Dual-layer corrugated steel plate-polyvinyl alcohol-engineered cementitious composite combined anti-knock shear wall

A technology of corrugated steel plates and polyvinyl alcohol, which is applied to walls, climate change adaptation, and building components, can solve problems such as weak anti-blast performance, reduced resistance, and collapse of steel structures, so as to avoid internal casualties and facility damage. The effect of improving the antiknock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

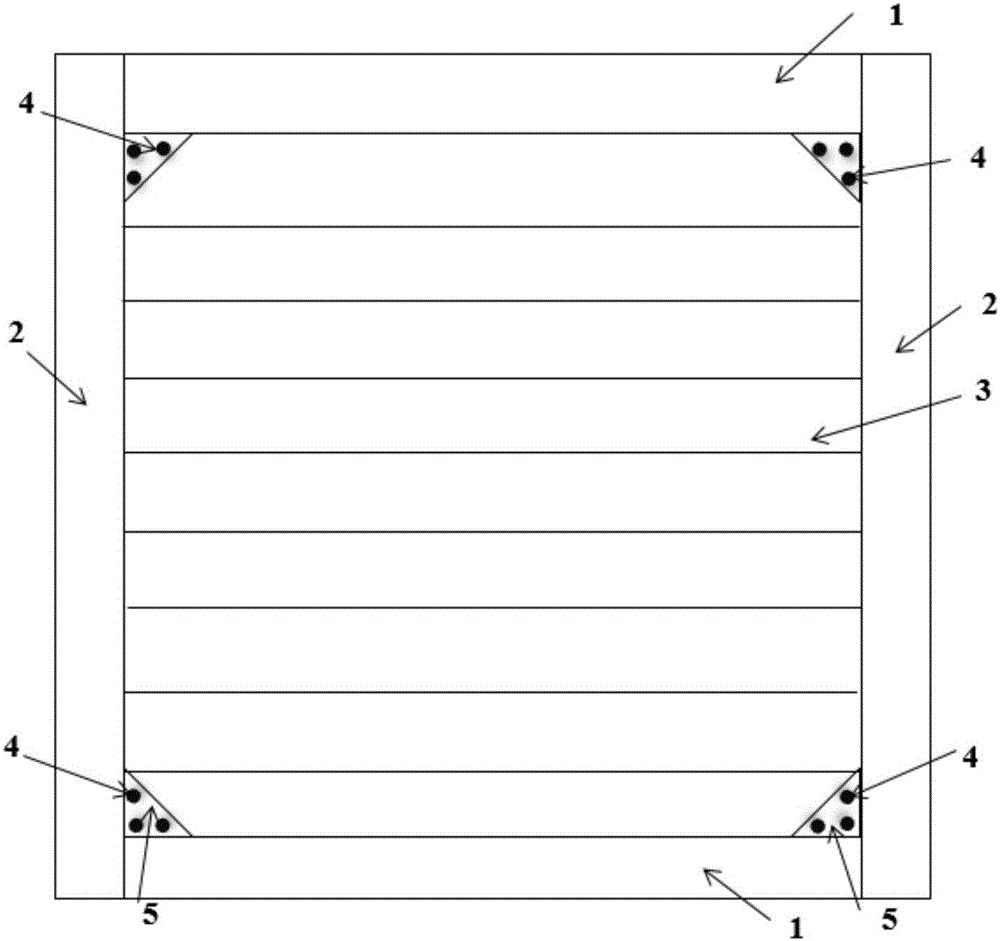

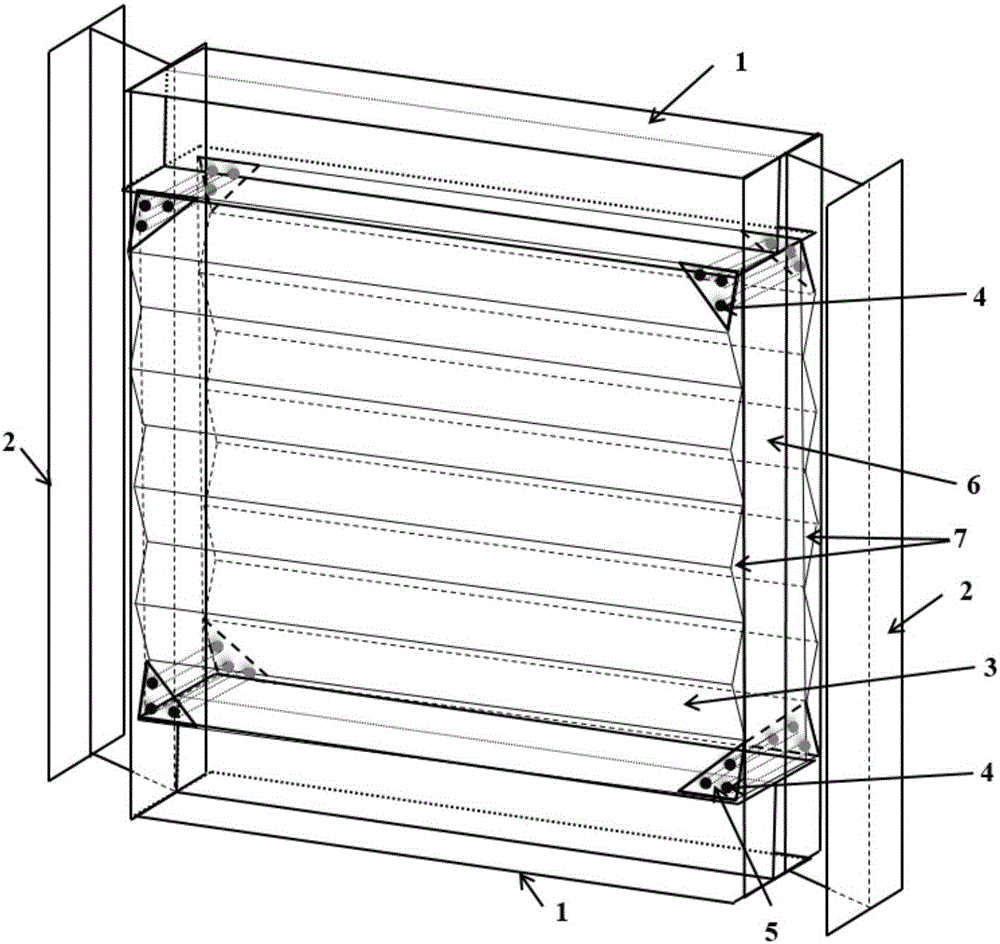

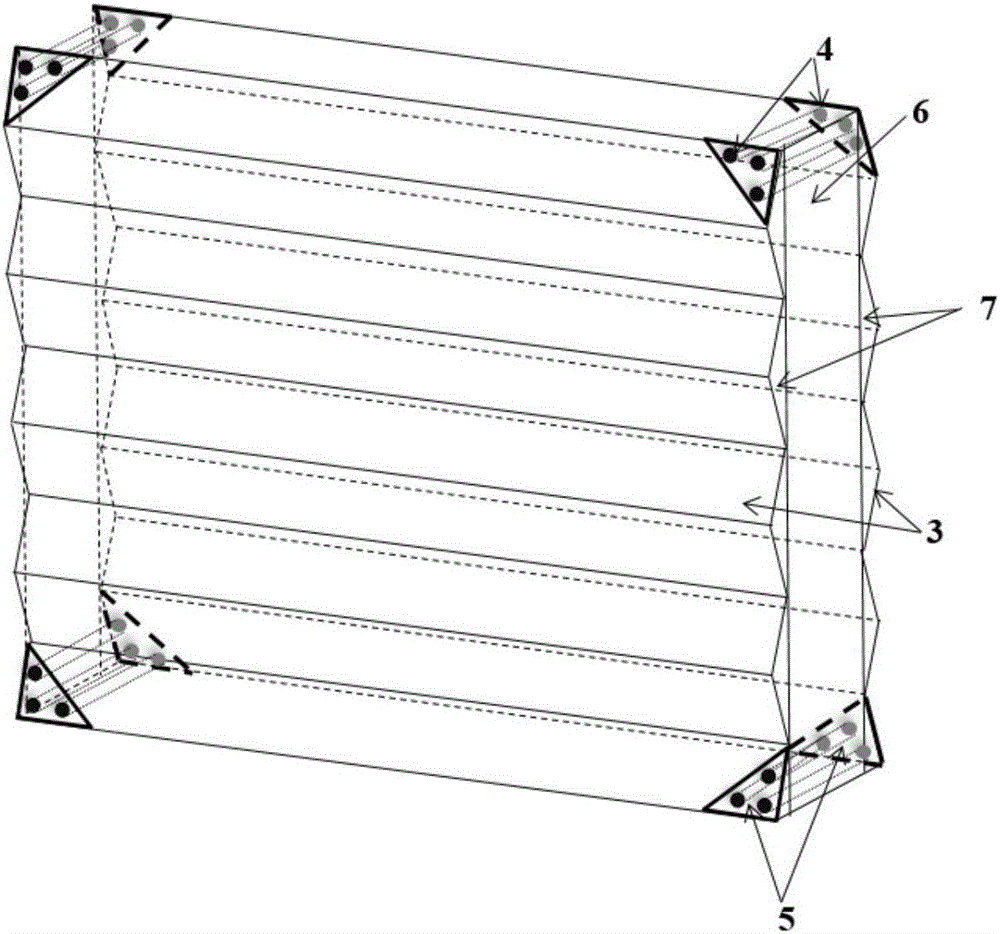

[0015] Such as Figure 1~3 As shown, a double-layer corrugated steel plate polyvinyl alcohol cement-based composite material combined explosion-resistant shear wall, including corrugated steel plate 3, PVA-ECC plate 6, foamed aluminum 7, H-shaped steel frame column 2 and H-shaped steel frame beam 1, The PVA-ECC plate 6 is made in the form of cast-in-place, and the two layers of corrugated steel plates 3 are respectively wrapped on the outside of the PVA-ECC plate 6, and the four corners of the two layers of corrugated steel plates 3 are aligned with the PVA - The ECC plates 6 are connected together by high-strength bolts 4, a steel backing plate 5 is arranged between the high-strength bolts 4 and the corrugated steel plate 3, and the foamed aluminum 7 is filled between the corrugated steel plate 3 and the PVA-ECC plate Between 6, a pair of H-shaped steel frame columns 2 and a pair of H-shaped steel frame beams 1 are connected to each other by welding to form a shear wall frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com