Patents

Literature

141 results about "Beam length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A beam can span its length minus the required bearing on either end, so a 12 foot long beam that requires 1.5 inches of bearing on either end can span 11 ft 9 inches.

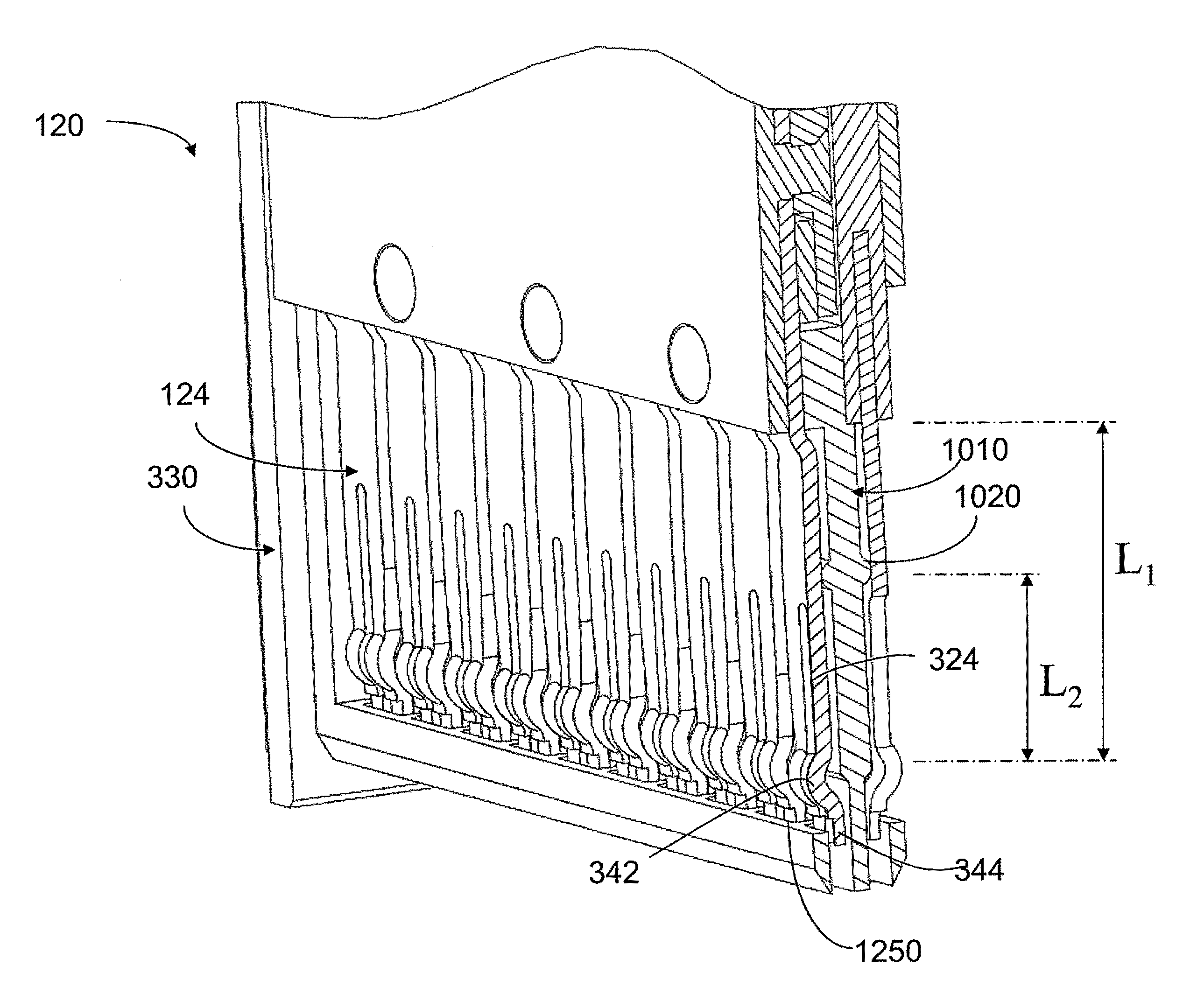

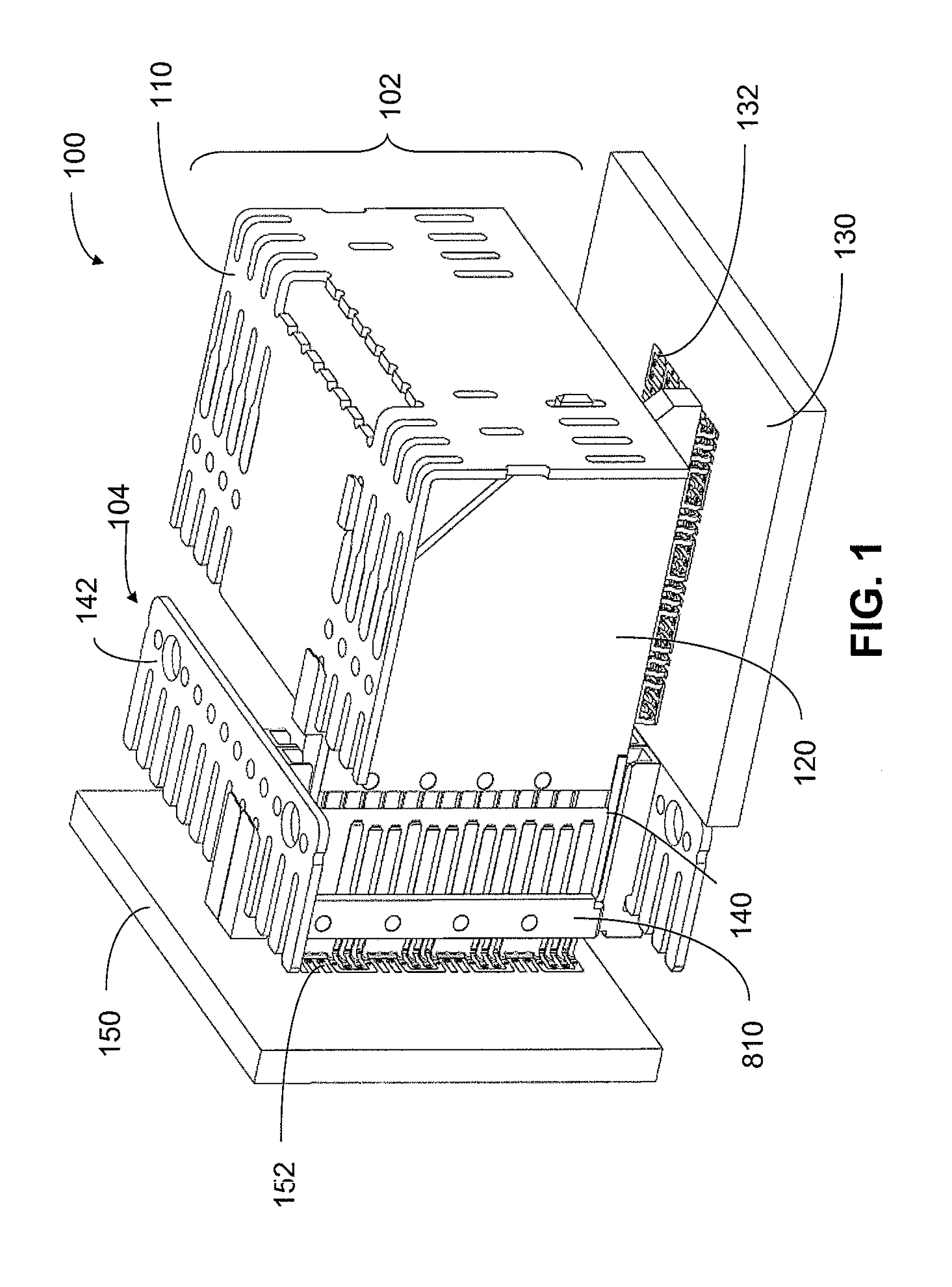

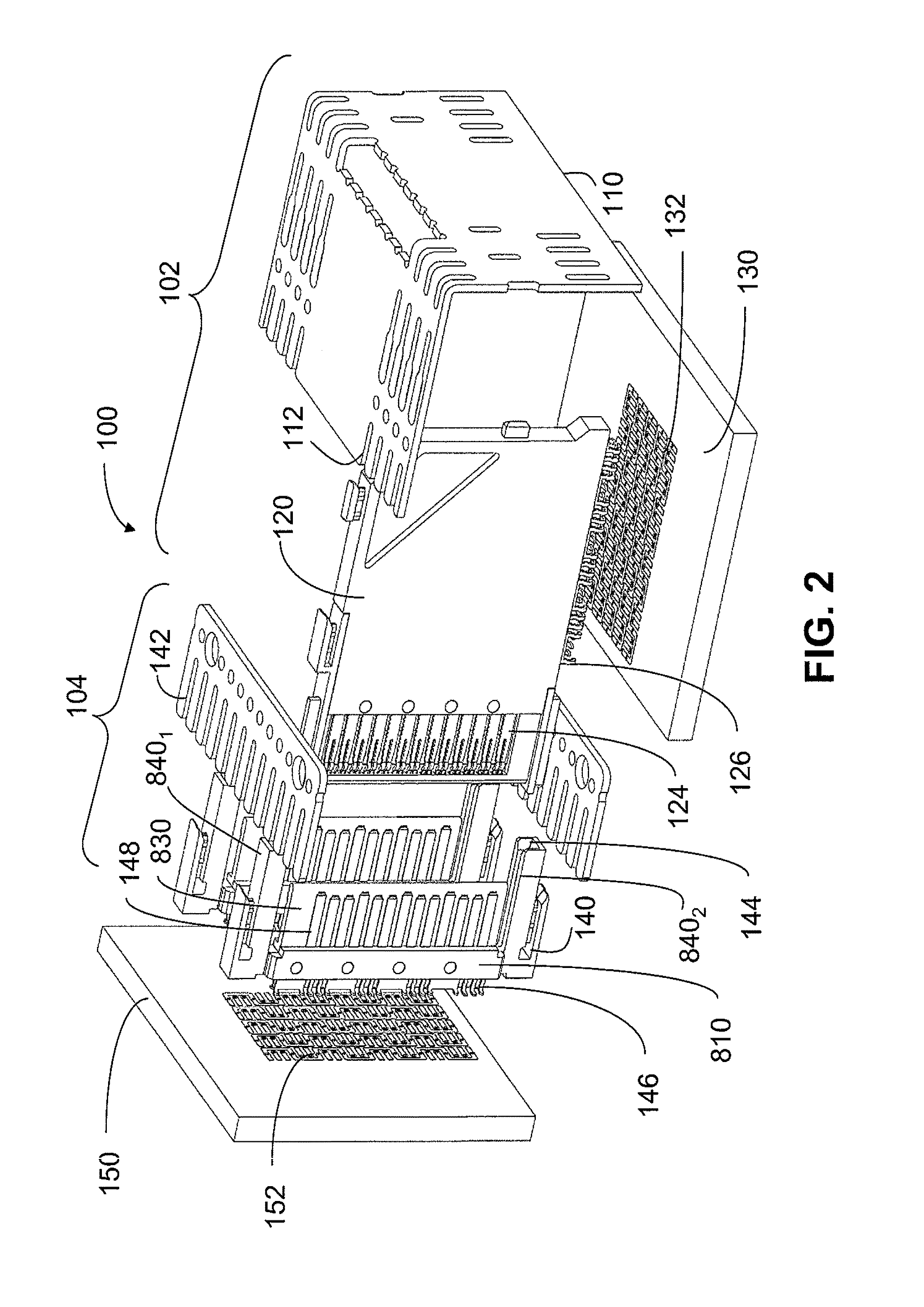

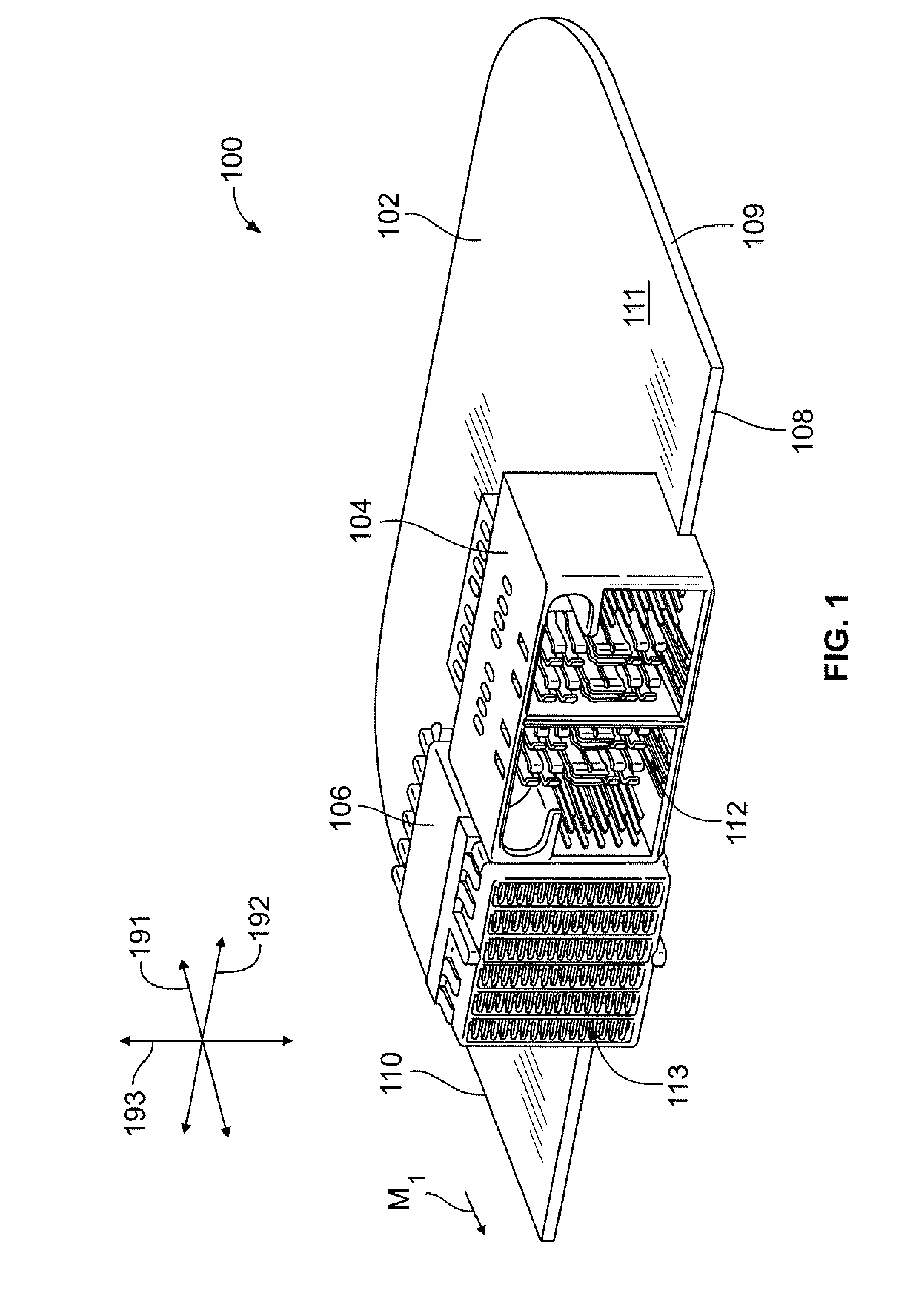

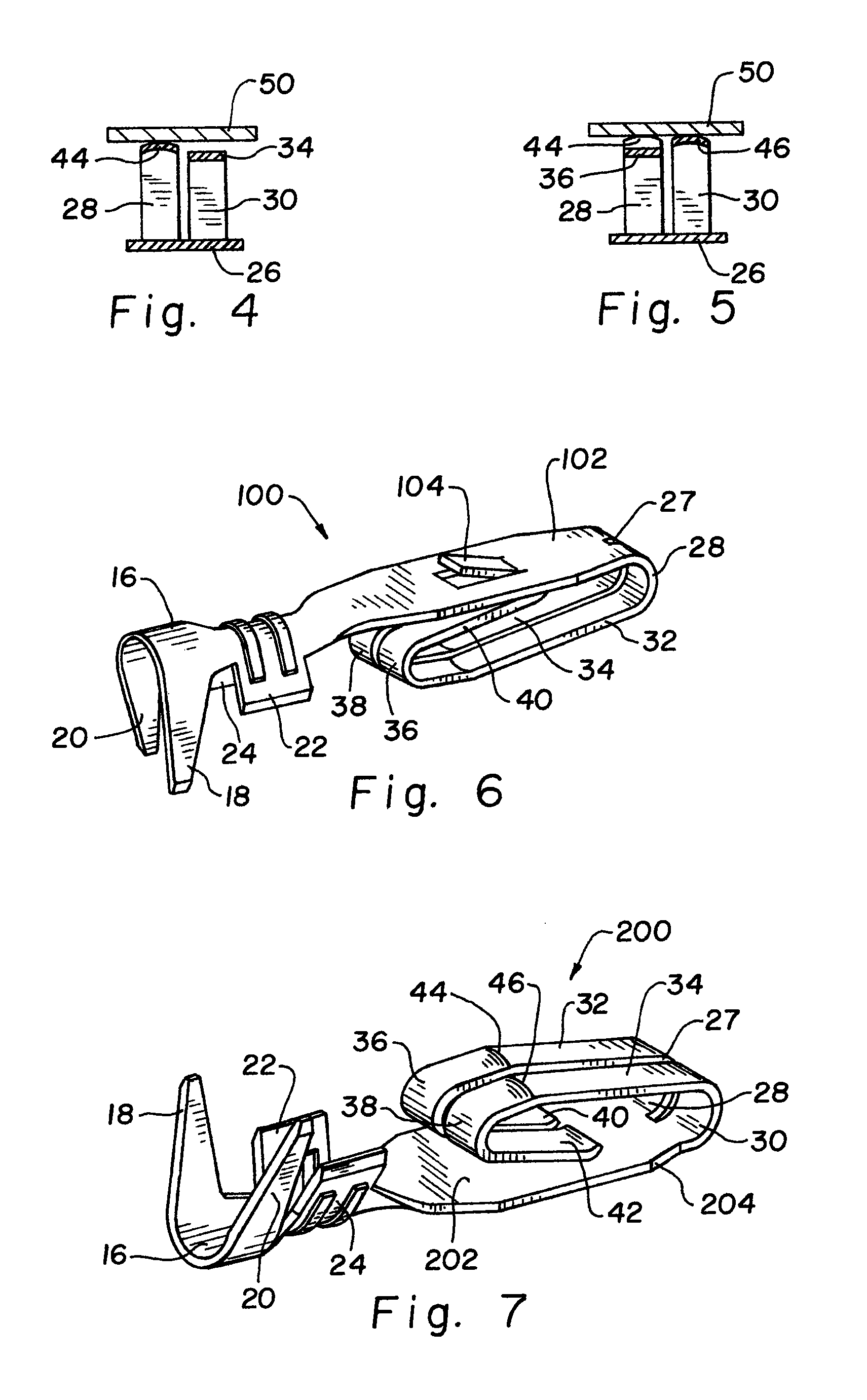

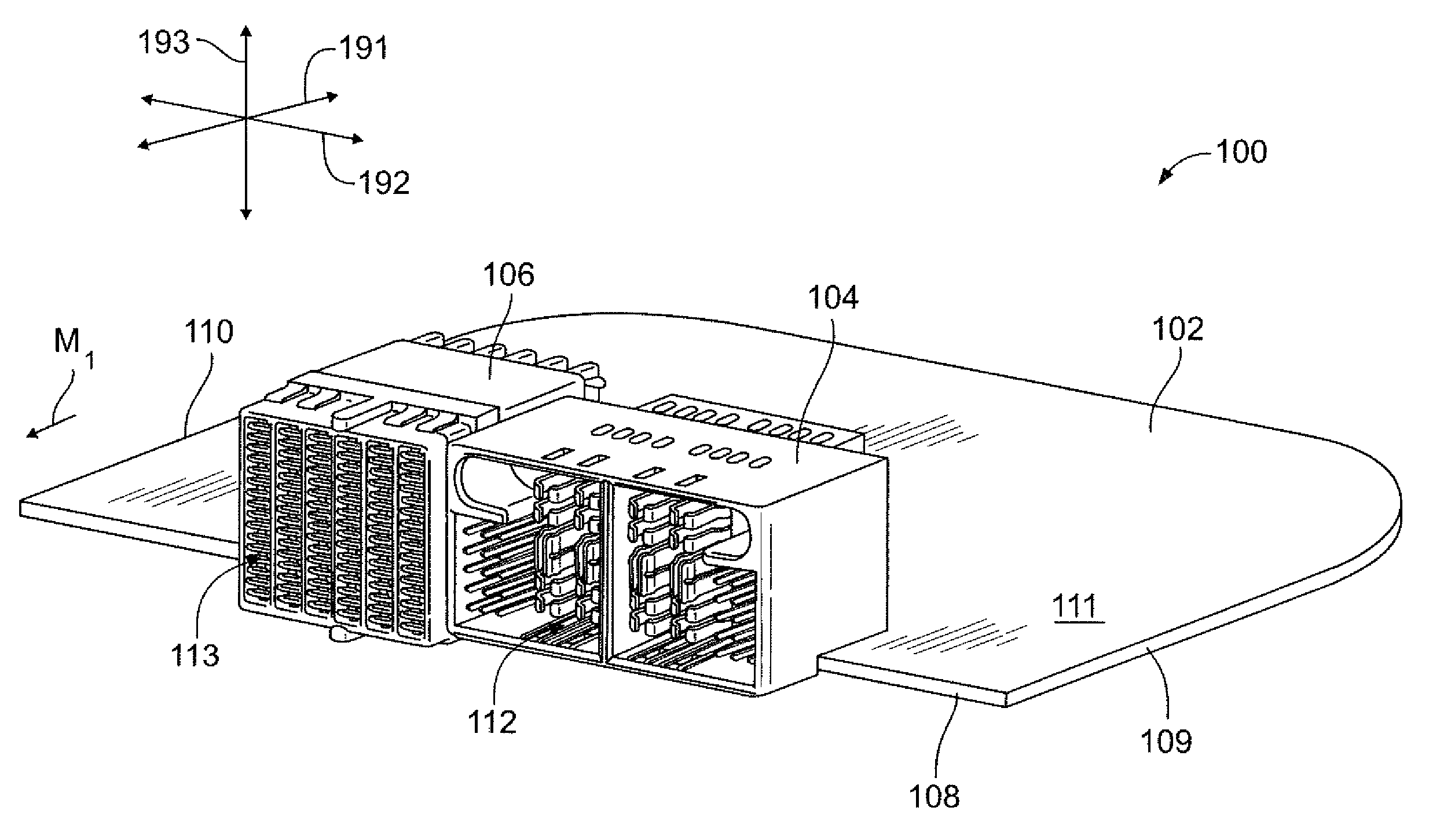

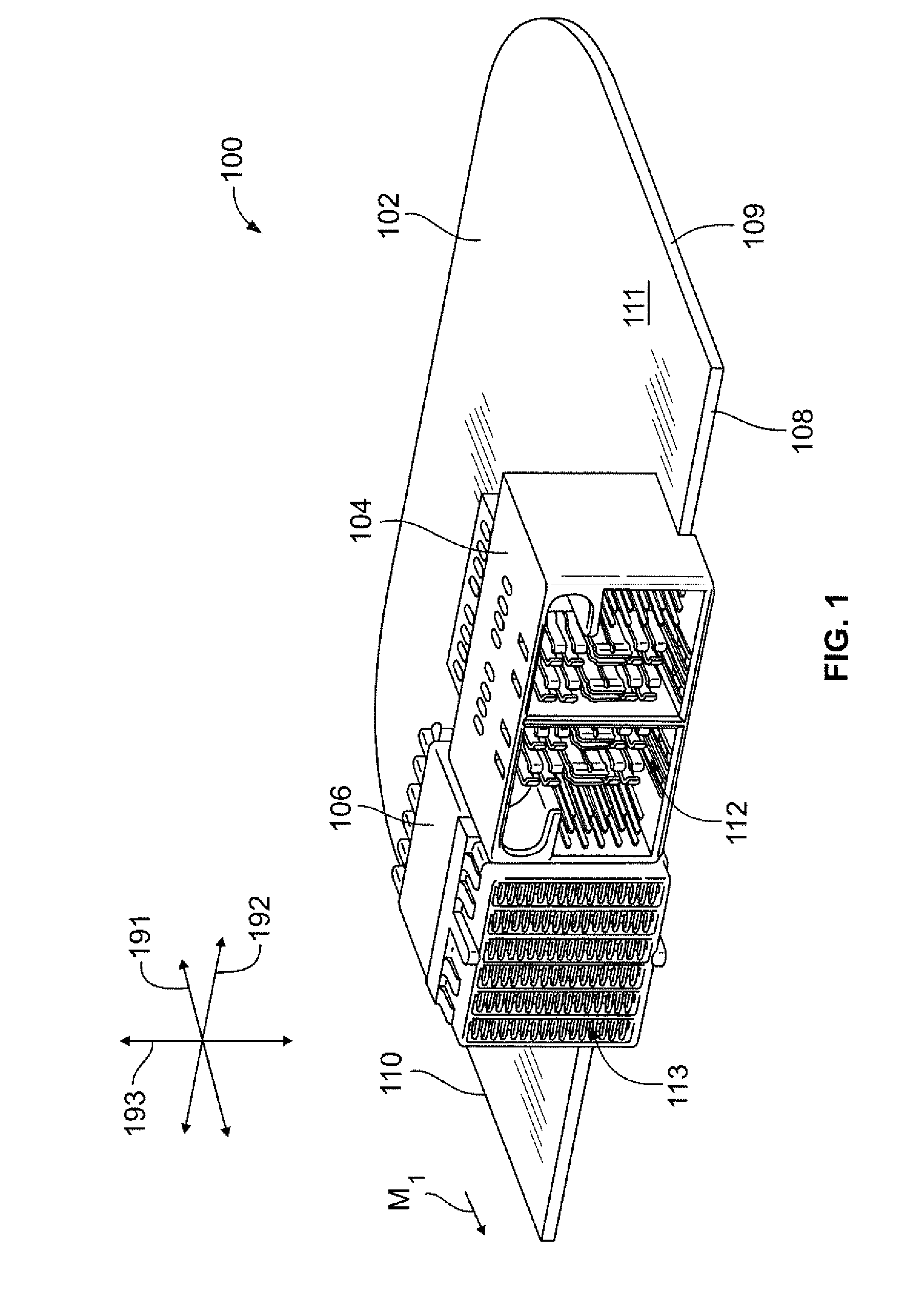

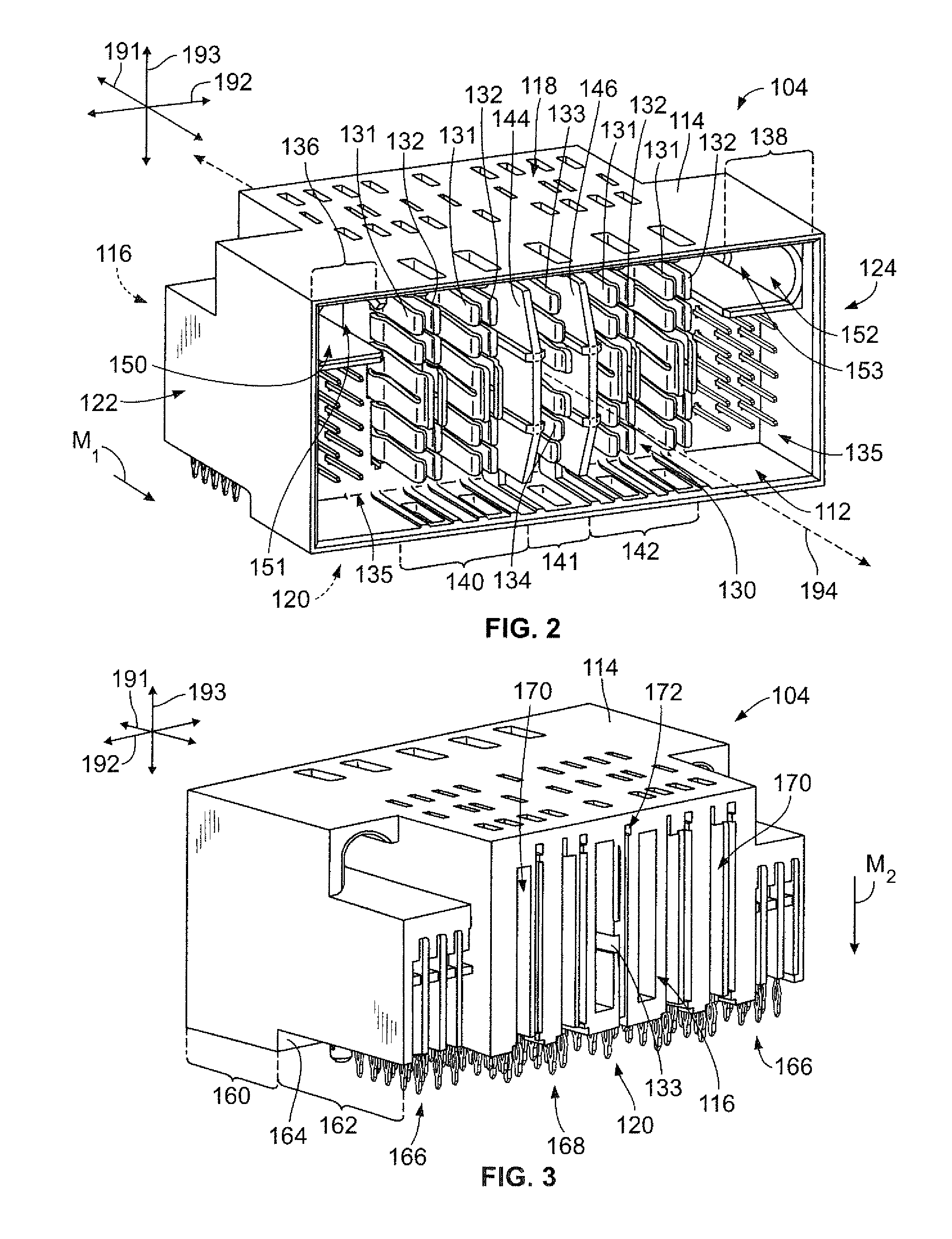

High density electrical connector with variable insertion and retention force

ActiveUS8182289B2Lower insertion forceImprove retentionTwo-part coupling devicesCoupling protective earth/shielding arrangementsElectricityHigh density

An interconnection system that includes a daughter card and backplane electrical connectors mounted to printed circuit boards at connector footprints. The spring rate of beam-shaped contacts in the daughter card connector increases while mating with the backplane connector so that the retention force may be greater than the insertion force. Such a change in spring rate may be achieved by positioning the beam-shaped contacts adjacent a surface of a connector housing. That surface may include a projection that aligns with the beam-shaped contact. When the connectors are unmated, the beam-shaped contact may be spaced from the projection. As the connectors begin to mate, a central portion of the beam-shaped contact may be pressed against the projection, which has the effect of shortening the beam length and increasing its stiffness.

Owner:AMPHENOL CORP

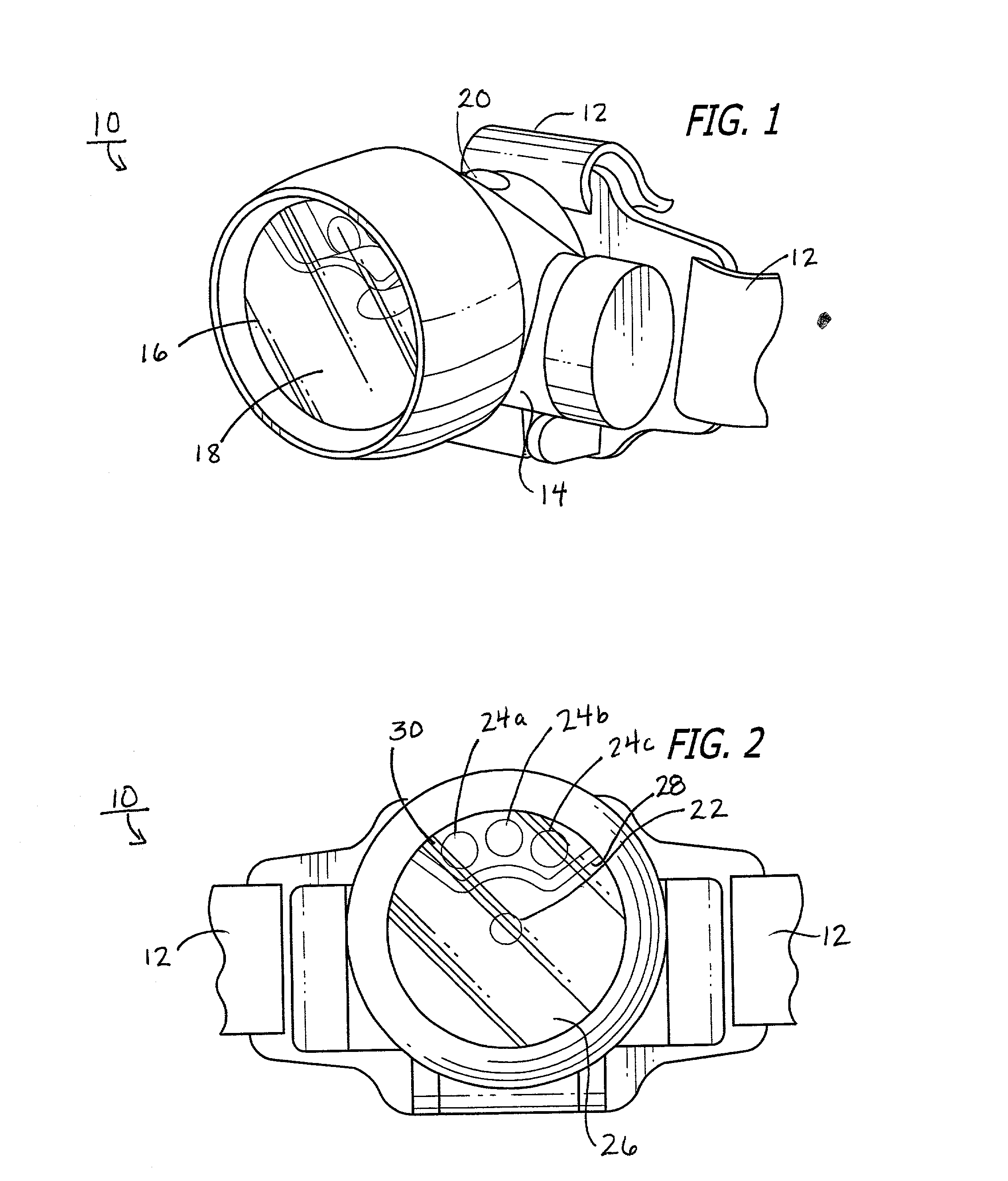

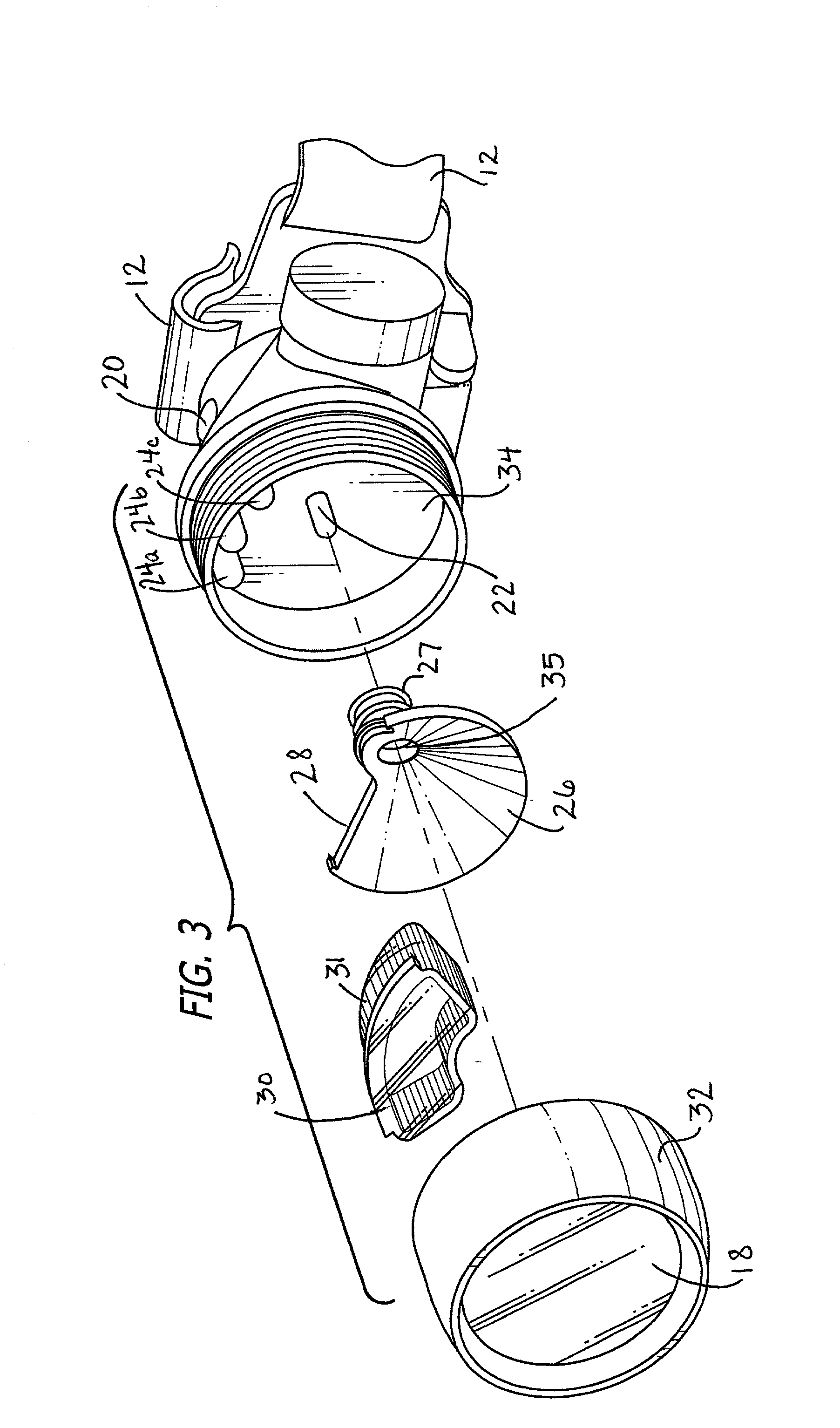

Modular connector with preload and beam length reduction features

Owner:TYCO ELECTRONICS SERVICES GMBH

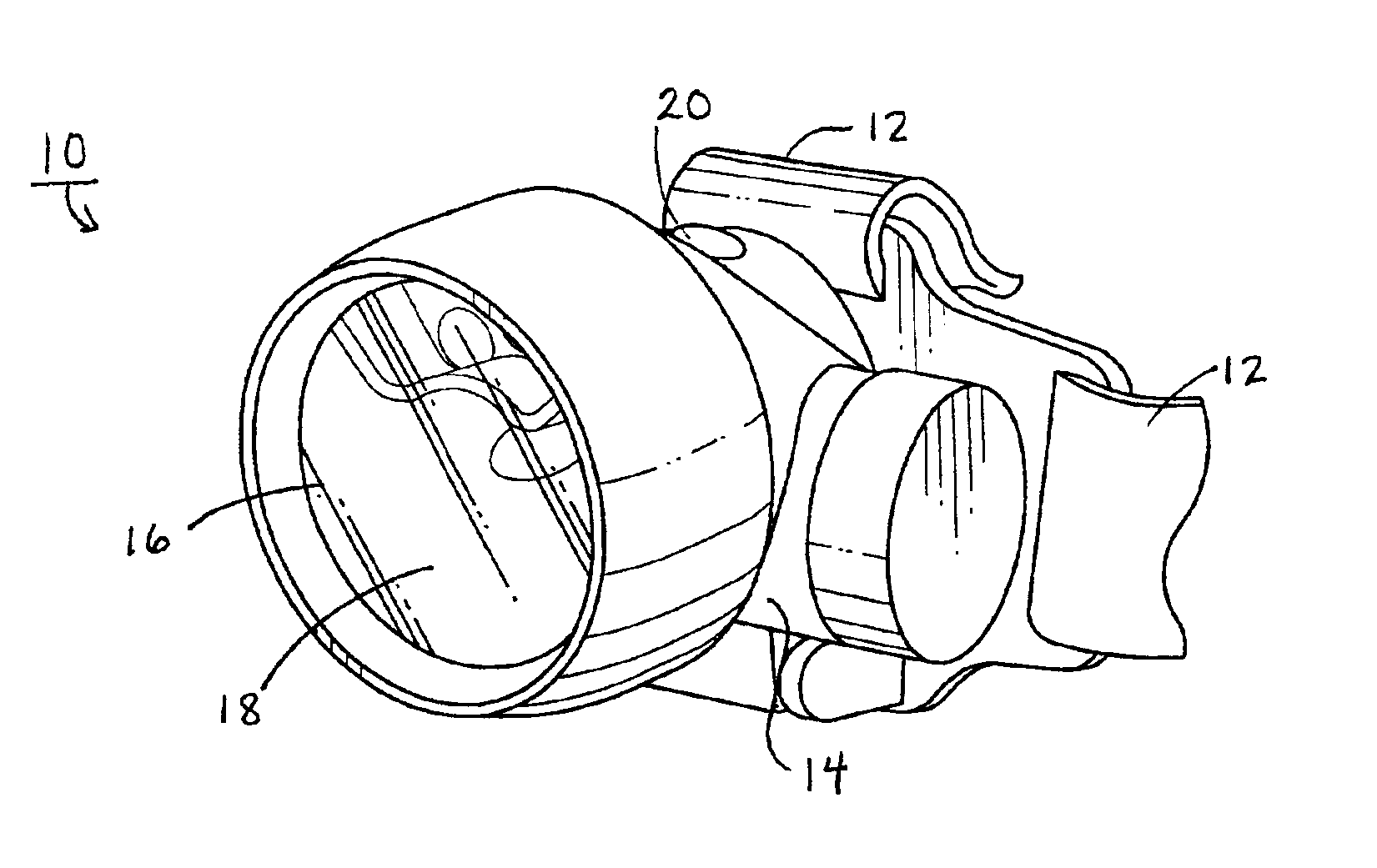

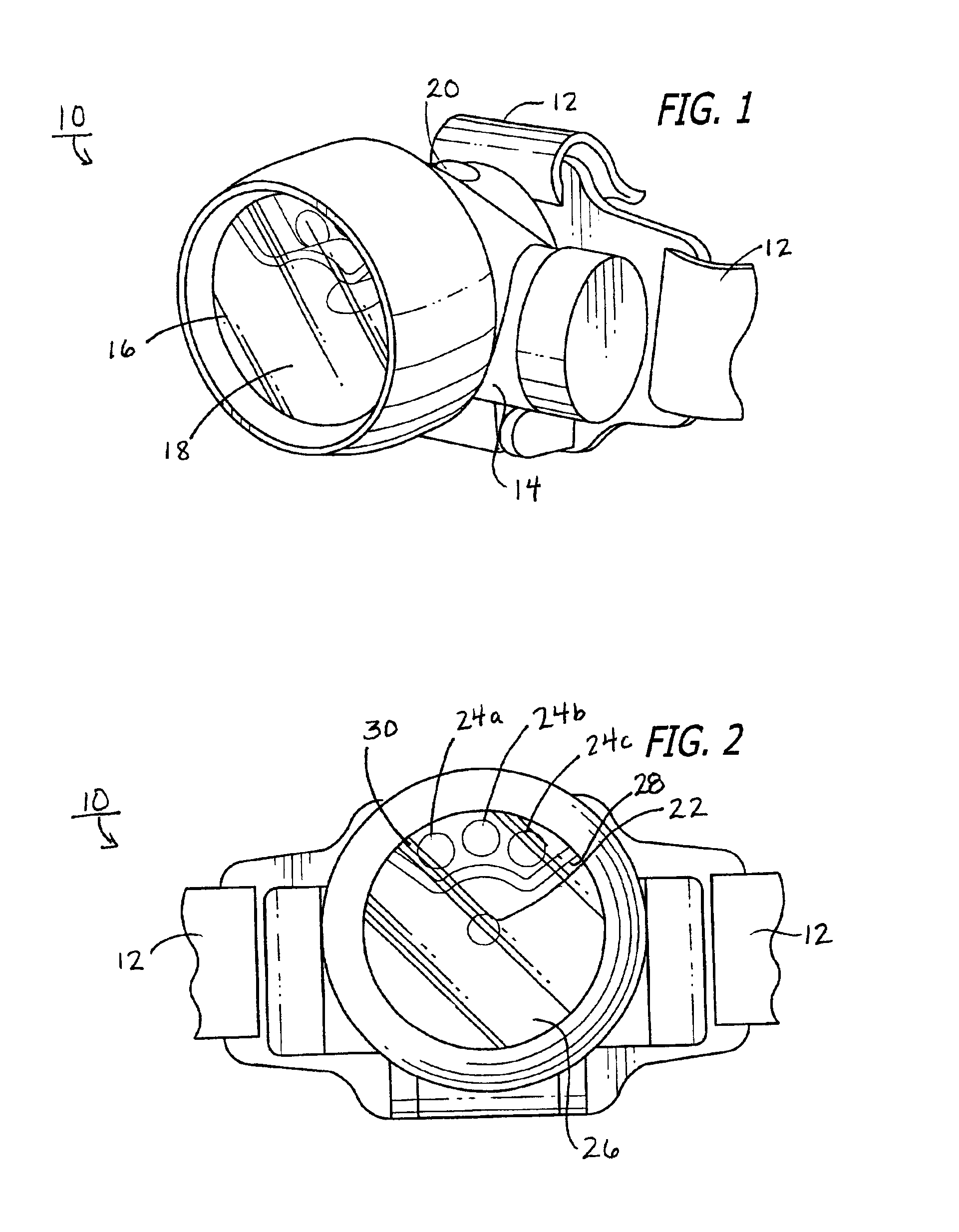

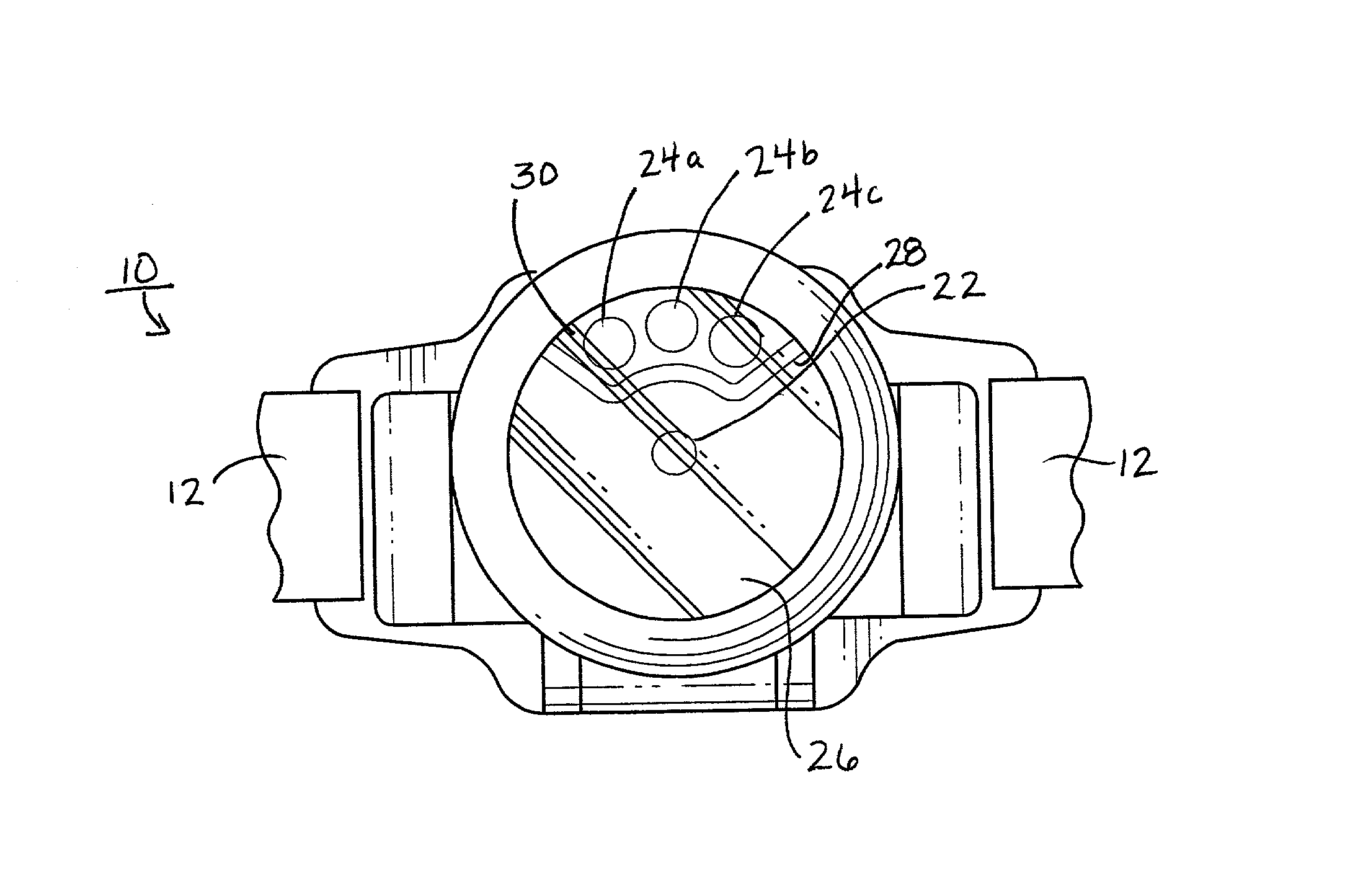

Electronically controlled multi-light flashlight

InactiveUS6890086B2Easy to useAvoid problemsElectrical apparatusLighting support devicesFlashlightLight-emitting diode

Provided is a flashlight that includes a plurality of light sources for providing a beam of light. Preferably, the light sources have different levels of power consumption, different brightnesses and / or different beam lengths. More preferably, the plurality of light sources includes at least one light-emitting diode (LED) and at least one incandescent lamp. A housing directs the beam of light and an integrated circuit controls illumination of the plurality of light sources, with a switch providing an input signal to the integrated circuit. In the preferred embodiment of the invention, the switch is a pushbutton switch and the integrated circuit is a multi-state electronic device that changes state when the signal is input from the switch, with different states of the integrated circuit causing different combinations of the light sources to become illuminated.

Owner:GOLD CORAL INT

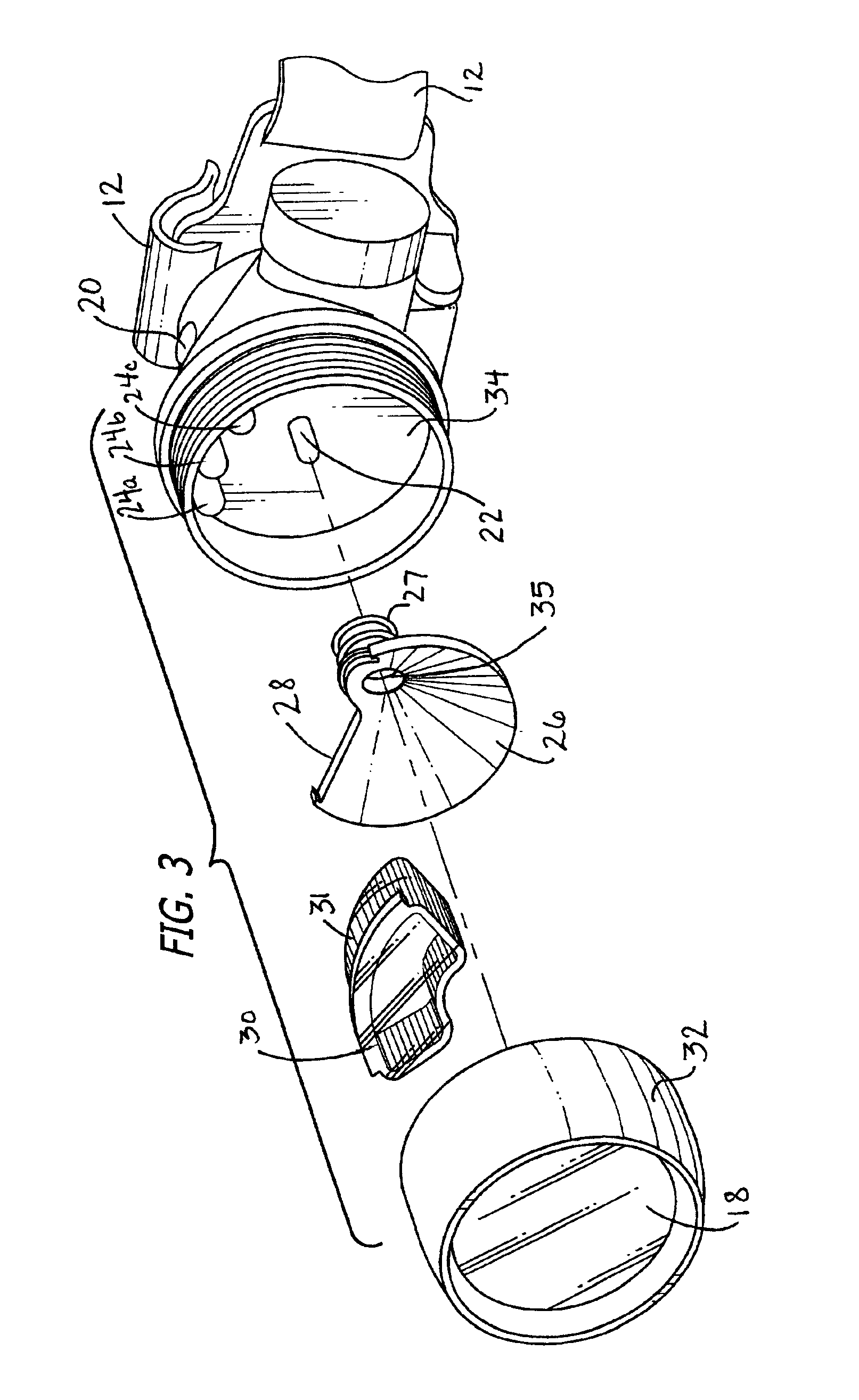

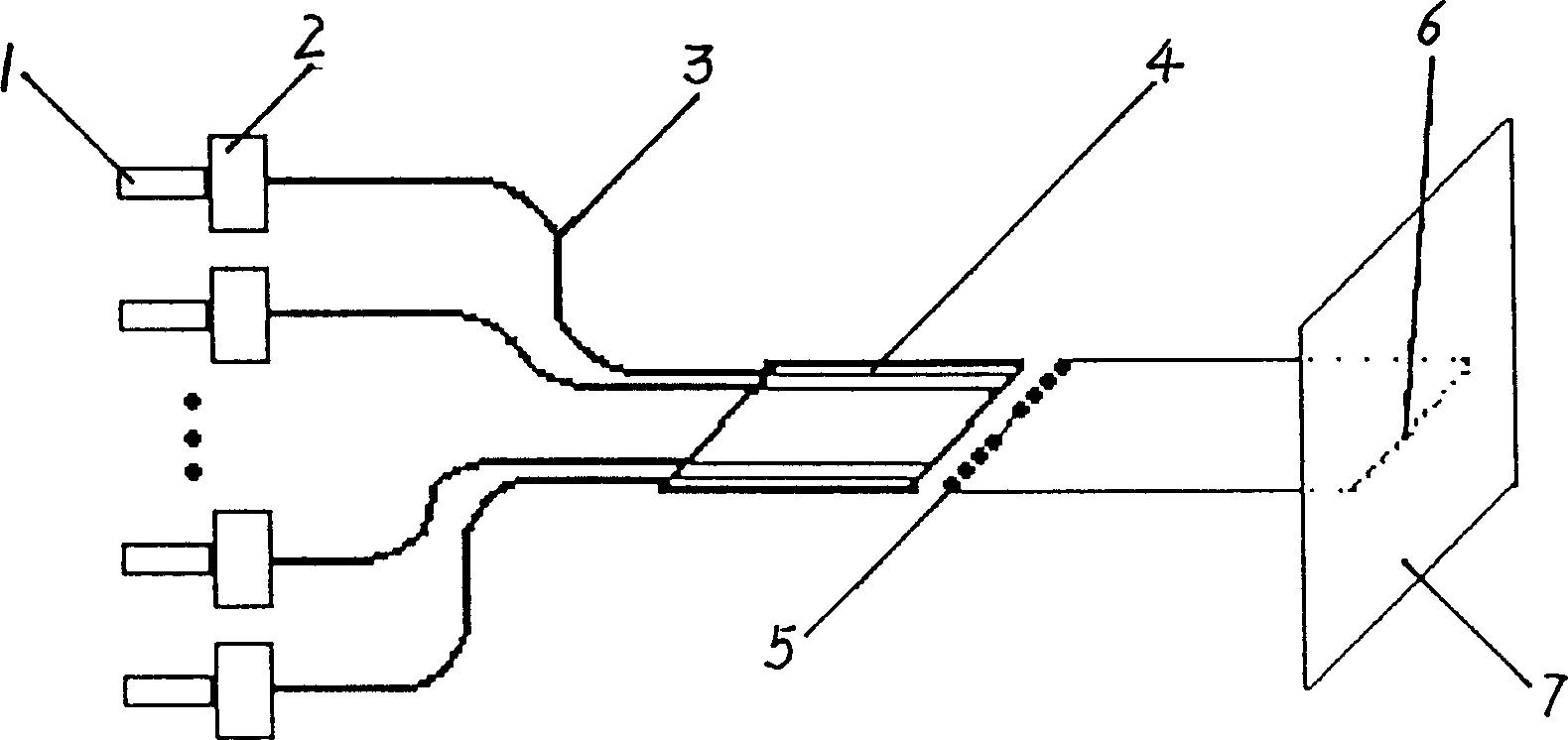

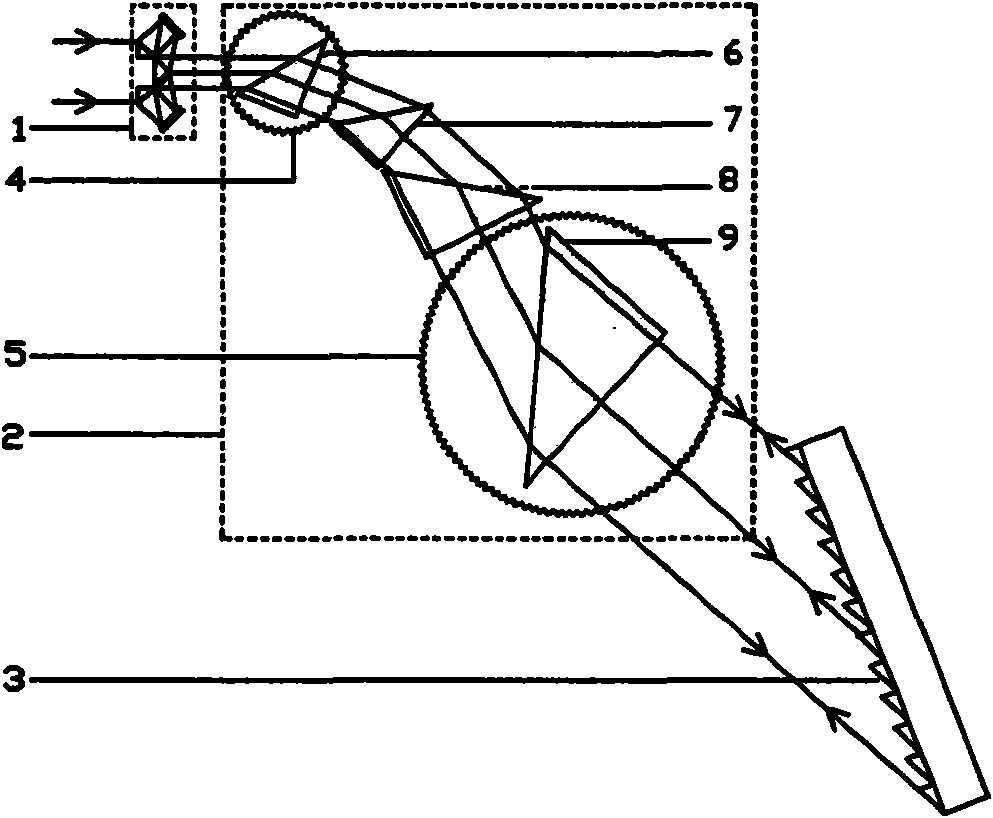

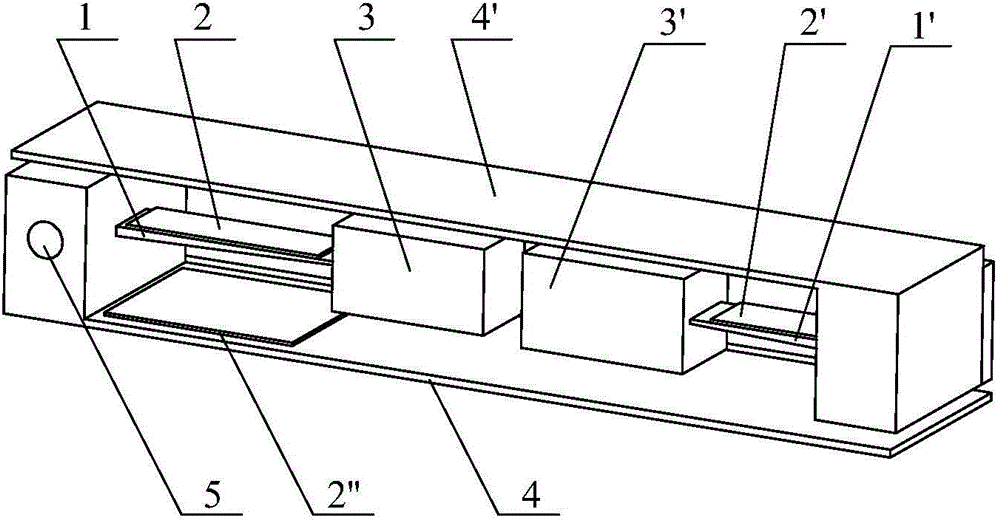

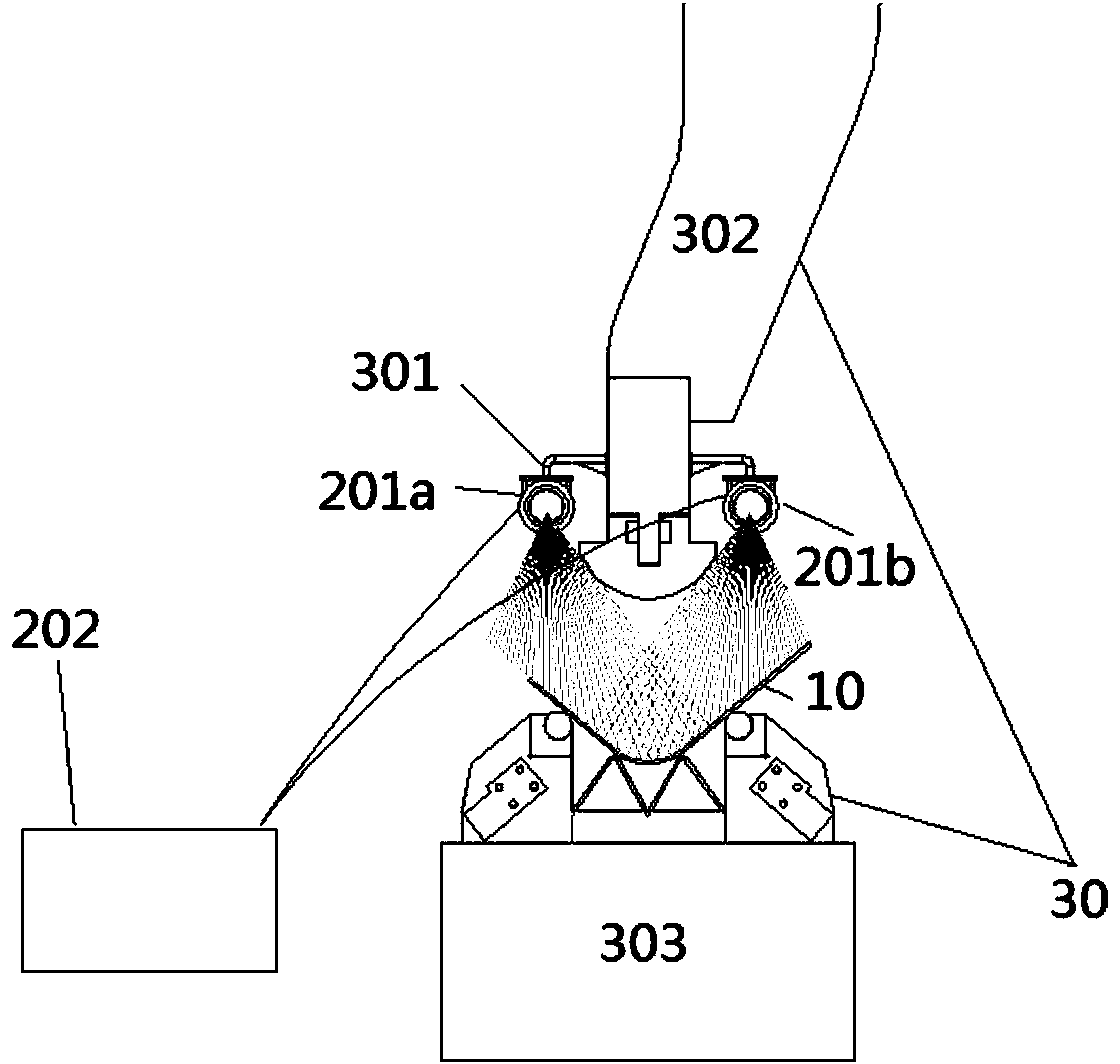

Method and apparatus for applying optical fiber array energy source to laser sintering rapid forming

InactiveCN1593817AImprove processing efficiencyNo reduction in processing qualityIncreasing energy efficiencyActive medium shape and constructionFiberFiber array

The invention relates to a kind of method of using fibre-optical array energy source for laser firing and quick forming and the device. The invention has not the disadvantages of current laser, such as only being suited to small piece and having low working efficiency. The invention uses a fibre-optical array, which is constituted of several high power semi conduct laser machine and fibre-optical lines, and forms a spiccato laser beam on the work surface with lenticule array. The above two fibre-optical arrays are sited oppositely, and send out two same conterminous laser beams and then form a consecutive beam. Controlling the beam length and the gap place with computer can frit complicated pattern. The invention includes several high power semi conduct laser machine and lenticule array, coupler, miniature model V fibre-optical seat, fibre-optical.

Owner:ZHONGBEI UNIV

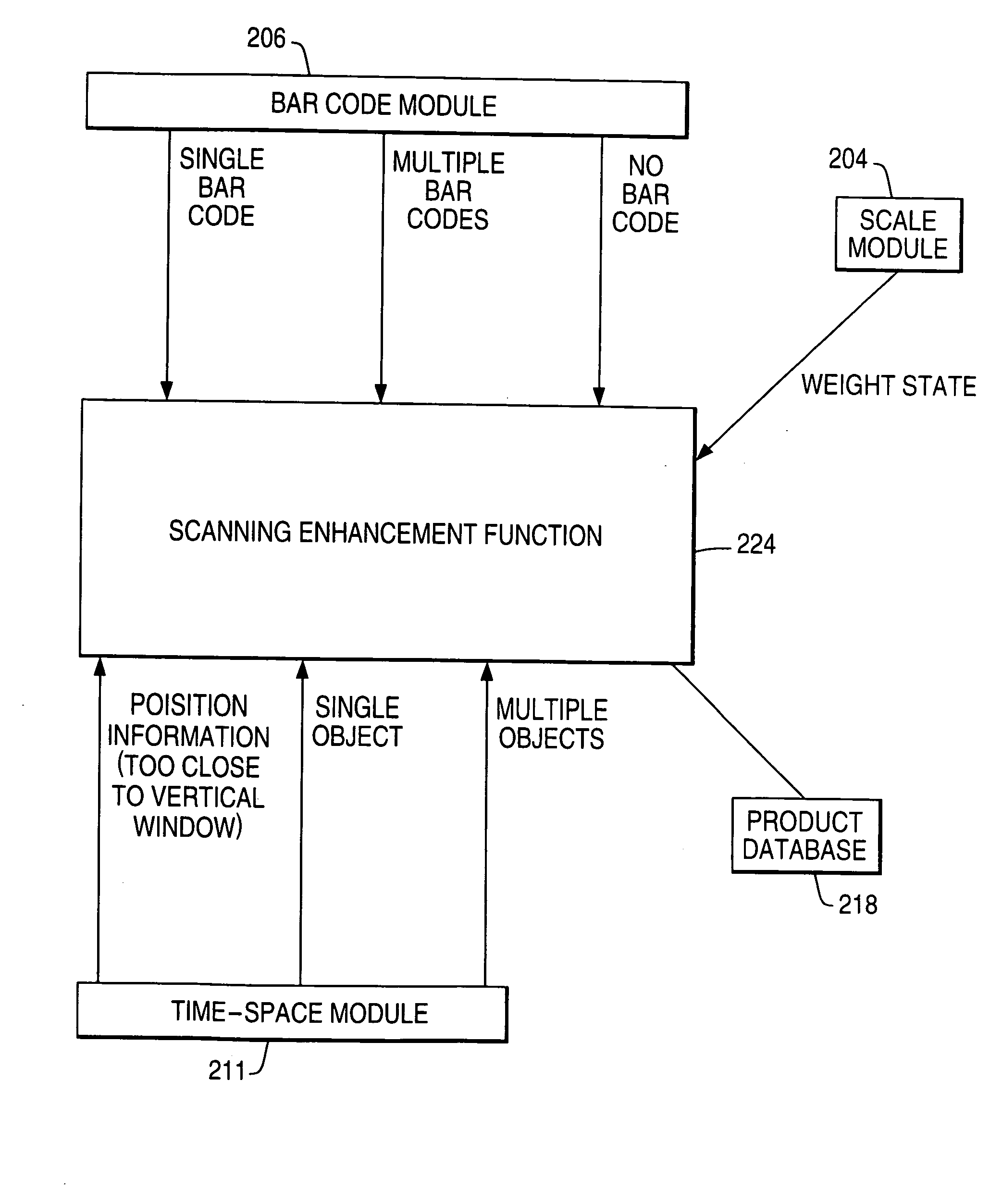

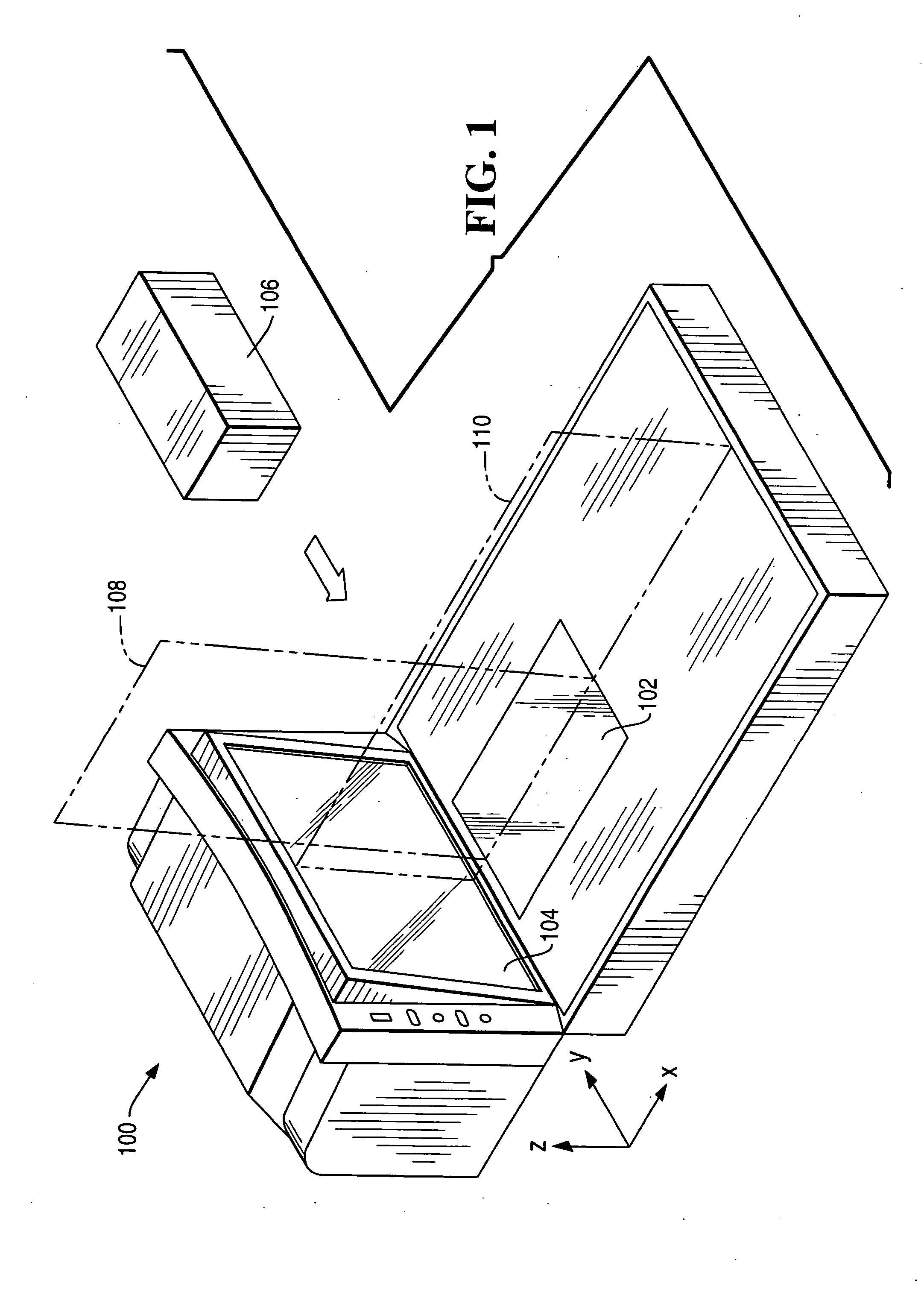

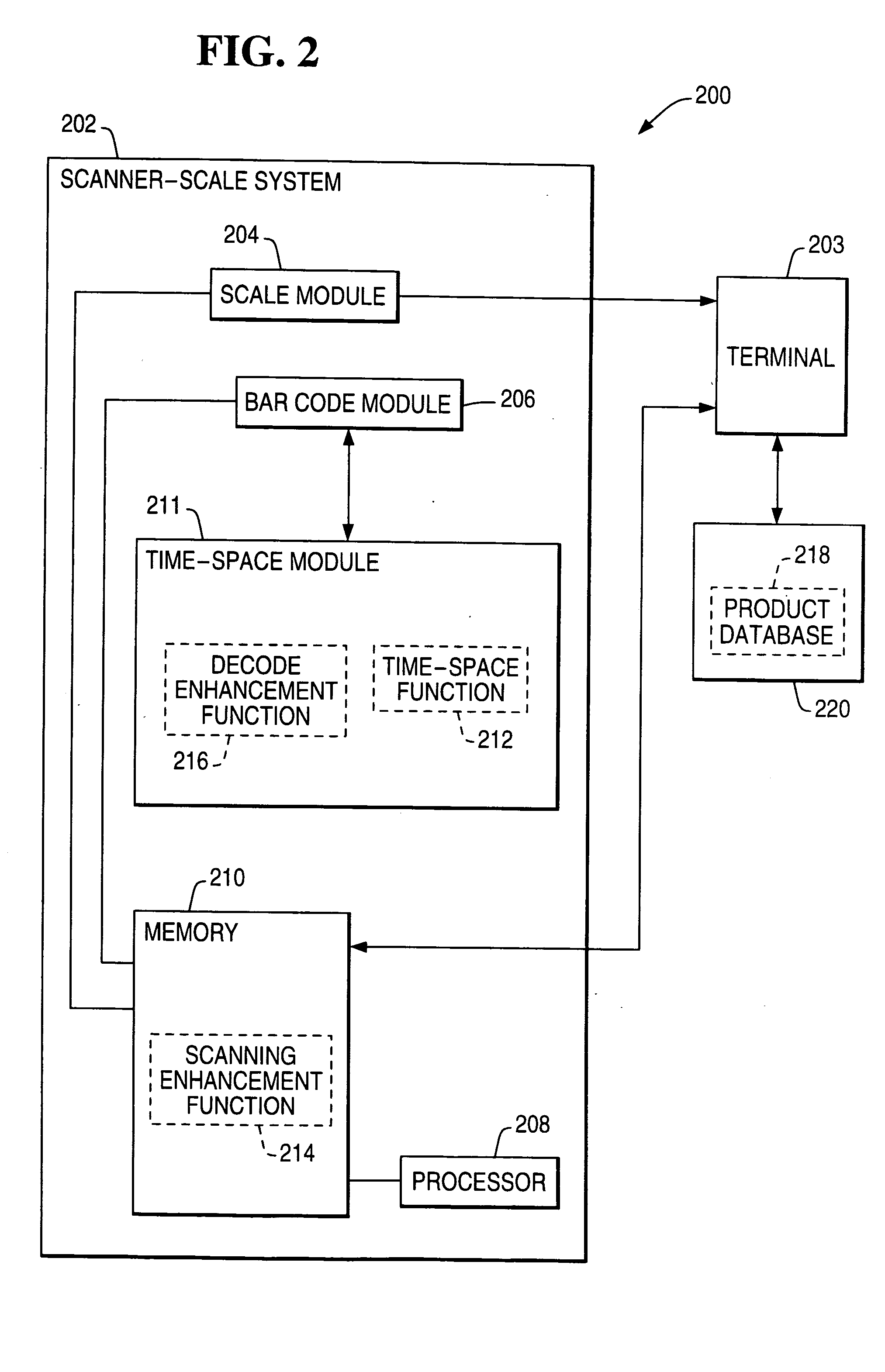

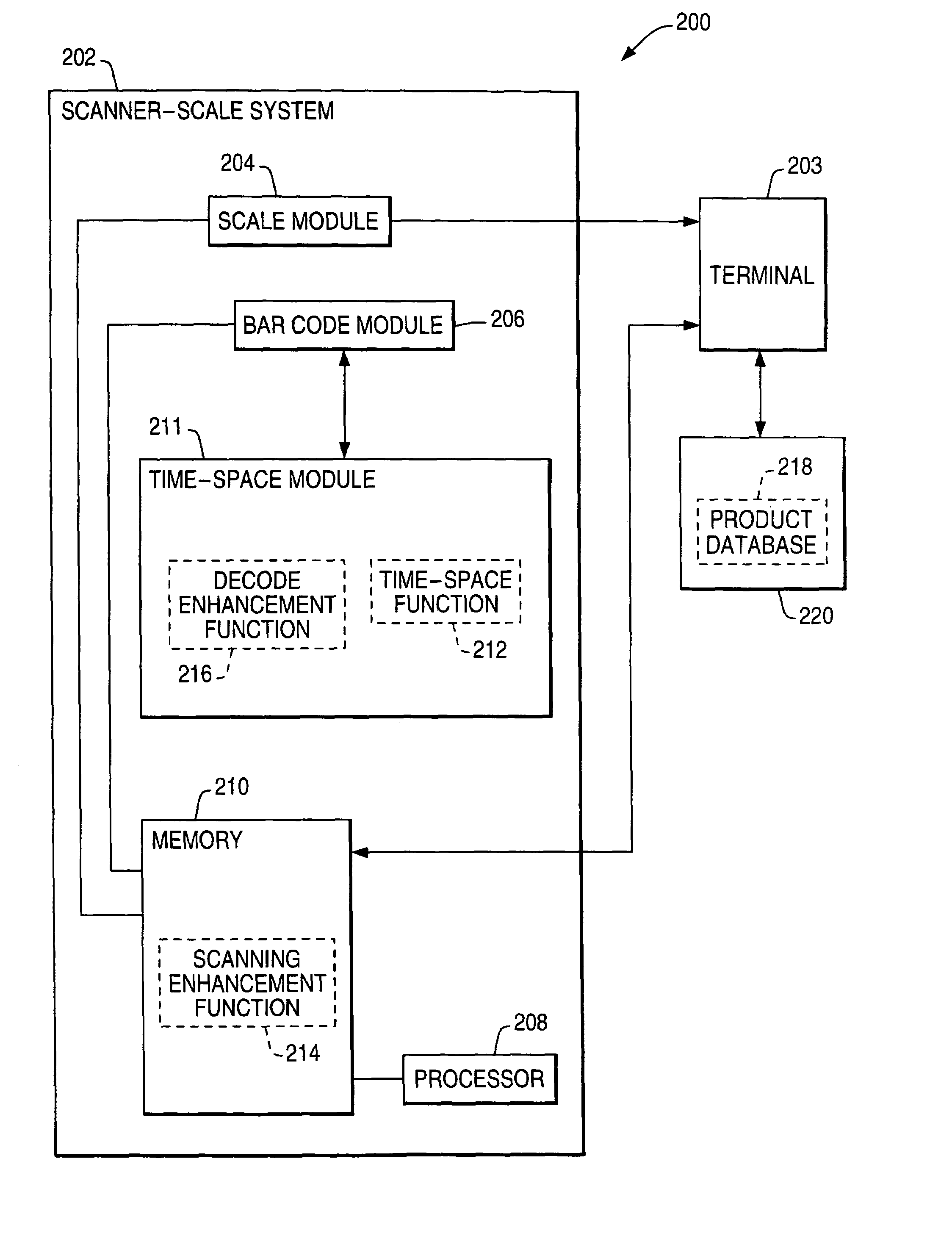

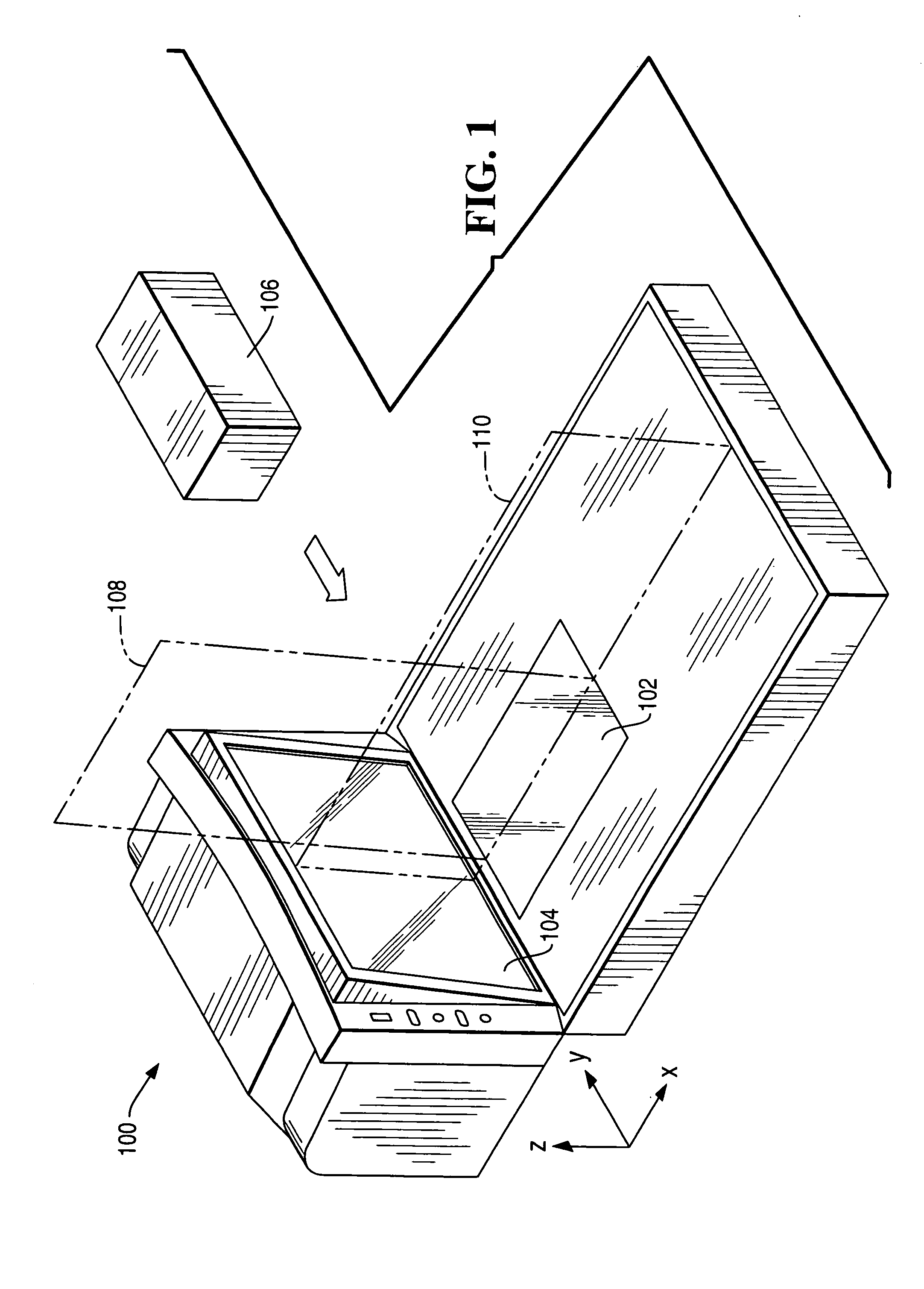

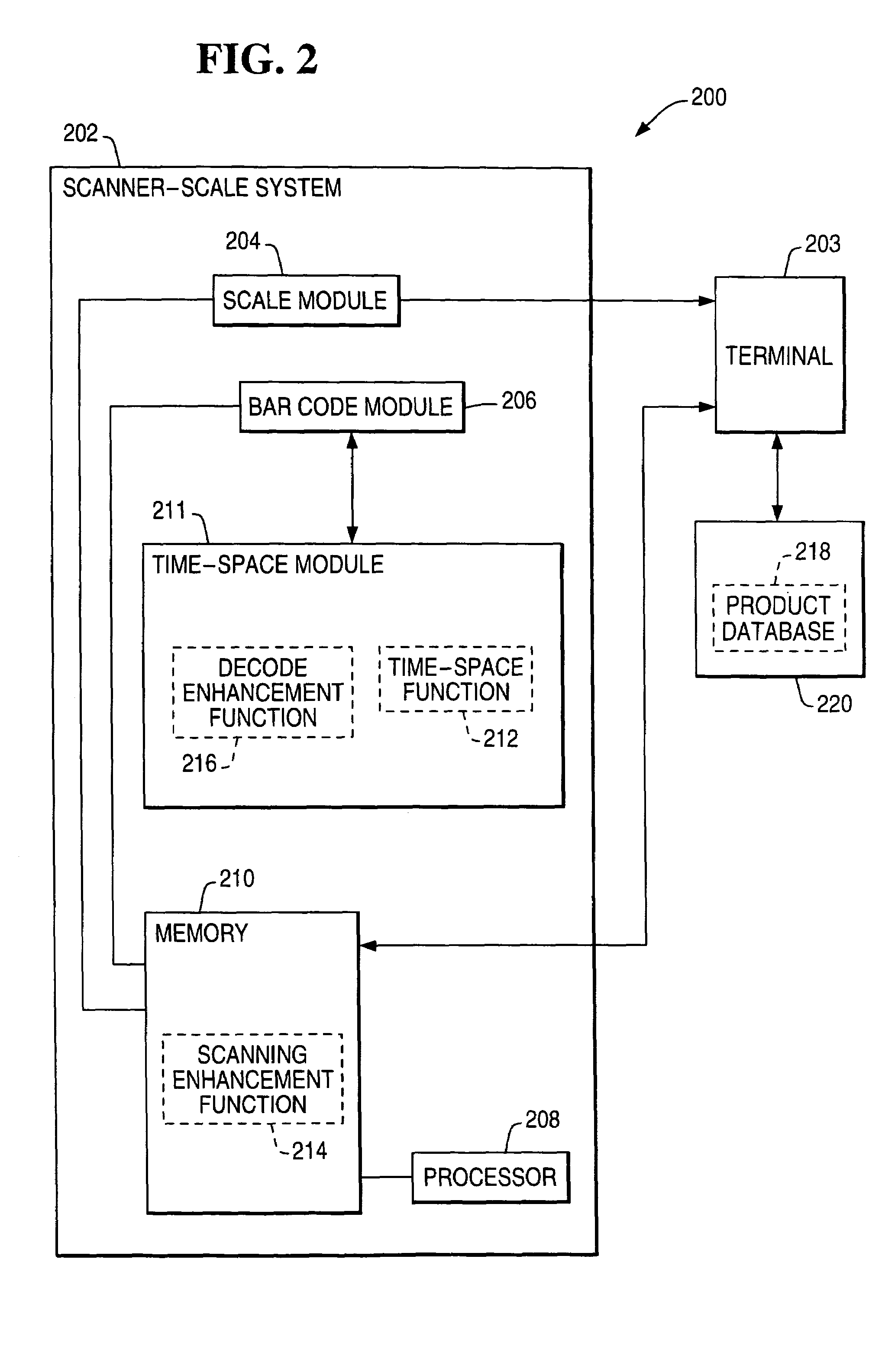

Methods and apparatus for using imaging information to improve scanning accuracy in bar code scanners

InactiveUS20050103850A1Improve accuracyCharacter and pattern recognitionVisual presentationBarcodeCoding decoding

Techniques for using imaging information computed from examining a scanner signal are described. When one or more objects passes within a field of view of a scanner, scan patterns emerging from one or more scanner windows and reflected from the objects back into the scanner windows produce one or more scanner signals. The scanner signals are processed to obtain beam position and beam length information to improve the accuracy of bar code decoding and to compute imaging information for objects within the field of view of the scanner. The imaging information for the objects is compared with bar code information for the objects. The expected number, size and shapes of objects indicated by the bar code information is compared with the actual number, size and shapes of objects in order to determine if valid scans occurred or if missed, double or otherwise erroneous scans occurred.

Owner:NCR CORP

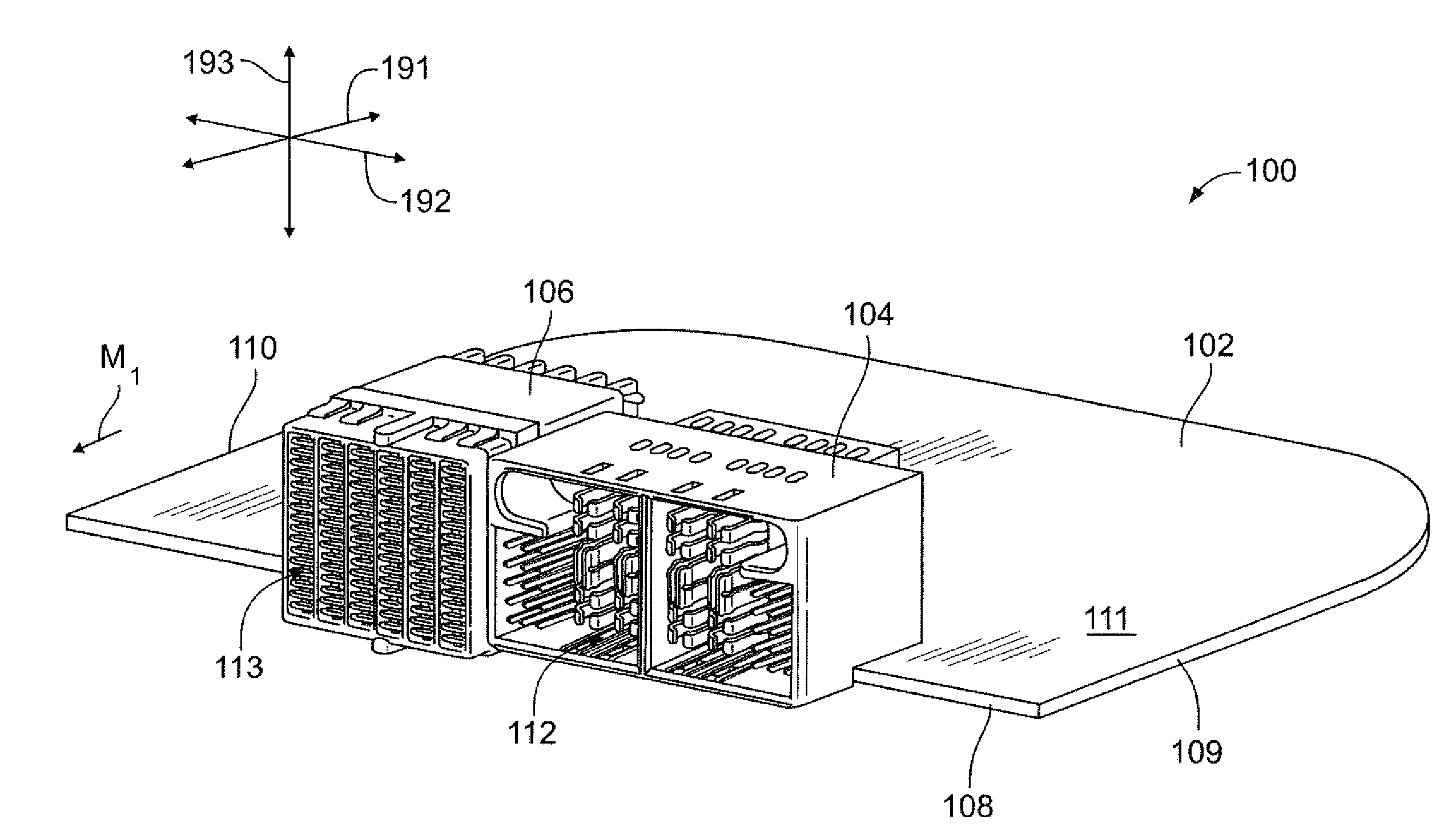

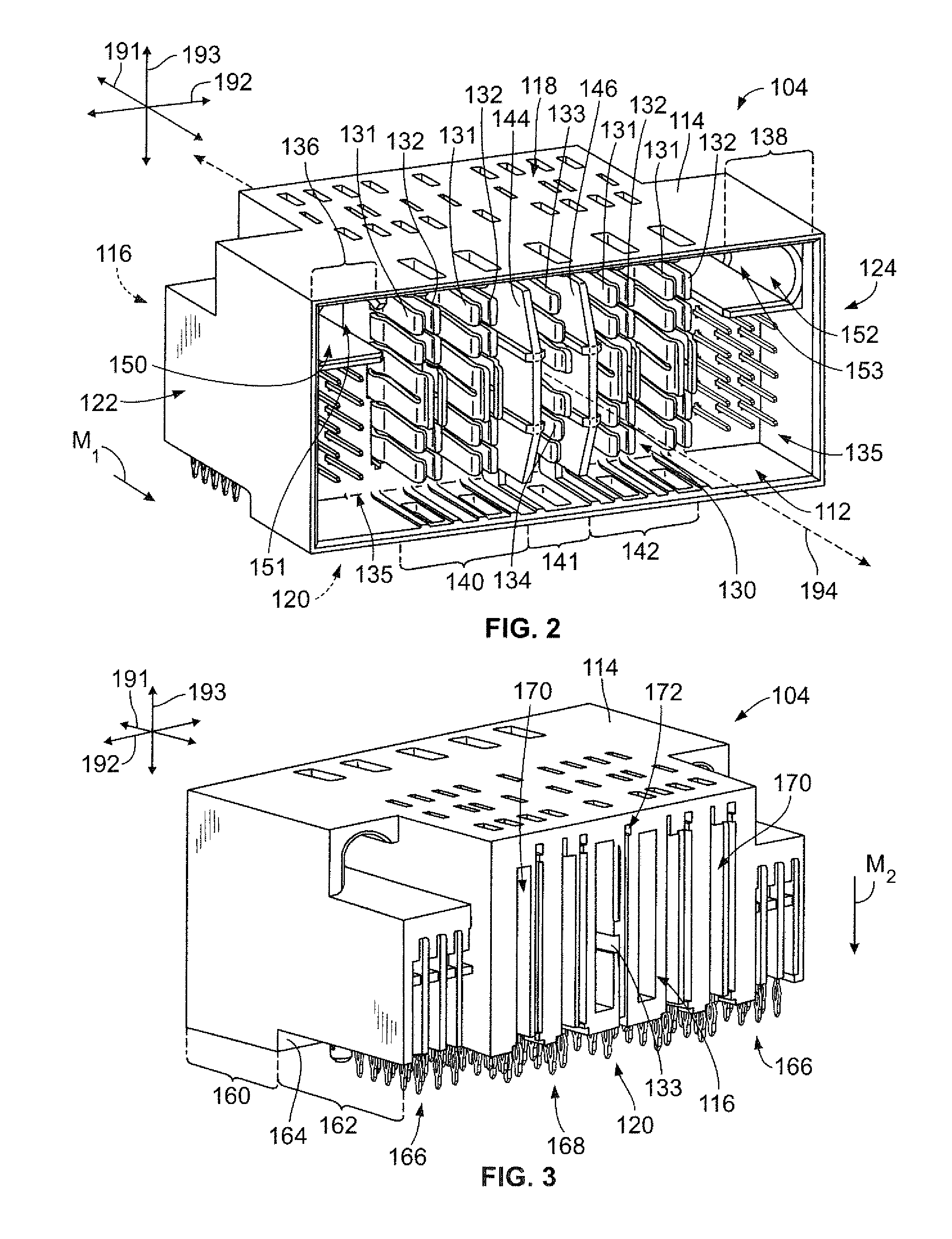

Electrical connector having an electrical contact with a plurality of contact beams

Electrical connector including a connector housing having a mating side that faces in a mating direction. The mating side configured to engage a mating connector. The electrical connector also includes an electrical contact held by the connector housing. The electrical contact includes a common body section and first, second, and third contact beams that are arranged along the mating side and have respective contact bases coupled to the body section. Each of the first, second, and third contact beams extend in the mating direction from the respective contact base to a respective distal end. Each of the first, second, and third contact beams has a beam length that is measured from the respective contact base to the respective distal end. The beam lengths of the first, second, and third contact beams being different from one another.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

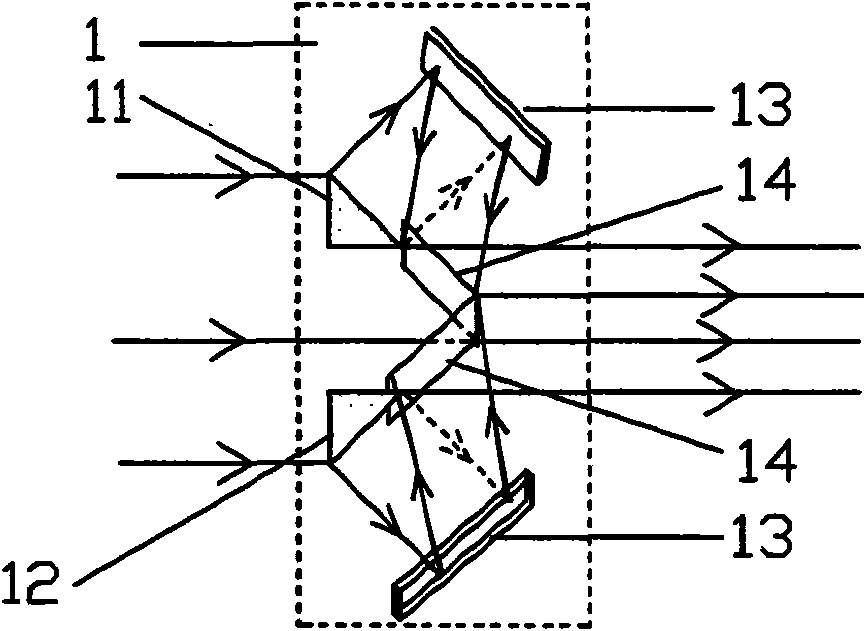

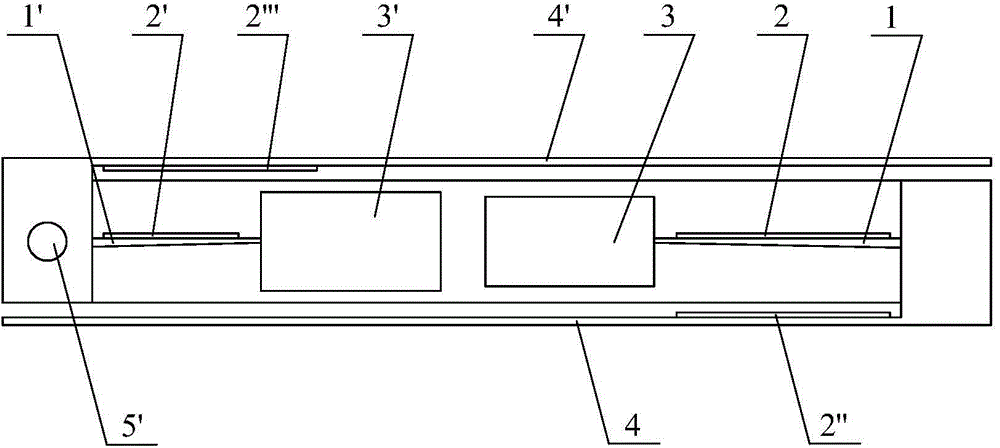

Line width compression device containing beam shaping and wavelength rotation tuning

ActiveCN101581866AShorten the lengthSmall sizeDiffraction gratingsPhotomechanical exposure apparatusLine widthCompression device

A line width compression device containing beam shaping and wavelength rotation tuning is composed of a beam shaper, a prism beam expander and a diffraction grating. The long axis of a rectangle beam is split into sub beams in a plurality of directions by placing a prism on a light path, the deflecting sub beams are overlaid with the short axis of an original beam by a high reflective mirror, thus realizing variation of length-width ratio of the beam and further reducing beam length requiring beam expansion and effectively reducing the grating length; the central wavelength tuning mechanism of a laser is realized by rotating the rotating floor of a fixed prism, a stepping motor rotating floor and a PZT nano rotating floor respectively realize rough tuning and precise tuning on two beam expansion prisms, and the incident angle of the beam and the grating is adjusted to realize rough tuning and precise tuning of the central wavelength of the laser. The invention can realize narrow line width laser output, the beam shaping can effectively reduce the size of the diffraction grating, the tuning of the central wavelength causes the structure to be compact and be easy for tuning, and the invention is applicable to multiple lasers, especially an excimer laser.

Owner:安徽中科春谷激光产业技术研究院有限公司

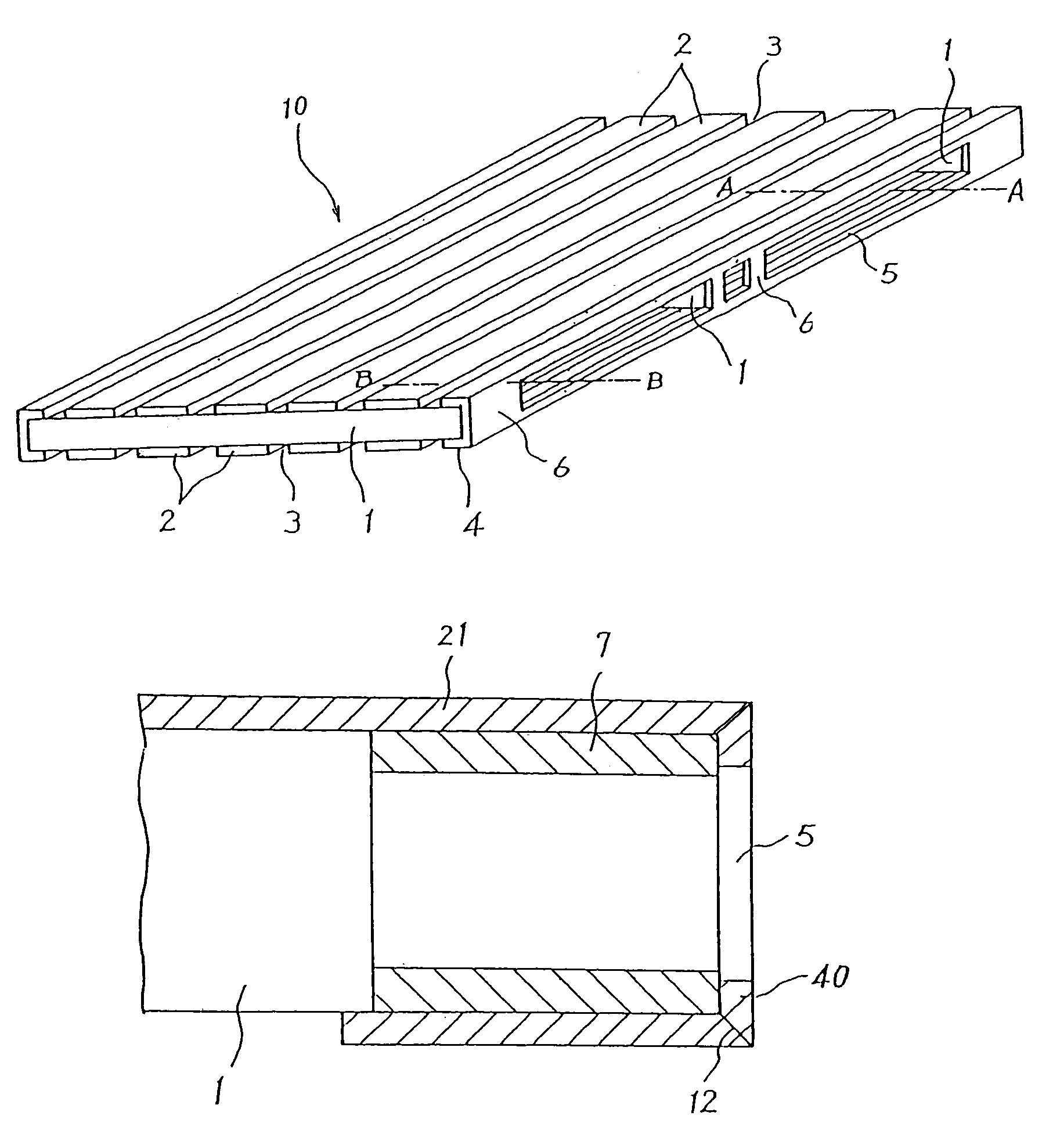

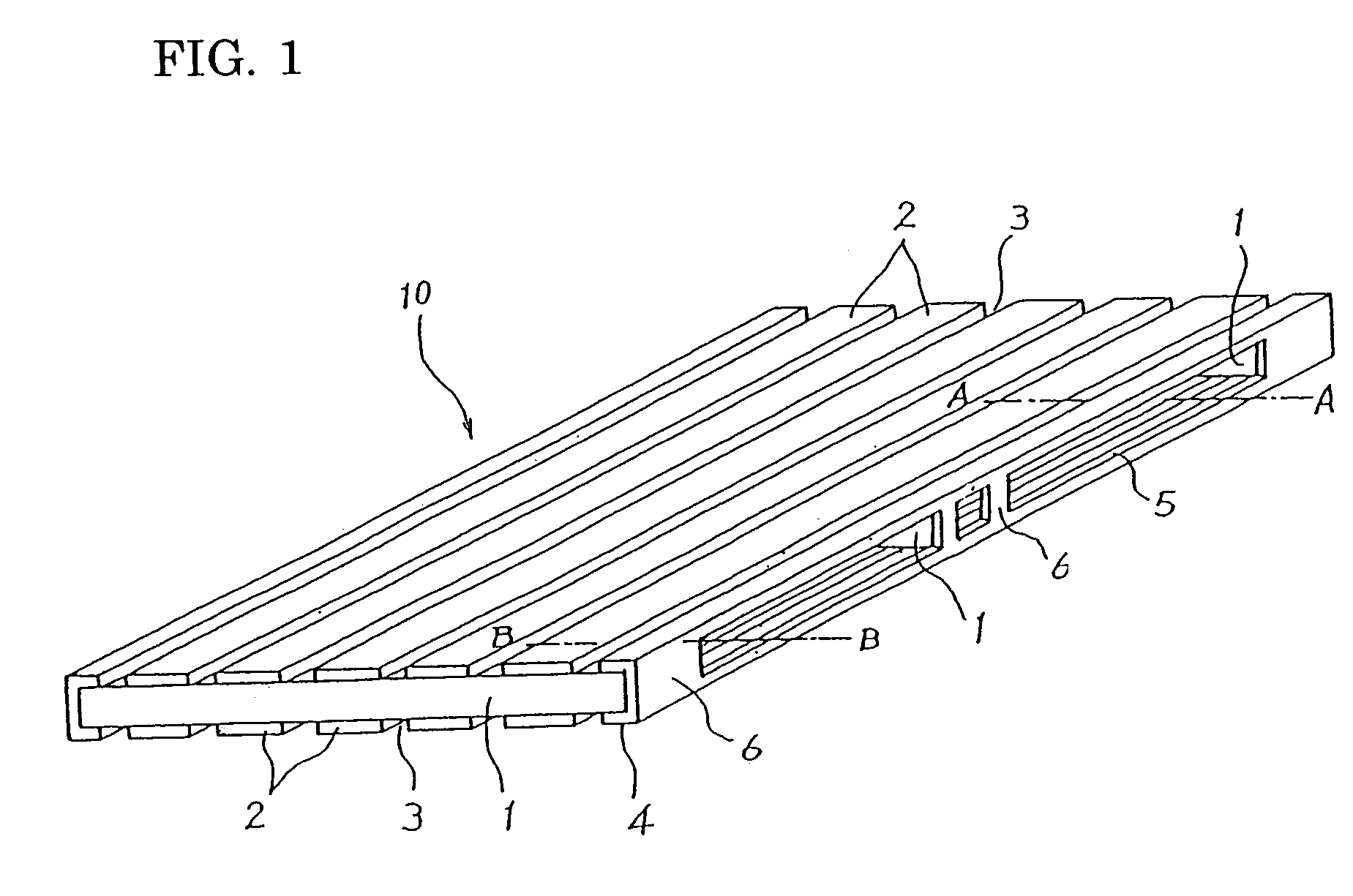

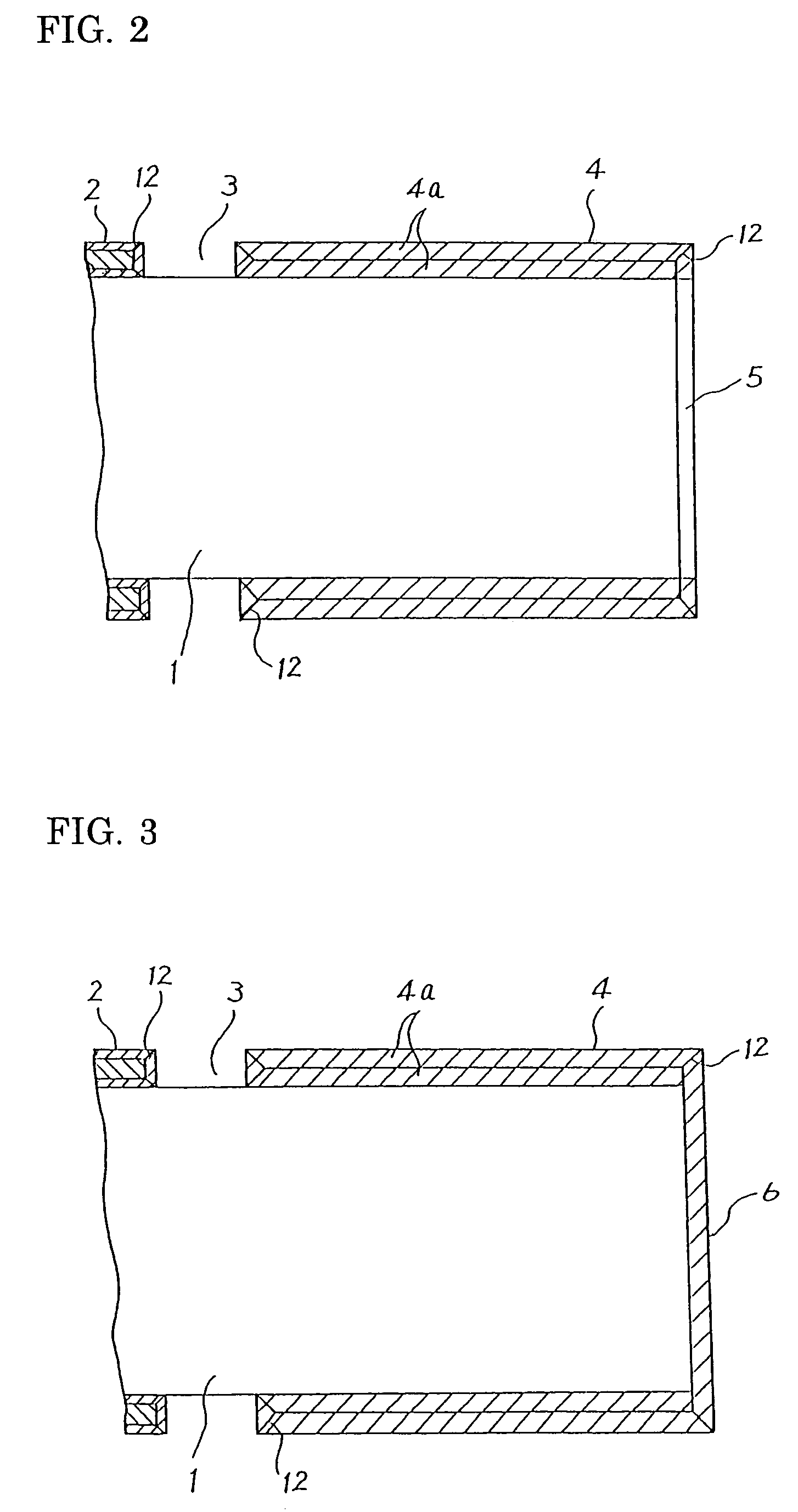

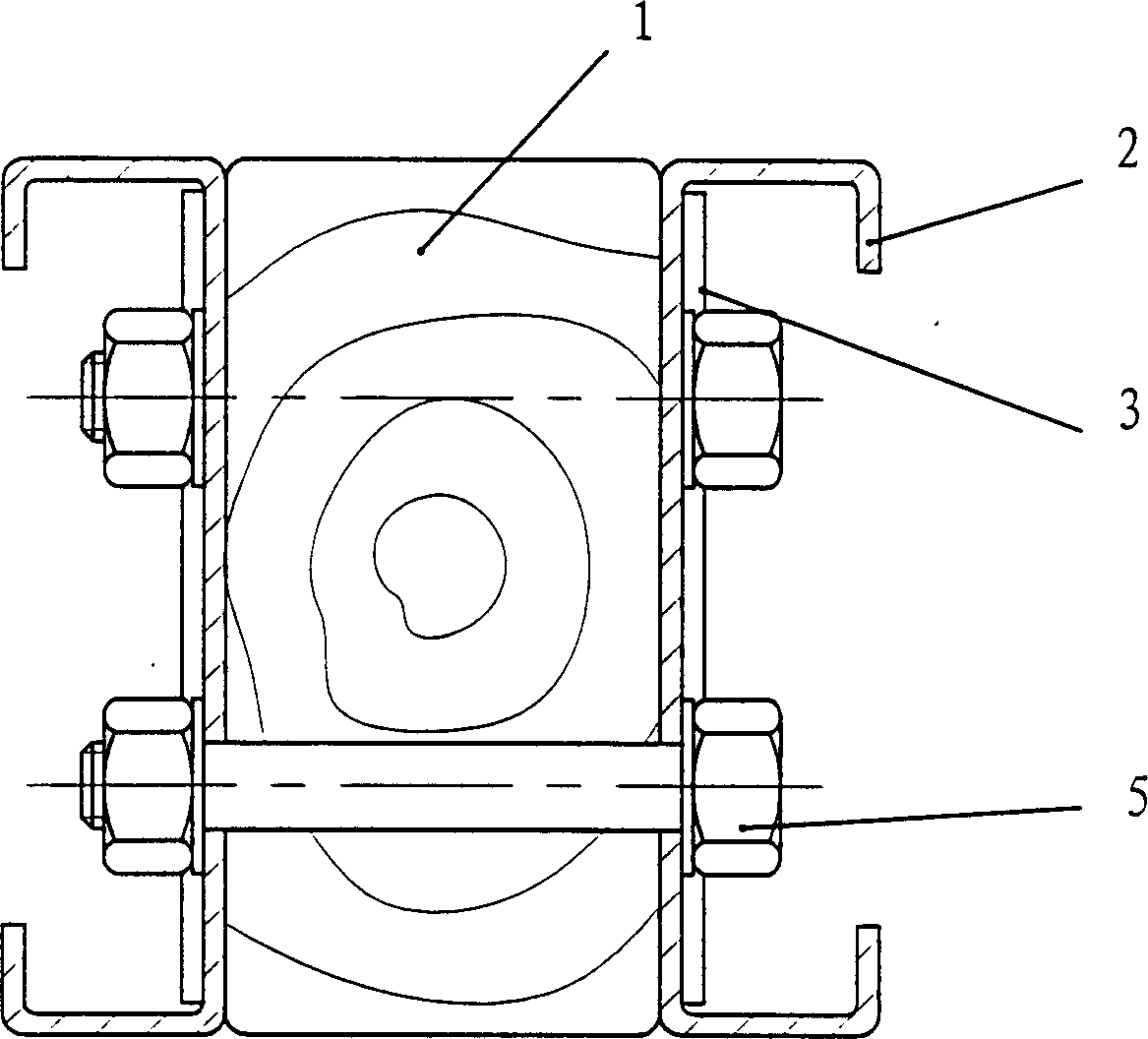

Cargo handling pallet

A cargo pallet has a framework including a plurality of beams that are each formed of a square hollow body of paperboard treated for water resistance and water repellency. Each beam is engaged at a predetermined distance with and adhered to a pair of channel-shaped bent edge members of paperboard material faced to each other. Strip-like boards are placed in parallel to each other on both the front and back faces of the beams with a gap provided between adjacent strip-like boards in a direction perpendicular to the beam length and adhered to the beams. Each of the strip-like boards is formed with a pattern paper treated for water resistance and water repellency that covers all of the periphery of front and back faces of an inner core member of thick paperboard. Fork insertion openings are provided in the edge members having paperboard reinforcing layers.

Owner:SHINEISHI SHOKO

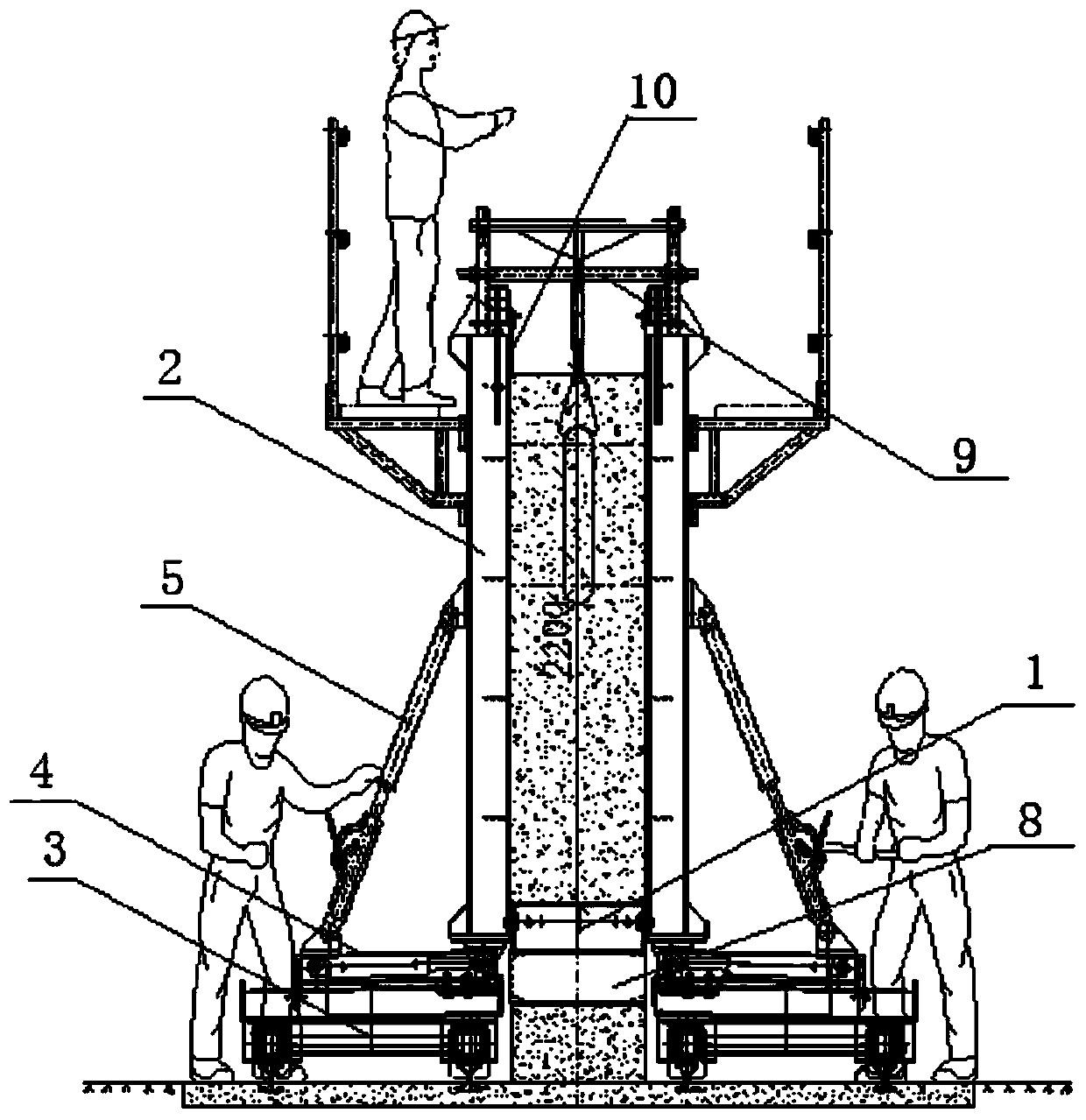

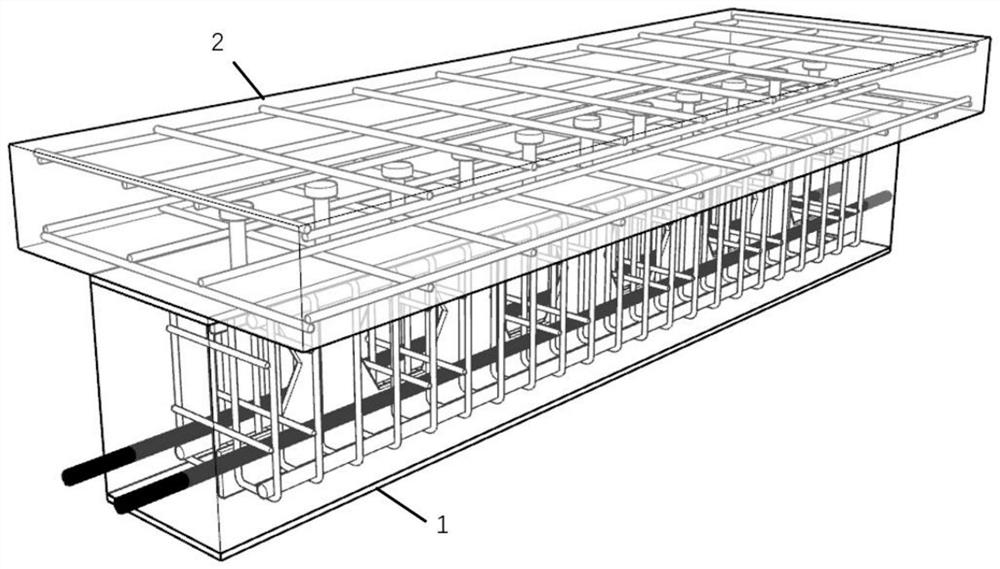

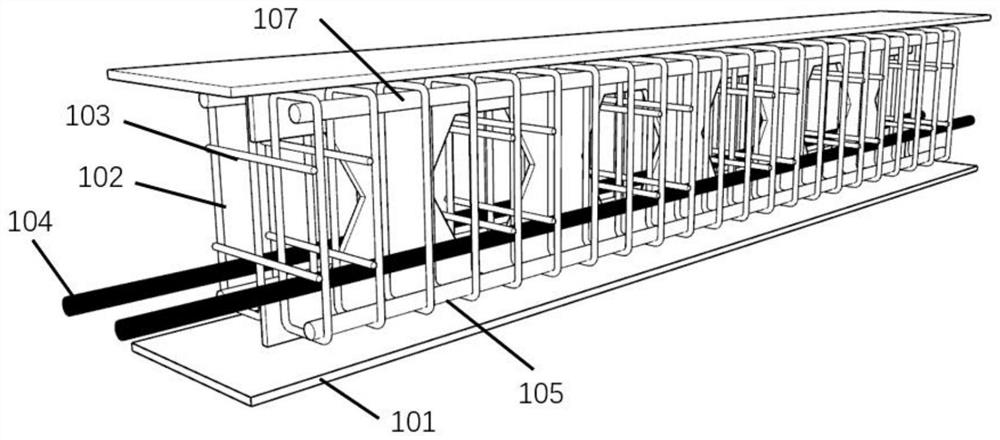

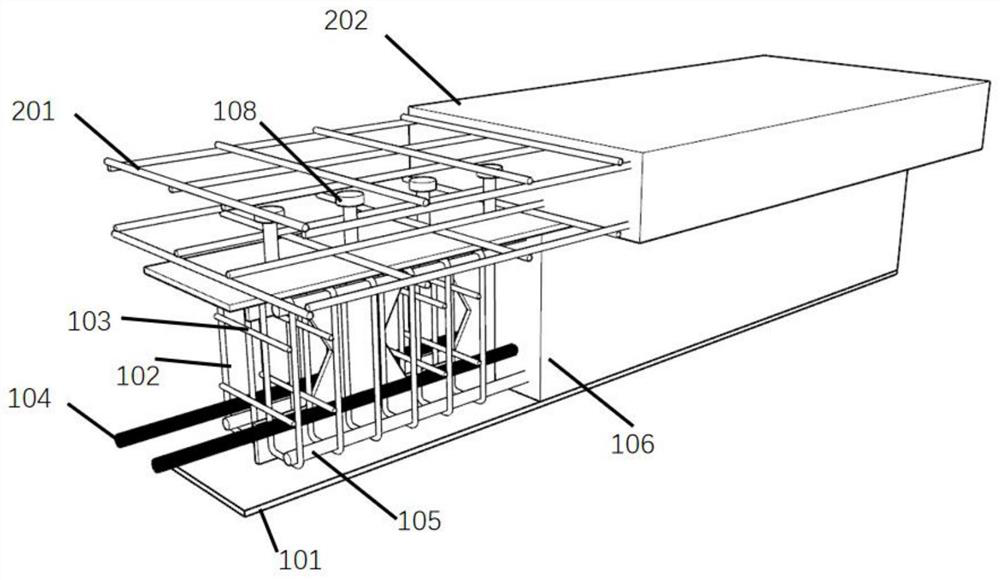

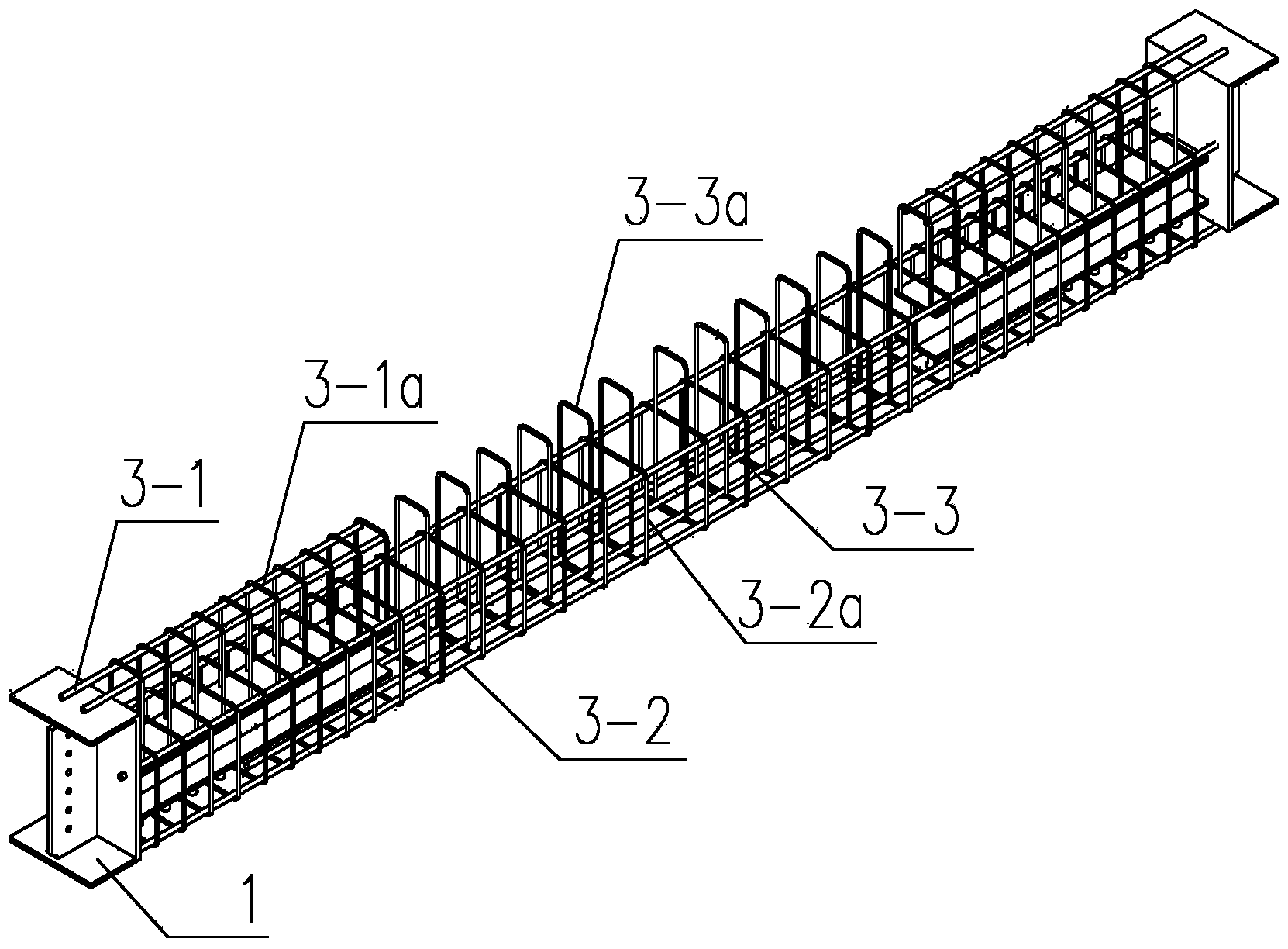

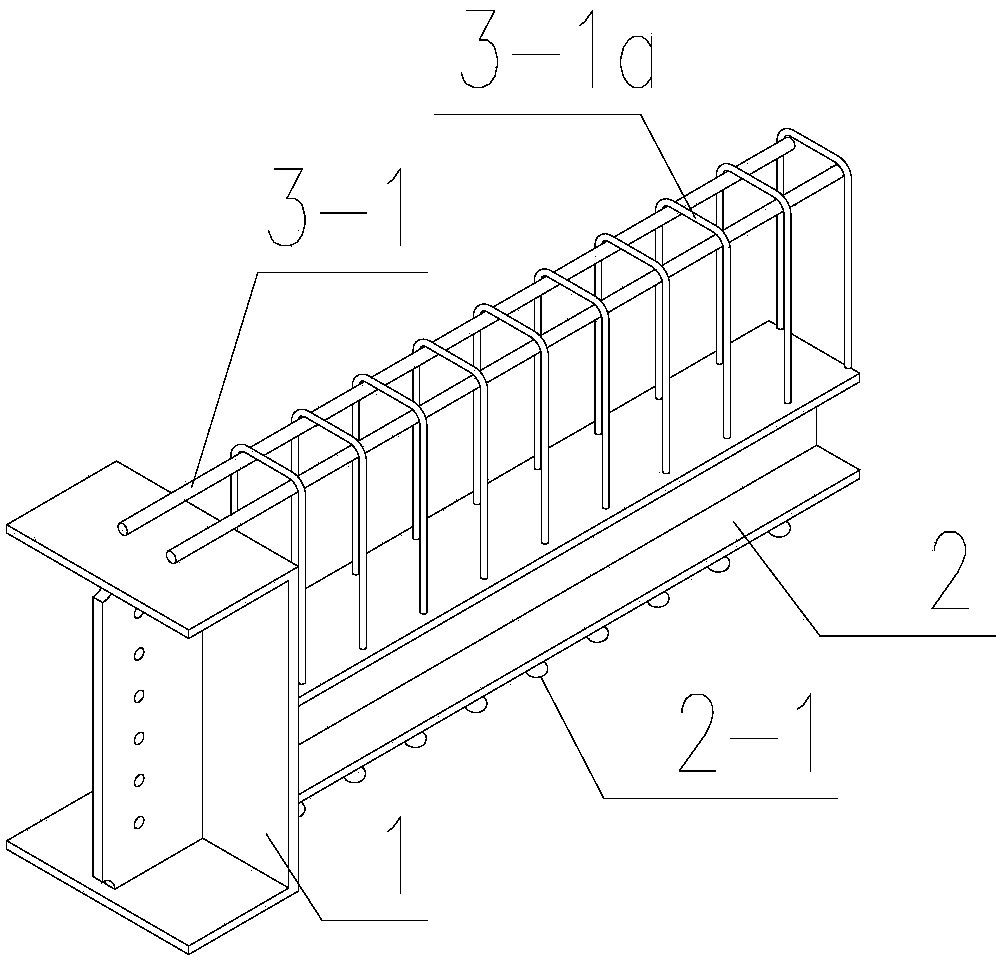

Auxiliary device for binding reinforcements of reinforced concrete beam and application thereof

InactiveCN102979311AReduce wasteHeight adjustableBuilding material handlingSocial benefitsConcrete beams

The invention relates to an auxiliary device for binding reinforcements of a reinforced concrete beam and application thereof. The device comprises two telescopic brackets and a cross bar, wherein the two telescopic brackets are arranged in parallel; and the cross bar is overlapped on the two brackets. The application of the auxiliary device is as follows: according to the condition of the beam depth, the heights of the brackets are regulated, so that the brackets are slightly higher than the beam; the auxiliary devices are arranged in pairs along the beam length direction at intervals of 3 to 5m and the auxiliary devices are placed on plate formworks at both sides of a beam formwork; beam upper main reinforcements are placed on the cross bars, beam stirrups are sleeved, beam lower main reinforcements are inserted and the reinforcements are bound to form a beam reinforcement skeleton; the beam reinforcement skeleton is pulled up, the auxiliary devices at the end where the reinforcement binding is completed are removed, the beam reinforcement skeleton is slowly placed into the beam formwork; and the pair of auxiliary devices at the upper part are moved to a next section to bind reinforcements of the section of beam. Compared with the prior art, the device disclosed by the invention is stably stressed, is convenient to use, has an adjustable height, can be reused, can be suitable for binding reinforcements with different beam depths, can be industrially produced in batches and has high social benefits and economic benefits.

Owner:SHANGHAI ZHONGJIN CONSTR GRP

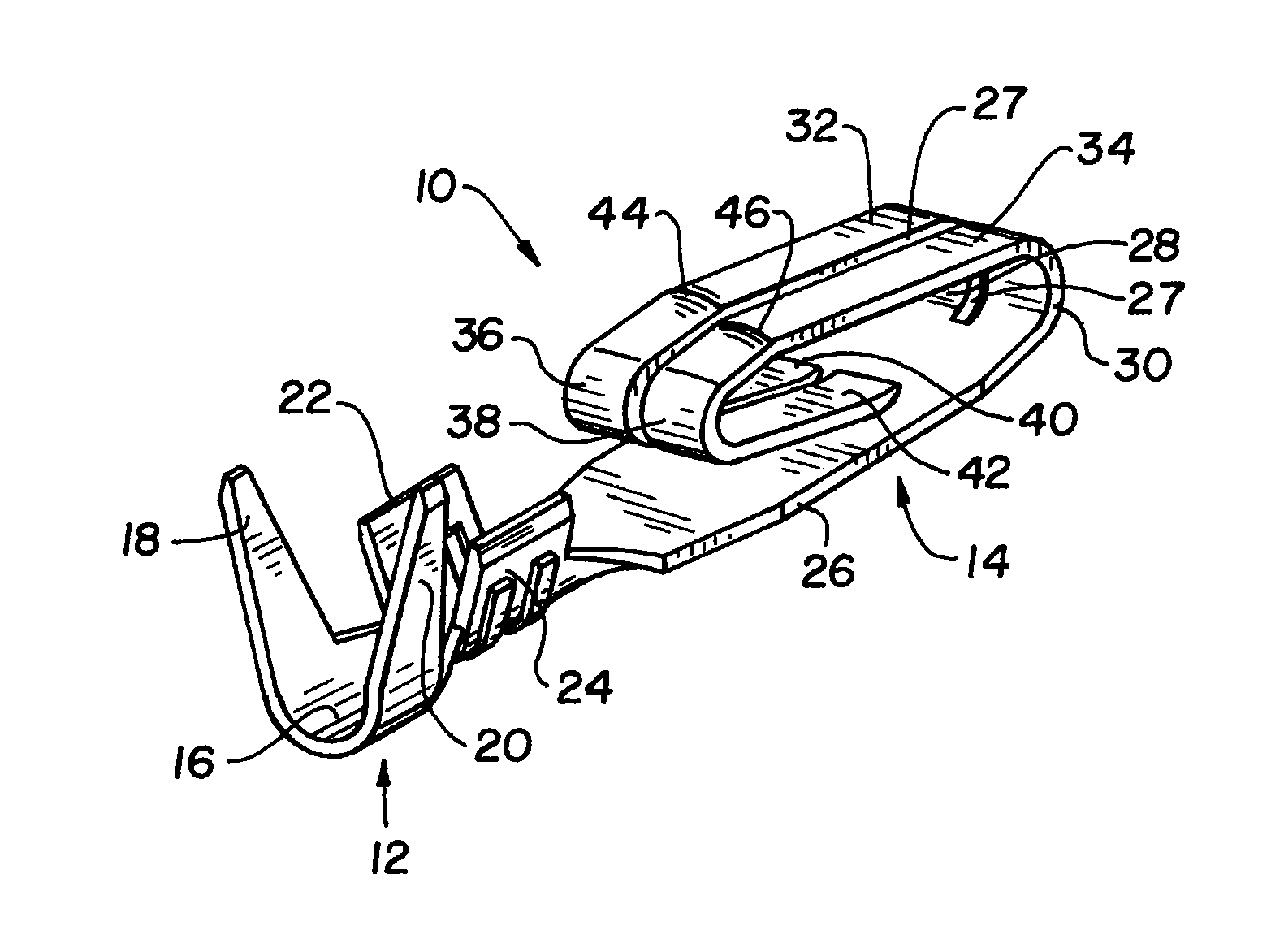

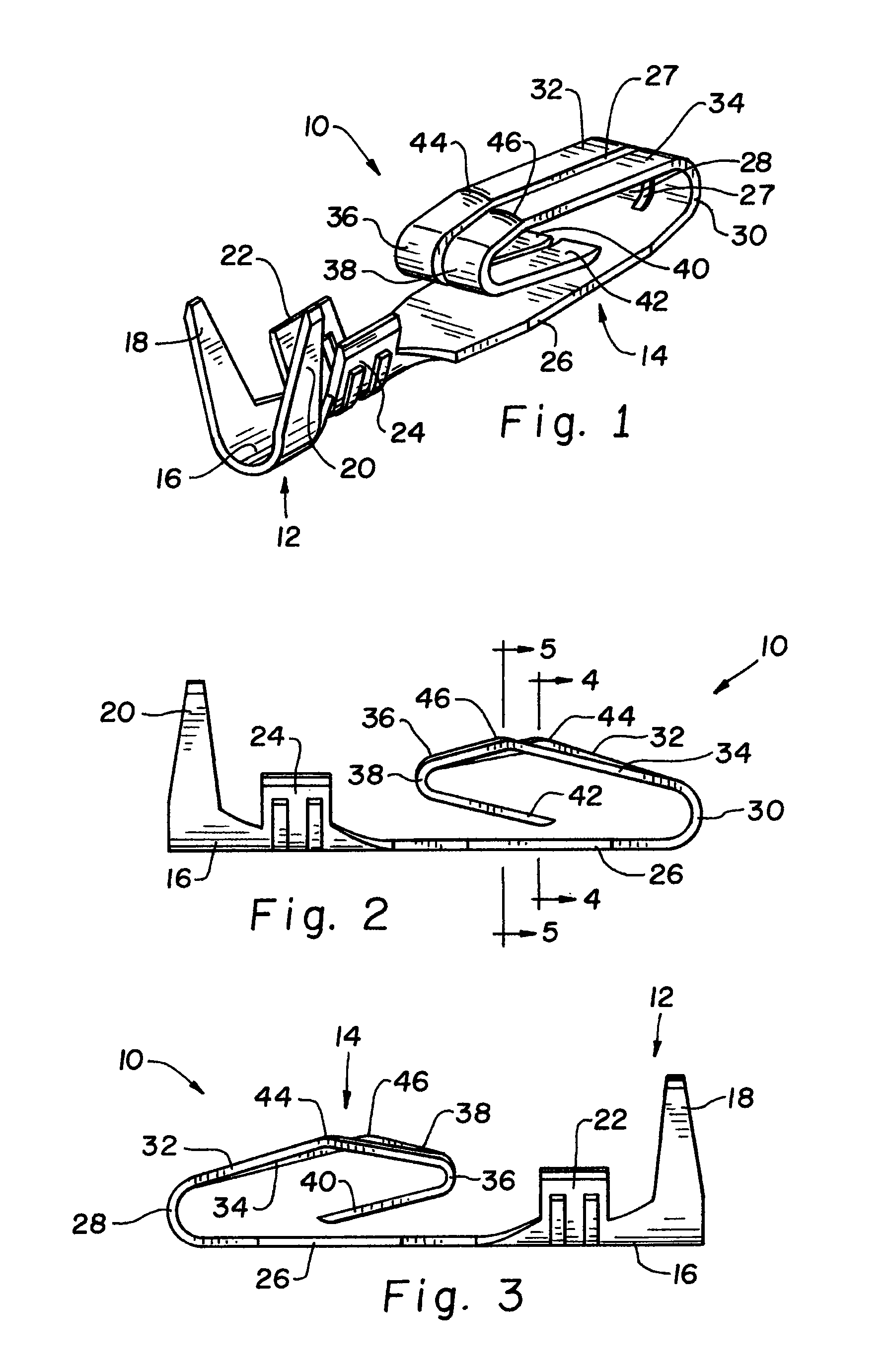

Bifurcated Electrical Contact

InactiveUS20100323564A1Increase opportunitiesImprove connectivityCoupling contact membersTwo-part coupling devicesLight beamContact zone

Owner:PANCON ILLINOIS LLC

Piezoelectric oscillator structure for vibration energy recycling

InactiveCN104868784AIncrease shock vibration energySo as not to damagePiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientNeutral line

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Methods and apparatus for using imaging information to improve scanning accuracy in bar code scanners

InactiveUS7059527B2Improve accuracyCharacter and pattern recognitionVisual presentationCoding decodingLight beam

Techniques for using imaging information computed from examining a scanner signal are described. When one or more objects passes within a field of view of a scanner, scan patterns emerging from one or more scanner windows and reflected from the objects back into the scanner windows produce one or more scanner signals. The scanner signals are processed to obtain beam position and beam length information to improve the accuracy of bar code decoding and to compute imaging information for objects within the field of view of the scanner. The imaging information for the objects is compared with bar code information for the objects. The expected number, size and shapes of objects indicated by the bar code information is compared with the actual number, size and shapes of objects in order to determine if valid scans occurred or if missed, double or otherwise erroneous scans occurred.

Owner:NCR VOYIX CORP

Electronically controlled multi-light flashlight

Provided is a flashlight that includes a plurality of light sources for providing a beam of light. Preferably, the light sources have different levels of power consumption, different brightnesses and / or different beam lengths. More preferably, the plurality of light sources includes at least one light-emitting diode (LED) and at least one incandescent lamp. A housing directs the beam of light and an integrated circuit controls illumination of the plurality of light sources, with a switch providing an input signal to the integrated circuit. In the preferred embodiment of the invention, the switch is a pushbutton switch and the integrated circuit is a multi-state electronic device that changes state when the signal is input from the switch, with different states of the integrated circuit causing different combinations of the light sources to become illuminated.

Owner:GOLD CORAL INT

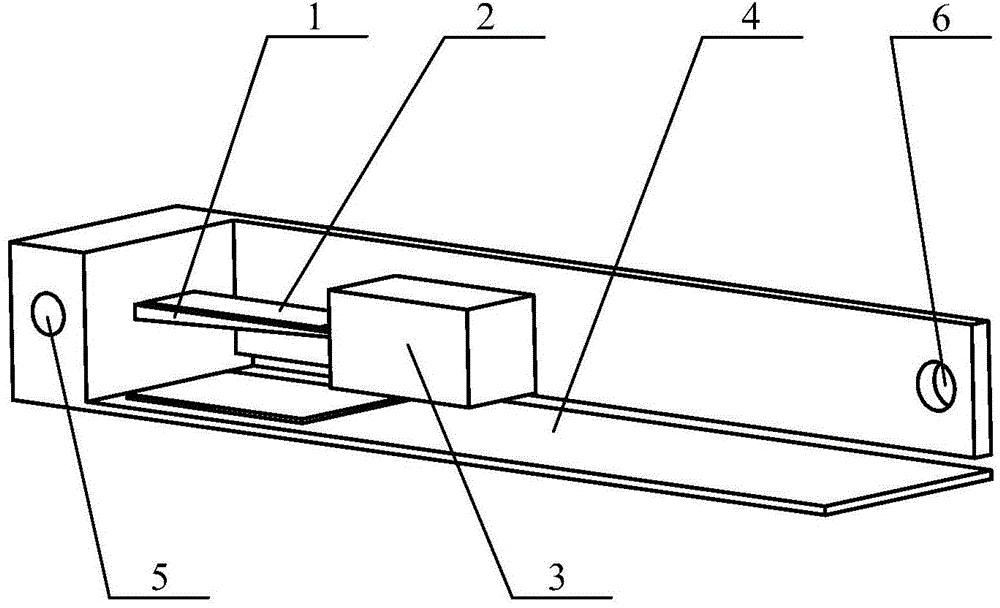

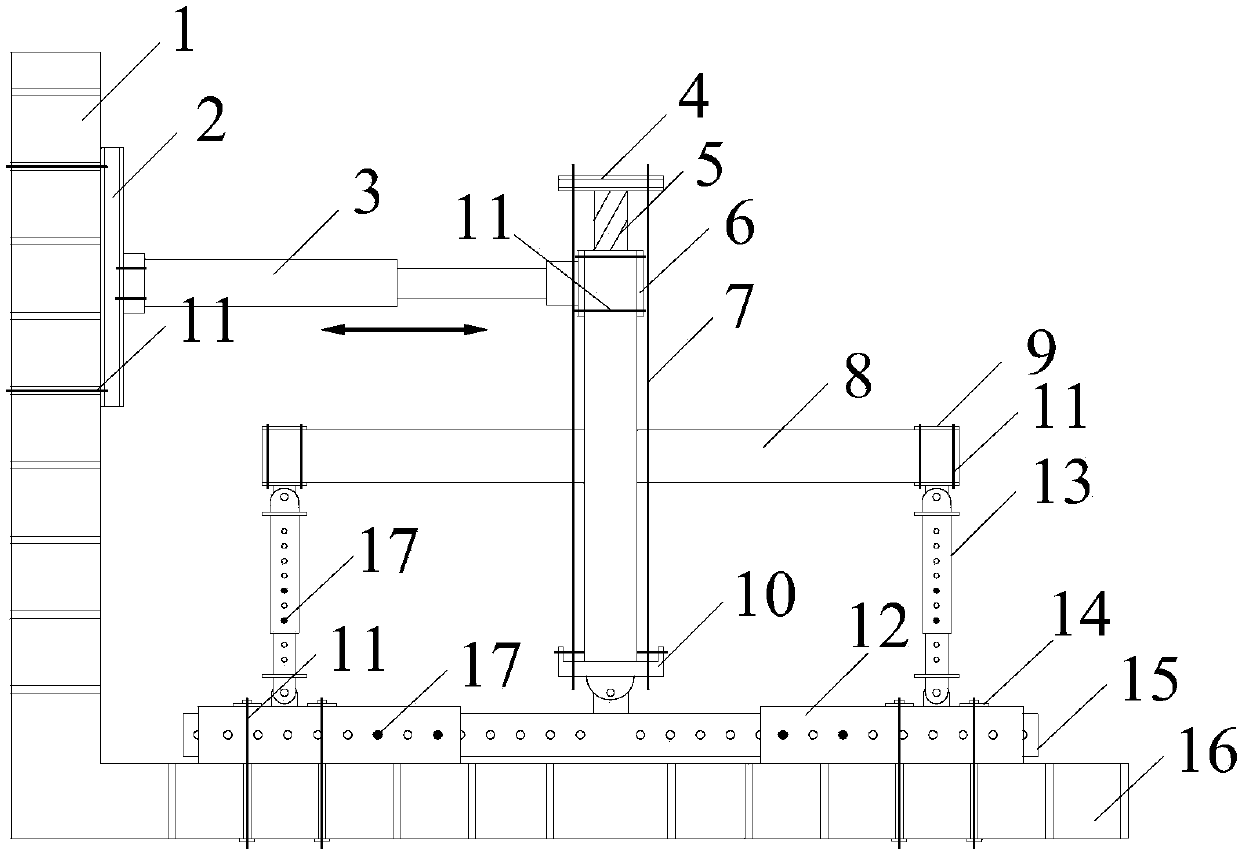

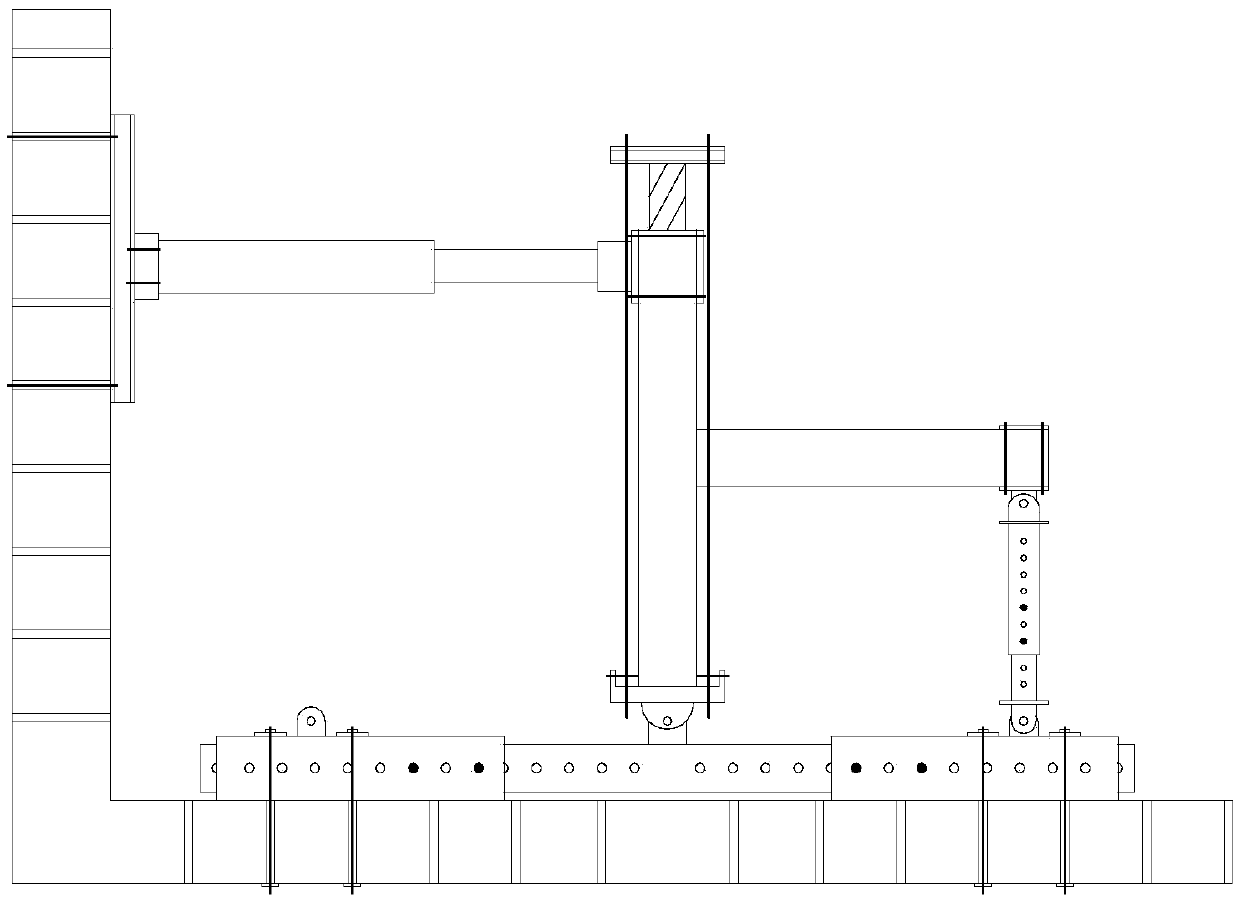

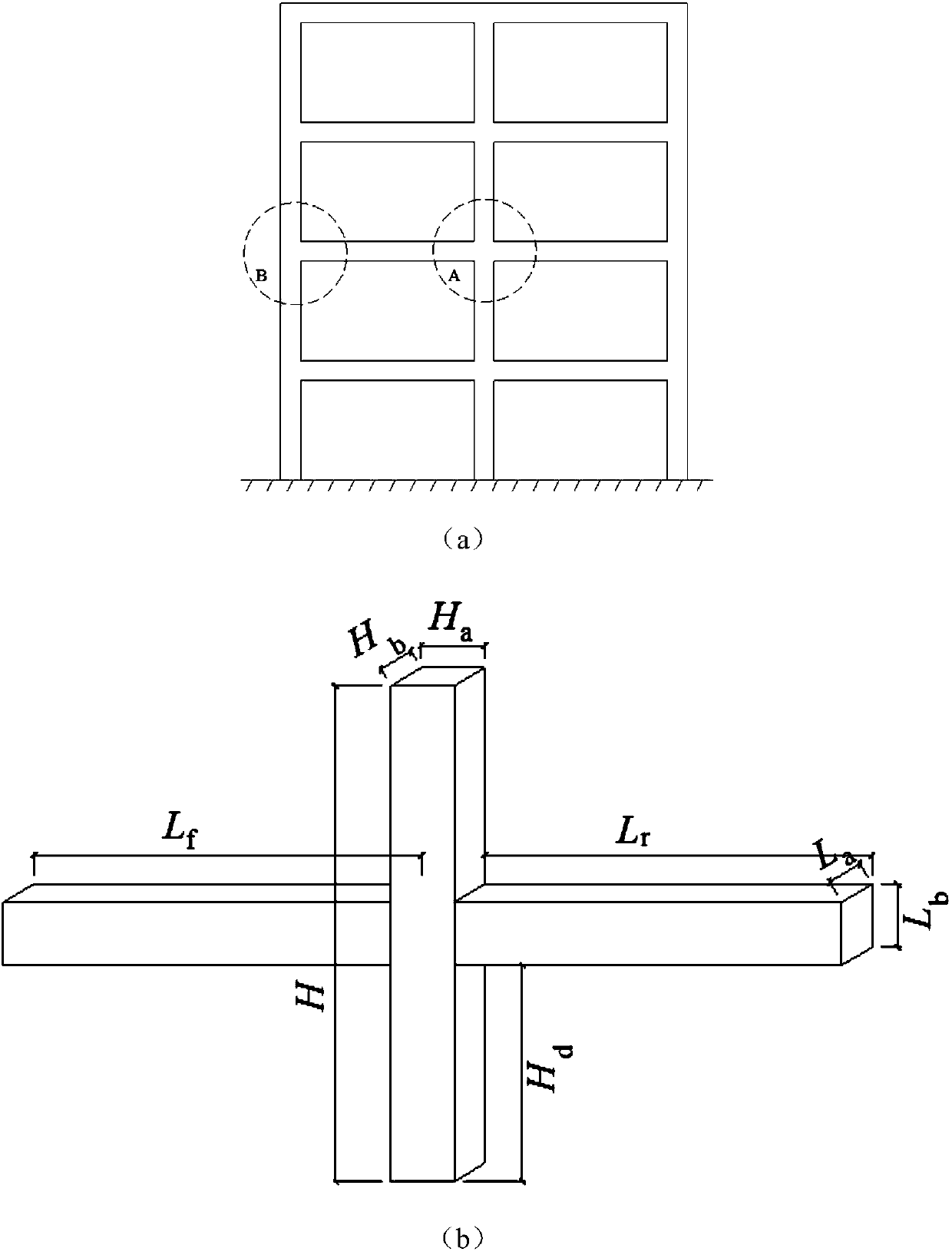

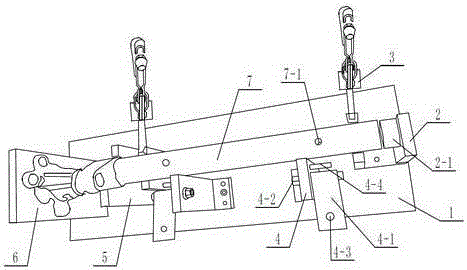

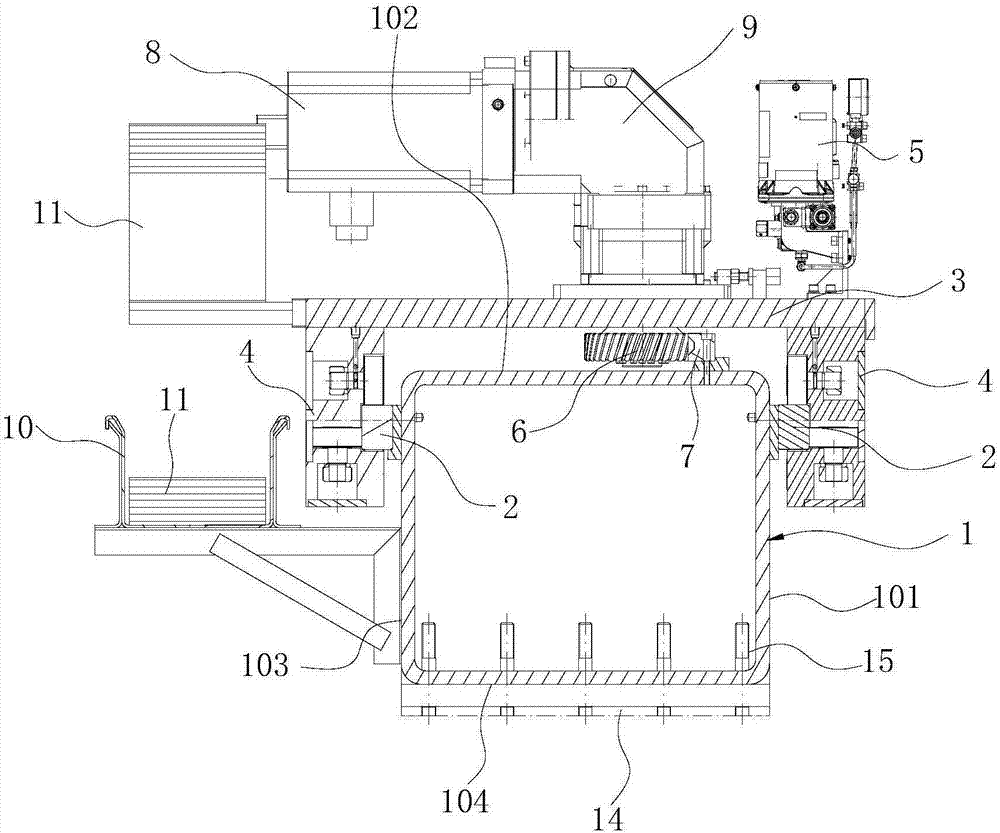

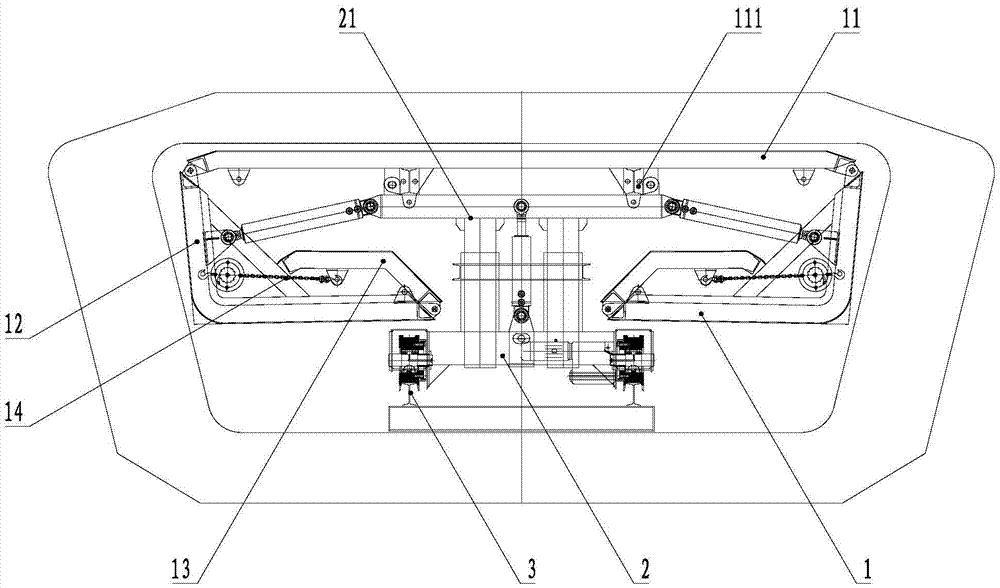

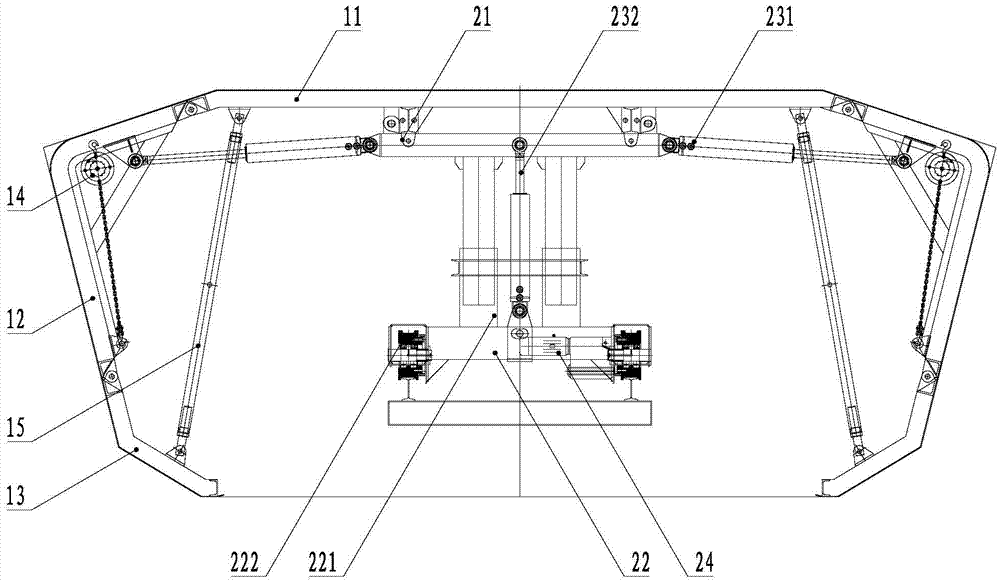

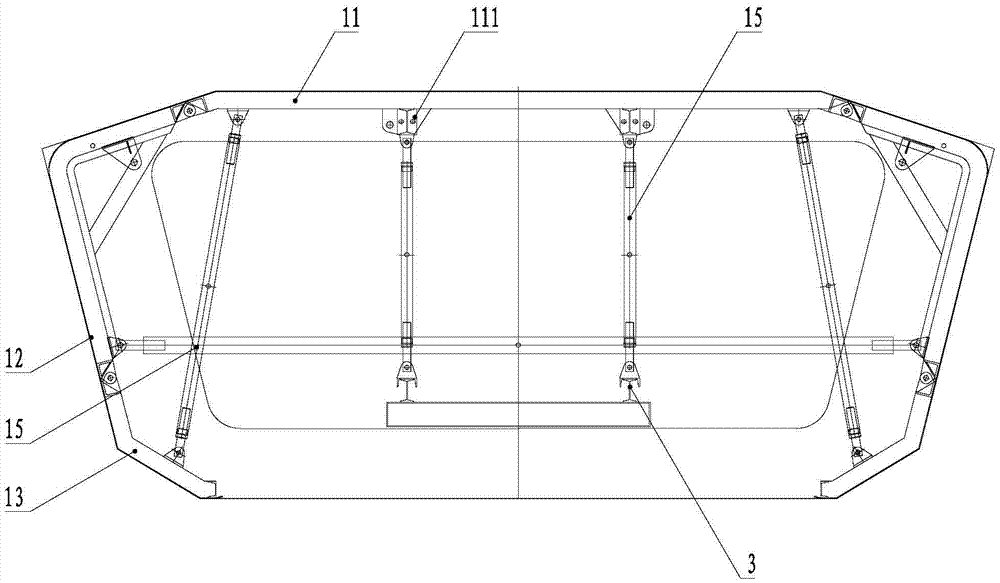

Adjustable frame node anti-vibration test loading device

InactiveCN107727343AReduce manpowerReduce waste of moneyVibration testingEngineeringHeight difference

The invention provides an adjustable frame node anti-vibration test loading device. A height difference converter block is arranged on a reaction wall, and is adjustable in height; one end of a loaderis connected with the height difference converter block, and the other end is connected to the side portion of an upper column end of a test piece; a column bottom hinge support is arranged on a rigid ground beam and is used for mounting a lower column end of the test piece; a jack is mounted on the upper column end of the test piece; the upper portion of the jack is provided with a column top rigid reaction plate; the column top rigid reaction plate and the column bottom hinge support are fixedly connected through a fixation connector; and a beam length adjusting square steel pipe sleeves the rigid ground beam to form a beam length adjusting mechanism. The beam length adjusting square steel pipe is mounted on the ground, and is adjustable in axial position. Each beam end adjustable support rod is adjustable in length, wherein one end of the each beam end adjustable support rod is connected with the beam length adjusting mechanism, and the other end there of is connected with the endportion of the test piece beam. The adjustable frame node anti-vibration test loading device is an internal force and self-balance loading system, is adjustable in size and can be used repeatedly.

Owner:YANGZHOU UNIV

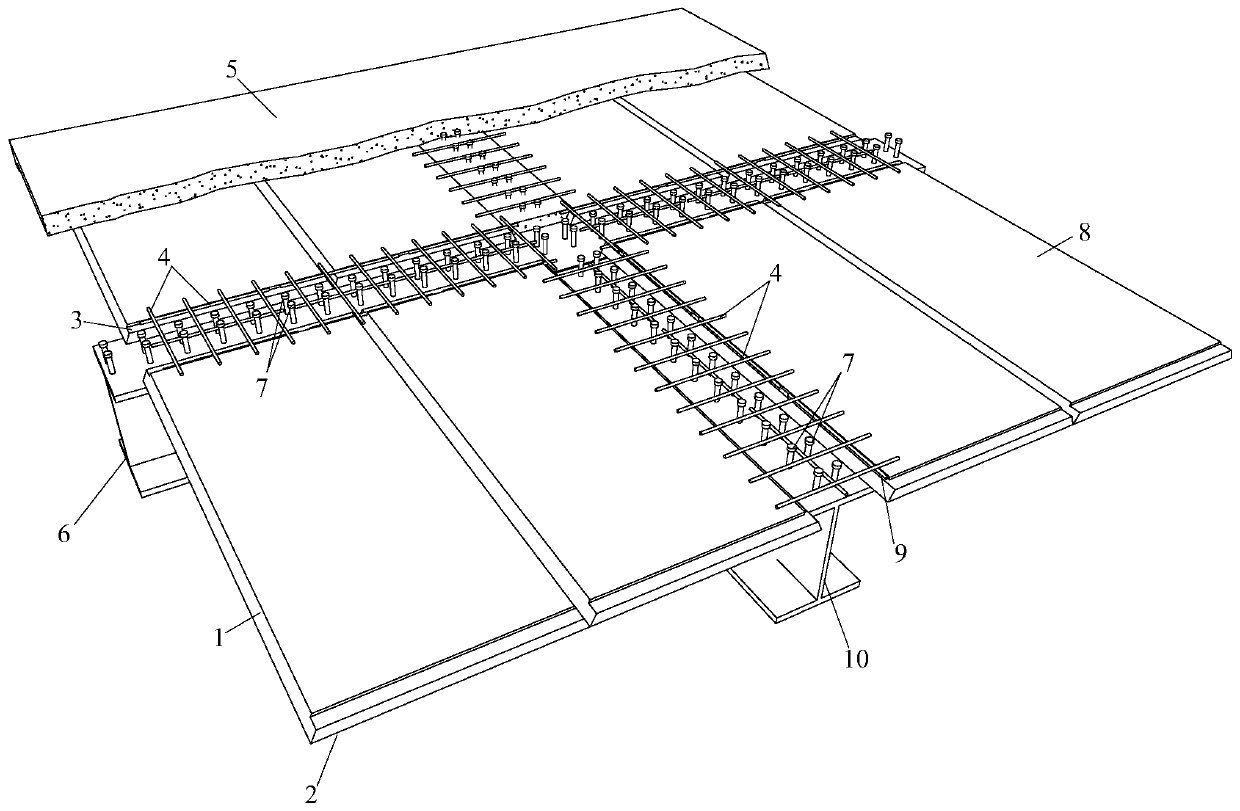

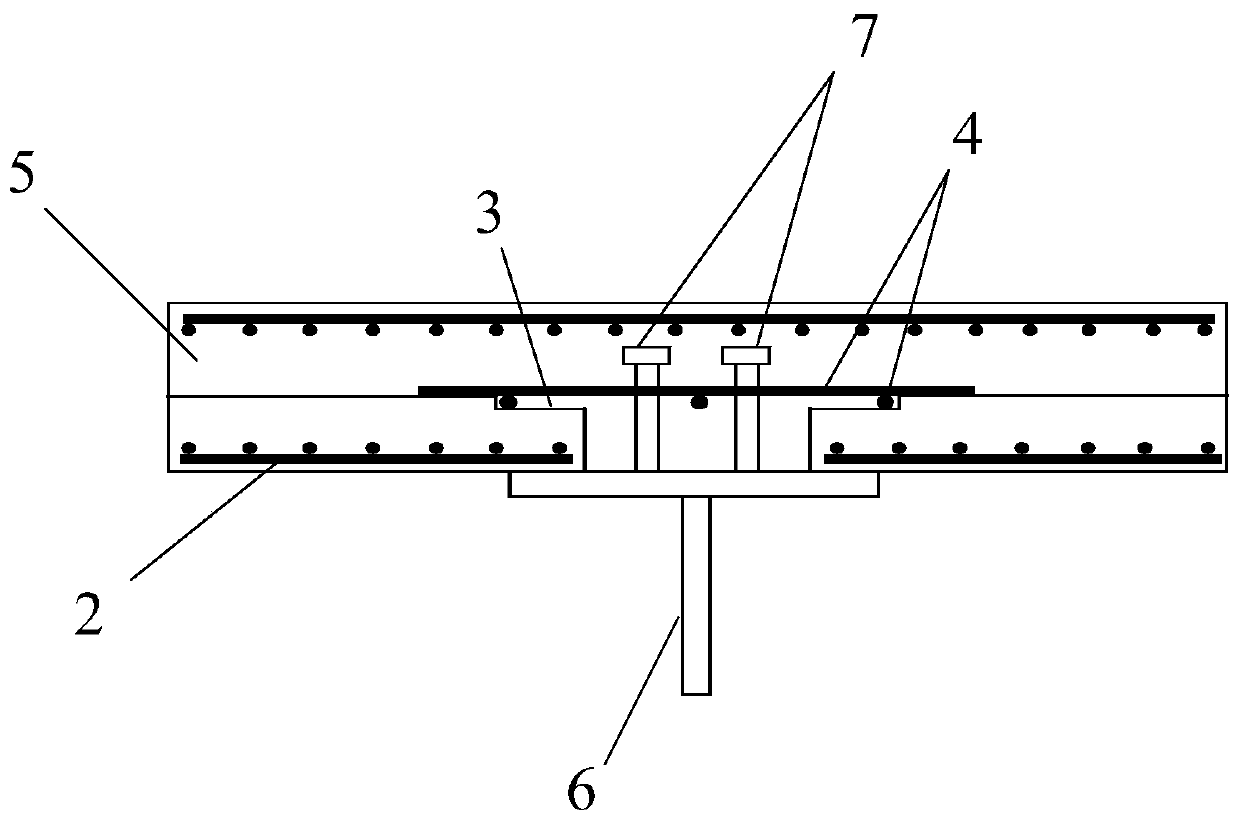

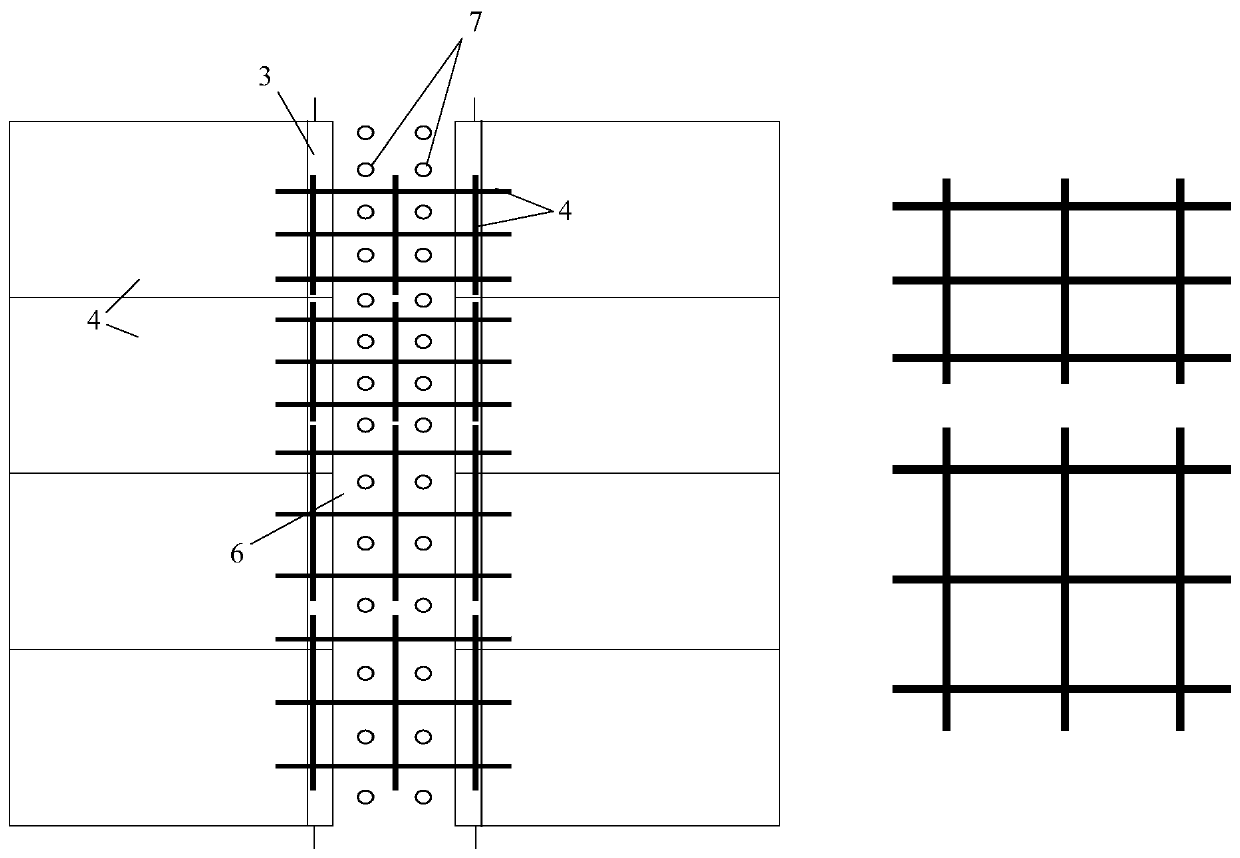

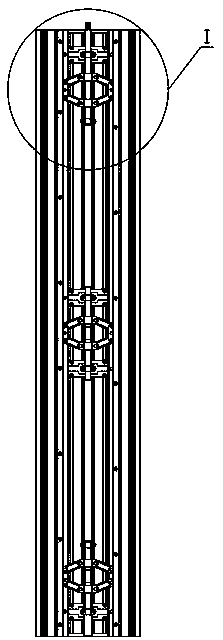

Longitudinal shear reinforcement and precast slab separated laminated slab composite beam

The invention relates to a longitudinal shear reinforcement and precast slab separated laminated slab composite beam, and belongs to the technical field of building structures. The longitudinal shearreinforcement and precast slab separated laminated slab composite beam comprises a concrete precast slab with a platform formed at the end, an additional reinforcement mesh unit and an upper concretepost-cast layer; no reinforcement stretches out of the slab end of the concrete precast slab with the platform formed at the end, meanwhile a step-shaped platform with the certain width is reserved atthe top of the precast slab, and the reinforcement mesh unit which is constituted by longitudinal and transverse reinforcements which are bundled is placed in the platform; and the transverse reinforcements play a longitudinal shear resistance role in the composite beam, the reinforcements in the beam length direction are parallelly placed in the step-shaped platform, and the positioning fixing effect is achieved. In the composite beam, traditional precast slab horizontal reinforcing bars are omitted, and through the modes that the step-shaped platform is formed at the slab end, and the reinforcement mesh unit is embedded, the longitudinal shear resistance problem of the composite beam and the longitudinal shear resistance reinforcement positioning problem are solved; and the longitudinalshear reinforcement and precast slab separated laminated slab composite beam is definite in force transmitting, convenient to construct, and suitable for laminated slab composite beam systems in thefields such as building engineering and bridge engineering.

Owner:TSINGHUA UNIV

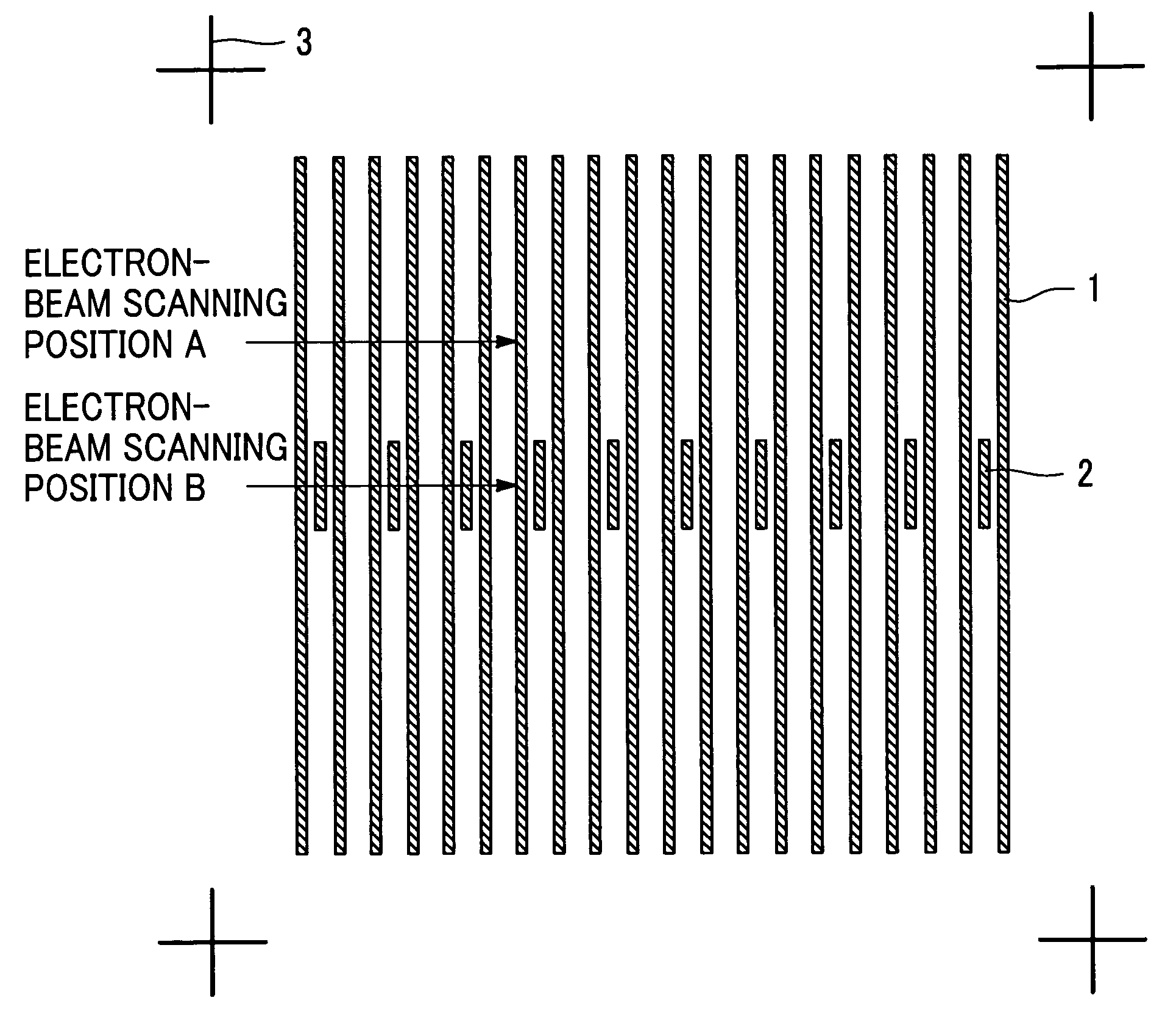

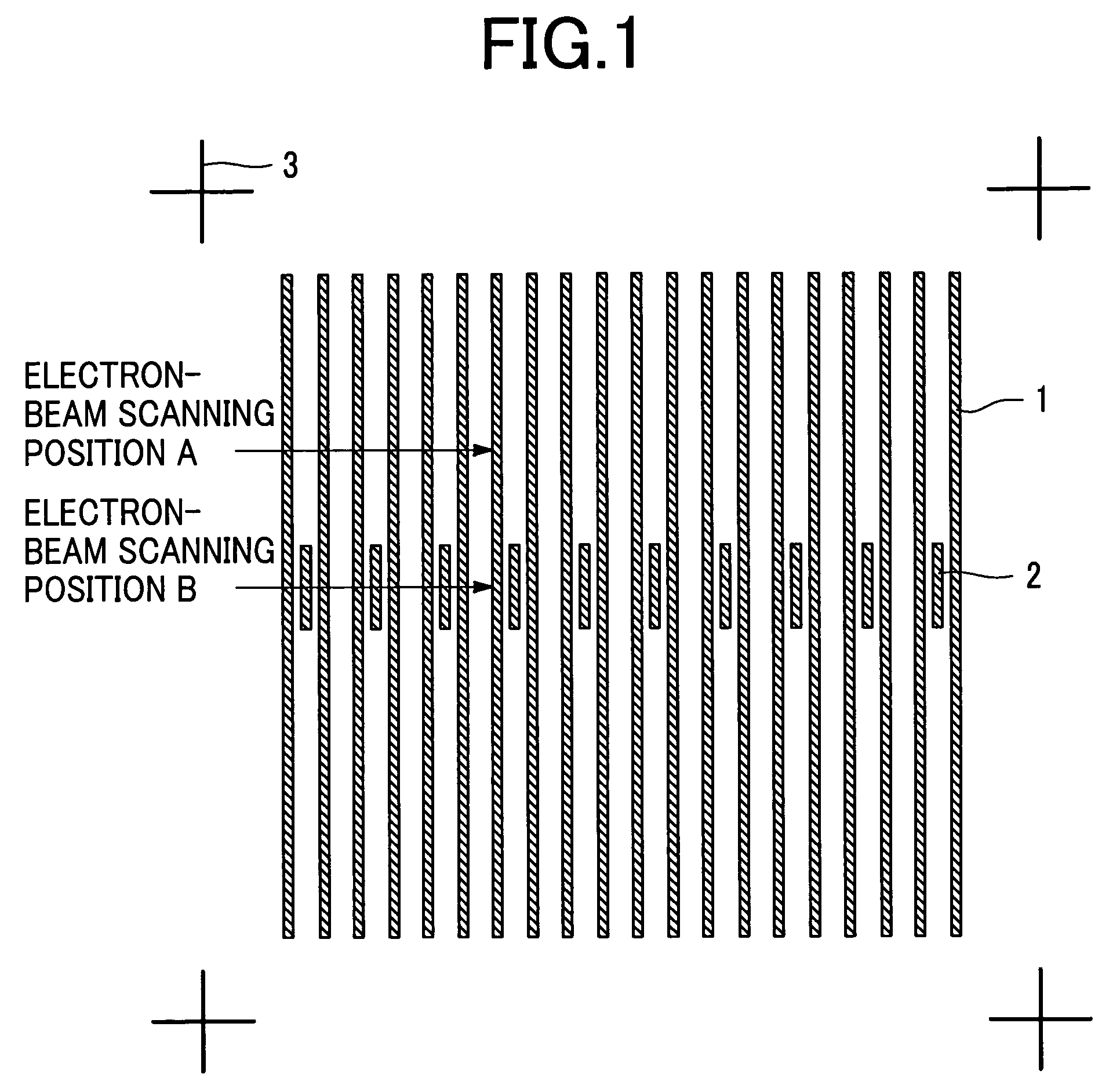

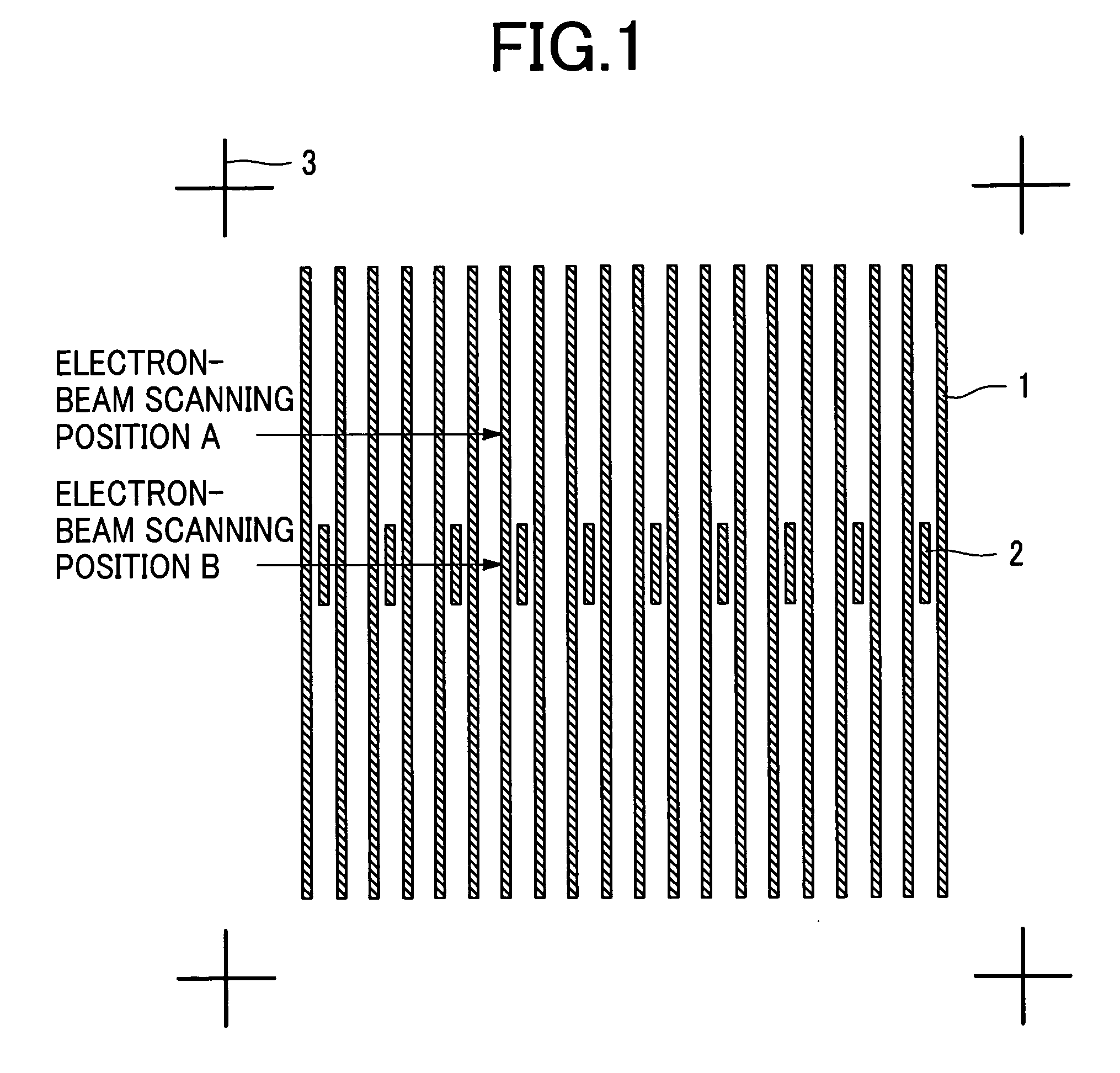

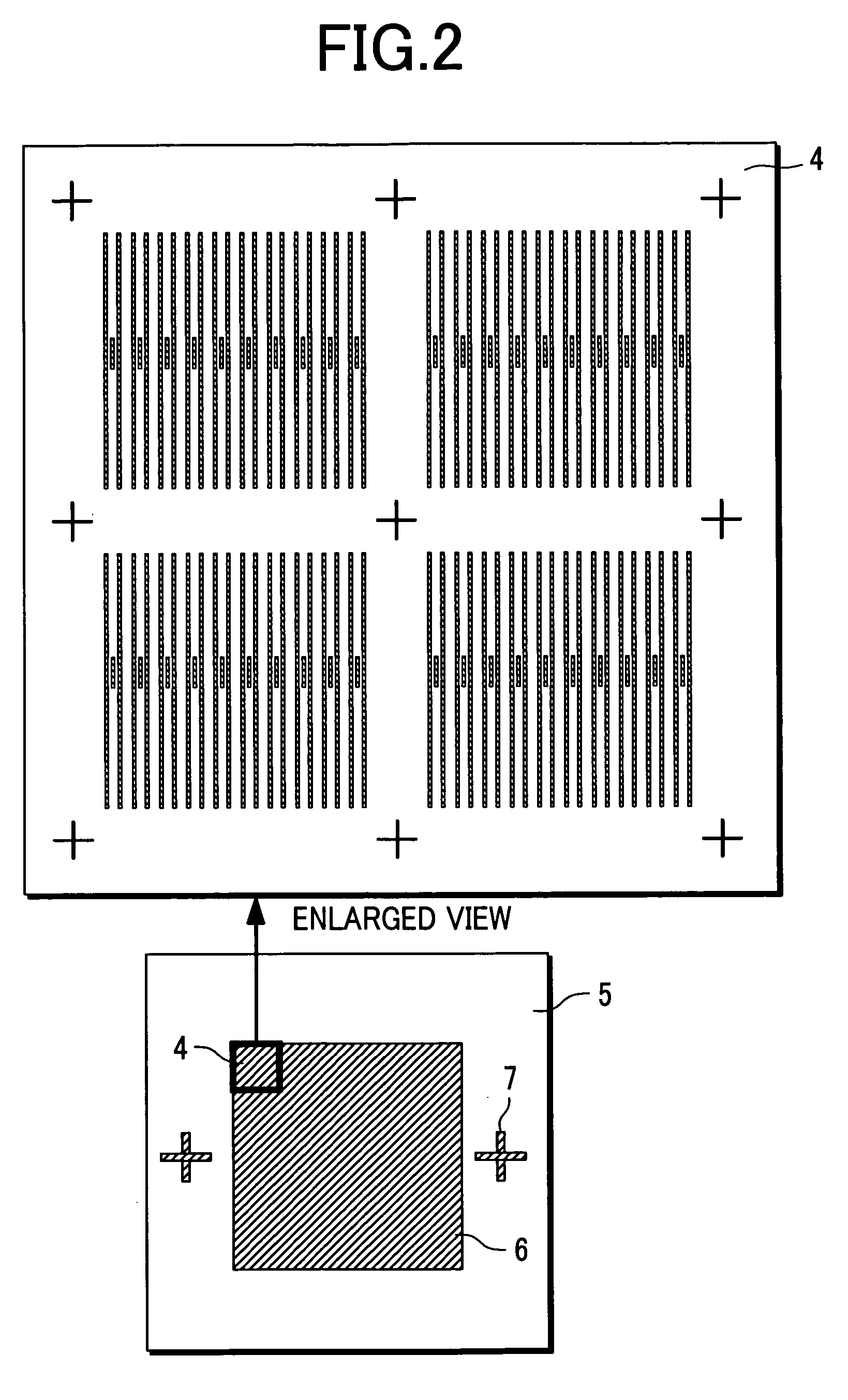

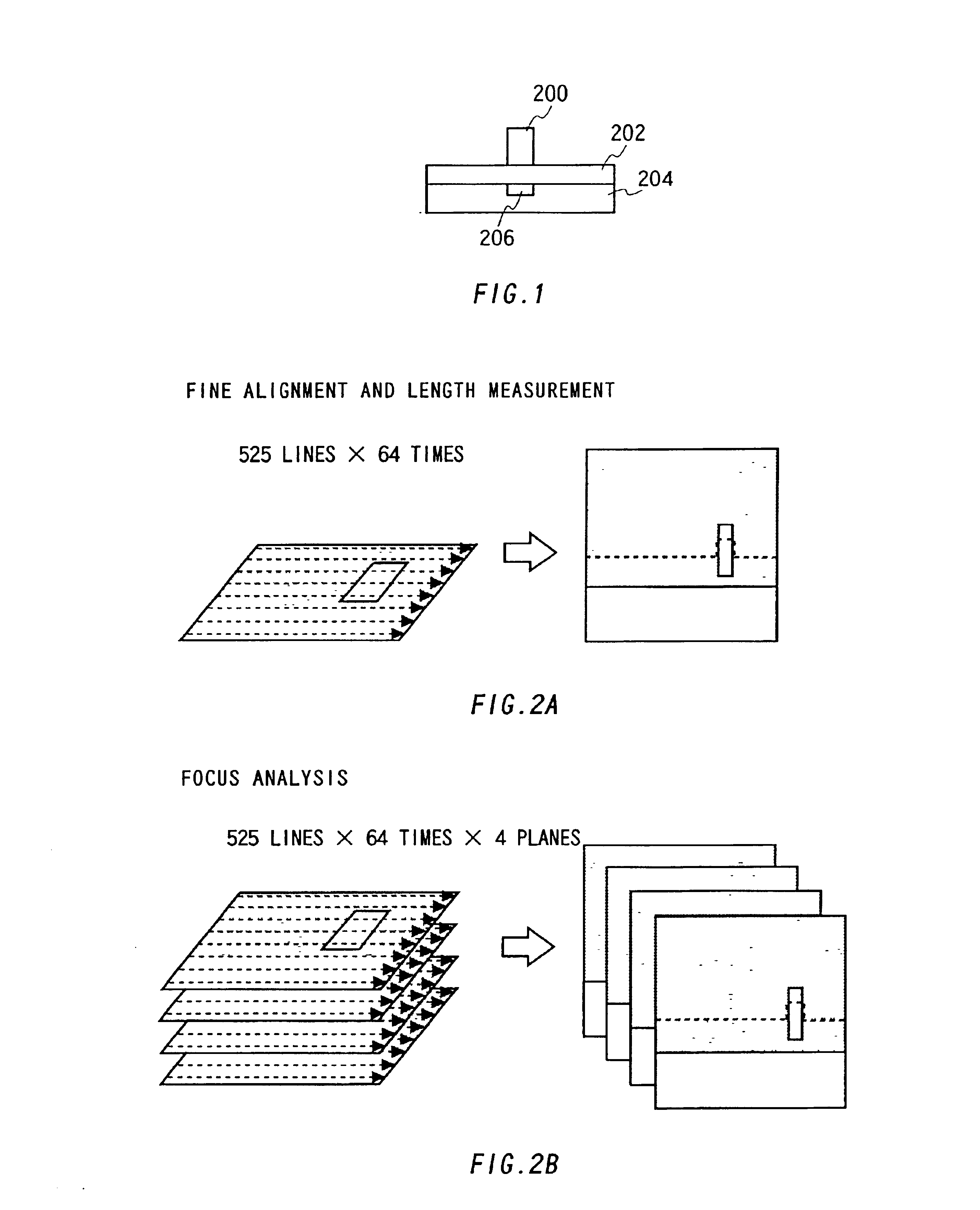

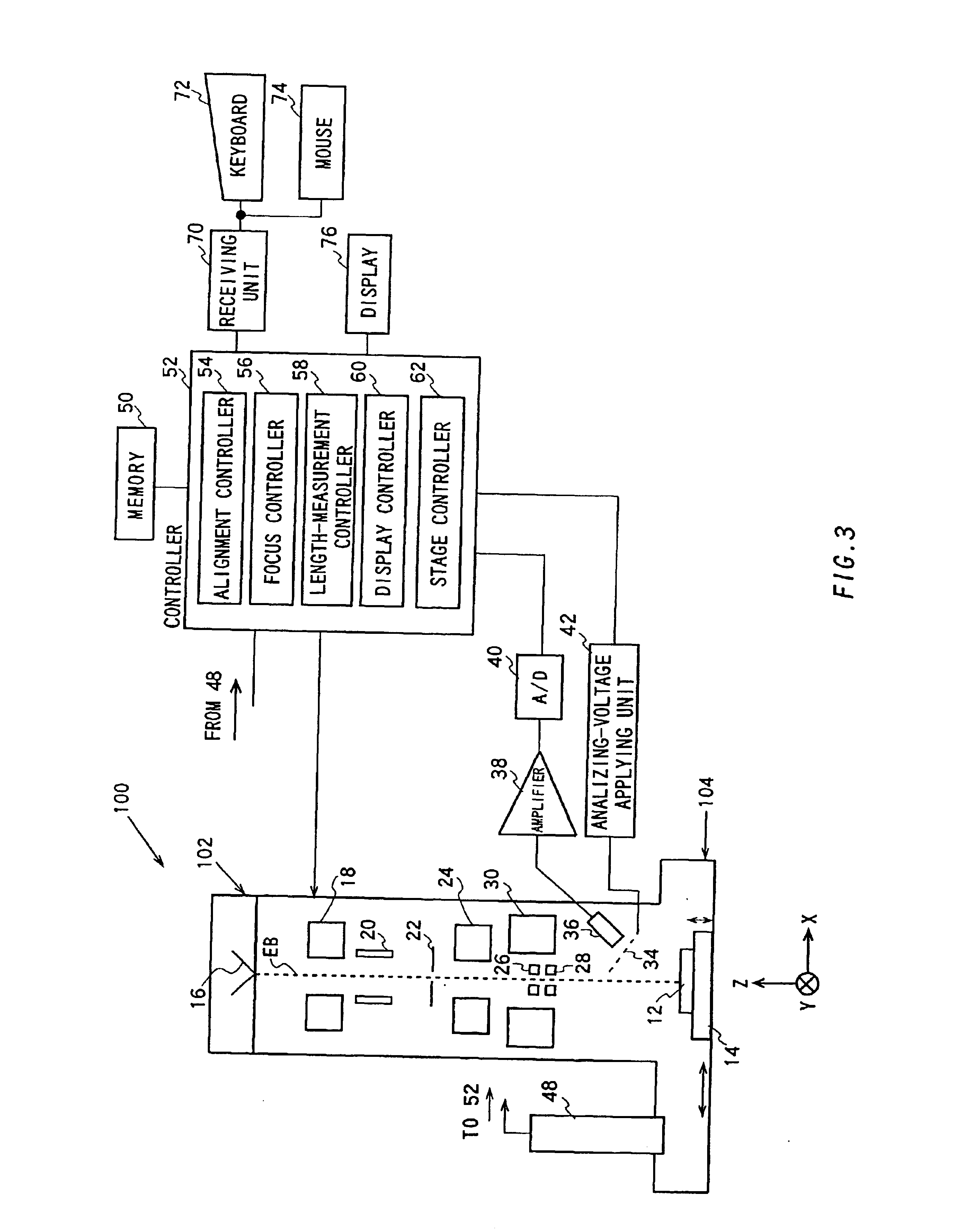

Standard member for length measurement, method for producing the same, and electron beam length measuring device using the same

InactiveUS7365306B2Higher-precision calibrationHigh resolutionMaterial analysis using wave/particle radiationElectric discharge tubesMeasurement deviceOptical measurements

Owner:HITACHI HIGH-TECH CORP

Standard member for length measurement, method for producing the same, and electron beam length measuring device using the same

InactiveUS20060237644A1Higher-precision calibrationHigh resolutionMaterial analysis using wave/particle radiationElectric discharge tubesMeasurement deviceOptical measurements

This invention provides an electron beam length measuring technology including a standard component for length measurement that has a finer standard dimension, and its producing method. The standard component for length measurement has a semiconductor member on which is arranged a pattern consisting of an array of first diffraction gratings whose pitch dimension is specified as an absolute dimension by an optical measurement method, wherein the pattern has a structure in which an array of second diffraction gratings different from the first diffraction gratings is arranged in a portion within the array of the first diffraction gratings in a predetermined cycle. Each one of the first diffraction gratings and the second diffraction gratings has a predetermined length and a predetermined width, respectively. The first diffraction gratings and the second diffraction gratings are arranged cyclically at respective predetermined intervals, and marks for specifying positions of the above-mentioned patterns are arranged in peripheral portions of the above-mentioned patterns. Moreover, the above-mentioned pattern contains an array pattern whose minimum pitch dimension is equal to or less than 100 nm. The electron beam batch exposure method is used as a pattern producing method.

Owner:HITACHI HIGH-TECH CORP

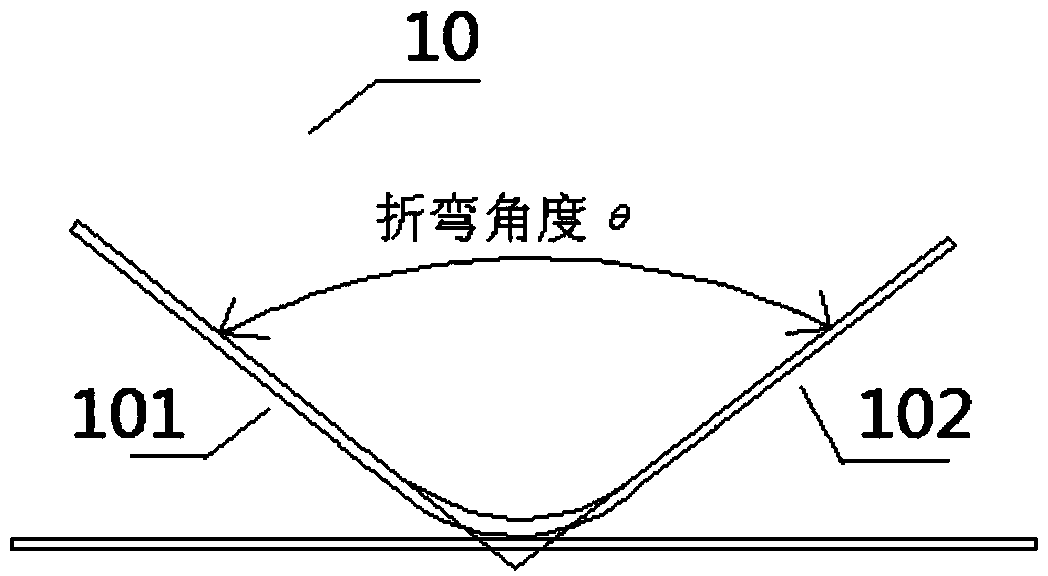

Plate bending angle detection device and method

ActiveCN103438835AIncrease productivityImprove measurement efficiencyUsing optical meansEngineeringMachining process

The invention discloses a plate bending angle detection device and method. A plate is provided with a first part and a second part which form a bending angle. The device comprises a scanner and a processor, wherein the scanner is used for emitting beams to the plate and generating a detection signal comprising beam lengths and emitting angles corresponding to a plurality of points on the first part of the plate and beam lengths and emitting angles corresponding to a plurality of points on the second part of the plate; the processor is used for determining a linear equation of the first part and a linear equation of the second part according to the detection signal and calculating the bending angle of the plate according to the linear equation of the first part and the linear equation of the second part. Therefore, the bending angle can be detected in real time in the plate processing process. The plate bending angle detection device and method improve production efficiency and measurement efficiency, are high in automation degree and free of manual intervention, and reduce labor force.

Owner:ZOOMLION HEAVY IND CO LTD

Linear PC track beam prefabrication construction method

InactiveCN109808054AShorten the timeImprove beam making efficiencyMouldsBuilding material handlingEngineeringPrefabrication

The invention discloses a linear PC track beam prefabrication construction method. The linear PC track beam prefabrication construction method comprises the operations of steel bar cage binding, bottom mold splicing, support seat installing, end mold installing, side mold adjusting, concrete pouring and demolding. According to the linear PC track beam prefabrication construction method, a moving type template system and corresponding fabrication working procedures are adopted, the bottom mold length is adjustable to deal with different beam types, beam lengths and beam heights, parallel operations are performed between the different working procedures, and the track beam prefabrication efficiency and precision are greatly improved.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

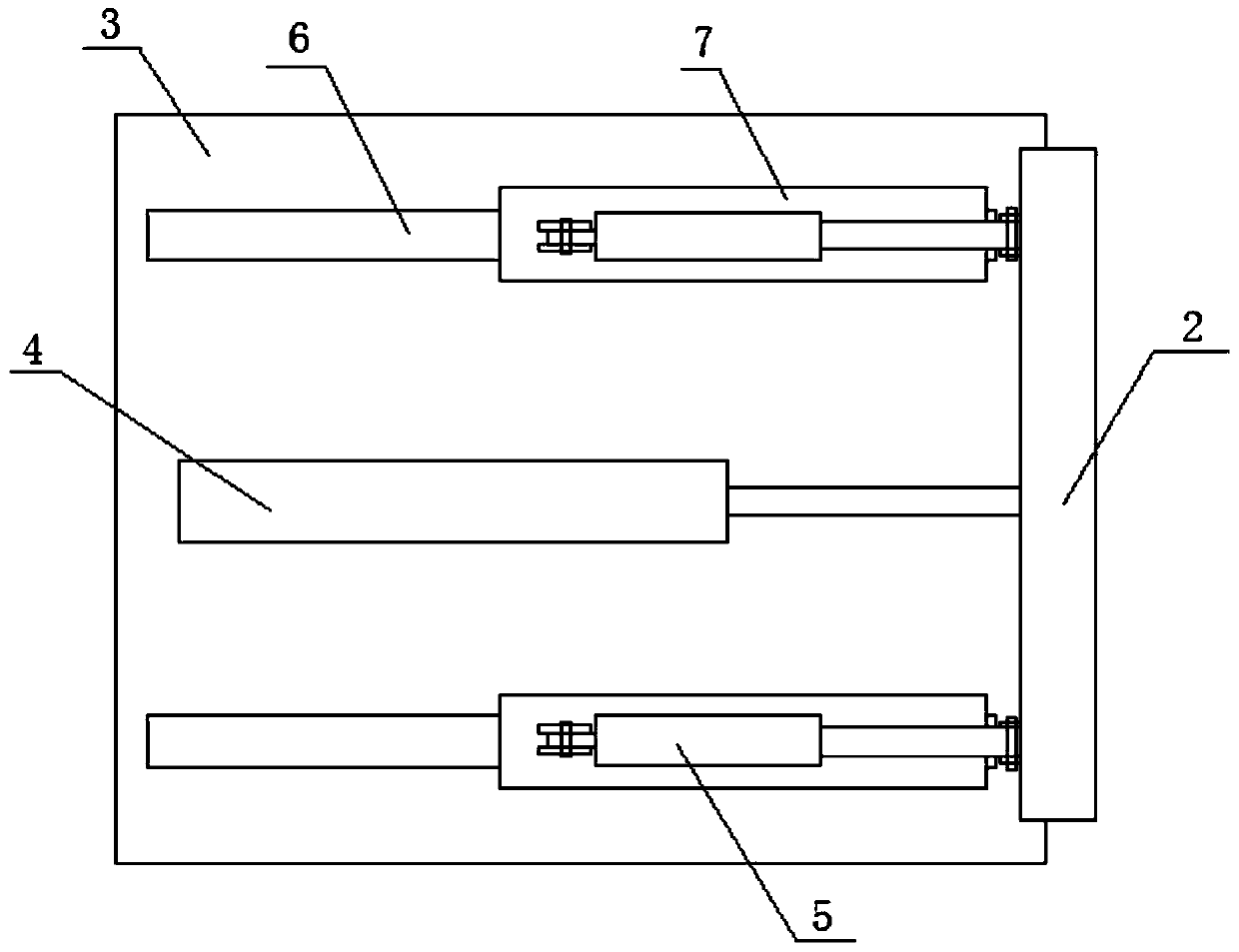

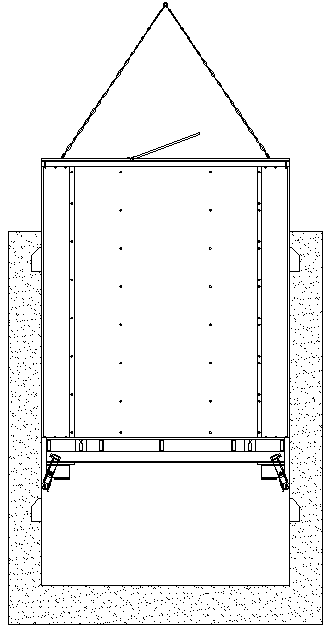

Integral lifting type formwork device for an elevator shaft

ActiveCN105507580AAdjustable sizeImprove construction efficiencyForms/shuttering/falseworksReusabilityTechnical performance

The invention relates to the field of construction and provides an integral lifting type formwork device for an elevator shaft. The device comprises a core tube in a rectangular structure, side boards with wall penetration wire holes are arranged on four lateral sides of the core tube respectively, a vertical column with a rectangular section is arranged at the joint of each two adjacent lateral sides, the lateral side of each vertical column is flush with the surface of the corresponding side board, a plurality of contraction devices enabling the side boards to move along the inner sides of the vertical columns are arranged inside the vertical columns, the lower portion of each vertical column is in movable connection with a base of the core tube, a plurality of claw seats in matched connection with latch boxes preset in walls are arranged below the base, and the claw seats in a horizontal state support the base and are in downwardly rotatable connection with the base. Arbitrary beam length adjustment in a certain range is realized, and convenience in adjustment and reusability are achieved; when the integral lifting type formwork device is used for establishing of a formwork platform, the formwork platform is enabled to be adjustable in size to adapt to construction of cylindrical cast-in-situ shear wall formworks different in section size; after construction is finished, the device can be lifted upwards to be directly used for construction of the elevator shaft at a lower storey, technical performances are promoted, construction efficiency is greatly improved, and reusability is achieved.

Owner:山东方正建筑新型材料有限公司

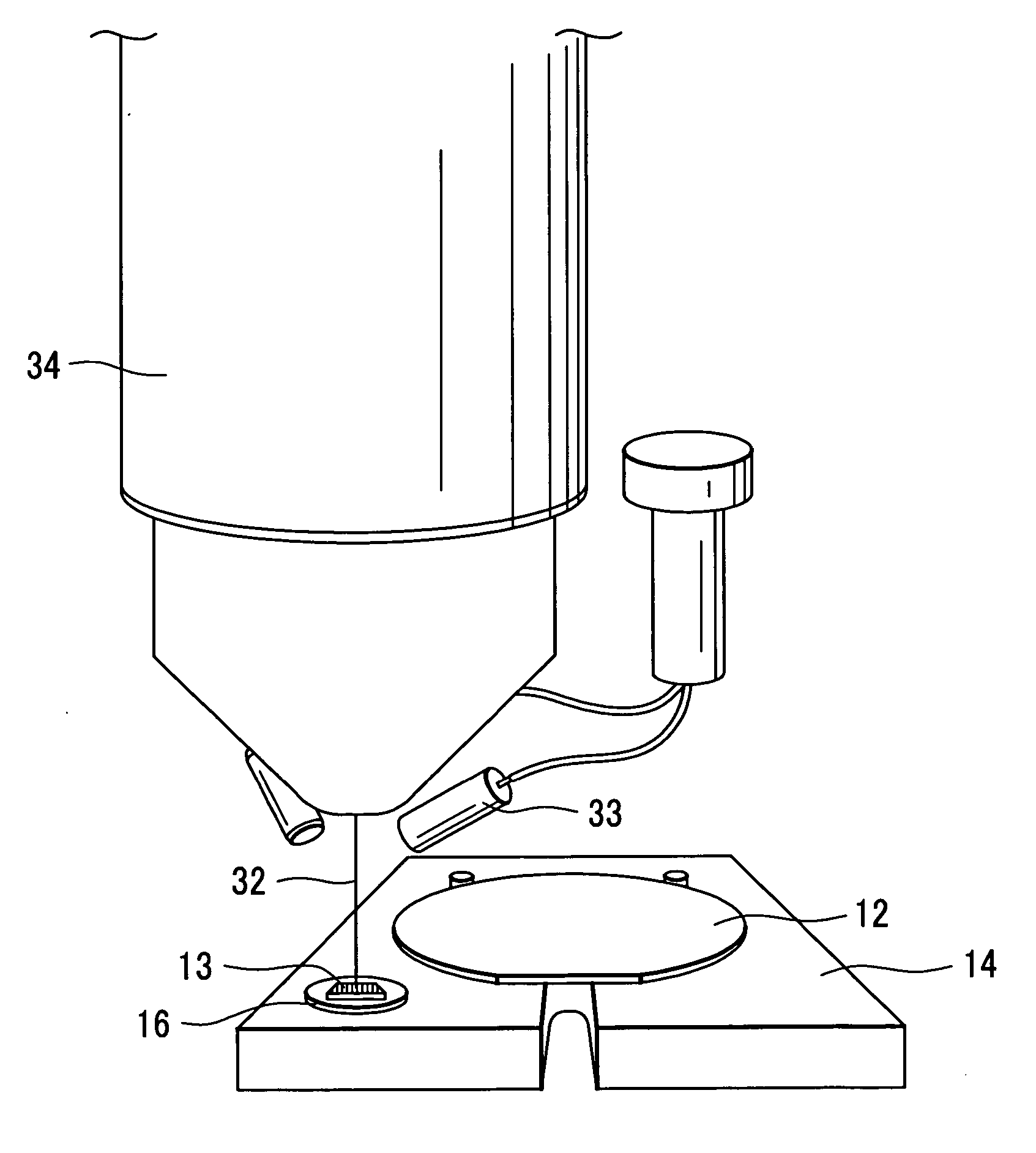

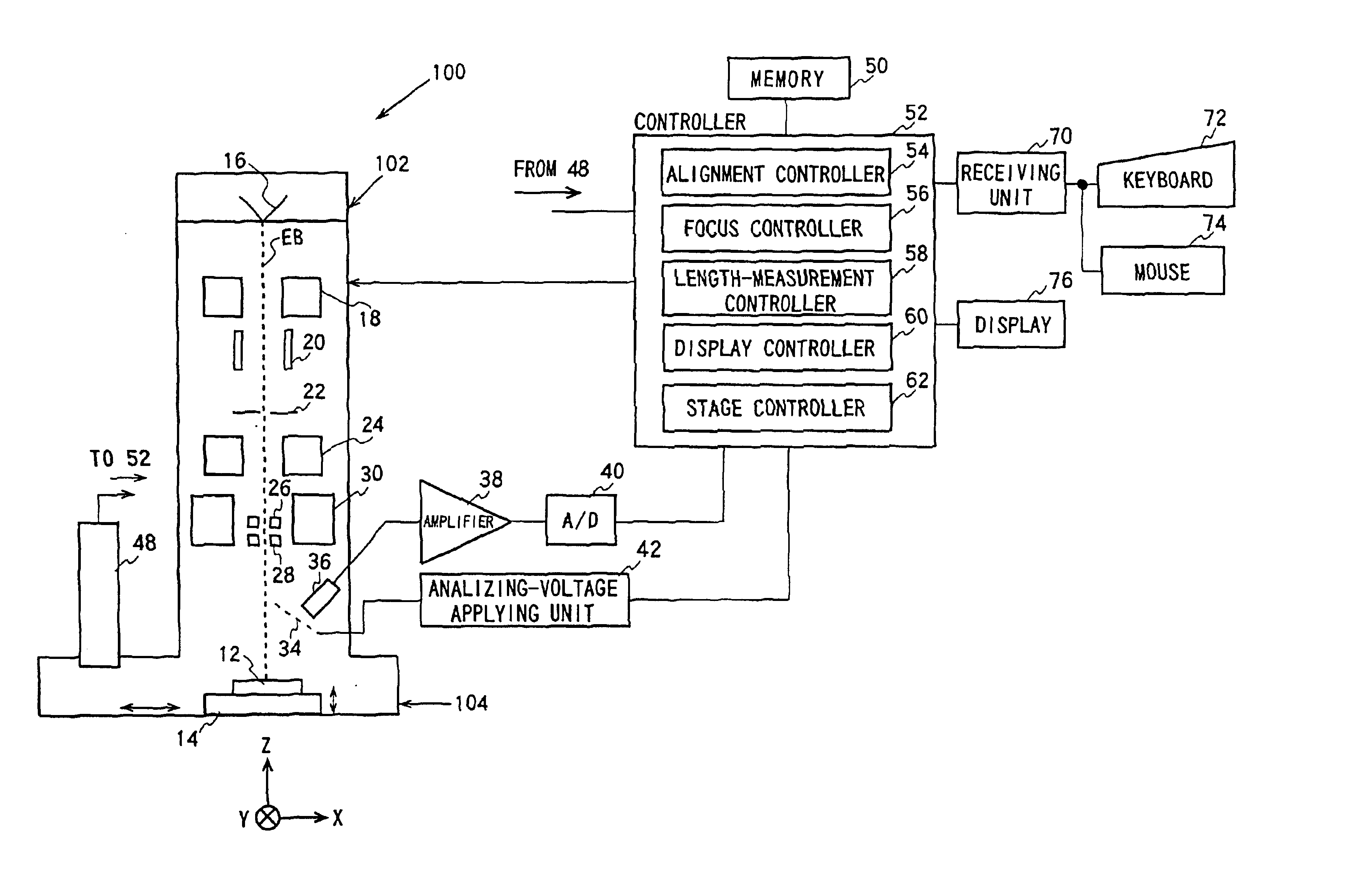

Electron beam length-measurement apparatus and measurement method

InactiveUS6844549B2Material analysis using wave/particle radiationElectric discharge tubesObject basedMeasurement device

An electron beam length-measurement apparatus for measuring a length of a predetermined portion of an object by using an electron beam, includes: an electron gun for emitting the electron beam; a deflecting unit for deflecting the electron beam; an object holding unit on which the object is to be placed; a detector for detecting electrons that are scattered by the electron beam; a memory for storing layout position information that specifies a layout position at which the predetermined portion of the object; a length-measurement scanning controller for controlling the deflecting unit to scan with the electron beam to allow the layout position on the object to be irradiated with the electron beam; and a measurement unit operable to measure the length of the predetermined portion of the object based on a changing manner of the electrons successively detected by the detector while the length-measurement scanning controller scans with the electron beam.

Owner:ADVANTEST CORP

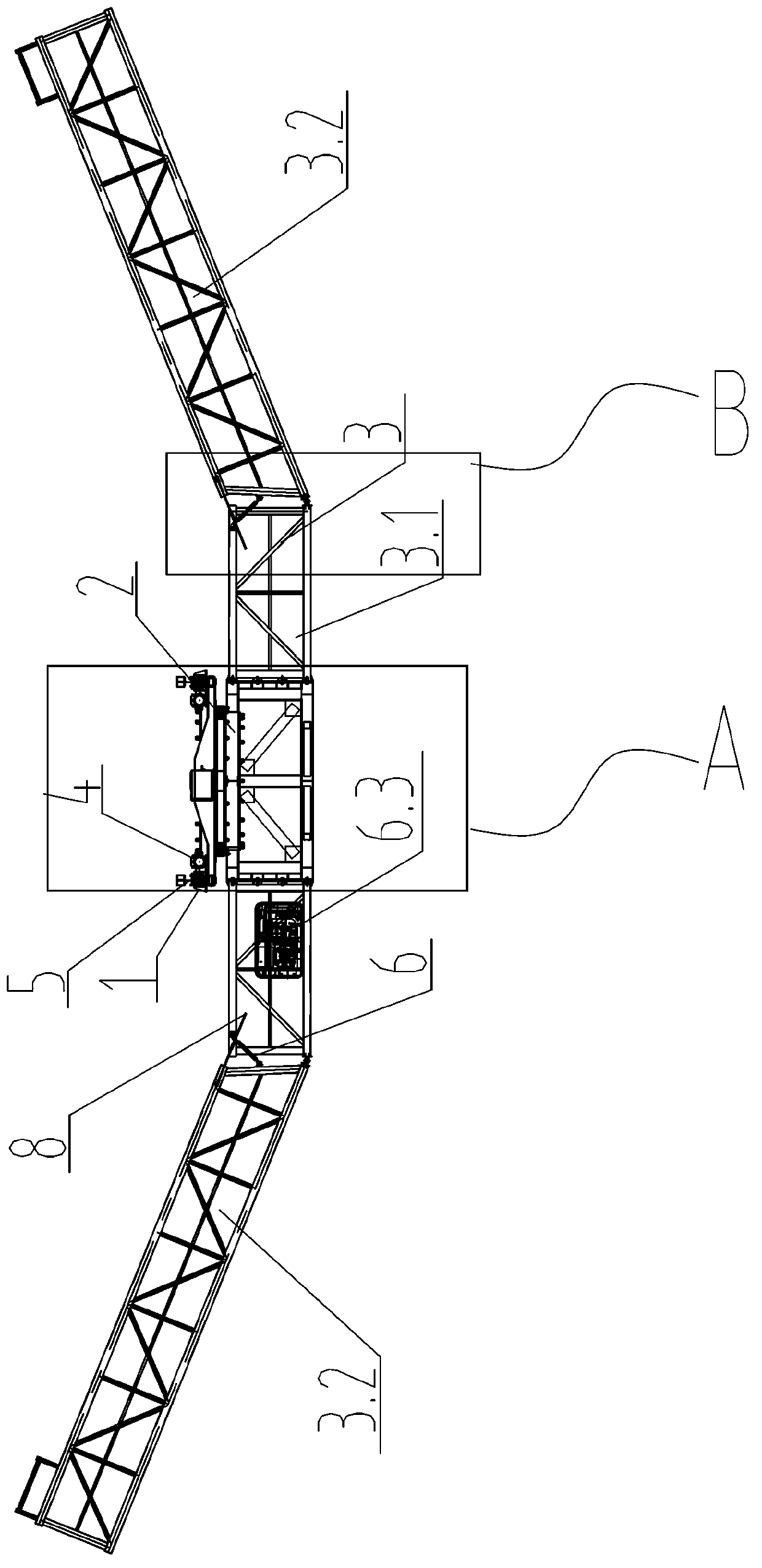

Total-length traveling rotary pile-passing beam bottom inspection vehicle system

ActiveCN102864740ALow external demandConvenient on-site workBridge structural detailsVehicle frameEmbedded system

The invention discloses a total-length traveling rotary pile-passing beam bottom inspection vehicle system. The system comprises inspection vehicle rails, a traveling mechanism, a traveling drive system and a vehicle frame, wherein the vehicle frame comprises a truss and folding arms arranged at the two ends of the truss; an amplitude variation mechanism for controlling the rising amplitude of the folding arms is arranged between the truss and the folding arms; a rotation device which makes the vehicle frame rotate horizontally is arranged on the truss; a detection element for detecting a rotation position is arranged on the inspection vehicle rail; and a safe protection device for connecting the truss and the folding arms is arranged on the vehicle frame. The system has the advantages of high automation degree, high economic indexes, high safety, convenience in operation, convenience and rapidness in inspection on beam bottom and the like, and can realize the beam bottom inspection on a multi-span continuous bridge structure in a total beam length range and in a barrier-free mode.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

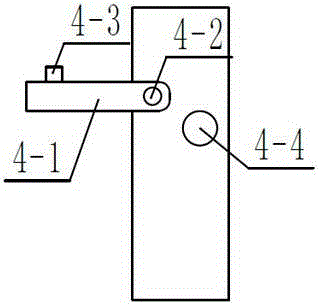

Tubular beam support testing tool

InactiveCN105180743ARapid Measurement EvaluationSimple structureMechanical measuring arrangementsEngineeringCam

A tubular beam support testing tool is composed of a base (1), a positioning testing base (2), fixing support bases (3), a hole testing base (4), a cam testing base (5), a latching fixing base (6) and a tubular beam support (7). Firstly the tubular beam support (7) is placed on the testing tool at a corresponding position, and then the right end of the tubular beam support (7) is fixed on the latching fixing base (6). Then a clamp of the fixing support base (3) on the left end is pressed down, then the fixing support base (3) on the right end is pressed down, a turnover plate structure (4-1) is turned over and presses a boss (4-3) into an installation hole (7-1) of the tubular beam support (7), and finally a plug gauge is used to test if the gap between the right end of the tubular beam support (7) and a positioning testing block (2-1) is within a predetermined range. The testing tool is simple in structure and convenient for use, can quickly measure and assess the positioning installation hole size of the tubular beam support, tubular beam length and other sizes, ensures consistency of product manufacturing, and improves product assembly efficiency.

Owner:JIANGSU KEXIN AUTOMOBILE DECORATION PARTS

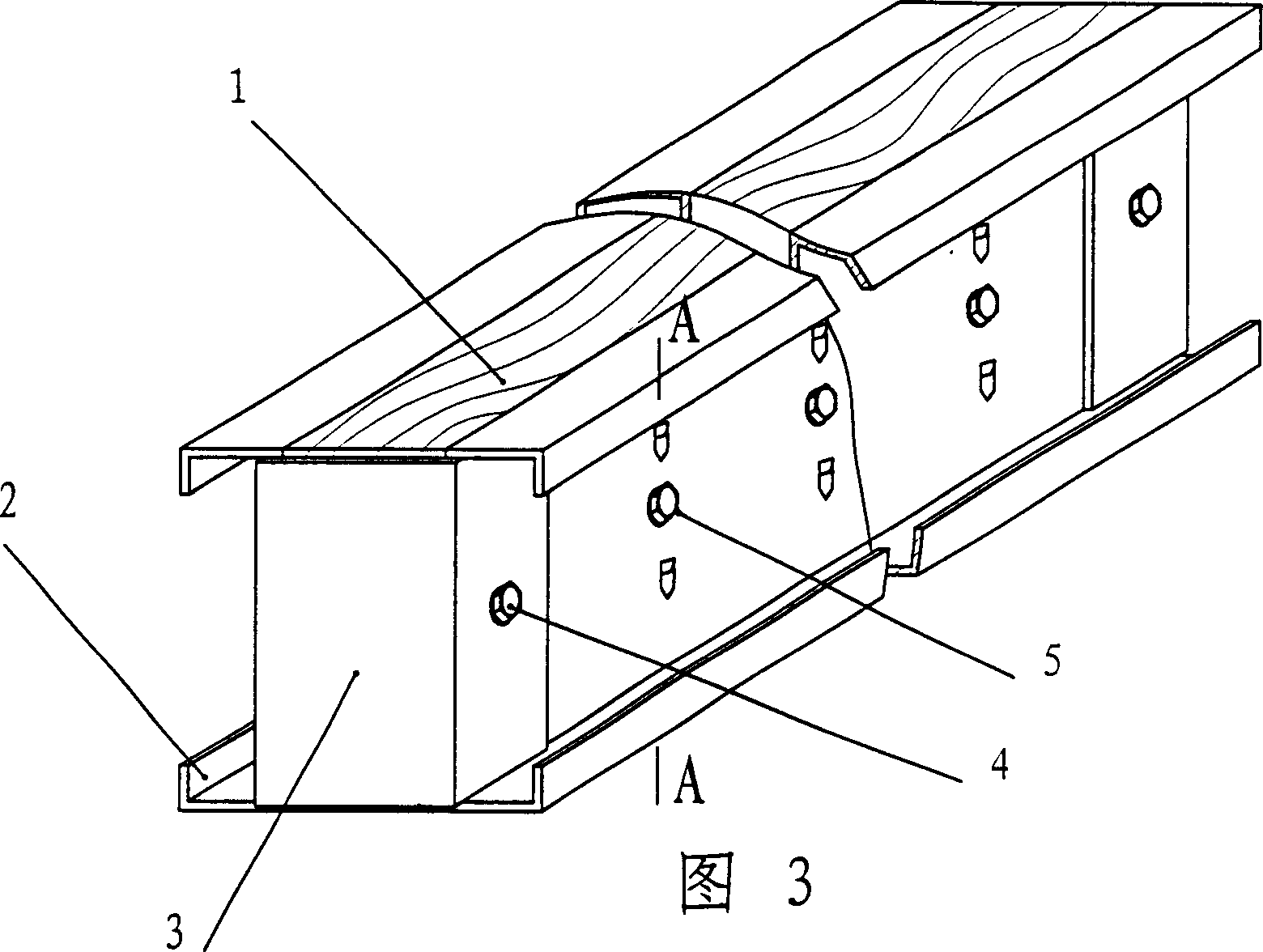

Steel and wood integrated I-shaped beam

InactiveCN1840836AStrong rigidityImprove versatilityLoad-supporting elementsForms/shuttering/falseworksShaped beamSheet steel

The invention discloses a steel-wood integration I-beam, which is composed of wooden beam, wherein the force type steel is connected to two lateral surfaces in the wooden beam length direction; two ends of wooden beam connects to roll end; the I-beam uses extrusion steel plate teeth and fastener to make the section steel and timber compact for one body; the steel-wood integration I-beam has stronger hardness, good versatility, which is fit for supporting of building form plate such as steel-wood mold plates, steel form, bamboo plywood and so on; the cost of the steel-wood integration I-beam is 50% aluminum alloy beam, 85% steel beam and 95% wood girder; The I-beam reduces the cost of transport and storage.

Owner:吴继武

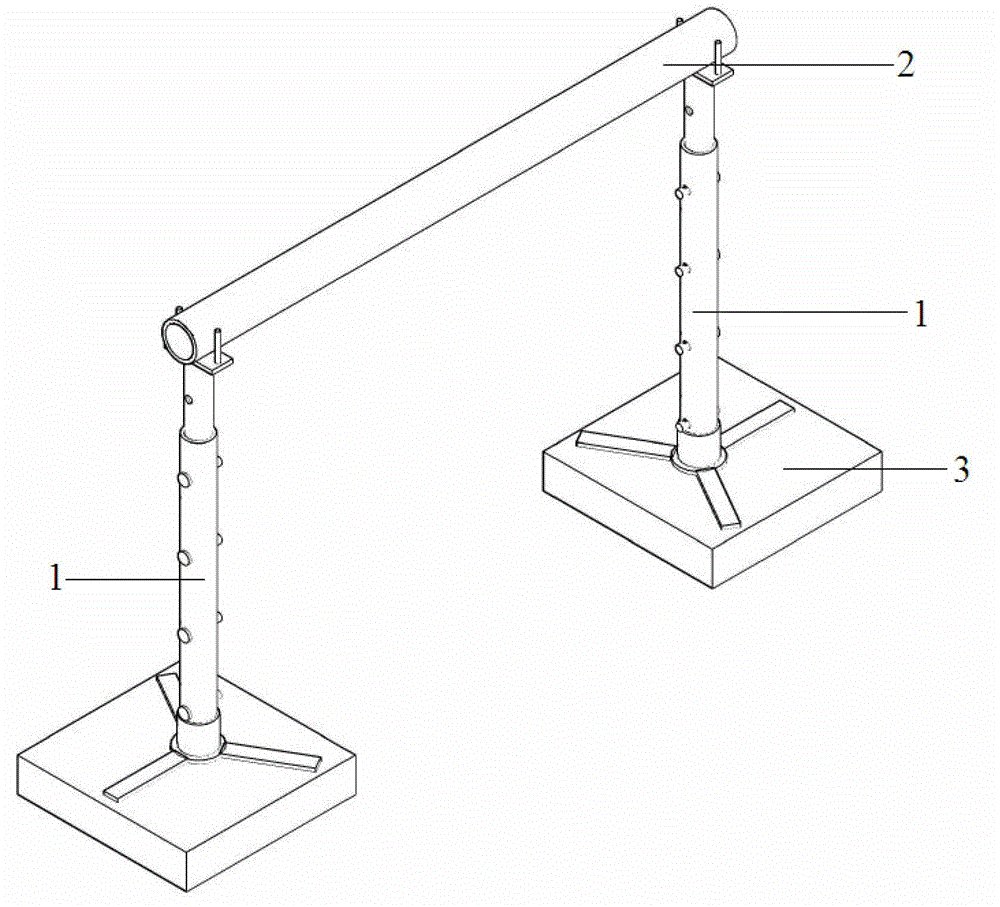

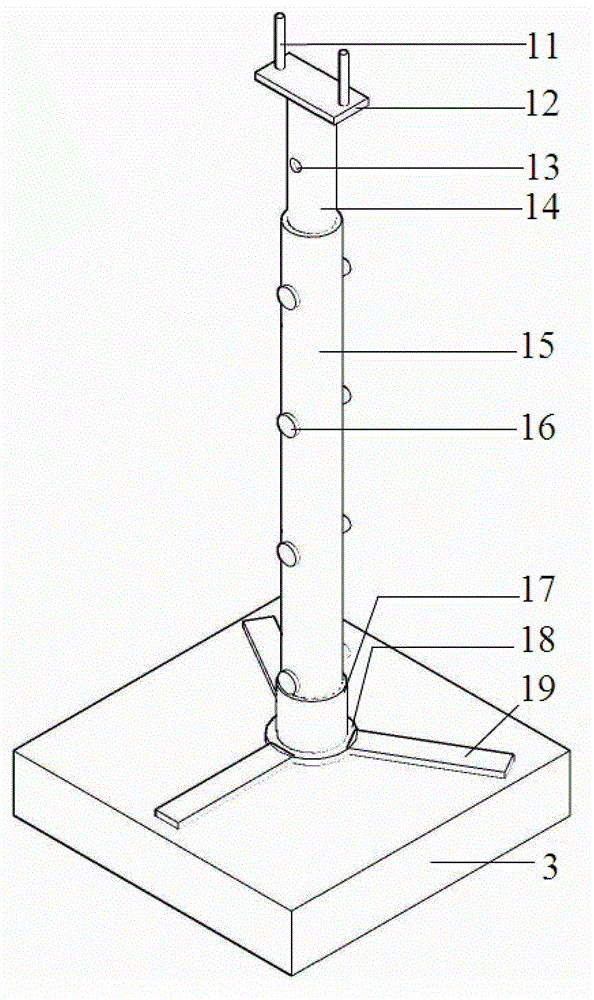

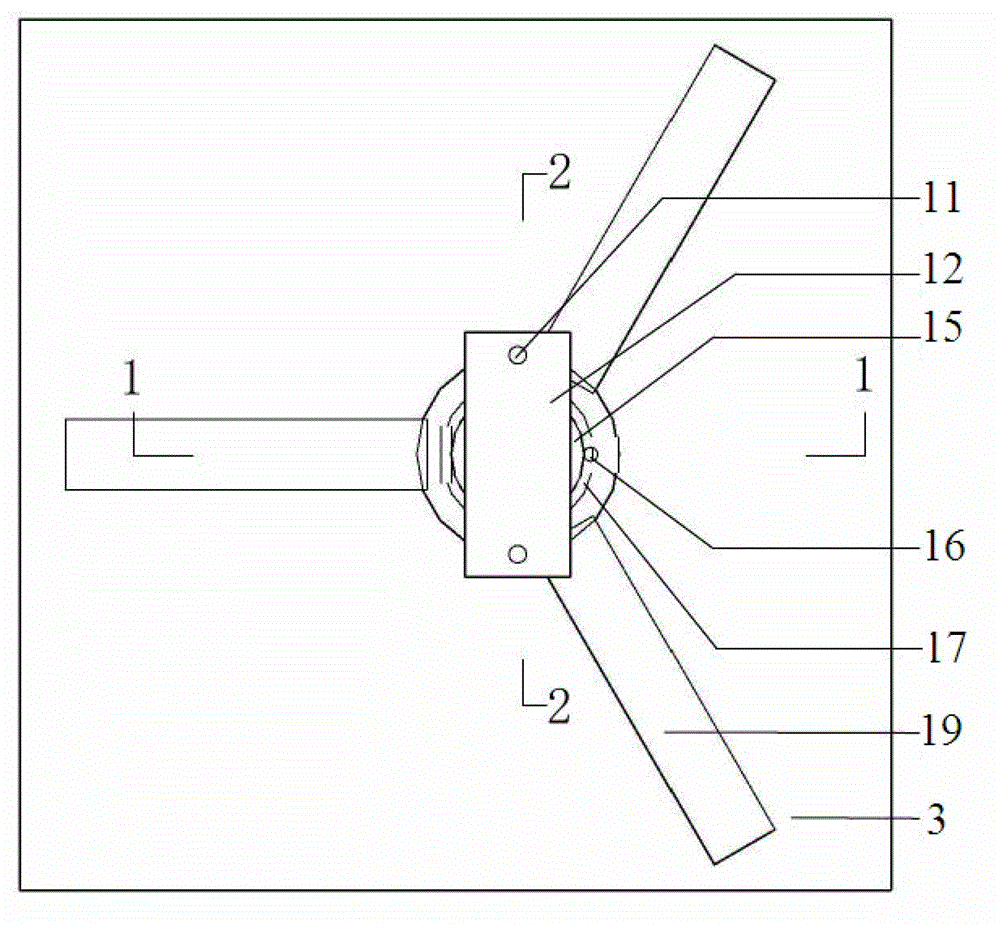

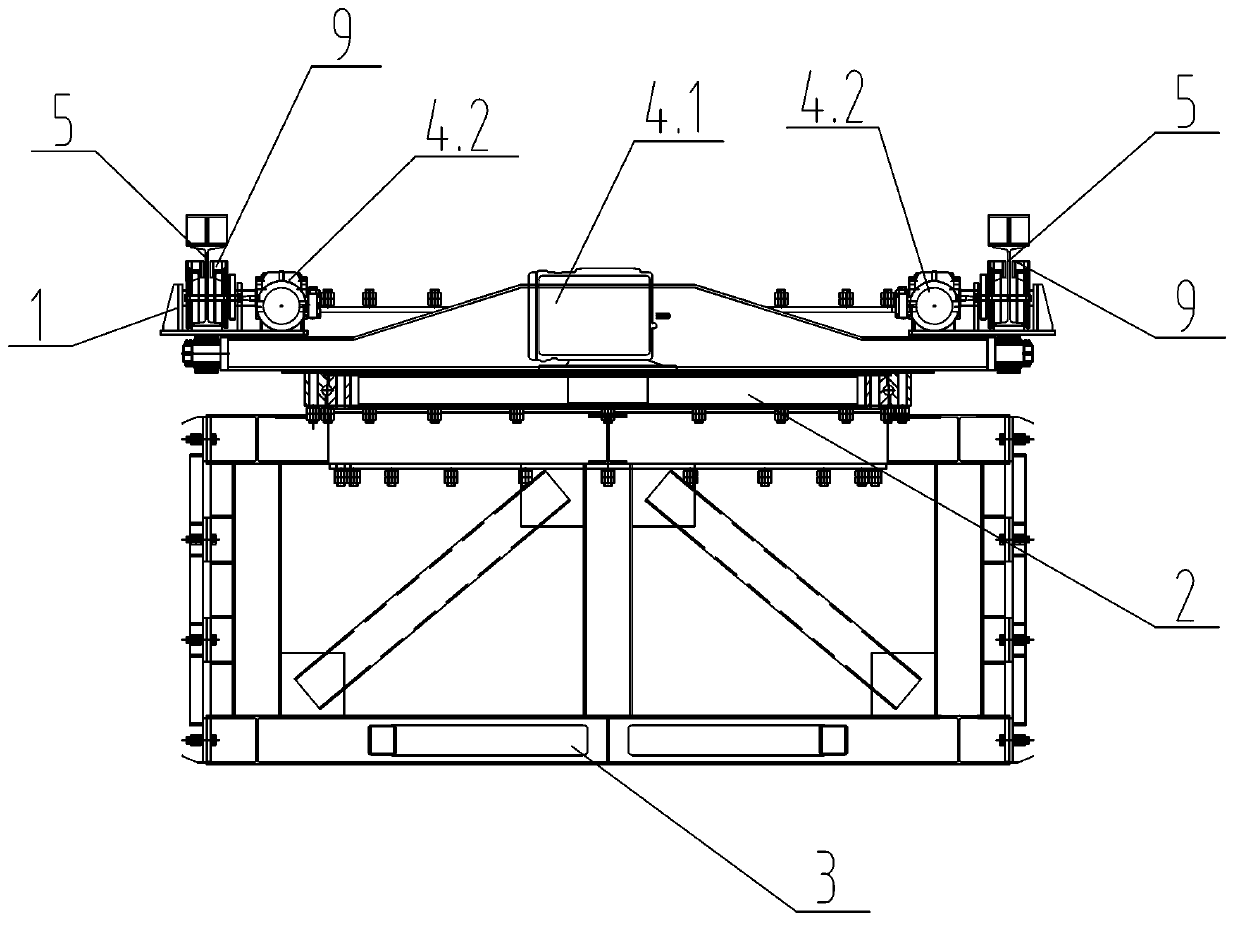

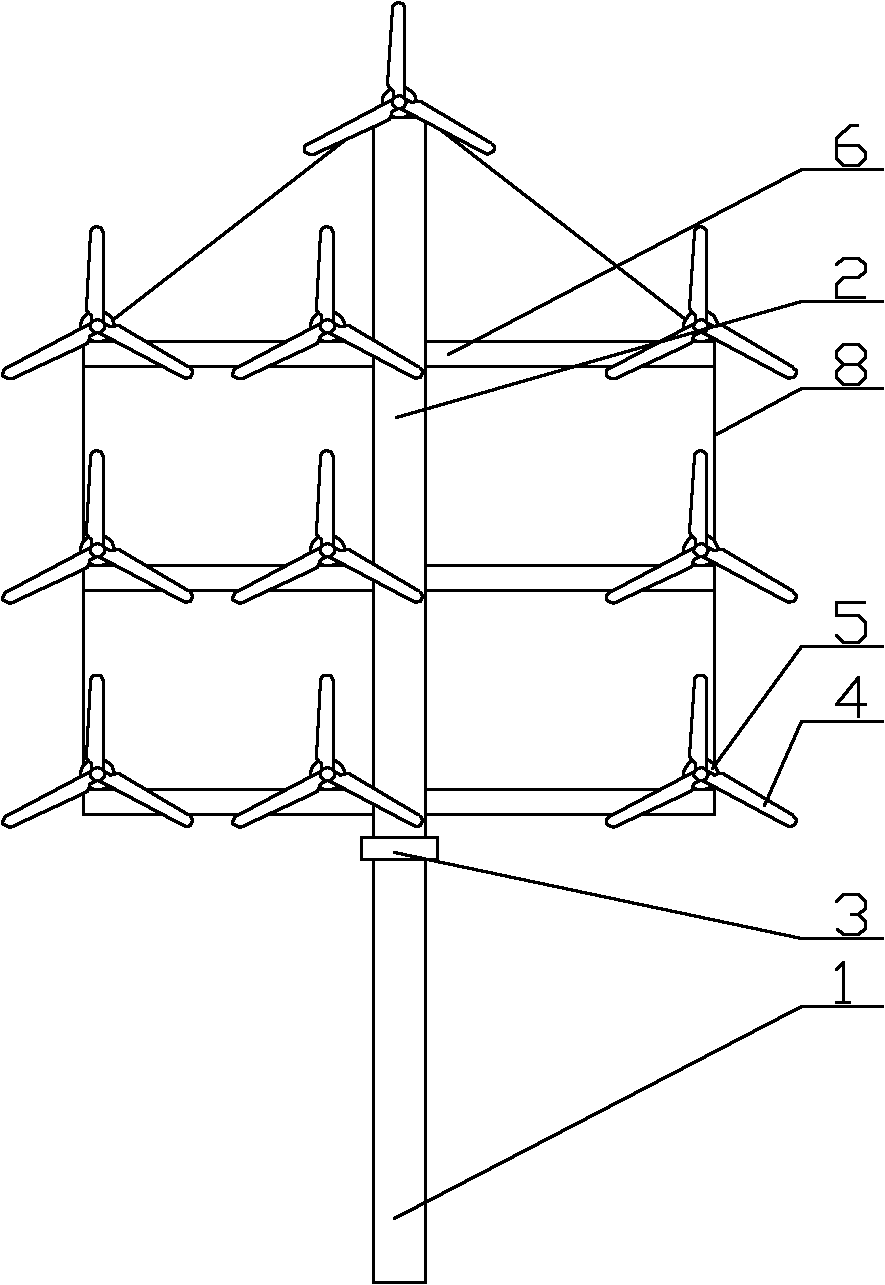

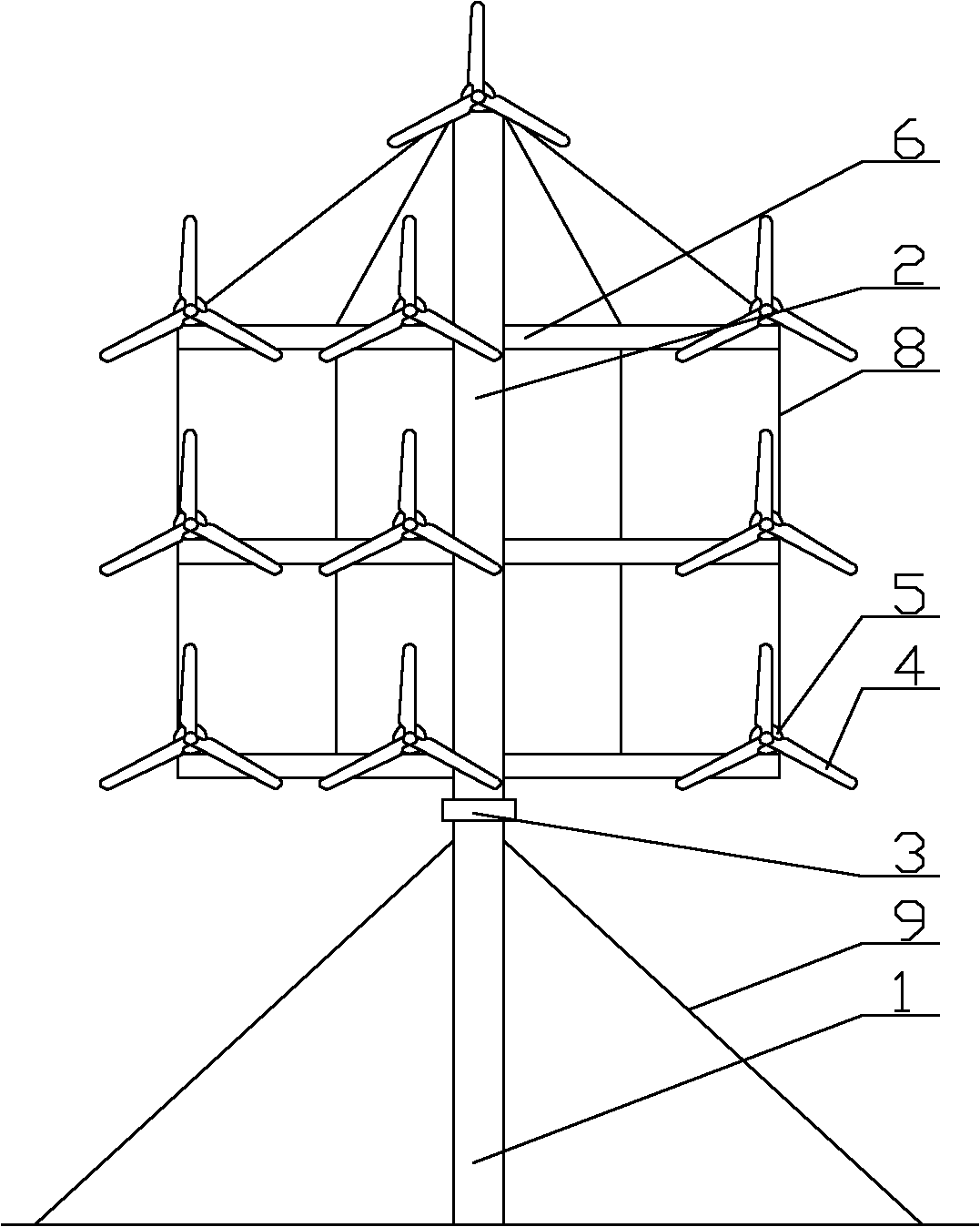

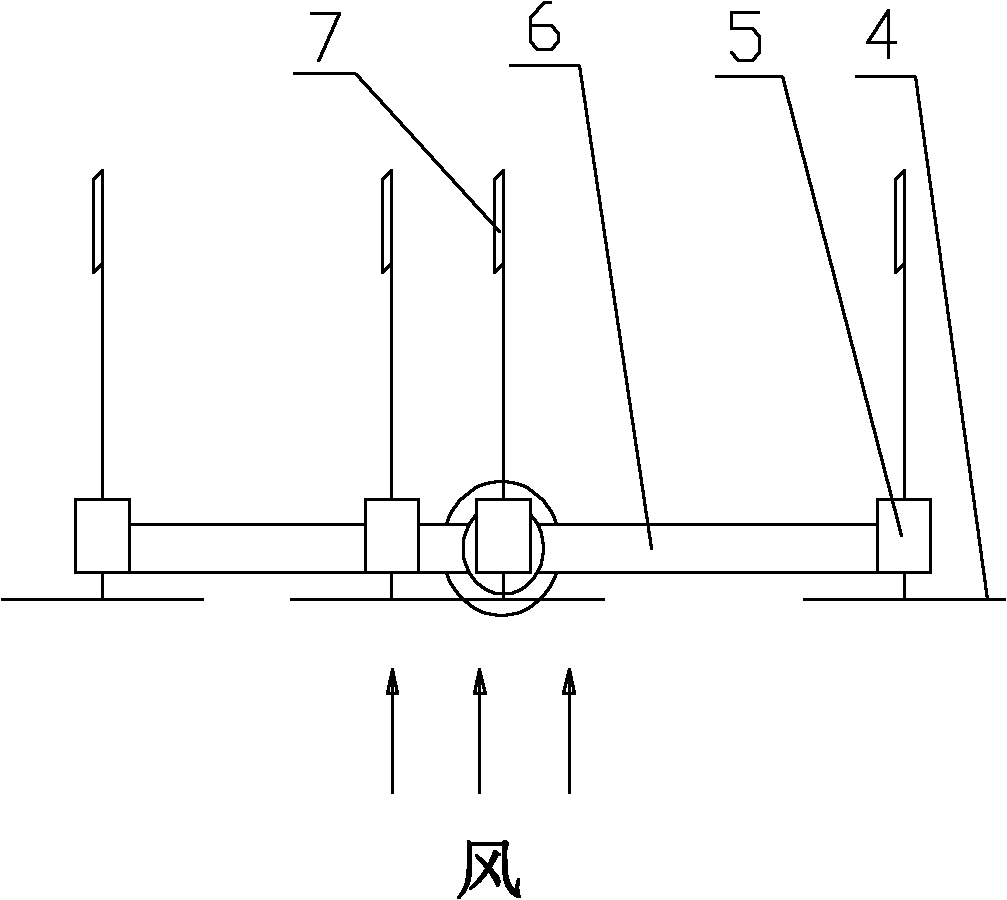

Multi-rotor wind power generation system with equal beam length

InactiveCN102322397ASolution to short lifeMature manufacturing technologyMachines/enginesWind motor combinationsEngineeringSmall footprint

The invention discloses a multi-rotor wind power generation system with equal beam length, which comprises a lower pylon 1, a rotary bearing 3, windmills, an upper pylon 2, a rope and / or a rod 8, beams 6 and a tail vane 7, wherein the rotary bearing is arranged between the upper pylon and the lower pylon; two sides of the upper pylon are respectively connected with one ends of the beams; the outer end of the uppermost beam is connected with the top end of the upper pylon through the rope and / or the rod; the outer ends of adjacent beams are connected through the rope and / or the rod; the lengths of the beams at two sides of the upper pylon are equal; the windmills are fixedly connected with the top of the upper pylon or / and the beams; the number of the windmills on the beams at one side is greater than that of the windmills on the beams at the other side; and the tail vane is connected with the upper pylon, the beams or / and an engine room through a pin roll. The multi-rotor wind power generation system has the advantages of long service life of the vane, small occupied area, low cost for installation and maintenance, favorable reliability, wide application range, low bearing stress, automatic wind resistance and yawing and small stress of the beams; and the rotary bearing or a rotary driving device in the engine room is omitted.

Owner:TIANJIN UNIV

Prestressed partially-encased steel T-shaped composite beam and construction method thereof

PendingCN112854595AMeet the requirements of energy saving and emission reductionAvoid Tensile PrestressingLoad-supporting elementsBuilding reinforcementsCrack resistancePre stress

The invention provides a prestressed partially-encased steel T-shaped composite beam. Based on a prestressed prefabricated assembly technology, the prestressed partially-encased steel T-shaped composite beam is mainly composed of a prestressed prefabricated rectangular composite beam and a cast-in-place concrete flange plate. The prestressed prefabricated rectangular composite beam comprises honeycomb profile steel, tie bars, closed stirrups, first in-beam longitudinal bars, second in-beam longitudinal bars, a plurality of prestressed steel strands, prefabricated UHPC (Ultra High Performance Concrete) and studs, wherein the tie bars are arranged in holes of the honeycomb profile steel and are perpendicular to a web of the profile steel; the closed stirrups are arranged between flanges of the honeycomb profile steel; the first in-beam longitudinal bars are arranged at the inner bottoms of the closed stirrups and are parallel to the beam length direction; the second in-beam longitudinal bars are arranged at the inner tops of the closed stirrups and are parallel to the beam length direction; the prestressed steel strands are arranged on the upper portions of the lower flanges of the honeycomb profile steel and are parallel to the beam length direction; the prefabricated UHPC is arranged between the flanges of the honeycomb profile steel in a filling mode; and the studs are arranged at the tops of the upper flanges of the honeycomb profile steel. The cast-in-place concrete flange plate comprises double-layer bidirectional steel bars and cast-in-place concrete, wherein the double-layer bidirectional steel bars are arranged in a cast-in-place flange plate body, and the cast-in-place concrete is arranged at the top of the prestressed prefabricated rectangular composite beam in a filling mode. The prestressed partially-encased steel T-shaped composite beam is excellent in stress performance, the crack resistance and flexural rigidity of the beam can be obviously improved, on-site construction is convenient and fast, and the construction period is shortened.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

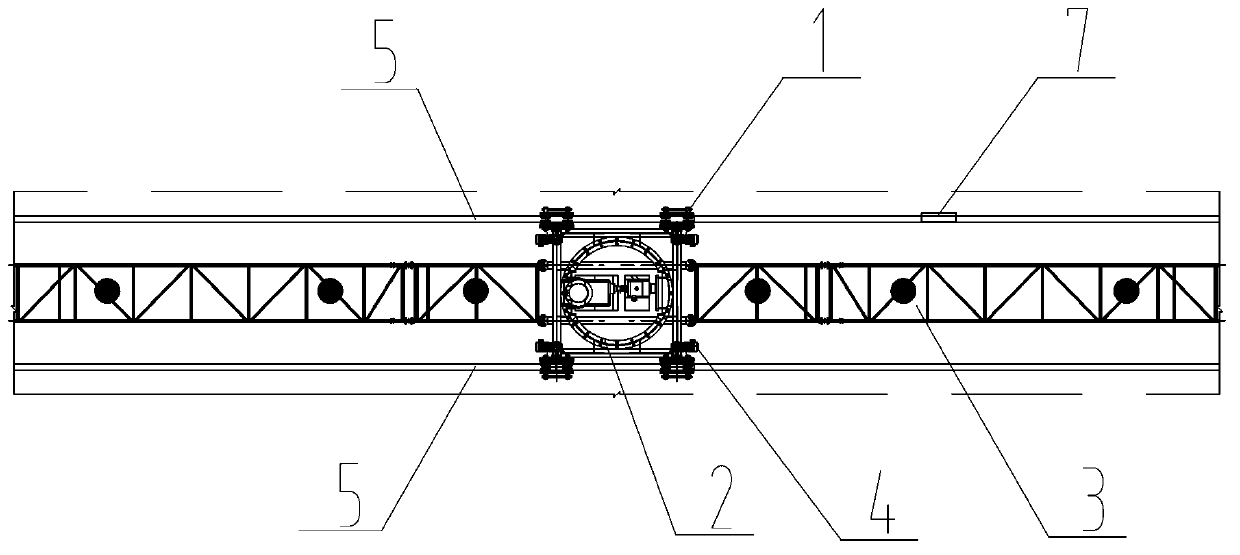

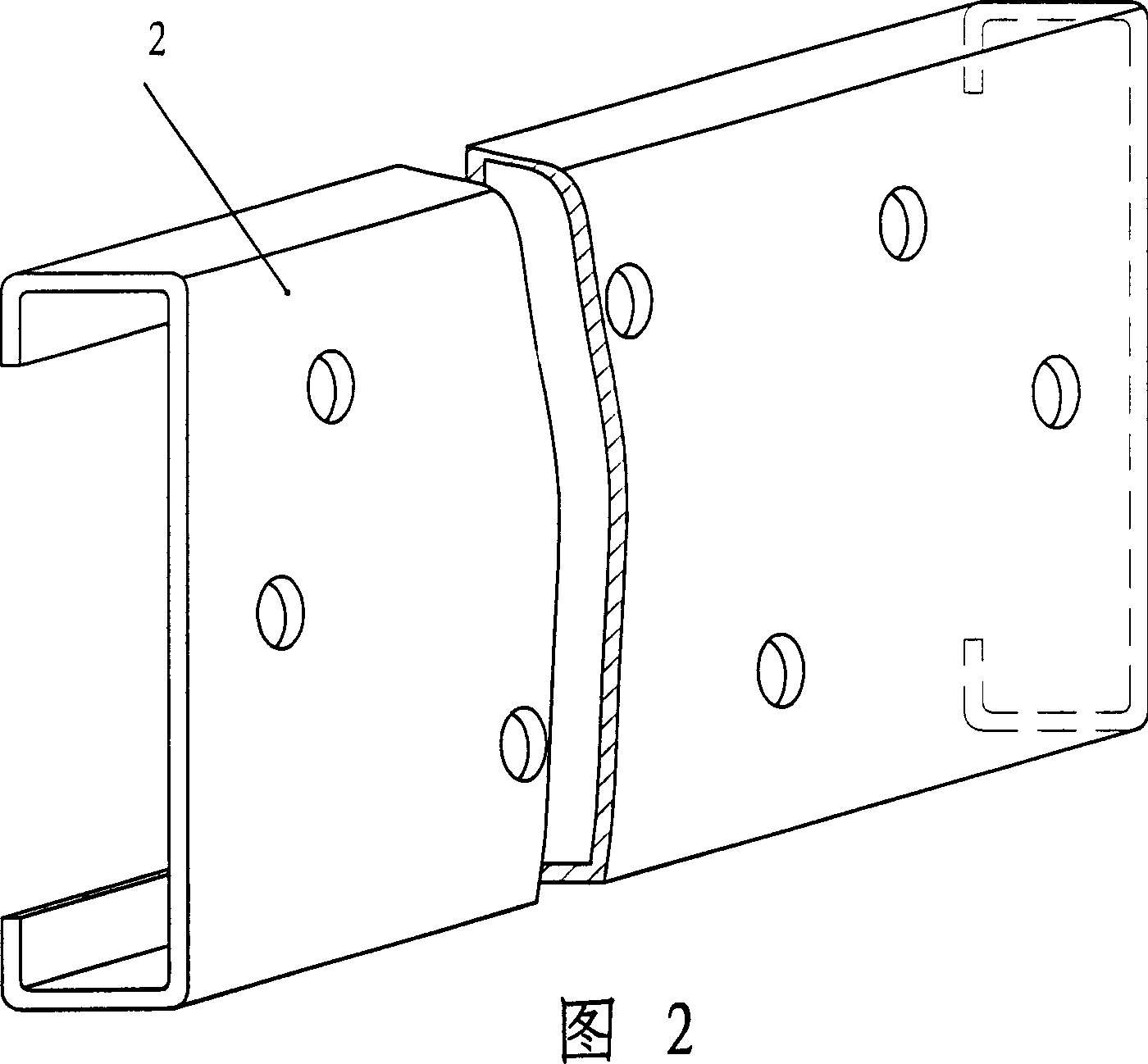

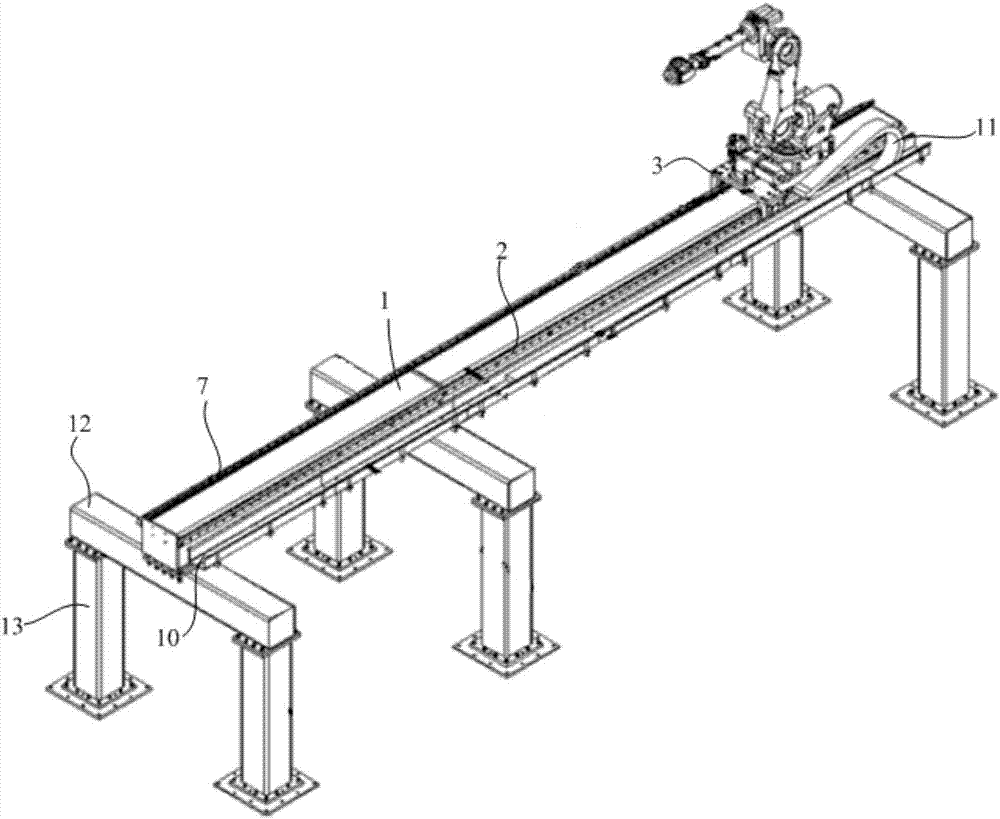

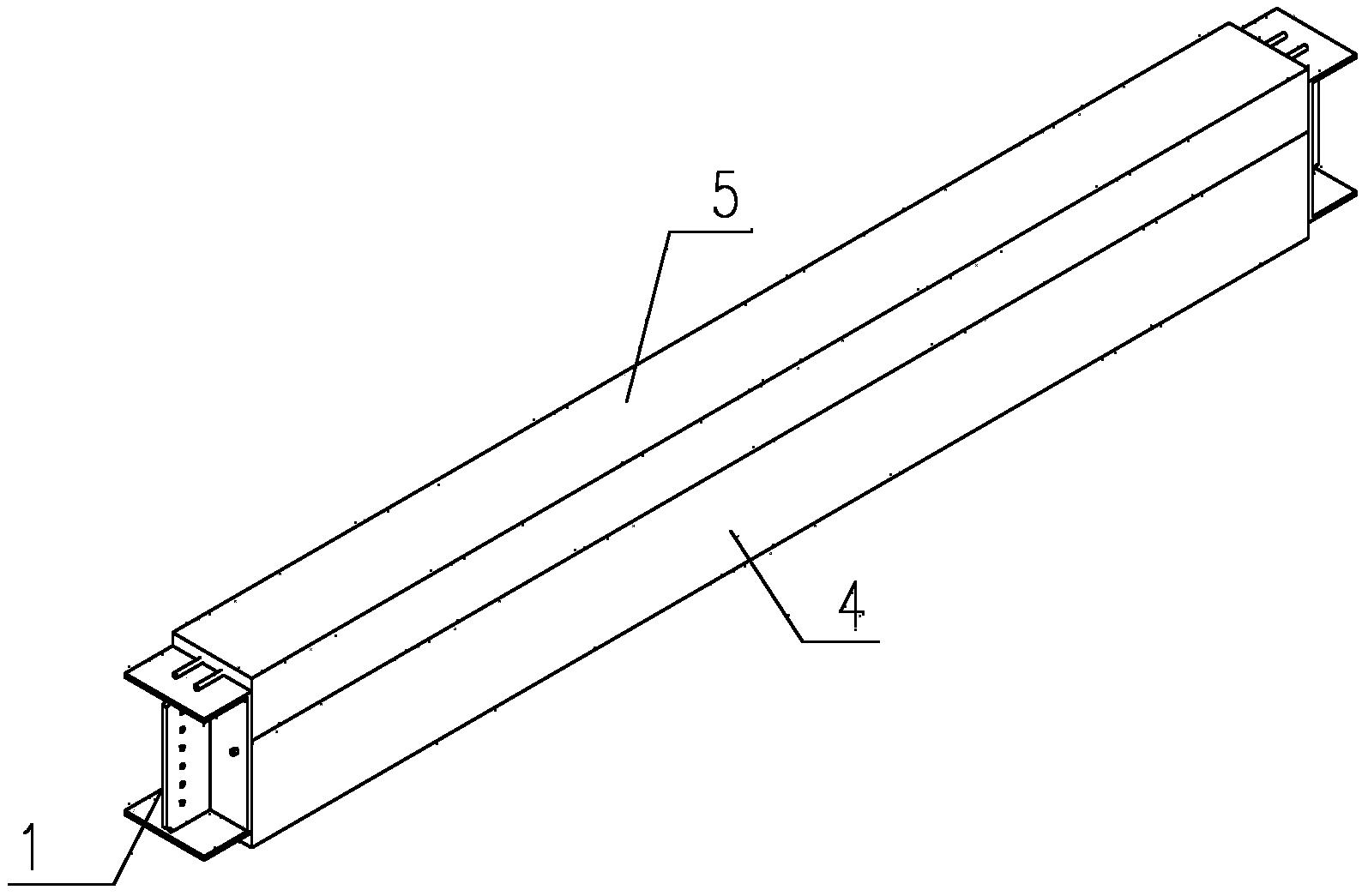

Truss robot guide rail assembly

The invention discloses a truss robot guide rail assembly. The truss robot guide rail assembly comprises a truss beam, a slide platen and a driving mechanism. The opposite two sides of the truss beam are correspondingly provided with guide rails. The length of the guide rails extend along the direction of the truss beam length. The slide platen is used for mounting a robot. One side of the slide plate adjacent to the truss beam is provided with pulley blocks cooperating with guide rail gaps. The pulley blocks comprise rolling wheels located on both sides of the guide rails and conducting rolling friction to the guide rails. The distance between the two rolling wheels is adjustable. The driving mechanism is used for driving the slide platen to move on the truss beam. By setting the pulley blocks, the relationship between the slide platen and the truss beam is rolling friction so that the friction and collision between the slide platen and the guide rails during the movement of the slide platen can be reduced and the noise can be reduced, and the distance between the two rolling wheels of arranged on two sides of the guide rails is adjustable, so that the request to the accuracy during the installation of the guide rails and the pulley blocks is reduced. When the pulley blocks are mounted on the guide rails, then the distance between the two rolling wheels is adjusted to achieve the installation of the guide rails and the pulley blocks.

Owner:GUANGZHOU SEAHAWN IND ROBOTICS

End-enhanced steel-reinforced concrete superposed beam

InactiveCN104110097AReach the role of a strong nodeAvoid wastingGirdersJoistsReinforced concreteSteel frame

The invention provides an end-enhanced steel-reinforced concrete superposed beam, which belongs to the field of architectural structures. A prefabricated shape steel frame is composed of tip shape steel connecting pieces, end H shape steel and a steel bar and steel reinforcement cage system, wherein shape steel frame end steel reinforcement cages are arranged between the tip shape steel connecting pieces and the top surfaces of the end H shape steel, a full-beam-length shape steel frame lower steel reinforcement cage is arranged between the tip shape steel connecting pieces located at two ends, a shape steel frame middle steel reinforcement cage is arranged between the inner ends of the end H shape steel located at two ends, concrete is poured along the shape steel frame lower steel reinforcement cage to form a prefabricated concrete steel-reinforced lower beam, and a concrete steel-reinforced upper beam is poured on the prefabricated lower beam along shape steel frame end and middle steel reinforcement cages, thereby forming the superposed beam. According to the invention, based on the loading characteristics of beam ends and the middle parts of the beam, the end H shape steel and steel-reinforced steel reinforcement cages at different parts are arranged to fully reinforce joints and improve bearing capability, and materials are saved and cost is reduced on the premise that structure safety is guaranteed.

Owner:HUBEI HONGYI BUILDING DECORATION ENG

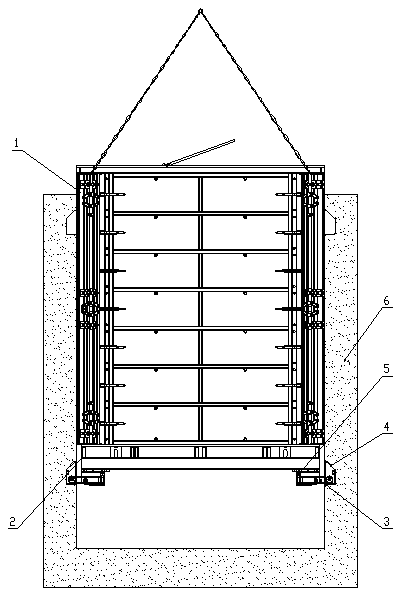

Segmented self-traveling type cast-in-place beam hydraulic inner mould and mould erecting and demoulding method thereof

InactiveCN105442454AImprove stabilityImprove economyBridge erection/assemblyPetroleum engineeringBeam length

The invention discloses a segmented self-traveling type cast-in-place beam hydraulic inner mould and a mould erecting and demoulding method thereof. A mould moving device (2) is composed of a mould moving trolley (22), a guide column device (21), lateral oil cylinders (231), an ejecting oil cylinder (232), a hydraulic system (23) and an electrical system (24). The mould moving device (2) is movably connected with segmented formworks (1) through the guide column device (21). The mould moving trolley (22) is arranged on rails (3), and a formwork set is divided into the segmented formworks (1) in the beam length direction. Each segmented formwork (1) is composed of a top plate (11), upper movable formworks (12) and lower movable formworks (13), wherein the left end and the right end of the top plate (11) are symmetrically provided with the upper movable formworks (12) in a hinged mode, and the other ends of the upper movable formworks (12) are hinged to one ends of the lower movable formworks (13). The lateral oil cylinders (231) are connected between the upper movable formworks (12) and the mould moving device (2). Chain hoists (14) can be connected between the upper movable formworks (12) and the lower movable formworks (13). The ejecting oil cylinder (232) is installed between the guide column device (21) and the mould moving trolley (22). The mould is safe, efficient, good in overall stability and good in economic efficiency.

Owner:湖南五新智能科技股份有限公司

Electrical connector having an electrical contact with a plurality of contact beams

ActiveUS9054470B2Coupling device connectionsClamped/spring connectionsEngineeringElectrical connector

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com