High-seismic-resistance light high-intensity reinforced column

A reinforced concrete column, high seismic technology, applied in the direction of columns, piers, pillars, etc., can solve the problem of less research on load-bearing structures, achieve high seismic performance, reduce the weight of the structure, and save time in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

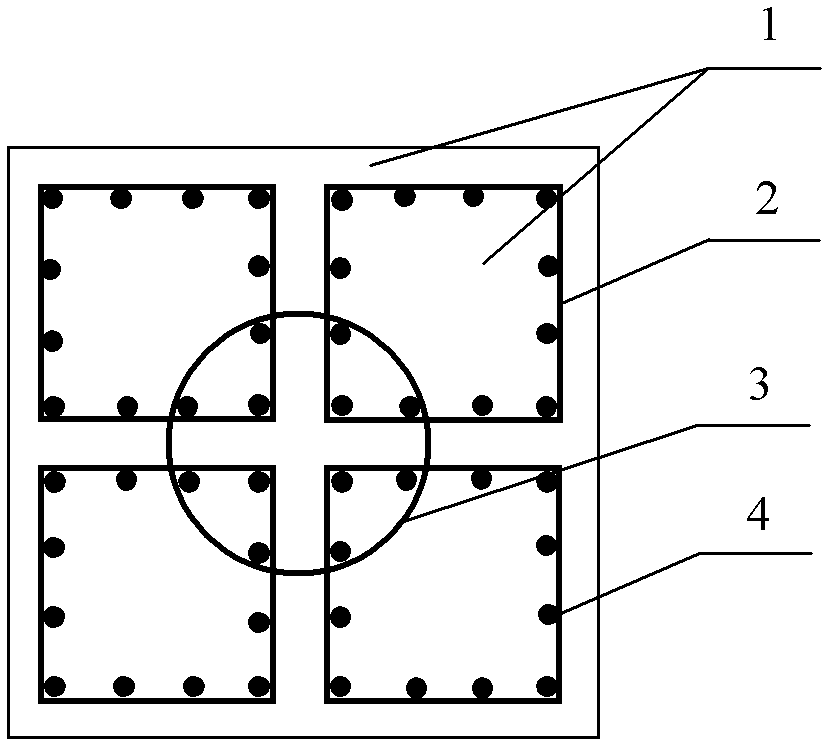

Embodiment 1

[0032] A high-seismic lightweight high-strength reinforced concrete column, as attached figure 1 As shown, the cross-section of the column is rectangular, the size is 450mm×450mm, and the column height is 1100mm. It is formed by pouring concrete after binding a reinforcement cage; the reinforcement cage is composed of 4 split stirrups of equal cross-section, center positioning stirrups and longitudinal bars, the split stirrups are rectangular spiral split stirrups, and the center positioning The stirrup is a central circular spiral positioning stirrup; the distance between the outer limbs of two adjacent split stirrups is 30mm; the central positioning stirrup and the stirrups of the four split stirrups of equal cross-section are arranged alternately and partially overlapped , 12 longitudinal bars are arranged on the inner side of each split stirrup, and 3 longitudinal bars are set at the overlapping part of the center positioning stirrup and the split stirrup; the side length ...

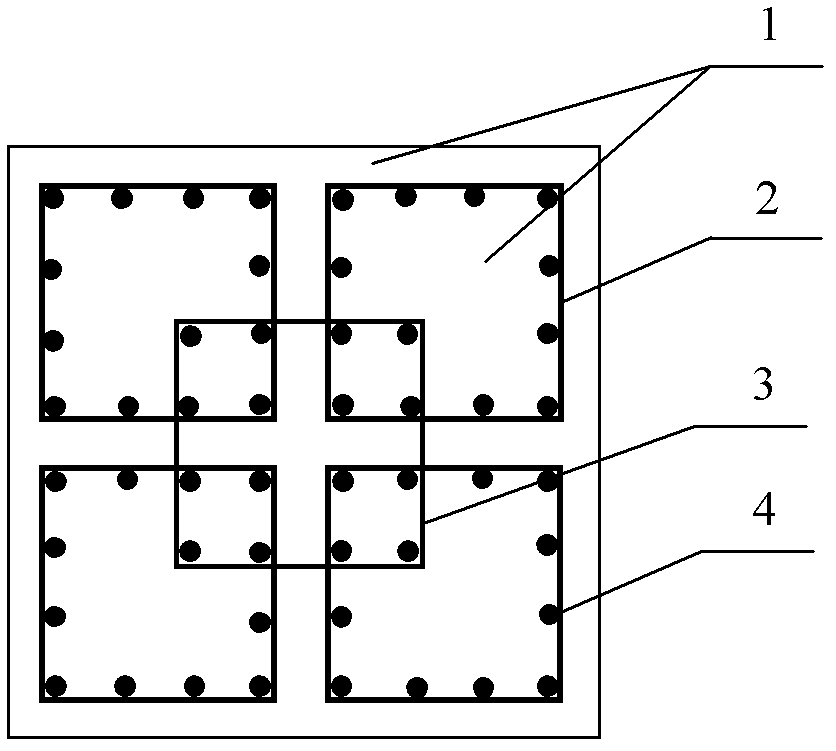

Embodiment 2

[0045] A high-seismic lightweight high-strength reinforced concrete column, as attached figure 2 As shown, the cross section of the column is rectangular, the side length is 450mm, and the column height is 1100mm. It is formed by pouring concrete after binding a reinforcement cage; the reinforcement cage (its reinforcement form) is composed of 4 split stirrups of equal cross-section, center positioning stirrups and longitudinal bars, and the split stirrups are rectangular spiral split Body stirrups, center positioning stirrups are central rectangular closed positioning stirrups; the distance between the outer limbs of two adjacent split stirrups is 35mm, the side length of split stirrups is 180mm, and the distance between stirrups is 45mm. A total of 12 longitudinal bars are arranged inside the split spiral stirrup; the side length of the center positioning stirrup is 190mm, the distance between the stirrups is 40mm, and 4 longitudinal bars are set at the overlapping part of ...

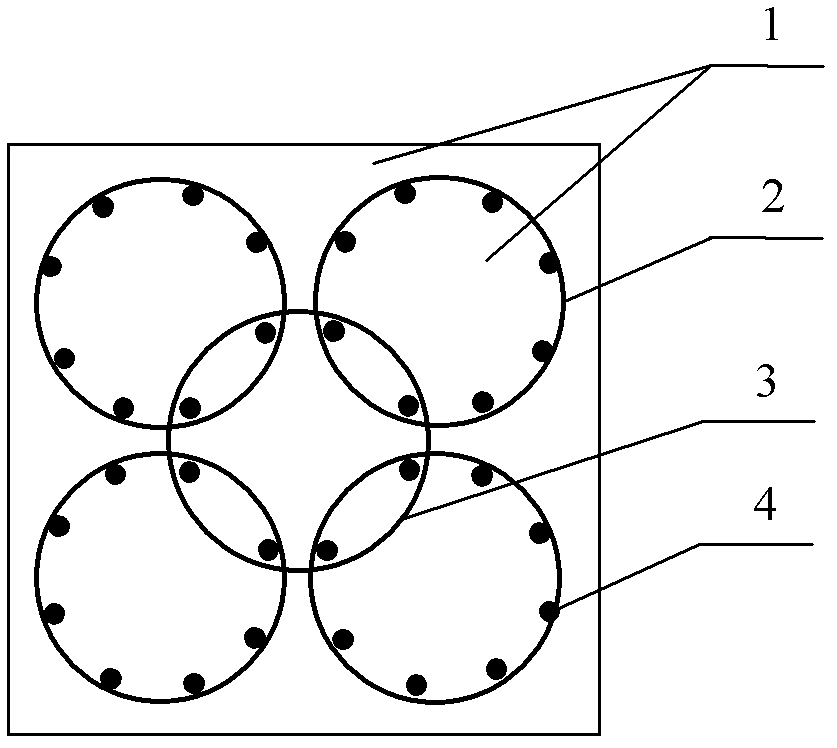

Embodiment 3

[0051] A high-seismic lightweight high-strength reinforced concrete column, as attached image 3 As shown, the cross-section of the column is rectangular, the size is 450mm×450mm, and the column height is 1100mm. It is formed by pouring concrete after binding a reinforcement cage; the reinforcement cage is composed of 4 split stirrups of equal cross-section, center positioning stirrups and longitudinal bars, the split stirrups are circular closed split stirrups, and the center The positioning stirrup is a central circular spiral positioning stirrup; the distance between the outer limbs of two adjacent split stirrups is 25mm, the diameter of the split stirrup is 180mm, and the distance between the stirrups is 40mm. A total of 8 longitudinal bars are set; the diameter of the central positioning stirrup is 190mm, the spacing of the stirrups is 50mm, and 2 longitudinal bars are set in the overlapping part of the positioning stirrup and the split stirrup. The longitudinal reinforc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com