Patents

Literature

62 results about "Engineered cementitious composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

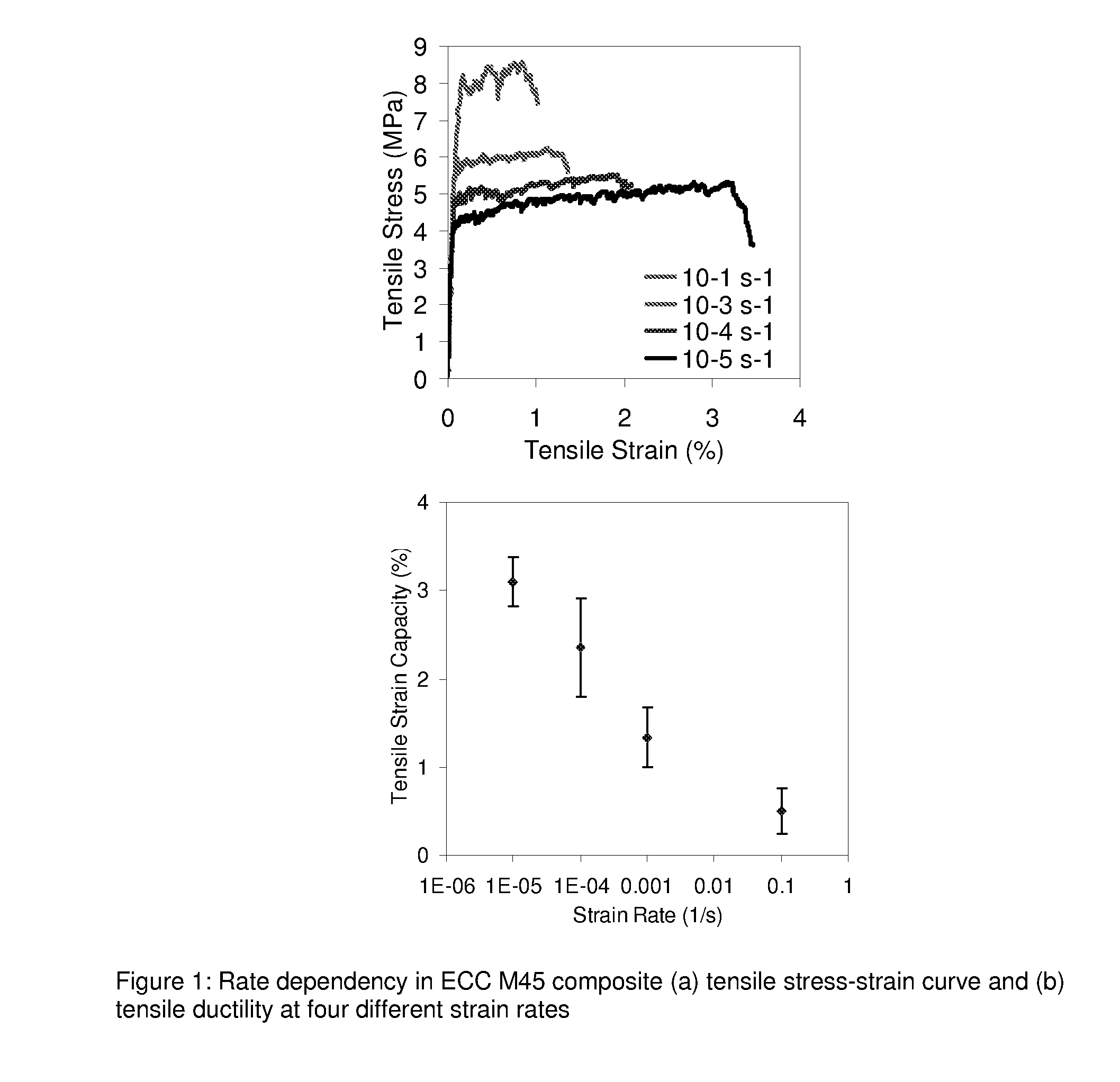

Engineered Cementitious Composite (ECC), also called Strain Hardening Cement-based Composites (SHCC) or more popularly as bendable concrete, is an easily molded mortar-based composite reinforced with specially selected short random fibers, usually polymer fibers. Unlike regular concrete, ECC has a strain capacity in the range of 3–7%, compared to 0.01% for ordinary portland cement (OPC) paste, mortar or concrete. ECC therefore acts more like a ductile metal like material rather than a brittle glass like material (as does OPC concrete), leading to a wide variety of applications.

Cementitious composites having wood-like properties and methods of manufacture

InactiveUS20080099122A1Harder to saw, nail or screwLow densityPlastic recyclingLaminationPorosityBuilding product

A method of manufacturing a cementitious composite includes: (1) forming mixing an extrudable cementitious composition by first forming a fibrous mixture comprising fibers, water and a rheology modifying agent and then adding hydraulic cement; (2) extruding the extrudable cementitious composition into a green extrudate, wherein the green extrudate is characterized by being form-stable and retaining substantially a predefined cross-sectional shape; (3) removing a portion of the water by evaporation to reduce density and increase porosity; and (4) causing or allowing the hydraulic cement to hydrate to form the cementitious composite. Such a process yields a cementitious composite that is suitable for use as a wood substitute. The wood-like building products can be sawed, nailed and screwed like ordinary wood.

Owner:E KHASHOGGI INDS

High Early Strength Engineered Cementitious Composites

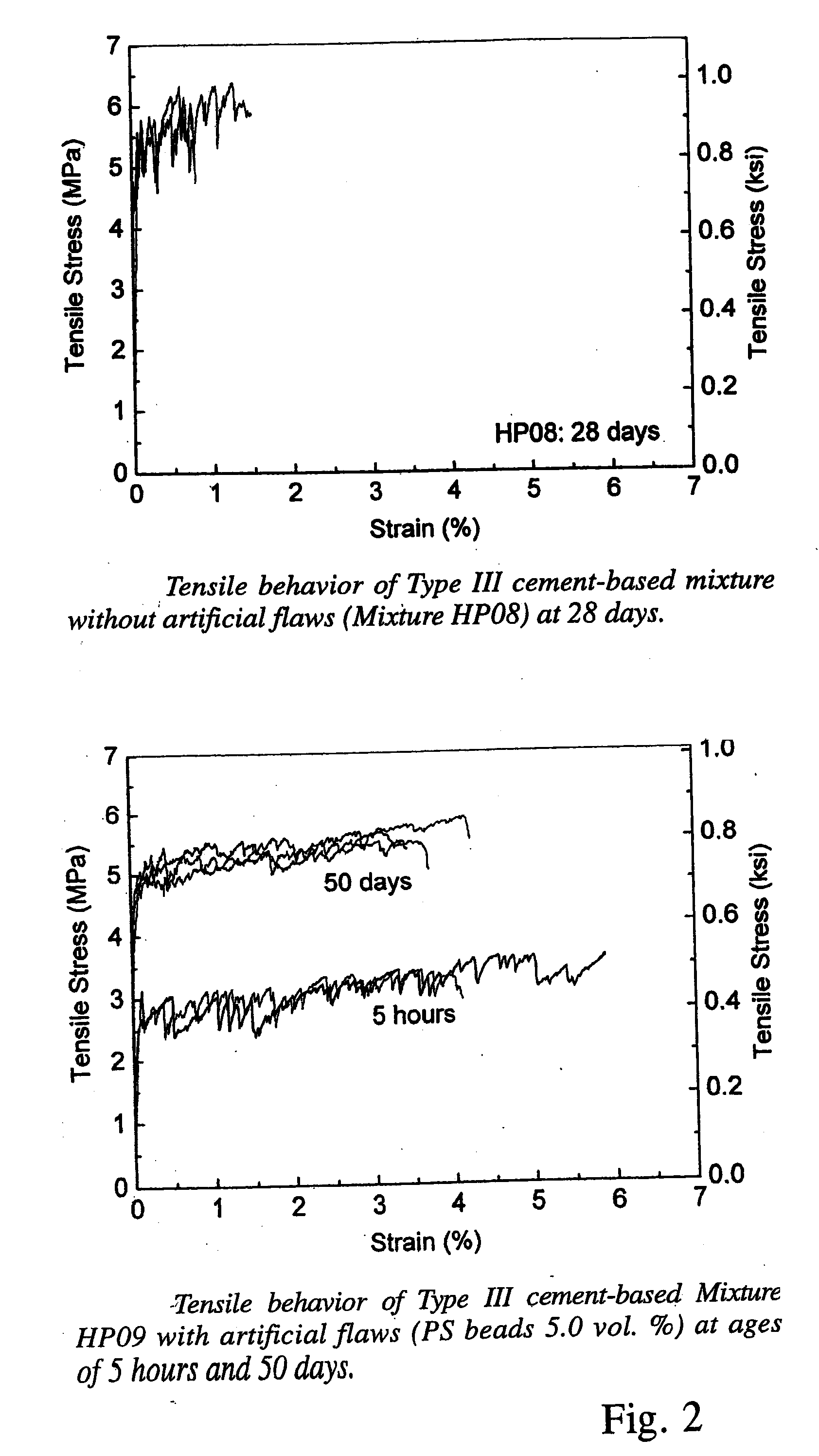

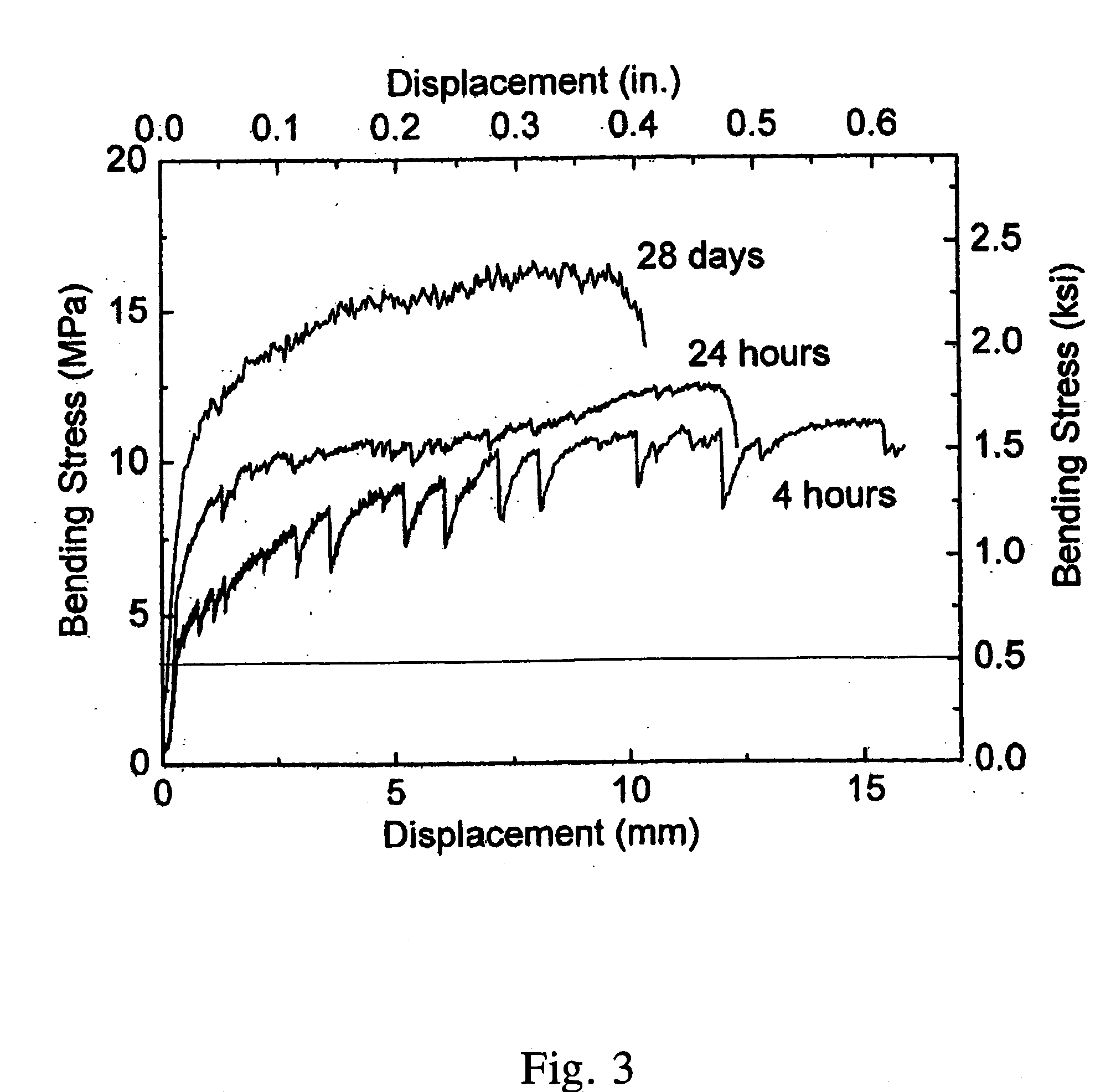

ActiveUS20070181040A1High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

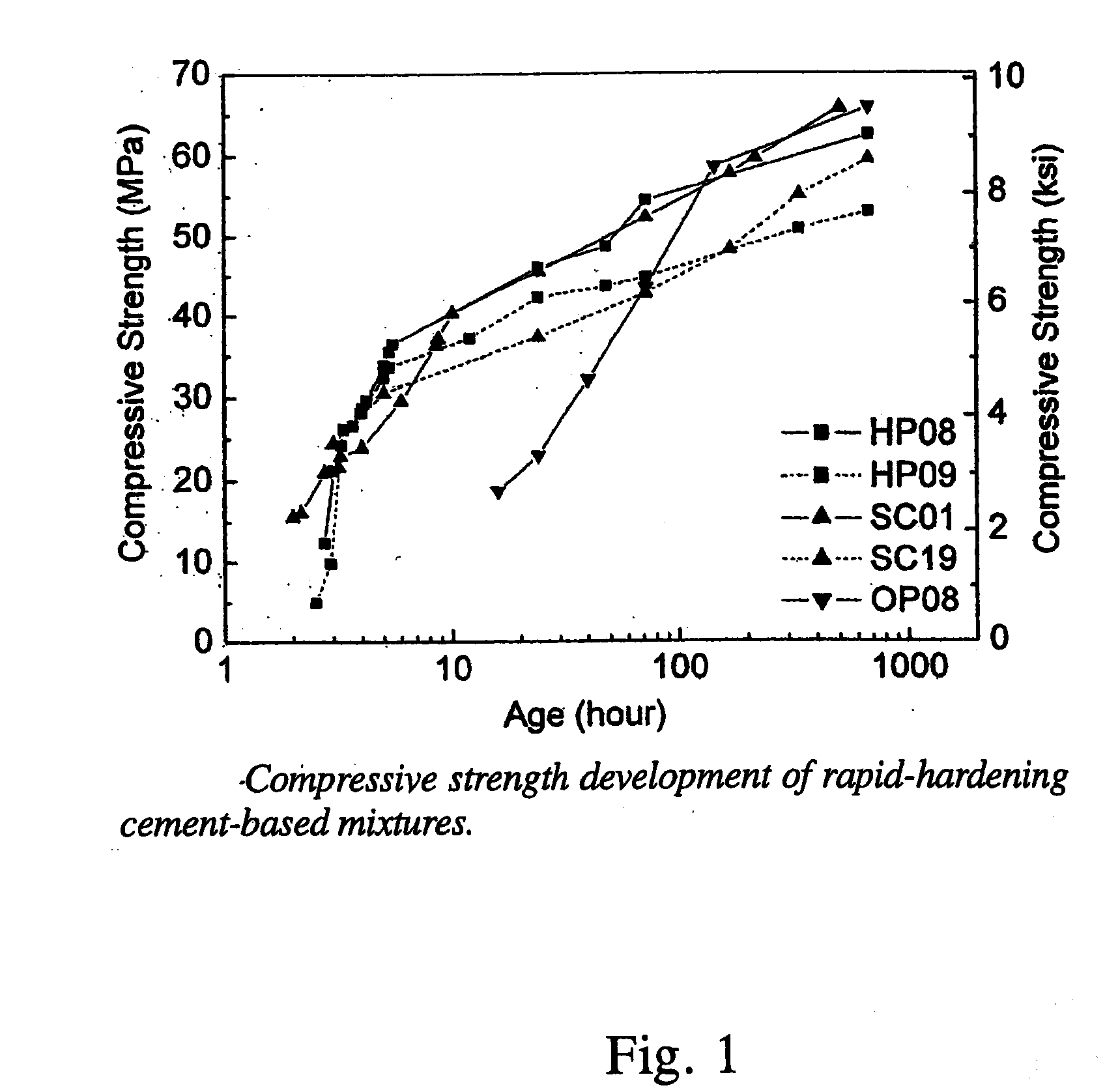

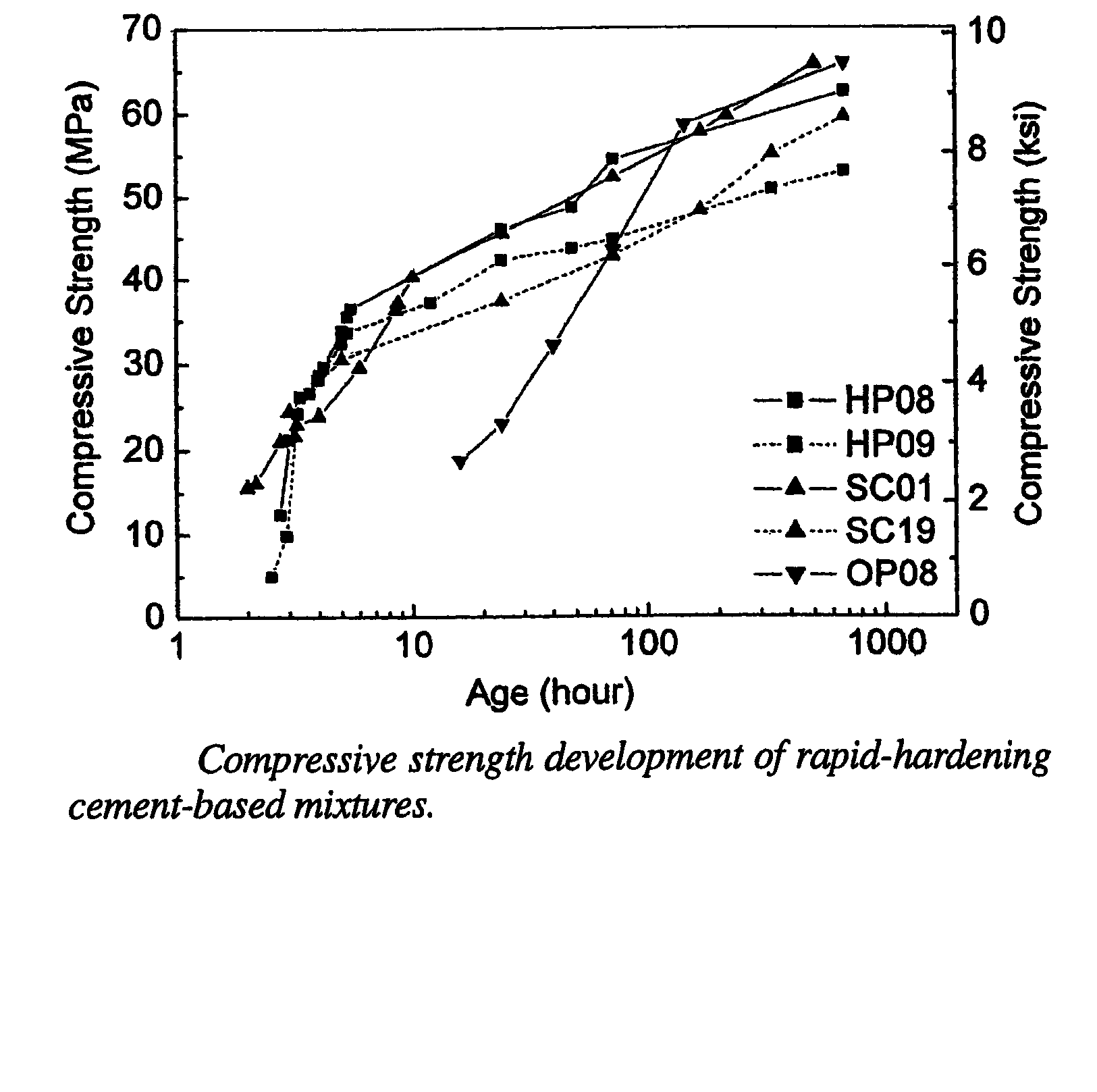

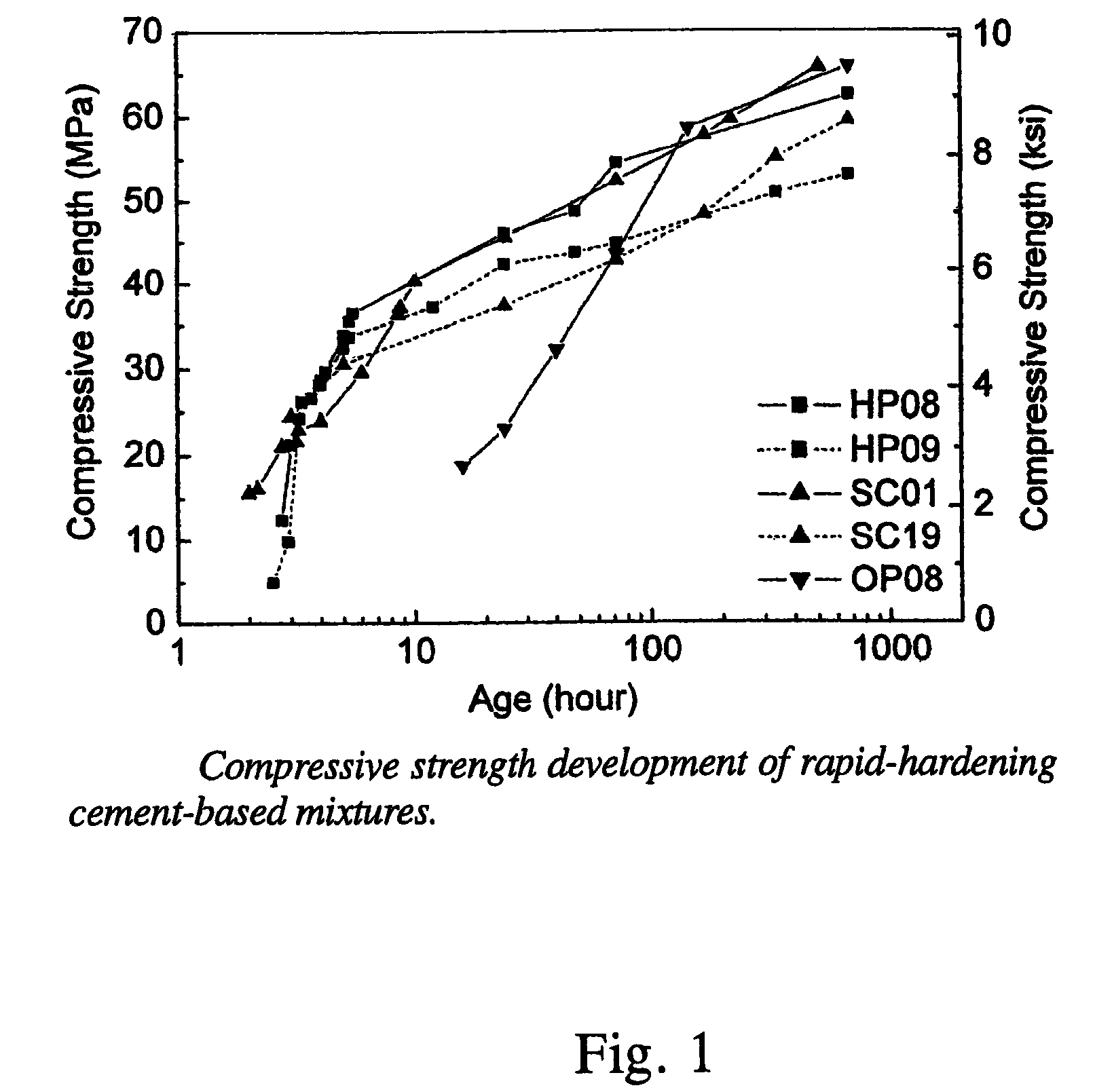

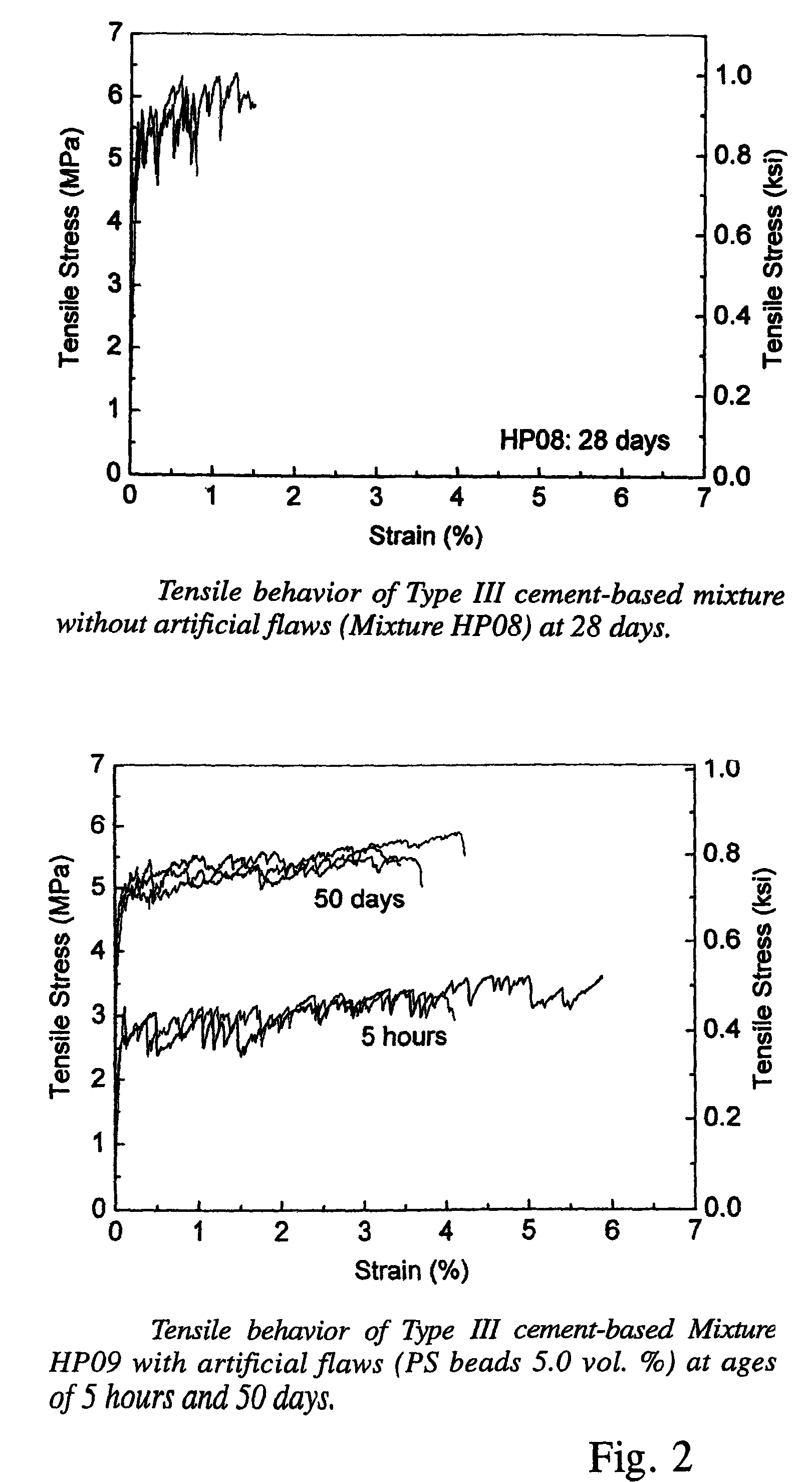

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

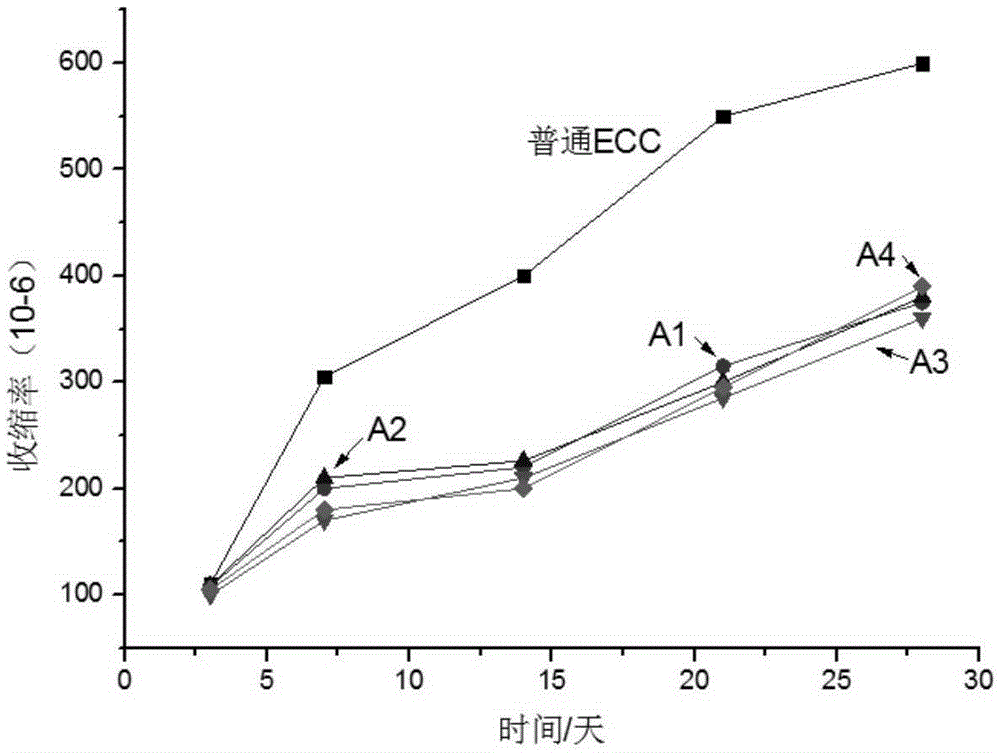

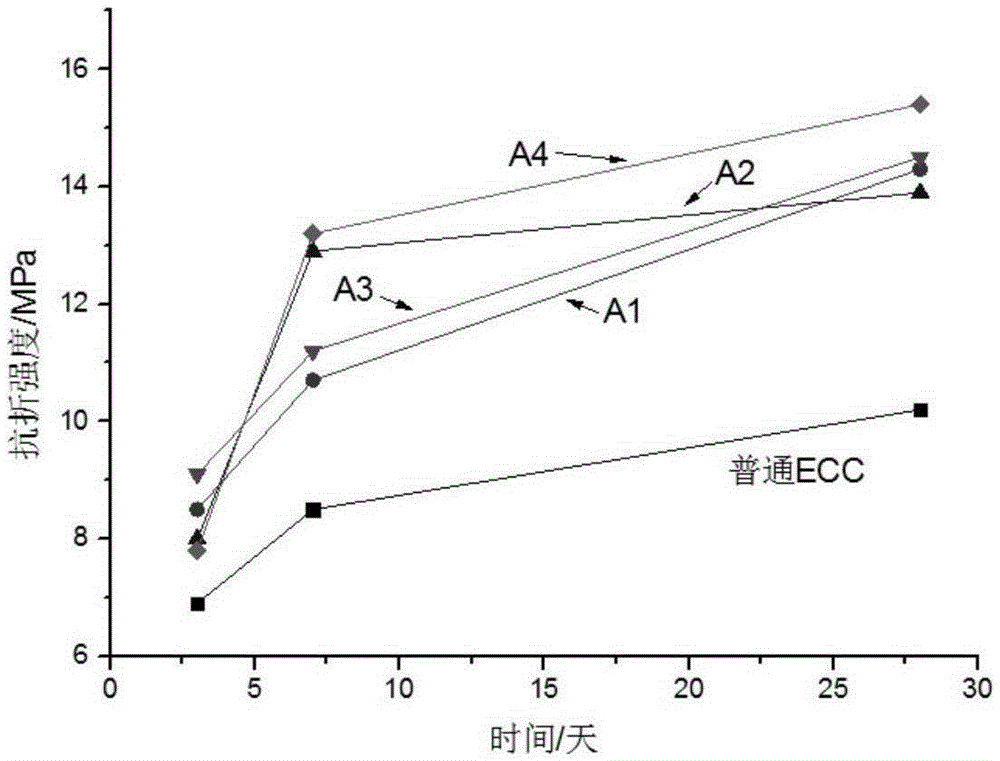

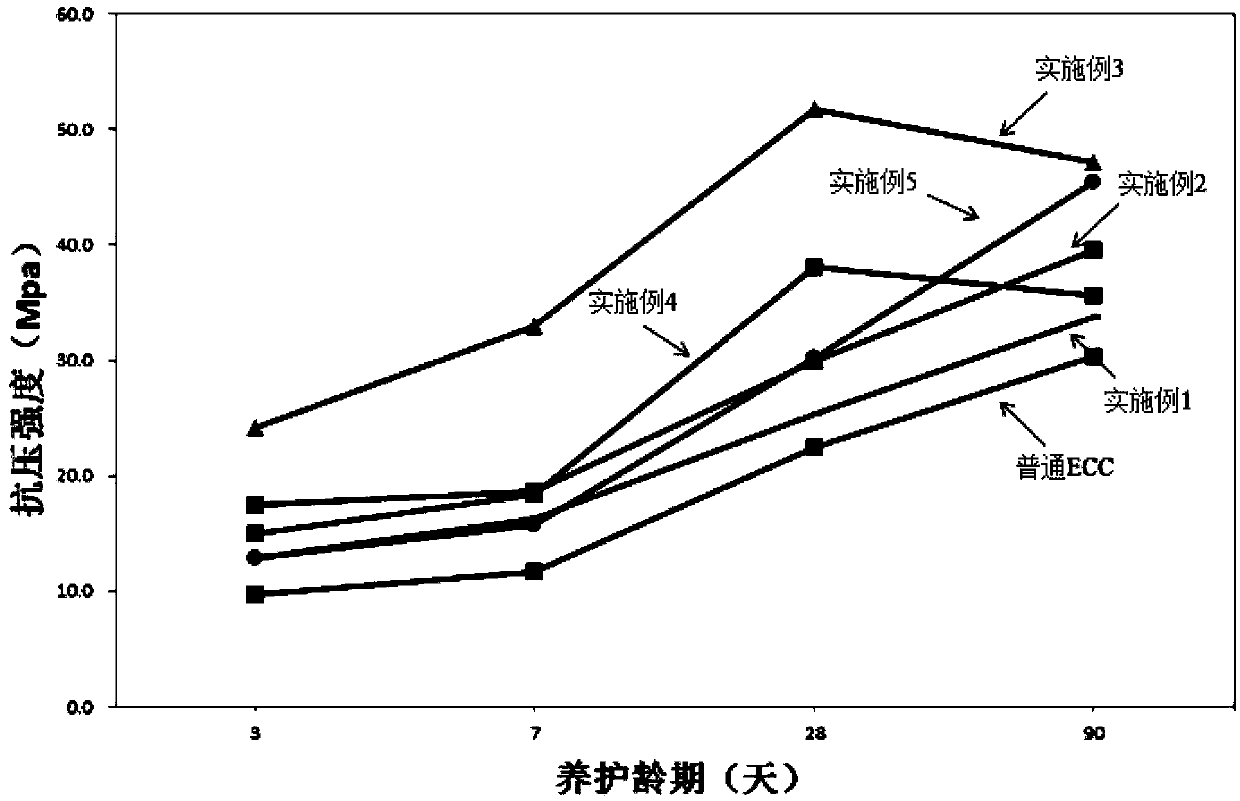

Graphene oxide modified cement-based composite material and preparation method thereof

ActiveCN105294027AHigh compressive strengthImprove flexural strengthClimate change adaptationSuperplasticizerEngineered cementitious composite

The invention relates to a graphene oxide modified cement-based composite material and a preparation method thereof. The graphene oxide modified cement-based composite material is prepared by mixing graphene oxide, polyvinyl alcohol fibers (PVA), cement, flyash, water, quartz sand, a polycarboxylate superplasticizer, a shrinkage reducing agent, a polymer and a defoaming agent according to a certain proportion. Compared with the prior art, the graphene oxide modified cement-based composite material has the advantages that the cement-based composite material has the advantages of higher compressive strength and breaking strength, low shrinkability, high toughness, high ductility, and the like compared with common ECC (engineered cementitious composite) and is especially suitable for repair and reinforcement of building structures with complex contours.

Owner:WUHAN UNIV OF TECH

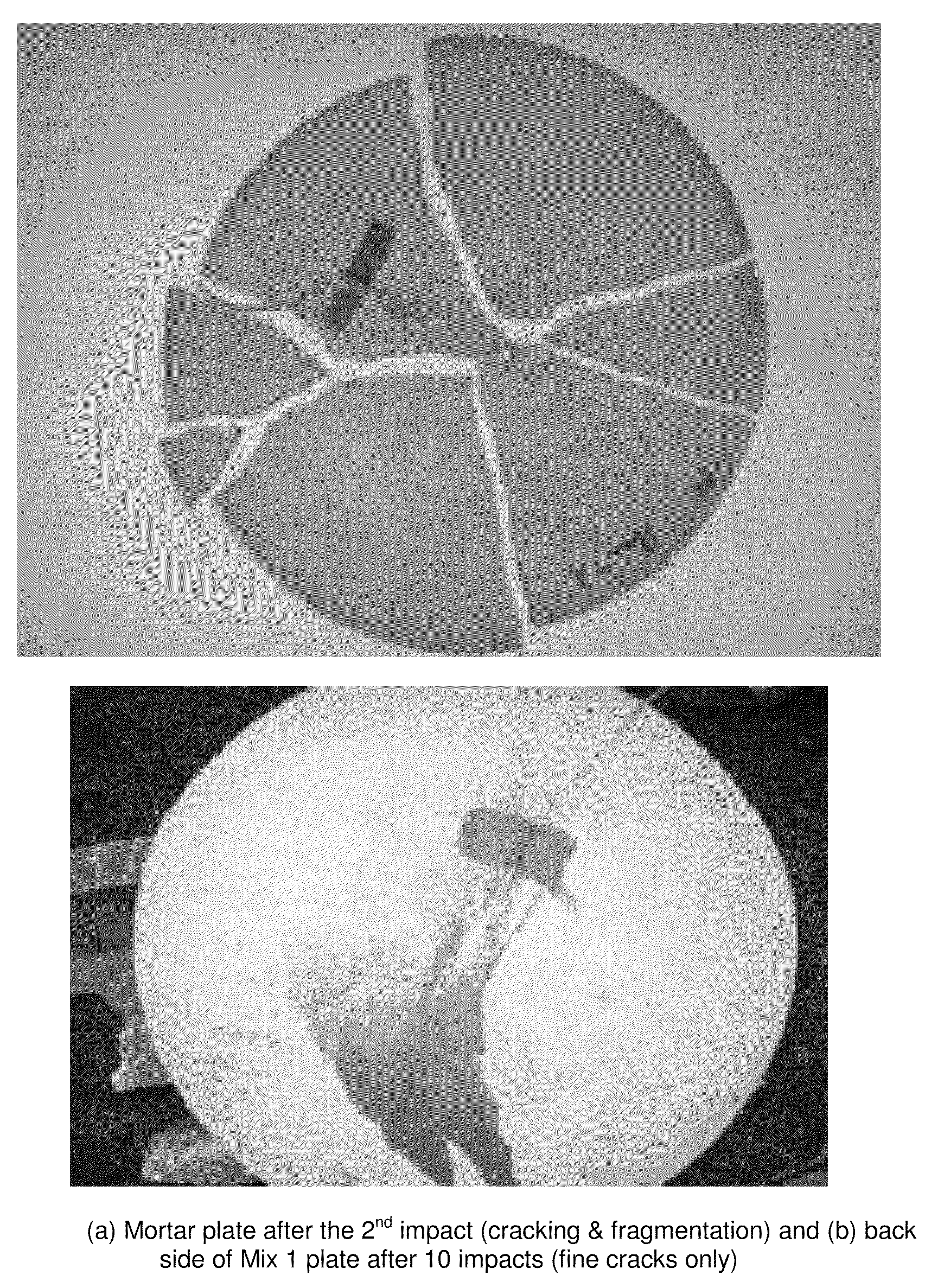

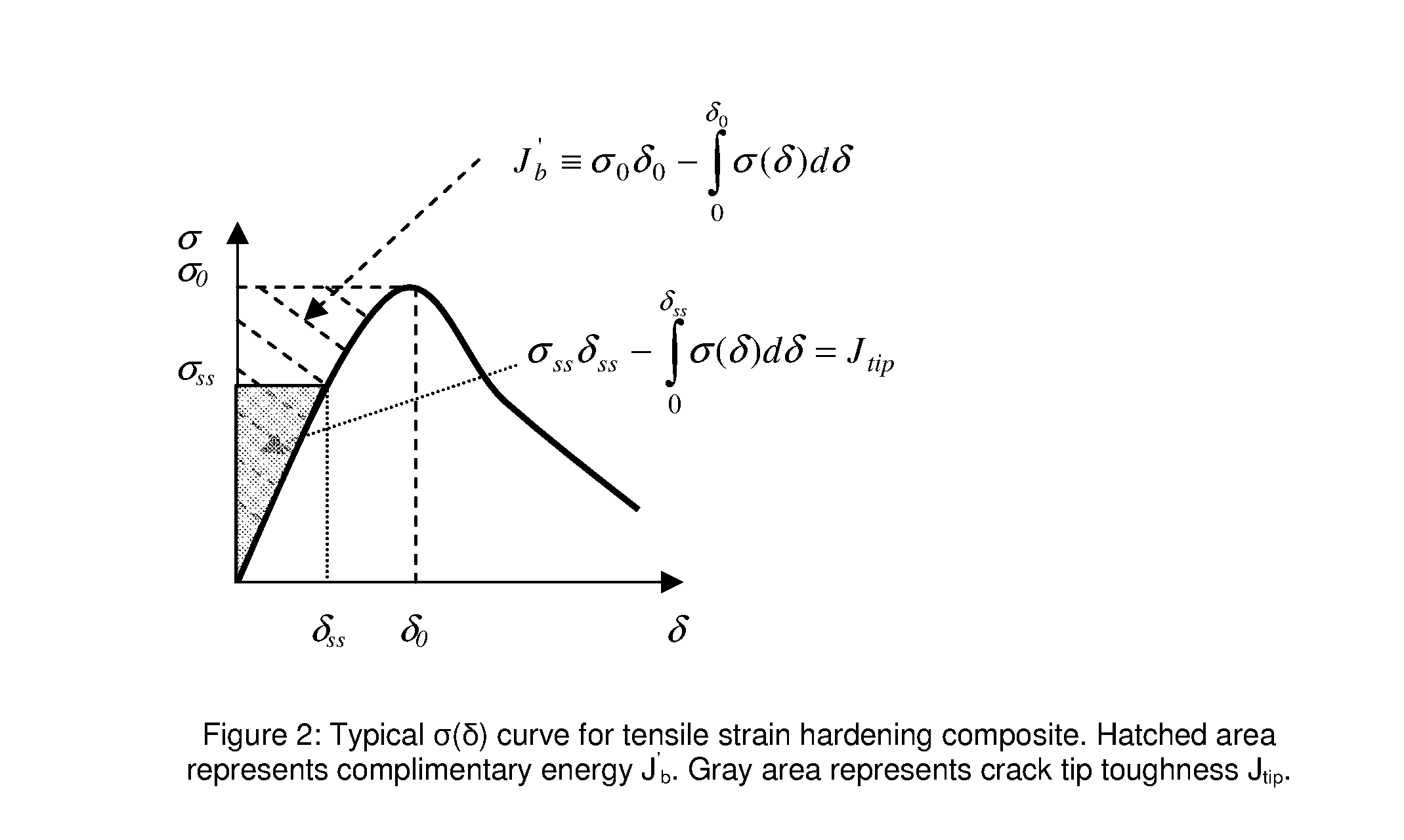

Impact resistant strain hardening brittle matrix composite for protective structures

InactiveUS20090075076A1Good tensile strain capacitySuppress localized brittle fractureSolid waste managementLayered productsResistant strainEngineered cementitious composite

An extremely ductile fiber reinforced brittle matrix composite is of great value to protective structures that may be subjected to dynamic and / or impact loading. Infrastructures such as homes, buildings, and bridges may experience such loads due to hurricane lifted objects, bombs, and other projectiles. Compared to normal concrete and fiber reinforced concrete, the invented composite has substantially improved tensile strain capacity with strain hardening behavior, several hundred times higher than that of conventional concrete and fiber reinforced concrete even when subjected to impact loading. The brittle matrix may be a hydraulic cement or an inorganic polymer. In an exemplary embodiment of the teachings, the composites are prepared by incorporating pozzolanic admixtures, lightweight filler, and fine aggregates in Engineered Cementitious Composite fresh mixture, to form the resulting mixtures, then placing the resulting mixtures into molds, and curing the resulting mixtures.

Owner:RGT UNIV OF MICHIGAN

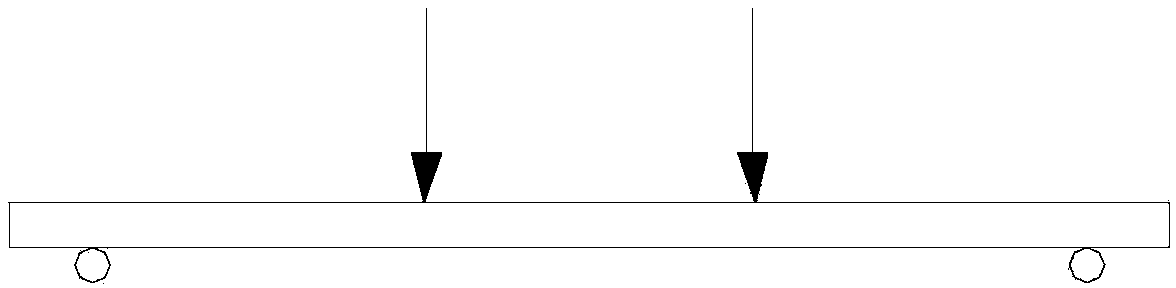

Engineered cementitious composite (ECC) repairing material and preparation method thereof

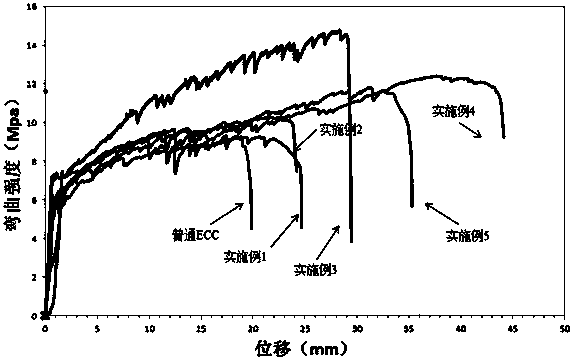

InactiveCN103387356AHigh compressive strengthImprove bending strengthSolid waste managementClimate change adaptationPolyvinyl alcoholFlexural strength

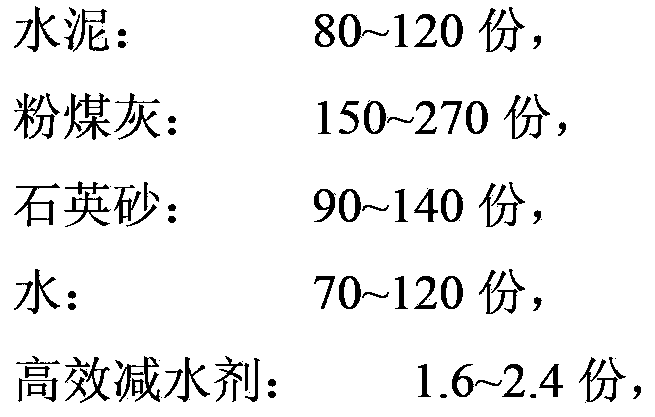

The invention discloses an engineered cementitious composite (ECC) repairing material comprising the following components: cement, coal ash, quartz sand, water, a water reducer, an early strength additive and polyvinyl alcohol fiber. All the components are stirred and mixed according to a certain sequence to obtain the ECC repairing material disclosed by the invention. Due to the addition of a great deal of cheap coal ash in raw materials, on one hand, the strength of a substrate material can be weakened and the high ductility of the material is ensured, and on the other hand, the price of the coal ash is far lower than that of an artificial defect material; the ECC repairing material has higher compressive strength and bending strength than a common ECC material; and meanwhile, a proper amount of early strength additive is added, the strength of the material used for seven days can be up to 80% of the final strength, and compared with the traditional engineered fiber reinforced cementitious composite material, the ECC repairing material has the advantages that the maintenance time is shortened, the material can be desterilized as soon as possible, and the material meets the general engineering requirement on the aspect of time. Therefore, the ECC repairing material has a favorable engineering application value.

Owner:SOUTHEAST UNIV

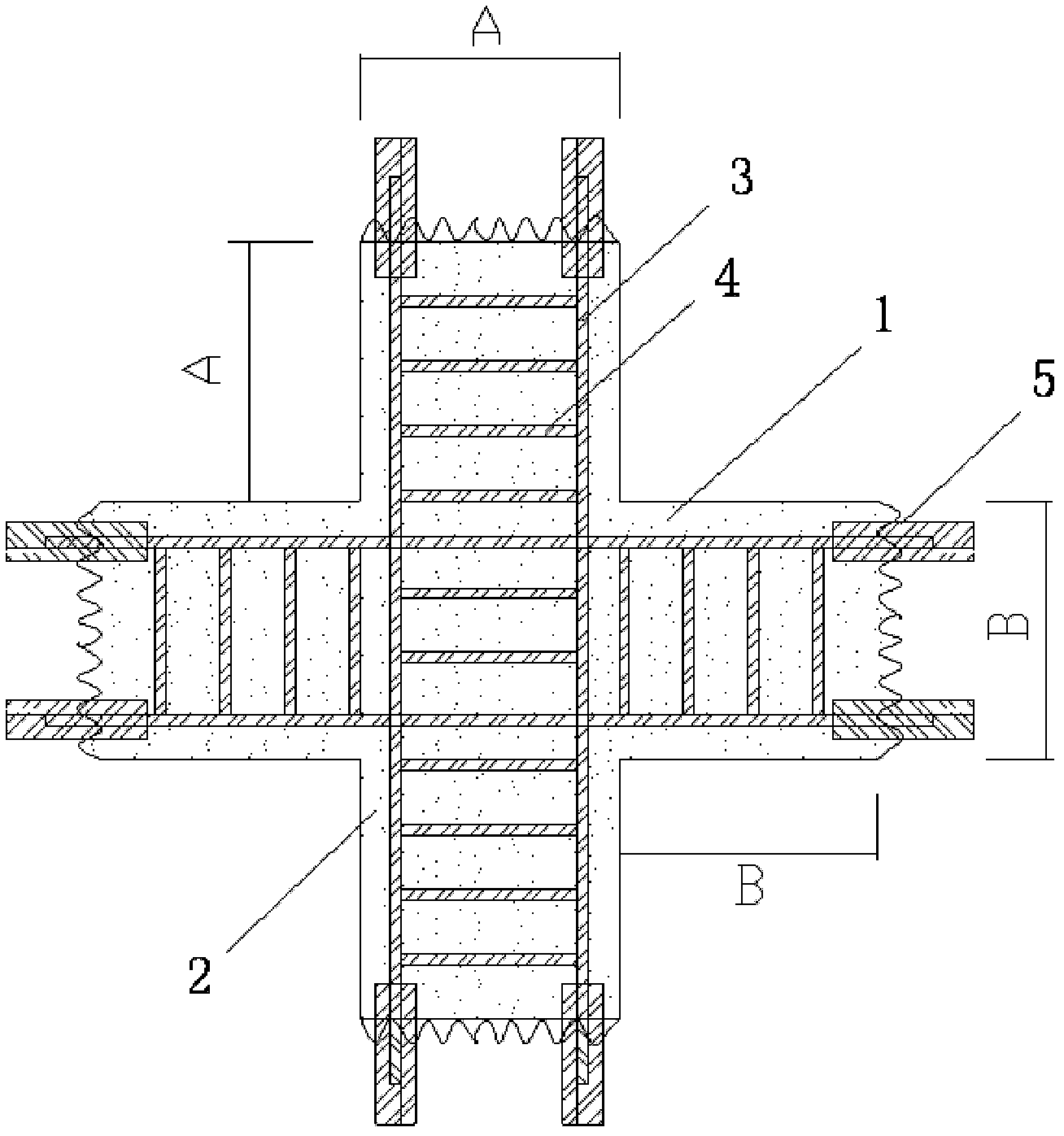

Prefabricated ECC-RC combination beam column joint component

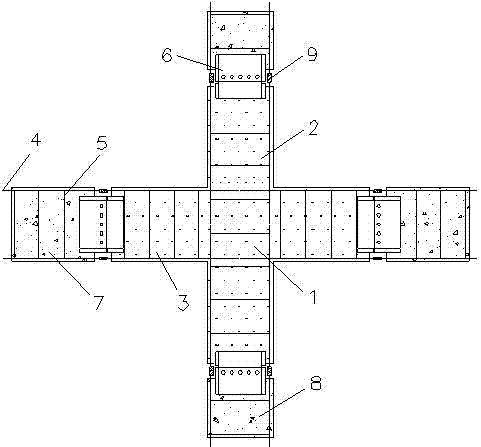

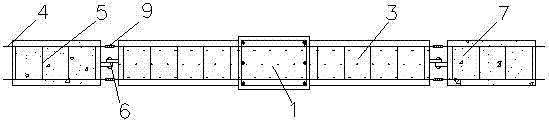

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

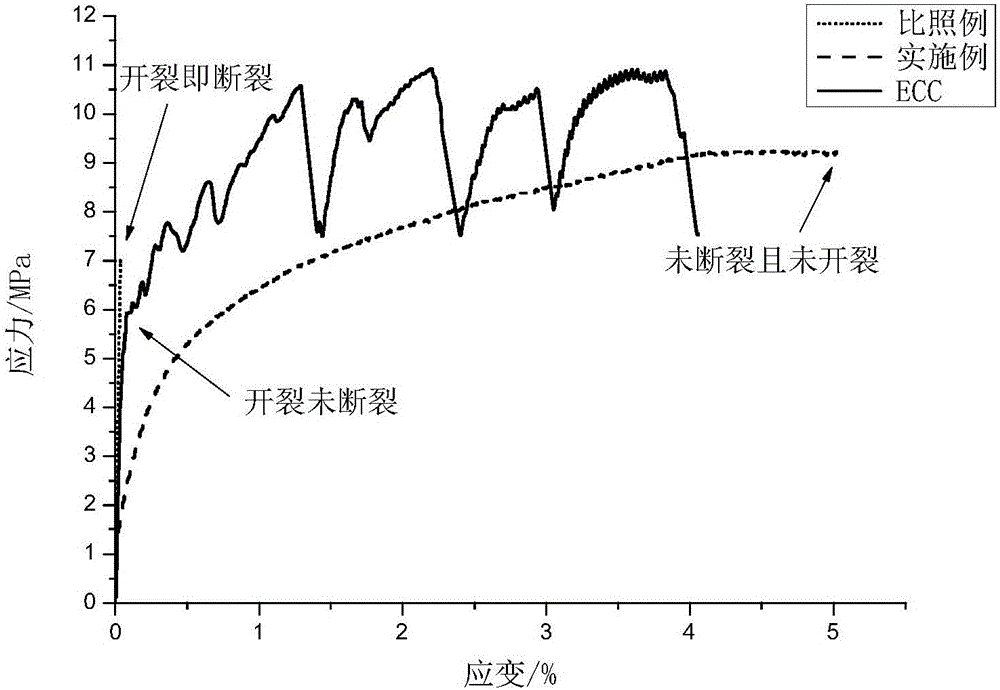

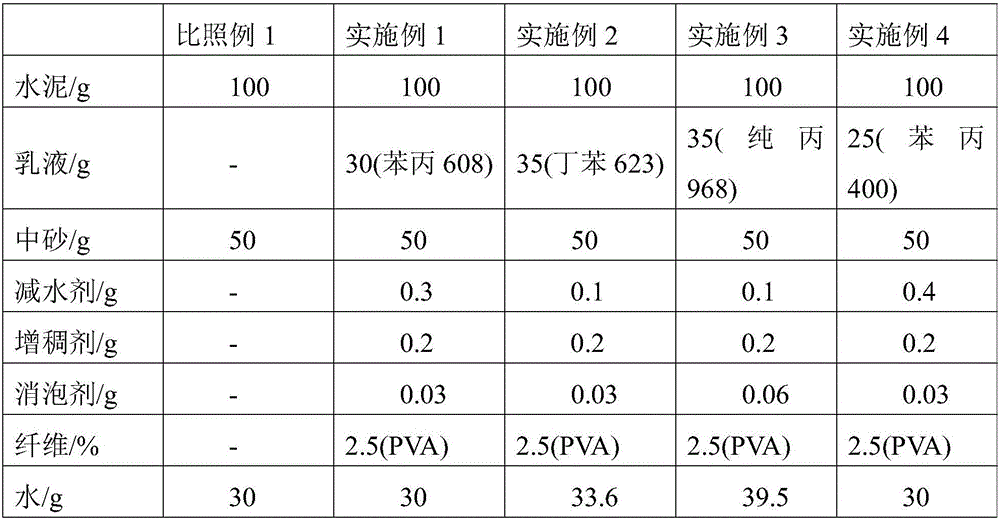

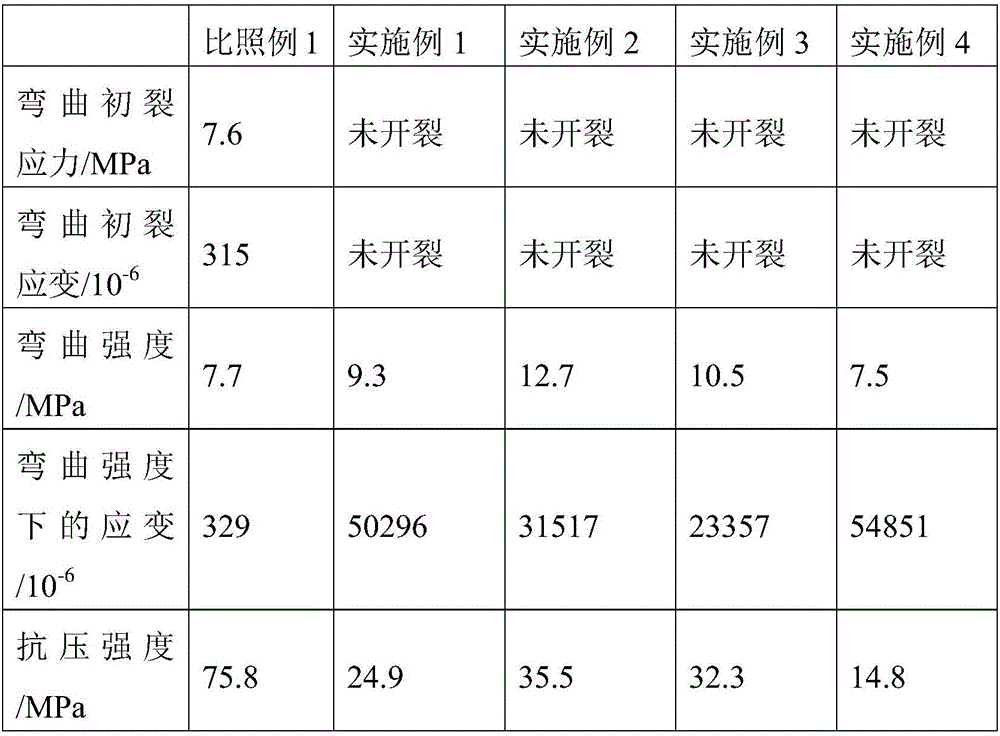

Ultrahigh-toughness fiber-reinforced polymer modified cementitious composite and preparation method

InactiveCN106478007AHigh bending strain at first crackHigh flexural crack stressPolymer modifiedPolymer science

The invention relates to an ultrahigh-toughness fiber-reinforced polymer modified cementitious composite and a preparation method. The ultrahigh-toughness fiber-reinforced polymer modified cementitious composite is prepared from raw materials in parts by weight as follows: 100 parts of comprising cement, 50 parts of medium sand, 25-35 parts of polymer emulsion (in terms of solid content), synthetic polymer fibers, 0.1-0.5 parts of a water reducing agent, an antifoaming agent, 0.1-0.5 parts of a thickener and 30-40 parts of water according to a formula, wherein the synthetic polymer fibers account for 2.5% of the total volume of the composite, and the antifoaming agent accounts for 0.05%-0.2% of the mass of the polymer emulsion. Compared with the prior art, the ultrahigh-toughness fiber-reinforced polymer modified cementitious composite has the advantages of ultrahigh initial cracking strain, higher bending stress, higher initial cracking stress and the like.

Owner:TONGJI UNIV

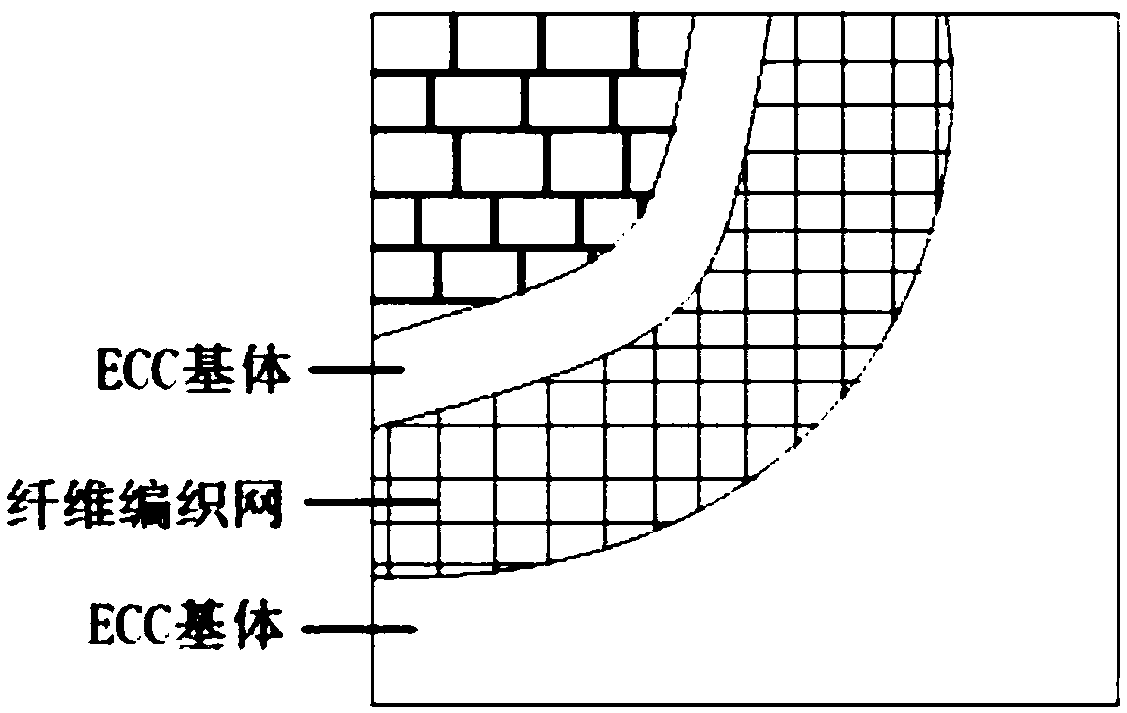

Reinforcement method of ECC (Engineered Cementitious Composite) fiber woven mesh for improving anti-seismic performance of masonry wall

InactiveCN108298904AImprove the deficiency of low enhancement efficiencyAvoiding the Problems Caused by Using EpoxyClimate change adaptationBuilding repairsFiberPre treatment

The invention relates to a reinforcement method of an ECC (Engineered Cementitious Composite) fiber woven mesh for improving the anti-seismic performance of a masonry wall, and belongs to a masonry wall repairing and reinforcing and construction method. The method comprises the steps that (1) a masonry wall to be reinforced is subjected to pretreatment; (2) dust on the surface of the masonry wallto be reinforced is cleaned; the masonry wall to be reinforced is wetted; then, a layer of ECC base body is smeared onto the surface of the masonry wall to be reinforced; (3) the fiber woven mesh is impregnated by polymer cement mortar and is then laid at the surface of the ECC base body; (4) a layer of ECC base body is smeared onto the surface of the fiber woven mesh again; (5) wet water curing is performed for 28 days until the service life of the ECC base body is reached. The anti-shearing and anti-bending performance of the masonry wall can be effectively improved; the risk that a masonrystructure generates serious damage or even collapse in an earthquake is reduced; the structure repairing work after strong earthquake is reduced or even omitted; the durability of the reinforcing structure is improved. Compared with a traditional reinforcing method, the reinforcement method has the advantages that the self weight of the masonry structure is hardly increased; the use space of a building after the reinforcement is hardly reduced; the construction is convenient.

Owner:CHINA UNIV OF MINING & TECH

FRP (Fiber Reinforced Plastic) pipe confined cement based composite material reinforced pier column structure

ActiveCN104675141AAct as a stopperPlay the role of hoop restraintClimate change adaptationBuilding repairsFiber-reinforced compositeEngineered cementitious composite

The invention discloses an FRP (Fiber Reinforced Plastic) pipe confined cement based composite material reinforced pier column structure applied to reinforcement of pier columns with all structures. The FRP pipe confined cement based composite material reinforced pier column structure comprises a pier column, a fiber reinforced composite material base arranged at the bottom of the pier column, a fiber reinforced composite material pipe arranged around the pier column, a limiter fixing the position of the fiber reinforced composite material pipe, and an engineering cement based composite material filling a gap between the fiber reinforced composite material pipe and the pier column. The advantages of the fiber reinforced composite material base, the fiber reinforced composite material pipe, the engineering cement based composite material and fiber grid meshes are integrated and can be fully played, the excellent performance of a single material can be greatly improved under the action of mutual adhesion of the fiber reinforced composite material base, the fiber reinforced composite material pipe, the engineering cement based composite material and the fiber grid meshes, and the bearing capacity, the erosion resistibility, the anti-seismic property, the ductility, the fatigue resistance and the durability of the pier column structure are effectively improved.

Owner:江苏恒美德新材料有限公司

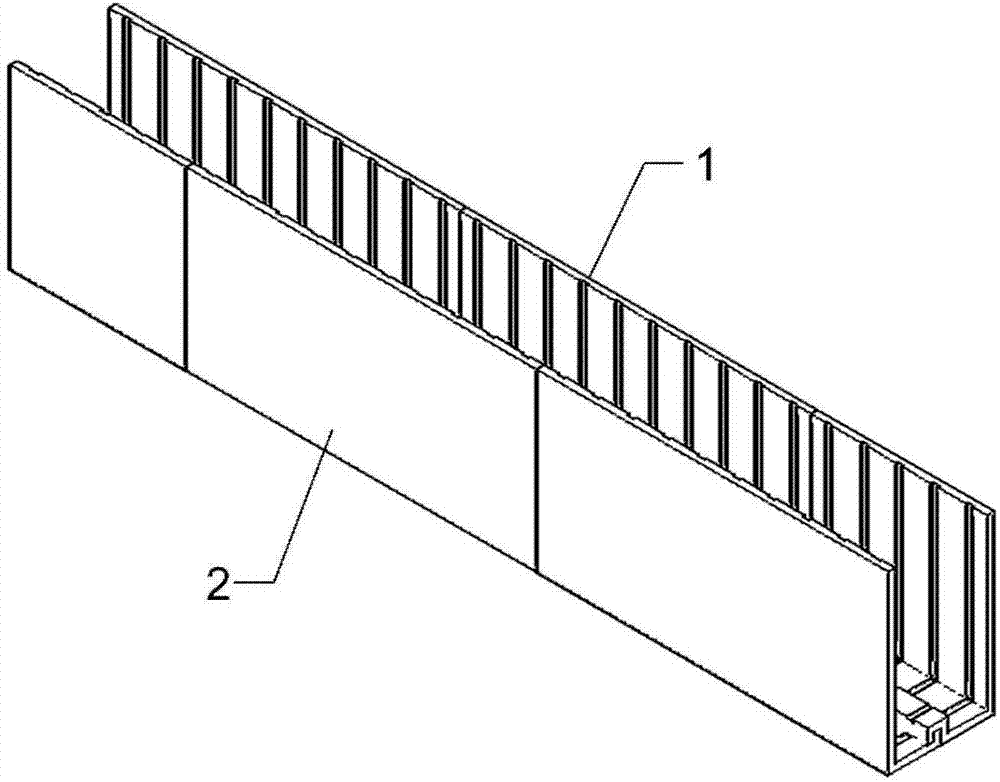

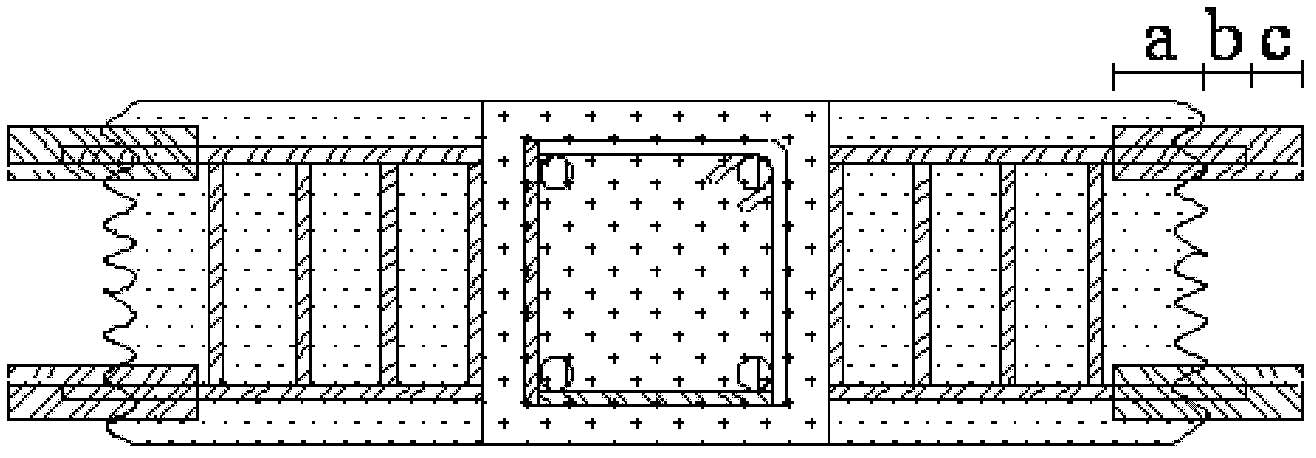

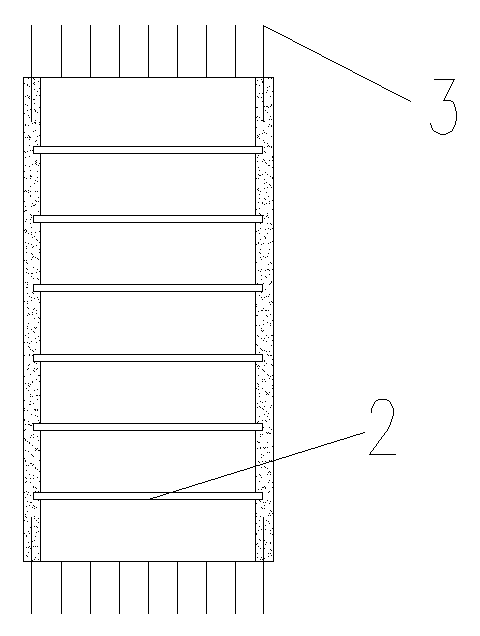

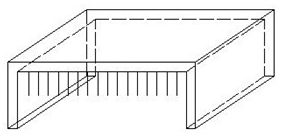

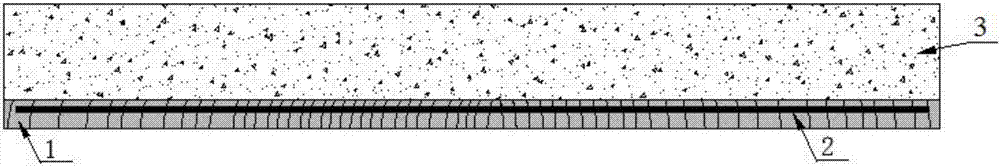

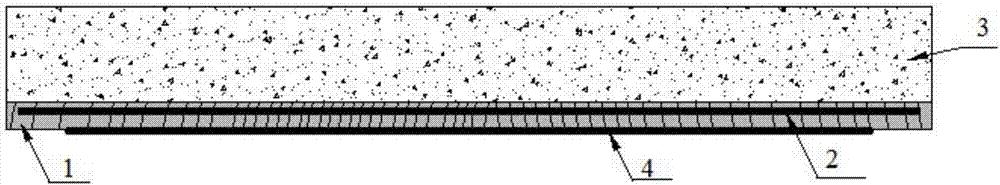

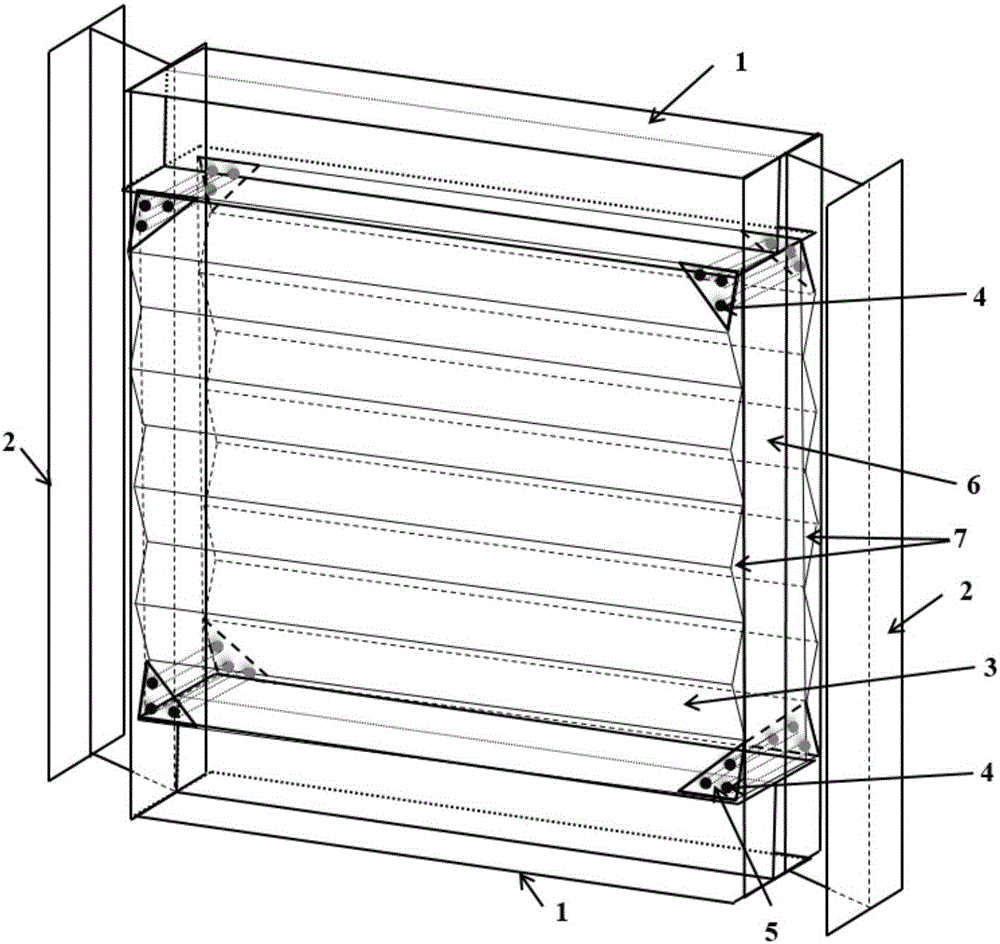

Interlocking dismountable anti-cracking anti-seepage permanent beam template

ActiveCN102777027AImprove and resolve disassemblyImprove and address utilizationGirdersForms/shuttering/falseworksHydraulic structureStructural engineering

The invention discloses an interlocking dismountable anti-cracking anti-seepage permanent beam template. A first corner panel and a second corner panel are connected by virtue of an adhesion agent in an interlocking manner. The beam template disclosed by the invention can be used as the beam template in a beam pouring stage of structures such as an industrial and civil building structure, a hydraulic structure and a seaport structure, is taken as a protective plate and an outer protective layer of the structure after pouring and moulding are carried out and bears a part of load. The beam template disclosed by the invention can be prepared from the following different types of materials: ultrahigh toughness cementitious composite (UHTCC), a non-metal fiber woven mesh short fiber combined reinforced cementitious composite and a steel wire mesh short fiber combined reinforced cementitious composite and has the characteristics of convenience in manufacturing, convenience in application, high durability and control over crack developing.

Owner:ZHEJIANG UNIV

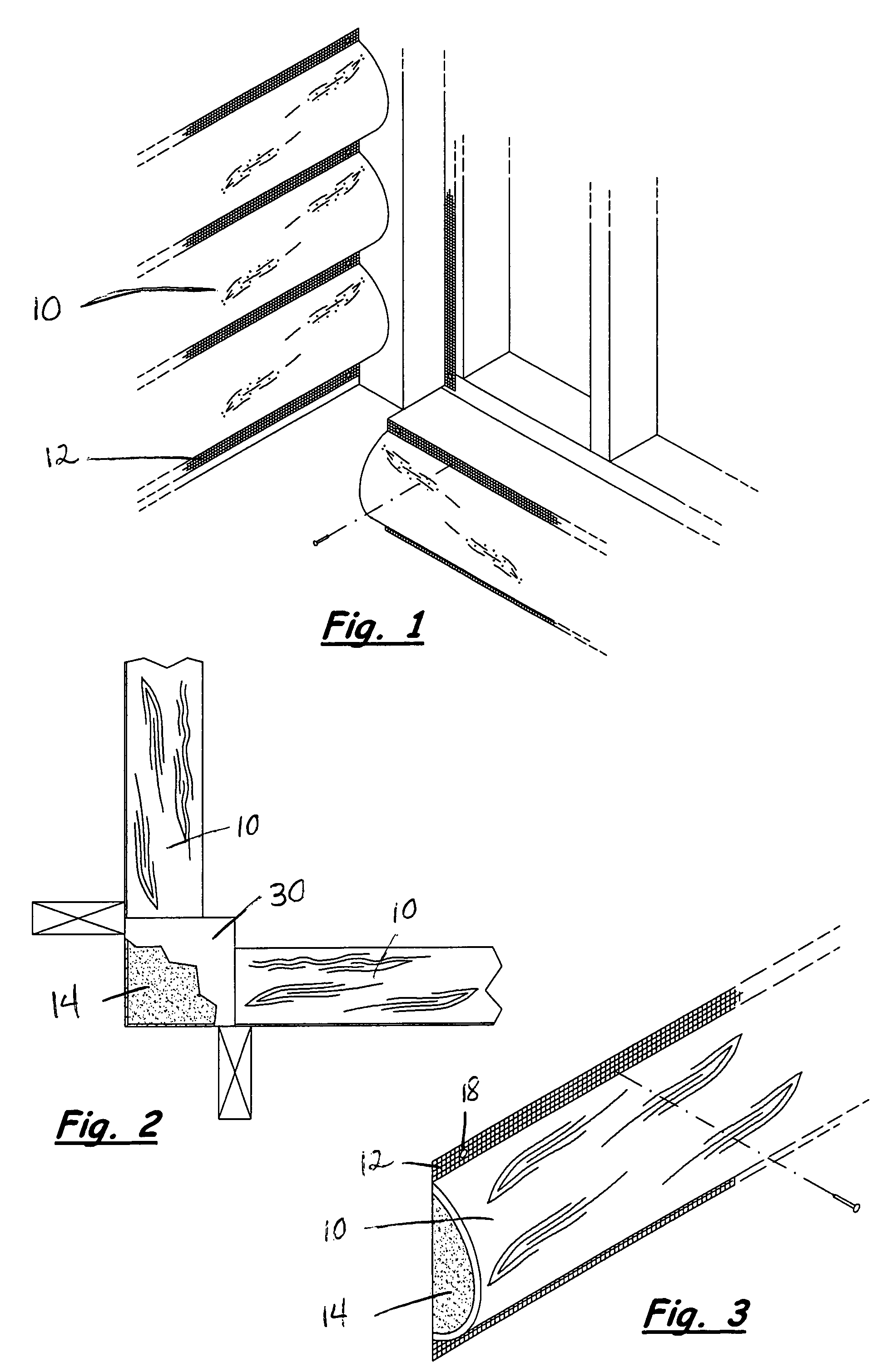

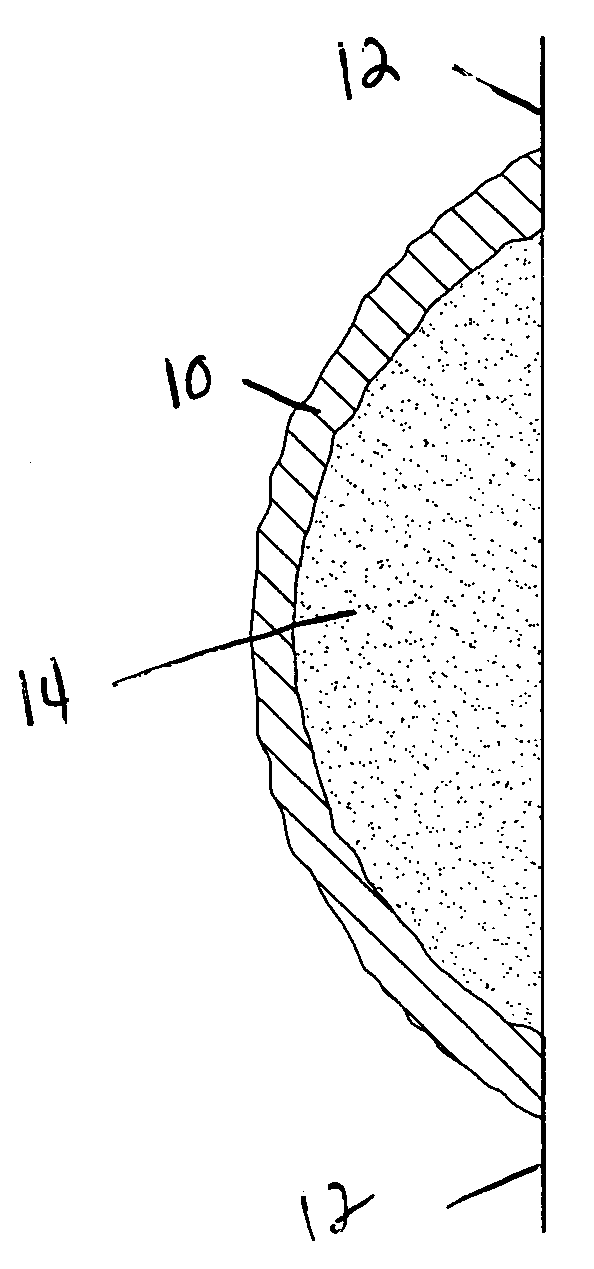

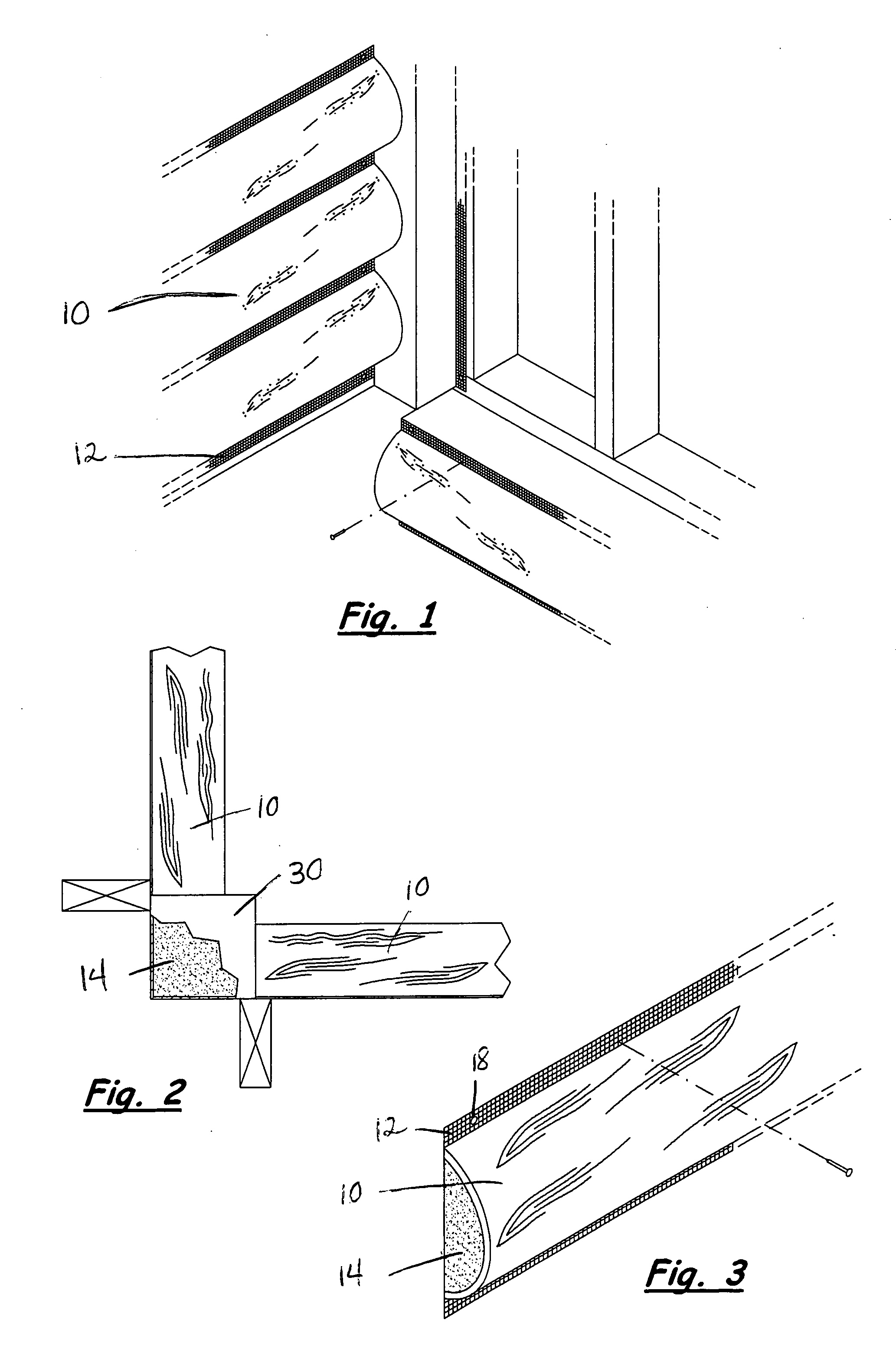

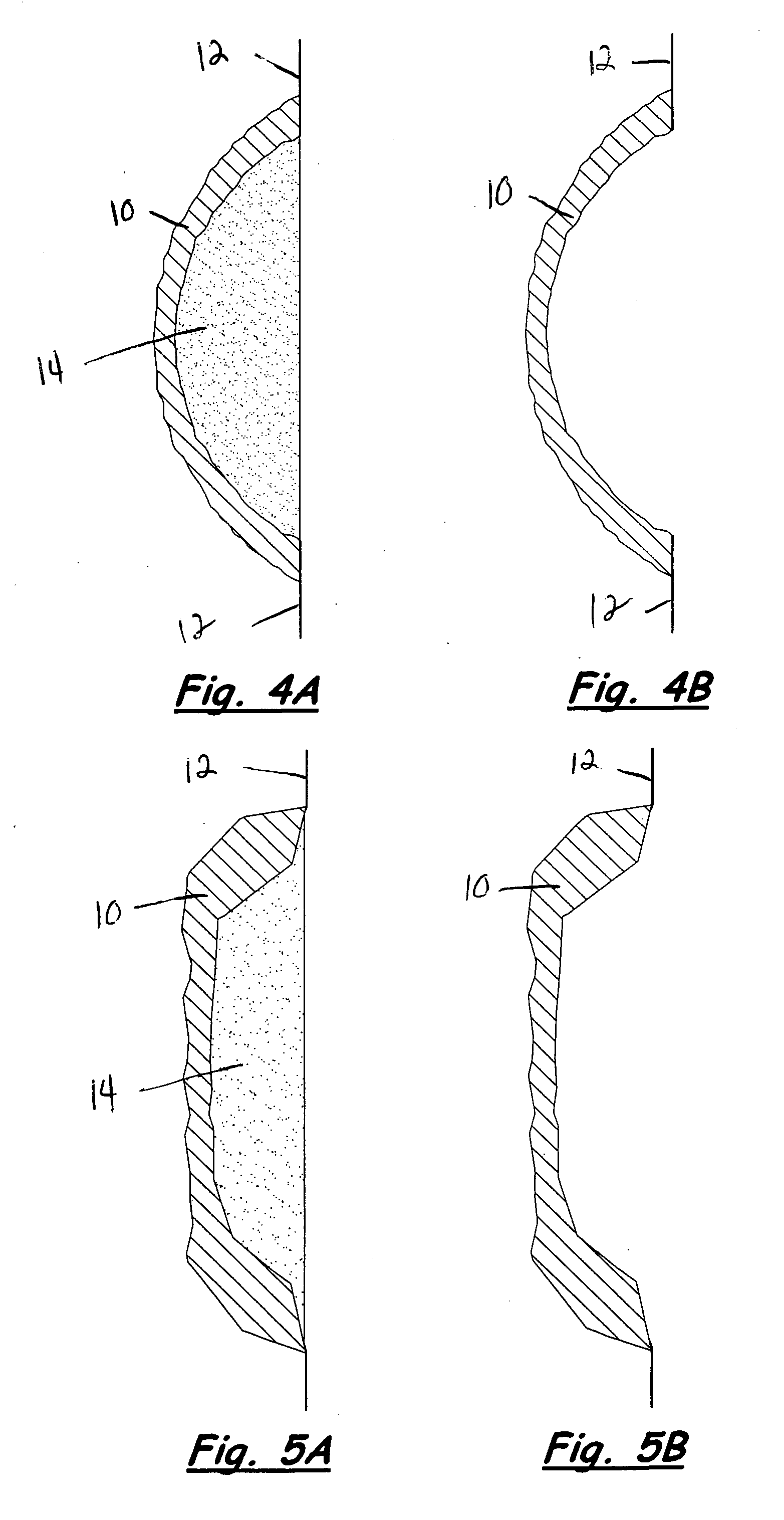

Simulated log siding

Simulated log siding is formed of an engineered cementitious composite. Single or dual flanges on each log piece is used to apply siding units to a surface. Some siding members are molded into a three dimensional configuration to appear as a structural wood log. Individual end pieces and molded tail clusters when used with the siding provide the appearance of the characteristic stacked or staggered corners of a log structure.

Owner:CONCRETE LOG SYST

Rubber-engineered cementitious composite and its preparation method

InactiveCN103396047AEasy to crackImprove deformation abilitySolid waste managementClimate change adaptationEnvironmental resistancePolymer science

The invention discloses a rubber-engineered cementitious composite, which comprises the following components: cement, fly ash, water, a water reducer and a rubber additive. The rubber additive is rubber powder or a mixture of rubber powder and quartz sand. The material is prepared by mixing according to certain proportion and order. Due to the adding of rubber powder, the deformability of engineered cementitious composite is increased. In addition, in the invention, a lot of fly ash and rubber powder are utilized as raw materials, the existing industrial waste residue and waste rubber not conducive to environmental protection are consumed, and meanwhile the dosage of quartz sand is reduced, thus being conducive to reducing carbon emission. Development of the rubber-engineered cementitious composite provided in the invention can greatly improve the performance of traditional engineered cementitious composites, thus facilitating application and promotion of engineered cementitious composites in the engineering field of China.

Owner:SOUTHEAST UNIV

Blocking-type bridge deck slab wet joint connecting form

PendingCN108708273AIncreased transfer shearIncreased bending moment capabilityClimate change adaptationBridge structural detailsFiberBridge deck

The invention provides a blocking-type bridge deck slab wet joint connecting form. A wet joint structure comprises a plurality of prefabricated concrete bridge deck slabs erected on longitudinal beams; a step-shaped wet joint in the direction along a bridge is formed between every two adjacent prefabricated concrete bridge deck slabs in a spaced mode; and the sides, close to the wet joints, of theprefabricated concrete bridge deck slabs are provided with upper-layer pre-embedded steel bars and lower-layer pre-embedded steel bars which all extend to the outer sides of the prefabricated concrete bridge deck slabs; super-strength engineered cementitious composites (ECC) are poured into the wet joints in a cast-in-place mode; and the every two adjacent prefabricated concrete bridge deck slabsare connected into a whole through adjacent wet joint concrete. According to the wet joint structure, the ability of transmitting shear force and bending moment of the wet joints is improved, and generating and expansion of cracks at the wet joints can be effectively prevented.

Owner:CHONGQING UNIV

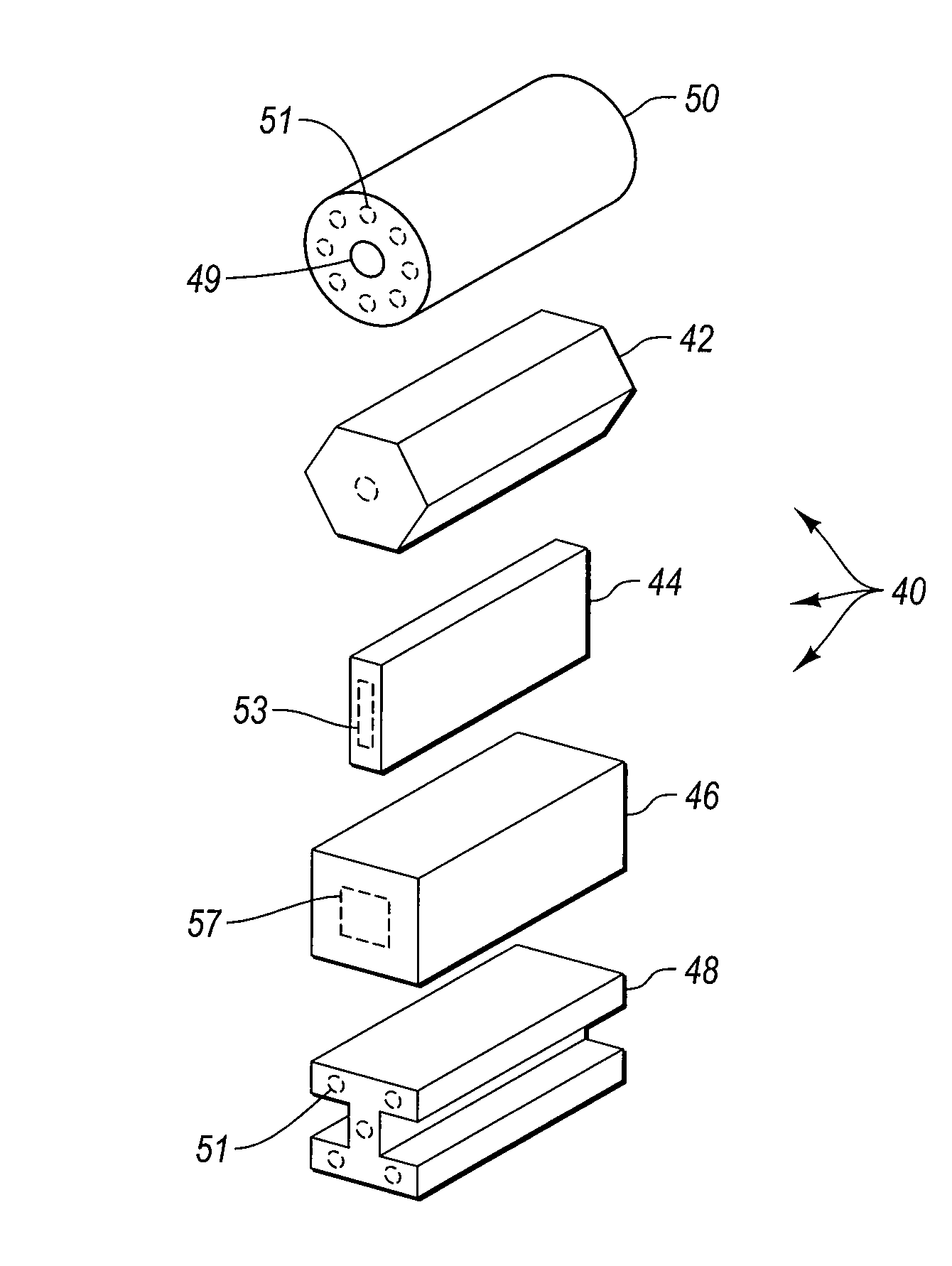

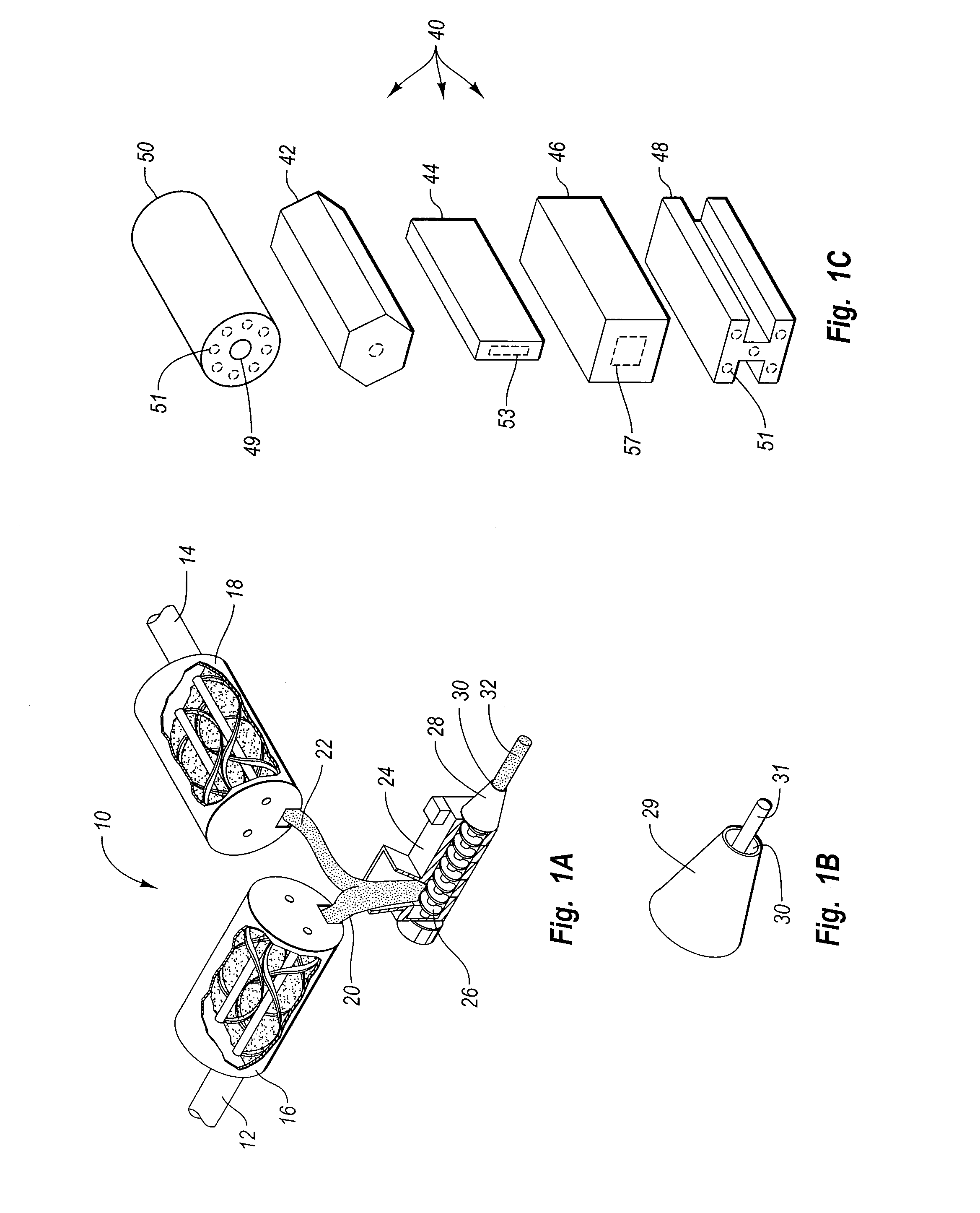

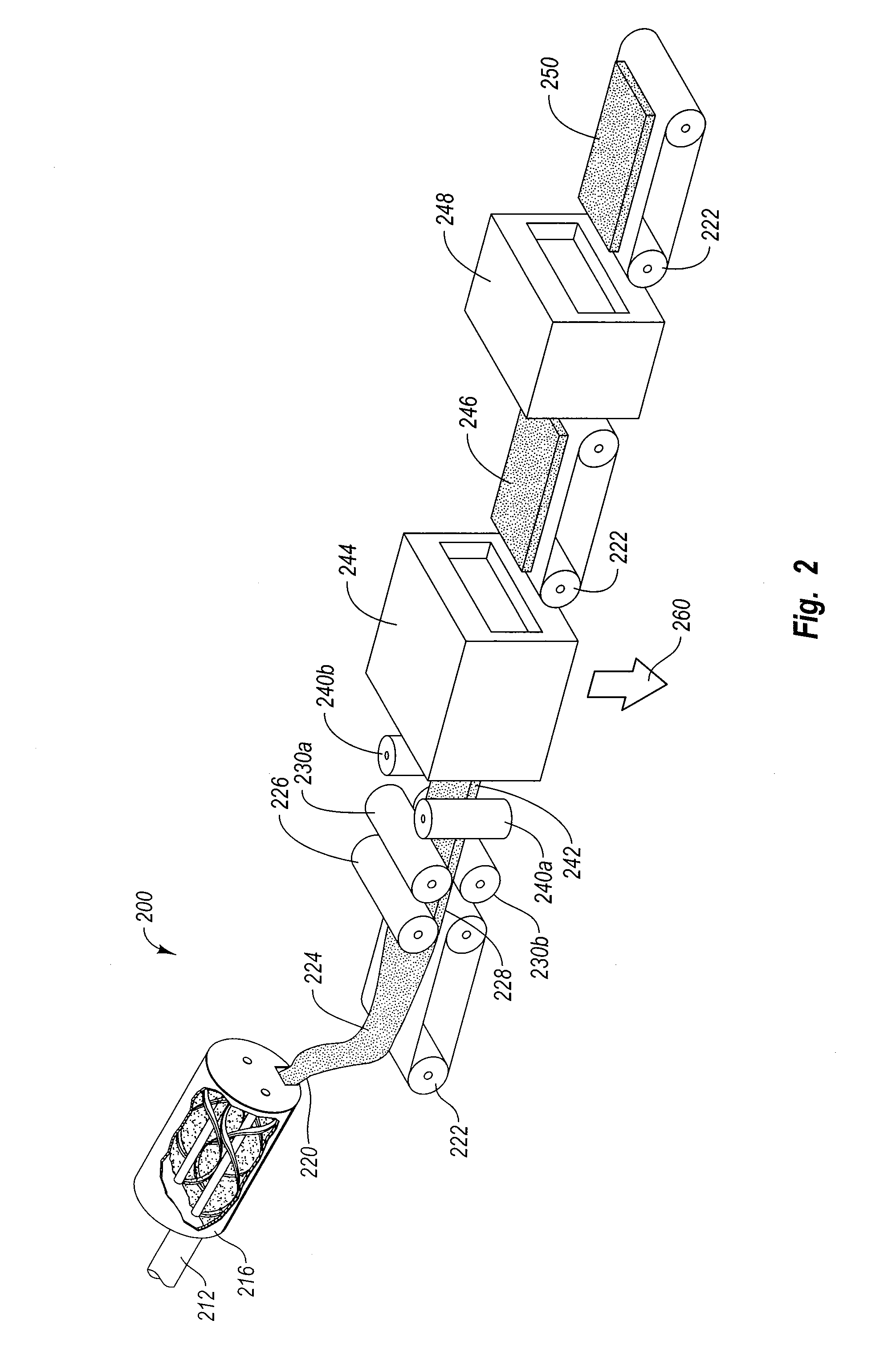

High early strength engineered cementitious composites

ActiveUS7799127B2High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

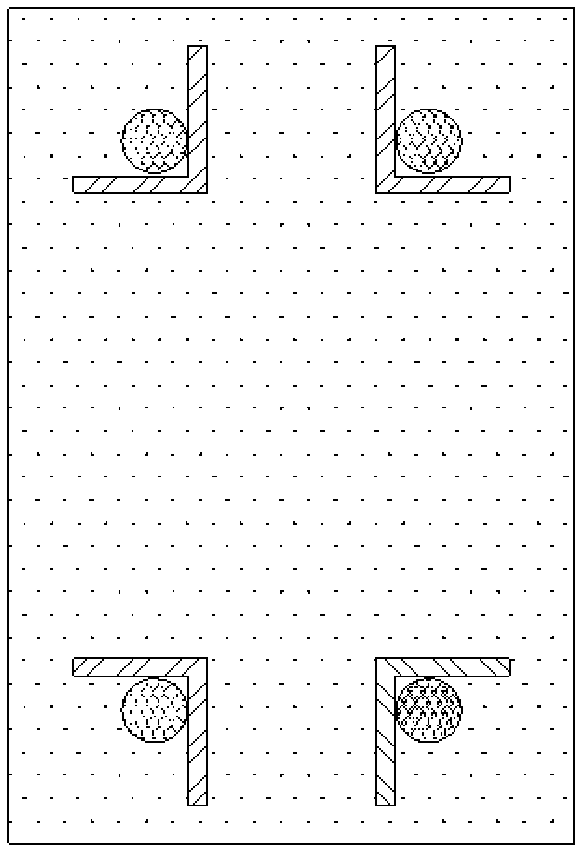

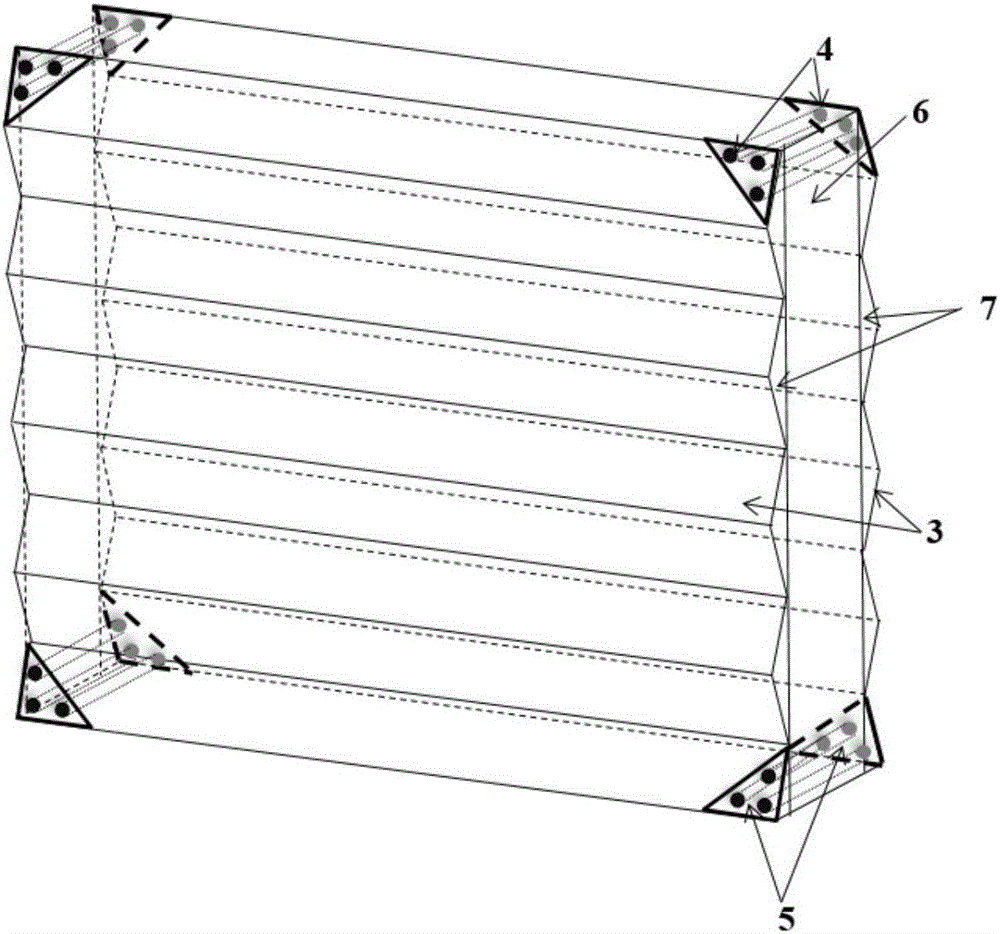

Prefabricated combined beam and column node member

InactiveCN102505760AGuaranteed stiffnessGuarantee welding qualityClimate change adaptationShock proofingReinforced concreteSteel bar

The invention relates to a prefabricated combined beam and column node member. The prefabricated combined beam and column node member comprises a cross beam and a vertical column which are intersected, wherein the cross beam as well as the vertical column comprises an ECC (engineered cementitious composite) material, longitudinal bars and stirrups, and a rectangular region where the cross beam and the vertical column are intersected and superposed is in the transverse width of A and the longitudinal height of B; the cross beam is in the transverse width of 2B plus A and the longitudinal height of B, and the longitudinal bars penetrate the full length of the cross beam and extend out of two beam ends by 10cm-15cm; and the vertical column in the longitudinal height of 2A plus B, and the longitudinal bars penetrate the full length of the vertical column and extend out of the two column ends by 10cm-15cm. The prefabricated combined beam and column node member disclosed by the invention is the prefabricated member which is formed by casting the steel bar-reinforced ECC material and is applied to an anti-seismic key part, in particular to a key node. Compared with an ordinary reinforced concrete member, the prefabricated combined beam and column node member can significantly improve the ductility and the anti-seismic performance of the structure, greatly reduce the use of the stirrups at the node under the condition of meeting the anti-seismic requirement and solve the difficult problem in construction caused by too dense stirrups in a node region.

Owner:SOUTHEAST UNIV

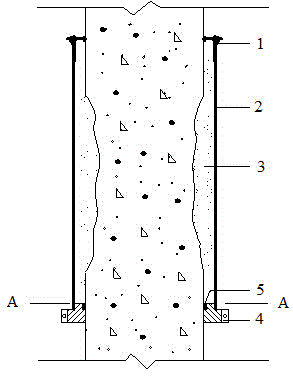

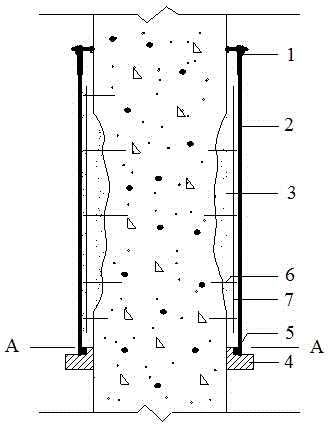

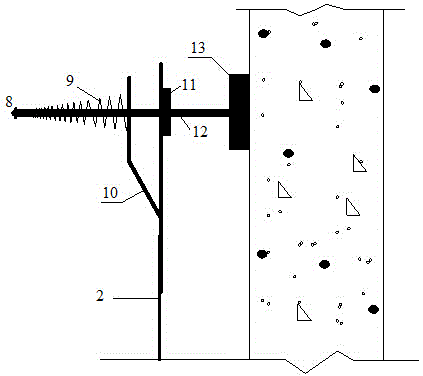

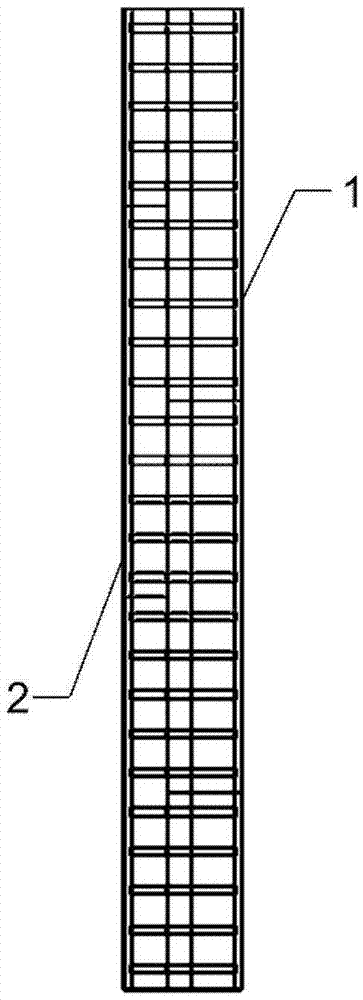

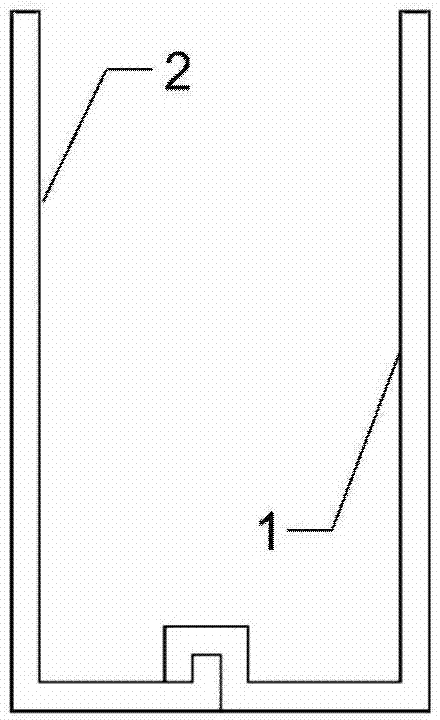

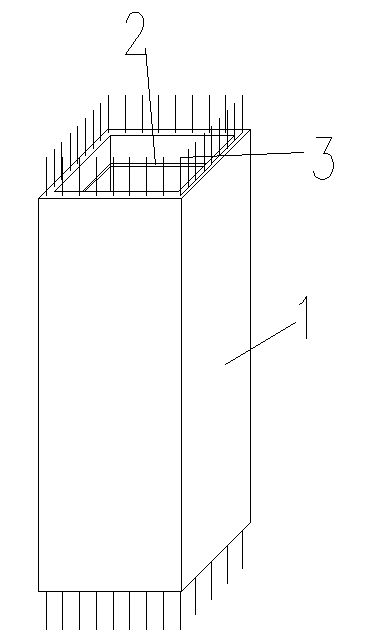

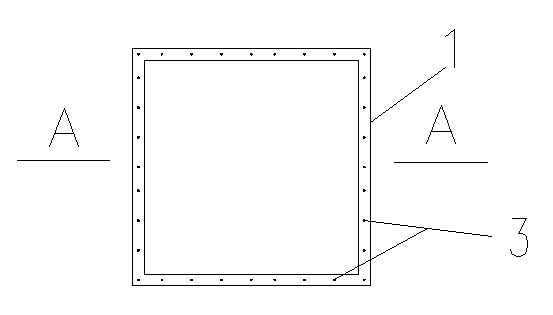

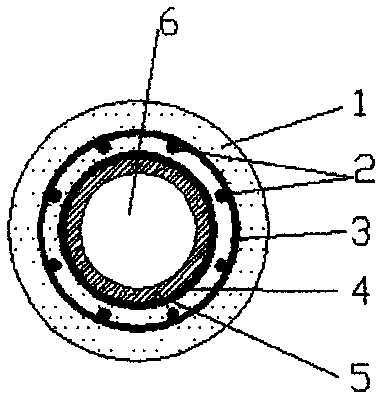

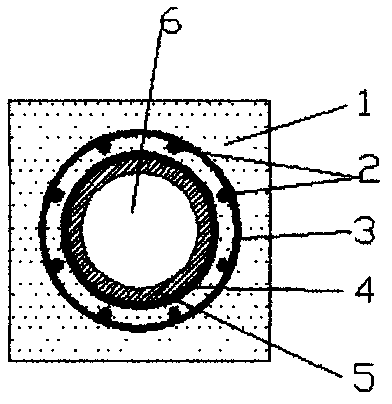

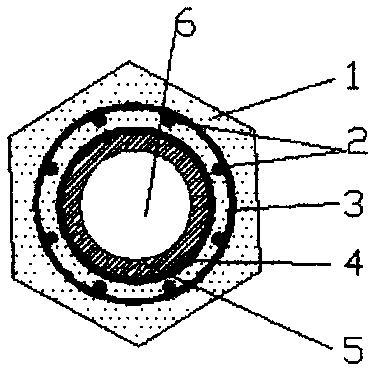

Highly durable permanent column template

InactiveCN103225398AIncreased durabilityHigh tensile ductilityClimate change adaptationForms/shuttering/falseworksEngineeringChloride ion penetration

The invention discloses a highly durable permanent column template. The column template comprises a column template body and is characterized in that the column template body is a thin-walled cylinder; grooves are formed in the surface on the inner side of the thin-walled cylinder; and reinforcement bars are embedded in the two ends of the thin-walled cylinder. The shape of the cross section of the column template body is the same with that of a column to be poured and is circular, rectangular or polygonal; the cross section size and the height of the column template body are the same with those of the column to be poured; and the thickness of the column template body is that of the protective layer of the column to be poured. The grooves are circularly formed in the surface on the inner side of the thin-walled cylinder of the column template body. The reinforcement bars are embedded in the thin-walled cylinder for 15 cm to 20 cm and extend out of the two ends of the thin-walled cylinder for 15 cm to 20 cm. The column template body is prefabricated with ECC (Engineered Cementitious Composites). The highly durable permanent column template has the advantages of high tensile ductility and excellent creak control capability, is superior to common concrete in chloride ion penetration resistance and water penetration resistance, can improve the durability of concrete structures, facilitates the construction, and shortens the construction time.

Owner:CHINA MCC17 GRP

High-strength steel bar enhanced engineered cementitious composites (ECC)-hollow steel pipe ultra high performance concrete (UHPC) combination column member and manufacturing method thereof

InactiveCN102587578AIncreased bending stiffnessImproved pressure stabilityStrutsClimate change adaptationShock resistanceRebar

The invention relates to a high-strength steel bar enhanced engineered cementitious composites (ECC)-hollow steel pipe ultra high performance concrete (UHPC) combination column member and a manufacturing method thereof, which are particularly applied in the field of pier column members with high-rise, overload and long-span structures. The member comprises ECC, a steel bar framework poured in the ECC, a steel pipe, UHPC poured on the inner wall of the steel pipe and a cavity. By the member and the method, the advantages of the ECC, a high-strength steel bar and the UHPC of a hollow steel pipe are integrated, so that respective advantages can be fully exerted, the problem of corrosion of the steel pipe and the steel bar is well solved, the durability of the member is effectively improved, the life cycle of the member is prolonged, and later-stage maintenance and reinforcement cost is reduced; and the member is high in bearing capacity, drawability, shock resistance and fatigue resistance. By a partial prefabrication production and partial on-site pouring construction method, the quality of the member can be easily ensured, a prefabricated part can be directly used for constructing an upper structure of a bearing member support, the increase of a construction speed is facilitated, and a construction cycle is shortened.

Owner:HENAN POLYTECHNIC UNIV

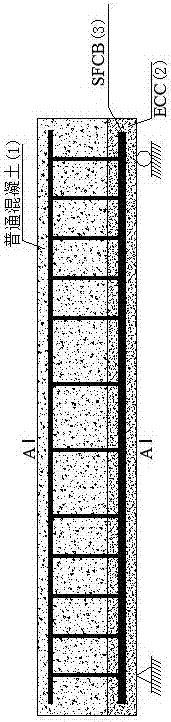

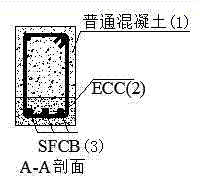

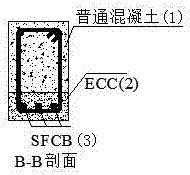

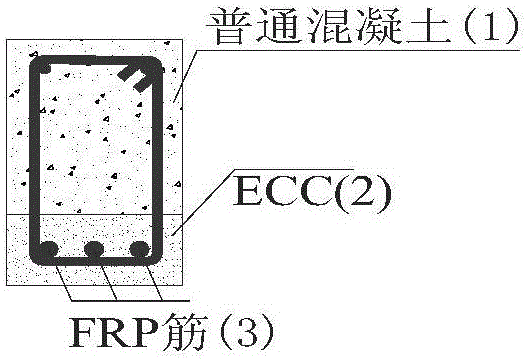

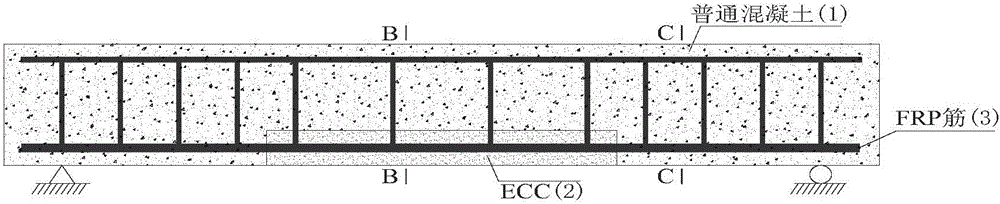

Novel steel-fiber composite bar (SFCB) and engineered cementitious composite (ECC)-concrete composite beam and preparation method thereof

InactiveCN107327078AHigh strengthReduce dosageClimate change adaptationCeramic shaping apparatusFiberConcrete beams

The invention discloses a novel steel-fiber composite bar (SFCB) and engineered cementitious composite (ECC)-concrete composite beam and a preparation method thereof and belongs to the technical field of building structures. Based on an ordinary reinforced concrete structure and a fiber reinforce plastic (FRP) reinforced concrete structure, an SFCB and an ECC are introduced, the cross section of the concrete beam is designed in a layered mode, a tensile longitudinal bar is replaced by the SFCB, and part of ordinary reinforced concrete around the tensile longitudinal bar is replaced by the ECC to form the SFCB and ECC-concrete composite beam. The ordinary reinforced concrete is still adopted in a compressive area, an interface area does not need a special treatment technology, after the ECC is poured, the ordinary concrete is directly poured, the SFCB serves as a tensile longitudinal bar, and the high tensile strength and corrosion resistance of the SFCB and the excellent tensile resistance of the ECC are comprehensively used to form the novel SFCB and ECC-concrete composite beam with the high bearing capacity and good durability.

Owner:YANGZHOU UNIV

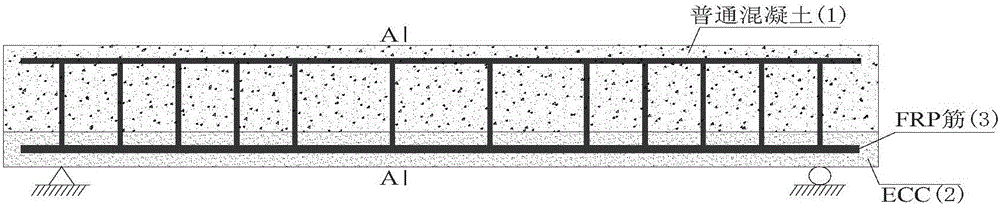

Fiber reinforced composite material rib and concrete composite beam

InactiveCN105888132AOvercoming softening propertiesSignificantly nonlinear deformationSolid waste managementClimate change adaptationFiber-reinforced compositeRebar

The invention discloses a fiber reinforced composite material rib and concrete composite beam which comprises fiber reinforced composite material ribs and concrete wrapping the peripheries of the fiber reinforced composite material ribs. The concrete wrapping the peripheries of the fiber reinforced composite material ribs in a composite beam stress area is an engineering cement-based composite. According to the composite beam, the reinforcing steel bar consumption is lowered, and the structural durability is high.

Owner:YANGZHOU UNIV

PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and preparation method thereof

InactiveCN108675716AImprove liquidityImprove compactnessClimate change adaptationCelluloseMicrosphere

The invention belongs to the technical field of building materials and in particular relates to a PVA-ECC (Polyvinyl Acetate-Engineered Cementitious Composite) high-toughness fiber cement based composite material and a preparation method thereof. The PVA-ECC high-toughness fiber cement based composite material is prepared from the following components in parts by weight: 25 to 35 parts of 525 white cement, 40 to 60 parts of quartz sand, 18 to 20 parts of titanium white, 1 to 10 parts of pitchstone vitrified microspheres, 0.5 to 2 parts of PVA cellulose, 6 to 8 parts of ionic liquid, 10 to 12 parts of crop straw powder, 3 to 6 parts of clay, 3 to 5 parts of diatomite, 3 to 5 parts of maleic anhydride, 1 to 3 parts of crystal whiskers, 3 to 6 parts of a silane coupling agent, 0.5 to 2 partsof cellulose ether, 0.3 to 2 parts of redispersible latex powder, 0.1 to 3 parts of a high-efficiency water reducing agent, 0.5 to 2 parts of an inorganic pigment and 90 to 100 parts of water. The preparation method comprises the following steps: taking the maleic anhydride, the clay, the diatomite and the PVA cellulose as raw materials to prepare a PVA fiber / clay / diatomite nano composite material, and then mixing and stirring the PVA fiber / clay / diatomite nano composite material with other raw materials.

Owner:吴远怀

Simulated log siding

Simulated log siding is formed of an engineered cementitious composite. Single or dual flanges on each log piece is used to apply siding units to a surface. Some siding members are molded into a three dimensional configuration to appear as a structural wood log. Individual end pieces and molded tail clusters when used with the siding provide the appearance of the characteristic stacked or staggered corners of a log structure.

Owner:CONCRETE LOG SYST

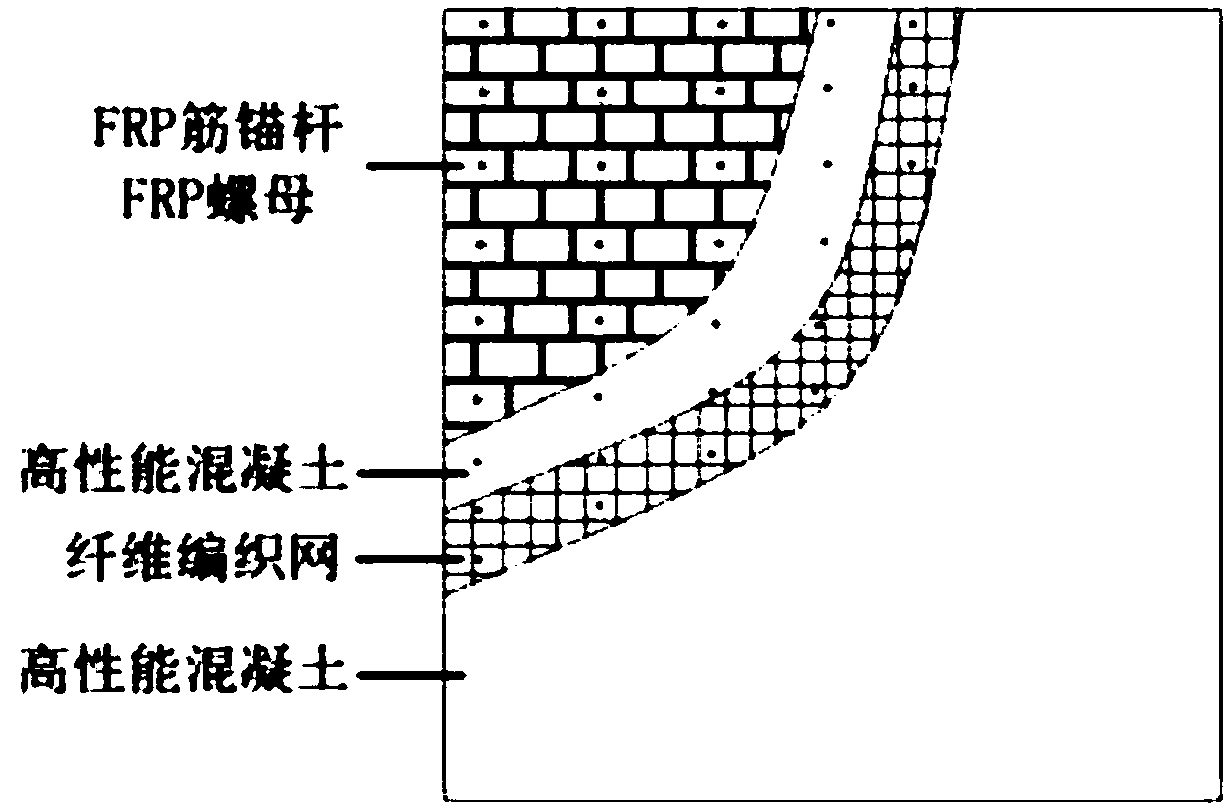

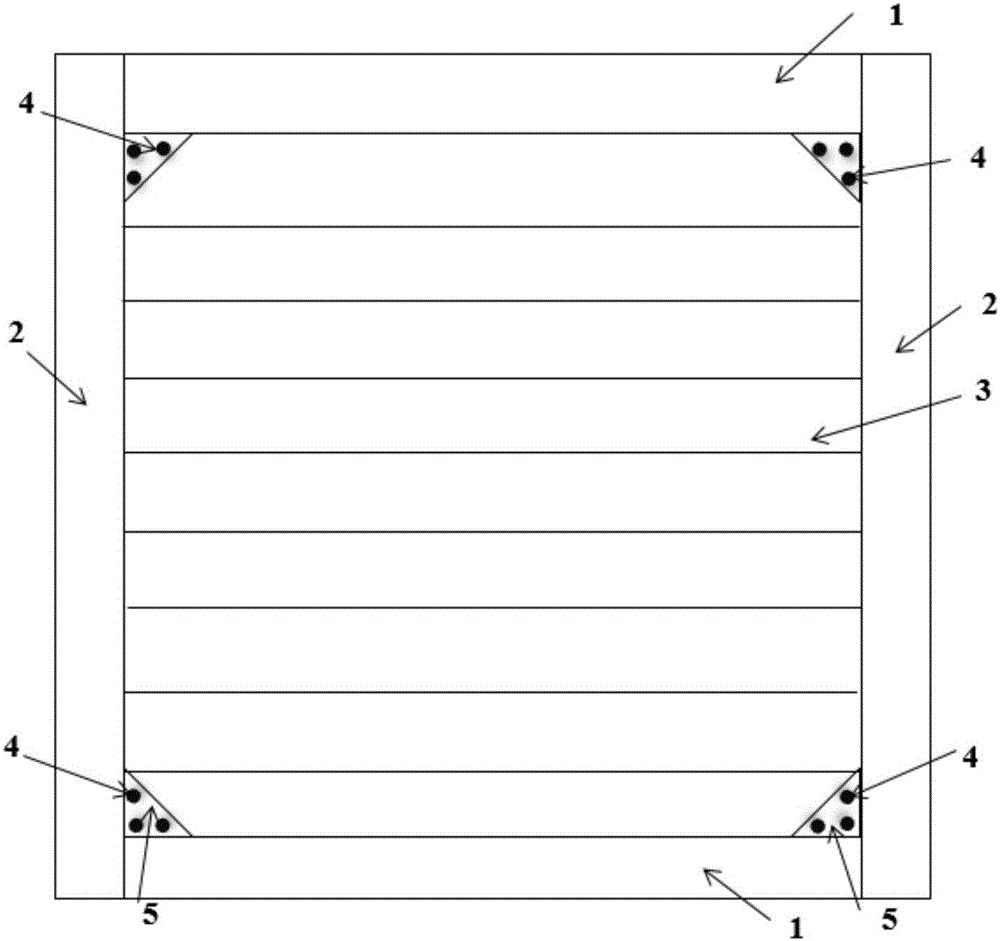

Reinforcement method of TRC for improving anti-seismic performance of multi-piece brick masonry wall

InactiveCN108532981AImprove seismic performanceImprove shear resistanceClimate change adaptationBuilding repairsFiberBrick masonry

The invention discloses a reinforcement method of TRC for improving an anti-seismic performance of multi-piece brick masonry wall, and belongs to the technical field of repair, reinforcement and construction of masonry walls. The reinforcement method comprises the steps that a plurality of penetrating circular holes are drilled in the wall to be reinforced, and fiber reinforced plastic (FRP) rib anchor rods are used for penetrating through the circular holes; the surface of the wall to be reinforced is coated with high-performance concrete, a fiber woven net is impregnated with epoxy resin, and the surface of the fiber woven net is coated with the high-performance concrete again; If one layer of fiber woven net can not meet the requirement of wall anti-seismic performance improvement, twoor more layers of fiber woven nets can be laid; and wet water curing is carried out until the high-performance concrete age is reached. According to the reinforcement method of TRC for improving the anti-seismic performance of the multi-piece brick masonry wall, in-plane shear resistance and out-of-plane bending resistance of the multi-piece brick masonry wall are improved, the risk of serious damage or even collapse of a masonry structure in earthquake is reduced, the inadaptability of a masonry material caused by the use of the epoxy resin in FRP reinforcement is avoided, deficiency of low reinforcement efficiency of engineered cementitious composite (ECC) reinforcement is effectively improved, and the integrity of multi-piece brick masonry wall is improved.

Owner:CHINA UNIV OF MINING & TECH

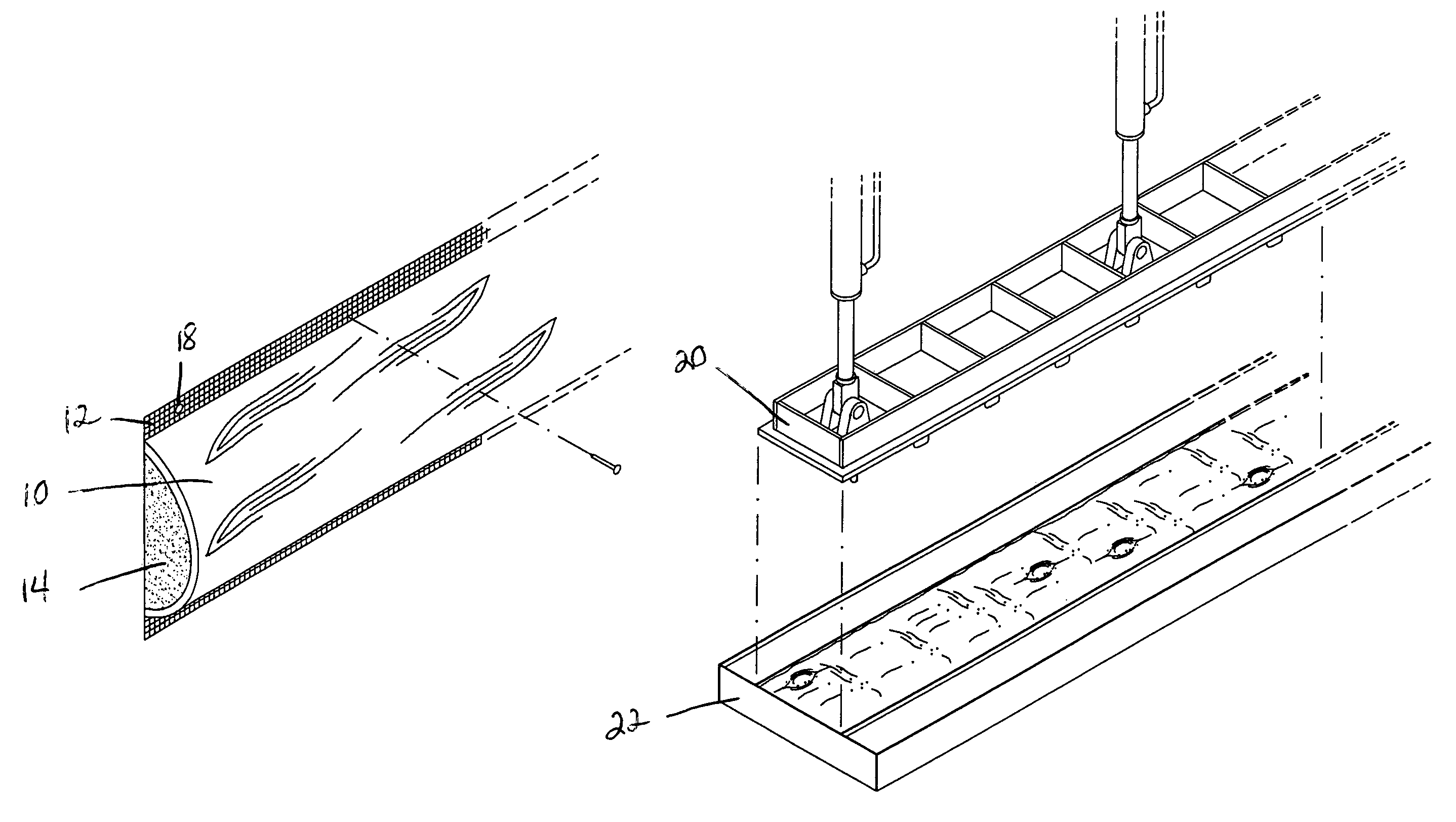

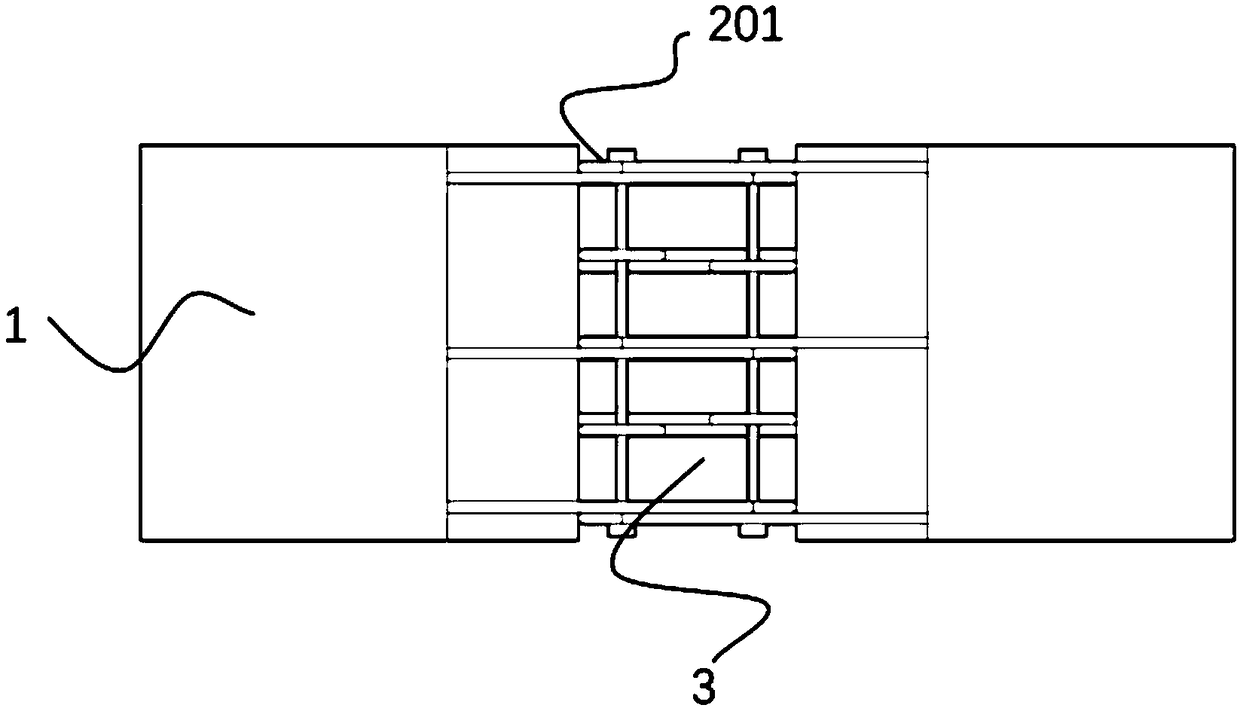

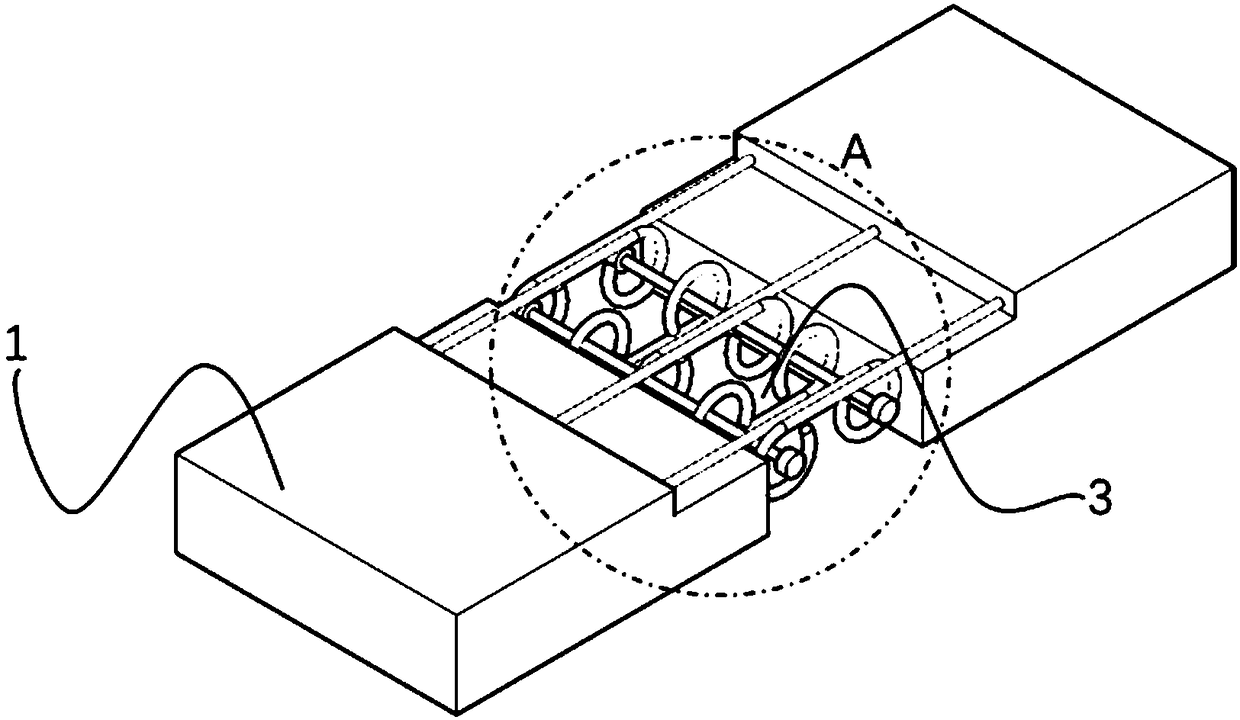

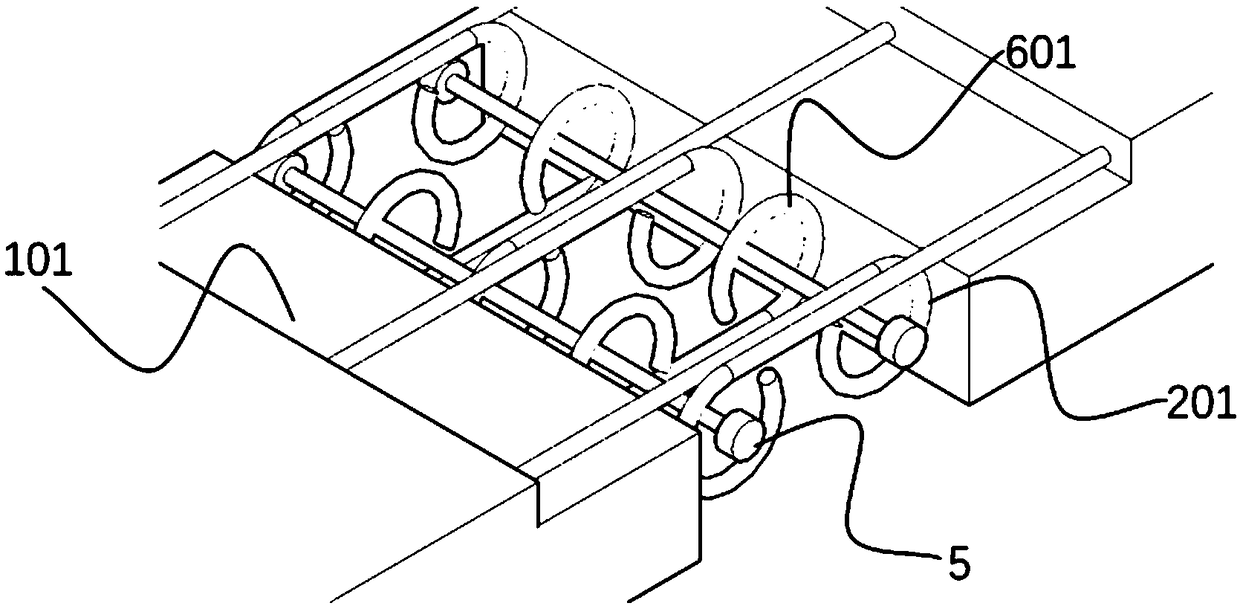

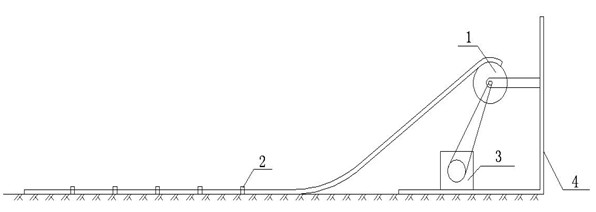

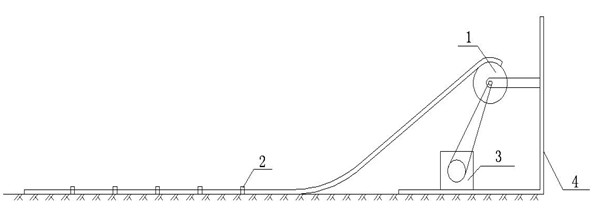

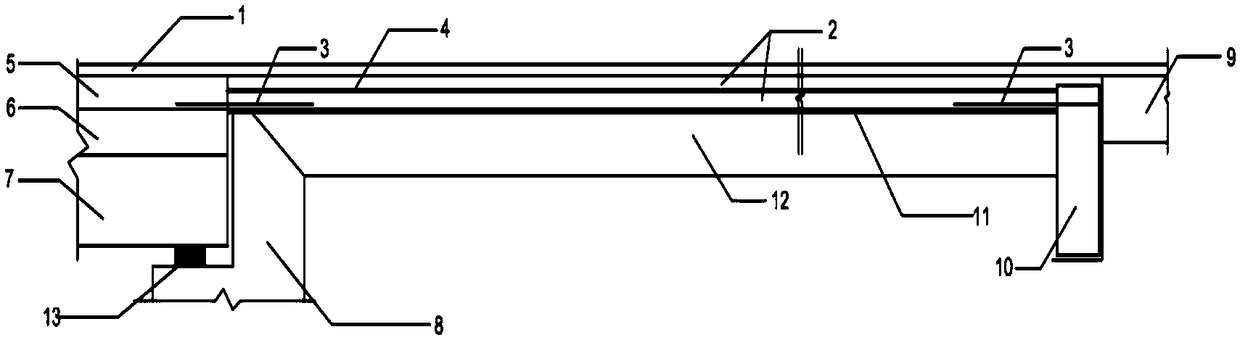

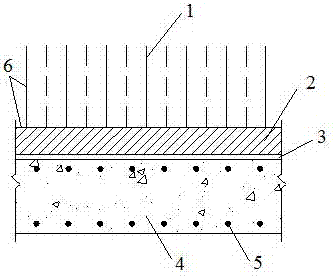

Method for paving prefabricated coilable engineered cementitious composites (ECC)

InactiveCN102094376AOvercoming the disadvantage of being late to trafficAvoid timeClimate change adaptationRoads maintainenceCarriagewayElectric machinery

The invention provides a method for paving prefabricated coilable engineered cementitious composites (ECC), which comprises the following steps: 1, prefabricating an ECC component, wherein the length of the ECC component is 100-200 m, the width is 3-4 m, and the thickness is 1-5 cm; 2, arranging a roller (1) on a support (4), and connecting a centre shaft of the roller (1) with a motor (3) so as to form a coiling device; 3, lifting one end of the prefabricated ECC component so as to lap the end of the prefabricated ECC component on the roller (1) of the coiling device, and on a length of the ECC component close to the lifted part of the ECC component, arranging a plurality of antiskid hairbrush boards (2) which cross the width of the ECC; 4, starting the motor (3) so as to clockwise drive the roller (1) to rotate by the centre shaft of the roller (1) and then coil the ECC component; and 5, transporting the roller (1) coiling the ECC component to a road construction site, aligning the two side edges of the roller with the direction of a lane, and reversely pushing the roller, then gradually releasing the ECC component to pave on a substrate or a surface layer until the paving is completed.

Owner:SOUTHEAST UNIV

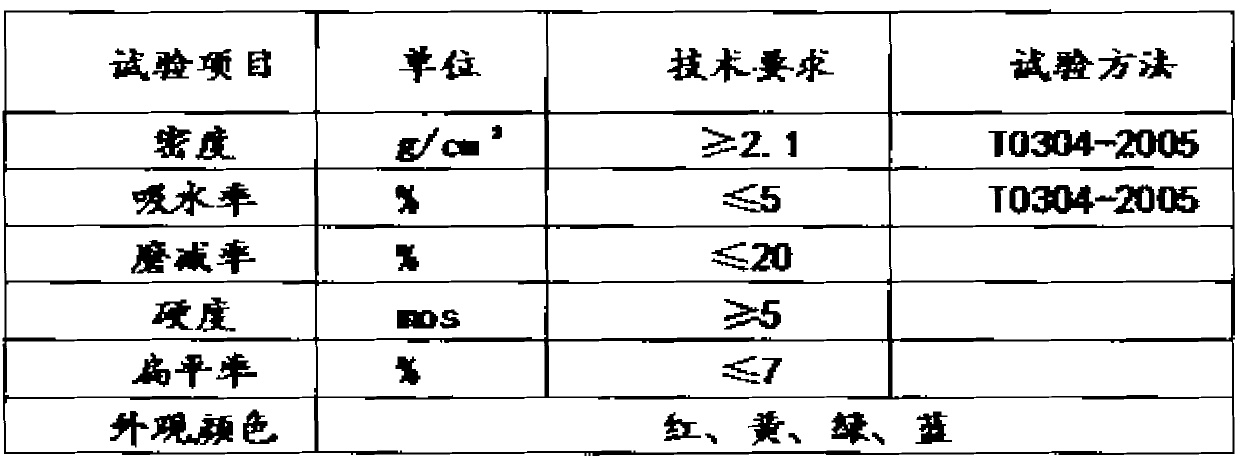

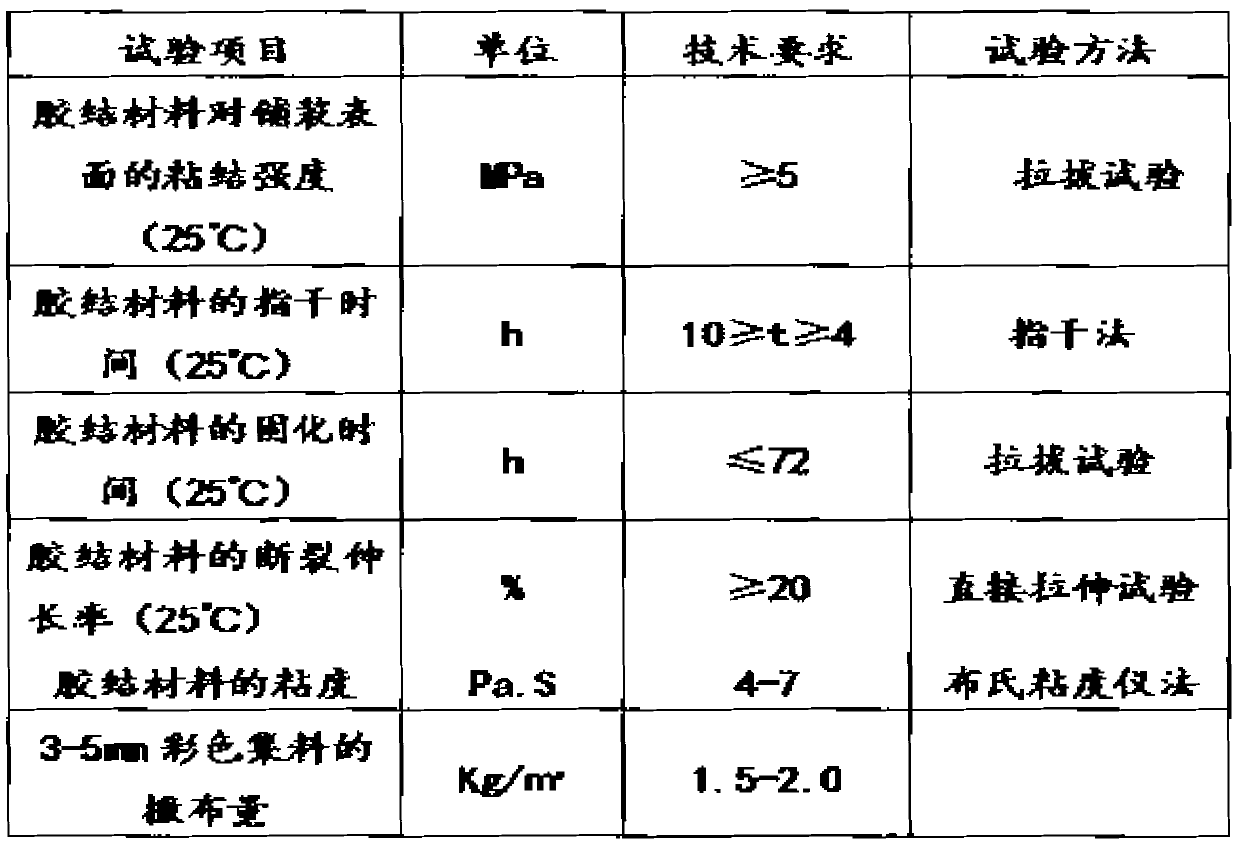

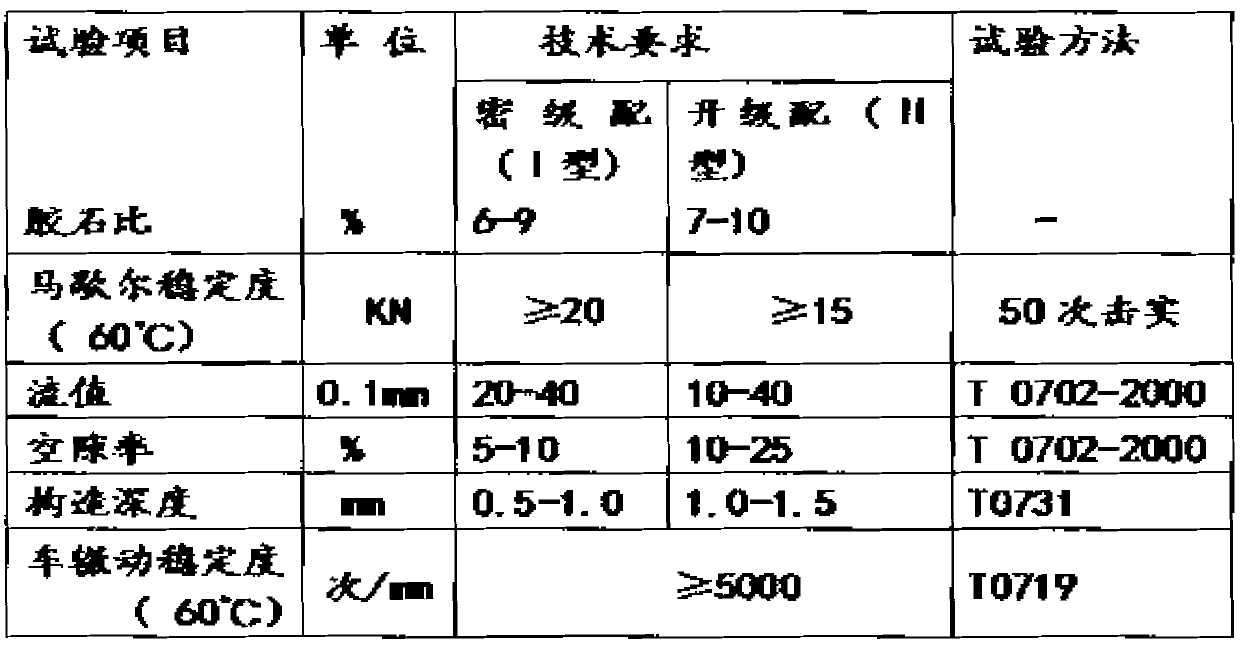

ECC (engineered cementitious composite) durable type colored road pavement structure and paving method thereof

ActiveCN103966935AImprove stabilityIncreased durabilityIn situ pavingsClimate change adaptationEpoxyStructural engineering

The invention discloses an ECC (engineered cementitious composite) durable type colored road pavement structure and a paving method thereof. The structure comprises an EC (expansive concrete) constraint bottom layer paved on the original road surface and a concrete surface layer which is paved on the EC constraint bottom layer and adopts epoxy resin as a cementing material, wherein the EC constraint bottom layer comprises a cementing material layer made of the epoxy resin and a colorful aggregate layer scattered on the cementing material layer. Compared with the prior art, the pavement structure has high stability and durability, good track resistance and water damage resistance at high and low temperature and low probability of aggregate falling condition, and the pavement performance is greatly improved by means of the concrete surface layer; the pavement structure has certain flexibility and improves resistance to thermal expansion and cold contraction, and the road is prevented from cracking, so that the service life of the road is prolonged; and besides, natural colorful road metal or artificial colorful calcinated ceramsite is selected in order to keep bright and lasting colors of the road and achieve the environmental protection purpose.

Owner:平安建设集团有限公司 +2

Reinforcing structure and reinforcing method of sea sand steel bar concrete beam

PendingCN106968455ASolve the carrying capacitySolve Excessive CracksClimate change adaptationBuilding repairsConcrete beamsRebar

The invention relates to the technical field of building engineering and discloses a reinforcing structure of a sea sand steel bar concrete beam. The reinforcing structure comprises a sea sand concrete layer and a reinforcing layer which are sequentially arranged in an adjoining mode from top to bottom. The reinforcing layer comprises a tensile steel bar and an ultrahigh toughness cement-based composite material layer covering the tensile steel bar. The invention further discloses a reinforcing method of the sea sand steel bar concrete beam. The reinforcing method comprises the steps that sea sand concrete on the periphery of the steel bars on the tensile side is cleaned up, the ultrahigh toughness cement-based composite material layer is poured outside the exposed tensile steel bar, and the poured ultrahigh toughness cement-based composite material layer is made to cover the tensile steel bar. According to the reinforcing structure and reinforcing method of the sea sand steel bar concrete beam, ECC (Engineered Cementitious Composites) are utilized to separately reinforce the sea sand steel bar concrete beam, or FRP (Fiber Reinforce Polymer)-ECC is utilized to reinforce the sea sand steel bar concrete beam in a combined mode, so that the bearing capacity of the sea sand steel bar concrete beam is effectively repaired, the ductility of the structure is improved, the situation that chloride ions and harmful media in the external environment corrodes the tensile steel bar is resisted, and the steel bar is prevented from being rusted for the second time, so that the durability of the structure is improved.

Owner:SHENZHEN UNIV

Engineered cementitious composite seamless bridge and construction method thereof

ActiveCN109322238ASolve problems that have adverse effects on normal drivingReduce tensionClimate change adaptationBridge structural detailsRoad surfaceAbutment

The invention belongs to the technical field of bridge building construction, and relates to an engineered cementitious composite seamless bridge and a construction method thereof. The engineered cementitious composite seamless bridge comprises a bridge abutment, a foundation beam and structural layers, the bridge abutment and the foundation beam are located on the two sides of a bridge correspondingly, a first asphalt concrete layer, a leveling layer and a hollow slab are arranged on the structural layer of the side, close to the pavement, of the bridge abutment from top to bottom, the firstasphalt concrete layer is located above the horizontal line on the top of thebridge abutment, the structural layer of the side, close to the pavement, of the foundation beam is a pavement base layer,the structural layer between the first asphalt concrete layer and the foundation beam is a composite material layer, the structural layer between the bridge abutment and the foundation beam is a concrete base layer, the composite material layer is located above the concrete base layer, the structural layer on the bridge surface is a second asphalt concrete layer, a carbon fiber net is horizontallyarranged in the middle of the composite material layer, and the carbon fiber net is located below the horizontal line at the top of the foundation beam. The problem that gaps of the bridge have bad effect on normal travelling of vehicles is solved.

Owner:SHANDONG UNIV

Modified graphene oxide fewer-sheet aqueous-phase uniform dispersion solution for cement-based composite material, and preparation method and application thereof

ActiveCN108948259AAchieve expansionAchieve strippingFlexural strengthEngineered cementitious composite

The invention discloses a modified graphene oxide fewer-sheet aqueous-phase uniform dispersion solution for a cement-based composite material, and a preparation method and an application thereof. Themodified graphene oxide less-sheet aqueous-phase uniform dispersion solution consists of the following materials in parts by mass: 100-200 parts of a graphene oxide sheet dispersion solution with themass percentage of 0.2%, 5-8 parts of an intercalated polymerization monomer, 10-15 parts of a comonomer, 0.2-0.5 part of an initiator and 1-2 parts of an alkaline substance. The invention also discloses the preparation method of the modified graphene oxide fewer-sheet aqueous-phase uniform dispersion solution. The preparation method has the innovation that a fewer-sheet (1-3 monolayer aggregates)graphene oxide nano-sheet uniform dispersion solution is prepared by intercalation, template effect and graft polymerization, and is mixed with blending water and is mixed into the cement-based composite material; the product is used for preparing the large-scale compact, regular and micro-structure cement-based composite material for large-volume engineering; the compressive strength and flexural strength of the cement-based composite material are increased by 56%-125% and 72%-137% respectively. Meanwhile, the structure of the cement-based composite material is compact and has strong osmosis-resistant and crack-resistant abilities.

Owner:SHAANXI UNIV OF SCI & TECH

Dual-layer corrugated steel plate-polyvinyl alcohol-engineered cementitious composite combined anti-knock shear wall

PendingCN106760058AAvoid casualtiesAvoid Facility DamageWallsClimate change adaptationPolyvinyl alcoholSteel frame

The invention relates to the technical field of construction, in particular to a dual-layer corrugated steel plate-polyvinyl alcohol-engineered cementitious composite combined anti-knock shear wall. The technical scheme includes that the anti-knock shear wall comprises dual-layer corrugated steel plates, PVA-ECC (polyvinyl alcohol-engineered cementitious composite) plates, foamed aluminum, a pair of H-shaped steel frame posts and a pair of H-shaped steel frame beams, wherein the dual-layer corrugated steel plates wrap the PVA-ECC plates, the positions between the corrugated steel plates and the PVA-ECC plates are filled with the foamed aluminum, the H-shaped steel frame posts and the H-shaped steel frame beams are connected mutually to form a shear wall frame, and the corrugated steel plates are fixedly connected with the shear wall frame. The dual-layer corrugated steel plate-polyvinyl alcohol-engineered cementitious composite combined anti-knock shear wall has the advantages that anti-knock performance of the corrugated steel plate shear wall can be improved, loss of lateral resistance of the corrugated steel plates due to bending of the corrugated steel plate shear wall is reduced, and local structural damage, casualties and property losses are avoided.

Owner:SHENYANG JIANZHU UNIVERSITY

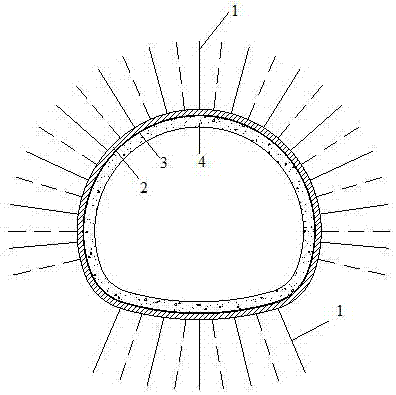

Composite lining for large-deformation surrounding rock section

ActiveCN107489431ACorrosion resistantHigh tensile strengthUnderground chambersClimate change adaptationFiberPolyvinyl alcohol

The invention discloses a composite lining for a large-deformation surrounding rock section. The composite lining comprises a primary support, a waterproof plate and a Polyvinyl alcohol Fiber-Engineered Cementitious Composite (PVA-ECC) secondary lining body. The primary support is composed of glass fiber anchor rods and a high-toughness PVA-ECC spray layer. The PVA-ECC secondary lining body is composed of steel bar reinforced PVA-ECC materials. The PVA-ECC materials comprise the components of cement, coal ash, sand, water, water reducing agents and PVA fibers. According to the composite lining for the large-deformation surrounding rock section, the flexibility and deformation capability of the lining can be significantly improved, the pressure of surrounding rock on the periphery of a tunnel is effectively released, the support requirement of the large-deformation tunnel can be met, the lining is prevented from cracking and being damaged, and the composite lining for the large-deformation surrounding rock section has the characteristics that construction is safe, convenient and rapid and other characteristics.

Owner:KUNMING UNIV OF SCI & TECH

3-mode blended fibers in an engineered cementitious composite

ActiveUS20140191436A1Improve mechanical propertiesLarge specific surface areaSolid waste managementClimate change adaptationCement compositesCellulose fiber

Disclosed herein are fiber reinforced cement composite materials incorporating a 3-mode fiber blend that includes cellulose pulp and synthetic fibers in a ratio selected to provide the composite material with improved water absorption characteristics and the same or improved mechanical properties as compared to equivalent composite materials reinforced with predominantly or all cellulose fibers. Also disclosed herein are fiber blends comprised of a combination of cellulose fibers and polypropylene fibers adapted to reinforce cementitious composite articles manufactured by the Hatschek process and autoclave cured.

Owner:JAMES HARDIE TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com