Assembled type support and protection structure based on outer steel arch and inner concrete plate and construction method of assembled type support and protection structure

A support structure and concrete slab technology, which is applied in the direction of earthwork drilling, bolt installation, shaft equipment, etc., can solve the problems of large radial support force, poor stability, and large roadway deformation of arc slabs, so as to speed up construction Speed, guaranteed synergy, reduced construction time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

[0043] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

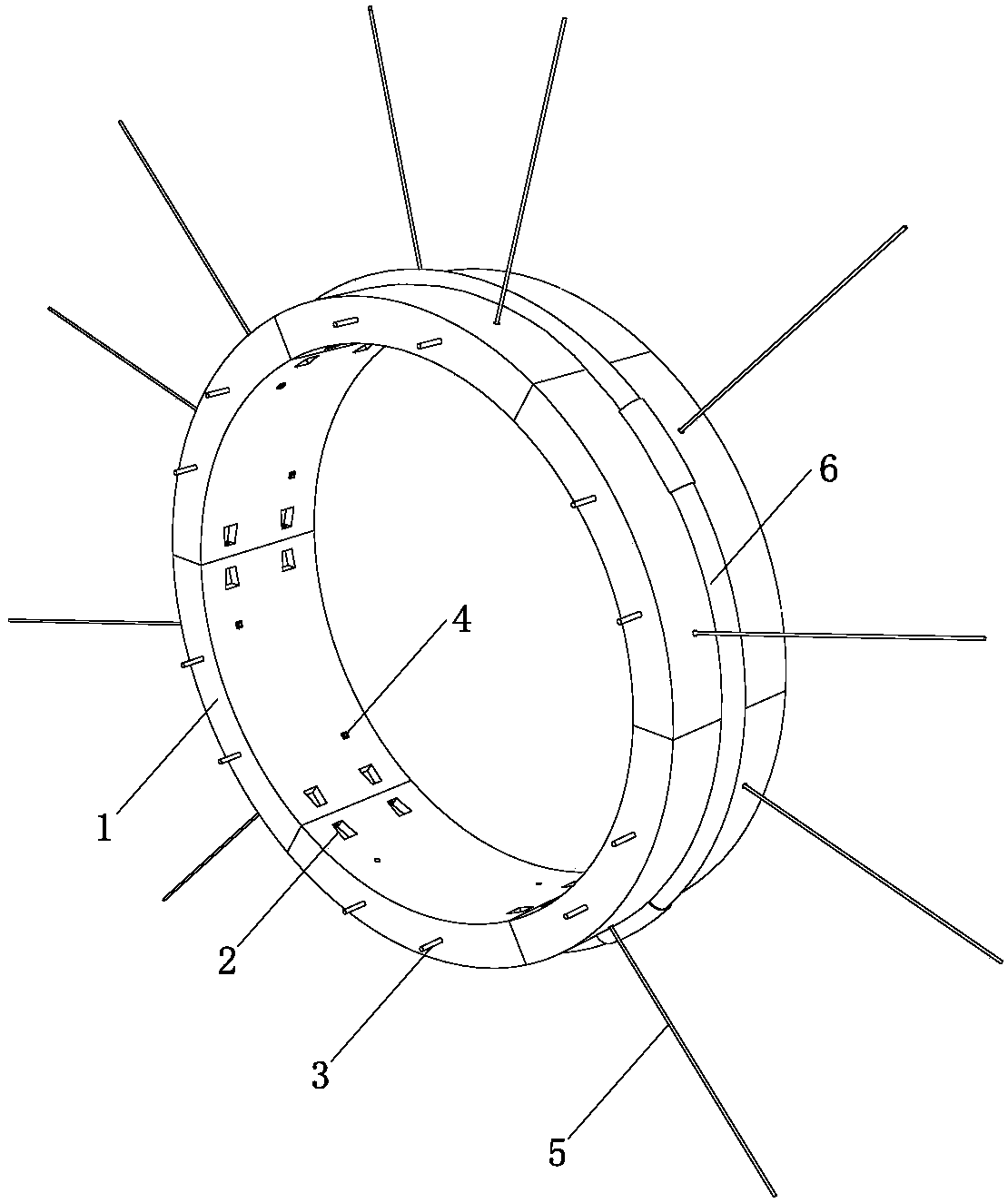

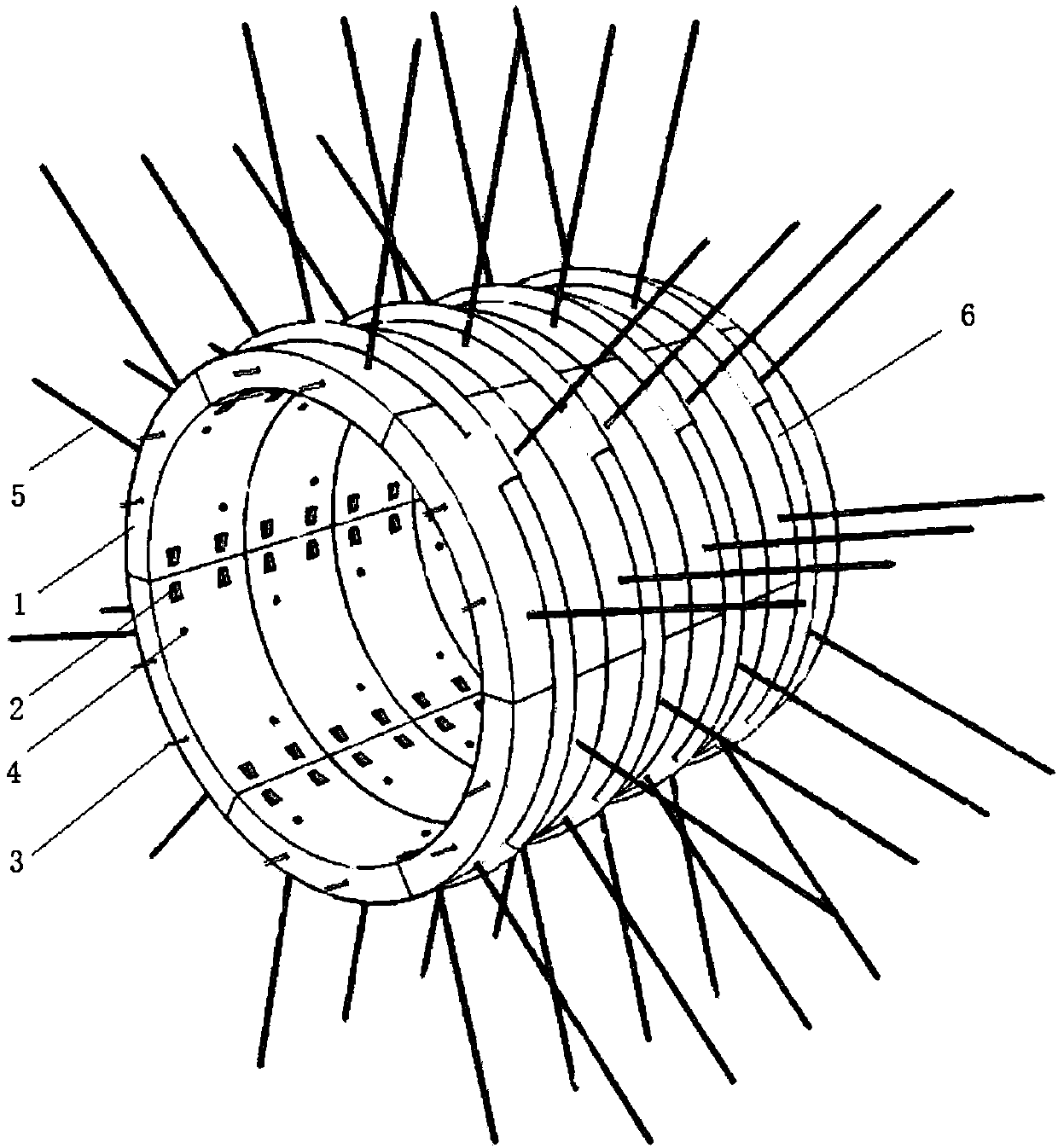

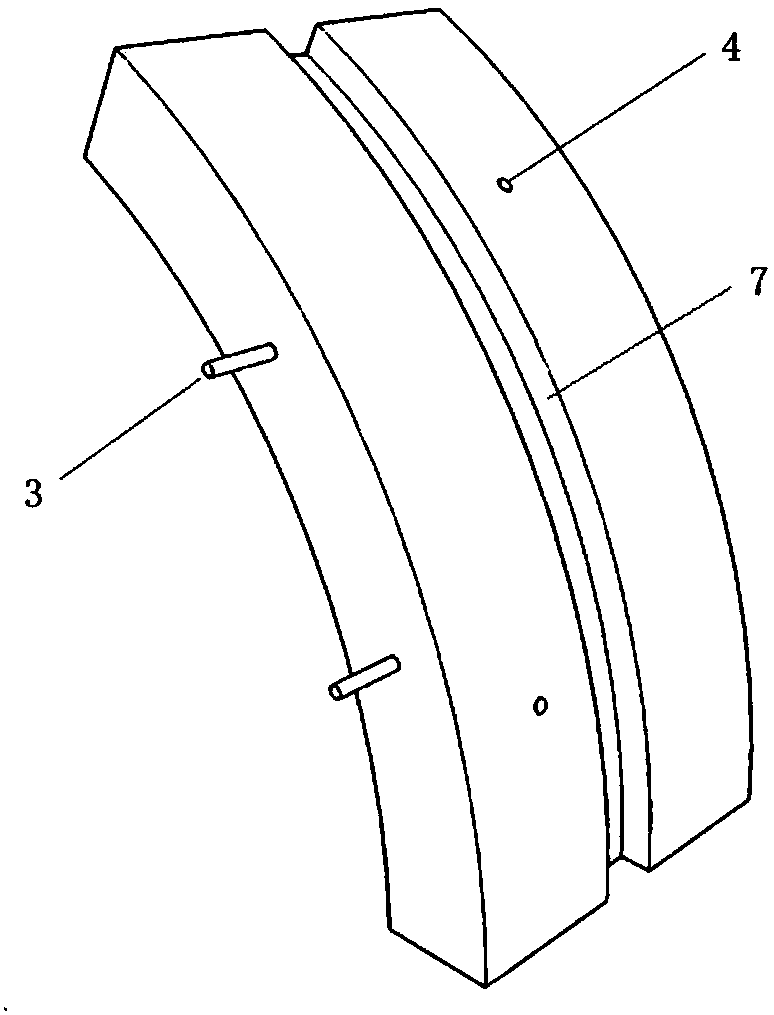

[0044] Such as figure 1 As shown, the present invention includes a steel arch 6 and a concrete support body, the concrete support body is a multi-section splicing structure, and the steel arch frame 6 is arranged on the outside of the concrete support body; the concrete support body and the steel arch frame 6 pass through the anchor The rod 5 is fixed on the surrounding rock of the roadway / tunnel. The concrete support body is composed of multi-segment concrete arc-shaped plates 1 spliced together. There are reserved anchor holes 4 (also used as post-grouting holes) and reserved bolt holes 2 on the concrete arc-shaped plates 1. The multi-segme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com