Improved covering and uncovering device and method for steel ladle whole process covering

A technology of covering and uncovering the whole process. It is used in metal processing equipment, casting melt containers, casting equipment, etc. It can solve the problems of large amount of civil engineering, limited scope of use, and increased manual operation, and achieves convenient operation and structure. Reasonable design to reduce the effect of radiation heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

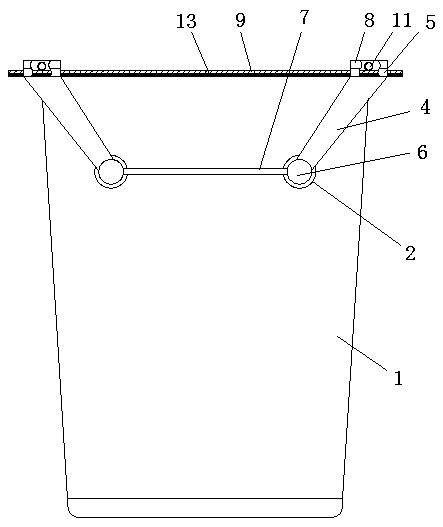

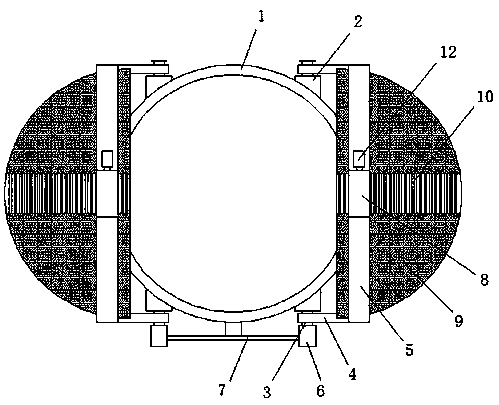

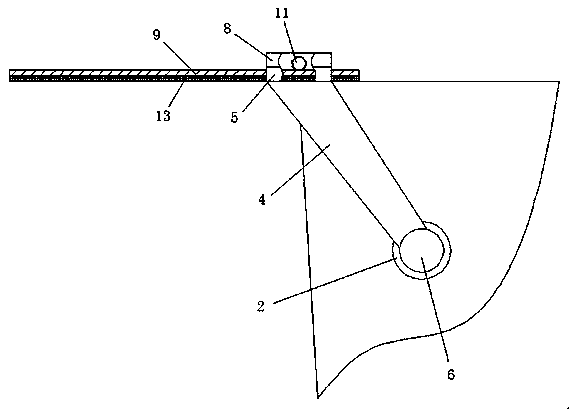

[0035] see Figure 1-4 As shown, this embodiment is an improved capping device for the whole process of ladle capping, including four positioning columns 2 welded on the upper part of the outer wall of the ladle 1, and the axes of the two positioning columns 2 on the same side coincide with each other . The rotation of the outer end of the positioning post 2 is limited by a rotating shaft 3, and the inner end of the rotating shaft 3 is provided with a T-shaped head, and the positioning post 2 is provided with a T-shaped turning groove cooperating with the T-shaped head. A support rod 4 is fixed on the outer side of the rotating shaft 3 , and two support rods 4 on the same side support a guide seat 5 together. The outer end of a rotating shaft 3 in each side is fixedly connected with the output shaft of the first rotating motor 6 through a coupling, and the first rotating motor 6 is fixed on the outer wall top of the ladle 1 by a motor bracket 7 .

[0036] A semicircular ladl...

Embodiment 2

[0039] The embodiment of the present invention provides an improved capping device for ladle capping in the whole process. On the basis of Embodiment 1, the first rotating motor 6 and the second rotating motor 12 are both PLCs capable of forward and reverse rotation. Control a three-phase asynchronous motor.

Embodiment 3

[0041] The embodiment of the present invention provides an improved capping device for the whole process of ladle capping. On the basis of Embodiment 1, the upper part of the guide seat 5 protrudes to form a driving seat 8, and the guiding seat 5 and the driving seat 8 are A one-piece structure made of steel material with interconnected cavities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com