Blocking-type bridge deck slab wet joint connecting form

A technology of wet joints and bridge decks, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of slowing down the construction speed, being unable to effectively prevent the generation and expansion of cracks, and increasing construction costs, so as to speed up the construction speed , reduce the dosage, and prevent the cracking of wet joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

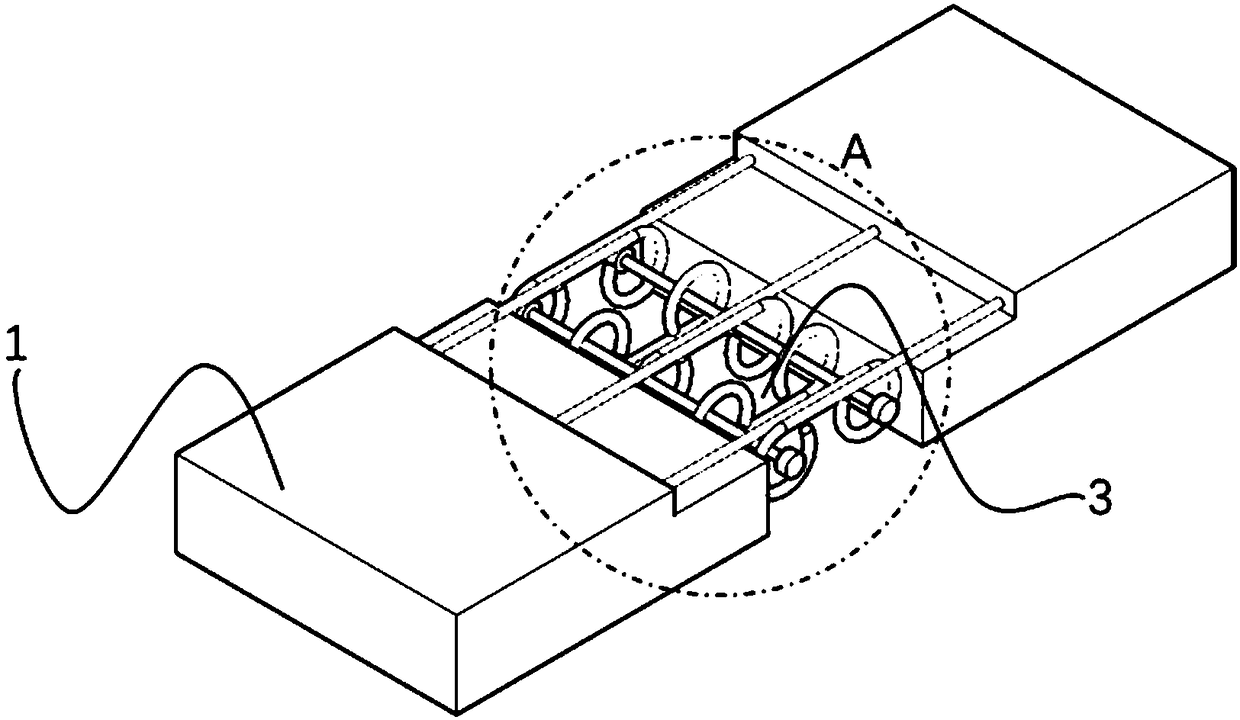

[0026] This embodiment discloses a wet joint connection form of segmented bridge decks, which includes a plurality of prefabricated concrete bridge decks 1 erected on longitudinal girders.

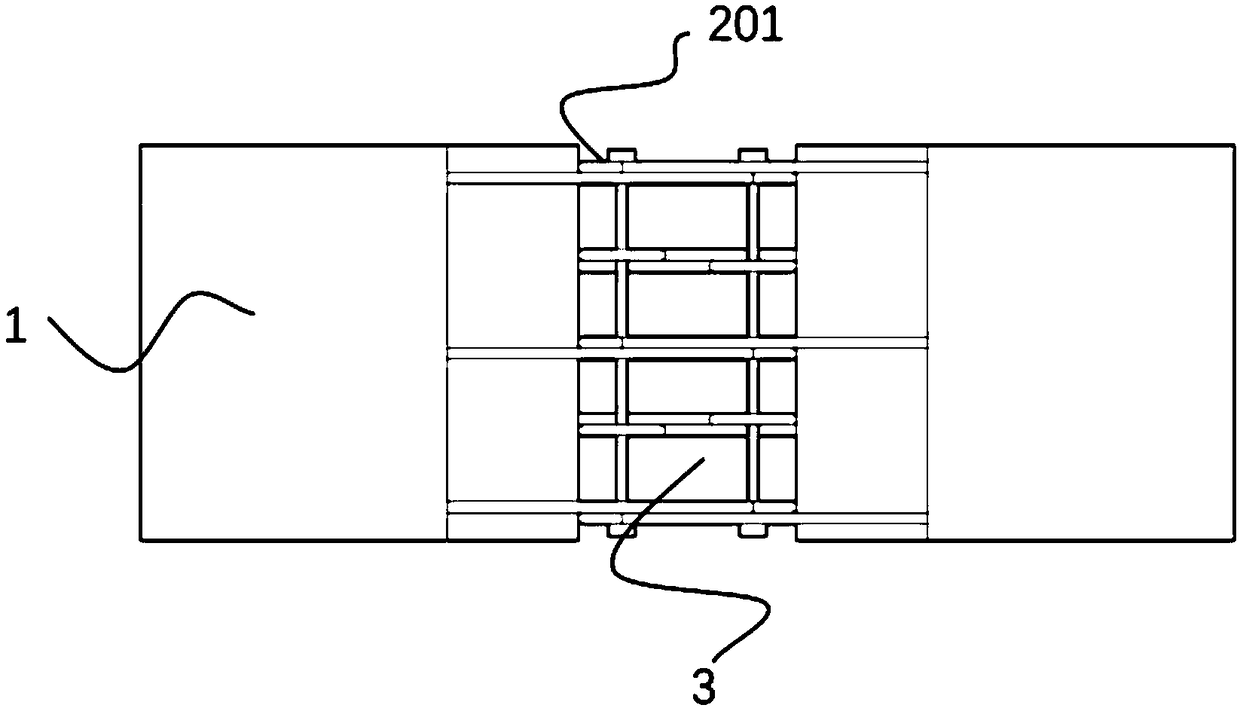

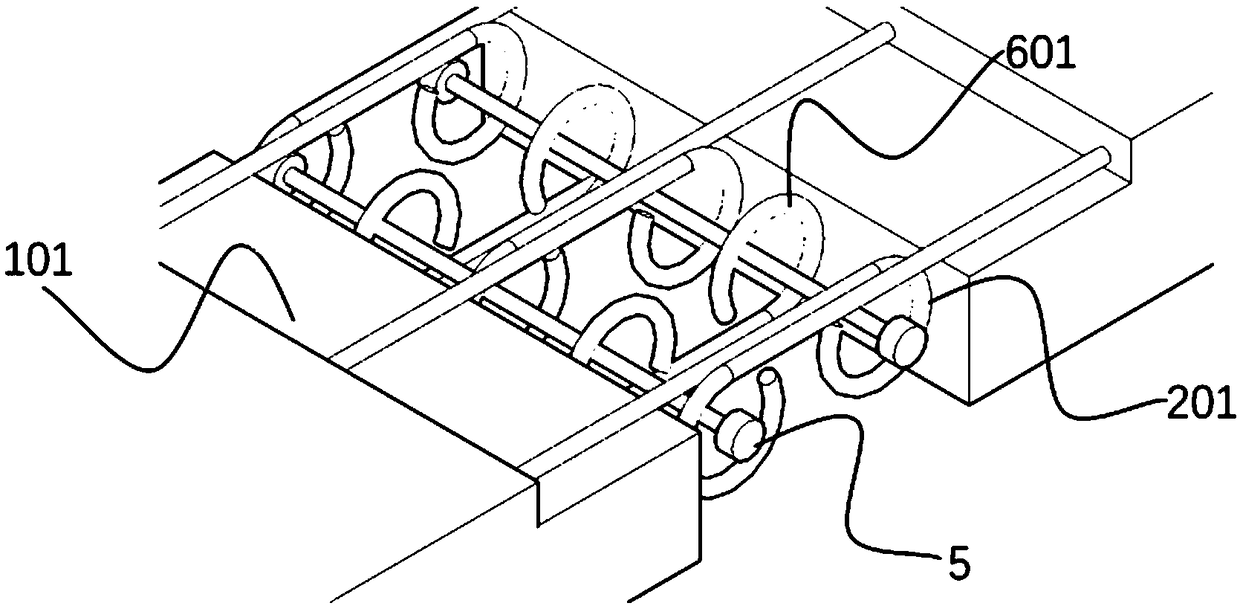

[0027] see figure 1 , 2 and 3, a cuboid is removed from the side near the wet joint of the precast concrete bridge deck 1 to form an alveolar 101 . Step-shaped wet joints 3 along the bridge direction are formed at intervals between two adjacent precast concrete bridge decks 1 .

[0028] The side of the precast concrete bridge deck 1 near the wet joint is provided with an upper layer of embedded reinforcement 2 and a lower layer of embedded reinforcement 6 extending to the outside of the precast concrete bridge deck 1 . Both the upper layer embedded steel bars 2 and the lower layer embedded steel bars 6 include a plurality of bars arranged at intervals along the direction of the bridge. The end of the overhanging portion of the upper pre-embedded steel bar 2 is bent to form a single ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com