Engineered cementitious composite seamless bridge and construction method thereof

A technology of ultra-high toughness and composite materials, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of harmful substances intrusion, easy damage, etc., to improve the bending resistance, reduce the tensile force of the main girder, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Construction method of seamless bridge made of ultra-high toughness cement-based composite material

[0048] 1) Pouring the abutment back of the abutment and building the roadbed, the roadbed is a concrete base, SBS modified asphalt synchronous crushed stone seal, road base;

[0049] Concrete base: clean up the dirt in the base; support formwork; pour C15 concrete base; vibrate and level the poured concrete;

[0050]SBS modified asphalt synchronous gravel seal: the synchronous gravel seal vehicle evenly spreads SBS modified asphalt and gravel, and uses rubber-tyred road rollers to closely follow the rolling;

[0051] Pavement base: The pavement base is cement-stabilized gravel; after the stabilized soil is mixed, it is transported by dump truck; the paving and shaping of the mixture are paved and leveled manually with paver.

[0052] 2) Preparation of ultra-high toughness cement-based composite materials.

[0053] ① Calculated per cubic meter, the masses of cement, fl...

Embodiment 2

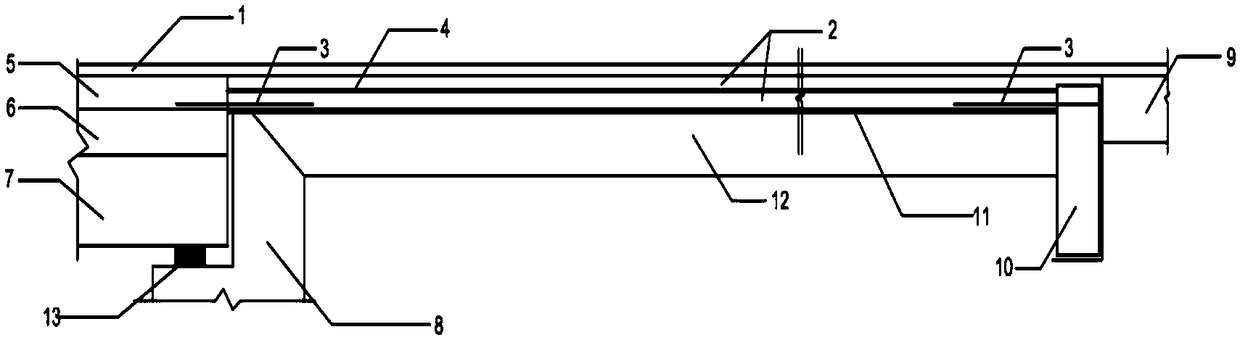

[0068] A seamless bridge made of ultra-high toughness cement-based composite materials, including an abutment 8 and a foundation beam 10, the abutment 8 and the foundation beam 10 are respectively located on both sides of the bridge, and the side of the abutment 8 close to the road surface is from top to bottom Set the first asphalt concrete layer 5, leveling layer 6, and hollow slab 7, the first asphalt concrete layer 5 is located above the horizontal line of the abutment top, the side of the foundation beam 10 near the road surface is the road base 9, the first asphalt Between the concrete layer 5 and the foundation beam 10 is a composite material layer 2, a concrete base layer 12 is set between the abutment 8 and the base beam 10, the composite material layer 2 is located above the concrete base layer 12, and the surface layer of the bridge deck is provided with an upper layer 1. A carbon fiber mesh 4 is arranged horizontally in the middle of the composite material layer 2, ...

Embodiment 3

[0079] Ultra-high toughness cementitious composite material (Engineered Cementitious Composite, referred to as ECC) is a kind of cement composite material with high performance. Experimental studies have found that this composite material exhibits obvious strain hardening characteristics under both tensile and bending loads, because it can convert the macroscopic cracking mode of a single crack in traditional cement-based materials under tension into multiple cracks. The microscopic cracking mode of fine cracks, so this material can still maintain a large bearing capacity and work with cracks after cracks appear. ECC materials have high ductility, high toughness and high energy absorption capacity. The maximum crack width at ultimate load is around 50 μm. The ultimate tensile strain measured by tensile and bending tests is above 3%, and the average crack distance is about 1mm. ECC has strong toughness and durability, and can meet the long-term vehicle load.

[0080] Carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com