellbore are trapped in, the first plugging agent and the second plugging agent are extruded and injected into the casing successively, and after injecting is completed, still standing is conducted for four hours; S4, the third plugging agent is injected into the casing, then the clear water is injected into the casing so as to jack the third plugging agent to the leakage point of the casing, and a reserved mortar face is located on the leakage point of the casing; S5, the well is shut down for waiting on cement setting for 72 hours; and S6, after the process of waiting on cement setting is completed, an unloading well opening adopts the pipe string to detect a mortar plugged face, and then plug drilling is conducted. According to the treatment method for casing channeling and casing leakage of the oil and gas production well,the one-time success rate for treatment of casing channeling and casing leakage caused by damage of the oil and gas production well, especially the shallow casing, reaches 90% or above, the types andthe using quantity of treatment agents are less, and the cost is reduced.

Owner:SICHUAN GUANGYA POLYMER CHEM

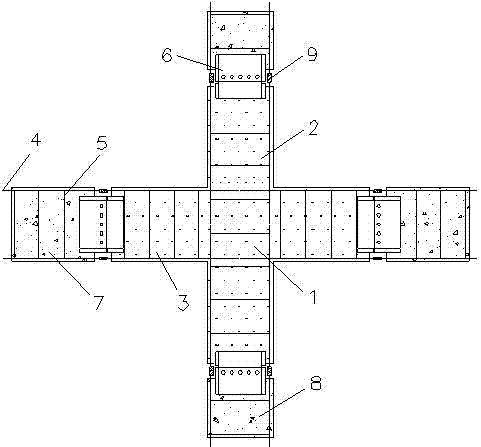

Edge joint connecting structure and method of prefabricated integrated type frame column beam

The invention relates to an edge joint connecting structure and method of a prefabricated integrated type frame column beam, and belongs to the field of prefabricated concrete structure engineering. The edge joint connecting structure of the prefabricated integrated type frame column beam is characterized by further comprising a tensile longitudinal bar, a U-shaped reinforcing steel bar, roughening layers and a concrete connecting layer, the upper connecting steel bar, namely the tensile longitudinal bar and the lower U-shaped steel bar are arranged at the joint portion of a prefabricated column, and right sections of the tensile longitudinal bar and the U-shaped steel bar are both tied with a stirrup I and buried in the prefabricated column. The edge joint connecting method of the prefabricated integrated type frame column beam includes producing the prefabricated column and a prefabricated beam in a factory, respectively arranging the roughening layers, correspondingly binding the tensile longitudinal bar and the U-shaped steel bar on the prefabricated column with a longitudinal bar and a stirrup II on the connecting section of the prefabricated beam corresponding on the construction site, and making the cast-in-place normal concrete connecting layer to realize connection between the column and the beam. Construction is facilitated, the period of construction is shortened, and seismic performance is enhanced.

Owner:CHINA MCC17 GRP

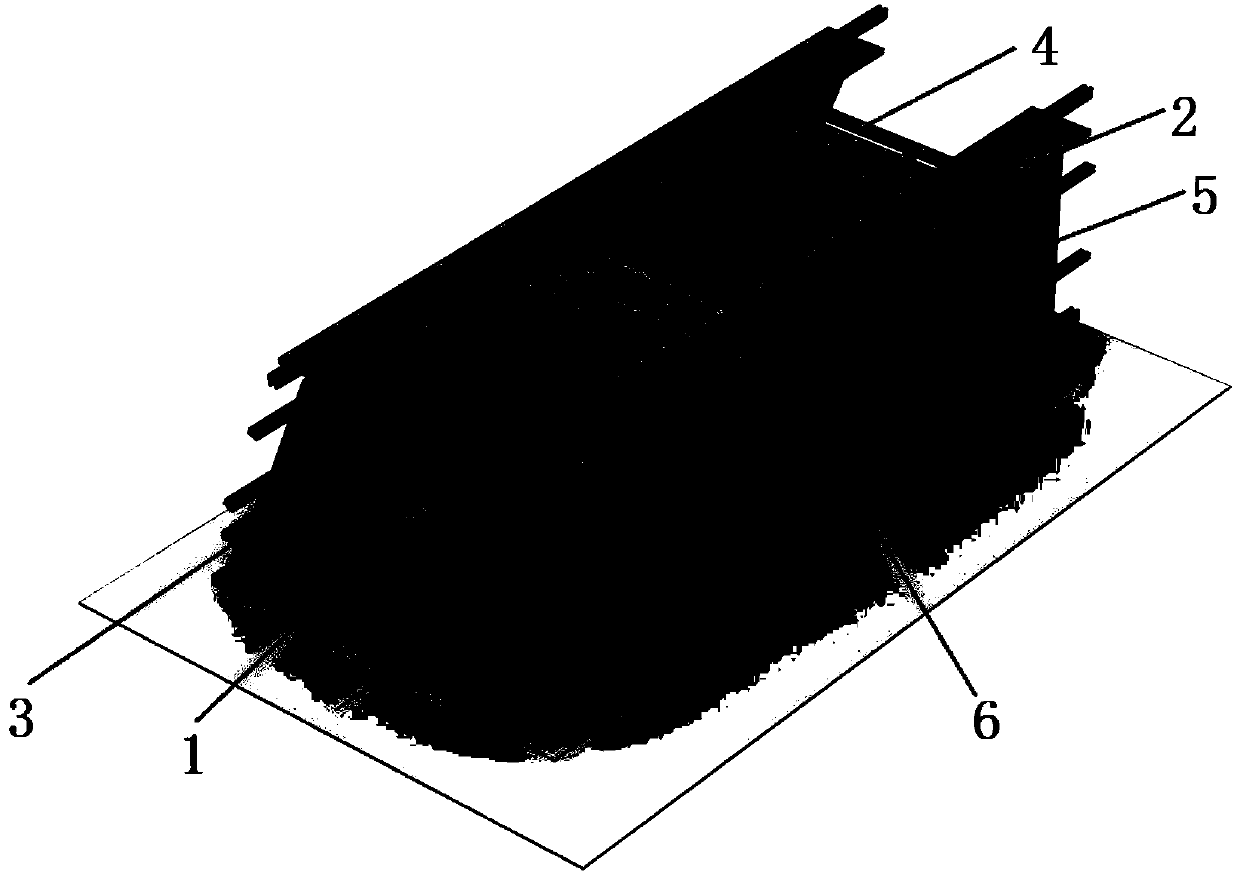

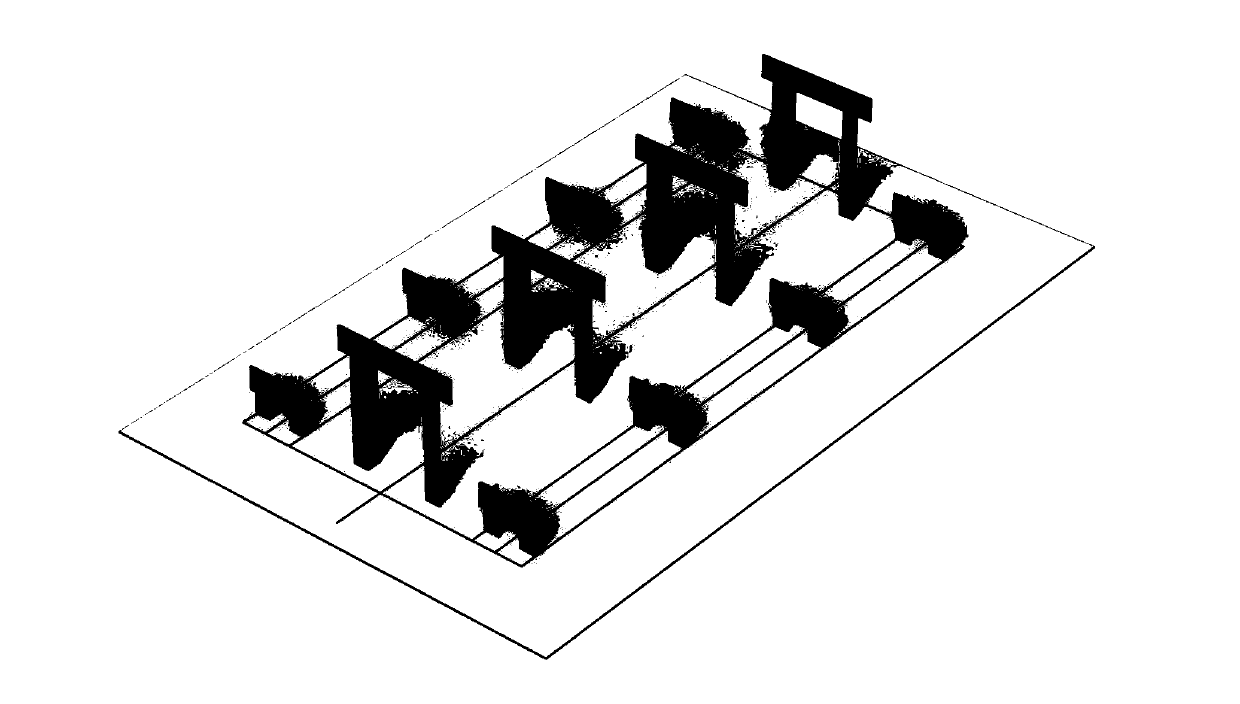

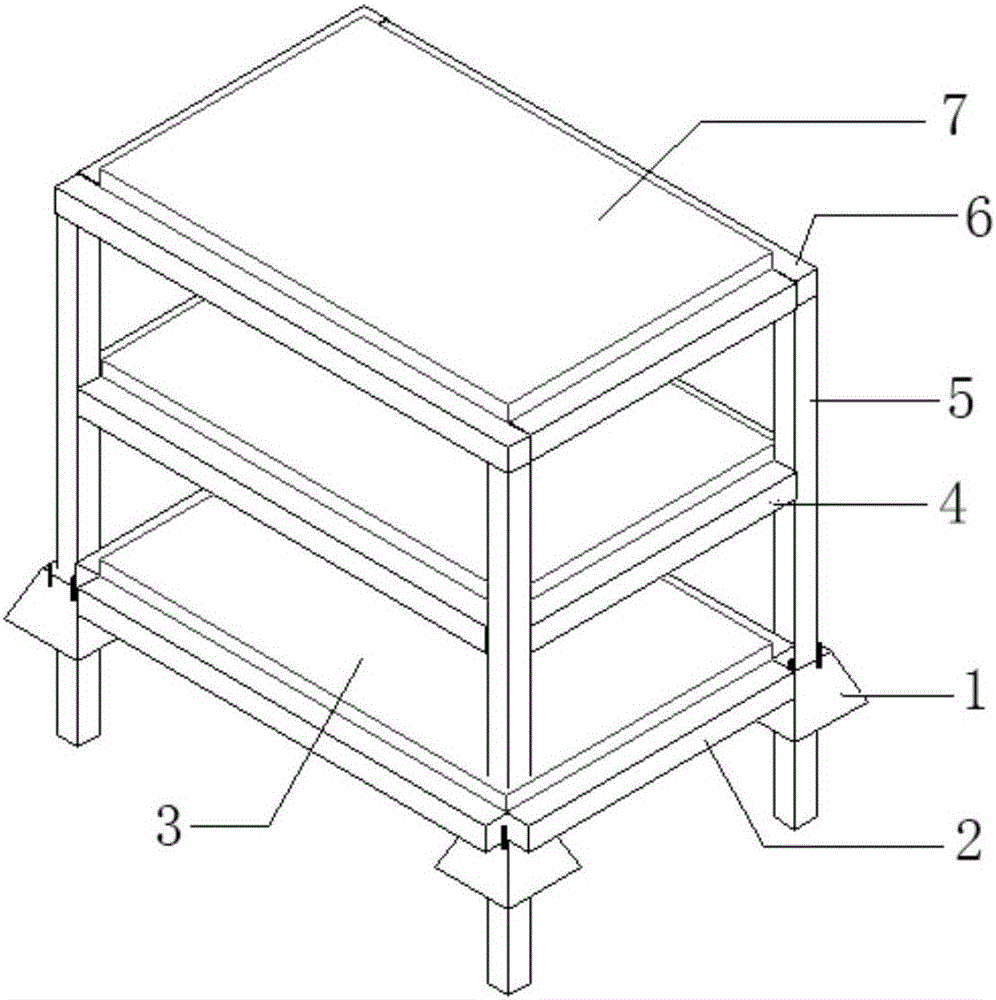

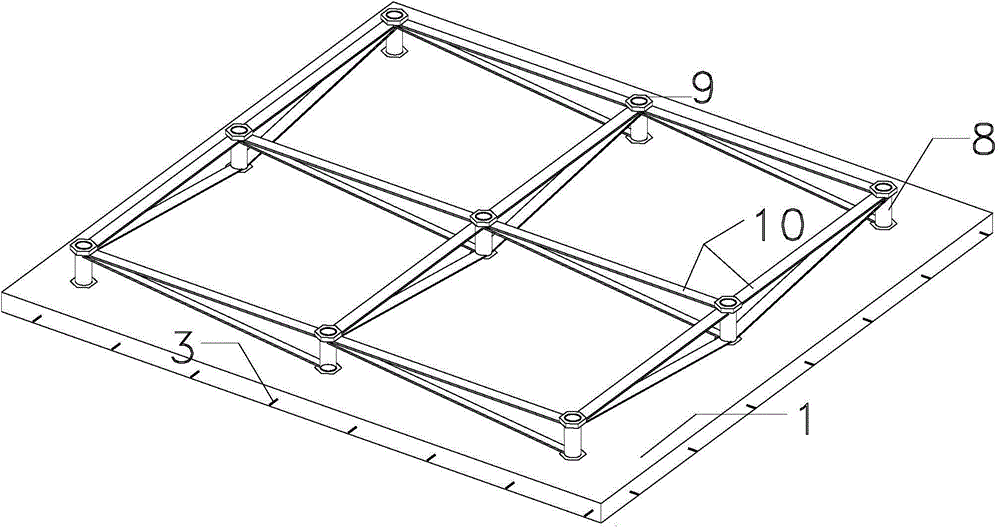

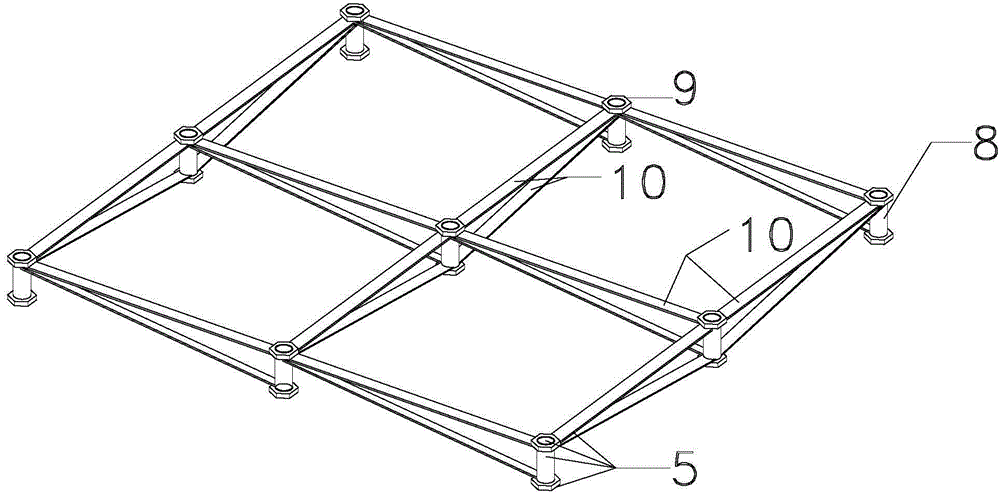

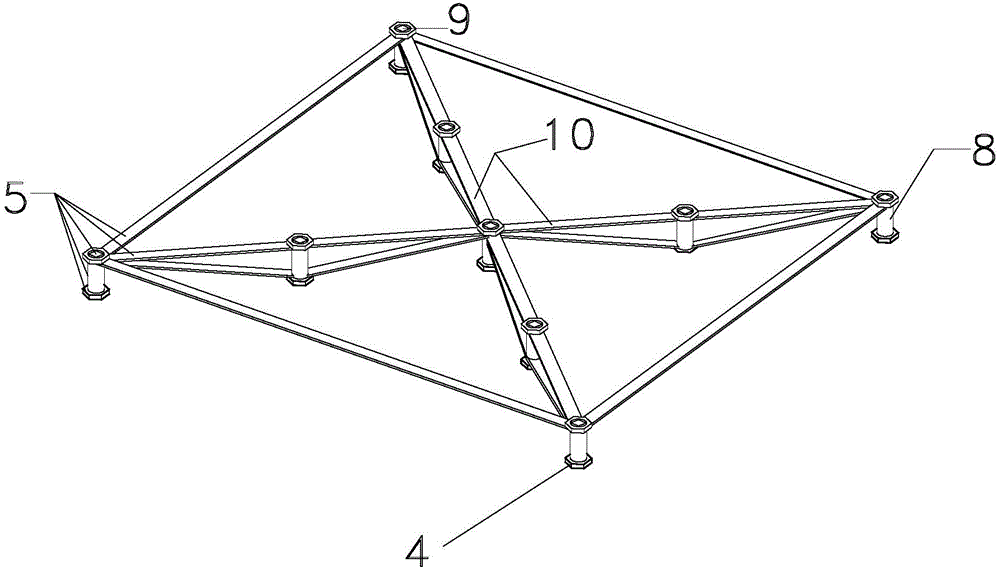

Assembled type garage structure system based on precast piles and method

ActiveCN105862900AEmission reductionGuaranteed verticalityArtificial islandsUnderwater structuresEngineeringVertical load

The invention discloses an assembled type garage structure system based on precast piles and a method. The assembled type garage structure system comprises the precast piles, horizontal supporting beams and independent foundations, wherein vertical load bearing parts of a garage structure are formed by the precast piles, and guide rails are arranged on the outer surfaces of the precast piles; the horizontal supporting beams comprise ground beams and superposed beams, the ground beams are arranged around the precast piles by one circle so as to support a bottom plate of a garage, and the superposed beams are arranged around the precast piles so as to support a garage floor plate or a garage top panel; the independent foundations are connected with the precast piles and the precast ground beams through designed grooves. All the structure members such as the precast piles and the independent foundations are machined in factories and can be assembled for construction, so that emission of pollutants at a construction site is reduced; through the guide rails and cooperation of the independent foundations and mounting flanges, the perpendicularity of the precast piles is guaranteed, the structure bearing capacity is well guaranteed, and structure precision is guaranteed; the precast piles and garage columns are integrated, so that not only is energy saved, but also construction efficiency of the underground garage is greatly improved.

Owner:SHANDONG UNIV

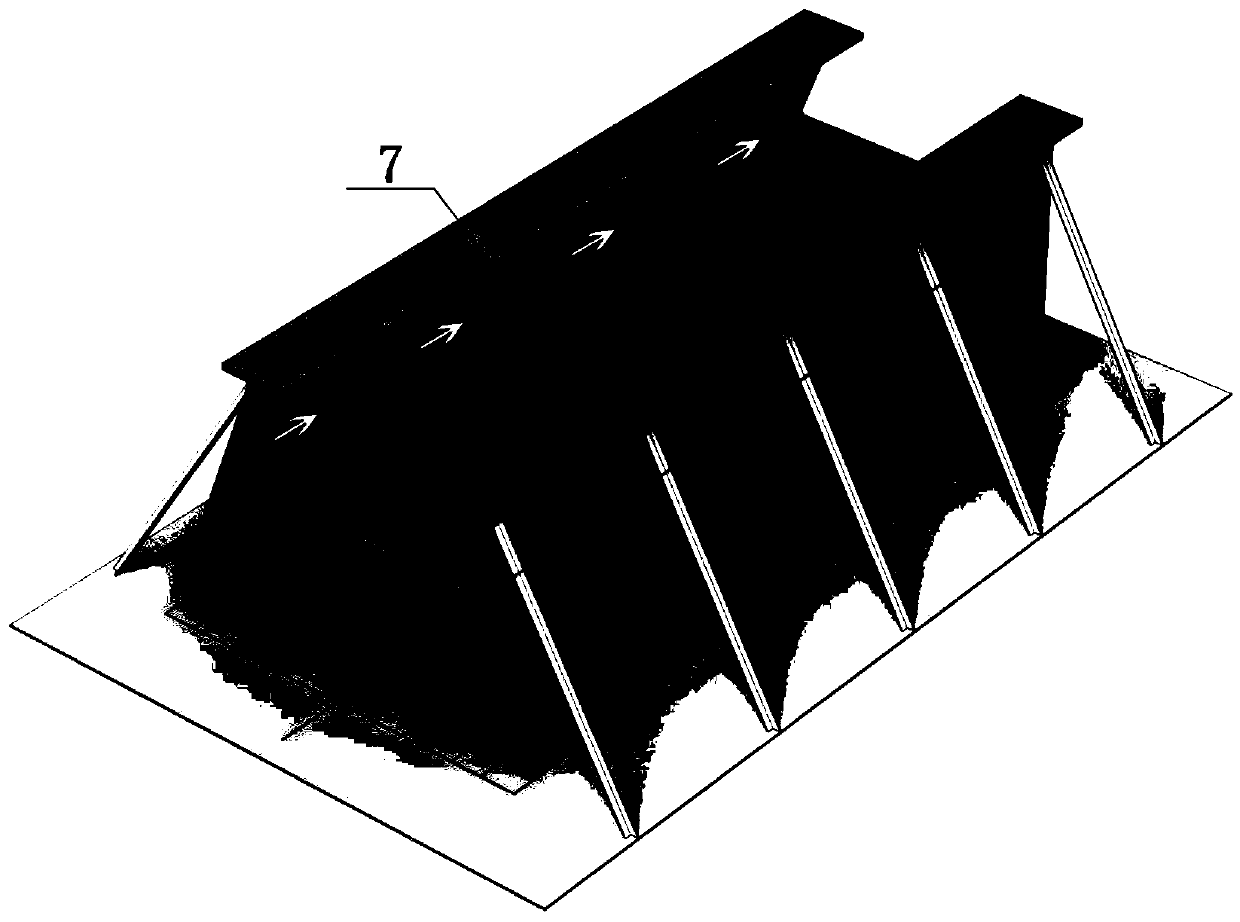

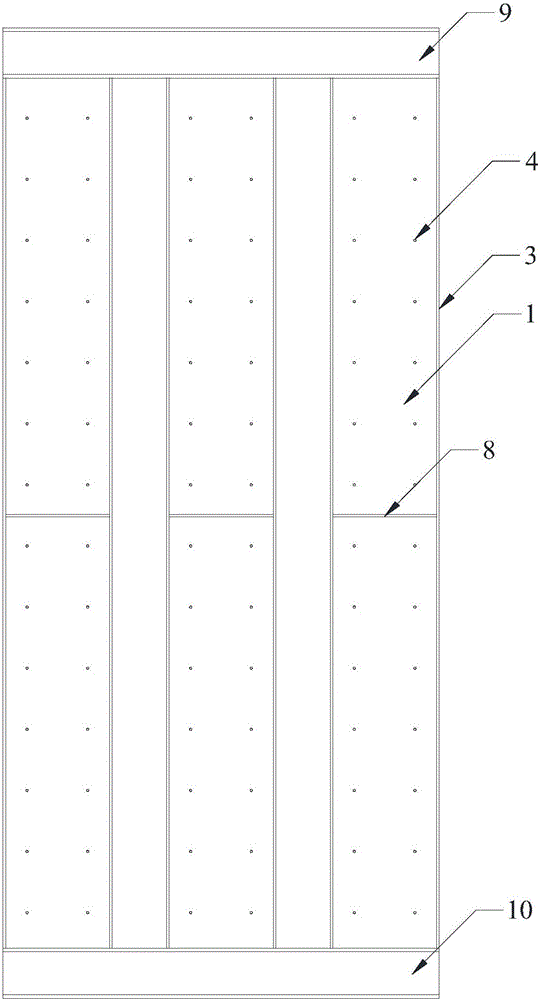

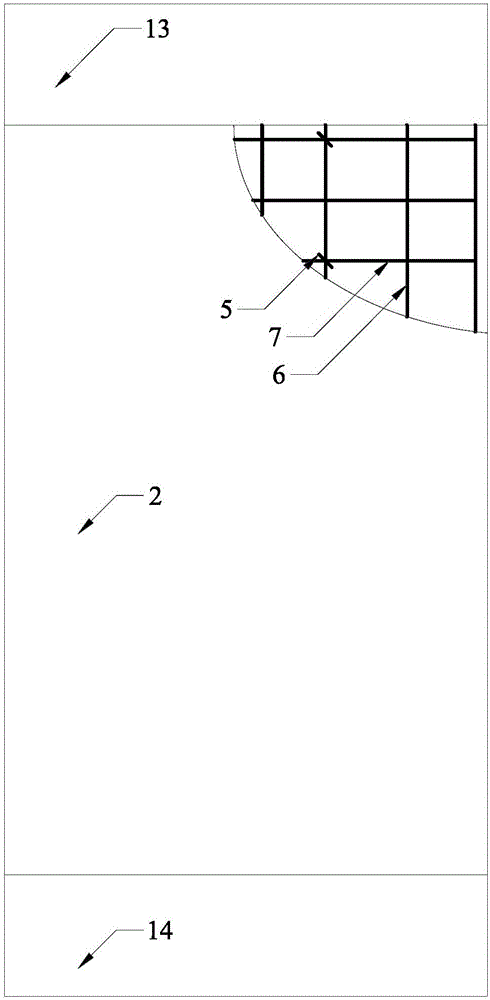

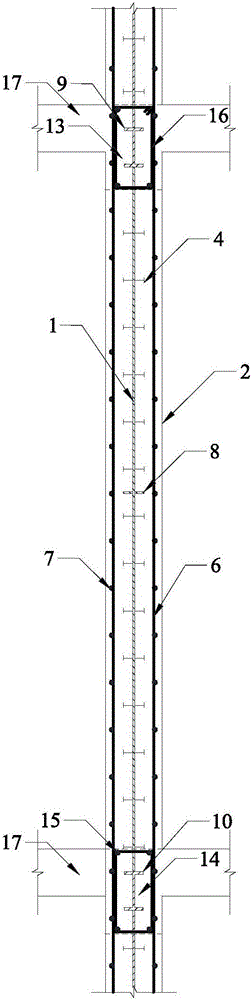

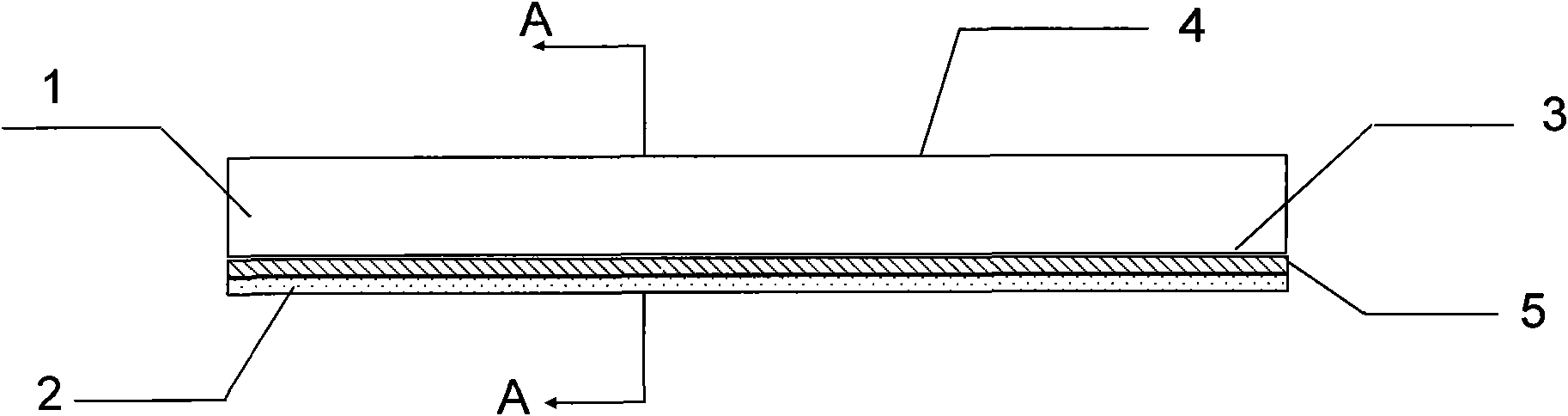

High-strength concrete composite shear wall with built-in segmented steel plates and construction method for same

ActiveCN106049708ALess prone to bucklingWork well togetherWallsHigh strength concreteHigh resistance

The invention belongs to the technical field of structure engineering and relates to a high-strength concrete composite shear wall with built-in segmented steel plates and a construction method for the same. The invention provides the high-strength concrete composite shear wall with the built-in segmented steel plates and further provides the building and construction method for the shear wall. The composite shear wall and the construction method for the same provided by the invention are characterized in that through segmented layout of the steel plate, concrete pouring and binding bar layout become convenient; a cooperative working ability of the steel plates and concrete is enhanced; bearing force is ensured; and deformability and an energy-dissipation capability of the composite shear wall can also be enhanced. In comparison with a composite shear wall covered by steel plates, the composite shear wall provided by the invention has higher resistance to high temperatures and can show better performance when a fire disaster takes place. Meanwhile, in comparison with a concrete composite shear wall with a whole steel plate, the shear wall provided by the invention has the advantages that conversion and transition among layers can be implemented through reduction of the quantity of the segmented steel plates; inter-layer rigidity transition becomes gentler; and the structure is also simpler.

Owner:TONGJI UNIV

Method for strengthening wood beam

ActiveCN101956464AImprove bearing capacityRecover and increase strengthBuilding repairsGirdersRenewable materialsEnergy consumption

The invention relates to the field of construction engineering, in particular to construction strengthening and modification and discloses a method for strengthening a wood beam. The method for strengthening the wood beam comprises the following steps of: (1) performing surface evenness treatment on a stressed surface of the wood beam, scrubbing with acetone, and if a bottom face has a crack or recess, mending by adopting mending glue; (2) selecting bamboo chips which are treated by surface processing and are 3 to 7 millimeters thick, 10 to 25 millimeters wide and as long as the wood beam, and scrubbing with the acetone; and (3) coating base glue on the drawn face of the wood beam, adhering at least one layer of bamboo chips on the stressed surface of the wood beam by using structural glue and pressing to ensure that the bamboo chips, the structural glue and the wood beam are bonded compactly. The method can effectively avoid dismantling the original structure, guarantee the bearing capability and durability of the wood beam and meet the subsequent use requirements. The bamboo chip is a regenerative material and has high anti-drawing strength, so that the resource and energy consumption of the construction strengthening and modifying industry can be effectively reduced by using the bamboo chips to strengthen the wood beam.

Owner:上海建科预应力技术工程有限公司

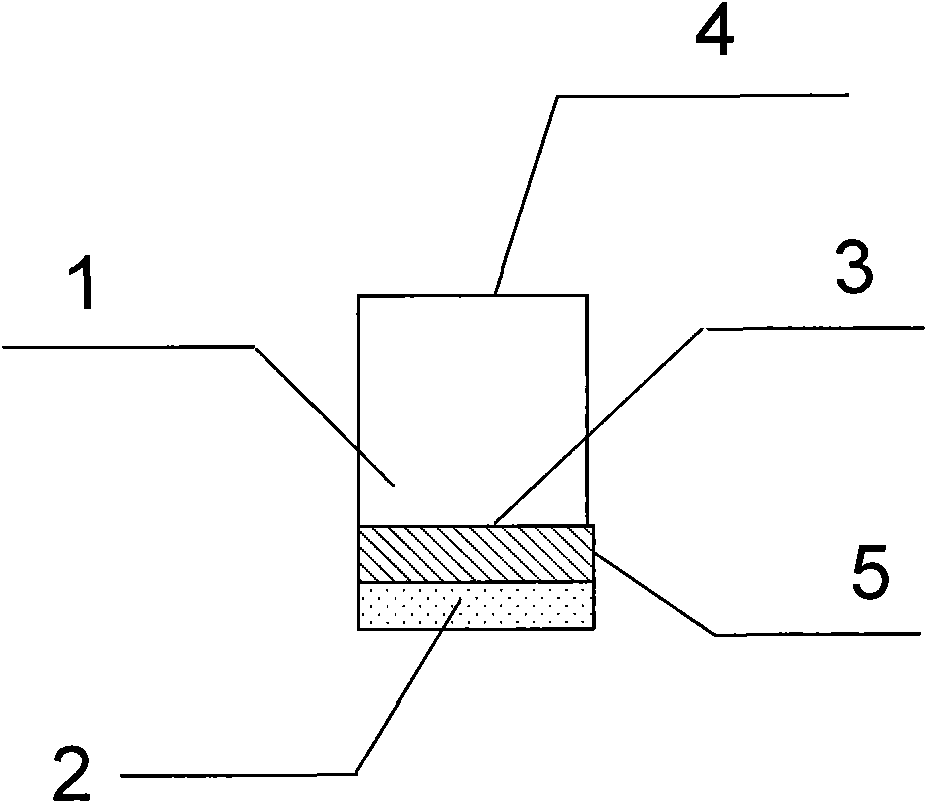

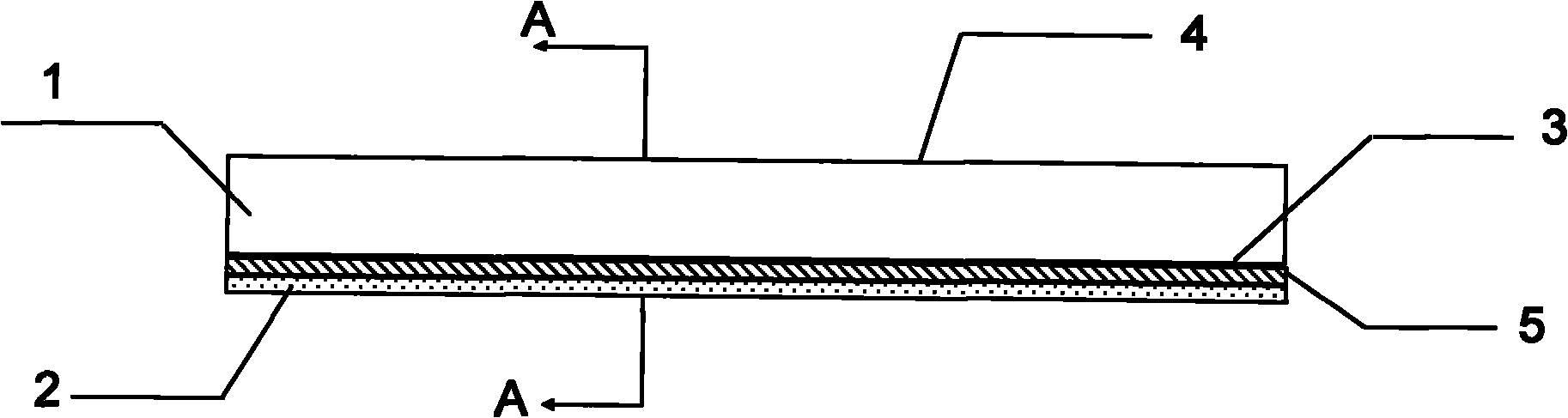

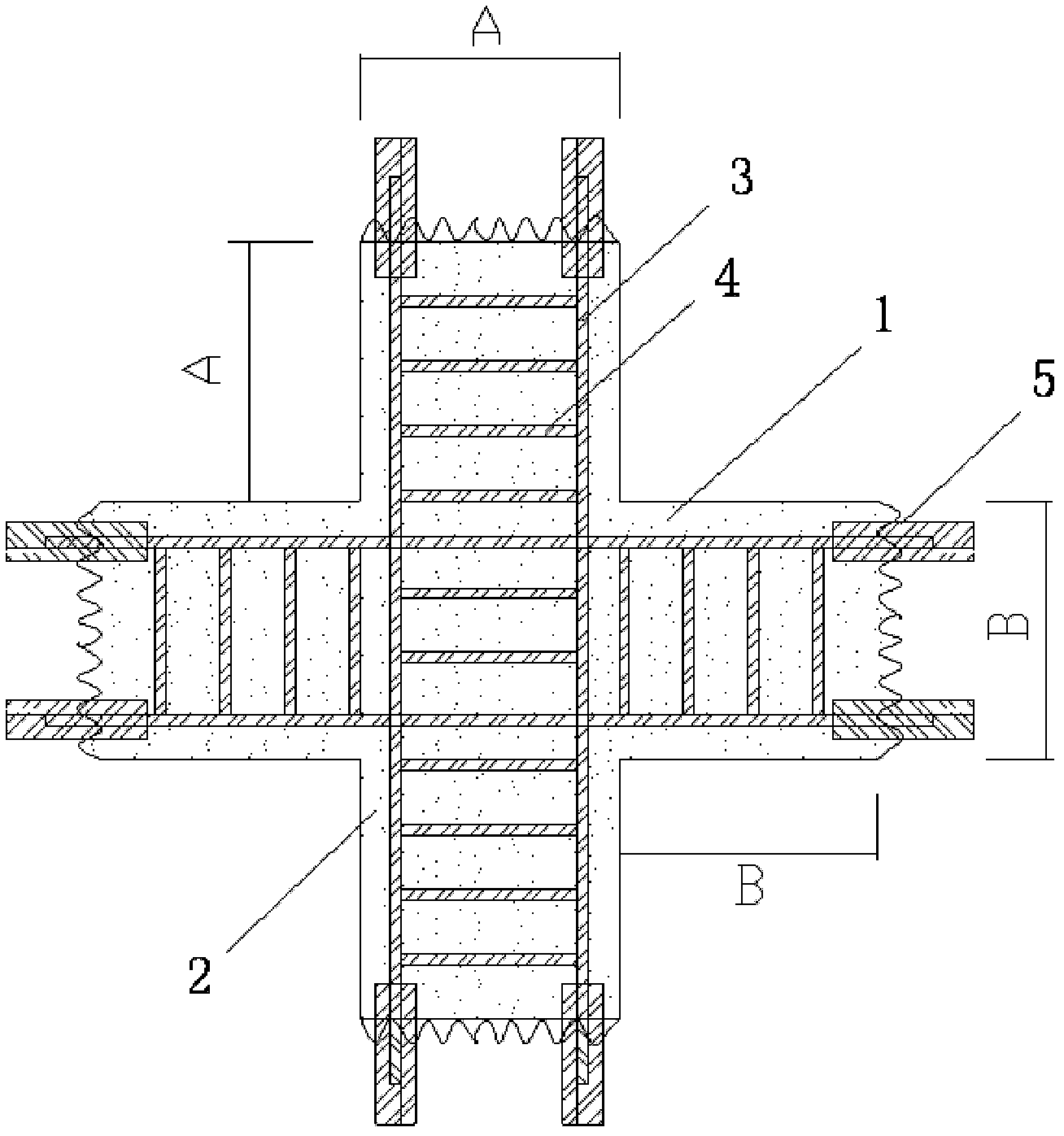

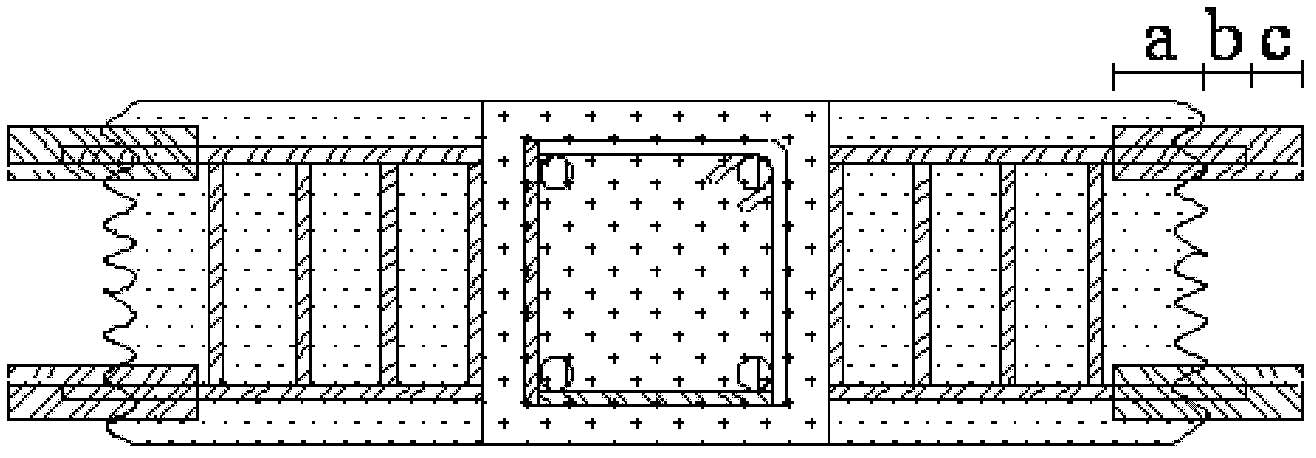

Prefabricated combined beam and column node member

InactiveCN102505760AGuaranteed stiffnessGuarantee welding qualityClimate change adaptationShock proofingReinforced concreteSteel bar

The invention relates to a prefabricated combined beam and column node member. The prefabricated combined beam and column node member comprises a cross beam and a vertical column which are intersected, wherein the cross beam as well as the vertical column comprises an ECC (engineered cementitious composite) material, longitudinal bars and stirrups, and a rectangular region where the cross beam and the vertical column are intersected and superposed is in the transverse width of A and the longitudinal height of B; the cross beam is in the transverse width of 2B plus A and the longitudinal height of B, and the longitudinal bars penetrate the full length of the cross beam and extend out of two beam ends by 10cm-15cm; and the vertical column in the longitudinal height of 2A plus B, and the longitudinal bars penetrate the full length of the vertical column and extend out of the two column ends by 10cm-15cm. The prefabricated combined beam and column node member disclosed by the invention is the prefabricated member which is formed by casting the steel bar-reinforced ECC material and is applied to an anti-seismic key part, in particular to a key node. Compared with an ordinary reinforced concrete member, the prefabricated combined beam and column node member can significantly improve the ductility and the anti-seismic performance of the structure, greatly reduce the use of the stirrups at the node under the condition of meeting the anti-seismic requirement and solve the difficult problem in construction caused by too dense stirrups in a node region.

Owner:SOUTHEAST UNIV

Composite floor slab and construction method thereof

The invention discloses a composite floor slab and a construction method thereof. The composite floor slab comprises a prefabricated base plate, a cast-in-place concrete composite layer, plate surface steel bars and plate bottom steel bars; lifting trusses are installed on the prefabricated base plate and connected with the prefabricated base plate through connecting nuts, and the lifting trusses can be disassembled after the prefabricated base plate is lifted to the specific location. The construction method for manufacturing the composite floor slab comprises the following steps that firstly, the prefabricated base plate on which the lifting trusses are installed is lifted to the specific location; secondly, supports are arranged on the bottom of the prefabricated base plate, and the lifting trusses are disassembled; thirdly, the plate surface steel bars are placed, the cast-in-place concrete composite layer is poured, after cast-in-place concrete reaches certain strength, the supports are disassembled, and the composite floor slab is formed. According to the composite floor slab and the construction method thereof, the component size is the same as a room, the assembly is not needed, no joint seam exists, the construction is convenient and fast, industrialization can be achieved, and the construction speed is greatly improved.

Owner:吴方伯

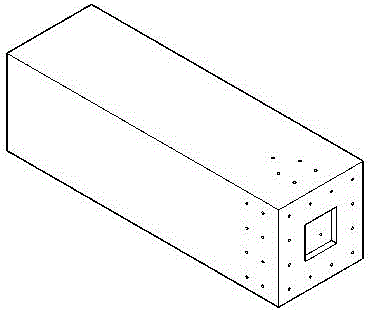

Giant cruciform combination column and manufacturing method thereof

ActiveCN104196164AGuaranteed bearing capacityNovel structural designStrutsMilling equipment detailsCruciformMechanical engineering

The invention discloses a giant cruciform combination column which comprises two pieces of T-shaped steel and a pieces of I-shaped steel, wherein the T-shaped steel is mounted at two sides of the I-shaped steel so as to form a cruciform column body structure with side plates; the upper part, the middle and the lower part of the column body structure are respectively provided with two layers of stiffening plates; studs are arranged on the side plates of the column body structure; corbels are arranged at the parts, connected with the stiffening plates, of the I-shaped steel. The invention further discloses a manufacturing method of the giant cruciform combination column. Based on the giant cruciform combination column and the manufacturing method thereof, the structure of the column is simplified to a maximum extent while the load-bearing capacity of the column is ensured, the raw materials and the cost are saved, and the effective usable area of a building is increased; the self-weight of the structure is reduced, and thus the structural seismic response is reduced.

Owner:JIANGSU HUNING STEEL MECHANISM

High-speed jacking and transferring control method

InactiveCN112193794AReduce weightImprove stabilityConveyorsControl devices for conveyorsStructural engineeringMachine

The invention discloses a high-speed jacking and transferring control method. A transferring machine is integrally nested in a conveying line without changing the distance between the conveying line structure and a roller. A jacking drive and a transferring transmission part are integrated in a lower assembly, and therefore the using method that main line conveying is in a belt type, and sorting motion is in a roller type is achieved, and the design aims that the structure is compact, field conveying line installation and layout are facilitated, the weight of a jacking assembly is reduced, high-speed transferring and sorting are achieved, and the whole machine jacking stability and sorting efficiency are improved are achieved. The high-speed jacking and transferring machine comprises the jacking assembly, a belt conveying assembly and the jacking drive and conveying assembly which are stacked and connected in the vertical direction. The jacking assembly is provided with an electric roller and a plurality of sets of driven rollers, wherein the electric roller and the driven rollers are arranged in a roller installing base. The belt conveying assembly comprises a plurality of sets ofbelt conveying pieces, and the arrangement direction of each set of belt conveying pieces is kept parallel to the conveying direction of the main line conveying line.

Owner:QINGDAO KENGIC AUTOMATION EQUIP CO LTD

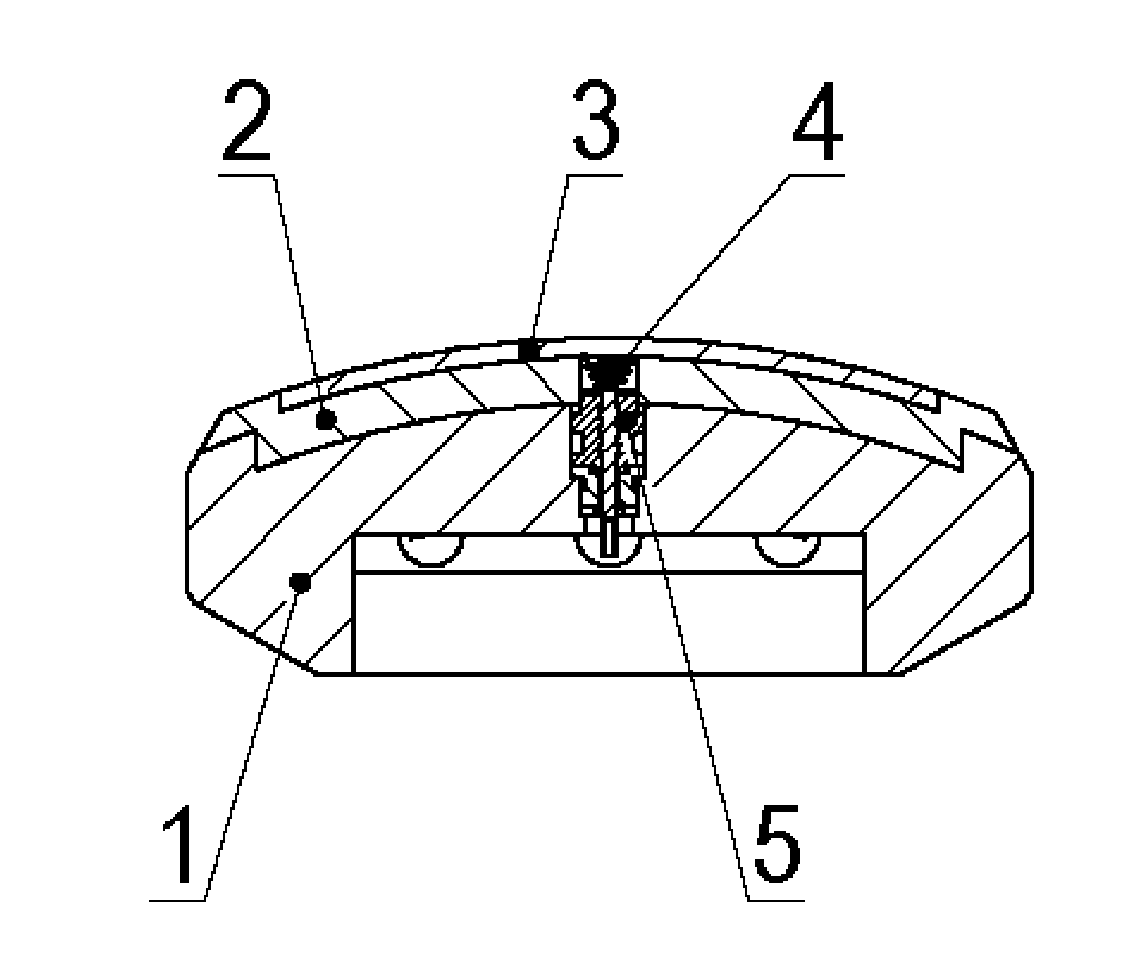

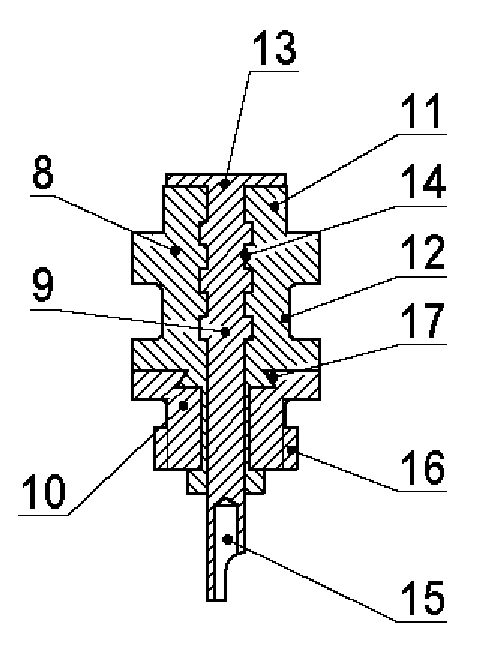

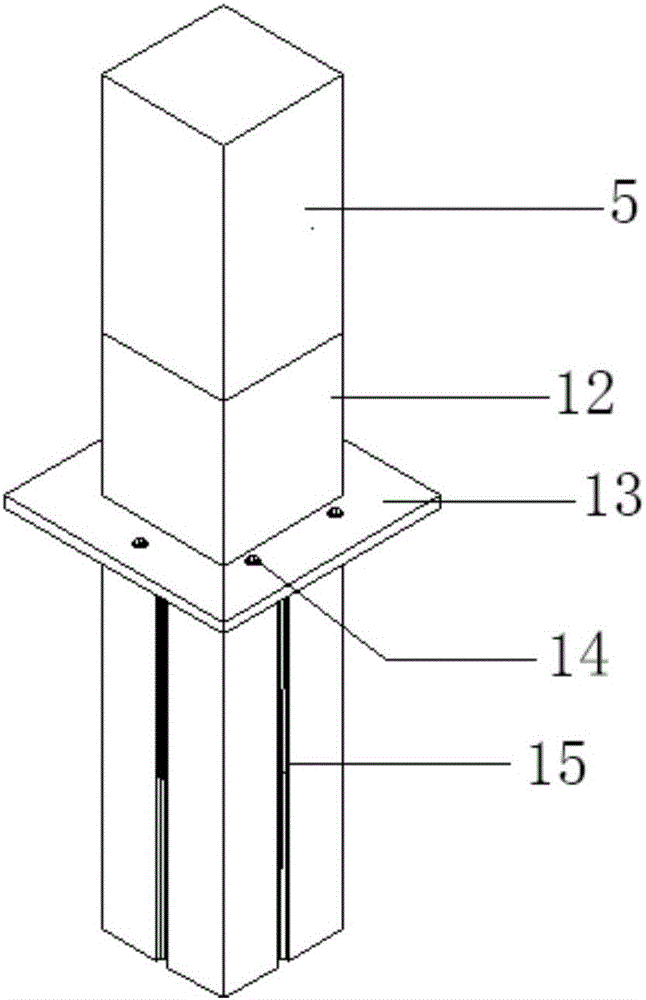

Prefabricated assembled integral framework column bottom grouting structure

InactiveCN105863049AGuaranteed bearing capacityImprove connection performanceBuilding reinforcementsAgricultural engineeringSteel bar

The invention relates to a prefabricated assembled integral framework column bottom grouting structure, which comprises a prefabricated framework column and an anti-shearing groove formed in the bottom of the prefabricated framework column; a grouting sleeve is prefabricated at the bottom of the prefabricated framework column at the same time, is arranged on the periphery of the prefabricated framework column, and is used for connecting a load-bearing steel bar of the prefabricated framework column; the lower part of the tube wall of the grouting sleeve is provided with a grouting hole; a slurry discharging hole is formed in the upper part of the tube wall of the grouting sleeve, i.e., the slurry discharging hole and the grouting hole are formed in the periphery of the prefabricated framework column from top to bottom; a PVC (polyvinyl chloride) pipe is arranged on the anti-shearing groove, and is arranged in an L shape; the vertical part of the PVC pipe is communicated with the anti-shearing groove; the transverse part of the PVC pipe extends out of the other side of the prefabricated framework column to form a high-position slurry discharging hole; the high-position slurry discharging hole is formed above the slurry discharging hole of the grouting sleeve. The prefabricated assembled integral framework column bottom grouting structure solves the problem that during the prefabricated framework column bottom grouting, air in the anti-shearing groove cannot be thoroughly exhausted.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

Method for repairing and reinforcing wood beam by carbon fibre bar

The invention provides a method for repairing and reinforcing a damaged wooden beam with a carbon fiber tendon. The damaged part of the wooden beam is cut, a timber pond is established in the center of a compressing fringe and a tensile fringe of replacing the wooden block and the wooden beam and the carbon fiber tendon is embedded with a structure adhesive, and a layer of vertical carbon fiber is pasted with the structure which is adhesive at the joint of replacing the wooden block and the wooden beam. The method of the invention is used to repair and reinforce the wooden beam, the whole damaged wooden beam is not required to be rearranged, the bearing capacity and the durability of the wooden beam are guaranteed, and the method is an effective method.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

Prefabricated guardrail

InactiveCN108487135AGuaranteed bearing capacityProtection securityFencingRoadway safety arrangementsBalusterEngineering

Owner:广东铭鸿建设有限公司

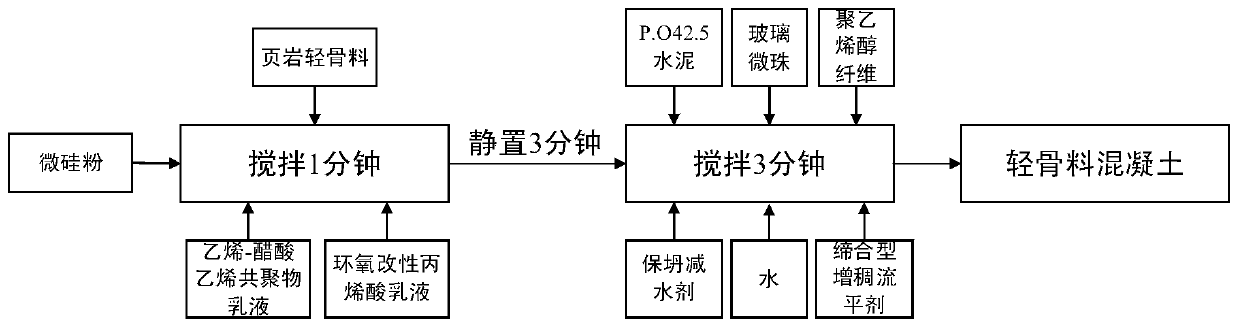

High-strength high-toughness self-leveling light aggregate concrete and preparation method thereof

The invention relates to high-strength high-toughness self-leveling light aggregate concrete and a preparation method thereof. The light aggregate concrete is made of cementing materials, leveling agents, toughening materials, sand, a crude aggregate and water through mixing, wherein the cementing materials are ordinary Portland cement, glass beads and nano micro silicon powder; the leveling agents are a slump-prevention type water reducing agent and an associated thickening leveling agent; the toughening materials are an ethylene-vinyl acetate copolymer emulsion, an epoxy modified acrylic emulsion and a polyvinyl alcohol fiber; the sand is medium sand; and the crude aggregate is shale macadam ceramsite. The preparation method comprises the following steps: firstly, uniformly stirring theethylene-vinyl acetate copolymer emulsion, the epoxy modified acrylic emulsion, the nano micro silicon powder and the shale macadam ceramsite for 1 minute, leaving the mixture to stand for 3 minutes,and further stirring the mixture with the sand, the cement, the glass beads, the water, the polyvinyl alcohol fiber and the associated thickening leveling agent for 3 minutes. The light aggregate concrete provided by the invention has the characteristics of being light in weight, high in strength, free of light aggregate floating, good in flowability, high in toughness and small in shrinkage, canbe applied to large-span bridges and auxiliary structures thereof, and can be also applied to industrial and civil high-rise buildings.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

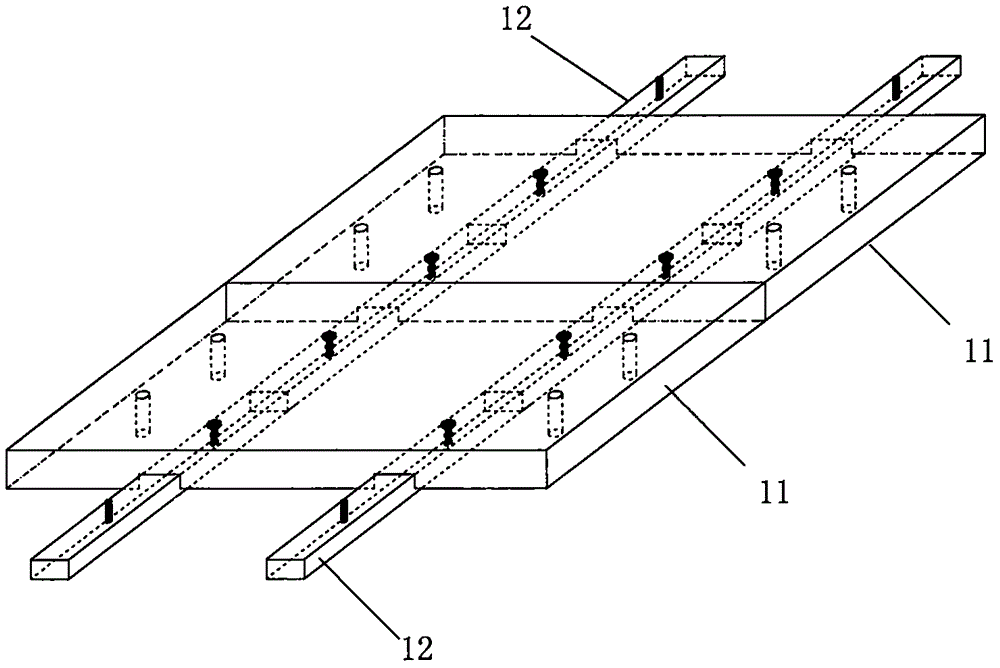

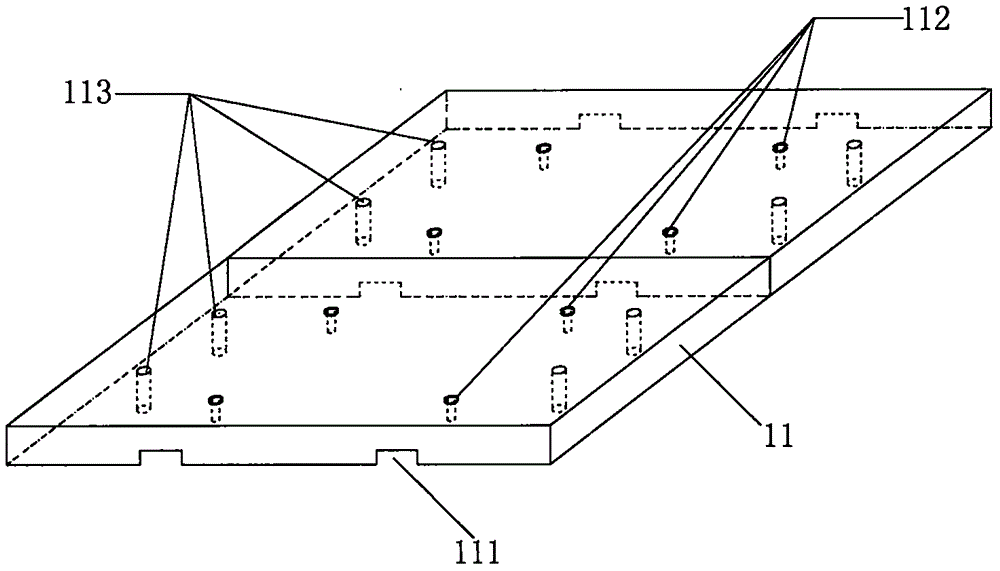

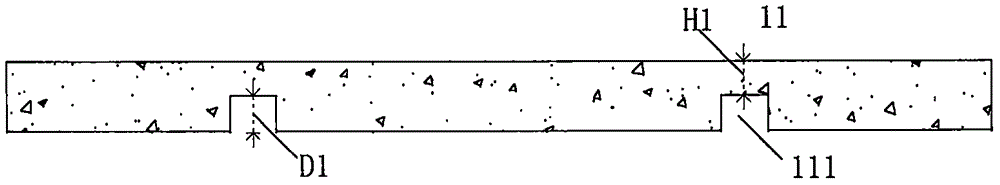

Pillow beam type precast concrete structure layer and assembling method thereof

ActiveCN105735076AImprove flatnessEasy to adjustSingle unit pavingsTemporary pavingsPrecast concrete

The invention provides a pillow beam type precast concrete structure layer and an assembling method thereof.The pillow beam type precast concrete structure layer comprises a plurality of precast concrete planks and a plurality of precast concrete beams; the bottoms of the precast concrete planks are provided with mounting grooves matched with the precast concrete beams in shape, and the precast concrete beams fixedly connect two or more concrete planks which are continuously laid through the mounting grooves, so that an integrated structural layer for bearing the load is formed.According to the pillow beam type precast concrete structure layer and the assembling method thereof, the precast concrete beams are arranged below the precast concrete planks, and in the assembling process, the precast concrete planks can be leveled through the precast concrete beams, so that it is guaranteed that the assembled structure layer has good flatness.

Owner:BEIJING BROAD HIGHWAY TRANSPORTATION TECH CO LTD

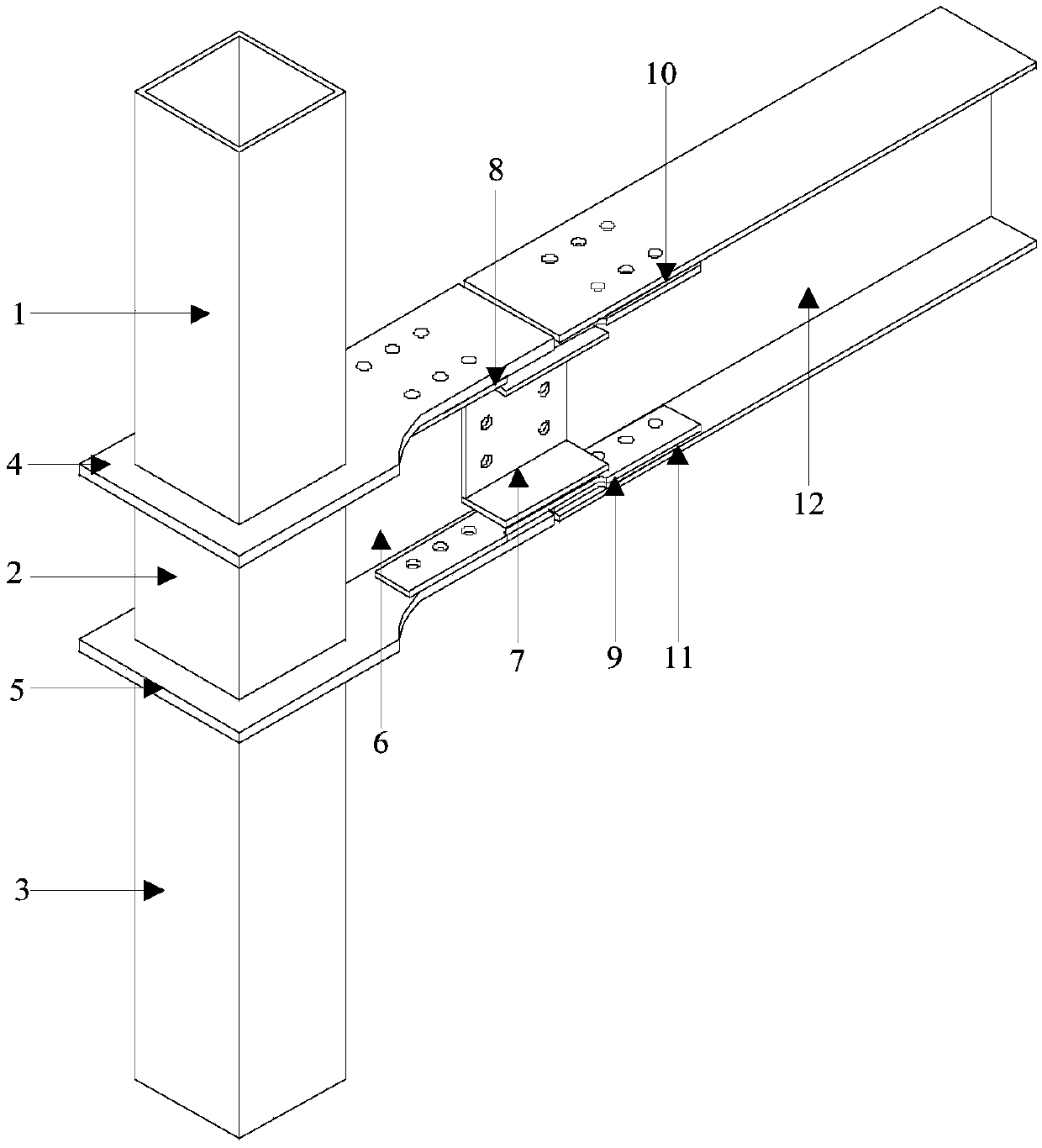

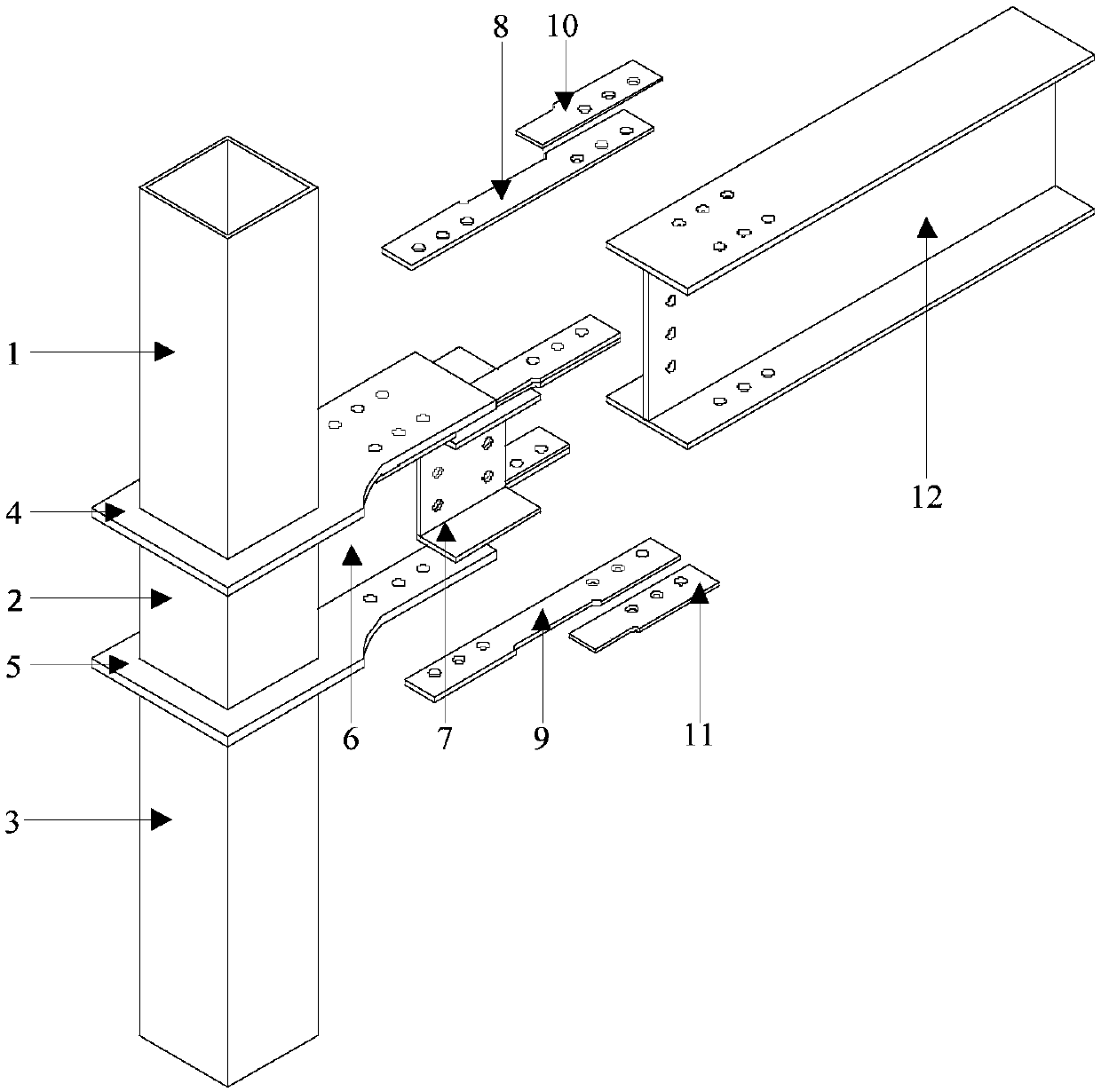

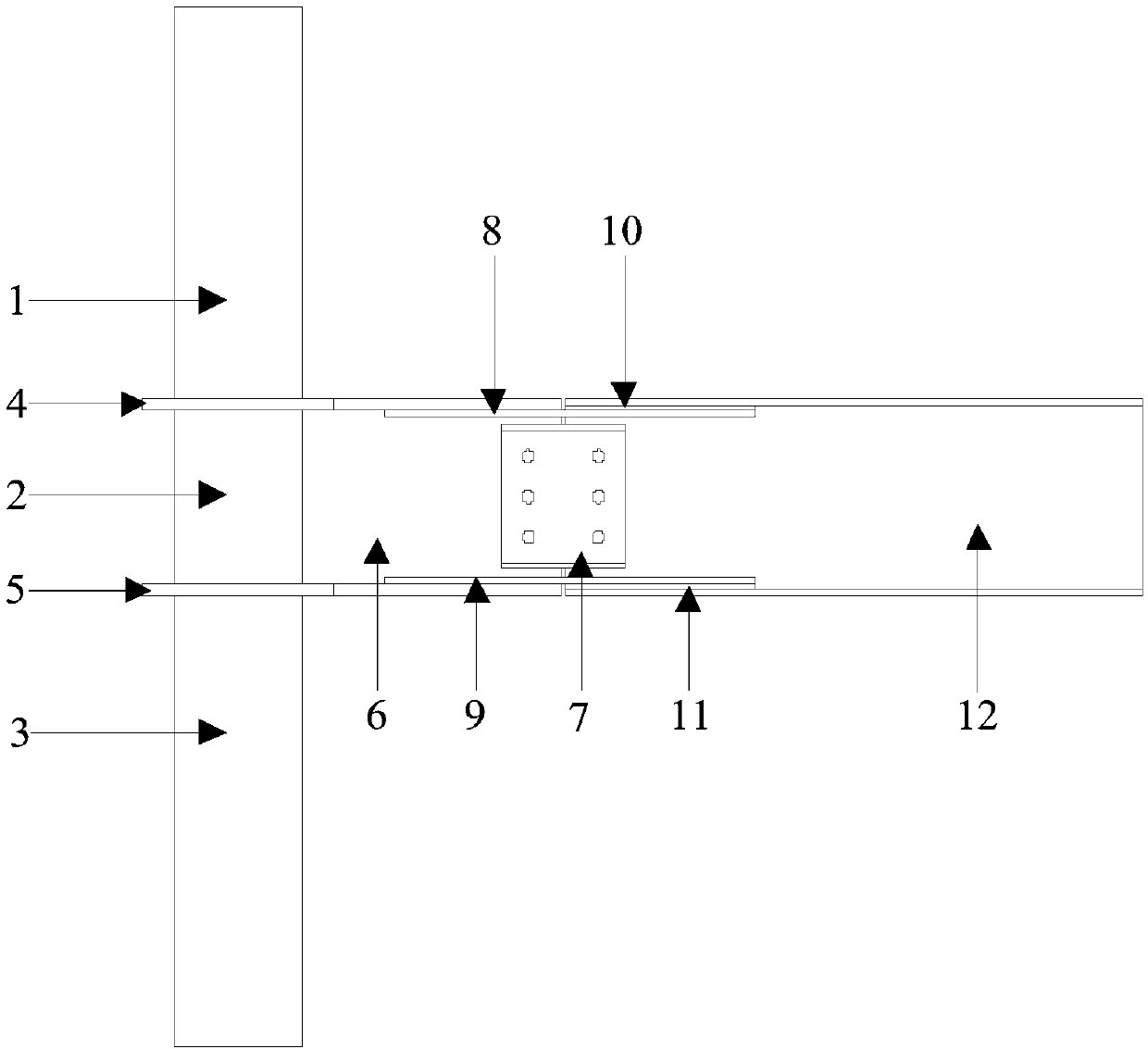

Assembly type anti-buckling groove type web shear member beam-column joint connection device capable of restoring functions

PendingCN109629684AEasy to makeGuaranteed accuracyProtective buildings/sheltersShock proofingCantilevered beamWeld seam

The invention relates to an assembly type anti-buckling groove type web shear member beam-column joint connection device capable of restoring functions, and belongs to the field of structural engineering. The beam-column joint connection device comprises a square steel tube column with a cantilever beam section, an H-shaped beam section and a connection device body. Welding parts of the joint connection device are all completed in a factory, the welding seam precision and quality are easier to control, and the construction speed and the construction quality can be improved; then assembly unitson a construction site are assembled and connected with the square steel tube column with the cantilever beam section through the H-shaped beam. Joint are beam end reinforcing and flange cover plateconnecting weakening integrated joints, a multi-energy-consumption mechanism can be realized, plastic hinges can be transferred to flange cover plates, and according to the anti-buckling idea, after being buckled, the connected flange cover plates abut against groove type web shear member flanges to control the buckling amplitude value of the flange cover plates; function restoration of the structure can be achieved only by replacing connecting plates after earthquakes.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com