Tubular beam support testing tool

A technology of pipe beams and inspection tools, which is applied to measuring devices, instruments, and mechanical devices, etc., can solve the problems of waste of manpower and material resources, increase of inspection procedures, and large accumulated errors, and achieve simple structure, convenient use, and improved product assembly. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

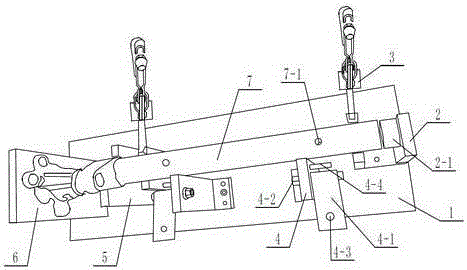

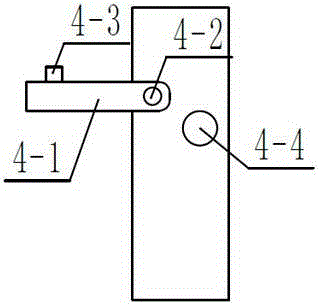

[0012] Depend on figure 1 , figure 2 Known, the present invention is a kind of pipe beam support check tool, by base 1, positioning detection seat 2, positioning detection block 2-1, fixed support 3, hole detection seat 4, flap structure 4-1, fixing bolt 4-2 , boss 4-3, limit column 4-4, cam detection seat 5, locking fixed seat 6, pipe beam support 7, the positioning detection seat 2 is installed on the rightmost end of the base 1, and the fixed support 3 is installed on the positioning The detection seat 2 is at the left end, the hole detection seat 4 is installed on the base 1 and is at the left end of the fixed support 3, the locking fixed seat 6 is installed at the leftmost end of the base 1, and the cam detection seat 4-3 is installed at the upper left of the base 1 And at the right end of the locking fixed seat 6, there are two hole detection seats 4, which are symmetrically distributed on the base 1 with the central position of the center line of the two installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com