Building stirrup rib production device with heating system for feet of omega-shaped supporting rib

A technology of heating system and production equipment, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of the unfavorable effect of dipping uniformity of feet, increased energy consumption, poor product consistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

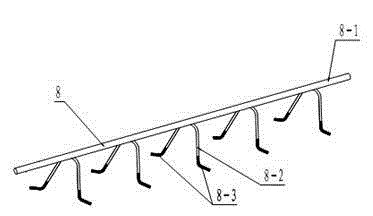

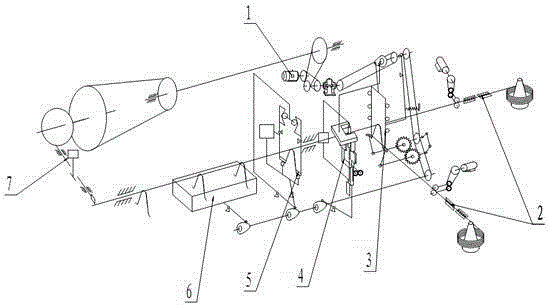

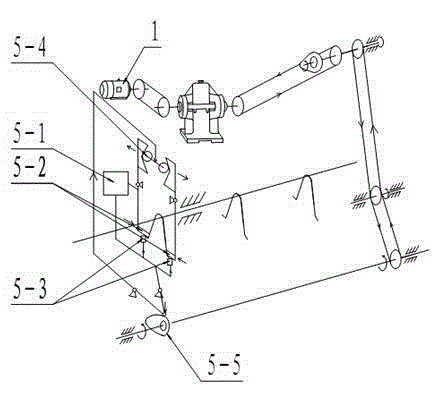

[0017] see figure 2 , image 3 , the present invention includes a transmission system 1, a wire feeding system 2, an Ω-shaped supporting rib forming execution system 3, a positioning welding execution system 4, an Ω-shaped supporting rib foot heating execution system 5, and an Ω-shaped supporting rib foot dipping execution system 6 , workpiece cutting execution system 7, PLC control system and frame; the heating execution system 5 of the Ω-shaped support rib foot includes a heating transformer 5-1, a first heating electrode 5-2, a second heating electrode 5-3 and a heating An electrode clamping drive mechanism, the heating transformer 5-1 is controlled by a PLC system, and its positive and negative poles are respectively connected to the first heating electrode 5-2 and the second heating electrode 5-3; the first heating electrode 5-2 It is matched with the vertical ribs on both sides of the Ω-shaped support rib 8-2, and the second heating electrode 5-3 is matched with the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com