Fiber reinforced composite material rib and concrete composite beam

A composite material, fiber-reinforced technology, applied in joists, girders, trusses, etc., can solve the problems of insufficient strength of FRP bars, large deflection and deformation of concrete, and low elastic modulus of FRP bars, and achieve excellent toughness and energy. Absorptive capacity, significant nonlinear deformation, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

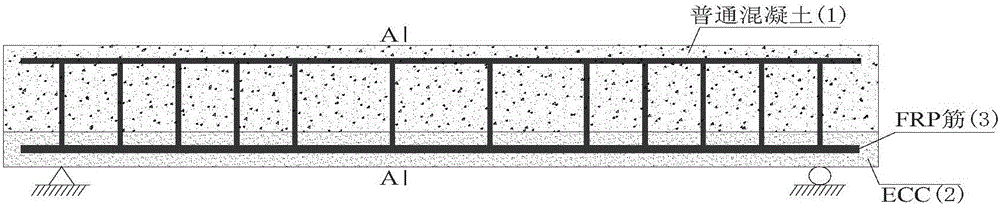

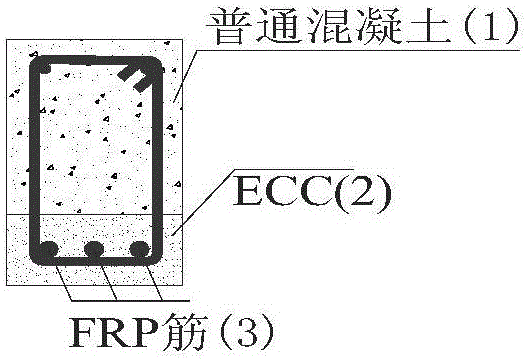

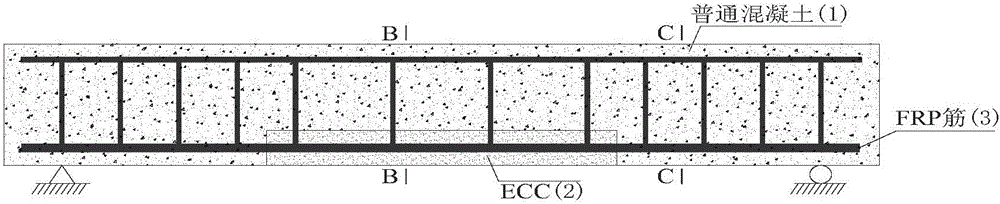

[0021] Such as Figures 1 to 5 As shown, the fiber-reinforced composite material-reinforced concrete composite beam of the present invention includes fiber-reinforced composite material reinforcement and concrete coated on the periphery of the fiber-reinforced composite material reinforcement, and the concrete coated around the fiber-reinforced composite material reinforcement in the tensile region of the composite beam It is a cement-based composite material for engineering.

[0022] Such as figure 1 , 2 As shown, the tensile region of the composite beam is along the entire longitudinal length of the composite beam.

[0023] Such as image 3 , 4 As shown in , 5, the tensile region of the composite beam is a beam segment with the moment control section of the beam as the center of symmetry and whose length is 1 / 4 to 1 / 2 of the beam length.

[0024] Preferably, the composition and weight content of the cement-based composite material for engineering are:

[0025] Cement 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com