Cargo handling pallet

a technology for handling pallets and cargo, applied in the field of pallets, can solve the problems of high weight and high cost of resin pallets, difficult distribution, and remarkably broken wooden pallets, and achieve the effects of safe and economically useful use, high strength, and convenient manufacturing and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

(Embodiment 1)

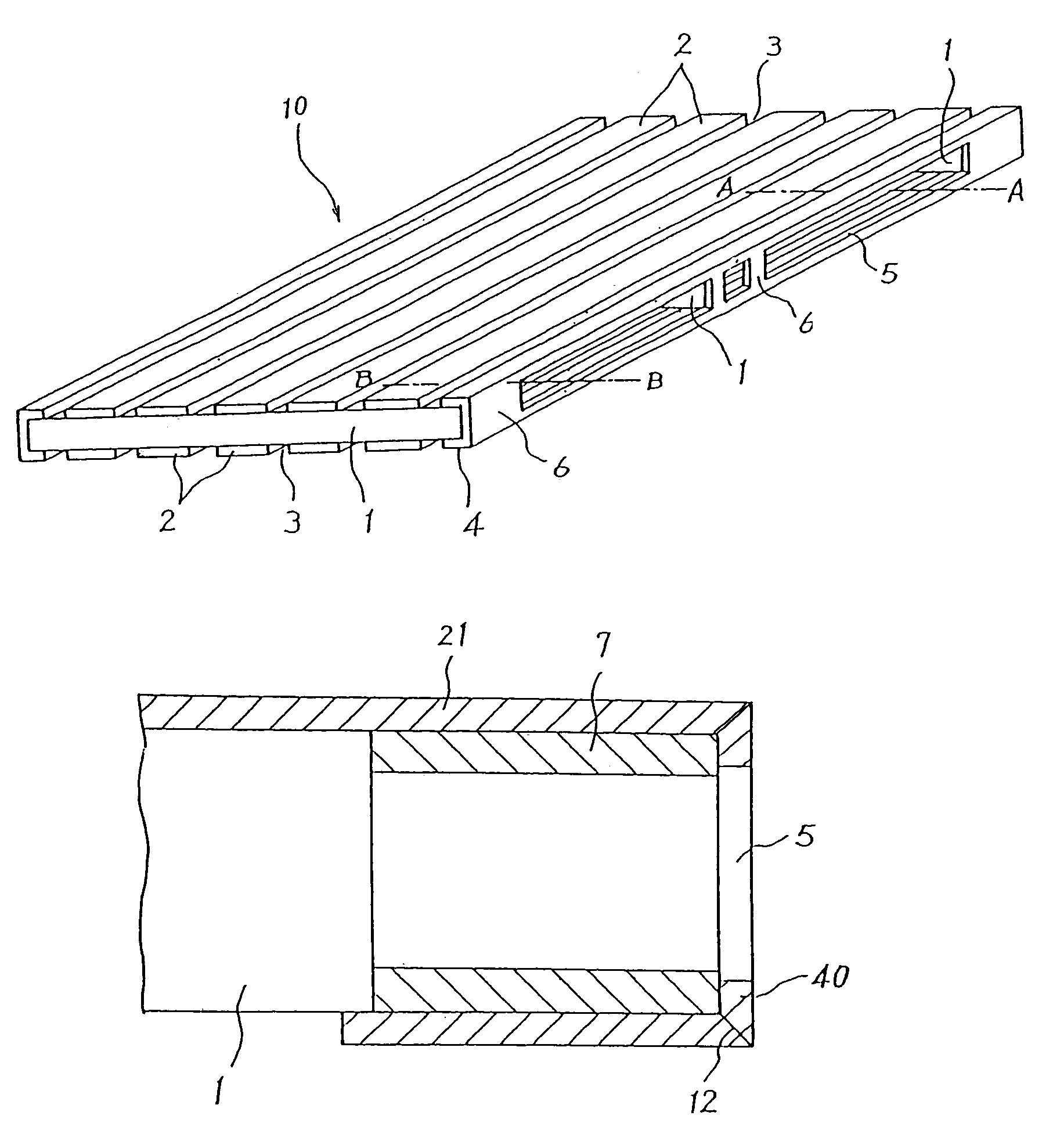

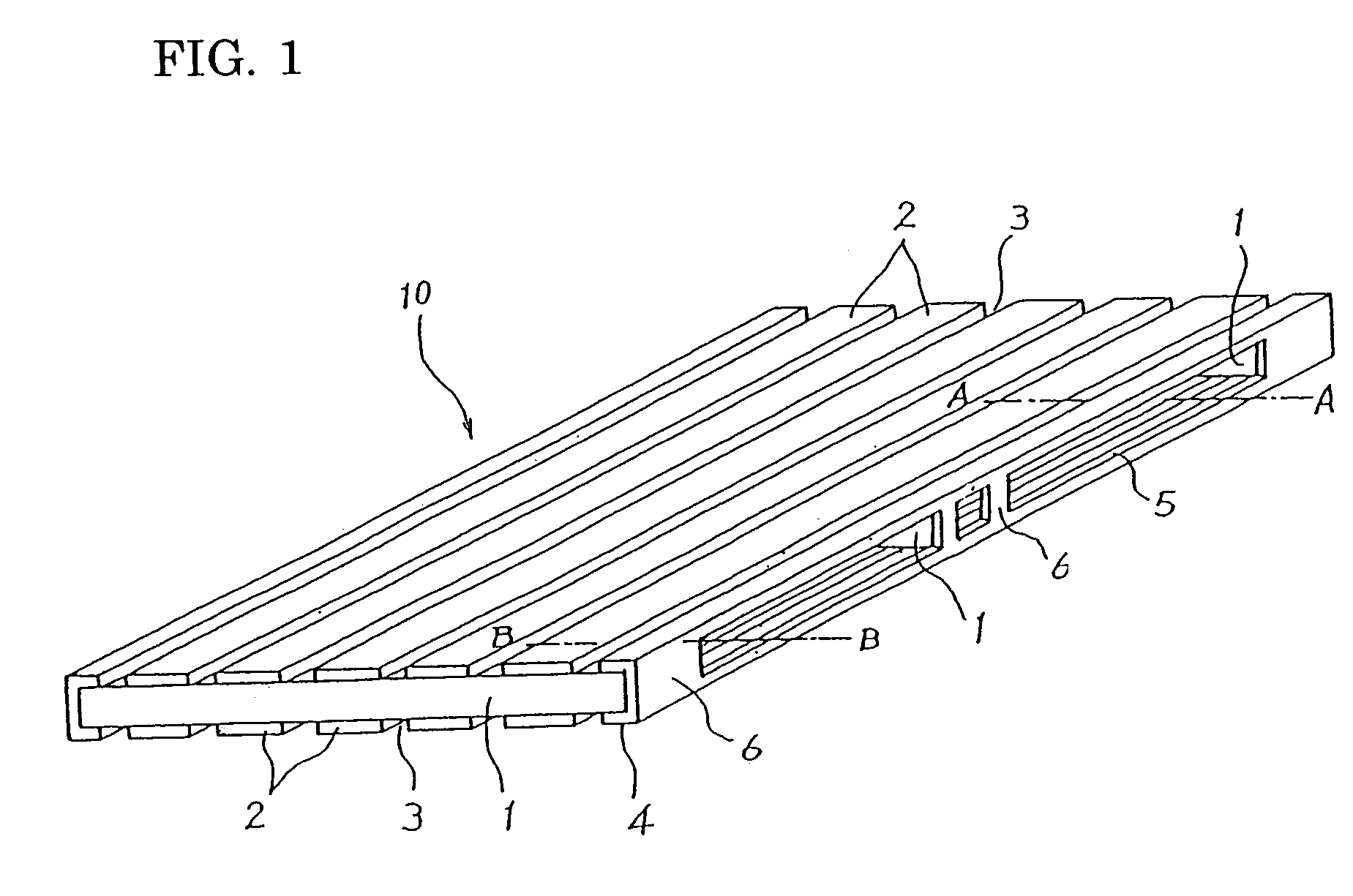

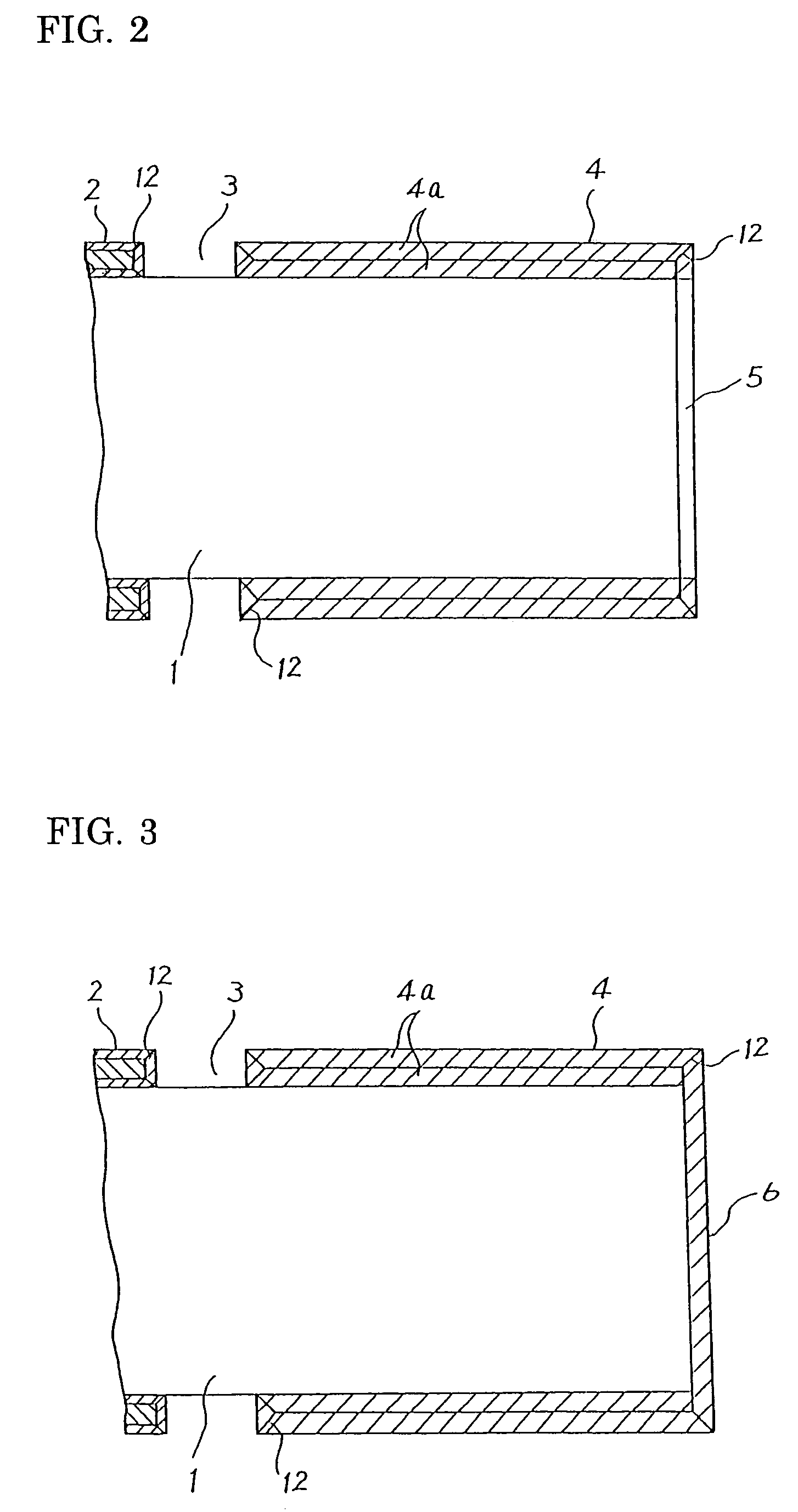

[0037]In FIG. 1, a reference numeral 10 designates a cargo handling (loading and unloading) pallet having the form of drainboard constructed in accordance with the invention. A reference numeral 4 designates a pair of individual elongated channel type bended edge members formed of paperboard faced to each other. As shown in FIGS. 2 and 3, upper and lower sides of the bended edge members comprise two layers 4a formed by bending paperboard materials of predetermined thickness along a V-cut groove 12 and superposing one upon another so as to have strength and rigidity and being surface-treated by coating for imparting water resistance and water repellent property to the layers 4a. The bended edge members 4 have a pair of right and left fork insertion openings 5 provided in their vertical wall face 6 thereof The portions where the fork insertion openings 5 are provided can have the strength and the rigidity against raising up by forks, maintained by means of the upper and ...

embodiment 2

(Embodiment 2)

[0046]The Embodiment 1 relates to the cargo loading and unloading pallet 10 is in the form of drainboard, but the Embodiment 2 relates to the cargo loading and unloading pallet having what is called flat boards (top flat board and lower flat board). In FIG. 13 a reference numeral 20 designates a cargo loading and unloading pallet having a top flat board provided and a reference numeral 21 designates the top flat board of paperboard material. The top flat board 21 has channel-shaped elongated bend portions 40 formed in a lateral direction and faced to each other in the two sides of the square paperboard material. A pair of fork insertion openings 5 are provided in the vertical walls 6 of the bend portions 40 of the top flat board 21. A reference numeral 1 designates beams of square hollow body of paperboard material, which is identical to that of the embodiment 1. These beams 1 are displaced at places where there are not located the pair of forks insertion openings 5 in...

embodiment 3

(Embodiment 3)

[0054]FIGS. 17 through 23 show Embodiment 3 of the invention. As shown in FIG. 22, the pallet 10 of Example 3 has the form similar to that of the pallet shown in FIG. 1, but the beams 1 may be characterized in that they are so adapted to have an improvement on the productivity, the pressure resistance, the strength of buckling resistance and the rigidity and to enable four way insertion of the fork of the forklift truck or the stacker in rightward or leftward directions in addition to the two way insertion thereof. The detailed construction thereof will be described hereinafter. Each of members described below is of paper board.

[0055]FIG. 17 shows an elongated square hollow body 60 to form square poles 60a and 60b of the beams 1a. The square hollow body 60 may be opened at both ends thereof.

[0056]FIG. 18 illustrates an example of producing a beam framework 65 shown in FIG. 19 at high productivity with the square hollow body 60 used. A plurality of square hollow bodies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com