Patents

Literature

70results about How to "Ensure product consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long-cycle and high-safety power lithium ion battery positive electrode material and preparation method thereof

InactiveCN105406056AUniform dispersion and depositionEvenly dispersedCell electrodesSecondary cellsElectrolytic agentElectrical battery

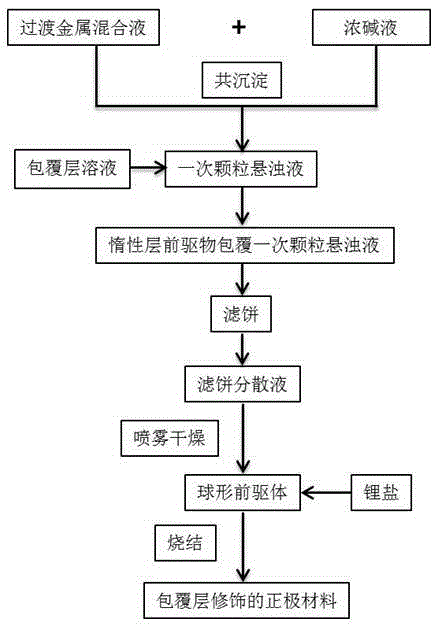

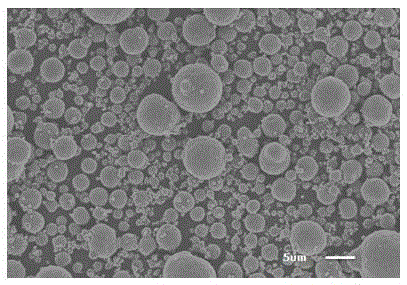

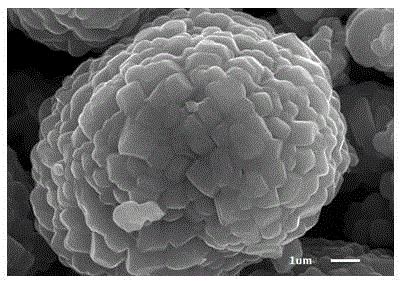

The invention discloses a long- cycle and high-safety power lithium ion battery positive electrode material and a preparation method thereof. The positive electrode material can be shown as a general formula LiNi<(1-a-b-c)>CoMnM<c>O2.xLiM<1>O<y>, wherein a is greater than 0 and less than 1, b is greater than 0 and less than 1, a+b+c is greater than 0 and less tan 1, x is greater than 0 and less than 0.1, and y is greater than 1 and less than 5; LiNi<(1-a-b-c)>CoMnM<c>O2 is a primary active crystalline particle of the positive electrode material, and is a lithiated composite oxide composed of nickel cobalt manganese and doping element M; and the LiM<1>O<y> is a coating layer coating crystal boundary of the primary active crystalline particle and surface of a polycrystalline secondary particle. The positive electrode material provided by the invention has high stability of crystalline main body, surface and crystal boundary, has good compatibility with electrolyte and is not liable to generate side reaction. The material provided by the invention is used for batteries, has long cycle life, high over-charging resisting capability, good high temperature and high voltage performance and high integral safety, and is particularly suitable for power batteries.

Owner:HUNAN SOUNDDON NEW ENERGY

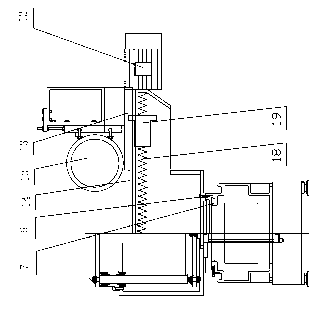

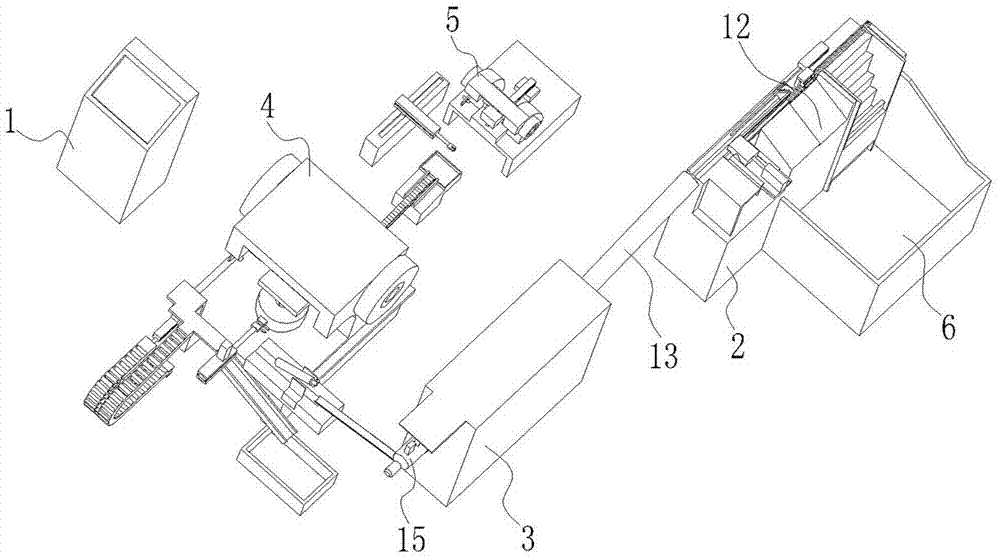

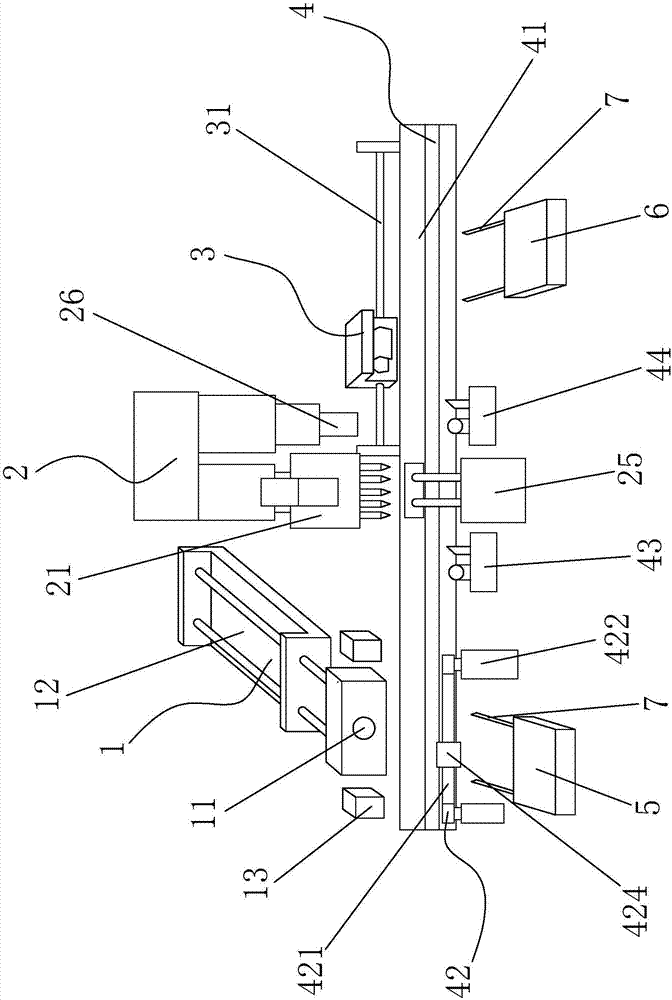

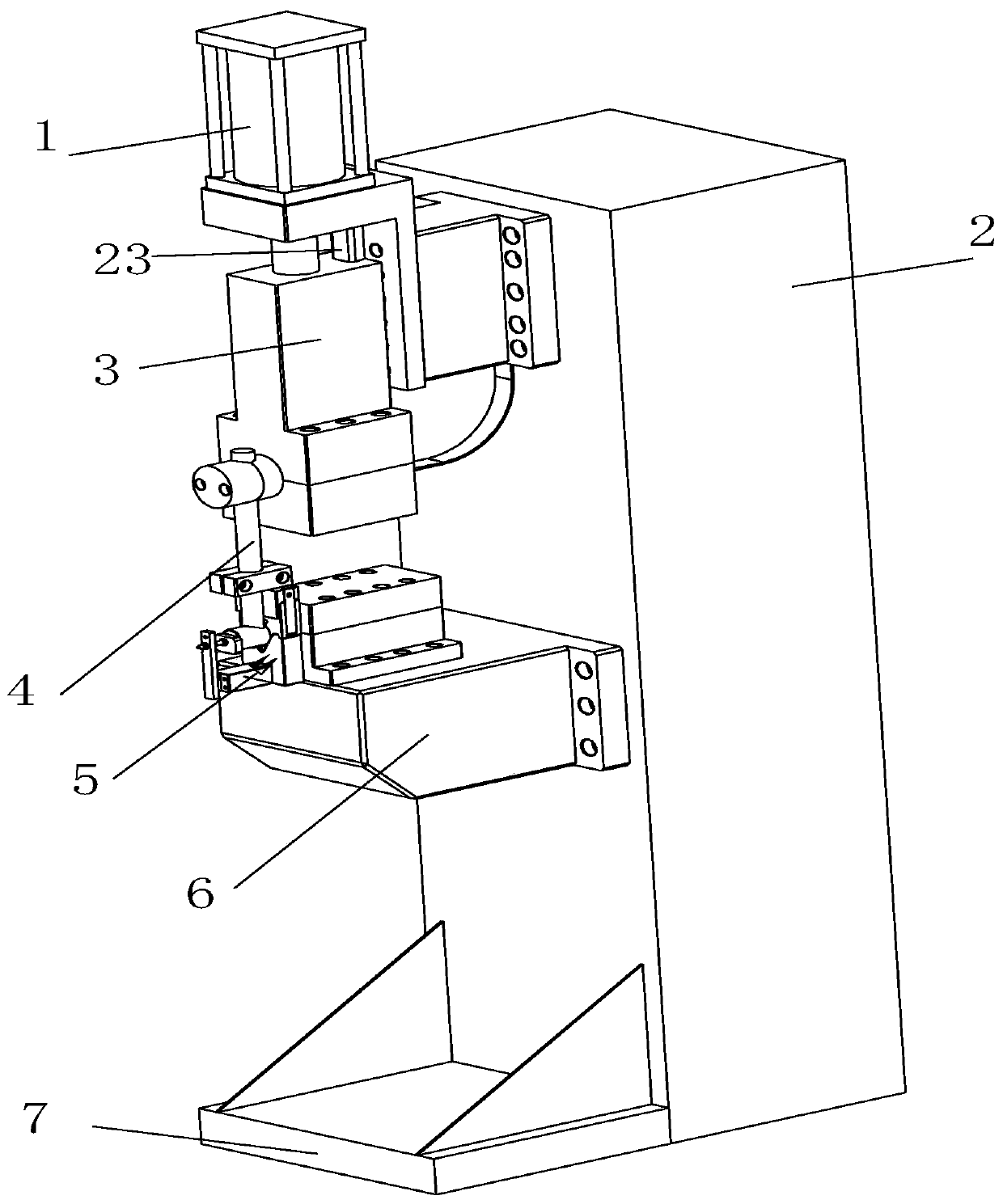

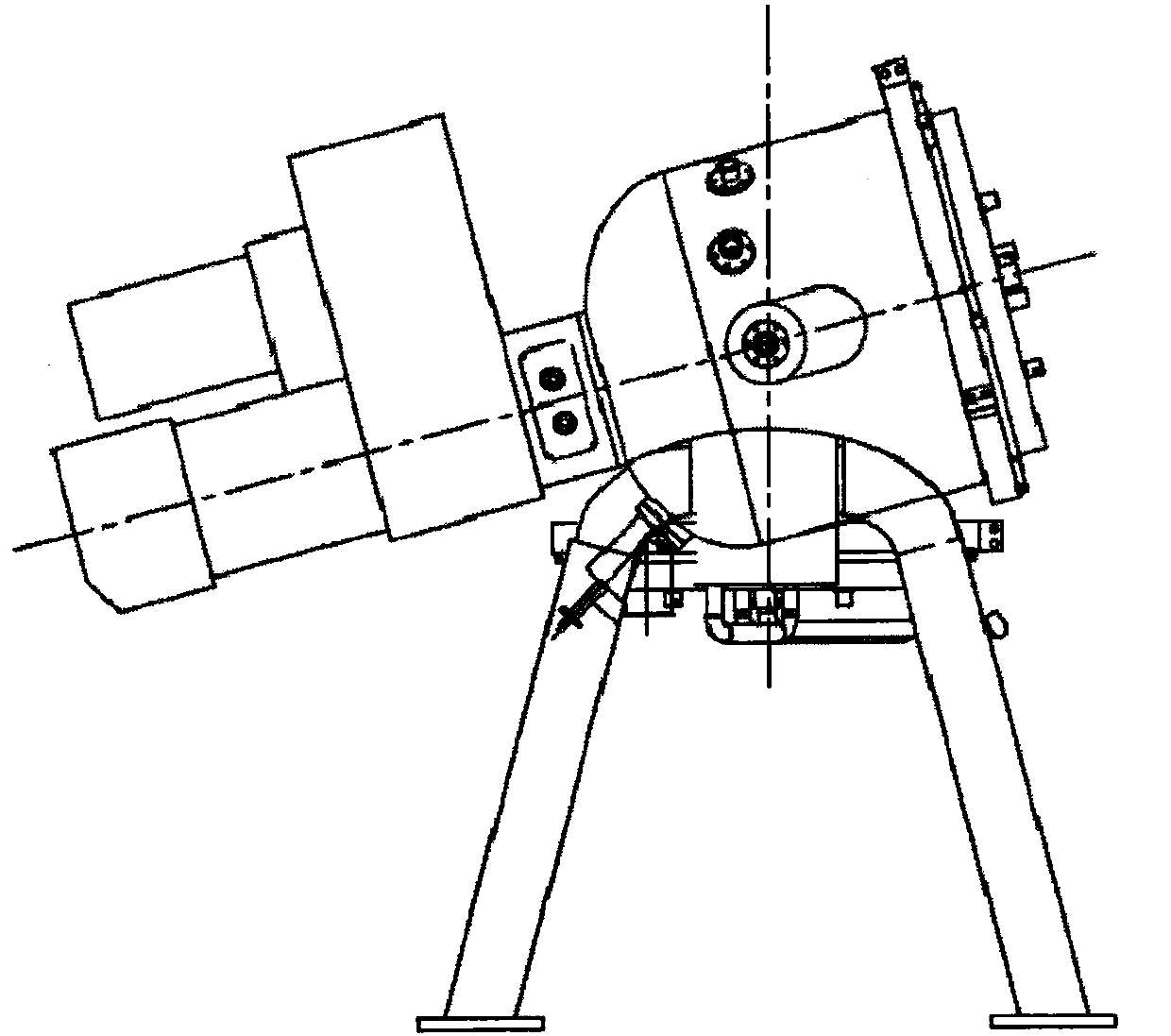

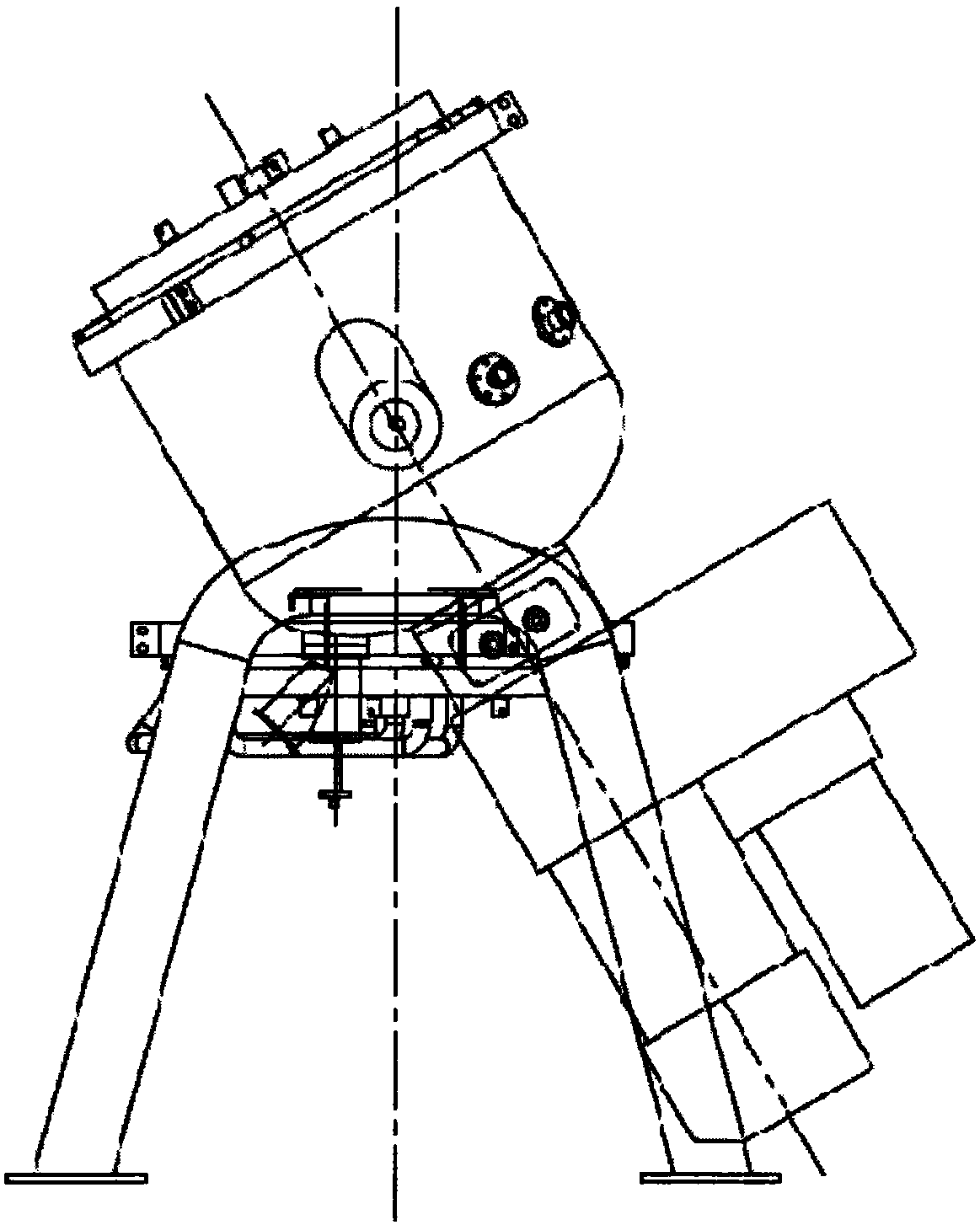

Dual-station cutting machine tool

InactiveCN102794784AGeneration of controlIncrease productivityMetal working apparatusElectrical controlElectric machinery

The invention discloses a dual-station cutting machine tool, relates to equipment for the end surface of a water blocking seal strip, and solves the problem that the water blocking seal strip of automotive glass needs to be clamped twice to finish one rubber strip at present. The dual-station cutting machine tool comprises a base, a machine body and an electric control cabinet, wherein a left box body is fixed on the left side of the machine body; a right box body is arranged on the right side of the machine body and fixed to a first sliding plate; the first sliding plate is movably fixed to a first guide rail of the machine body parallel to the machine body through a sliding groove; common clamping devices are fixed to the left box body and the right box body; cylinders are arranged below the common clamping devices; power heads are fixed to the upper parts of the left box body and the right box body respectively; a cutting tool bit is fixed at one end of each power head through a shaft; a motor is mounted at the other end of each power head; the cutting tool bit is driven by the motor and can rotate up and down around the shaft; and the common clamping devices on the left side and the right side and the cutting tool bits are opposite to each other respectively. According to the dual-station cutting machine tool, the two ends of the rubber strip can be processed at the same time, multiple rubber strips can be clamped, the production efficiency is high, the conformity of production is guaranteed and the unqualified products are avoided.

Owner:山东水星博惠汽车部件股份有限公司

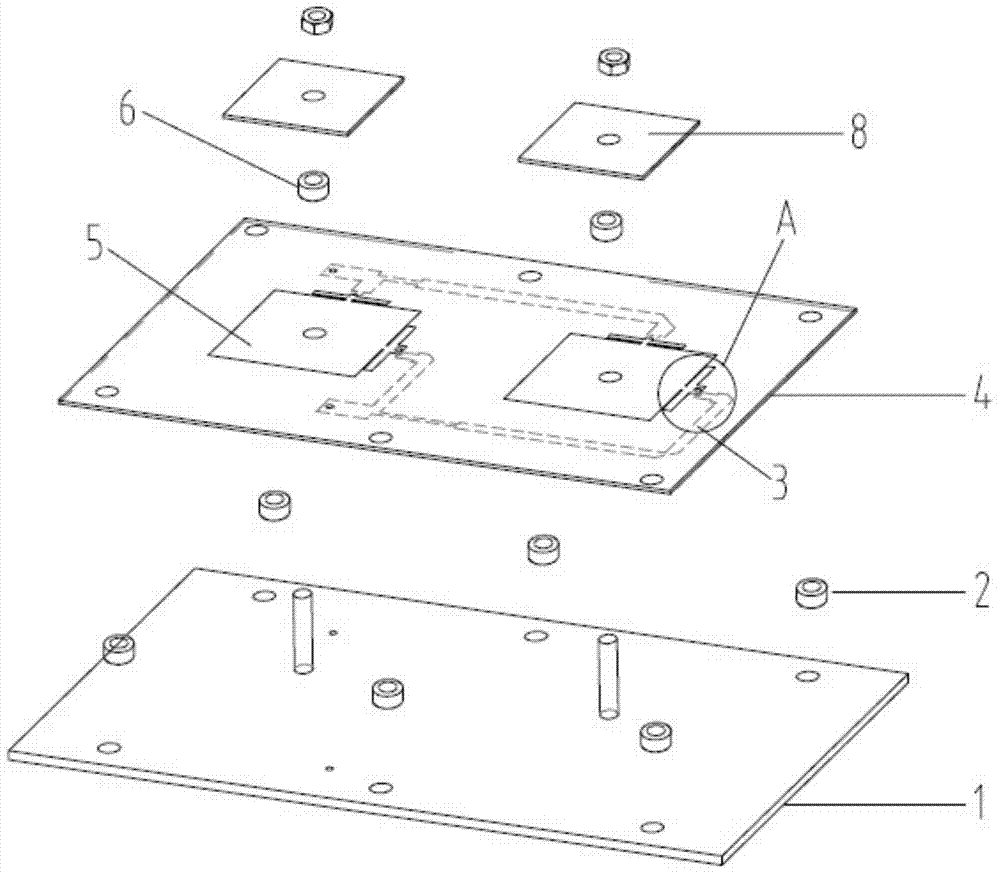

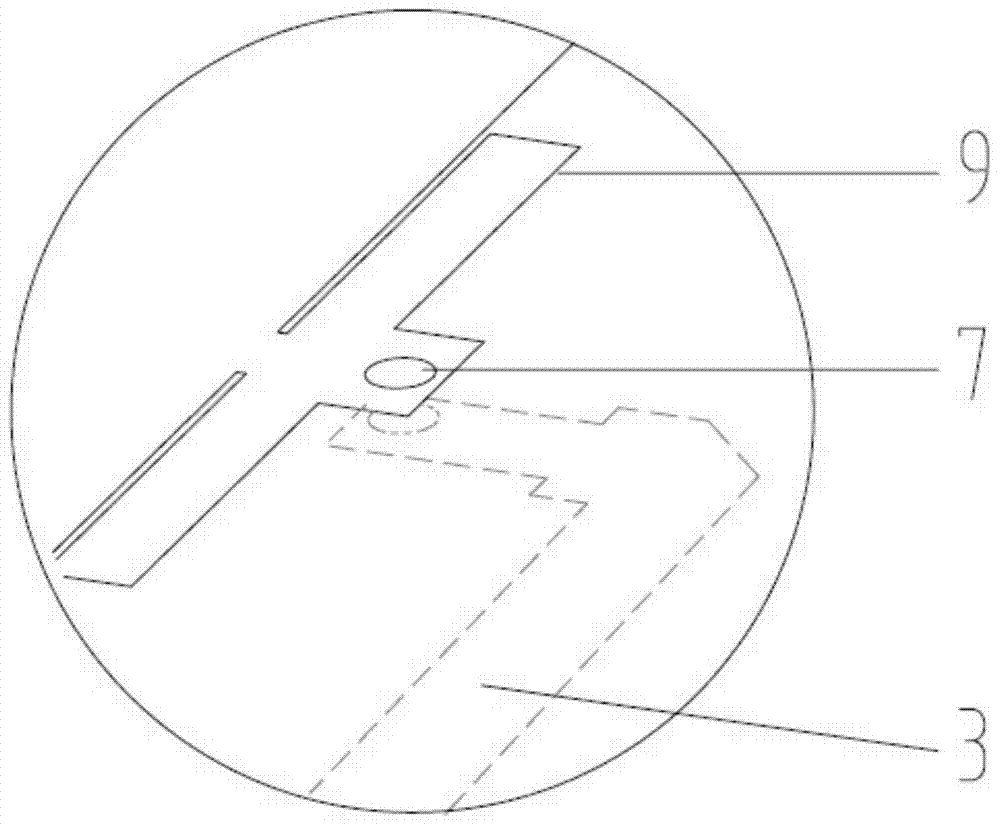

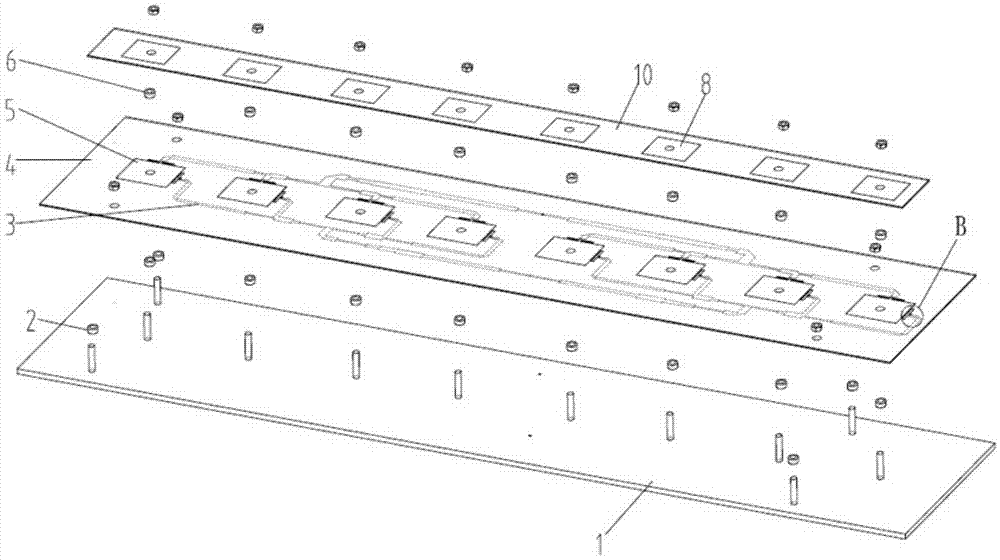

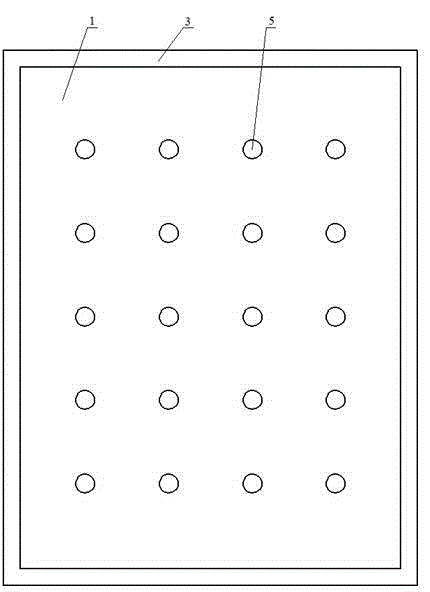

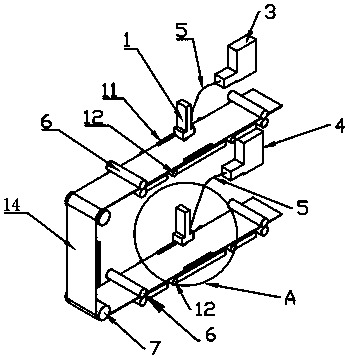

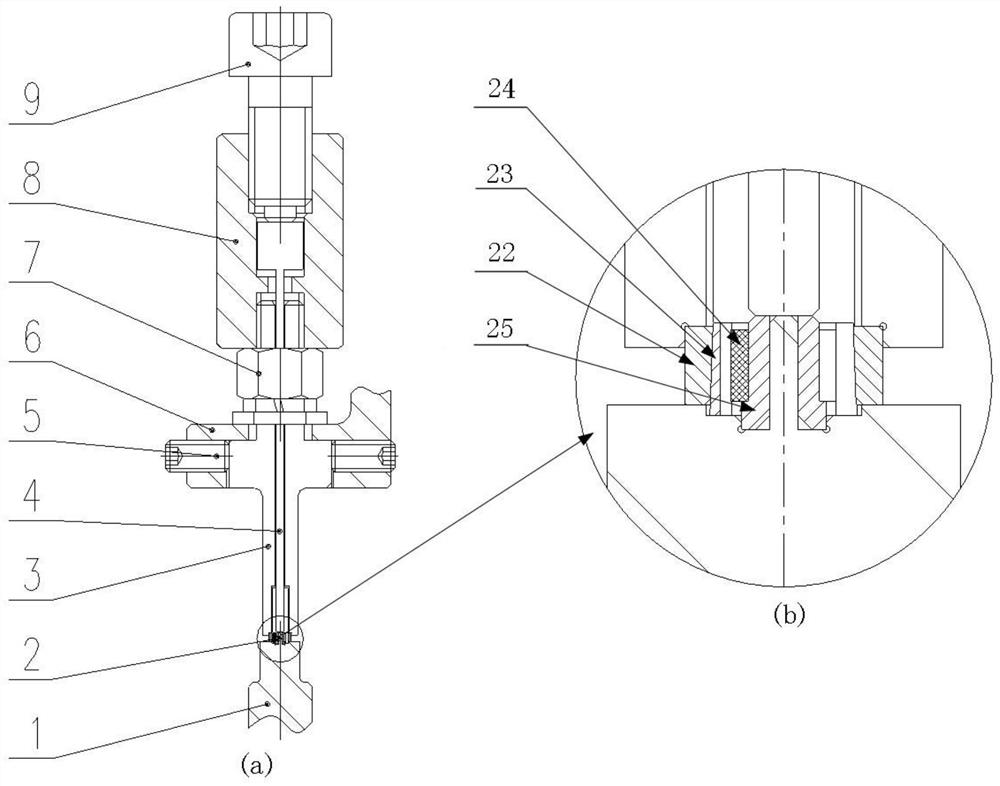

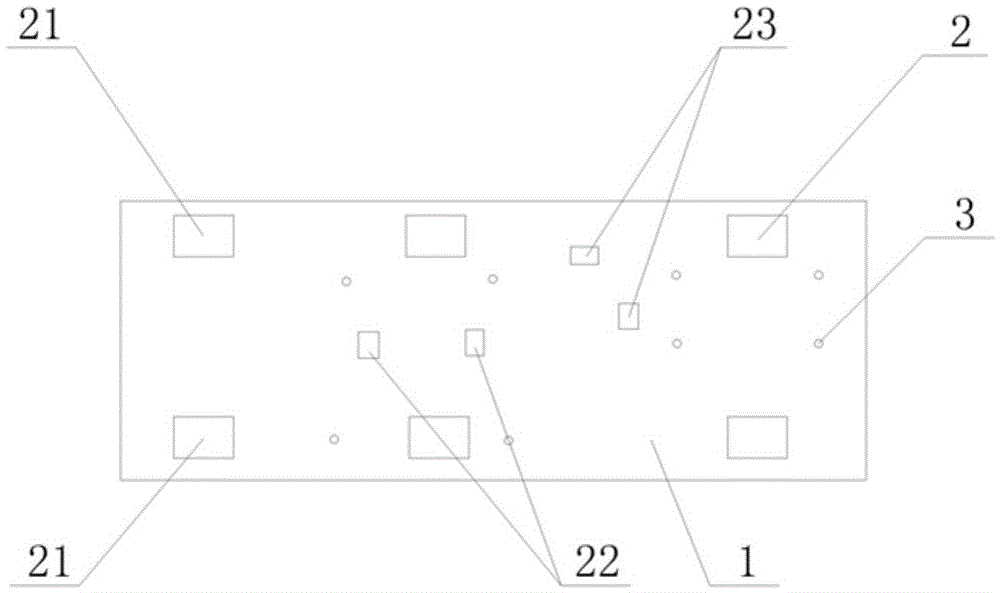

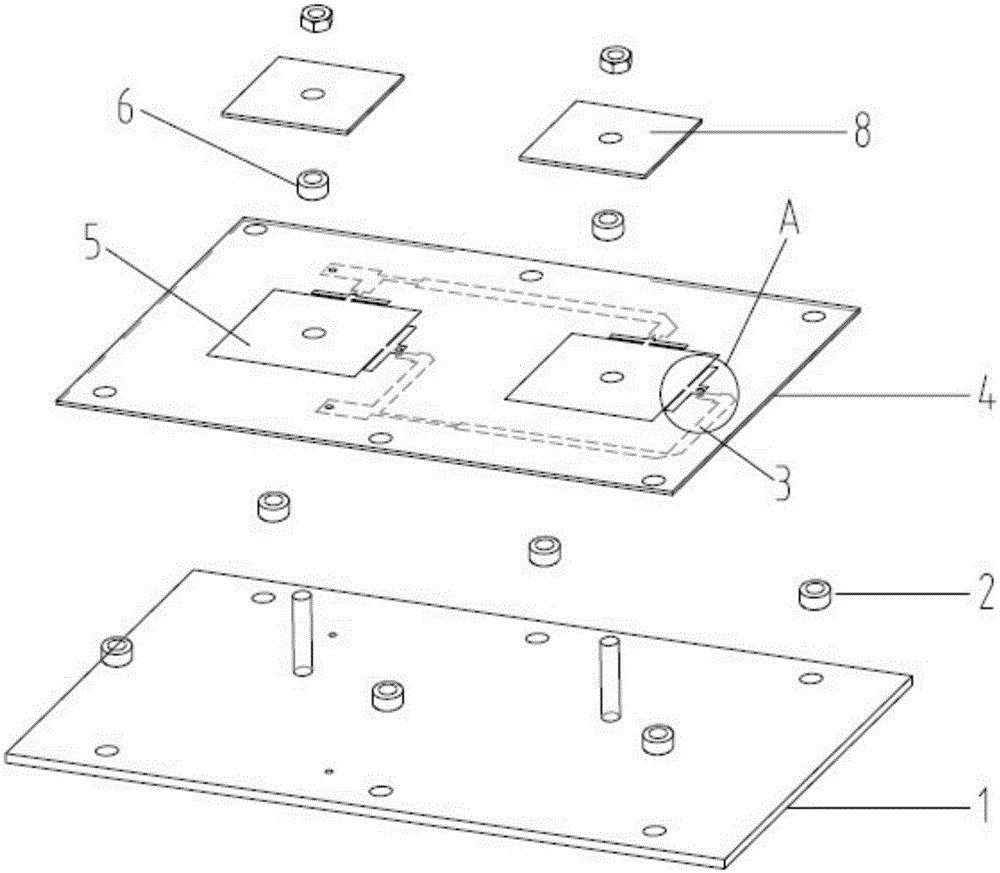

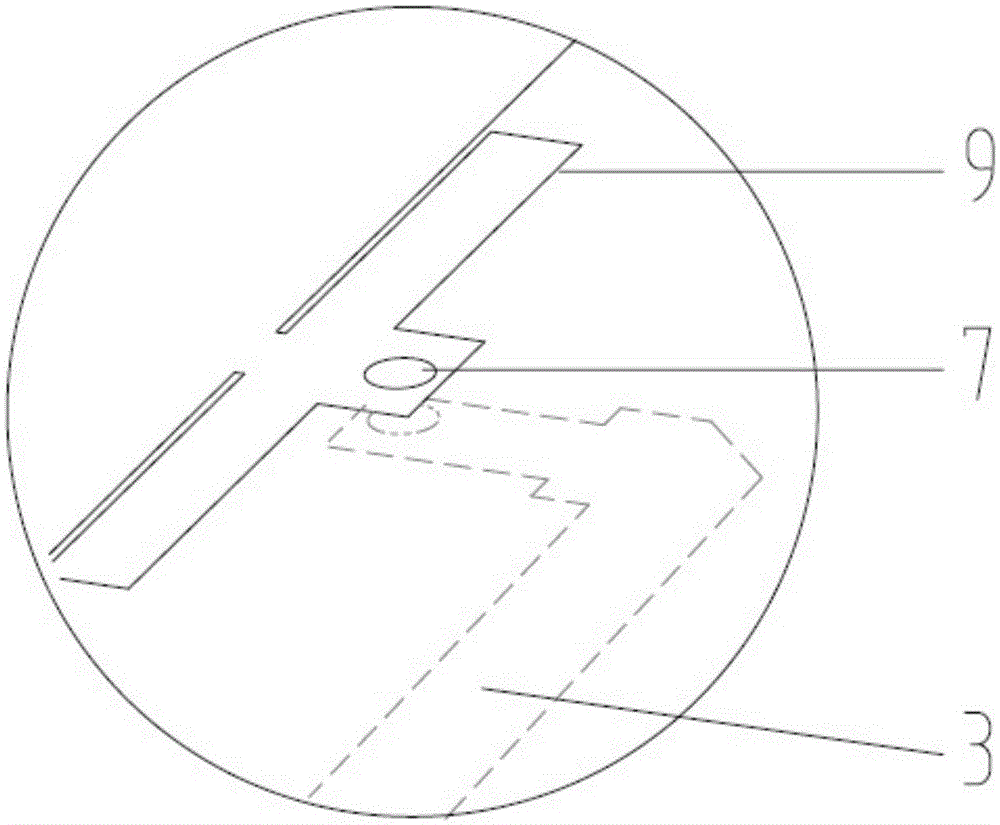

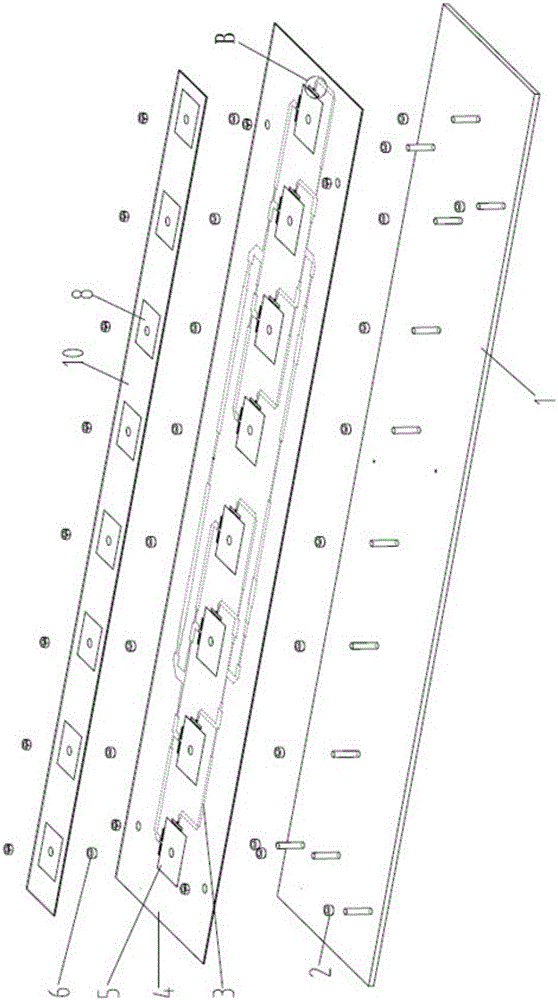

Array antenna

InactiveCN103490143AGuaranteed high gainEnsure product consistencyAntenna arraysAntenna supports/mountingsElectrical and Electronics engineering

The invention discloses an array antenna which comprises a bottom plate, a printed circuit and a printed circuit base board. The printed circuit base board is arranged on the bottom plate through a supporting column, an air layer is formed between the printed circuit base board of the bottom plate, the printed circuit is arranged on the lower surface of the printed circuit base board, the printed circuit is arranged above the air layer and under the printed circuit base board, a printing radiating unit is positioned on the upper surface of the printed circuit base board, and the printing radiating unit is electrically connected with the printed circuit. The array antenna is low in cost, high in gain and good in production conformity.

Owner:FOSHAN LANBOWANJIN TECH CO LTD

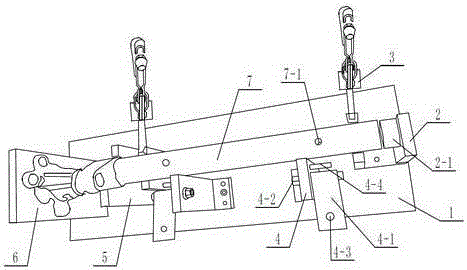

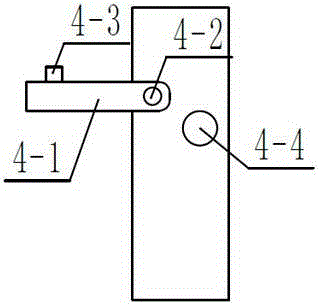

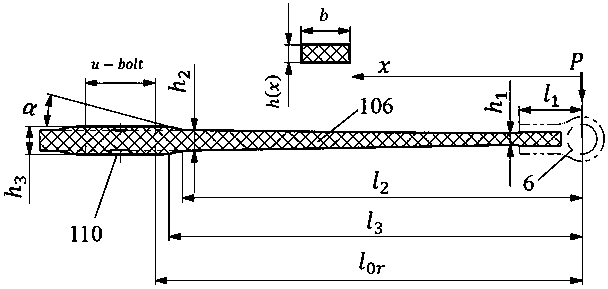

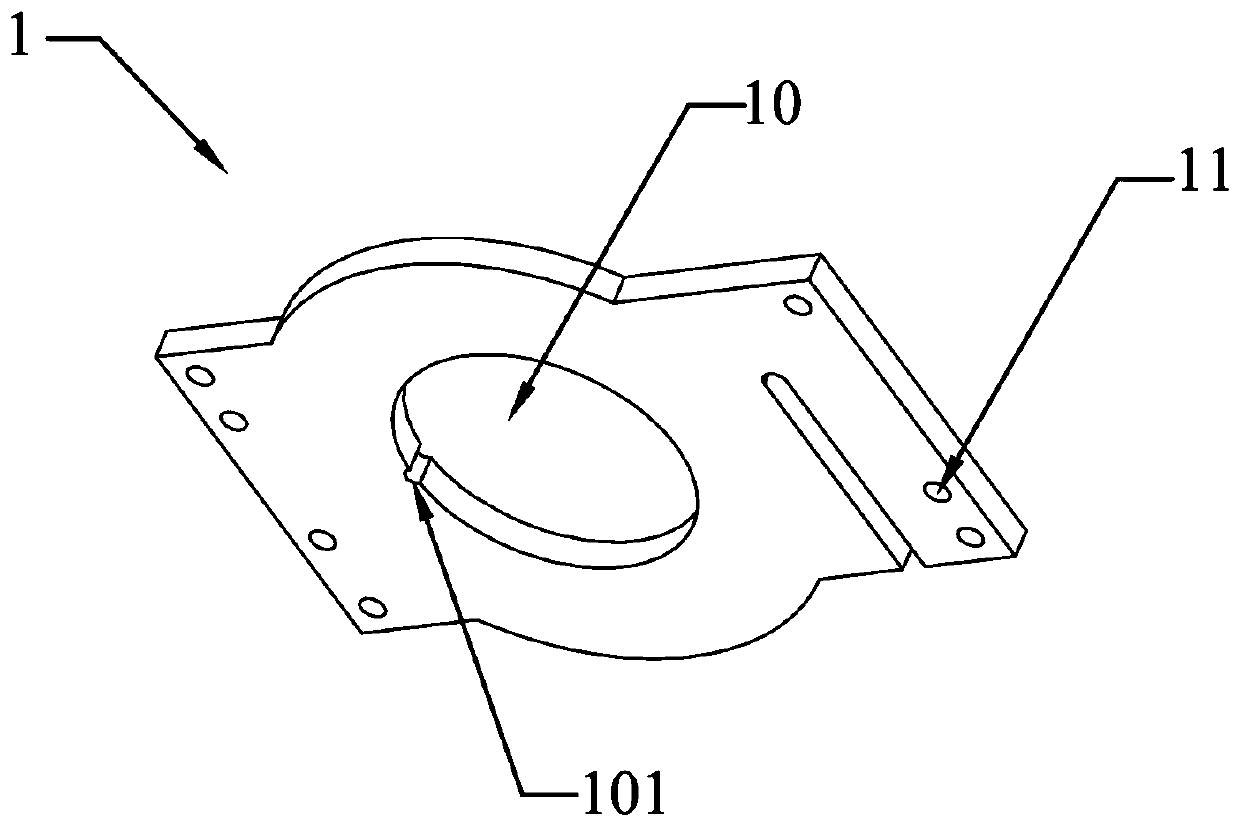

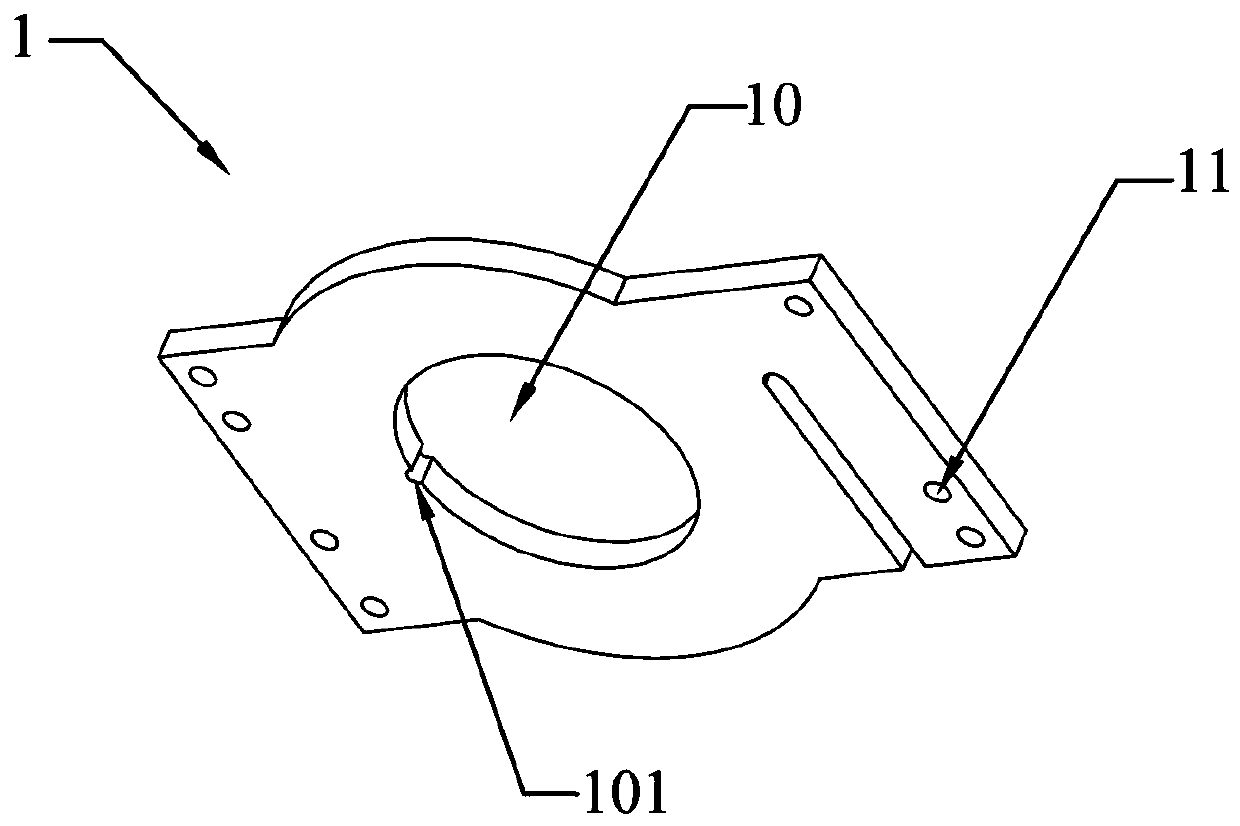

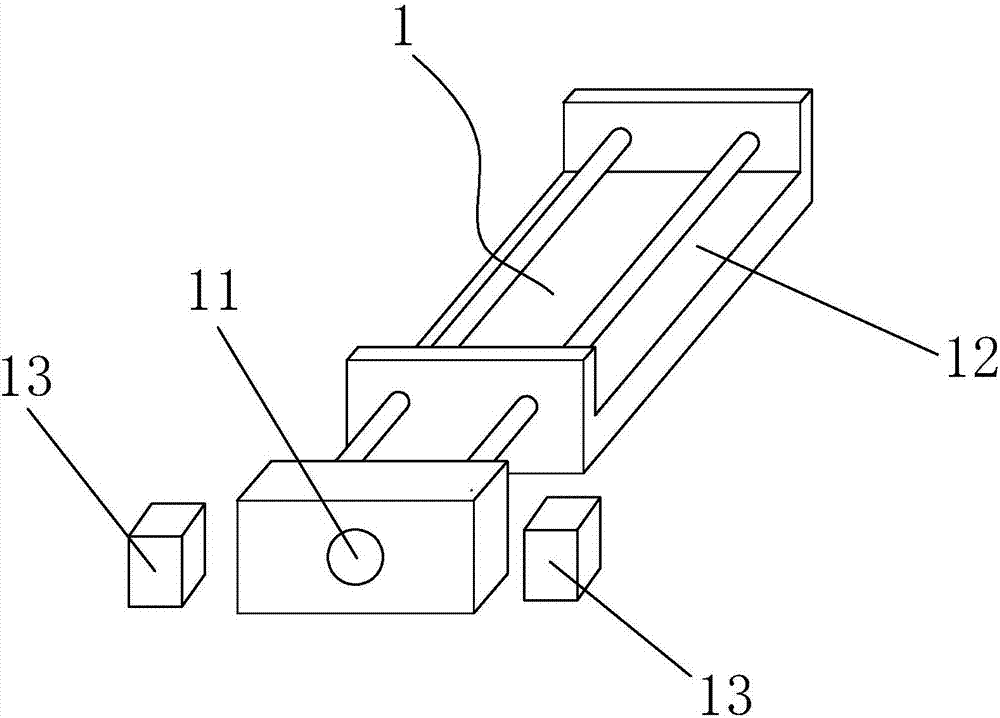

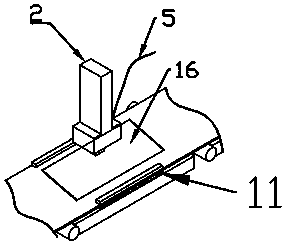

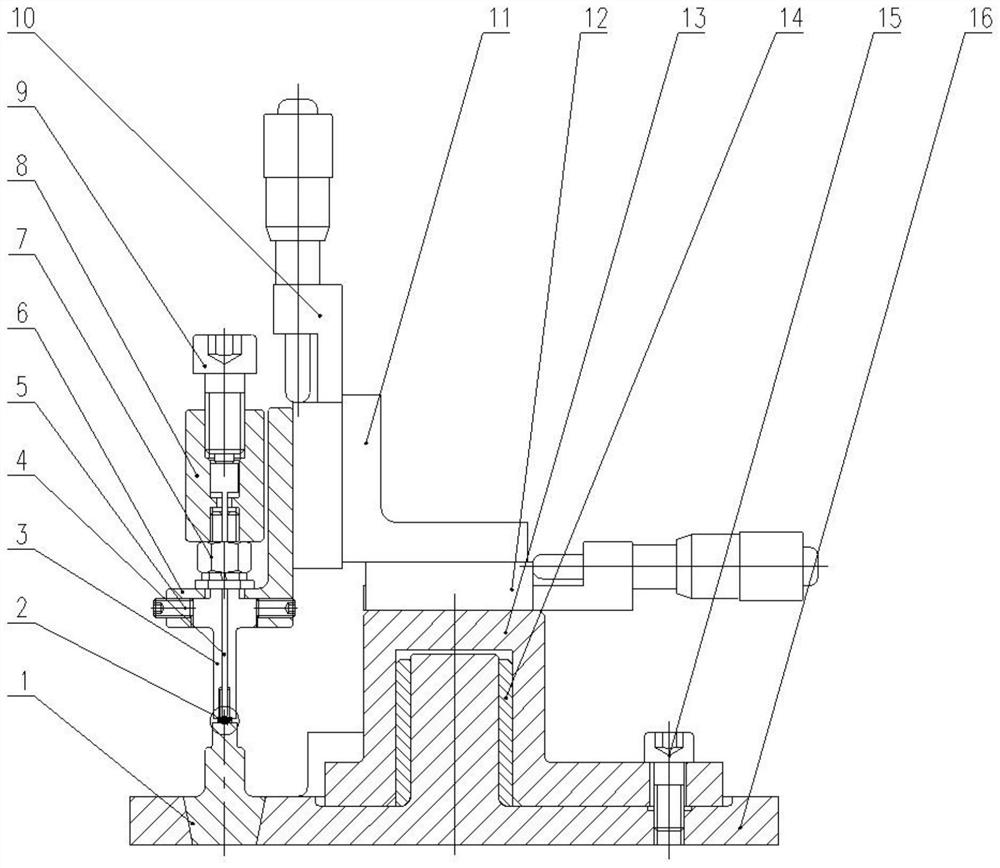

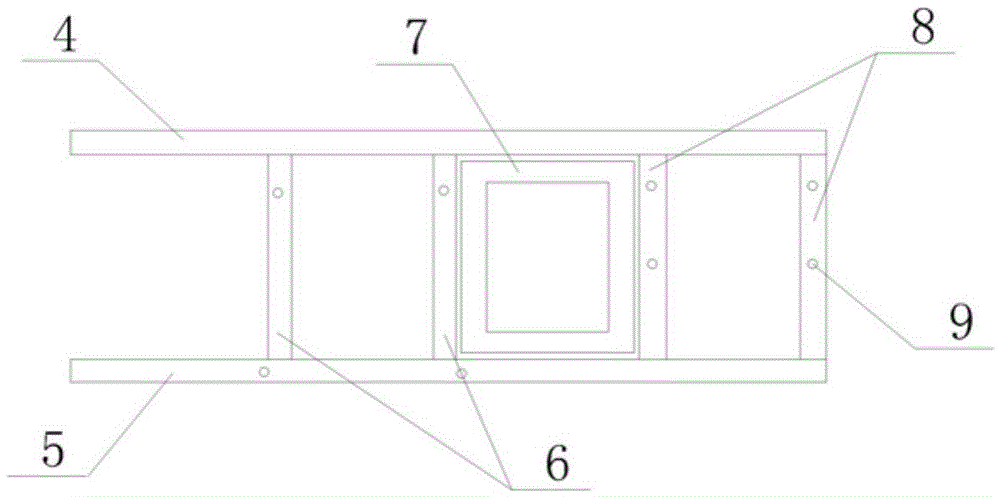

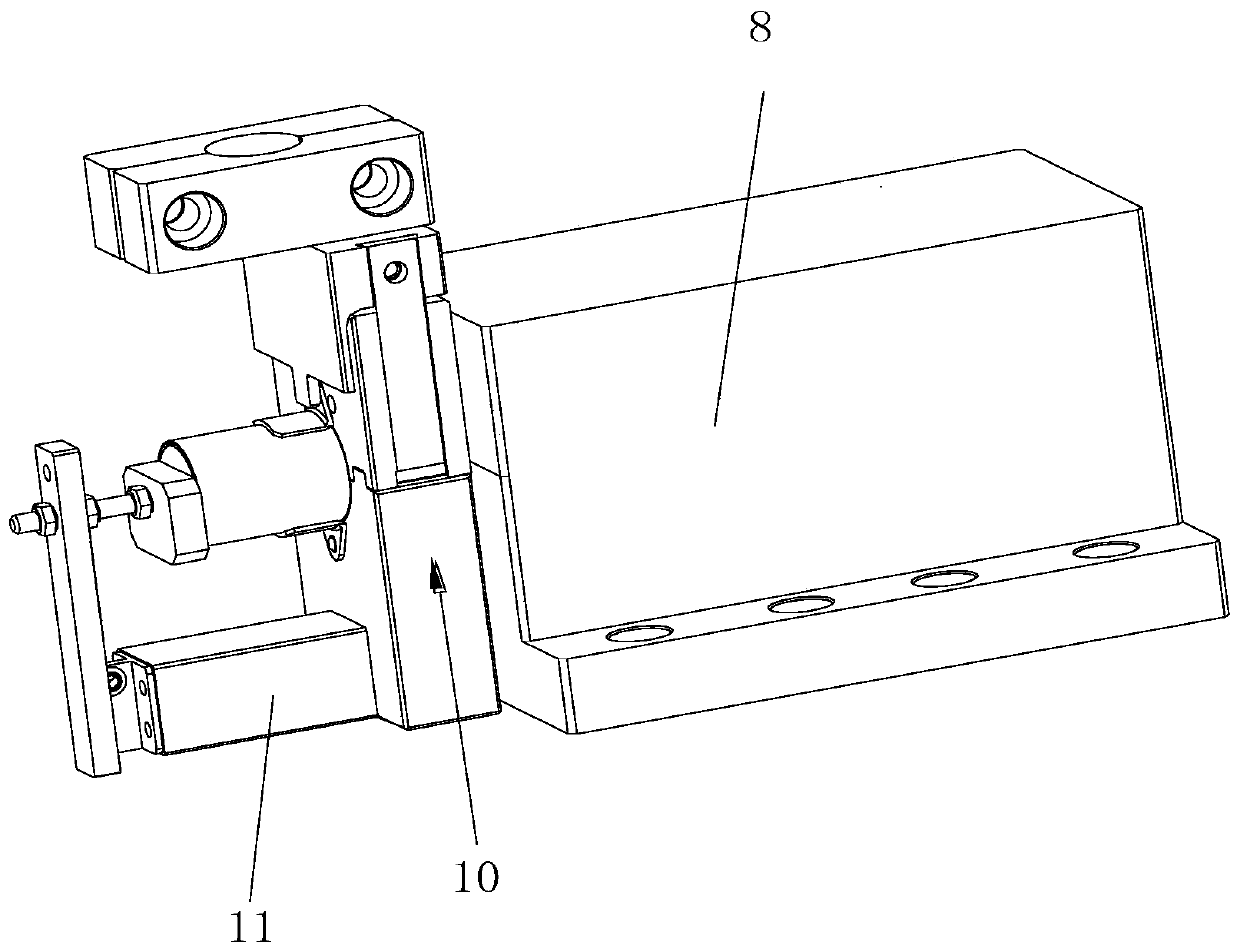

Tubular beam support testing tool

InactiveCN105180743ARapid Measurement EvaluationSimple structureMechanical measuring arrangementsEngineeringCam

A tubular beam support testing tool is composed of a base (1), a positioning testing base (2), fixing support bases (3), a hole testing base (4), a cam testing base (5), a latching fixing base (6) and a tubular beam support (7). Firstly the tubular beam support (7) is placed on the testing tool at a corresponding position, and then the right end of the tubular beam support (7) is fixed on the latching fixing base (6). Then a clamp of the fixing support base (3) on the left end is pressed down, then the fixing support base (3) on the right end is pressed down, a turnover plate structure (4-1) is turned over and presses a boss (4-3) into an installation hole (7-1) of the tubular beam support (7), and finally a plug gauge is used to test if the gap between the right end of the tubular beam support (7) and a positioning testing block (2-1) is within a predetermined range. The testing tool is simple in structure and convenient for use, can quickly measure and assess the positioning installation hole size of the tubular beam support, tubular beam length and other sizes, ensures consistency of product manufacturing, and improves product assembly efficiency.

Owner:JIANGSU KEXIN AUTOMOBILE DECORATION PARTS

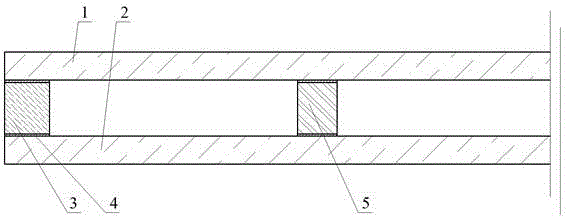

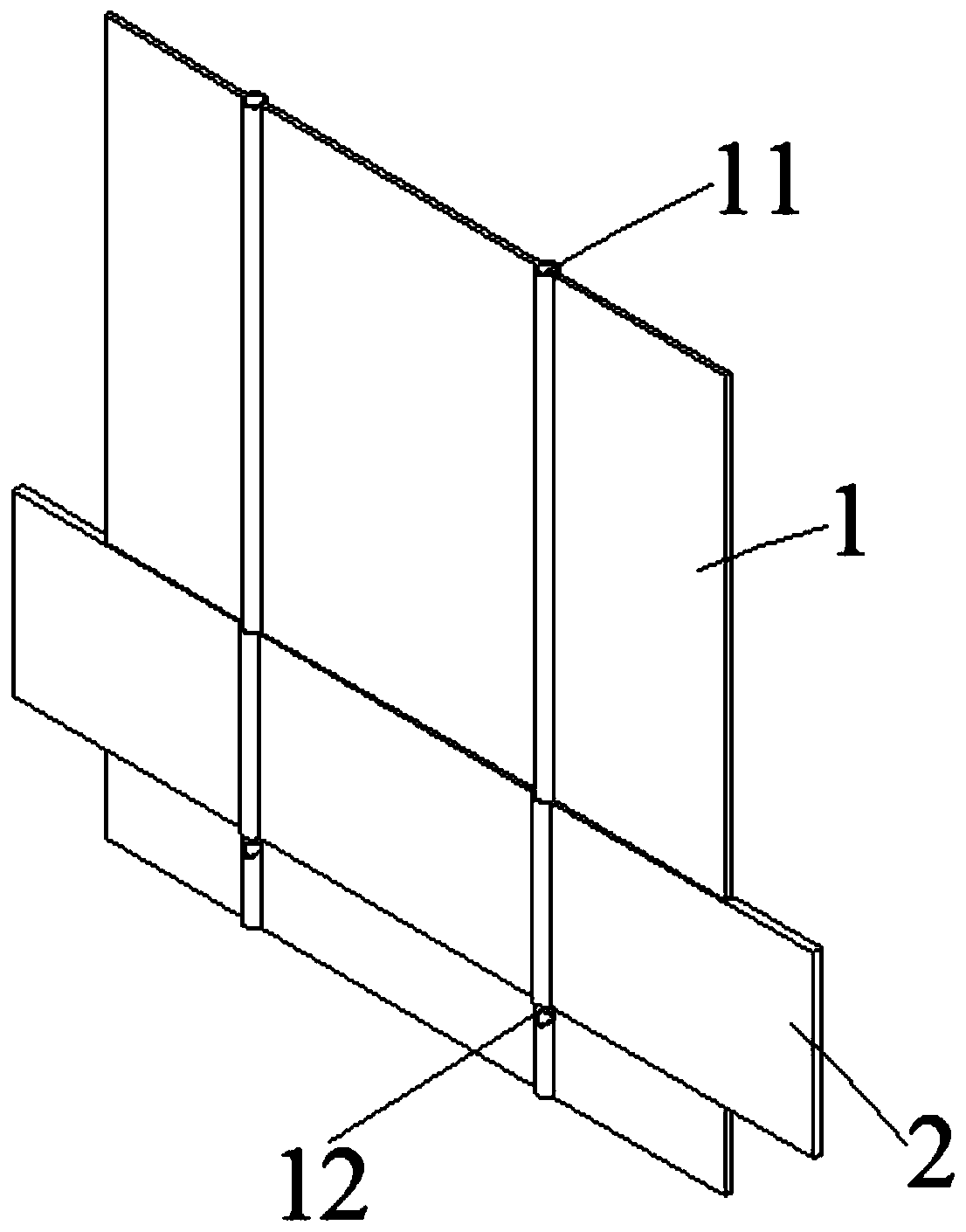

Negative pressure hollow glass and preparation method thereof

The invention discloses a piece of negative pressure hollow glass which comprises a piece of upper glass, a piece of lower glass and a frame, wherein the peripheries of the upper glass and the lower glass are sealed and connected together through the frame and an ultraviolet curing adhesive inside a vacuum side sealing furnace; a sealed negative pressure hollow layer is formed between the upper glass and the lower glass. The preparation method of the negative pressure hollow glass is simple in process, the prepared negative pressure hollow glass and reinforced negative pressure hollow glass can overcome the defects of conventional hollow glass and negative pressure glass, the air-tightness and the service life of the negative pressure hollow glass can be effectively ensured, and mechanical, automatic and large-scale production can be achieved.

Owner:戴长虹

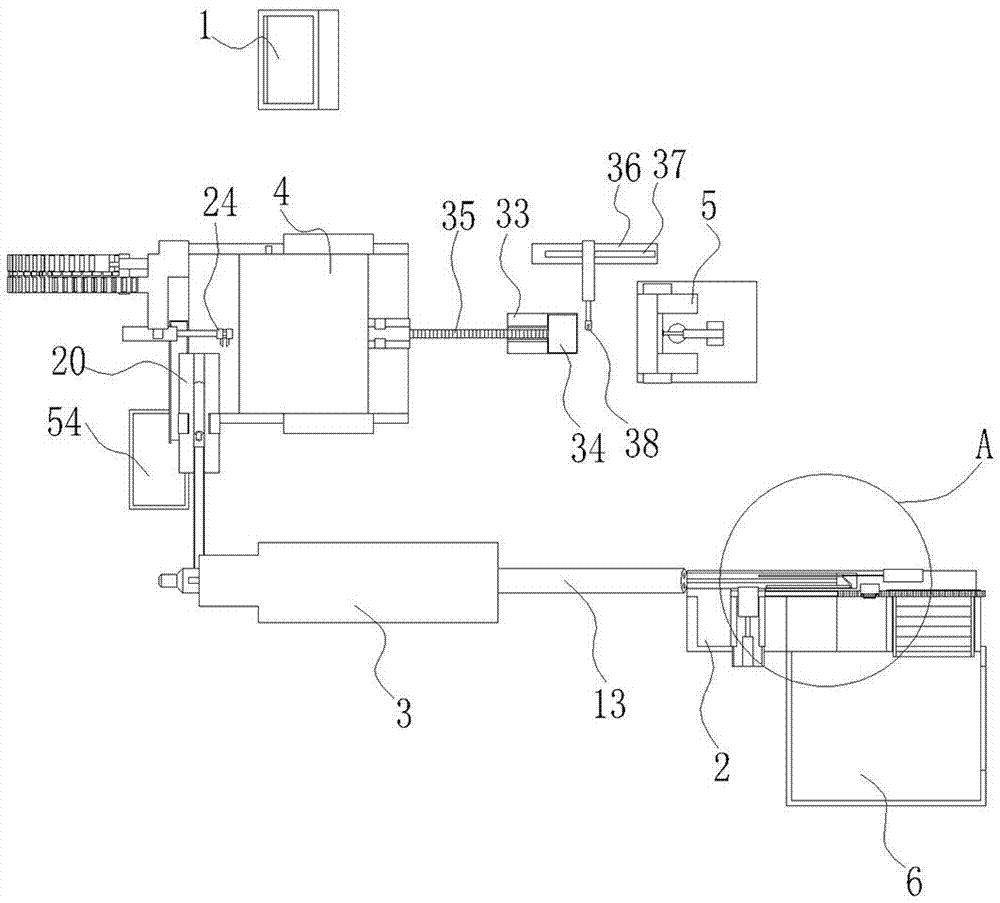

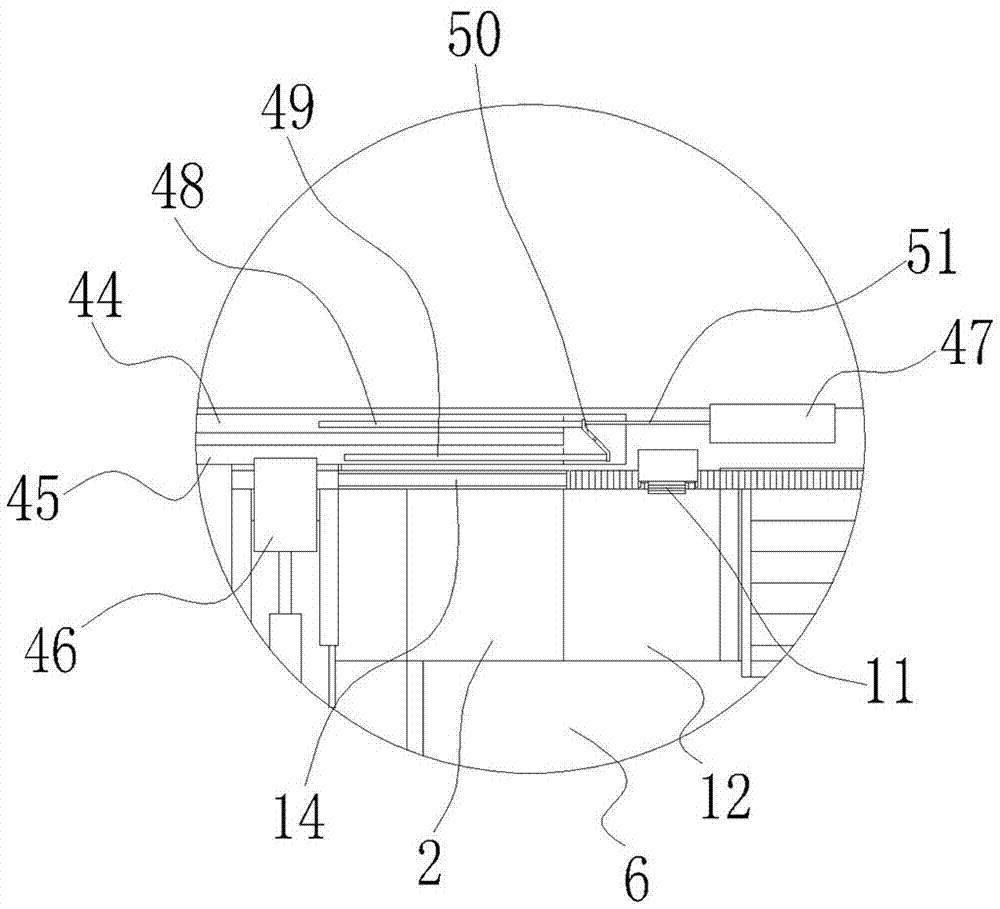

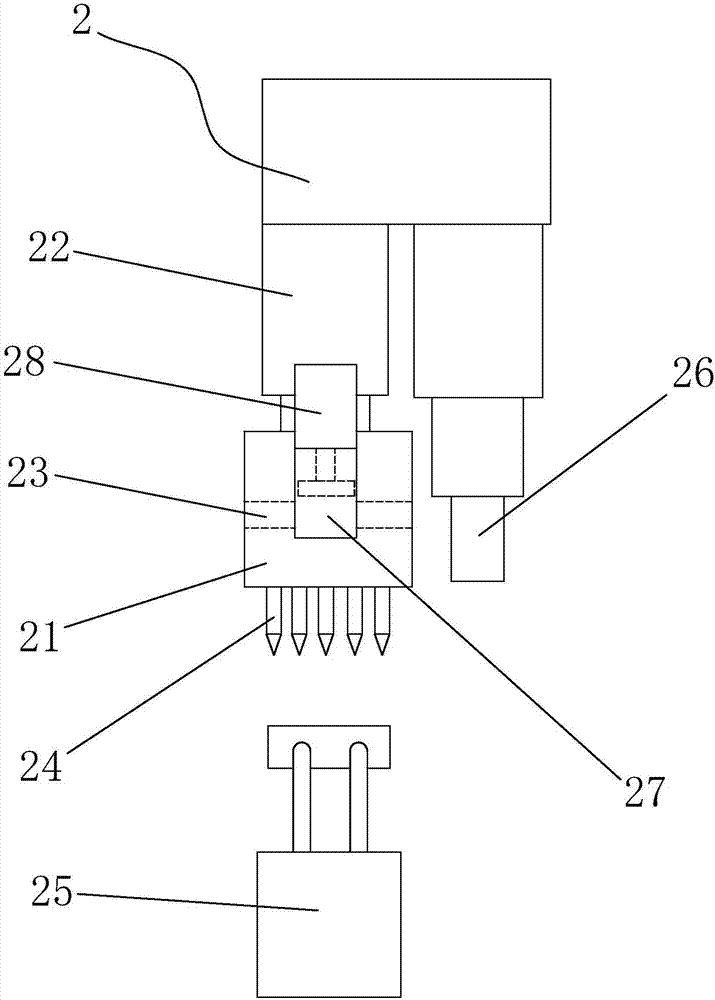

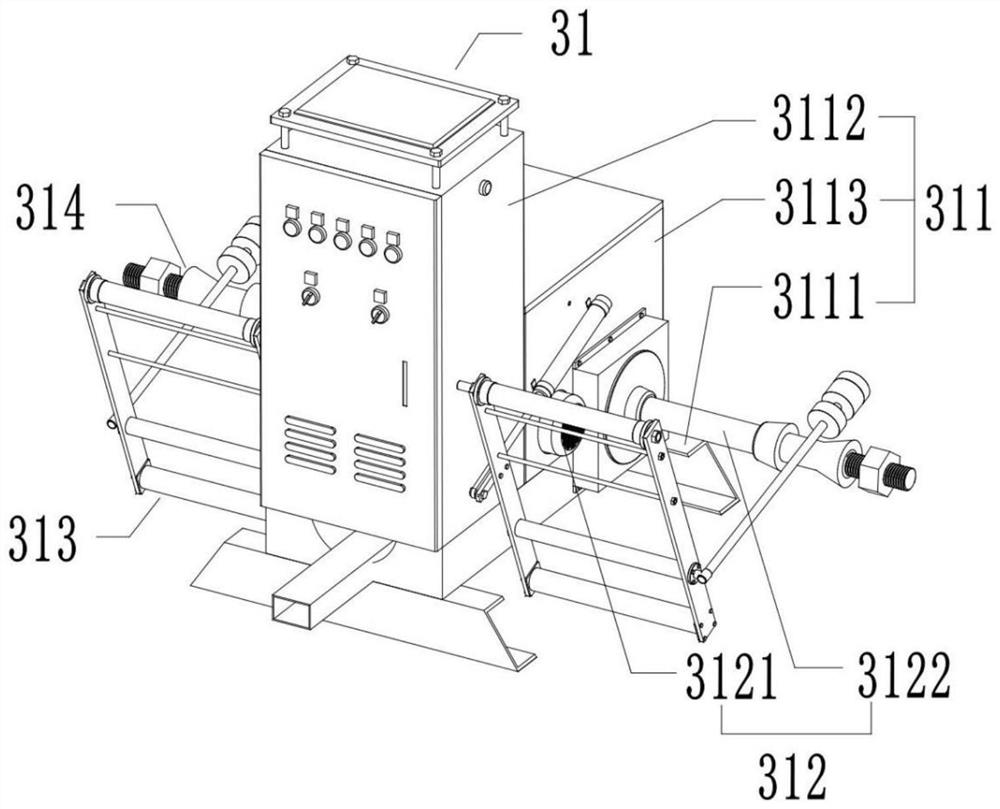

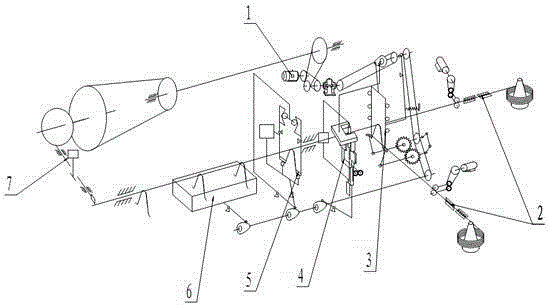

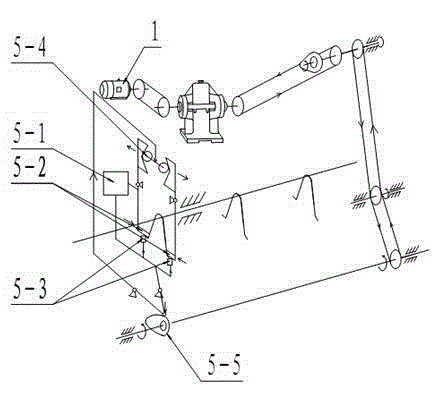

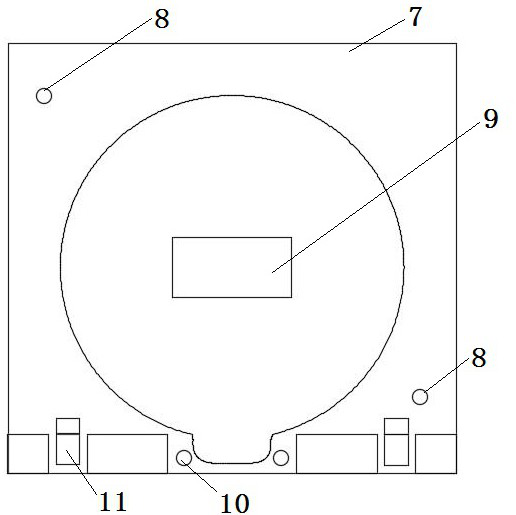

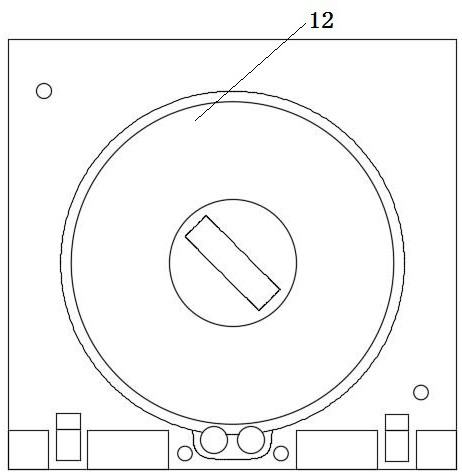

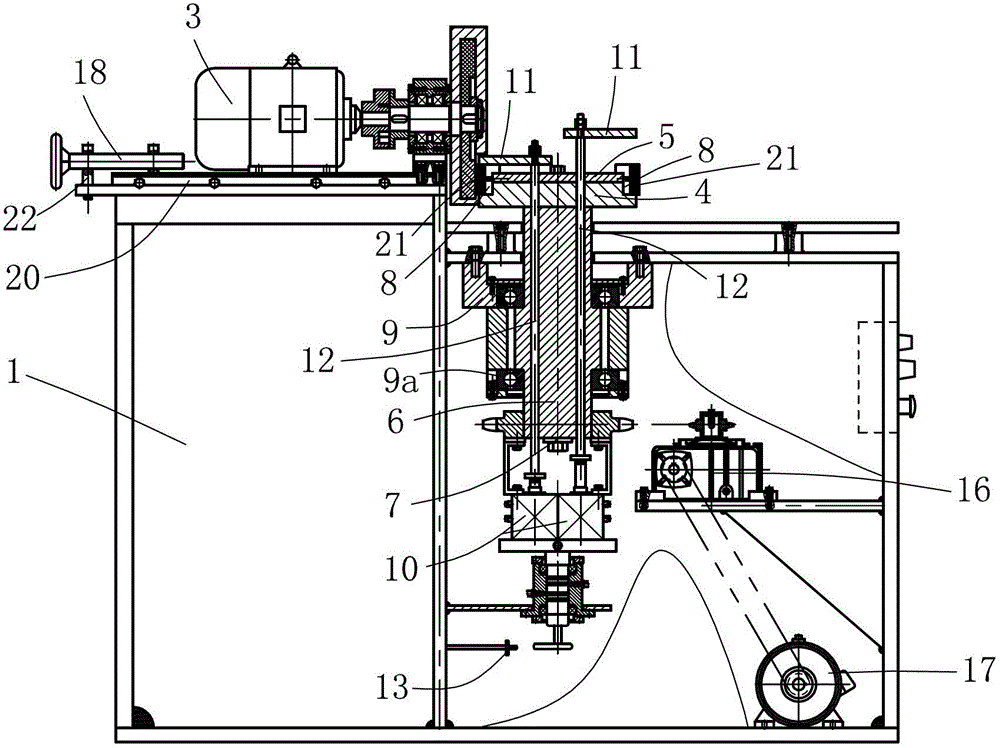

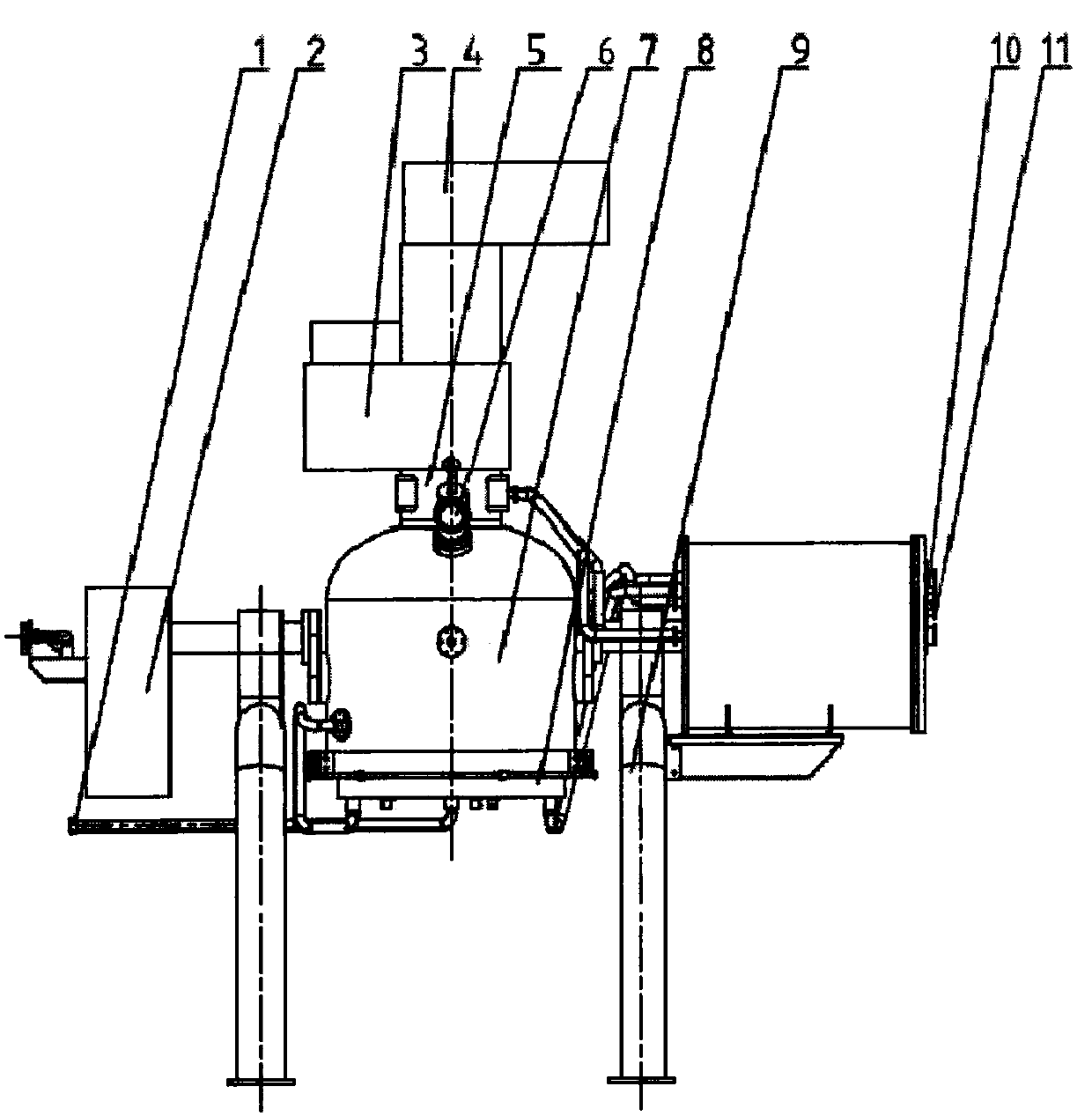

Copper rod automatic forging and trimming equipment

PendingCN107214518AGuaranteed high qualityEnsure product consistencyMetal-working feeding devicesForging/hammering/pressing machinesEngineeringHeating furnace

The invention discloses an automatic forging and trimming equipment for copper rods, which comprises a control box, a fuselage, a heating furnace, a forging press and a trimming punch arranged in sequence according to the process, and the control box is connected with the forging press and the trimming press respectively. The trimming punch is electrically connected, the forging punch forges the copper bar into a semi-finished product, and the trimming punch processes the semi-finished product into a finished product. The invention realizes fully automatic production from copper rods (raw material) to finished copper products. By precisely controlling the temperature of the heating furnace, the high quality and consistency of copper products can be ensured, labor costs can be reduced, and the probability of work-related injuries can be greatly reduced. The market competitiveness of copper products meets the strict requirements of customers in all aspects of products.

Owner:岑攀益

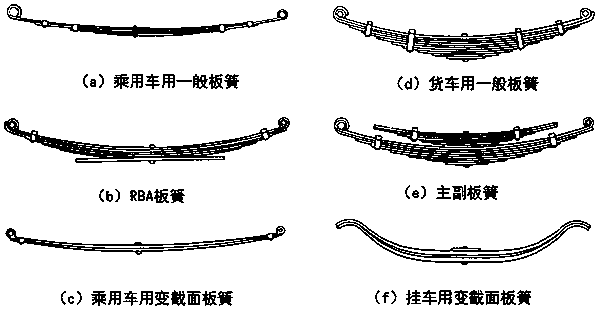

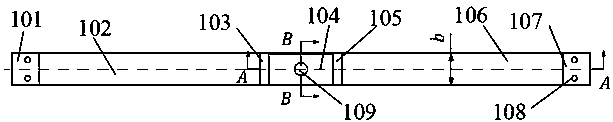

Leaf spring and manufacturing technology thereof

ActiveCN107606014AReduce weightImprove local stressLeaf springsDomestic articlesDynamic stiffnessFiber

The invention relates to a leaf spring and a manufacturing technology thereof. The leaf spring comprises a leaf middle section, a transition section, a variable-section section and a winding lug installing section, and all the sections are the same in width. The material of the leaf spring is an FRP composite material. The manufacturing technology comprises the fiber cloth weaving procedure, the fiber cloth laminating procedure, the laminated layer spot welding procedure, the pre-forming procedure, the cutting procedure, the HP-RTM procedure, the unloading and shaping procedure and the post-machining procedure. The technical scheme solves the problems of design and process of leaf spring leaves in the prior art, the leaf spring leaf performance is improved, the volume production beat is fast, and the market value of the leaf spring is huge; one leaf spring can be independently used, two leaf springs can be combined to form a main and auxiliary spring structure, different loads are achieved, and all steel plate spring structures can be replaced by changing structures of winding lugs and other accessories; complete fracture at a time is avoided, the active failure mode is achieved, and the vehicle running safety is sufficiently guaranteed; the weight of a leaf spring suspension is reduced, the dynamic stiffness is very small, the vehicle running smoothness is improved, and fuel affinity is improved as well; and the service life is 5 or more times of the steel plate springs, and the cost of using the leaf spring by users is greatly reduced.

Owner:合肥前卫复合材料有限公司 +1

PCB board of planar transformer and preparation method thereof

PendingCN110233028ASolve the problem of low winding efficiencySolve the flow phenomenonPrinted circuit assemblingTransformers/inductances coils/windings/connectionsCooking & bakingConductor Coil

The present invention discloses a PCB board of a planar transformer and a preparation method thereof. Both surfaces of a PCB substrate with a through hole are subjected to colloid injection molding, and a double-surface wire-winding part integrated with the PCB substrate is formed. The two surfaces, on the PCB substrate, of the double-surface wire-winding part are symmetrical structures, the center of the double-surface wire-winding part is a via hole identical with the through hole, and the via hole is aligned with the through hole to form a magnetic core hole used for allowing a magnetic core to pass through. The periphery of the via hole is bulged to form a wire-blocking part. The hole wall of the magnetic core hole is provided with a wire-passing slot used for allowing one metal wire to pass through, so that the two surfaces of the double-surface wire-winding part are subjected to planar wire-winding from inside to outside at the same time, and thus two series-connected coils, located on both surfaces of the PCB substrate, are formed. According to the PCB board, the coating of a self-adhesive layer on both surfaces of the PCB substrate is unnecessary, and thus the time of coating the self-adhesive layer is reduced; and a series of problems, for example, the adhered self-adhesive layer gathers in a wire-winding process caused by the flowing phenomenon of the self-adhesive layer in a baking process, are solved.

Owner:SHENZHEN SUNLORD ELECTRONICS

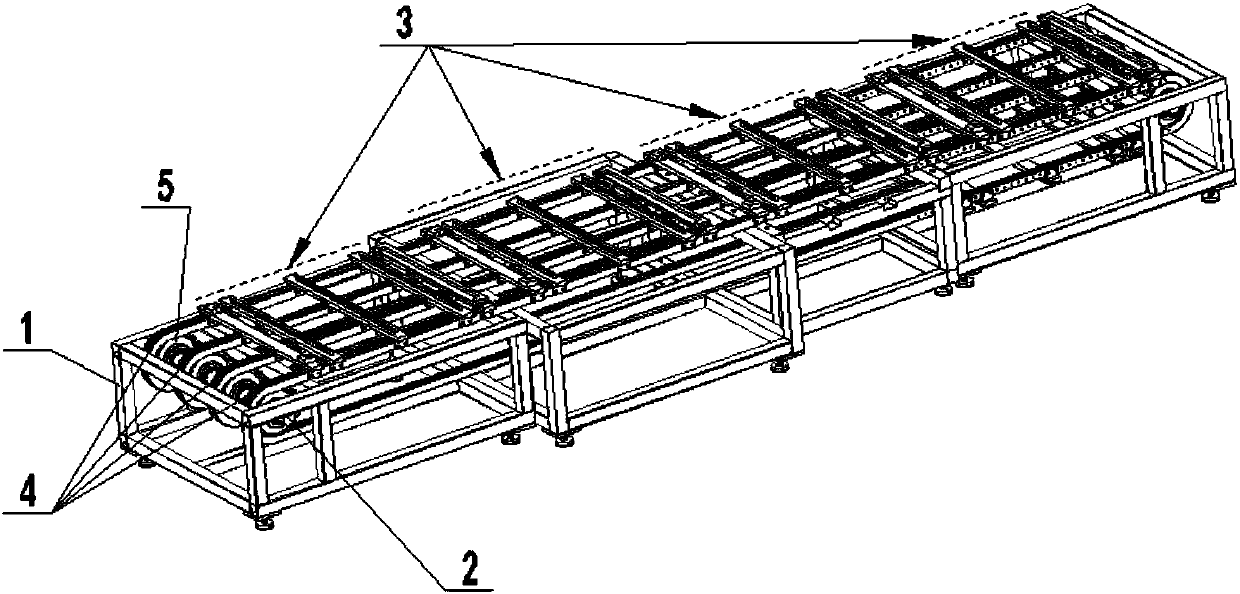

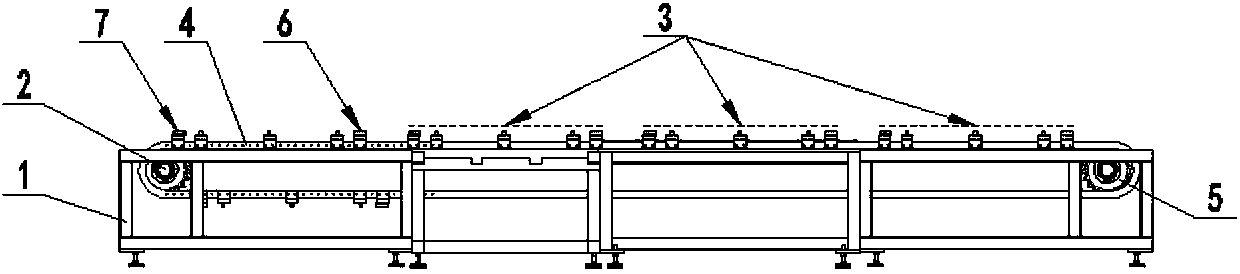

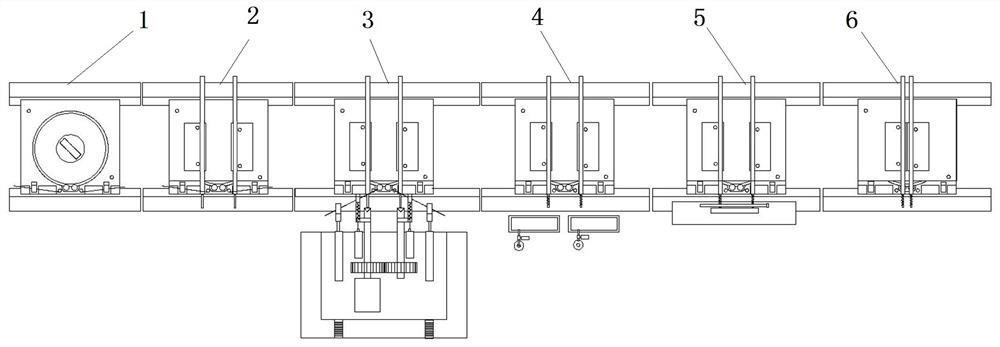

Conveying equipment for automated production line for steel grid plates

The invention provides conveying equipment for an automated production line for steel grid plates. The conveying equipment comprises a rack, transmission shafts, multiple clamp mechanisms and multipletransmission belts. The two ends of the transmission shafts are mounted at the two sides of the rack through bearing seats correspondingly. Each transmission shaft is provided with multiple transmission wheels, wherein the number of the transmission wheels on one transmission shaft is the same as that of the transmission wheels on another transmission shaft. Each transmission belt is connected with the transmission wheels at the corresponding positions of all the transmission shafts an engaged manner. Each clamp mechanism comprises a limiting device A, a limiting device B and two or more clamp bearing plates. Each clamp bearing plate is mounted on the corresponding transmission belt. Each limiting device A and the corresponding limiting device B are mounted on the corresponding clamp bearing plates correspondingly. By means of the conveying equipment, all the clamp mechanisms used in all procedures for producing the steel grid plates are unified into the fixed form and mounted on an annular conveying belt of a conveying mechanism, so that the clamp mechanisms enable the manufacturing procedure positions to be changed with operation of the conveying belt; the automation level of steel grid plate production is raised; and product precision, quality and conformance are improved.

Owner:张文安

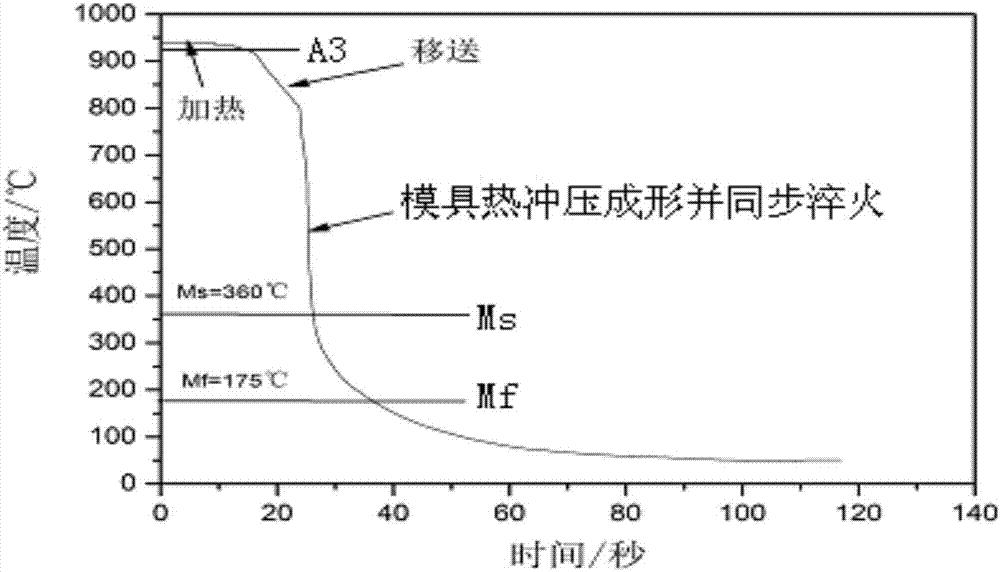

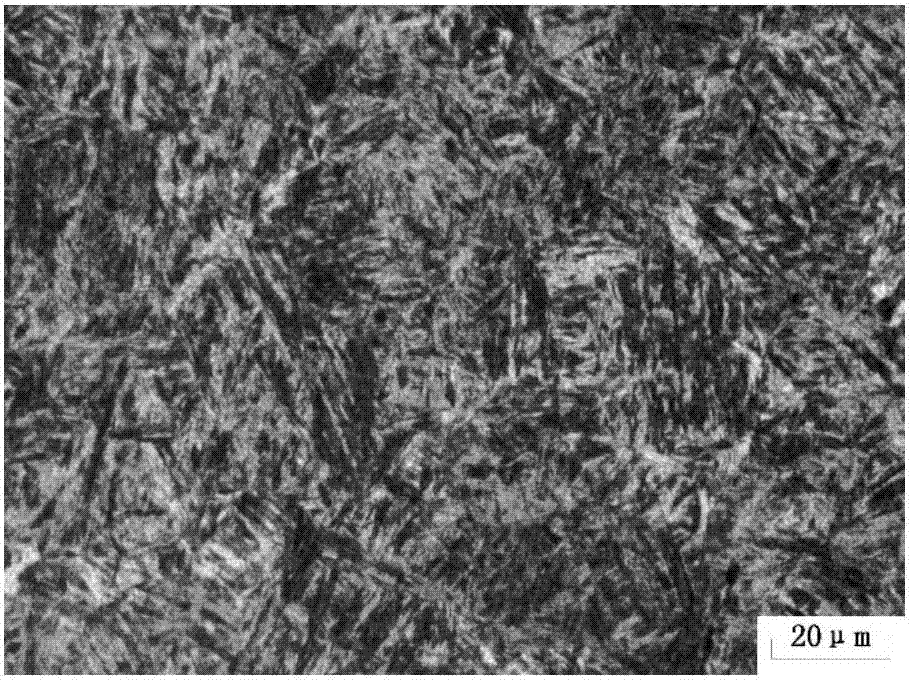

Method for producing hot stamping forming bulletproof piece

ActiveCN107083475AEnsure product consistencyEnsure product quality consistencyHot stampingMartensite transformation

The invention discloses a method for producing a hot stamping forming bulletproof piece. According to the hot stamping forming bulletproof piece, a bulletproof steel plate with the thickness being larger than 1.8mm is heated to a fully-austenitic area at first and then is stamped to be in a certain shape; and meanwhile, quenching is achieved by means of rapid cooling in the forming process so that the bulletproof piece can achieve a super-strength mechanical property, for example, the tensile strength is not lower than 1550MPa, and the capacity of resisting bullet shooting or breaking is achieved. The method is characterized by including the following steps that the bulletproof steel plate with the thickness being larger than 1.8mm is heated to be fully austenitic and then is subjected to mold hot stamping forming so that the bulletproof piece can be formed, austenite is synchronously quenched into martensite in a mold, the mold is provided with a quenching device used for cooling the bulletproof piece, flowing cooling media are contained in the quenching device, and the bulletproof piece is cooled below the martensite transformation finishing temperature Mf through the cooling media to be turned into a martensite bulletproof piece.

Owner:CENT IRON & STEEL RES INST +1

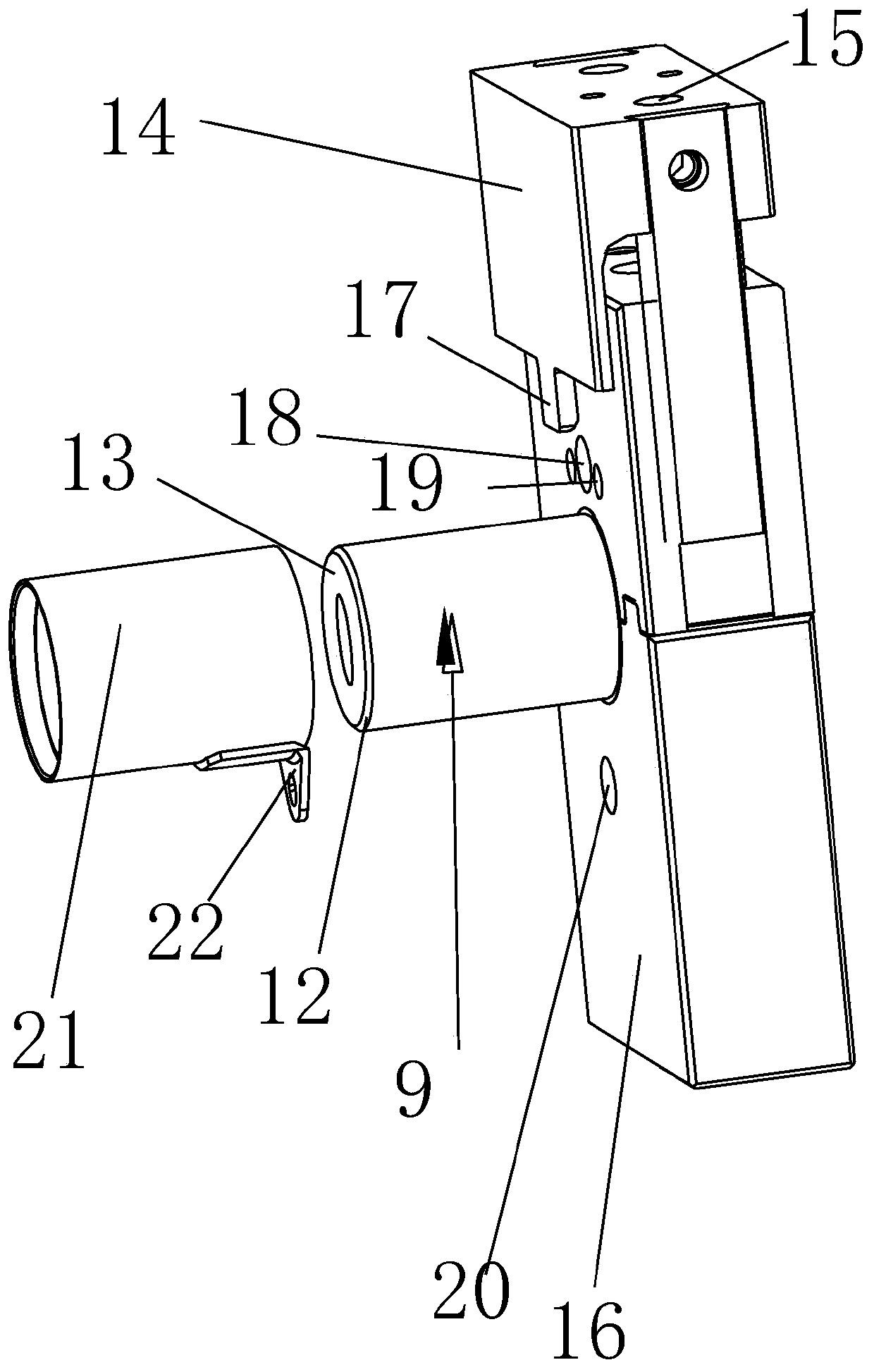

Quantitative glue dispenser

PendingCN107511300AEnsure product consistencyReduce labor intensityLiquid surface applicatorsCoatingsMotor driveEngineering

The invention discloses a quantitative glue dispenser which comprises a glue dispenser body, wherein the glue dispenser body comprises a material taking device, a glue dispensing device, a material discharging device and a conveying device, wherein the material taking device, the glue dispensing device and the material discharging device are respectively arranged along a conveying path of the conveying device; the glue dispensing device comprises a glue injection module for placing to-be-injected glue; a glue injection motor for quantitatively outputting glue is arranged in the glue injection device; a pressing injection block is arranged on a rotating shaft of the glue injection motor; and the glue injection motor drives the pressure injection block to move downwards so as to quantitatively output the glue from the glue injection module. The quantitative glue dispenser disclosed by the invention can ensure that the glue dispensing amount of each group of direct-embedded LEDs meets a production requirement, so that the glue dispensing amount of each group of direct-embedded LEDs is uniform and balanced, and the production consistency of the direct-embedded LEDs is guaranteed; and therefore, quality problems can be avoided.

Owner:JIANGMEN JIANGHAI DISTRICT KAIHUI PHOTOELECTRIC EQUIP CO LTD

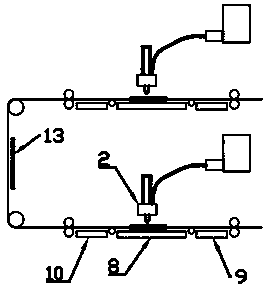

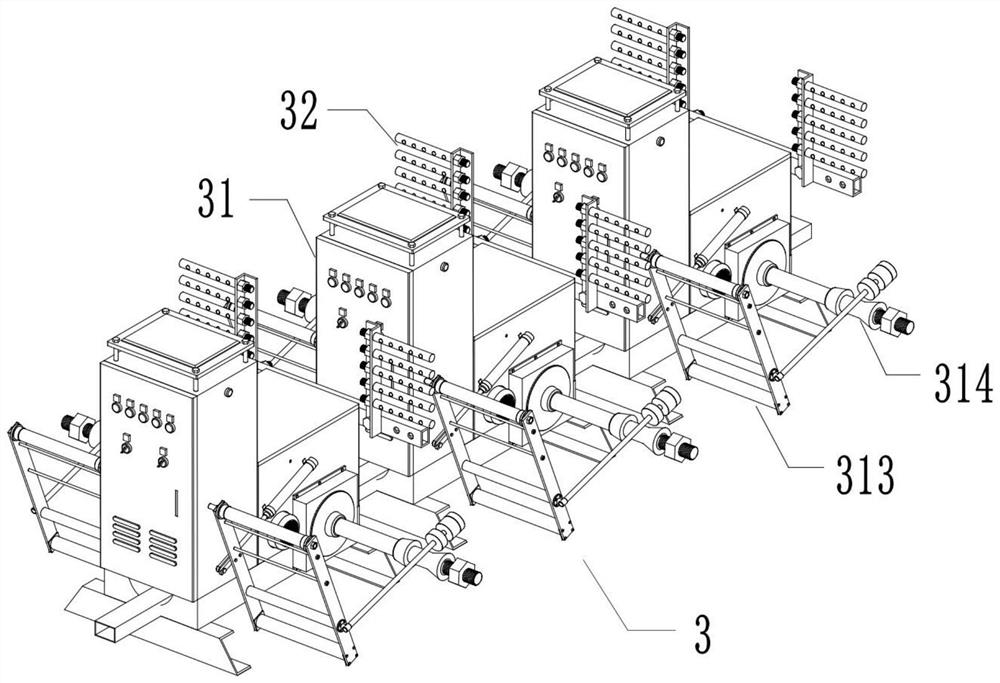

Catalyst continuous spray device used for fuel cell membrane electrode production

PendingCN110433985AImprove efficiencyReduce manufacturing costCell electrodesFinal product manufactureFuel cellsComputer module

The invention discloses a catalyst continuous spray device used for fuel cell membrane electrode production. The catalyst continuous spray device comprises at least two spray modules, a heating moduleand at least bearing rollers. Each spray module comprises a spray nozzle, a material conveying pump, a material conveying pipe, transmission rollers and reverse rotation rollers. The heating module comprises heating plates and a heating box. Each spray nozzle is connected with the corresponding material conveying pump through the material conveying pipe and is located above the corresponding transmission rollers and the corresponding bearing rollers. The corresponding bearing wheels are located on the two sides below each spray nozzle. The reverse rotation rollers are located between the spray modules. A spray area is arranged between every two corresponding bearing rollers. The corresponding transmission rollers are arranged at the front end and the rear end of each spray area and can freely move in the spray area in the horizontal direction and the vertical direction. The spray modules can be arrayed in an up-down, left-right or L-shaped manner. The material conveying pumps are of adiaphragm type, a liquid injection type, a gear type or a rotor type.

Owner:洺源科技(大连)有限公司

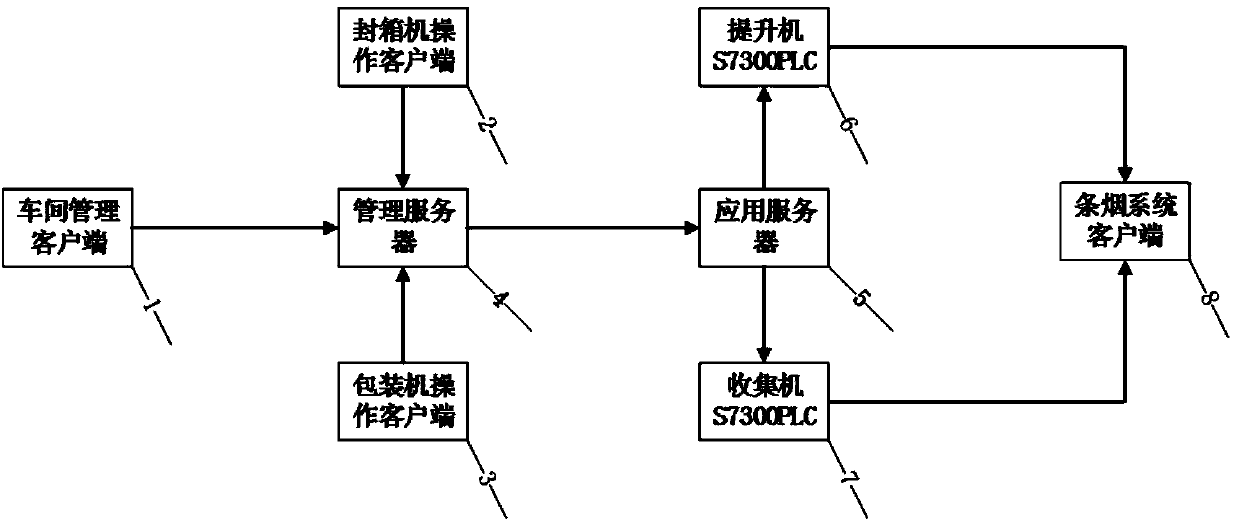

Automatic mark replacement system for cigarette conveying equipment and detection method

ActiveCN104176331ARealize linkage control productionEnsure product consistencyPackaging automatic controlAutomatic controlEmbedded system

The invention relates to an automatic mark replacement system for cigarette conveying equipment. The automatic mark replacement system comprises a workshop management client, a case sealer operation client, a packer operation client, a management server, an application server, an elevator PLC (Programmable Logic Controller) system, a collector PLC (Programmable Logic Controller) system and a cigarette system client, wherein the workshop management client, the case sealer operation client and the packer operation client are respectively connected to the management server, the management server is connected with the application server, the application server is respectively connected with the elevator PLC (Programmable Logic Controller) system and the collector PLC (Programmable Logic Controller) system, the elevator PLC (Programmable Logic Controller) system and the collector PLC (Programmable Logic Controller) system are respectively connected to a cigarette system client, and the cigarette system client is used for monitoring whether the marks of the elevator PLC (Programmable Logic Controller) system and the collector PLC (Programmable Logic Controller) system are replaced or not and is used for product statistics. The automatic mark replacement system for the cigarette conveying equipment automatically controls the cigarette mark replacement for a packer and an elevator as well as a case sealer and a collector, thereby ensuring production conformity among different processes.

Owner:CHINA TOBACCO ZHEJIANG IND

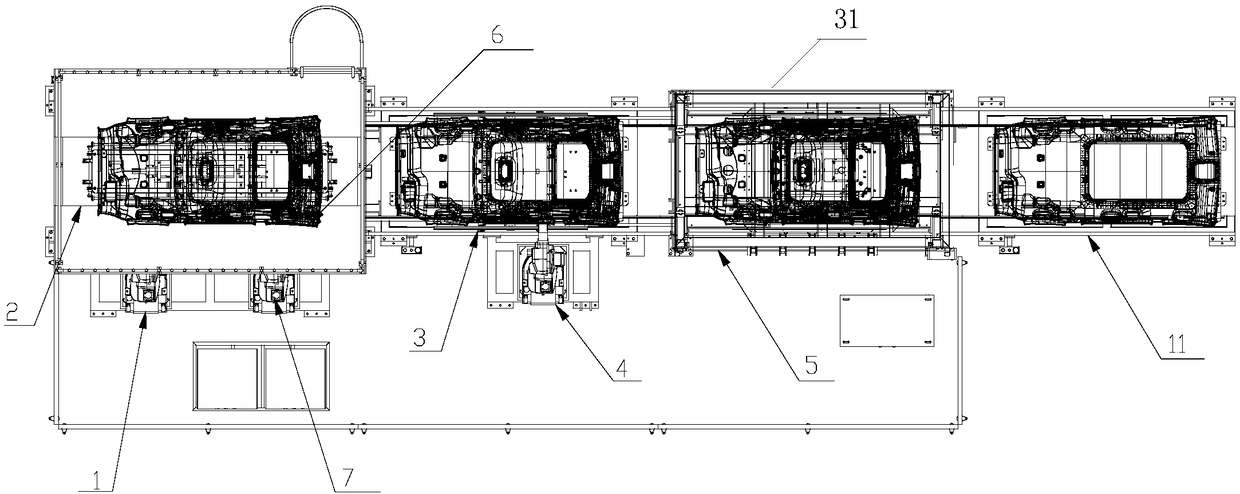

Forming method of carbon fiber composite material for vehicle

PendingCN111941875ASave heating and cooling processIncrease productivityDomestic articlesEpoxyCompression molding

The invention discloses a forming method of a carbon fiber composite material for a vehicle. The forming method mainly comprises the steps of carbon cloth cutting, laying and preforming, resin soakingand compression molding forming, specifically, the carbon cloth cutting step adopts the means that a plurality of laid layer drawings are formed in a decomposition mode in the thickness direction andthen guided into a cutting machine, and the resin soaking step adopts the means of quickly curing epoxy resin and the like. According to the forming method, the production efficiency of carbon fibercomposite material parts for the vehicle can be greatly improved, the cycle time of a single process can be within 5 minutes, the internal porosity of a product can be controlled to be about 0.5%, thesurface quality of the product is improved, the time is saved for coating pretreatment, the production consistency is guaranteed, and the mechanical property of the product can also be improved to acertain extent.

Owner:江苏国新新能源乘用车有限公司 +2

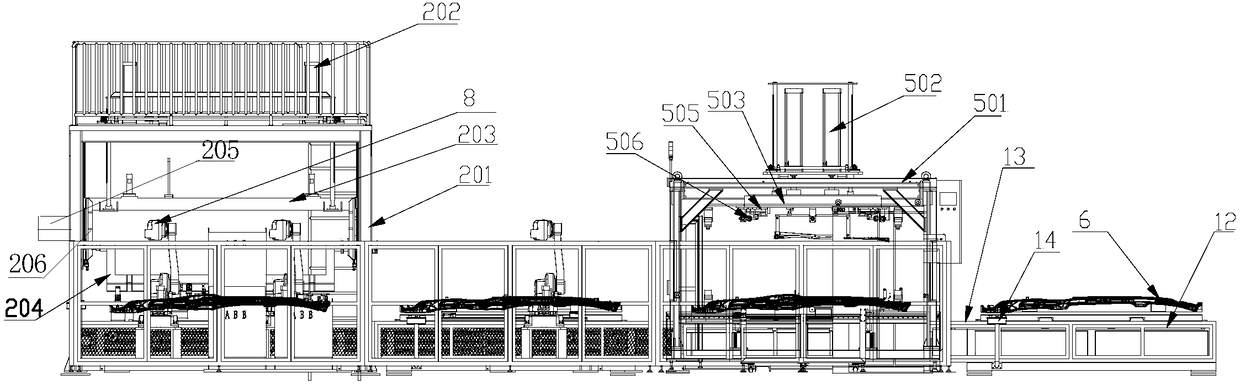

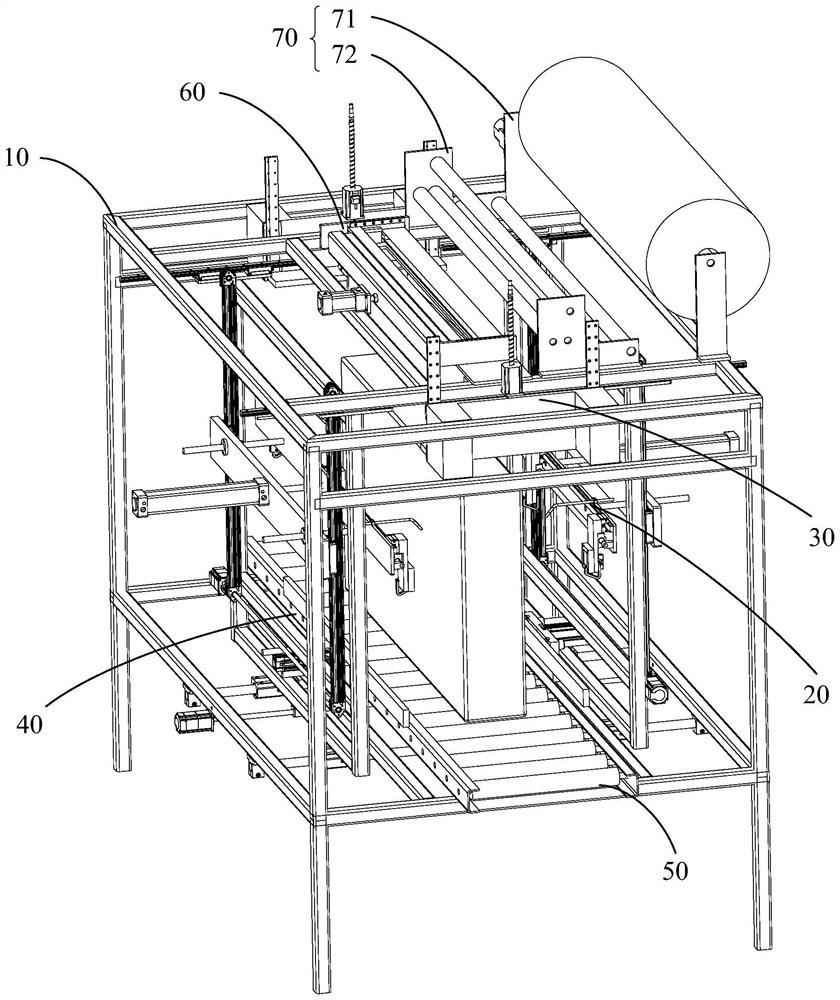

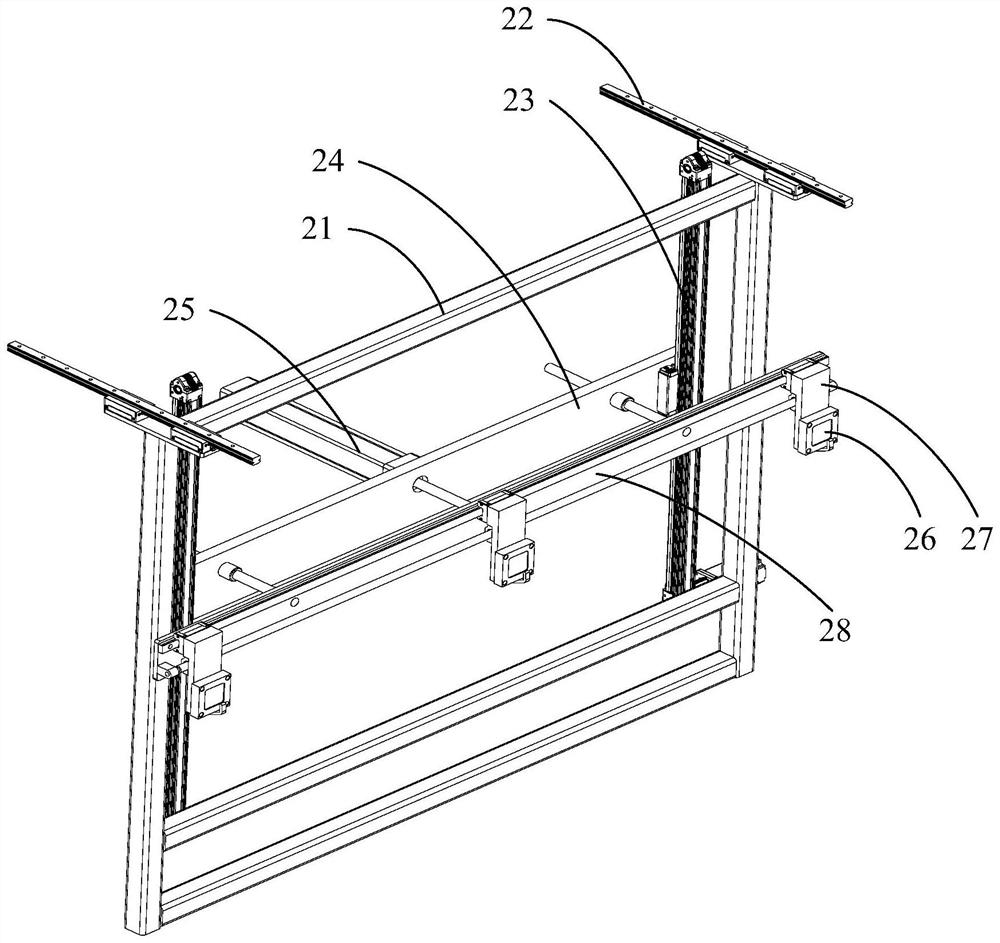

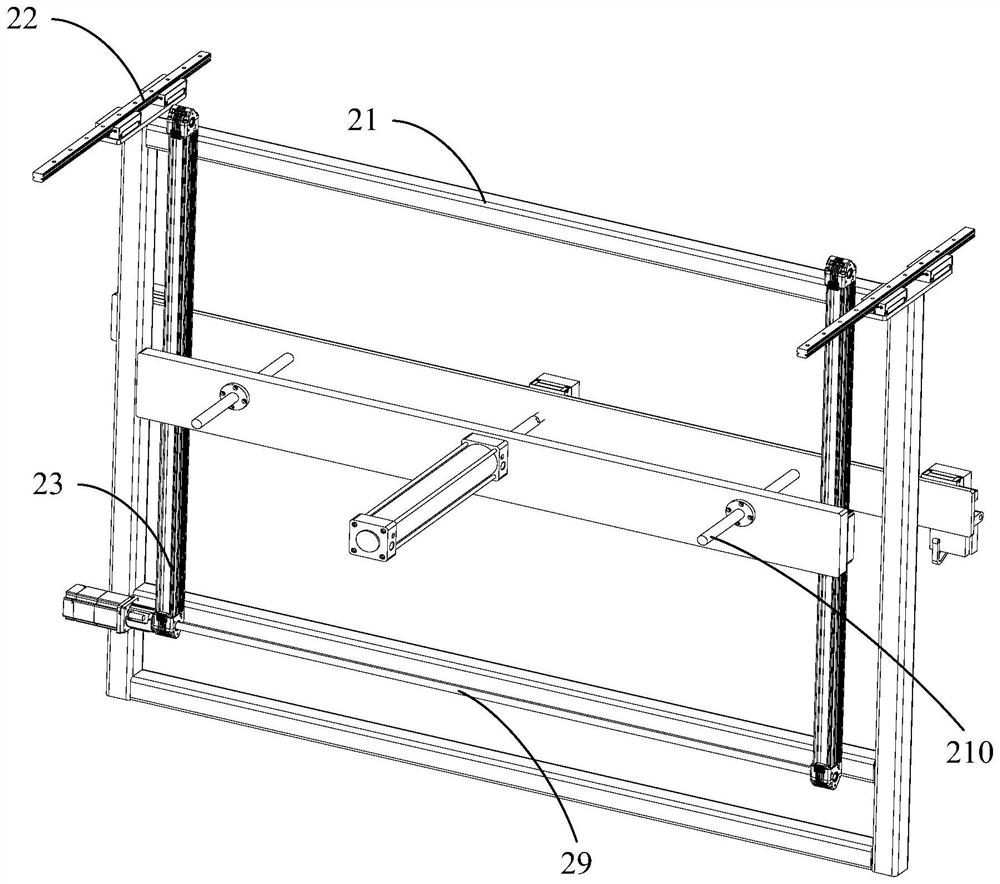

Automobile ceiling automatic assembly line

InactiveCN108465609AReduce usageReduce investmentLiquid surface applicatorsCoatingsMotor driveControl system

The invention discloses an automobile ceiling automatic assembly line which comprises a first robot gumming machine system, a turnover type automatic assembly machine, a first production conveying machine, a second robot gumming machine system, a second production conveying machine, an automatic covering machine and a controlling system. The first robot gumming machine system and the second robotgumming machine system comprise four-axis robots. Each four-axis robot is provided with a gum dispensing head. The turnover type automatic assembly machine comprises a first rack, first lifting air cylinders, a horizontal rod connected to the output shafts of the first lifting air cylinders, an swinging rod arranged below the horizontal rod, and a rotary motor drives the swinging rod to swing. Special purpose machines such as the turnover type automatic assembly machine and the automatic covering machine save the operators and ensure the uniformity of product specification and production consistency, and improve product quality. The equipment is designed according to the requirements of the production process to achieve functional requirements.

Owner:重庆广精欣科技有限公司 +1

Bagging machine

InactiveCN112777044ALabor savingIncrease productivityWrapper twisting/gatheringIndividual articlesWorkbenchIndustrial engineering

The invention provides a bagging machine which comprises a rack, a workbench, an adsorption assembly, a clamping assembly and a sealing assembly. The workbench is arranged at the bottom of the rack and used for containing to-be-bagged materials. The adsorption assembly is movably arranged on the rack and used for adsorbing plastic bags and pulling the plastic bags to be arranged on the to-be-bagged materials in a sleeving mode. The clamping assembly is movably arranged on the rack and used for clamping the to-be-bagged materials sleeved with the plastic bags to move. The sealing assembly is arranged on the rack, located between the adsorption assembly and the workbench and used for sealing the plastic bags. According to the technical scheme, manual bagging is replaced, labor is saved, production efficiency is improved, and production consistency and bagging stability are ensured.

Owner:TCL KING ELECTRICAL APPLIANCES HUIZHOU

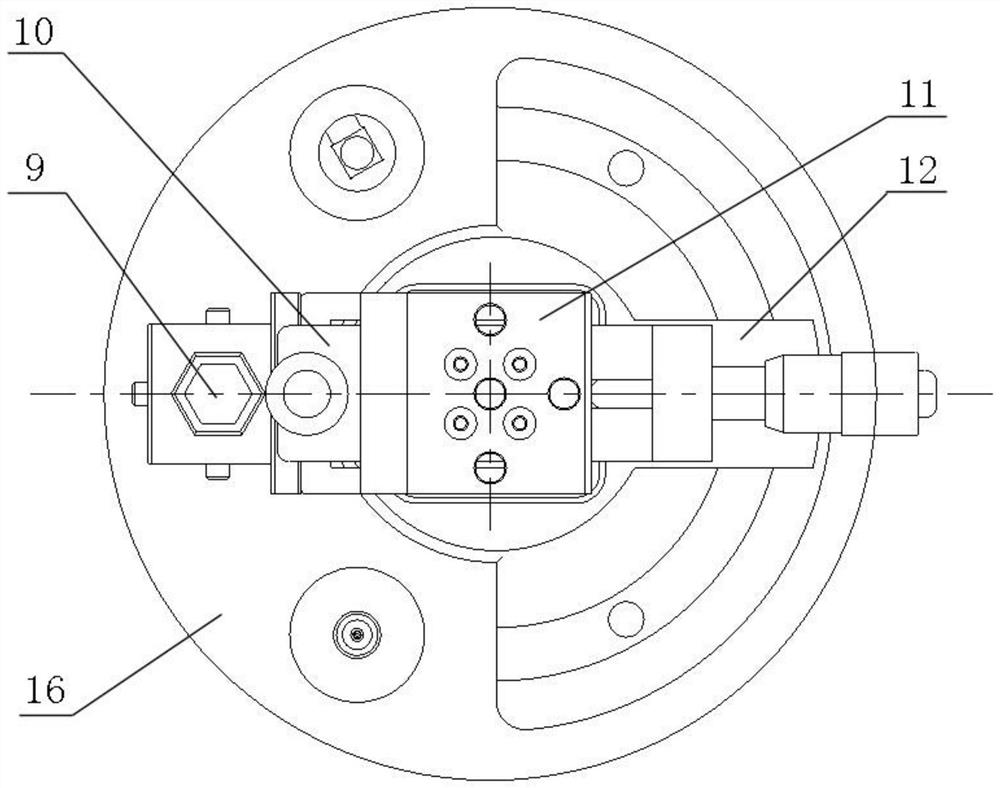

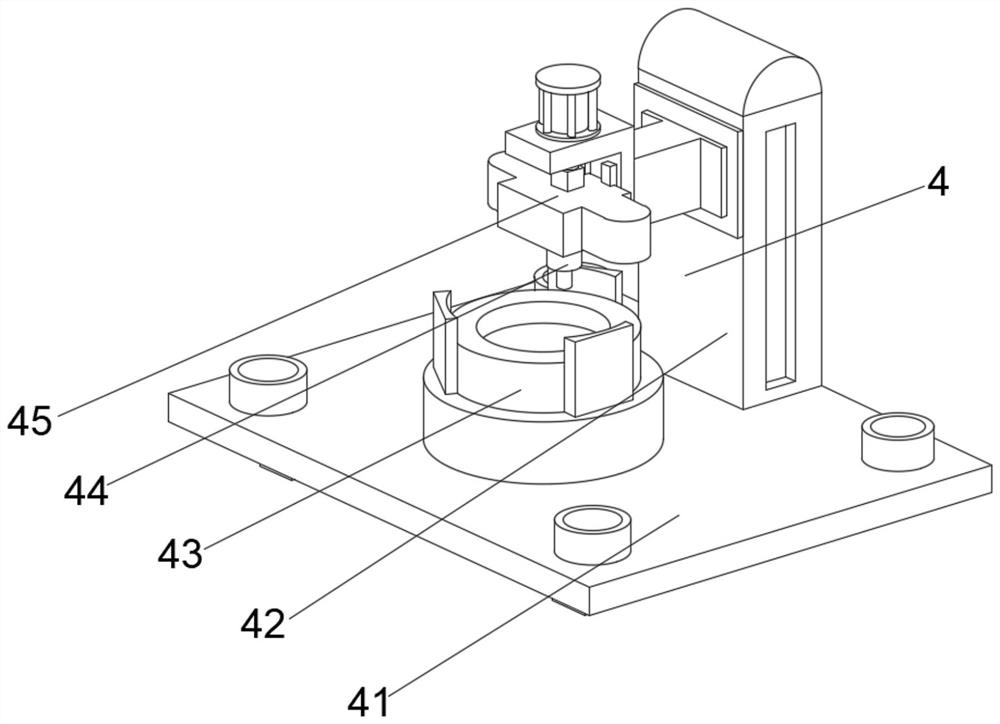

Assembly tool for miniature acceleration sensor

ActiveCN112643591AImprove assembly work efficiencyExpand the scope of useAssembly machinesWork holdersEngineeringMechanical engineering

The invention discloses an assembly tool for a miniature acceleration sensor. The assembly tool comprises a multidirectional adjusting mechanism, a pressure head, a clamp and an ejector pin. The pressure head is connected with the adjusting end of the multidirectional adjusting mechanism; the first end of the pressure head is used for cooperating with the first end of the clamp to install the acceleration sensor; the mounting direction of the clamp is parallel to the second direction; a part of the acceleration sensor is positioned and placed at the first end of the clamp; a channel for the ejector pin to move is formed in the pressure head; and the ejector pin is movably arranged in the channel, and the first end of the ejector pin is matched with the first end of the clamp to install the acceleration sensor. According to the assembly tool, the clamp can be replaced, and is suitable for the assembly of various types of sensors. Under the condition that the clamp is not replaced, inner and outer conical rings, a piezoelectric patch and a positioning ring can be assembled, and the assembling efficiency and the product consistency are ensured; and the axial assembly size between the inner conical ring and the outer conical ring can be accurately controlled through a vertical fine adjustment platform, and therefore the pre-tightening force of the piezoelectric patch is effectively controlled.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

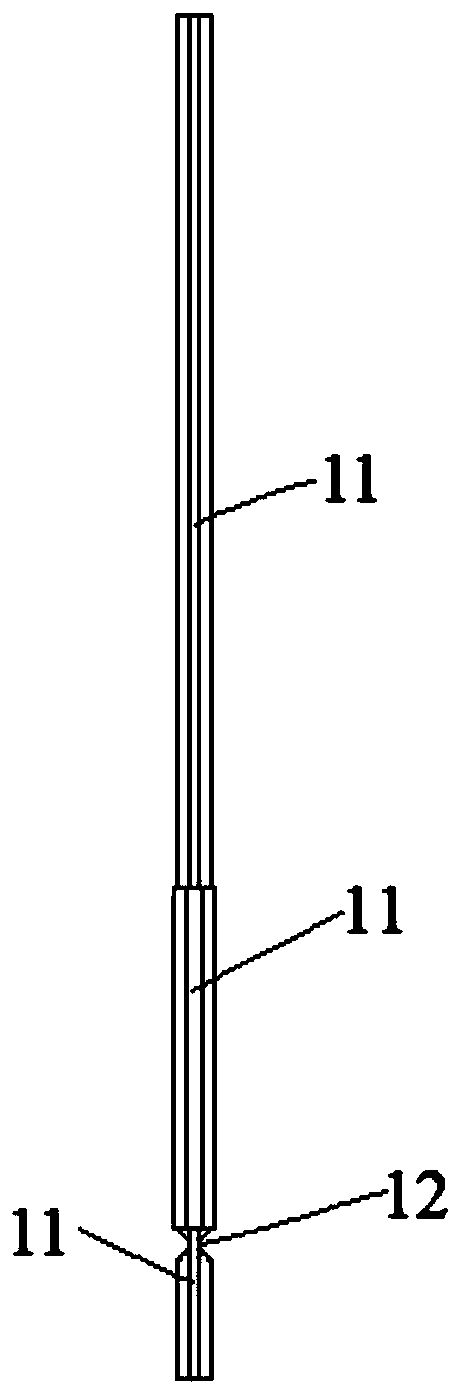

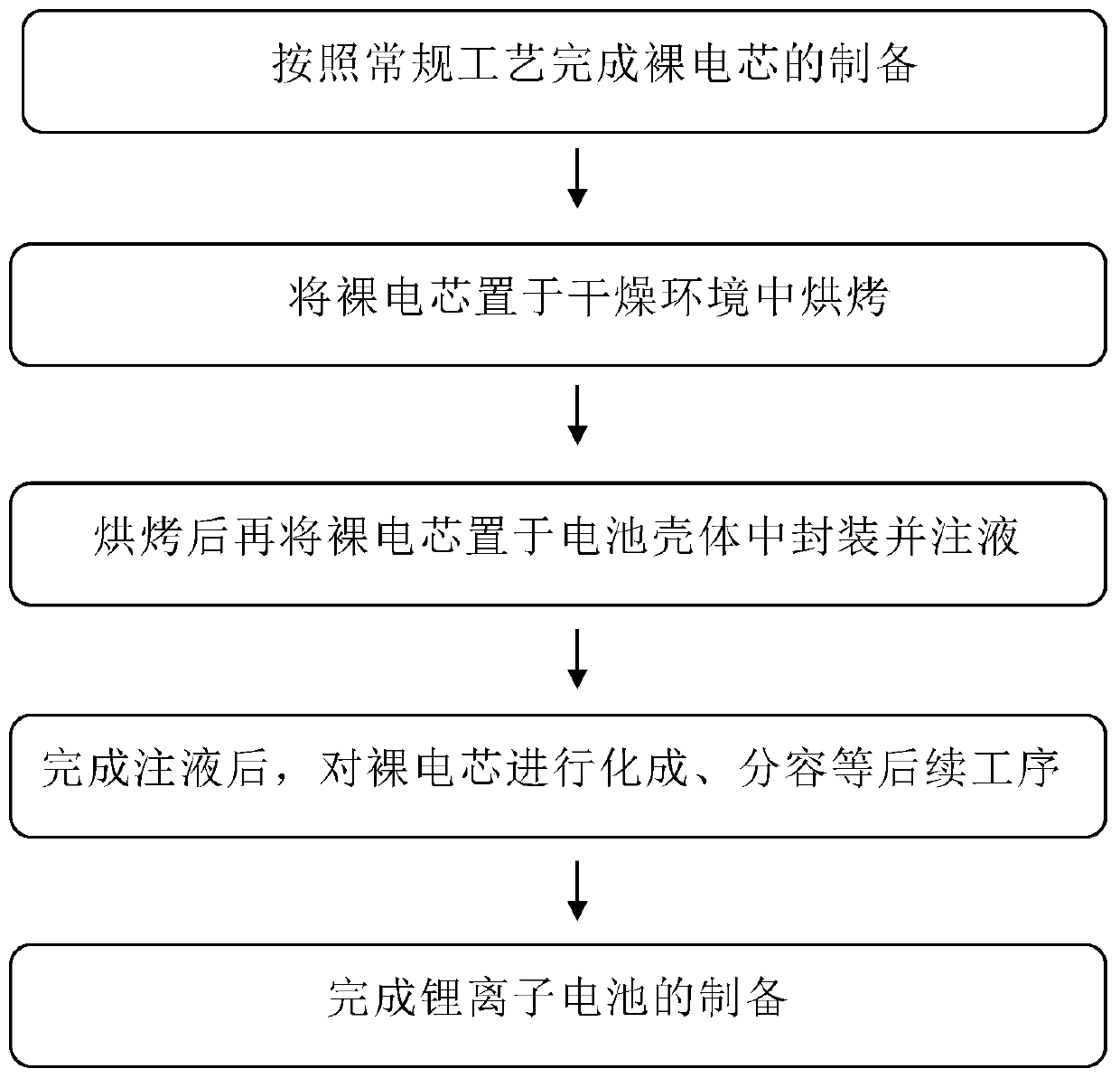

Manufacturing method of lithium ion battery

InactiveCN110828905AReduce usageReduce areaFinal product manufactureCell component detailsPhysical chemistryPlastic film

A manufacturing method of a lithium ion battery comprises the following steps of S1, placing a bare cell in a dry environment for baking, placing the bare cell in a battery shell after baking, and injecting a liquid in the dry environment, wherein the bare cell is connected with a tab with a channel, and the channel is used for a liquid injection process of the bare cell; and S2, after liquid injection is completed, carrying out a formation process, discharging a gas generated by formation from the channel, then sealing the channel, and completing manufacturing of the lithium ion battery. Compared with the prior art, by using the method of the invention, the bare cell is baked firstly, and a baking speed of the unpackaged bare cell is greatly increased due to a fact that the unpackaged bare cell is not wrapped by an external aluminum-plastic film. Besides, the tab with the channel is adopted for liquid injection so that an electrolyte is injected into the battery from an internal channel of the tab, and meanwhile, the gas generated by formation is discharged from the channel so that use of the aluminum-plastic films can be reduced, a large number of aluminum-plastic films are saved, and production cost is reduced.

Owner:东莞汇洋动力科技有限公司

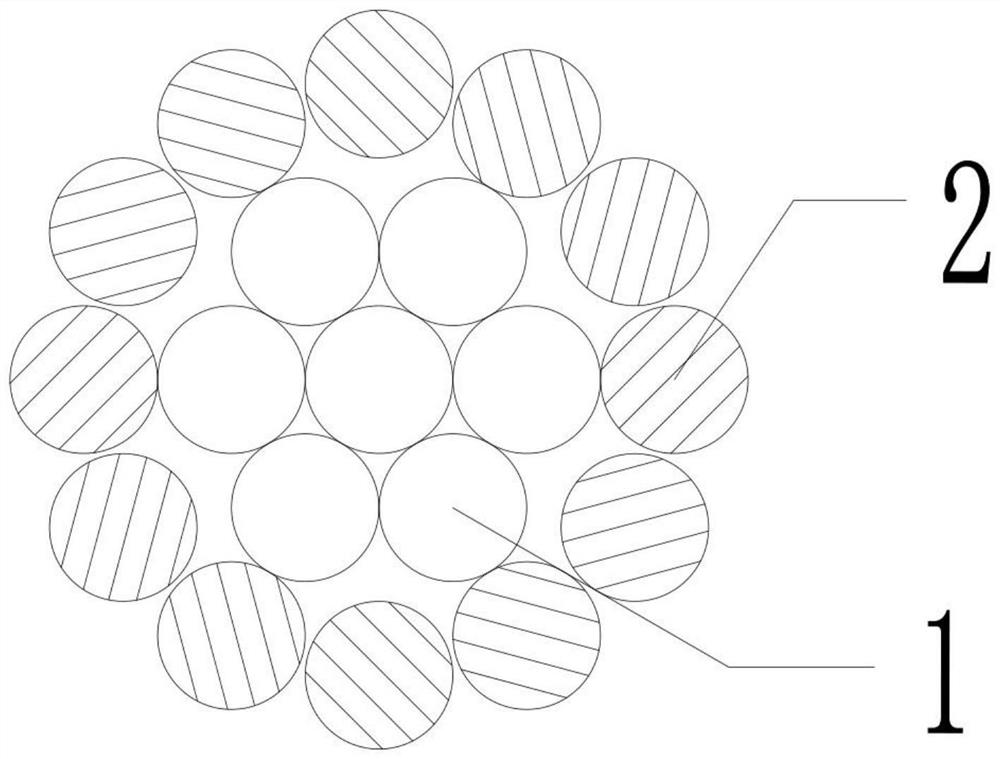

Processing technology of tensile composite conductor for cable and composite conductor

PendingCN112489886AEnsure structural stabilityQuality assuranceNon-insulated conductorsApparatus for feeding conductors/cablesElectrical conductorEngineering

The invention provides a processing technology of a tensile composite conductor for a cable and the composite conductor, the processing technology comprises stranding processing and annealing processing, the stranding processing adopts a 19-strand or 37-strand regular stranding mode, aluminum alloy monofilaments and copper monofilaments are arranged in a layered manner through a layered transaction pay-off rack, stranded wires are supplied to a stranding machine, the inner layer of the conductor is an aluminum alloy monofilament, the outer layer of the conductor is a copper monofilament, and the layered transaction pay-off rack controls the pay-off tension of each layer of monofilament to be different. By adopting the processing technology, preparation of the composite conductor of which the inner layer is the aluminum alloy monofilament and the outermost layer is the copper monofilament can be realized, the structural stability of the composite conductor is ensured, the whole processing technology process is simple and practical, and the percent of pass of finished products is high.

Owner:TONGYONG TIANJIN ALUMINUM ALLOY PROD CO LTD

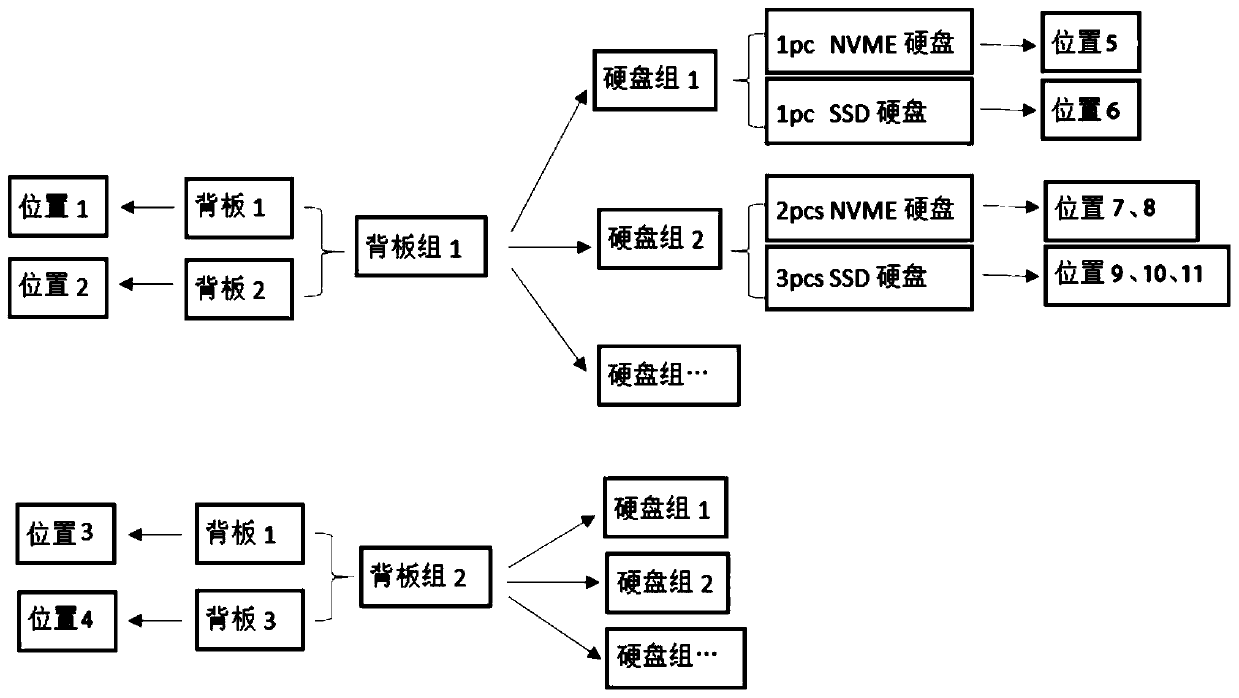

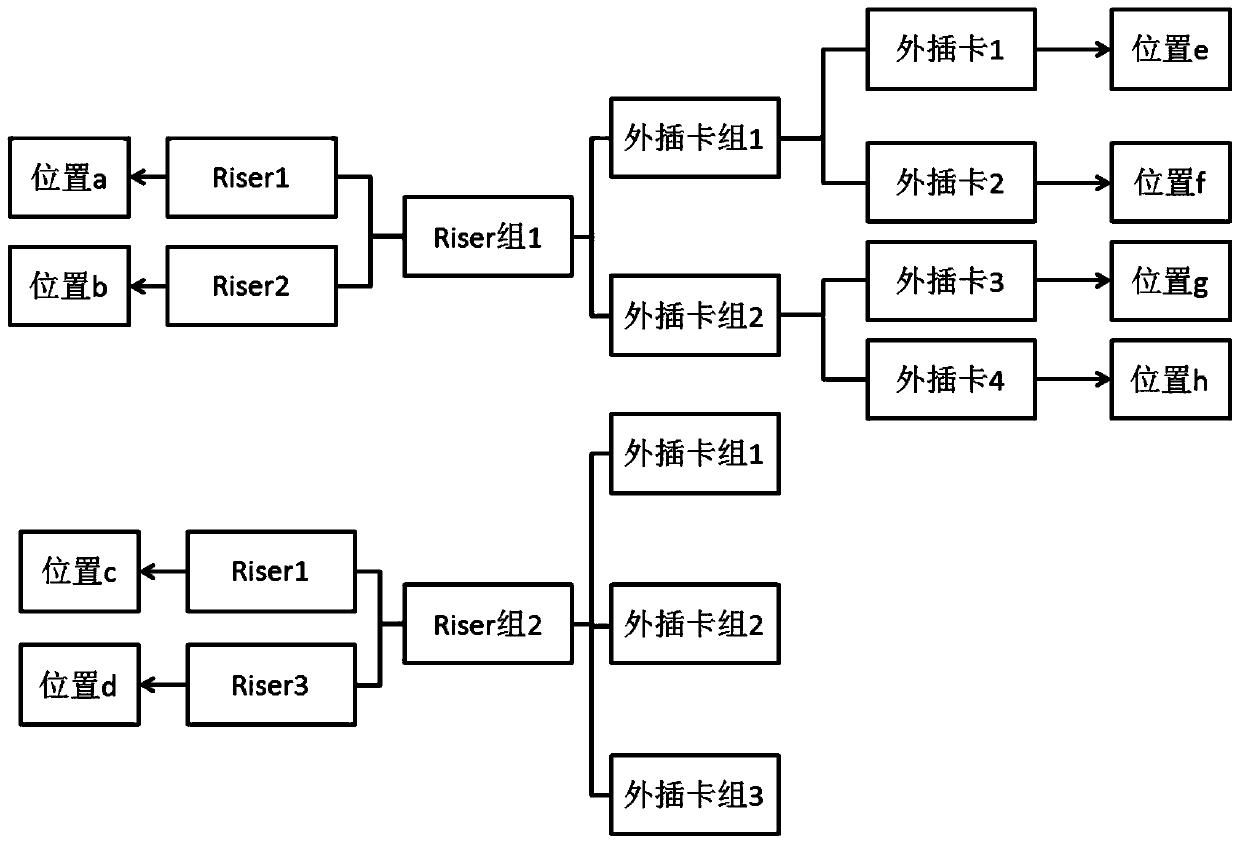

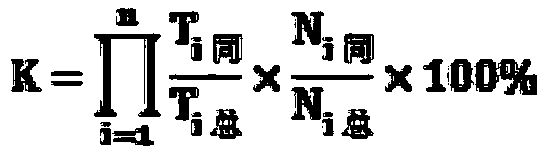

Production task configuration system and method based on MES system

ActiveCN110599018AConvenient automatic configurationReduce human interventionResourcesManufacturing computing systemsPosition NumberComputer science

The invention discloses a production task configuration system based on an MES system, and the system comprises a basic data maintenance module used for storing a matching scheme library of server parts; a production order maintenance module used for identifying production order configuration, calling a matching scheme determined by an MES big data module and determining the position number of each part according to the matching scheme; theMES big data module used for calculating the similarity between the production order configuration and each matching scheme, and modifying and determining aproduction order matching scheme; and a production and use module used for judging the material code of the part according to the serial number of the to-be-installed part and outputting a corresponding position number. The invention further discloses a corresponding method of the system. A hard disk group, an external plug-in card group and other components are cascaded under the corresponding backboard group and Riser group and MES big data similarity matching is performed, so that the system can automatically configure the positions of the components of the production order conveniently, and the production consistency is ensured.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

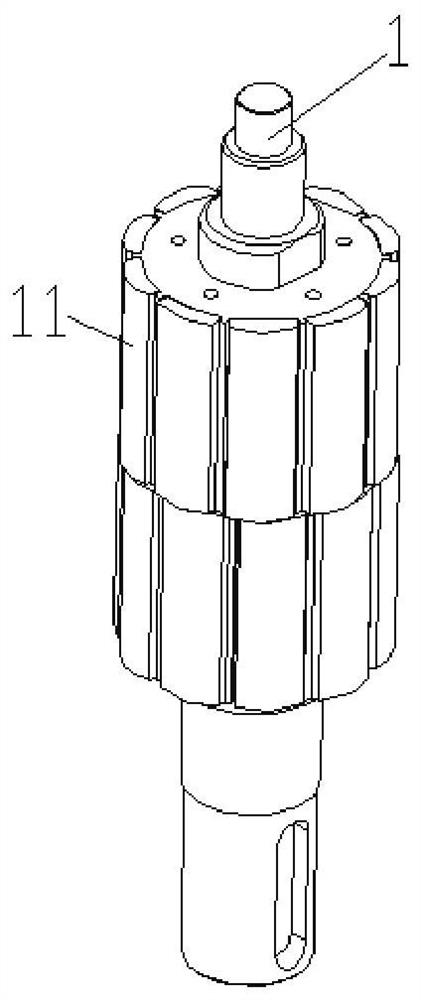

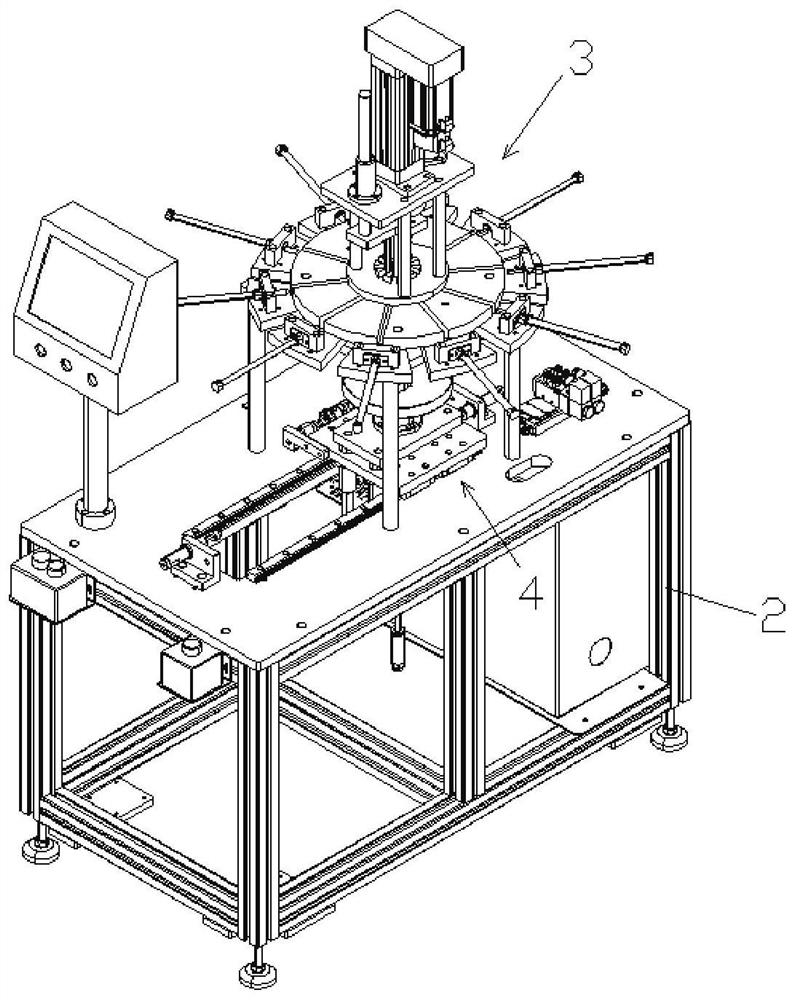

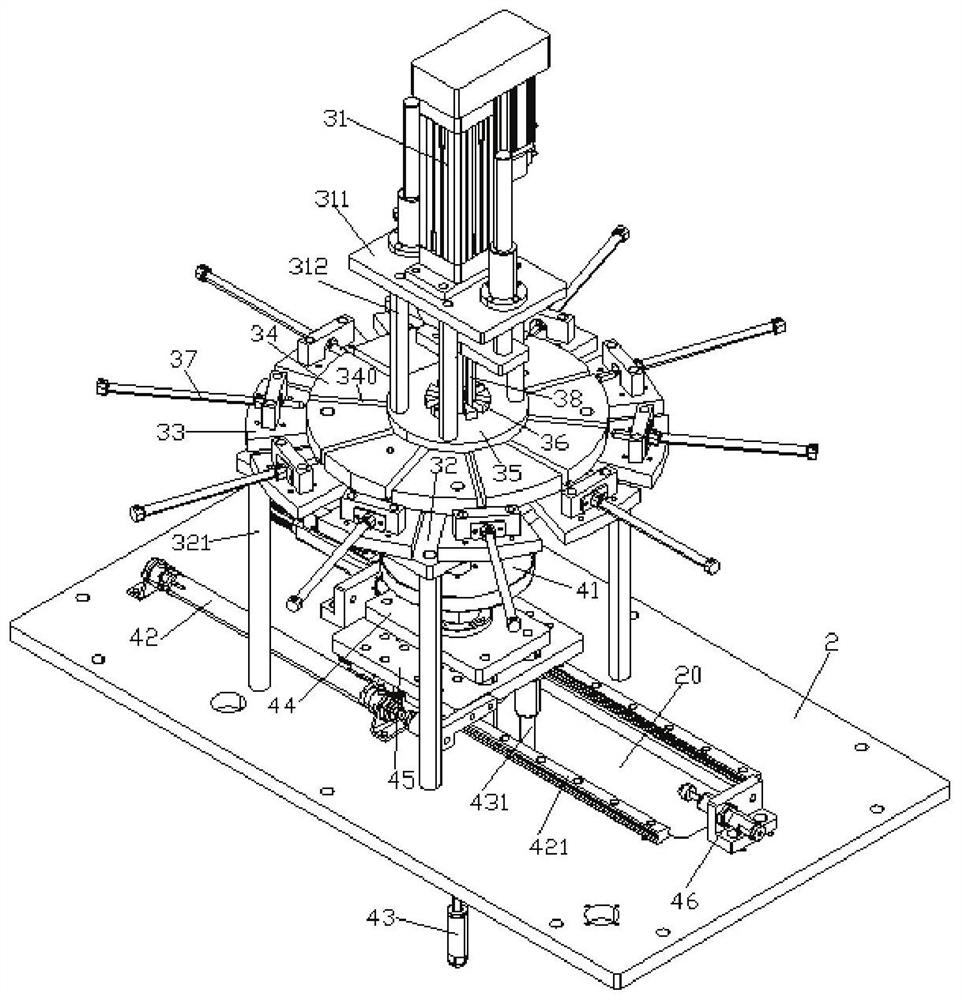

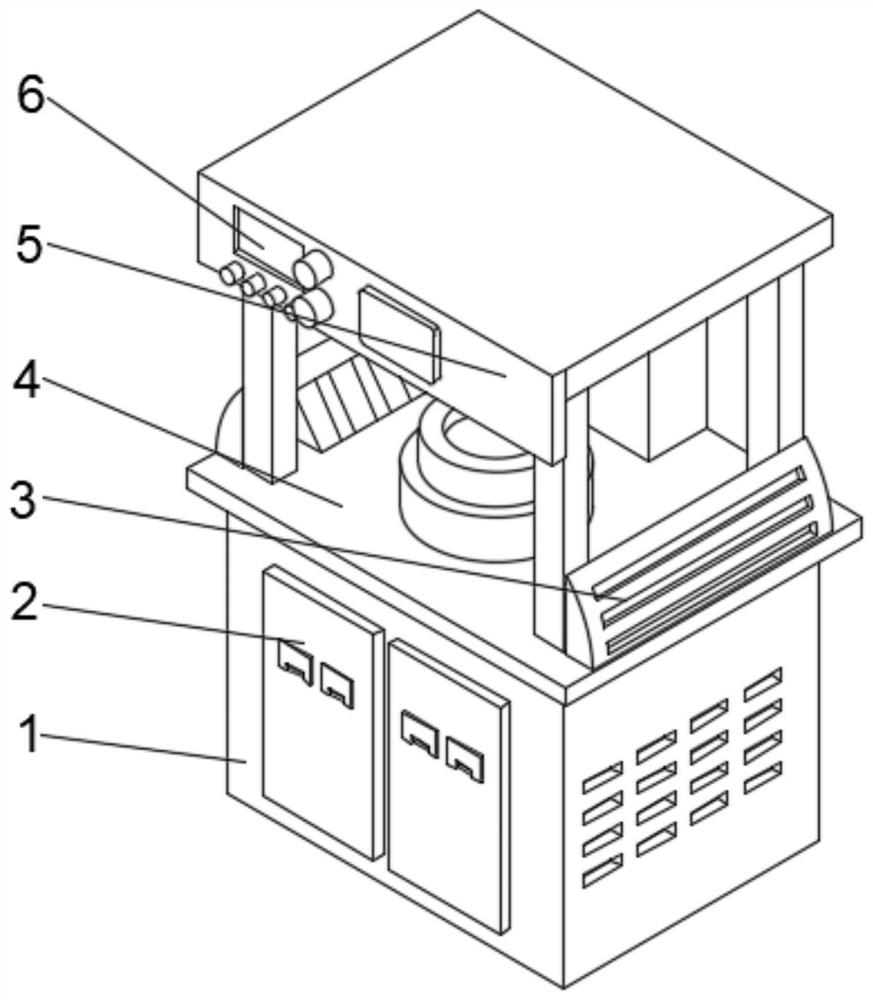

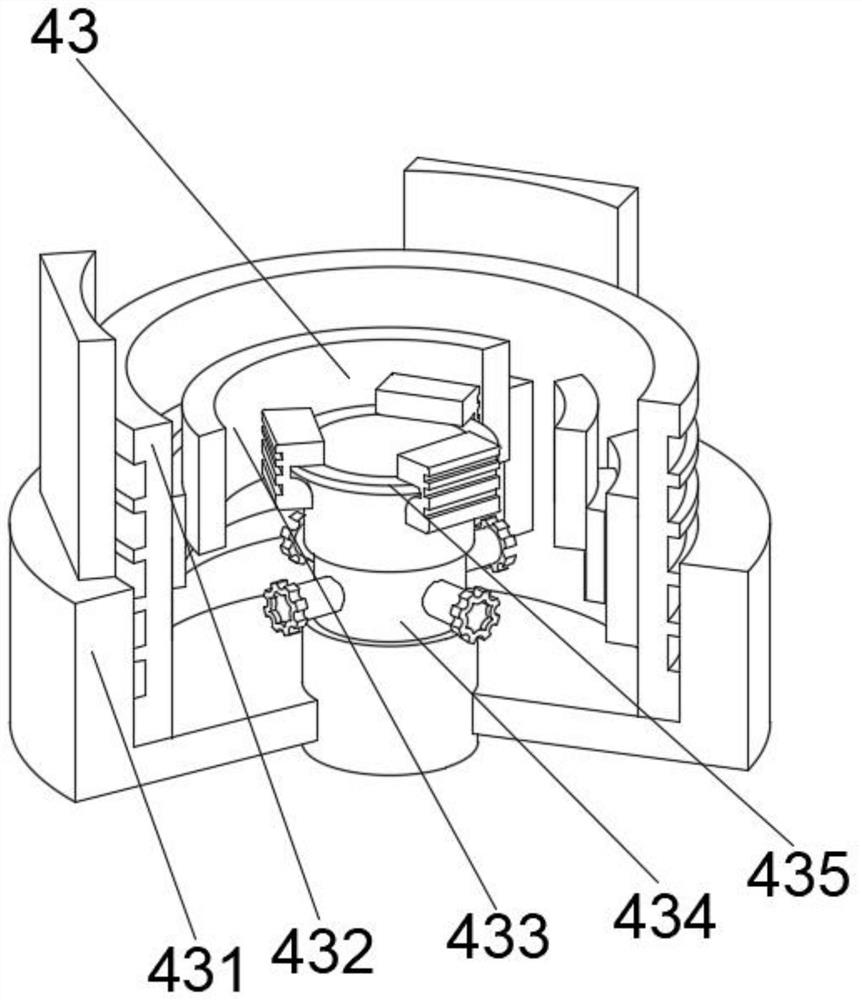

Semi-automatic rotor magnetic steel pasting device

PendingCN112910198ASimple structureEasy to operateManufacturing stator/rotor bodiesEngineeringStructural engineering

Owner:WUXI XINJIE ELECTRICAL

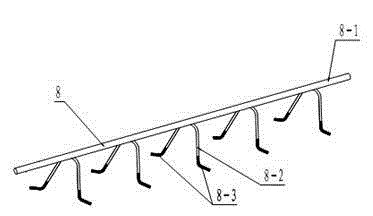

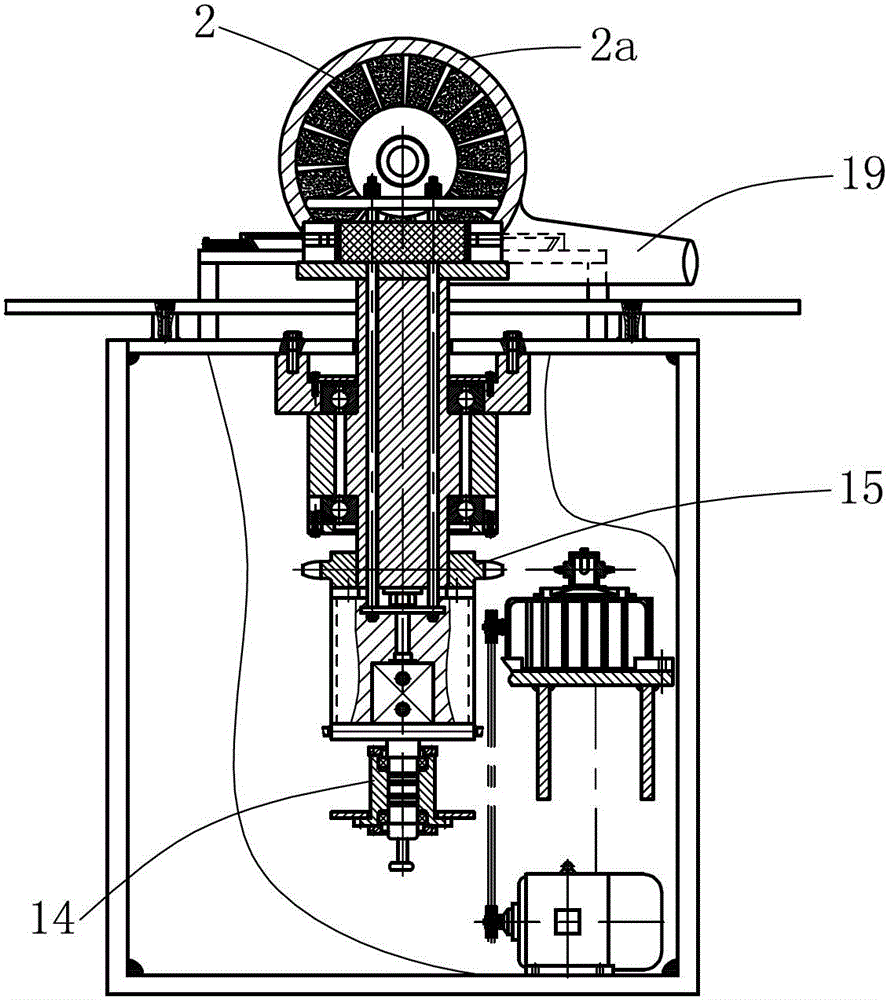

Building stirrup rib production device with heating system for feet of omega-shaped supporting rib

InactiveCN103056070ADip evenlyReduce consumptionPretreated surfacesCoatingsControl systemTransformer

A building stirrup rib production device with a heating system for feet of an omega-shaped supporting rib can be used for fulfilling continuous automation production of the building stirrup ribs. The production device comprises a transmission system, a wire feeding system, a forming executing system for the omega-shaped supporting rib, a tack welding executing system, a heating executing system for the feet of the omega-shaped supporting rib, a dipping executing system for the feet of the omega-shaped supporting rib, a workpiece cutting executing system, a PLC control system and a rack, wherein the production device is characterized in that the heating executing system for the feet of the omega-shaped supporting rib is provided with a heating transformer which is connected with the PLC control system, and the heating executing system for the feet of the omega-shaped supporting rib is arranged behind the tack welding executing system. The production device can locally heat the dipping position of the omega-shaped supporting rib, and thus not only reduces consumption of energy and plastic powder materials, but also enables the dipping of the feet of the omega-shaped supporting rib to be relatively uniform, so that workpiece quality and product consistency can be ensured.

Owner:STATE GRID CORP OF CHINA +2

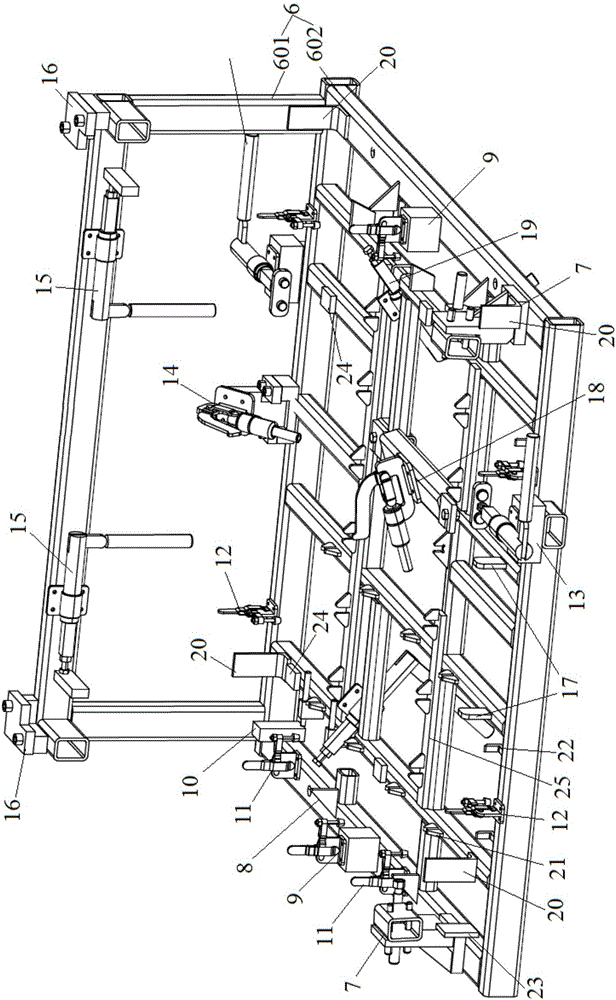

Welding tool for cabin accessory support assembly

InactiveCN105479068AAvoid time costReduce labor costsWelding/cutting auxillary devicesAuxillary welding devicesNacelleEngineering

The invention relates to a welding tool for a cabin accessory support assembly. The welding tool comprises a welding tool body. A plurality of pieces of locating angle iron are arranged on the welding tool body. The positions of the locating angle iron are matched with the edges of corresponding welded components. The locating angle iron is arranged to locate and weld all parts of the cabin accessory support assembly, lineation does not need to be carried out in advance, and all parts only need to be placed at corresponding positions for welding according to the mounting requirement. The whole process can be completed simply through independent operation of a technician, time cost and labor cost are greatly reduced, and post resources are saved.

Owner:SHAANXI TONGJIA AUTOMOBILE

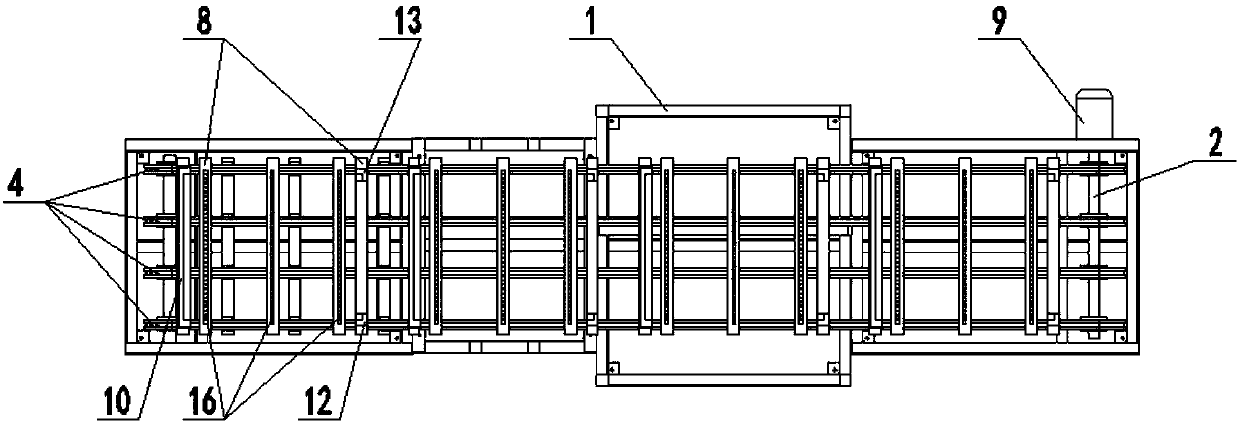

Equipment and process for automatically packaging secondary lead of miniature current transformer for instrument

ActiveCN114038682AReduce in quantityReduce demandManufacture of electrical instrumentsCoils manufactureWire cuttingProcess engineering

The invention discloses equipment and process for automatically packaging a secondary lead of a miniature current transformer for an instrument, and the equipment comprises a special tool for placing and processing each miniature current transformer, an assembly line, and a feeding module, a wire feeding module, a winding module, a welding module, a wire cutting module and a wire plugging module station which are sequentially distributed on the assembly line. The feeding module, the wire feeding module, the winding module, the welding module, the wire cutting module and the wire plugging module station are sequentially carried out in an assembly line mode; a tool backflow channel is arranged below the assembly line, and the whole circulating production and machining process is completed. According to the invention, most original key manual operation procedures can be automatically completed through the equipment, the production efficiency is improved, the production consistency of products is guaranteed, meanwhile, the requirements for the number of operators and the procedure capacity are greatly reduced, and the auxiliary welding equipment automatically controls the liquid level height, so that heating operation area can be greatly reduced, the post illumination requirement is reduced, and therefore the overall production energy consumption is reduced.

Owner:浙江炬源物联科技有限公司

Friction plate milling machine

InactiveCN102744657AQuality improvementEnsure production consistencyRevolution surface grinding machinesGrinding/polishing safety devicesPneumatic pressureGrinding wheel

The invention discloses a friction plate milling machine, which comprises a machine frame assembly, a grinding wheel, a grinding wheel driving motor, a reversed T-shaped round platform, a component positioning plate, a component rotating spindle, a bearing seat, a pressure plate pneumatic reversing induction contact, a pressure plate pneumatic reverser, a chain wheel and chain mechanism, a worm and gear variator and a spindle rotating machine; the upper part of the step surface of the reversed T-shaped round platform and the peripheral region of the component positioning plate form two circumferentially arranged friction plate accommodation spaces together; two thin cylinders are arranged below the component rotating spindle; a pneumatic pressure plate is arranged above each friction plate accommodation space correspondingly; each pneumatic pressure plate is correspondingly provided with two component compression connecting pull rods; and the lower ends of the two component compression connecting pull rods are connected with one of the two thin cylinders. The friction plate milling machine has good processing product quality and high milling efficiency, thereby guaranteeing the straightness accuracy, planarity, verticality and concentricity of friction plate better.

Owner:CHONGQING BISHAN HONGXIANG AUTO PARTS

Circular shell welding device

PendingCN110328473AAppearance detectionIncrease production costWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to a circular shell welding device. The circular shell welding device comprises a cylinder, a welding machine, a sliding block, a welding joint, a rotary welding module, a workbench and a engine base, wherein the engine base is connected with the lower end of the welding machine; the workbench is connected with the middle of the side face of the welding machine; the rotary welding module is connected with the workbench; the cylinder is connected with the upper end of the welding machine; the cylinder is connected with the sliding block; the sliding block is connected withthe welding joint; the rotary welding module includes a servo motor, a mandrel, a guide block and a fixed cylinder; the servo motor passes through the guide block to be connected with the mandrel; and the fixed cylinder is arranged at the bottom of the guide block and connected with the guide block. The welding device achieves the automatic welding process of a circular shell, so that the production efficiency is greatly improved without manual operation in the whole process; and the welding effect is good, so that the product scrap rate is low, and the enterprise cost is reduced.

Owner:苏州神本精密机械有限公司

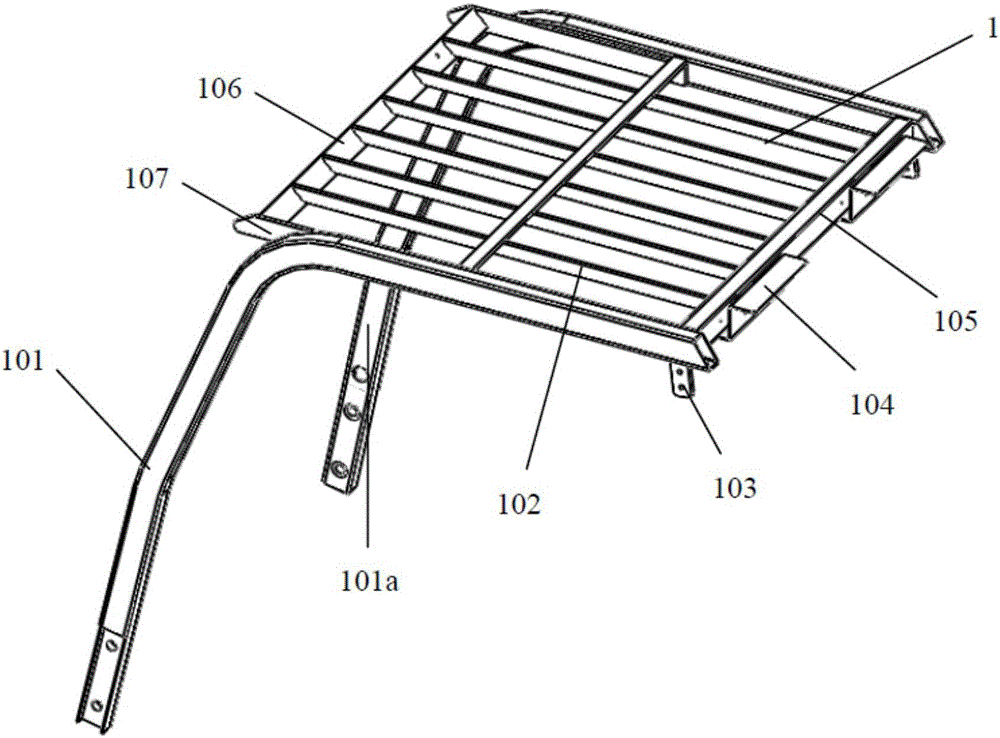

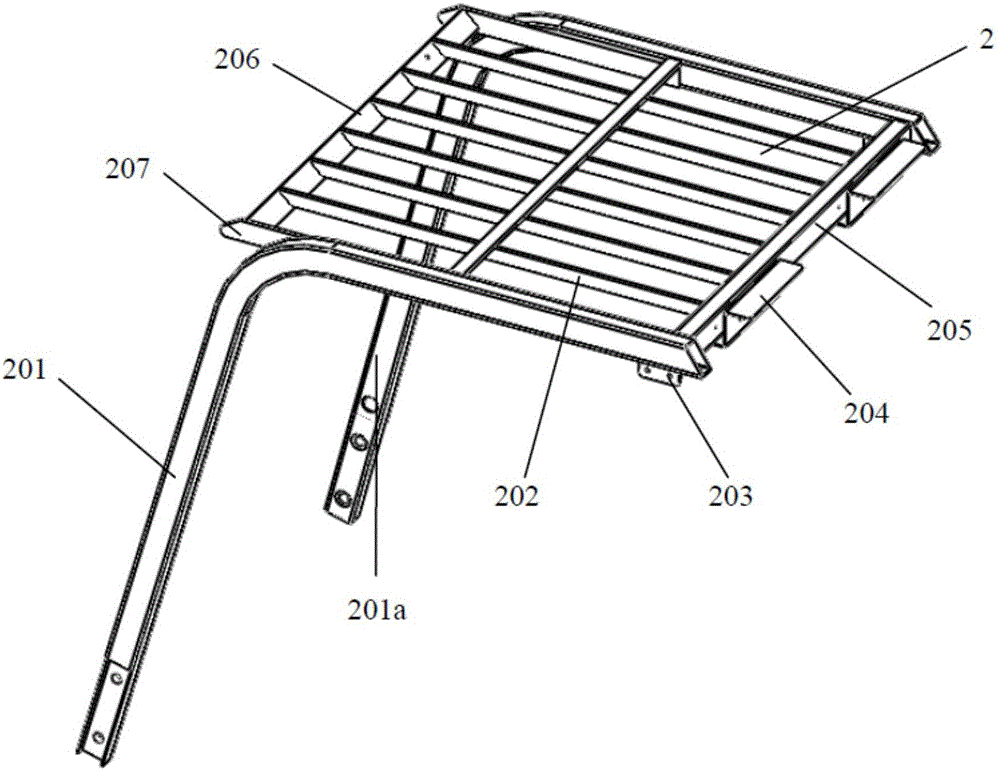

Welding tool, welding processing equipment having same and welding method

ActiveCN104759822BEasy to makeEasy to useWelding/cutting auxillary devicesAuxillary welding devicesWeld seamIndustrial engineering

The invention discloses a welding tool, welding equipment provided with the welding tool and a welding method. The welding tool comprises a carrying frame and a positioning and clamping device. The positioning and clamping device is arranged on the carrying frame and used for positioning and clamping a canopy guard frame and / or a load backrest of a forklift. The positioning and clamping device is provided with a horizontal bottom frame and a vertical bottom frame which is vertically connected with the horizontal bottom frame. The welding tool can be used for assembly welding of the canopy guard frame and the load backrest of the forklift at the same time, is high in universality, easy to manufacture and convenient to use, can effectively reduce cost input, shortens the preparation period, reduces production land, substantially improves production efficiency and guarantees welding seam quality and product uniformity. The welding tool can further weld the canopy guard frame and the load backrest of the forklift in cooperation with a welding robot, omits the rivet welding procedure, achieves automatic welding of the robot, avoids the interference caused by human factors and saves the feeding time for workers. Besides, the welded product uniformity is good.

Owner:WUHU RUICHUANG FORKELEVATOR

Turnover type filtering, washing and drying machine and using method thereof

InactiveCN108050798AIncrease the heating areaPrevent leakageDrying solid materials without heatDrying chambers/containersPulp and paper industryPollution

The invention provides a turnover type filtering, washing and drying machine. The machine is characterized in that a filtering bottom plate assembly is arranged at the bottom of a container cavity, and the bottom of the filtering bottom plate assembly is connected with a vacuumizing and mother liquor discharging port system through a pipeline; a discharging port is formed in an upper sealing headof the container cavity, and the upper sealing head of the container cavity is further hermetically connected with a lifting and stirring device; and the container cavity is connected with a turnoverdevice for realizing turnover of the whole container cavity, a material inlet is formed in the turnover device, and the material inlet communicates with the container cavity. The invention further provides a using method of the turnover type filtering, washing and drying machine. According to the turnover type filtering, washing and drying machine, the structure is simple, use is convenient, and overturning can be achieved; a filtering and washing station is in a vertical state so that filtering can be quickly carried out; a drying station is in a horizontal state so that the heating area of the material can be increased and heating efficiency can be improved; a discharging station is in an inverted state so that material discharging can be thorough and the yield can be increased; and meanwhile, residues of material discharging and leakage of the discharging port are avoided, occurrence of endogenous pollution is avoided, and the crystal form of products and consistency of the productsare guaranteed.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Novel motor shell welding equipment

InactiveCN113478079AImprove stabilityAvoid injuryWelding/cutting auxillary devicesManufacturing dynamo-electric machinesElectric machineryStructural engineering

The invention discloses novel motor shell welding equipment. The equipment comprises a welding main body, wherein box doors are arranged at the two sides of the bottom of the front face of the welding main body; a welding device is fixedly connected to the top of the welding main body; blocking frames are fixedly connected to the two sides of the top of the welding device; a cover plate is fixedly connected to the tops of the blocking frames; and the right side of the front surface of the cover plate is fixedly connected with a control panel. The invention relates to the technical field of motor shells. According to the novel motor shell welding equipment, a laser welding device has good stability during welding, the situation of blocking is not prone to occurring in the moving process, so that the accuracy during welding is improved, and the situation of repeated welding or welding missing is avoided; and clamping blocks are arranged on the welding platform, the connecting position of the device can be fixed, sparks generated during welding are conveniently intercepted, workers are effectively prevented from being injured, the cover plate can prevent the sparks from splashing upwards, and the use safety of the device is further improved.

Owner:彭鹏飞

An array antenna

InactiveCN103490143BEnsure product consistencyLow costAntenna arraysAntenna supports/mountingsElectrical and Electronics engineering

The invention discloses an array antenna which comprises a bottom plate, a printed circuit and a printed circuit base board. The printed circuit base board is arranged on the bottom plate through a supporting column, an air layer is formed between the printed circuit base board of the bottom plate, the printed circuit is arranged on the lower surface of the printed circuit base board, the printed circuit is arranged above the air layer and under the printed circuit base board, a printing radiating unit is positioned on the upper surface of the printed circuit base board, and the printing radiating unit is electrically connected with the printed circuit. The array antenna is low in cost, high in gain and good in production conformity.

Owner:FOSHAN LANBOWANJIN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com